Life Cycle Costing Analysis: Tools and Applications for Determining Hydrogen Production Cost for Fuel Cell Vehicle Technology

Abstract

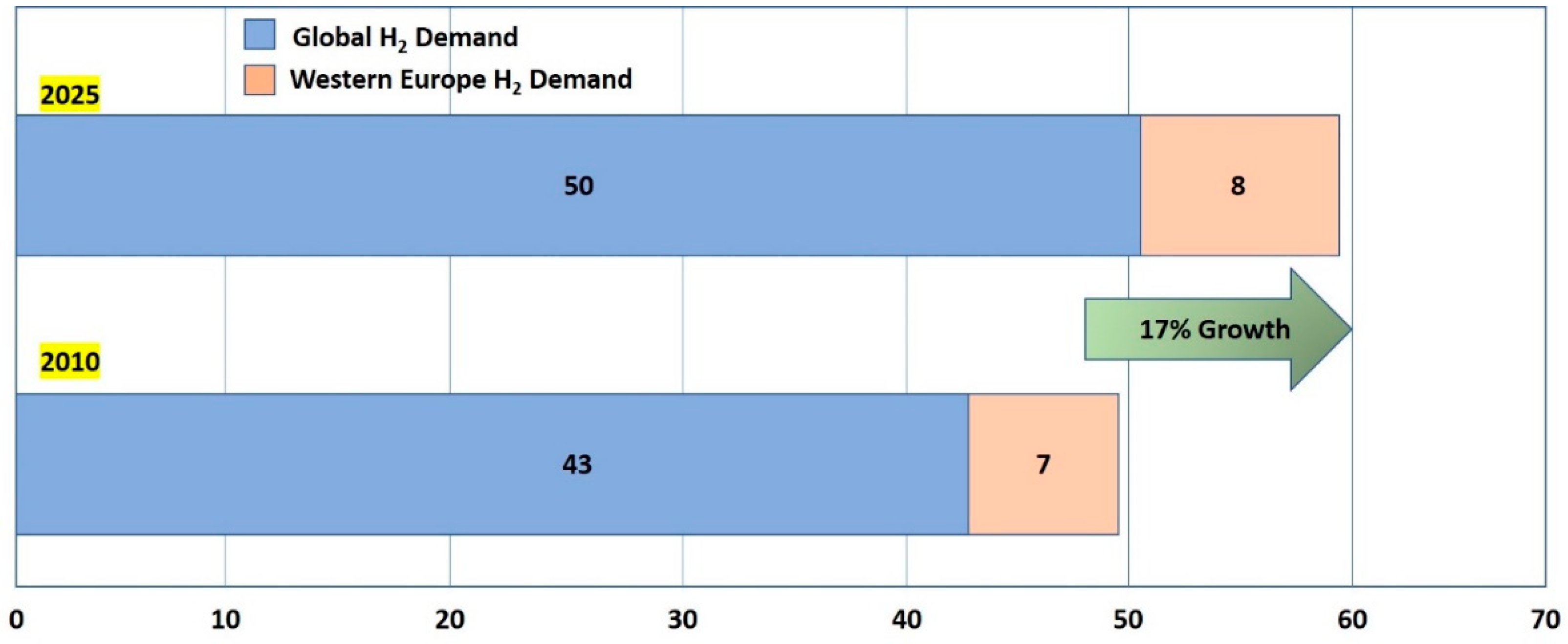

:1. Introduction

2. Methodology

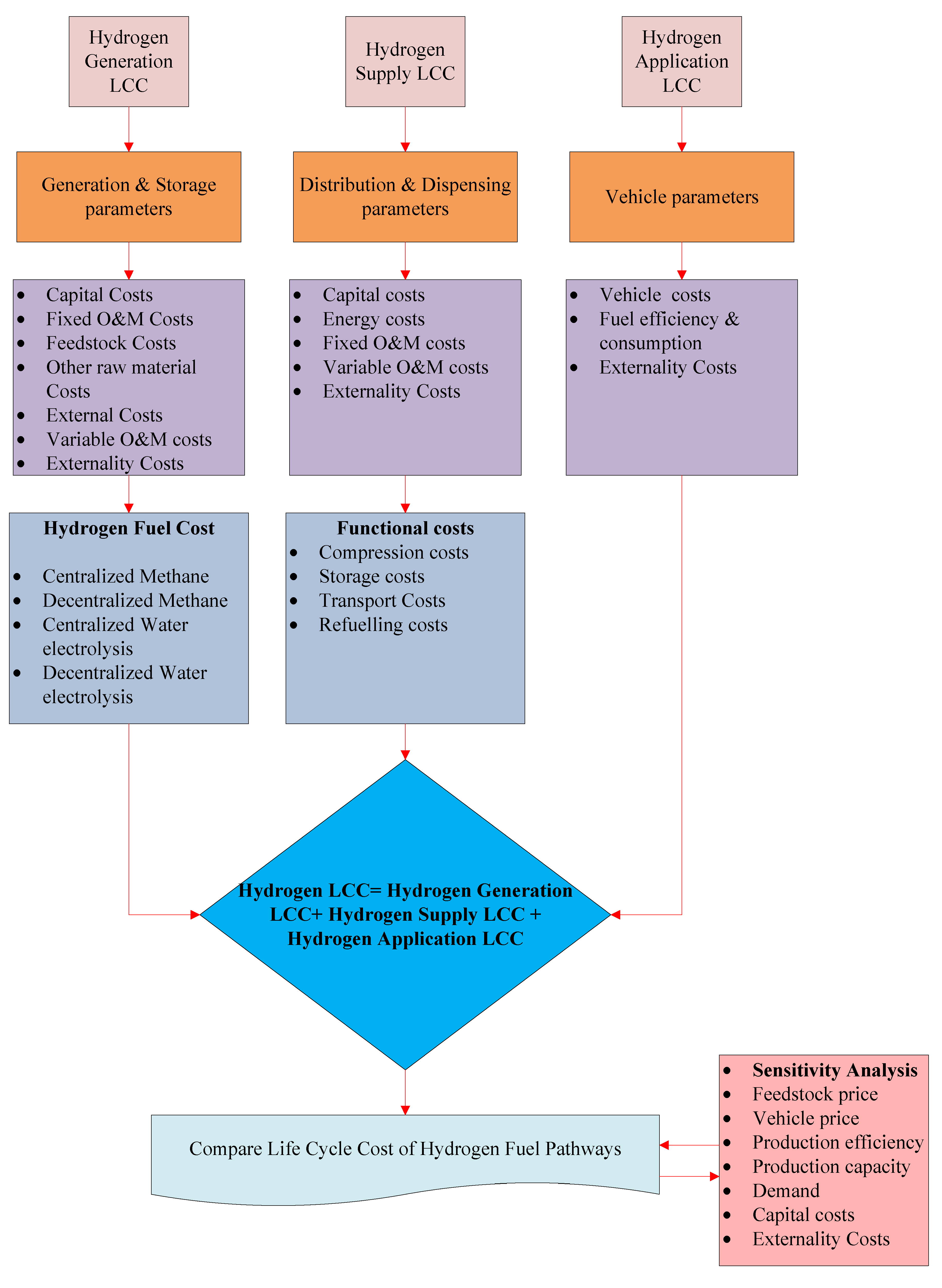

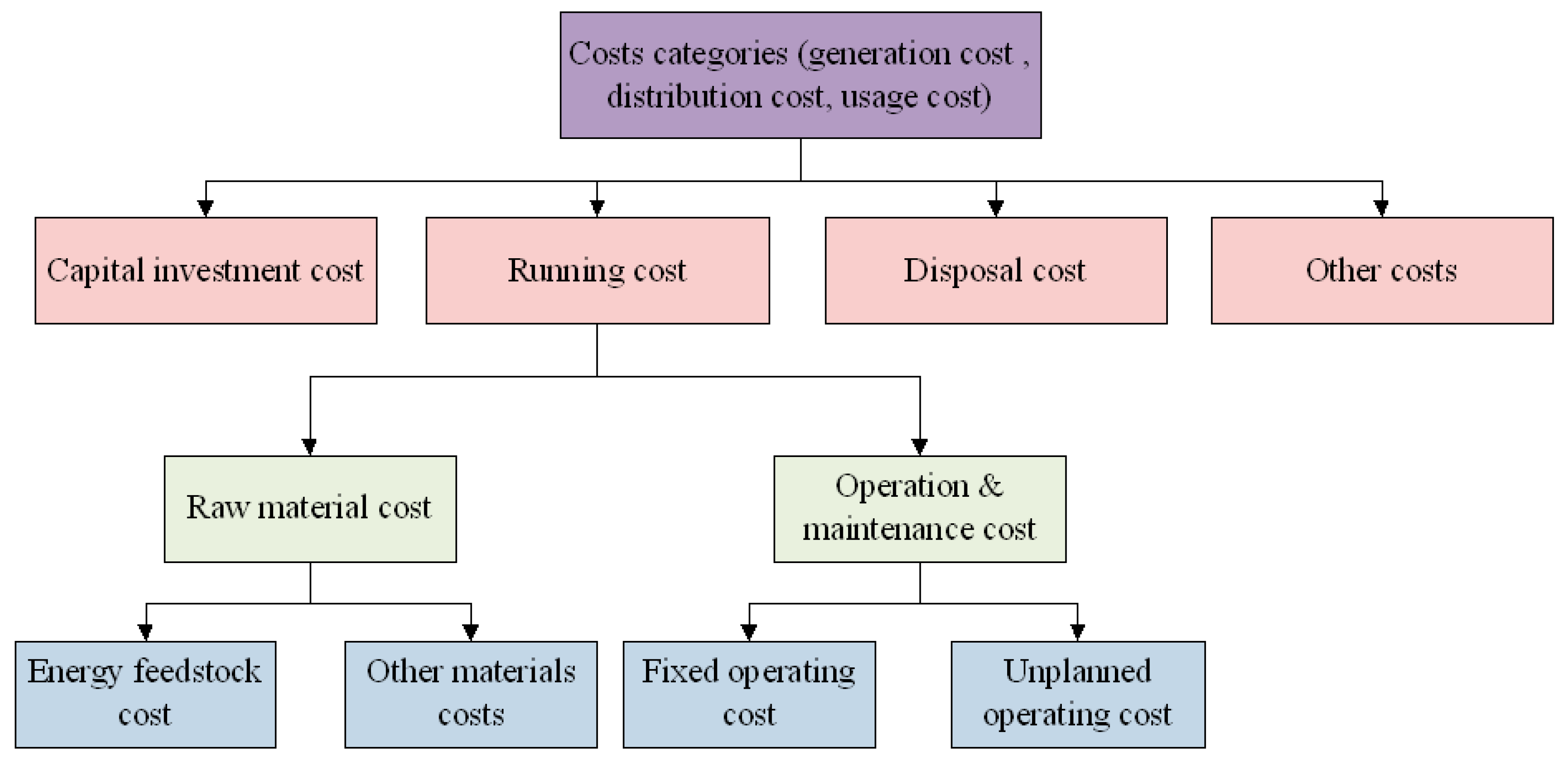

2.1. The Life Cycle Costing Model

2.2. Economic Analysis

3. Case Study

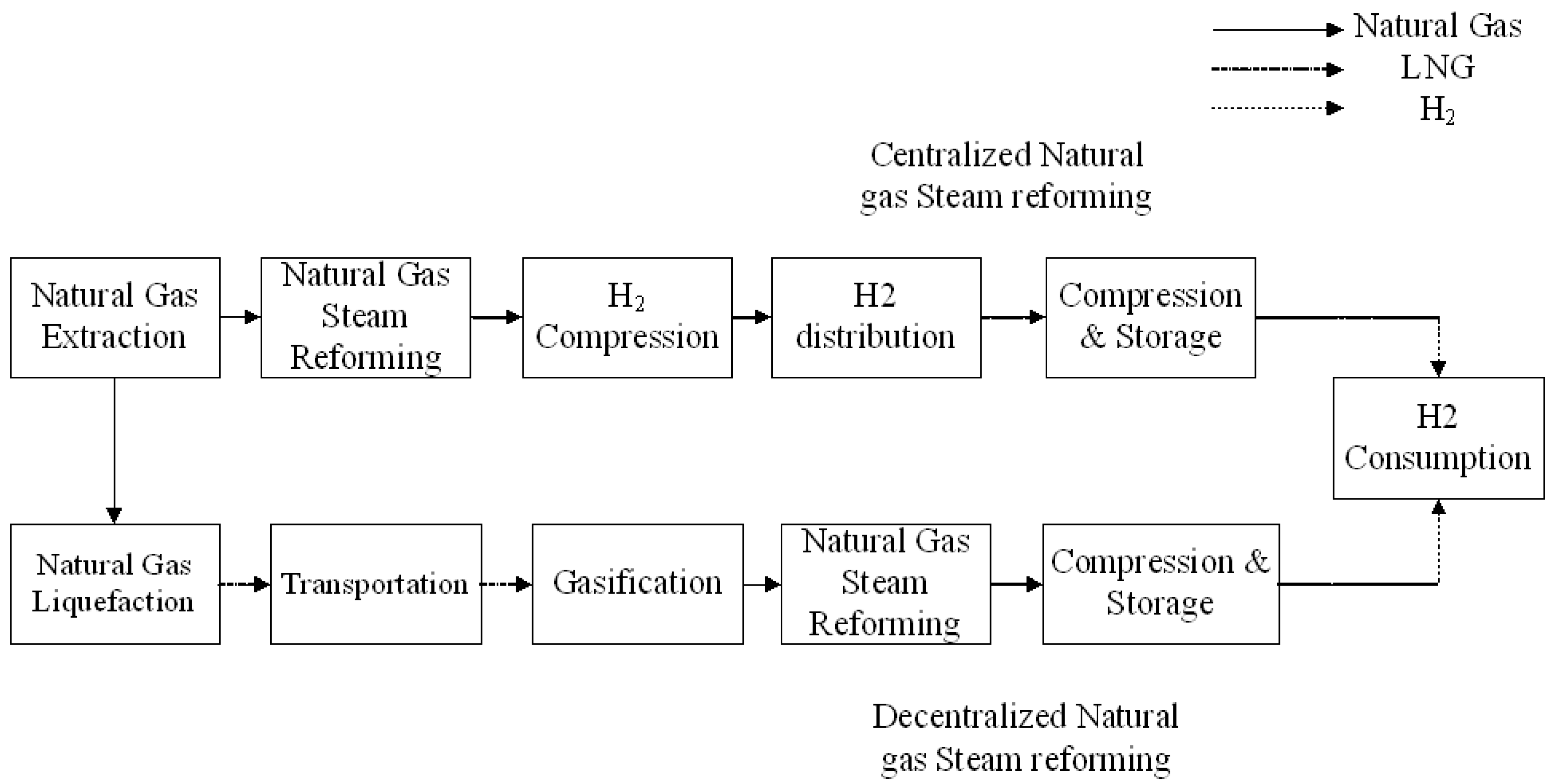

3.1. Natural Gas Steam Reforming

3.2. Water Electrolysis

4. Results and Discussion

