Using Load Forecasting to Control Domestic Battery Energy Storage Systems

Abstract

:1. Introduction

2. Materials and Methods

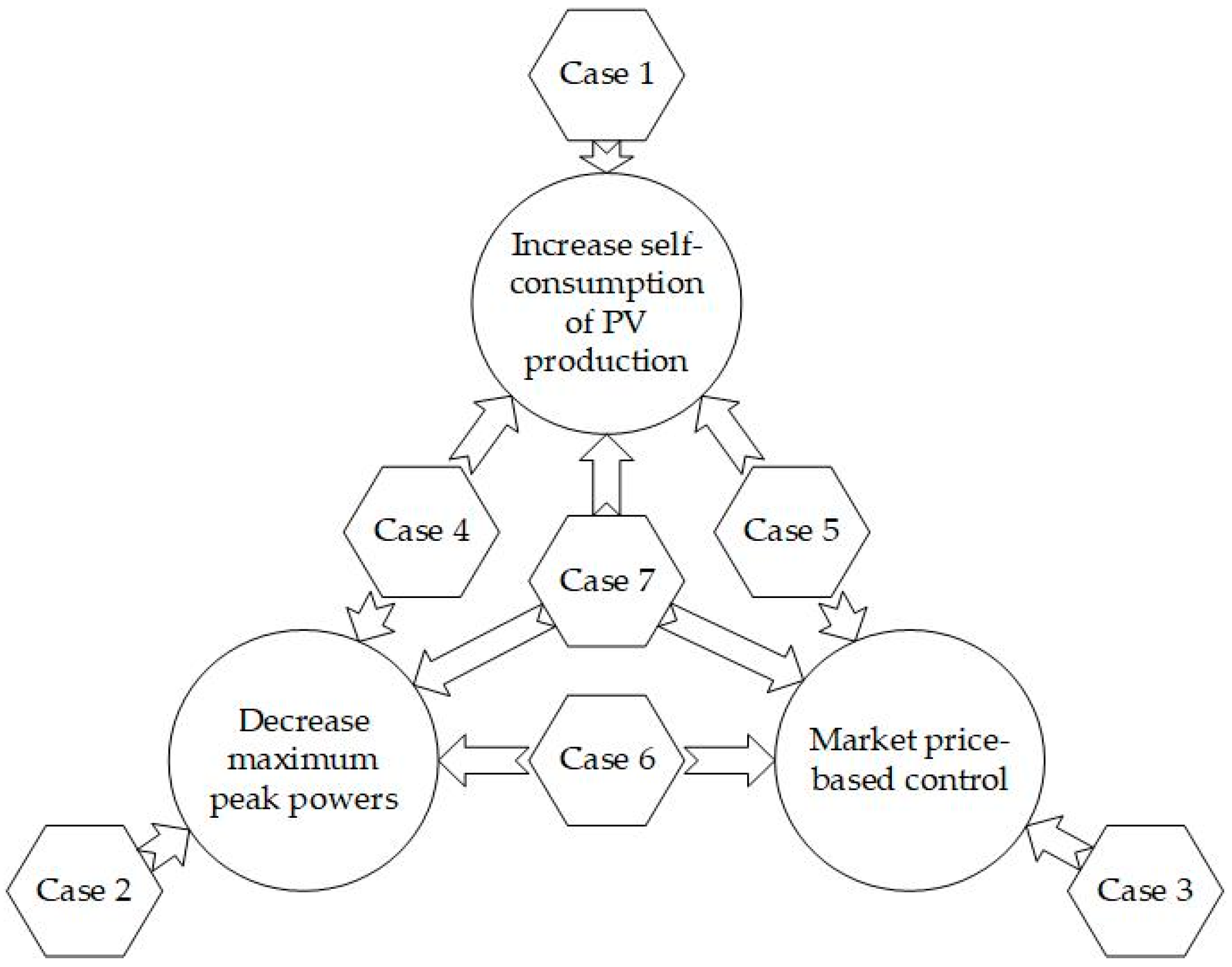

2.1. Battery Energy Storage System (BESS) Control Targets

2.1.1. Storing Surplus Photovoltaic (PV) Production

- In Finland, prosumers can sell surplus electricity to ERs, but the selling price is approximately only a third of the purchase price, because customers have to pay distribution prices and electricity taxes on purchased energy. It is profitable to avoid buying electricity from the grid by using PV self-production. If production is higher than consumption at some times, surplus energy has to be sold to the grid. Self-consumption of PV production can be increased by using BESS. The cost benefit of using BESS to increase PV self-consumption EBBESS,pv comes from the price difference between total selling price Ct,s and total purchase price Ct,p of electricity, which can be described by Equation (1):

- Using BESS to store surplus PV production is a simple process, but control could be challenging. Before midday, when the surplus PV production is usually the highest, the battery should be empty enough and ready to receive energy. Control can be implemented very simply; e.g., the battery is discharged empty during the evening for consumption and charged during daytime, when surplus energy is available. This kind of simple control does not utilize BESS optimally. Production and consumption vary from day to day, and BESS is sized using some kind of average values. With accurate load and production forecasts, BESS can be utilized optimally.

- The northern location of Finland means that PV production is high in summer and very low in winter. Long days in summer means that PV production is widely available during the day. In winter, days are very short and PV production is negligible. Usually electricity consumption is higher in winter than summer. As a result, available surplus energy varies a lot throughout the year. BESS is needed mostly in summer and very little at other times. Using BESS to increase self-consumption of PV production allows BESS to also be used for other control targets.

2.1.2. Decrease Maximum Peak Power

- Distribution tariffs can include a power-based component. This means that customers can obtain cost savings by discharging BESSs during peak power. Control of BESS can be implemented so that the battery is fully charged the whole time to await peak power. When the power increases above the selected level, the BESS is discharged to decrease consumption. This could work if customers have only a few individual peaks in consumption and power levels are very stable. Optimal utilization of BESS requires accurate load forecasts so that power levels can be optimized and the BESS can prepare for situations when the power peak lasts longer than an hour. One hour is the commercial unit for determining the peak power in power-based tariffs (i.e., highest average hourly power calculated by measured hourly energy). Cost savings from using BESS to decrease maximum peak power EBBESS,p can be calculated with Equation (2):

- In Finland, a lot of electricity is used to heat buildings. The highest power peaks usually occur in the coldest time of winter. Electric saunas usually cause the highest peaks among individual electric devices in buildings. Without any special devices, cold weather and electric saunas require BESSs to decrease power in typical Finnish residential buildings. Weather-dependent loads can be forecast using weather forecasts, but the load of heating a sauna depends on the customer’s choice, so it can be difficult to forecast.