4.1. Hydrogen Production and Storage Life Cycle Costs

4.2. Life Cycle Cost for Hydrogen Transportation and Dispensing

4.3. Hydrogen Application Life Cycle Costs

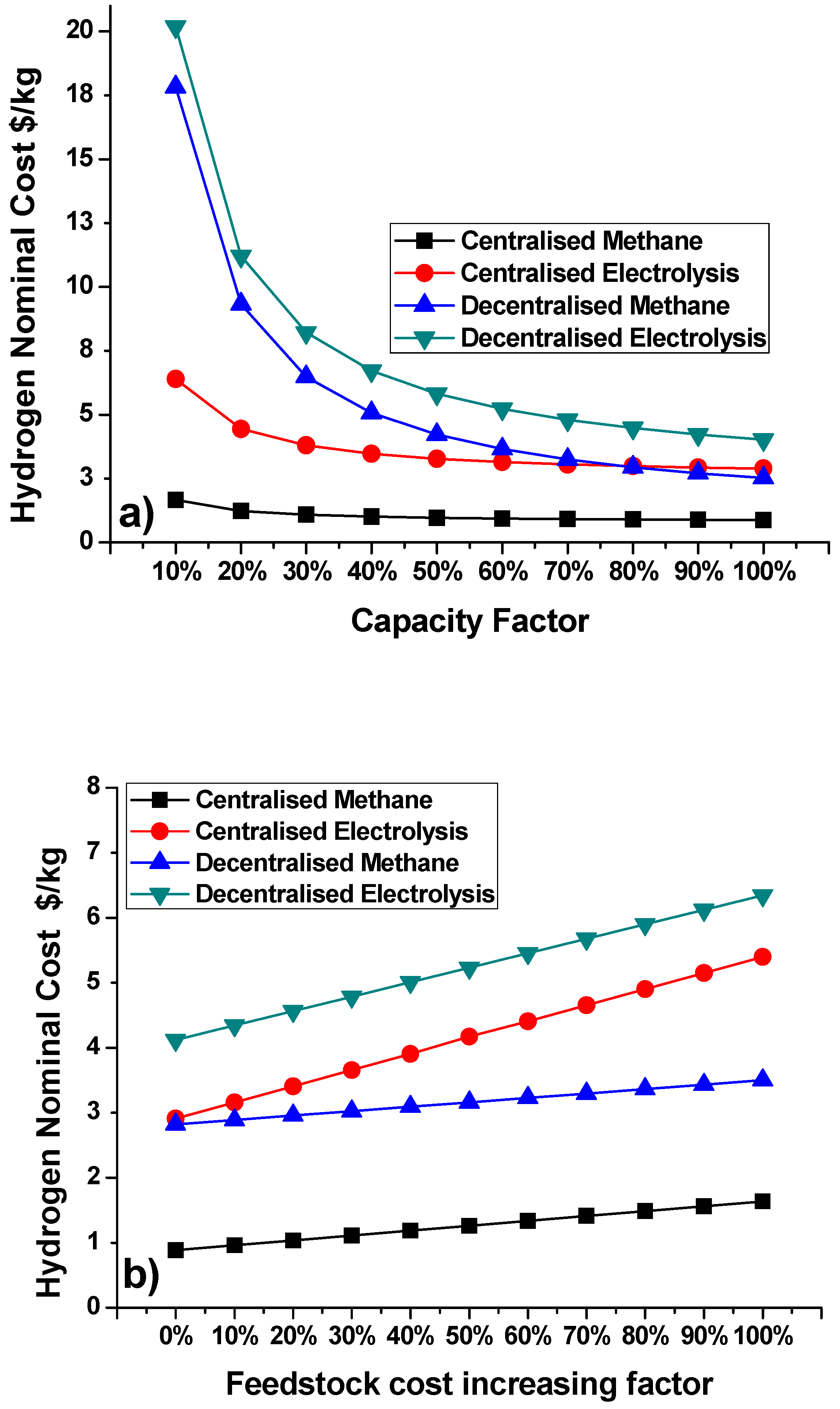

4.4. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Data | Centralised Methane Reforming | Decentralised Methane Reforming | Centralised Electrolysis | Decentralised Electrolysis | Units |

|---|---|---|---|---|---|

| Number of Hydrogen Units (Assumed) | 1 | 2 | 1 | 1 | |

| Plant Design Capacity (Typical available plant) | 380,000 | 1500 | 52,300 | 1500 | kg/day |

| Capacity Factor (assumed) | 90% | 85% | 95% | 95% | |

| Efficiency of the Process [44] | 80% | 75% | 75% | 70% | |

| Hydrogen Storage Pressure (Typical available storage system) | 70 | 35 | 70 | 35 | MPa |

| Hydrogen Storage Capacity [45] | 98,589 | 49,294 | 49,294 | 49,294 | kg |

| Hydrogen Compressor Power [45] | 74,472 | 64,223 | 74,472 | 64223 | kWe |

| Plant Capital Cost, corrected to year 2018 based on reference [44] | 52,673,000 | 640,000 | 29,234,000 | 840,000 | USD |

| Indirect Depreciable Costs (calculated) | 7,374,220 | 70,400 | 2,923,400 | 92,400 | USD |

| Non Depreciable Costs (calculated) | 50,000 | 25,000 | 50,000 | 25,000 | USD |

| Installation Costs [46], (Forecasted to 2018) | 21,069,200 | 64,000 | 5,846,800 | 84,000 | USD |

| Feedstock Usage Calculated (Lower Heating Value of Hydrogen % Lower Heating Value of Feedstock) % Conversion Efficiency Price of electricity (0.05370 USD/kWh) | 4.1 (Nm3/kg H2) | 4.4 (Nm3/kg H2) | 44.5 (kWh/kg H2) | 47.7 (kWh/kg H2) | |