2.1.3. Market Price-Based Control

- The third control target of BESS is market price-based control. The basic idea is to charge the BESS at hours when the electricity price is low and discharge when the price is high for one’s own electricity demand. In Finland, a customer’s contract with an ER can be based on the electricity market prices in Nord Pool day-ahead spot markets [21]. Nord Pool publish the prices for the next day between 13:00 and 14:00 CET, so in Finland the prices for next day will be available at 15:00 local time at the latest. Electricity prices are known for the next 10 to 33 h. The control system can optimize the utilization of the BESS for the period when prices are known, or an optimization period can be chosen. Unknown hourly prices in the optimization period can be forecasted. The cost savings from market price-based control EBBESS,mc can be calculated by Equation (3):

- Both charging and discharging cause energy loss, as Equation (3) shows. Using BESS for market price-based control can be profitable only if the difference between low and high price is so large the benefits outweigh the losses. Additionally, using the BESS decreases the lifetime of the battery, so the benefits must also compensate for this. The benefit from market price-based control is the least of the control targets in this study, relative to the used BESS cycles. Therefore, the control system must be careful that the BESS is used for market-price control only when it is profitable.

2.1.4. Combination of Control Targets

- Different control targets can be utilized by the BESS. When optimizing its utilization with different control targets, the control system must know which target is most profitable at any given moment. Usually this is not difficult, because the BESS is needed to store surplus PV production at midday in the summer and to decrease maximum peak power in coldest winter. Additionally, the profitability of market price-based control is usually much lower than that of other control targets [2,5]. If there is a situation where the BESS is needed to both decrease peak power and store surplus PV production, it is better to first decrease peak power, because even at only one hour the power decrease could fail. These situations are still very rare, so the basic rules for combining different control targets can be formed easily.

- With ideal load forecasting, it is easy to optimize the utilization of BESS, but errors in load forecasting can cause failure in optimal control, e.g., BESS is empty when energy is needed to decrease peak power. This kind of situation is possible when the power peak cannot be predicted in the load forecast and just before the peak the price of electricity was high and the BESS was discharged empty. Accuracy of load forecasting is very important when control targets are combined.

2.2. Simulation Model

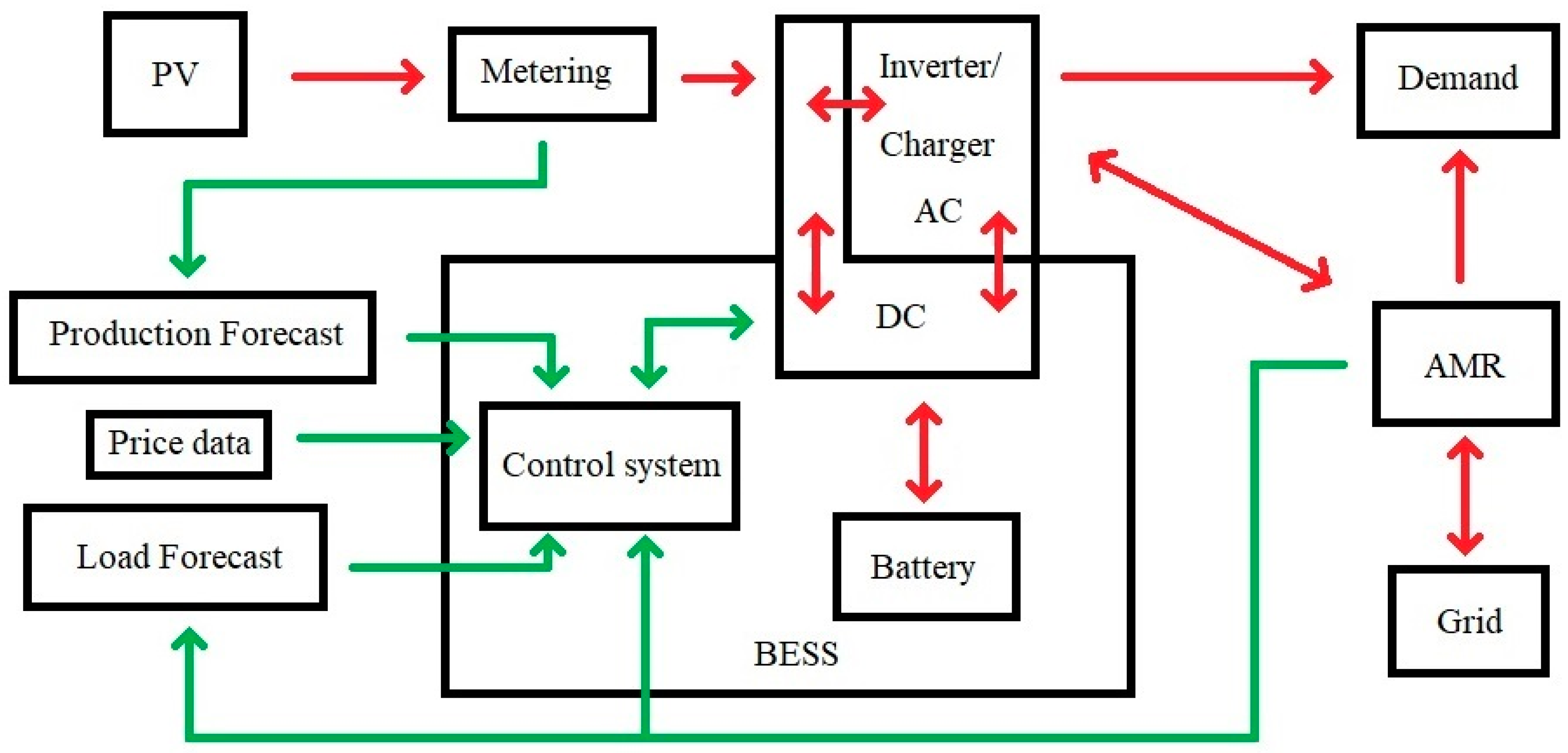

- This study is based on simulations using ordinary household customers’ demand data, with BESS added to the households’ electricity system. The simulation model is presented in Figure 1, which shows the directions of power flow and information data flow with red and green arrows, respectively. In the basic situation, PV power flows through the metering to the inverter, where it can go straight to the household to meet demand or to the BESS, and if the amount of produced energy is higher than the demand and the storage capacity is full, it can be fed to the grid and measured by automatic meter reading (AMR). If PV production cannot meet the energy need, it can be taken from the grid to meet the demand or to the BESS.