| Raw materials Usage Water consumed for process production, | 12.5 | 16.3 | 11.0 | 11.0 | l/kg H2 |

| Labour Costs (assumed for typical industry) | 25,000 | 10,000 | 25,000 | 10,000 | USD |

| Timeline of Alternative | Centralized | Decentralized |

|---|---|---|

| Cash flow year | 2018 | 2018 |

| Start of Construction | 2025 | 2025 |

| Start of Operation | 2027 | 2026 |

| End of Operation | 2066 | 2045 |

| Study Period | 40 | 20 |

| Planned Replacement Period | 10 | 10 |

| Construction Period | 2 | 1 |

| Plant Operation | 40 | 20 |

| Economic Data | Centralized Methane | Centralized Electrolysis | Decentralized Methane | Decentralized Electrolysis |

|---|---|---|---|---|

| After-Tax Real IRR | 10.0% | 10.0% | 10.0% | 10.0% |

| Inflation Rate | 3.9% | 3.9% | 3.9% | 3.9% |

| Depreciation Length | 40 | 40 | 20 | 20 |

| Tax Rate | 15% | 15% | 15% | 15% |

| Working Capital (% Operating Cost) | 15% | 15% | 15% | 15% |

| Salvage Value (% Total Capital Investment) | 10% | 10% | 10% | 10% |

| % of Capital Investment During Construction year 1 | 40% | 25% | 100% | 100% |

| % of Capital Investment During Construction year 2 | 60% | 75% | 0% | 0% |

| % Fixed Operating Costs at Start up | 100% | 100% | 100% | 100% |

| % Revenue at Start up | 50% | 50% | 100% | 100% |

| % Variable operating Costs at start up | 75% | 75% | 50% | 50% |

| Decommissioning Costs | 10% | 10% | 10% | 10% |

| Data | Value | Unit |

|---|---|---|

| Capacity of vehicle | 920 | kg |

| Transport distance | 300 | km |

| Average speed of vehicle | 80 | km/h |

| Vehicle average consumption | 0.094 | L/km |

| Loading time | 4 | h |

| Hydrogen Dispensing | Value | Unit |

|---|---|---|

| Hydrogen Dispensing Pressure | 40 | Mpa |

| Hydrogen Dispensing Capacity | 73,941 | kg |

| Hydrogen Dispensing Compressor Power | 66,145 | kWe |

| FCV Data | Value |

|---|---|

| Fuel Tank | USD 975 |

| Electric Motor | USD 1560 |

| Inverter | USD 250 |

| Battery | USD 3000 |

| Fuel cell system | USD 15,985 |

| Vehicle body | USD 2600 |

| Other BOP materials Costs | USD 14,700 |

| Average distance travelled | 25,000 km/year |

| Mileage of FCV | 300 km |

| Consumption for distance travelled | 3 kg H2 |

References

- Moliner, R.; Lázaro, M.J.; Suelves, I. Analysis of the strategies for bridging the gap towards the Hydrogen Economy. Int. J. Hydrogen Energy 2016, 41, 19500–19508. [Google Scholar] [CrossRef]

- Milner-Elkharouf, L.; Khzouz, M.; Steinberger-Wilckens, R. Catalyst development for indirect internal reforming (IIR) of methane by partial oxidation. Int. J. Hydrogen Energy 2020, 45, 5285–5296. [Google Scholar] [CrossRef]

- Lemus, R.G.; Martínez Duart, J.M. Updated hydrogen production costs and parities for conventional and renewable technologies. Int. J. Hydrogen Energy 2010, 35, 3929–3936. [Google Scholar] [CrossRef]

- Balat, M. Potential importance of hydrogen as a future solution to environmental and transportation problems. Int. J. Hydrogen Energy 2008, 33, 4013–4029. [Google Scholar] [CrossRef]

- Prospects for Hydrogen and Fuel Cells; Energy Technology Analysis; International Energy Agency: Paris, France, 2005.

- FCH. Hydrogen Roadmap Europe: A sustainable Pathway for the European Energy Transition; Fuel Cells and Hydrogen: Bruxelles, Belgium, 2019. [Google Scholar]

- IRENA. Hydrogen from Renewable Power: Technology Outlook for the Energy Transition; International Renewable Energy Agency: Abu Dhabi, UAE, 2018. [Google Scholar]

- Brown, D.R. Worldwide Hydrogen Production Capacity at Refineries. Available online: https://h2tools.org/node/820 (accessed on 12 July 2020).

- Moreno-Benito, M.; Agnolucci, P.; McDowall, W.; Papageorgiou, L.G.; Kravanja, Z.; Bogataj, M. Towards a sustainable hydrogen economy: Role of carbon price for achieving GHG emission targets. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1015–1020. [Google Scholar]

- Anandarajah, G.; McDowall, W.; Ekins, P. Decarbonising road transport with hydrogen and electricity: Long term global technology learning scenarios. Int. J. Hydrogen Energy 2013, 38, 3419–3432. [Google Scholar] [CrossRef]

- Southall, G.D.; Khare, A. The feasibility of distributed hydrogen production from renewable energy sources and the financial contribution from UK motorists on environmental grounds. Sustain. Cities Soc. 2016, 26, 134–149. [Google Scholar] [CrossRef]

- Khzouz, M.; Gkanas, E.I.; Girella, A.; Statheros, T.; Milanese, C. Sustainable hydrogen production via LiH hydrolysis for unmanned air vehicle (UAV) applications. Int. J. Hydrogen Energy 2020, 45, 5384–5394. [Google Scholar] [CrossRef]

- Forsberg, C.W. Future hydrogen markets for large-scale hydrogen production systems. Int. J. Hydrogen Energy 2007, 32, 431–439. [Google Scholar] [CrossRef]

- Khzouz, M.; Gkanas, E.I.; Du, S.; Wood, J. Catalytic performance of Ni-Cu/Al2O3 for effective syngas production by methanol steam reforming. Fuel 2018, 232, 672–683. [Google Scholar] [CrossRef]

- Petrillo, A.; De Felice, F.; Jannelli, E.; Minutillo, M. Chapter 5—Life Cycle Cost Analysis of Hydrogen Energy Technologies. In Hydrogen Economy; Scipioni, A., Manzardo, A., Ren, J., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 121–138. [Google Scholar] [CrossRef]

- Khamis, I.; Malshe, U.D. HEEP: A new tool for the economic evaluation of hydrogen economy. Int. J. Hydrogen Energy 2010, 35, 8398–8406. [Google Scholar] [CrossRef]

- Thengane, S.K.; Hoadley, A.; Bhattacharya, S.; Mitra, S.; Bandyopadhyay, S. Cost-benefit analysis of different hydrogen production technologies using AHP and Fuzzy AHP. Int. J. Hydrogen Energy 2014, 39, 15293–15306. [Google Scholar] [CrossRef]

- Ally, J.; Pryor, T. Life cycle costing of diesel, natural gas, hybrid and hydrogen fuel cell bus systems: An Australian case study. Energy Policy 2016, 94, 285–294. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Comparative life cycle assessment of hydrogen, methanol and electric vehicles from well to wheel. Int. J. Hydrogen Energy 2017, 42, 3767–3777. [Google Scholar] [CrossRef]

- Li, Y.; Chen, D.W.; Liu, M.; Wang, R.Z. Life cycle cost and sensitivity analysis of a hydrogen system using low-price electricity in China. Int. J. Hydrogen Energy 2017, 42, 1899–1911. [Google Scholar] [CrossRef]

- Sun, H.; He, C.; Wang, H.; Zhang, Y.; Lv, S.; Xu, Y. Hydrogen station siting optimization based on multi-source hydrogen supply and life cycle cost. Int. J. Hydrogen Energy 2017, 42, 23952–23965. [Google Scholar] [CrossRef]

- Moreno-Benito, M.; Agnolucci, P.; Papageorgiou, L.G. Towards a sustainable hydrogen economy: Optimisation-based framework for hydrogen infrastructure development. Comput. Chem. Eng. 2017, 102, 110–127. [Google Scholar] [CrossRef] [Green Version]

- Adami Mattioda, R.; Teixeira Fernandes, P.; Luiz Casela, J.; Canciglieri Junior, O. Chapter 7—Social Life Cycle Assessment of Hydrogen Energy Technologies A2—Scipioni, Antonio. In Hydrogen Economy; Manzardo, A., Ren, J., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 171–188. [Google Scholar] [CrossRef]

- Lucas, A.; Neto, R.C.; Silva, C.A. Energy supply infrastructure LCA model for electric and hydrogen transportation systems. Energy 2013, 56, 70–80. [Google Scholar] [CrossRef]

- Sun, Y.; Ogden, J.; Delucchi, M. Societal lifetime cost of hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2010, 35, 11932–11946. [Google Scholar] [CrossRef] [Green Version]

- Petrillo, A.; Mellino, S.; Petrillo, A.; Cigolotti, V.; Autorino, C.; Jannelli, E.; Ulgiati, S. A Life Cycle Assessment of lithium battery and hydrogen-FC powered electric bicycles: Searching for cleaner solutions to urban mobility. Int. J. Hydrogen Energy 2017, 42, 1830–1840. [Google Scholar] [CrossRef]

- Cantuarias-Villessuzanne, C.; Weinberger, B.; Roses, L.; Vignes, A.; Brignon, J.-M. Social cost-benefit analysis of hydrogen mobility in Europe. Int. J. Hydrogen Energy 2016, 41, 19304–19311. [Google Scholar] [CrossRef] [Green Version]

- Kuckshinrichs, W.; Ketelaer, T.; Koj, J.C. Economic Analysis of Improved Alkaline Water Electrolysis. Front. Energy Res. 2017, 5. [Google Scholar] [CrossRef] [Green Version]

- Reuß, M.; Grube, T.; Robinius, M.; Stolten, D. A hydrogen supply chain with spatial resolution: Comparative analysis of infrastructure technologies in Germany. Appl. Energy 2019, 247, 438–453. [Google Scholar] [CrossRef]

- Yang, C.; Ogden, J. Determining the lowest-cost hydrogen delivery mode. Int. J. Hydrogen Energy 2007, 32, 268–286. [Google Scholar] [CrossRef] [Green Version]

- Reuß, M.; Grube, T.; Robinius, M.; Preuster, P.; Wasserscheid, P.; Stolten, D. Seasonal storage and alternative carriers: A flexible hydrogen supply chain model. Appl. Energy 2017, 200, 290–302. [Google Scholar] [CrossRef]