- Decision-making for battery charging and discharging occurs in the BESS control system. It controls the inverter/charger, which gives feedback on the battery conditions. Additionally, the control system includes a battery management system (BMS), which takes care of battery health. In the decision-making process, the control system uses the information from load and production forecast, upcoming electricity prices, and feedback from the charge controller and AMR. Load and production forecasts are based on weather forecasts and mathematical models, but these can be corrected based on PV production metering and data from AMR.

2.2.1. Household Electric System Model

2.2.2. PV Model and Production Forecast

- Solar irradiance modeling is based on the Reindl model [23], which is a suitable model for diffuse irradiance with south-tilted solar panels in the conditions of Finland [22]. In the model, global irradiance Gi is the sum of beam irradiance Gb,i, diffuse irradiance Gd,i and reflected irradiance Gr,i. In modeling, it is most important to find out the time series of solar irradiation. How strong is the solar irradiation on solar panels at different times? Solar irradiance depends on the location on the Earth and the angles of tilted PV panels. In this study, modeled solar panels are tilted at a 45° angle to face south.

- The amount of PV production depends on the cloudiness. In the Reindl model, cloudiness is modeled by a brightening factor. In [24], a model for cloudiness probability in Finland is presented, and it is based on cloudiness changing randomly, but based on probability. The same time series of solar radiation was utilized in all simulations so that the circumstances are stable.

- In actual systems, production forecasting has been utilized in control systems. In this paper, where load forecast is under study, the production forecast is assumed as ideal so that this does not affect the results of load-forecasting effects.

2.2.3. BESS Model and Control System

- Modeling of the battery type is undertaken via the efficiency of BESS Beff, which is a combination of battery efficiency and power electronics efficiency, i.e., inverter/charger DC side in Figure 1. In this study, the efficiency of power electronics on the inverter/charger DC side ηdc was 99%. The battery type was a lithium iron phosphate (LFP, LiFePO4) cathode with a graphite anode. A lithium-ion (Li-ion) battery was chosen because it is currently the best commercial solution for residential use, with high efficiency, developed technology, and long lifetime. The LFP cell type was chosen because it has good safety features and a very long lifetime, and the specific energy is not as high as other Li-ion batteries. It is a good choice for use in stationary home systems [25].

- Battery loss modeling was presented previously (e.g., in [8] by Koskela et al.). Loss depends on SOC and charging or discharging current. Very high or low SOC increases the loss and decreases the lifetime of the battery [26]. For this reason, the SOC limits of the battery were set at 25–95%. In Li-ion batteries, the internal serial resistance Rb is approximately constant between these SOC limits [27]. Therefore, the modeling of battery loss can be implemented with constant serial resistance of 0.026 Ω, which was studied for LFP cell type in [28] by Weniger et al. Charging and discharging losses are not equal, but when the battery use is cyclic, we can use average values for both processes. Charging and discharging efficiency ηc can be calculated with Equation (7):

- The control system in this paper makes it possible to combine multiple control targets, and it is a novel structure. The basic operation of the control system is that it tells the inverter/charger when to charge the battery and when to discharge. Optimization of the BESS for control targets based on minimizing customers’ electricity cost and its rules are described in Section 2.1. Firstly, if customers’ electricity cost depends on peak power, BESS is used to decrease maximum peak power. This is implemented via an algorithm which is presented in [8]. Based on the load forecasting, the control system calculates the power level that is possible to keep below by using BESS. If average power during a pricing period goes over this limit, the battery is discharged. Errors in load forecast can cause failure. Based on the amount of failure, a new target power level is determined.

- Secondly, if customers have their own PV production, maximizing self-consumption is the next target. If the battery is not used to decrease maximum peak power, it is discharged empty before the high production hours of midday. When it is necessary to do this depends on the production forecast and load forecast. Control systems estimate the potential needs of SOC levels in the battery based on the forecasts. The BESS stores the surplus energy from PV, which is used later when it is needed. Stored energy can be used immediately when consumption increases higher than production, but this can be delayed for other control targets.

2.3. Load Forecast

2.4. Initial Data

2.4.1. Consumption Data

- Customers’ consumption data were collected from actual customers between January 2014 and August 2016. The data were measured using customers’ AMR measurements from the area of one DSO in Finland. The total number of customers is 1525, but for the simulations 100 customers were selected randomly. These are basic household customers who live in detached houses, which mainly use electric heating, but the heating method can vary. The study group also included a few larger customers, such as farms. Data from 2015 were used for simulating the effects and the other data were used in load forecasting.

2.4.2. Electricity Prices

- A customer’s electricity bill in Finland consists of three parts: the ER part, the DSO part and taxes. Both the ER and DSO parts typically include basic charges (€/month), but customers cannot affect this by using the BESS, and for this reason basic charges are not included in the calculations in this study. The ER pricing used here is typical market prices based on tariffs in Finland, where hourly price is based on the day-ahead spot prices of the Nord Pool (Finland area prices) [21]. ERs add a 0.25 c/kWh margin to the market price, and if surplus energy from PV production is fed into the grid, ERs buy this energy for the same market price, but the margin is taken off. The margin forms the income of ERs.

- In this study, two distribution tariffs of a DSO are used. One is the power-based tariff, which is calculated for the same area where the group under study lives [7]. The power-based tariff includes an energy charge (0.72 c/kWh) and a power charge (7.23 €/kW/month). The power charge is based on the highest hourly average power of the month. The power-based tariff is used so that all possible BESS control targets are available. Because the power-based tariff is not yet widespread, the general distribution tariff in the same area is also used. The general tariff is widely used in Finland; it includes only an energy charge (5.21 c/kWh) [30]. All prices in this study include a 24% value added tax. In Finland, customers have to pay an electricity tax (2.79 €/kWh) on purchased energy. In this study, customers do not need to pay the DSO for surplus energy that is fed into the grid, and this is the typical situation in Finland.

2.4.3. Weather Data

- Load forecasting is based on outside temperature. Additionally, temperature and solar radiation data are used in the PV model. All weather data were taken from the open data of the Finnish Meteorological Institute [31]. Temperature data are measured hourly, and were measured at the Juupajoki weather station, which is the closest station to customers in the study group.

2.5. Study Cases

3. Results

3.1. Simulations with Power-Based Distribution Tariff

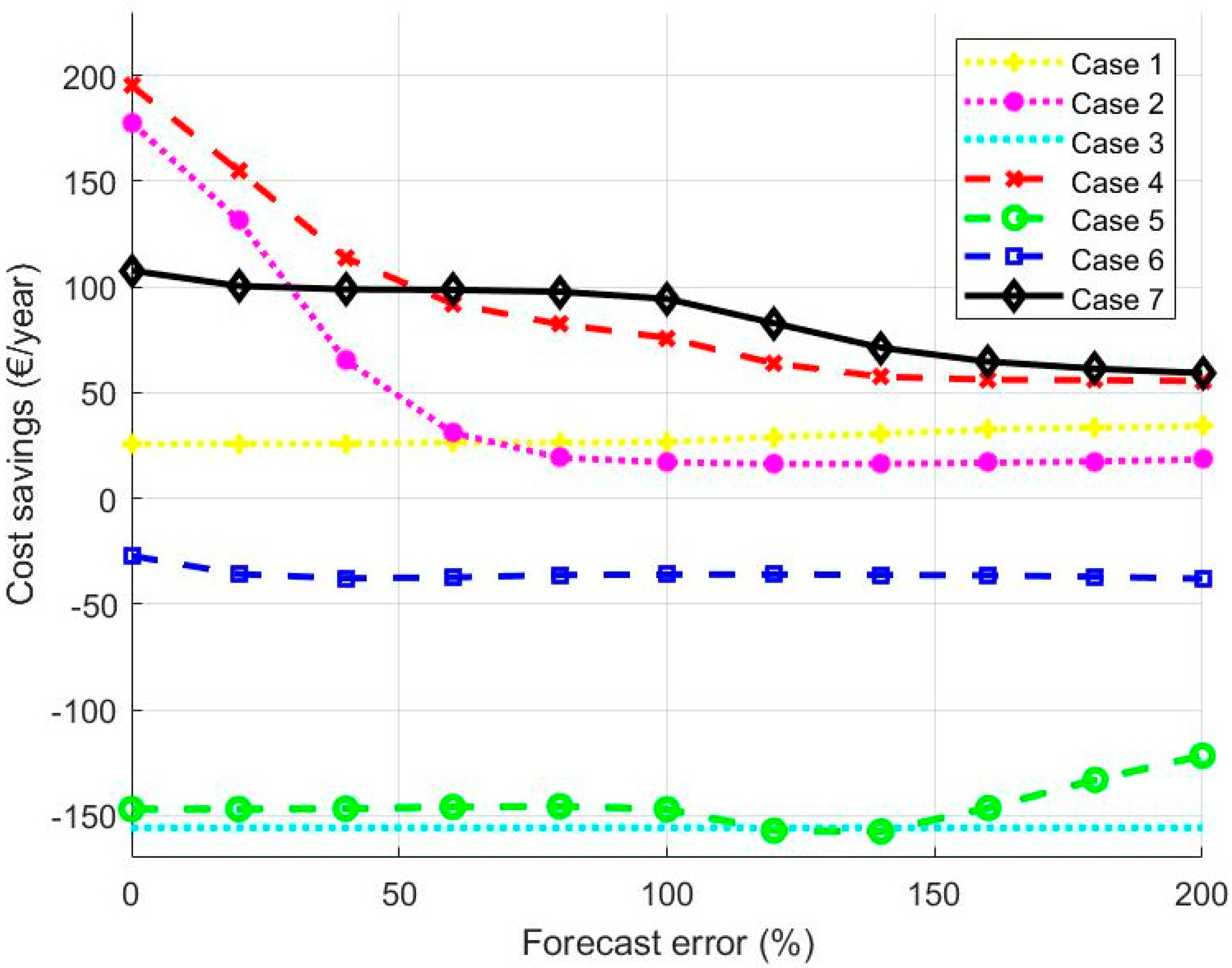