- Zhao, G.; Nielsen, E.R.; Troncoso, E.; Hyde, K.; Romeo, J.s.S.n.; Diderich, M. Life cycle cost analysis: A case study of hydrogen energy application on the Orkney Islands. Int. J. Hydrogen Energy 2019, 44, 9517–9528. [Google Scholar] [CrossRef]

- Zhang, Y.; Hua, Q.S.; Sun, L.; Liu, Q. Life Cycle Optimization of Renewable Energy Systems Configuration with Hybrid Battery/Hydrogen Storage: A Comparative Study. J. Energy Storage 2020, 30, 101470. [Google Scholar] [CrossRef]

- Salkuyeh, Y.K.; Saville, B.A.; MacLean, H.L. Techno-economic analysis and life cycle assessment of hydrogen production from natural gas using current and emerging technologies. Int. J. Hydrogen Energy 2017, 42, 18894–18909. [Google Scholar] [CrossRef]

- Pereira, S.R.; Coelho, M.C. Life cycle analysis of hydrogen—A well-to-wheels analysis for Portugal. Int. J. Hydrogen Energy 2013, 38, 2029–2038. [Google Scholar] [CrossRef]

- Sabio, N.; Kostin, A.; Guillén-Gosálbez, G.; Jiménez, L. Holistic minimization of the life cycle environmental impact of hydrogen infrastructures using multi-objective optimization and principal component analysis. Int. J. Hydrogen Energy 2012, 37, 5385–5405. [Google Scholar] [CrossRef]

- Yao, F.; Jia, Y.; Mao, Z. The cost analysis of hydrogen life cycle in China. Int. J. Hydrogen Energy 2010, 35, 2727–2731. [Google Scholar] [CrossRef]

- Salkuyeh, Y.K.; Saville, B.A.; MacLean, H.L. Techno-economic analysis and life cycle assessment of hydrogen production from different biomass gasification processes. Int. J. Hydrogen Energy 2018, 43, 9514–9528. [Google Scholar] [CrossRef]

- Barringer, H.P.; Weber, D.P. Life Cycle Cost Tutorial. In Proceedings of the Fifth International Conference on Process Plant Reliability, Marriott Houston Westside Houston, TX, USA, 2–4 October 1996. [Google Scholar]

- Fabrycky, W.J.; Blanchard, B.S. Life Cycle Cost and Economic Analysis; Prentice Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

- Korpi, E.; Ala-Risku, T. Life cycle costing: A review of published case studies. Manag. Audit. J. 2008, 23, 240–261. [Google Scholar] [CrossRef] [Green Version]

- Khzouz, M.; Gkanas, E.I. Experimental and numerical study of low temperature methane steam reforming for hydrogen production. Catalysts 2018, 8, 5. [Google Scholar] [CrossRef] [Green Version]

- Serdaroglu, G.; Khzouz, M.; Gillott, M.; Shields, A.; Walker, G.S. The effect of environmental conditions on the operation of a hydrogen refuelling station. Int. J. Hydrogen Energy 2015, 40, 17153–17162. [Google Scholar] [CrossRef]

- Mueller-Langer, F.; Tzimas, E.; Kaltschmitt, M.; Peteves, S. Techno-economic assessment of hydrogen production processes for the hydrogen economy for the short and medium term. Int. J. Hydrogen Energy 2007, 32, 3797–3810. [Google Scholar] [CrossRef]

- Amos, W.A. Costs of Storing and Transporting Hydrogen; National Renewable Energy Laboratory: Golden, CO, USA, 1998. [Google Scholar]

- Energy, D.O. Hydrogen Program. Available online: http://www.hydrogen.energy.gov/index.html (accessed on 12 July 2020).

| Scope of Study | Framework of Study | Area of Investigation | Ref |

|---|---|---|---|

| Social cost-benefit analysis framework for fuel cell vehicle versus internal combustion engine vehicle. | Cost benefit analysis framework was introduced; considering economic comparison, external costs estimation and social–economic comparison. | Cost Benefit Analysis of German Market based on previous published study for fuel cell electric vehicle, including externality costs in Europe for society benefits analysis. | [27] |

| Techno-economical characterization for Alkaline water electrolysis. | Alkaline water electrolysis life cycle was studied focusing on the metrics’ approach and the approaches to specify realistic projections of sensitive technical and economic parameters, such as investment cost or future electricity cost. | The weighted average cost of capital for alkaline water electrolysis was used for analysis for cost estimation and financial analysis on three different production sites. | [28] |

| Techno-economic modelling of future hydrogen supply chains with spatial resolution. | Study evaluates all parts of the supply chain, from hydrogen production to refilling, the case of Germany for the target year 2050, considering a spatial resolution regarding costs, primary energy demand and CO2 emissions. It also optimizes potential for hydrogen distribution. | Simulation approach of each step of the supply chain using optimization method. | [29] |

| Techno-economic model of future hydrogen supply chains. | Investigates the application area of different hydrogen supply chain architectures through a point-to-point analysis based on the methodology of the lowest-cost hydrogen delivery mode investigated by [30], full supply chain from hydrogen production by electrolysis, large-scale storage, transportation and fuelling. | Well-to-tank analysis to estimate greenhouse gas emissions for conditioning a transportation fuel | [31] |