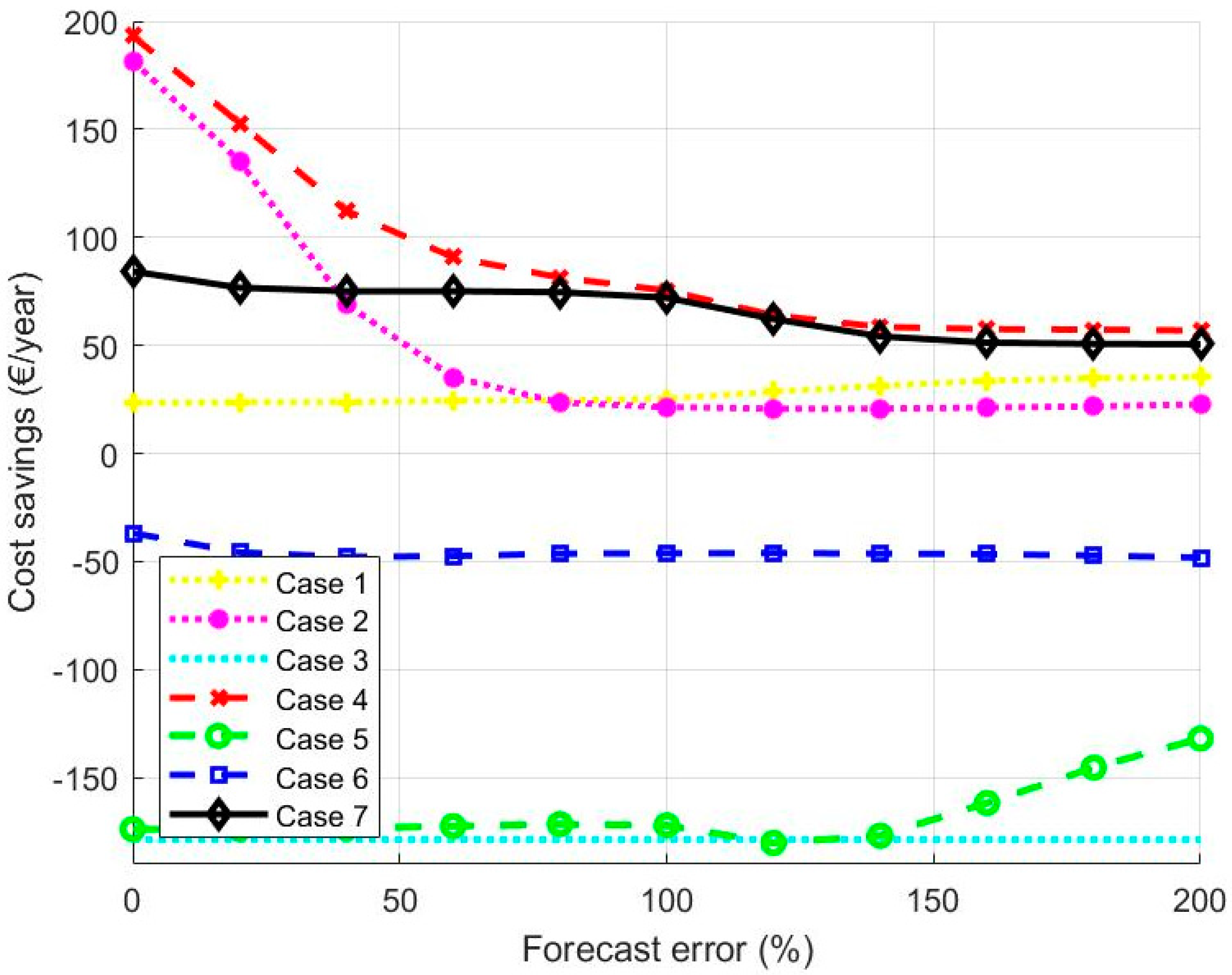

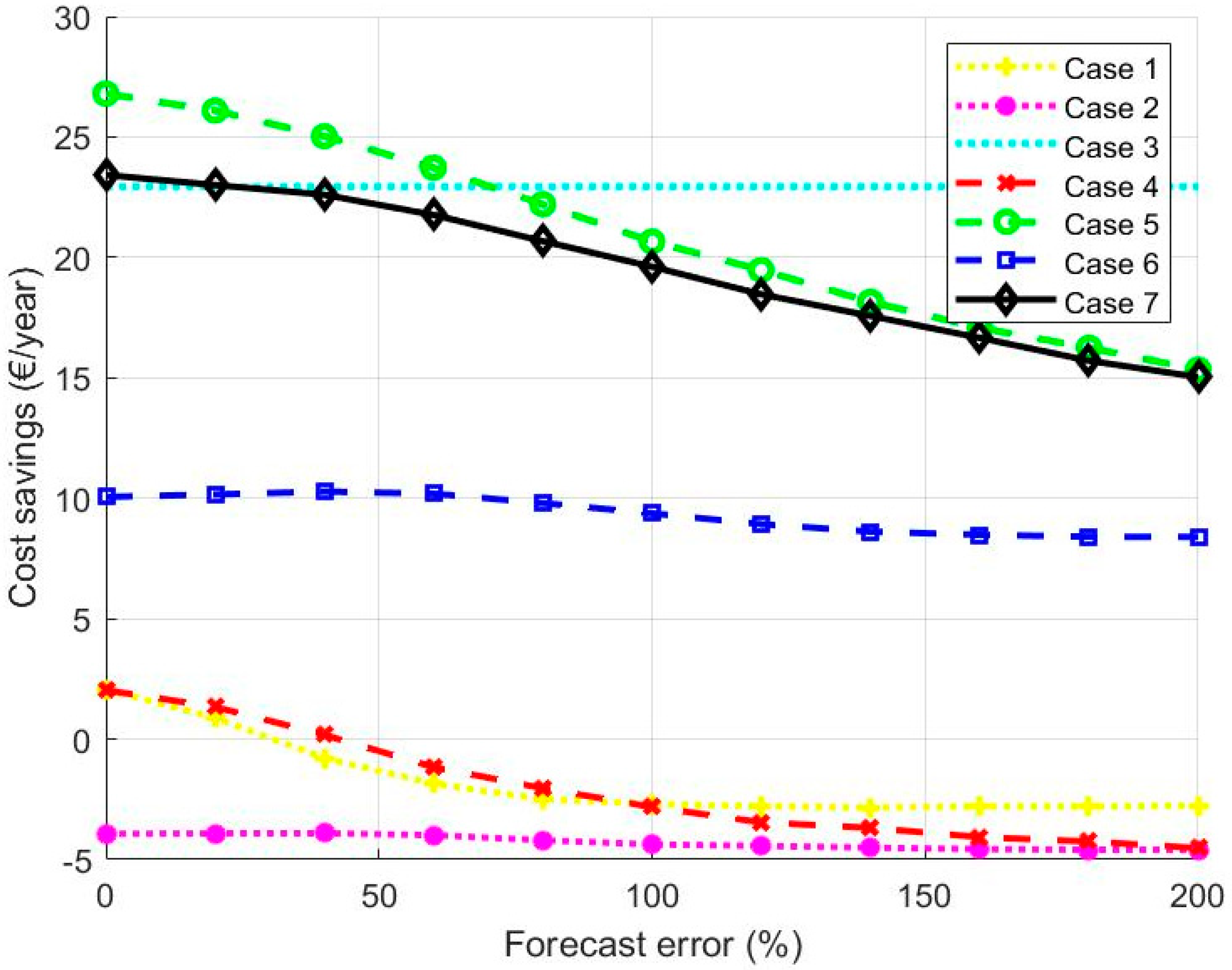

- In simulations, every customer had the added production of 3 kWp solar panels. The results are shown as average cost savings in the study group. Cost savings are presented as the function of forecast error. The results were calculated with the basic and random methods of modeling forecast errors. First, simulations were made with the power-based distribution tariff, where all possible cases (control targets) are meaningful.

3.1.1. Basic Method

- In case 1, the total cost savings increase marginally around the 100% forecast error, when the forecast error increases. This effect is caused by control inaccuracy. In the basic method of load forecasting, the direction of the error is the same at all error levels. Therefore, when the error increases, the control system increases its preparedness to store surplus energy. The same effect can be seen in case 5, which combines market price-based control (case 3) with case 1. In case 2, improved load forecasting strongly increases the cost savings when the forecast is very accurate. When the forecast error is over 80%, cost savings are almost constant. In case 3, the curve is flat. The negative number is leading from the increasing maximum peak power in market price-based control. Additionally, forecast errors do not notably affect the cost savings from market price-based control if decreased maximum peak power is not involved. The control system knows the whole time when high and low prices occur, so it uses BESS capacity maximally to shift the load from high price to low price, and it does not care about the load forecast.

- Cost savings from the distribution tariff and electricity tax mostly affect total cost savings, as shown by the similar shape of curves in Figure 4 and Figure 5. Cost savings from the distribution tariff in cases where market price-based control is involved are lower than total cost savings. Additionally, in cases where decreased maximum peak power is involved, cost savings are higher.

3.1.2. Random Method

3.2. Simulations with General Distribution Tariff

3.2.1. Basic Method

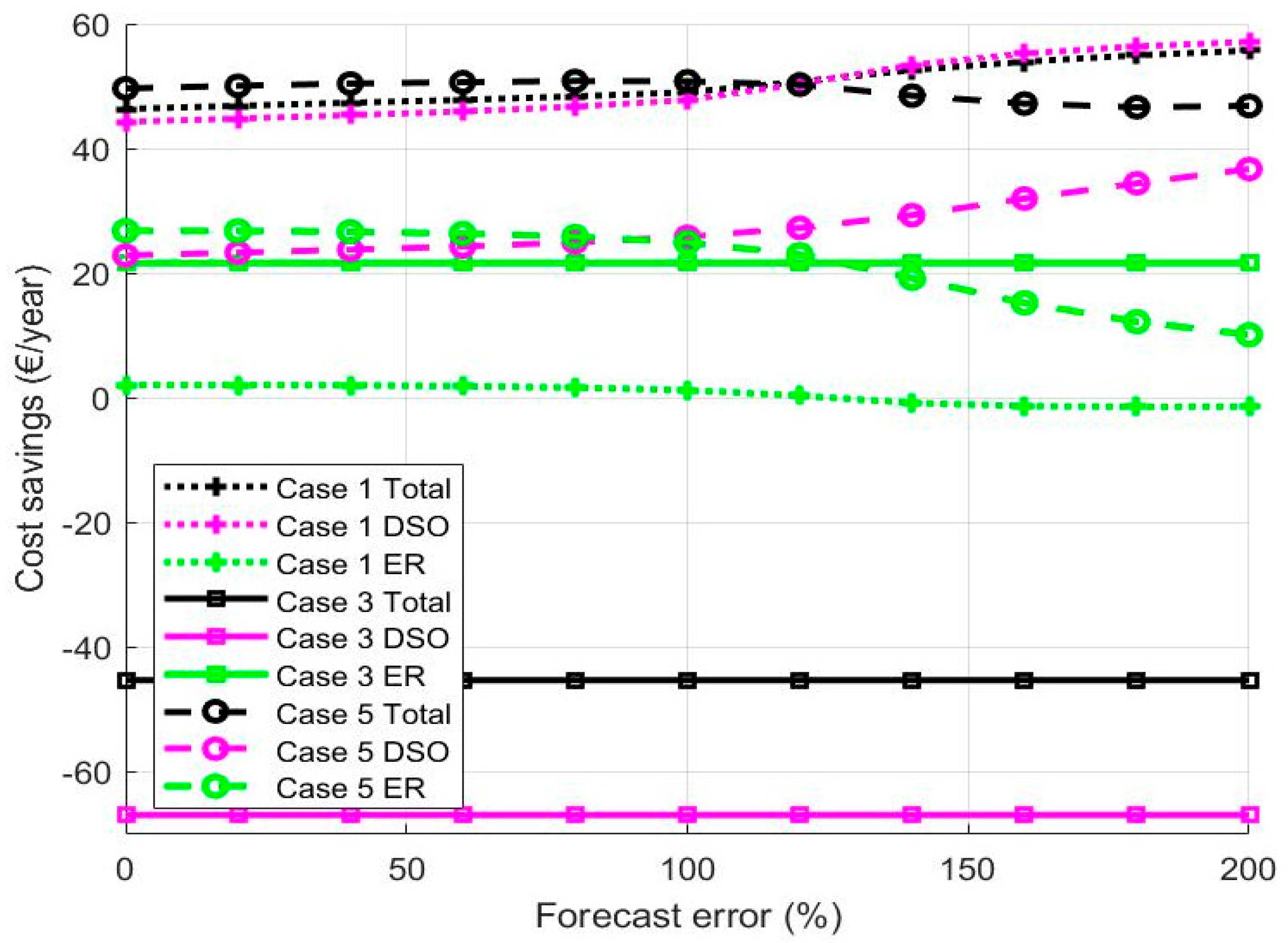

- When the basic method for modeling the error of load forecast is used, case 5 gives the highest cost savings before the error level of 120%. The results of this is shown in Figure 10. After that, as with the power-based tariff, the cost savings in case 1 increase and rise higher than in case 5. This is caused by the inaccuracy of the control system and the knowledge of the load profile in the basic method. The total cost savings in case 3 is not as negative as it is with the power-based tariff, but is still negative. This is because the control in case 3 does not care about the grid feeding from storage during high prices. This feature is involved in case 5, when the rise in cost savings is strongly positive. The main finding is that the effect of forecast error is not significant with the general distribution tariff and the differences between error levels are only marginal.