| Cost of hydrogen applications are compared with conventional energy supply. | Five scenarios have been developed to compare the cost of using hydrogen with conventional energy sources, taking into account the cost of CO2 emissions. | Methodology of life cycle cost is employed to conduct the cost of hydrogen production and application for islands and specific applications. | [32] |

| Economic model is developed to evaluate the investment and operational cost. | Build an economic evaluation model that describes the investment cost and operational cost, making the mathematical optimization to reach a minimum total annual cost of Hybrid Battery/Hydrogen Storage. | Optimizing the life cycle capital was formulated to determine the optimal configuration of a hybrid renewable energy. | [33] |

| Techno-economic analyses and life cycle assessments of four hydrogen production technologies using natural gas as a feedstock. | Understanding of the techno-economic and life cycle environmental performance of a set of emerging hydrogen production technologies. | Technical and financial conditions under which each technology is expected to be attractive are explored for carbon price. | [34] |

| Well-To-Wheel (WTW) analysis for hydrogen. | Global emission model for integrated systems (GEMIS) interacted with greenhouse gases, regulated emissions, and energy use in transportation (GREET) for Portugal. | Greenhouse gases emissions (GHGs) compared with the gasoline vehicle from different hydrogen production routes. | [35] |

| Integrate multi-objective optimization with principal component analysis to address the environmentally conscious design of hydrogen networks. | A Framework has been proposed for optimizing hydrogen supply chains in accordance with several environmental indicators. | Multi-objective mixed-integer linear program (MILP) is formulated that takes into account the simultaneous minimization of the most significant impacts of life cycle assessment (LCA) for Spain. | [36] |

| Life cycle including the effect on environment. | Demonstrate the costs of every step and to discuss their relationship for coal hydrogen production. | The minimum cost of each production step was analysed and focused on strategic selection for China. | [37] |

| Techno-economic analyses and life cycle assessment (LCA). | Two main gasification processes for producing hydrogen from biomass showing minimum hydrogen selling price. | Evaluate and compare the impact of gasification technology on the techno-economic and life cycle environmental performance of hydrogen production from biomass. | [38] |

| Life cycle costing analysis framework for hydrogen production and utilization. | Apply the method of life cycle cost for hydrogen production and utilization via analysis the feasible economic tools for forecasting hydrogen cost by developing an economic model framework including sensitivity analysis criteria. | Engineering economic tools that can be applied in general/universal form for estimating feasible hydrogen production systems, considering major cost breakdown structure to simplified life cycle model using Microsoft Excel as the tool. | Current study |

| Hydrogen Production | Hydrogen Supply | Hydrogen Use |

|---|---|---|

|

|

|

| Equation Number | Equation | Abbreviation |

|---|---|---|

| (1) | ||

| (2) | : is j cost value | |

| (3) | : is j cost value | |

| (4) | ||

| (5) | ||

| (6) | ||

| (7) | ||

| (8) | ||

| (9) | ||

| (10) | ||

| (11) | ||

| (12) | ||

| (13) | ||

| (14) | ||

| (15) | ||

| (16) | ||

| (17) | ||

| (18) | ||

| (19) | ||

| (20) | ||

| (21) |

| Hydrogen Alternative | Life Cycle Cost of Generation and Storage (USD/kg) |

|---|---|

| Centralized methane reforming | 0.90 |

| Decentralized methane reforming | 3.83 |

| Centralized electrolysis | 2.92 |

| Decentralized electrolysis | 4.30 |

| Hydrogen Alternative | Life Cycle Cost of Transportation and (USD/kg) |

|---|---|

| Centralized methane reforming | 0.41 |

| Centralized electrolysis | 0.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khzouz, M.; Gkanas, E.I.; Shao, J.; Sher, F.; Beherskyi, D.; El-Kharouf, A.; Al Qubeissi, M. Life Cycle Costing Analysis: Tools and Applications for Determining Hydrogen Production Cost for Fuel Cell Vehicle Technology. Energies 2020, 13, 3783. https://doi.org/10.3390/en13153783

Khzouz M, Gkanas EI, Shao J, Sher F, Beherskyi D, El-Kharouf A, Al Qubeissi M. Life Cycle Costing Analysis: Tools and Applications for Determining Hydrogen Production Cost for Fuel Cell Vehicle Technology. Energies. 2020; 13(15):3783. https://doi.org/10.3390/en13153783

Chicago/Turabian StyleKhzouz, Martin, Evangelos I. Gkanas, Jia Shao, Farooq Sher, Dmytro Beherskyi, Ahmad El-Kharouf, and Mansour Al Qubeissi. 2020. "Life Cycle Costing Analysis: Tools and Applications for Determining Hydrogen Production Cost for Fuel Cell Vehicle Technology" Energies 13, no. 15: 3783. https://doi.org/10.3390/en13153783

APA StyleKhzouz, M., Gkanas, E. I., Shao, J., Sher, F., Beherskyi, D., El-Kharouf, A., & Al Qubeissi, M. (2020). Life Cycle Costing Analysis: Tools and Applications for Determining Hydrogen Production Cost for Fuel Cell Vehicle Technology. Energies, 13(15), 3783. https://doi.org/10.3390/en13153783