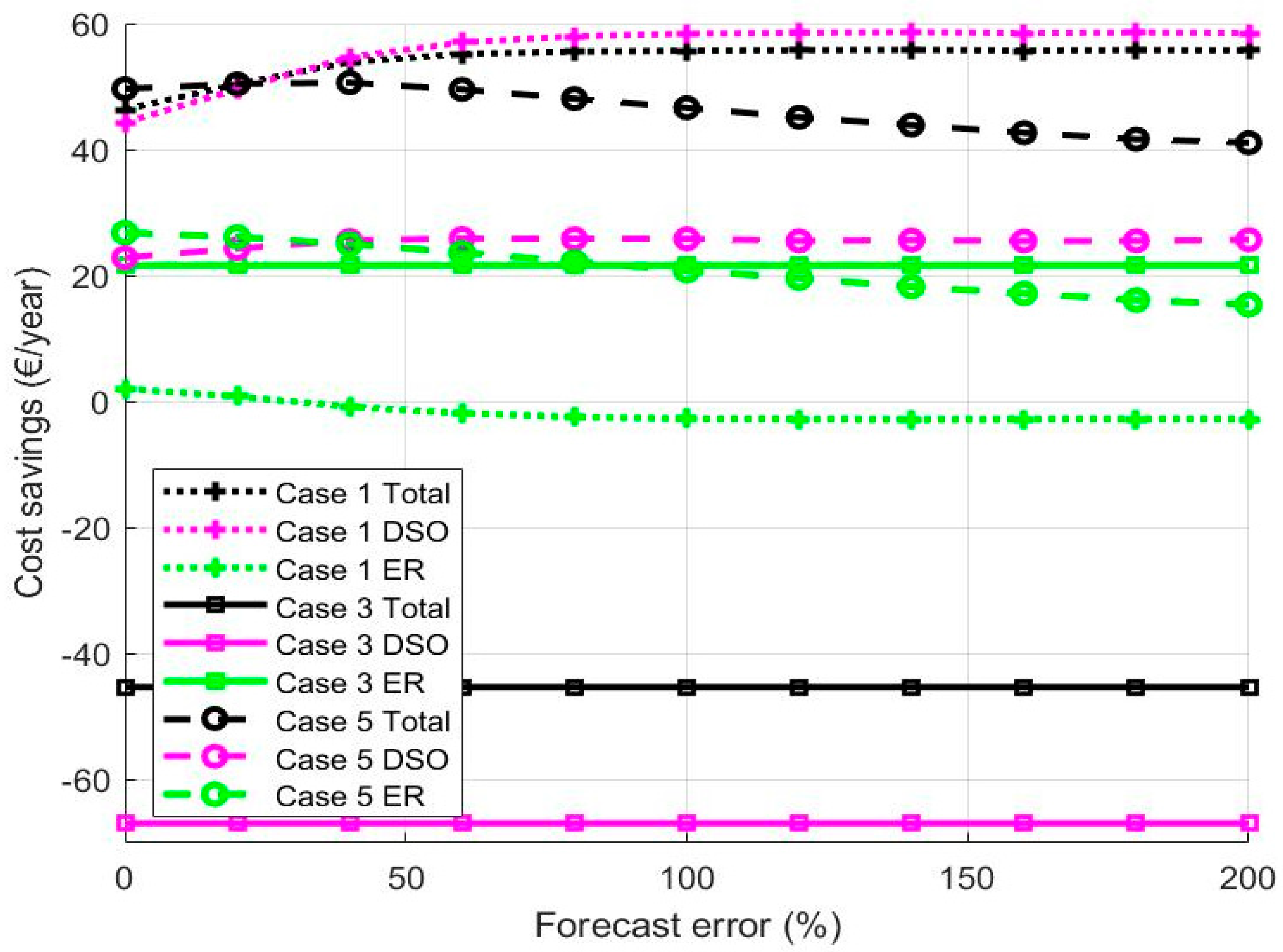

3.2.2. Random Method

- When the random method is used, the levels of cost savings are very similar to the basic method and the differences between error levels are only marginal. The results with the random method is shown in Figure 11. The biggest difference between basic and random methods is that the changes that happen after the 100% error level with basic the method happen before the 60% error level with the random method. When the random method is used, it seems that with current load forecast accuracy (100%), it is not profitable to use the combination of control targets (case 5) instead of case 1. However, when the basic method is used, the combination of control targets is the most profitable.

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karjalainen, S.; Ahvenniemi, H. Pleasure is the profit—The adoption of solar PV systems by households in Finland. Renew. Energy 2019, 133, 44–52. [Google Scholar] [CrossRef]

- Koskela, J.; Rautiainen, A.; Järventausta, P. Using electrical energy storage in residential buildings—Sizing of battery and photovoltaic panels based on electricity cost optimization. Appl. Energy 2019, 239, 1175–1189. [Google Scholar] [CrossRef]

- Jiménez-Castillo, G.; Muñoz-Rodriguez, F.J.; Rus-Casas, C.; Talavera, D.I. A new approach based economic profitability to sizing the photovoltaic generator in self-consumption systems without storage. Renew. Energy 2020, 148, 1017–1033. [Google Scholar] [CrossRef]

- Hirvonen, J.; Kayo, G.; Cao, S.; Hasan, A.; Sirén, K. Renewable energy production support schemes for residential-scale solar photovoltaic systems in Nordic conditions. Energy Policy 2015, 79, 72–86. [Google Scholar] [CrossRef]

- Koskela, J.; Rautiainen, A.; Järventausta, P. Utilization possibilities of electrical energy storages in households’ energy management in Finland. Int. Rev. Electr. Eng. 2016, 11, 607–617. [Google Scholar] [CrossRef]

- Honkapuro, S.; Haapaniemi, J.; Haakana, J.; Lassila, J.; Partanen, J.; Lummi, K.; Rautiainen, A.; Supponen, A.; Koskela, J.; Järventausta, P. Jakeluverkon Tariffirakenteen Kehitysmahdollisuudet ja Vaikutukset (Development Options for Distribution Tariff Structures); No. 65; LUT Scientific and Expertise Publications: Lappeenranta, Finland, 2017. (In Finnish) [Google Scholar]

- Lummi, K.; Rautiainen, A.; Järventausta, P.; Heine, P.; Lehtinen, J.; Hyvärinen, M.; Salo, J. Alternative power-based pricing schemes for distribution network tariff of small customers. In Proceedings of the IEEE PES innovative smart grid technologies Asia (ISGT Asia), Singapore, 22–25 May 2018. [Google Scholar]

- Koskela, J.; Lummi, K.; Mutanen, A.; Rautiainen, A.; Järventausta, P. Utilization of electrical energy storage with power-based distribution tariffs in households. IEEE Trans. Power Syst. 2019, 34, 1693–1702. [Google Scholar] [CrossRef]

- Koponen, P.; Ikäheimo, J.; Koskela, J.; Brester, C.; Niska, H. Assessing and comparing short term load forecast performance. Energies 2020, 13, 2054. [Google Scholar] [CrossRef]

- Goebel, C.; Cheng, V.; Jacobsen, H.-A. Profitability of residential battery energy storage combined with solar photovoltaics. Energies 2017, 10, 976. [Google Scholar] [CrossRef] [Green Version]

- Ayuso, P.; Beltran, H.; Segarra-Tamarit, J.; Pérez, E. Optimized profitability of LFP and NMC Li-ion batteries in residential PV applications. Math. Comput. Simul. 2020, in press. [Google Scholar] [CrossRef]

- Kuleshov, D.; Peltoniemi, P.; Kosonen, A.; Nuutinen, P.; Huoman, K.; Lana, A.; Paakkonen, M.; Malinen, E. Assesment of economic benefits of battery energy storage application for the PV-equipped households in Finland. J. Eng. 2019, 18, 4927–4931. [Google Scholar]

- Hesse, H.C.; Martins, R.; Musilek, P.; Naumann, M.; Truong, C.M.; Jossen, A. Economic optimization of component sizing for residential battery storage systems. Energies 2017, 10, 835. [Google Scholar] [CrossRef]

- Pilz, M.; Ellabban, O.; Al-Fagih, L. On optimal battery sixing for households participating in demand-side management schemes. Energies 2019, 12, 3419. [Google Scholar] [CrossRef] [Green Version]

- Kharseh, M.; Wallbaum, H. How adding a battery to a grid-connected photovoltaic system can increase its economic performance: A comparison of different scenarios. Energies 2019, 12, 30. [Google Scholar] [CrossRef] [Green Version]

- Schram, W.L.; Lampropoulos, I.; Van Sark, W.G.J.H.M. Photovoltaic system coupled with batteries that are optimally sized for household self-consumption: Assessment of peak shaving potential. Appl. Energy 2018, 223, 69–81. [Google Scholar] [CrossRef]

- Litjens, G.B.M.A.; Worrell, E.; Van Sark, W.G.J.H.M. Economic bnefits of combining self-consumption enhancement with frequency restoration reserves provision by photovoltaic-battery systems. Appl. Energy 2018, 223, 172–187. [Google Scholar] [CrossRef]

- Litjens, G.B.M.A.; Worrell, E.; Van Sark, W.G.J.H.M. Assesment of forecasting methods on performance of photovoltaic-battery systems. Appl. Energy 2018, 221, 358–373. [Google Scholar] [CrossRef]

- Dongol, D.; Feldmann, T.; Schmidt, M.; Bollin, E. A model predictive control based peak shaving application of battery for a household with photovoltaic system in a rural distribution grid. Sustain. Energy Grids Netw. 2018, 16, 1–13. [Google Scholar] [CrossRef]

- Beltran, H.; Ayuso, P.; Pérez, E. Lifetime expectancy of Li-ion batteries used for residential solar storage. Energies 2020, 13, 568. [Google Scholar] [CrossRef] [Green Version]

- Nord Pool. Elspot Day-a-Head Electricity Prices. Available online: https://www.nordpoolgroup.com/Market-data1/Dayahead/Area-Prices/ALL1/Hourly/?view=table (accessed on 20 May 2020).

- Vartiainen, E. A new approach to estimating the diffuse irradiance on inclined surfaces. Renew. Energy 2000, 20, 45–64. [Google Scholar] [CrossRef]

- Reindl, D.T.; Beckman, W.A.; Duffie, J.A. Diffuse fraction corrections. Sol. Energy 1990, 45, 1–7. [Google Scholar] [CrossRef]

- Hellman, H.-P.; Koivisto, M.; Lehtonen, M. Photovoltaic power generation hourly modelling. In Proceedings of the 2014 15th International Scientific Conference on Electric Power Engineering (EPE), Brno, Czech Republic, 12–14 May 2014. [Google Scholar]

- Fernão Pires, V.; Romero-Cadaval, E.; Vinnikov, D.; Roasto, I.; Martins, J.F. Power converters interfaces for electrochemical energy storage system—A review. Energy Convers. Manag. 2014, 86, 453–475. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L.-A.; Dekkiche, A.-I. A generic battery model for the dynamic simulation of hybric electric vehicles. In Proceedings of the International Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007. [Google Scholar]

- Parvini, Y.; Vahidi, A. Maximizing changing efficient of lithium-ion and lead acid batteries using optimal control theory. In Proceedings of the International American Control Conference, Chicago, IL, USA, 1–3 July 2015. [Google Scholar]

- Weniger, J.; Tjaden, T.; Quasching, V. Sizing of residential PV battery system. Energy Procedia 2014, 46, 78–87. [Google Scholar] [CrossRef] [Green Version]

- Mutanen, A. Improving Electricity Distribution System State Estimation with AMR-based Load Profiles; Tampere University of Technology: Tampere, Finland, 2018; p. 91. [Google Scholar]

- Distribution Prices, Elenia. Available online: https://www.elenia.fi/sahko/siirtotuotteet (accessed on 20 May 2020).

- Open Data, Finnish Meteorological Institute. Available online: httpt://en.ilmatieteenlaitos.fi/open-data (accessed on 20 May 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koskela, J.; Mutanen, A.; Järventausta, P. Using Load Forecasting to Control Domestic Battery Energy Storage Systems. Energies 2020, 13, 3946. https://doi.org/10.3390/en13153946

Koskela J, Mutanen A, Järventausta P. Using Load Forecasting to Control Domestic Battery Energy Storage Systems. Energies. 2020; 13(15):3946. https://doi.org/10.3390/en13153946

Chicago/Turabian StyleKoskela, Juha, Antti Mutanen, and Pertti Järventausta. 2020. "Using Load Forecasting to Control Domestic Battery Energy Storage Systems" Energies 13, no. 15: 3946. https://doi.org/10.3390/en13153946