1. Introduction

The distinct characteristics of Non-Interconnected Island (NII) Systems usually demand a different approach when considering the relevant operation of the energy market compared to the interconnected system. In particular, in the case of NIIs the electricity is supplied by autonomous systems producing energy mainly from local thermal stations (conventional diesel generators, etc.) as well as RES stations. Such islands may not be able to be connected to the mainland grid due to technical, technological or economic difficulties.

The small size of NII systems is quite difficult to support any competition in generation justifying the establishment of a market with many suppliers. Thus, a different approach in the operation of the energy market, compared to the interconnected system, shall usually be adopted. In the case of Greece, where the NII energy market comprises 29 NII systems, the Greek legislation adopts a cost optimization approach considering the actual production cost of conventional units, where, unlike standard electricity markets, the market participants do not submit priced offers. Unit commitment and load dispatch is, instead, performed taking into account the operational cost of conventional units, while RES energy is considered as a priority to be injected in the grid.

Demand response schemes, allowing modifications in the system’s load profile, could be proven quite beneficial in the case of NII system, allowing the demand-side to assist the operation of the system. Smart devices, like smart washing machines or smart air-conditioning systems, can provide management capabilities for the typical user’s electricity demand. However significant demand management capabilities are offered from systems with a greater consumption. In particular, desalination systems that are used to supply clear water to an island community, usually require a significant energy demand of around 2–4 kWh per m

3 of produced clear water [

1]. Such a demand indicates a significant opportunity for the application of demand response schemes that could assist in lowering the operational cost of conventional electricity production units and increase the RES penetration in the NII systems.

Procedures concerning the reduction of the energy consumption of desalination units [

2] or the management of the desalination systems’ operation [

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15] have been proposed in literature. Studies, like reference [

3] mainly concern the maximization of the desalination system operator’s profit by participating in the energy market (by exploiting the market prices, etc.). Moreover, similar studies aim to manage the operation of the desalination system in order to minimize the annual operational cost of the system and maximize the water production [

4]. Similarly, studies propose ways to manage the operation of desalination units in order to minimize the life-time cost of the system [

5,

6] or calculate the pay-back period of the system [

7]. Moreover, studies [

5,

8,

9,

10] are limited to studying smaller systems that could autonomously operate with RES units covering their own energy consumption or particularly concerning small isolated communities [

11]. However, none of the aforementioned studies [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15], takes into account the constraints linked with the whole system operation in order to better exploit the elasticity that can be offered by the desalination system. In this respect, any constraints linked with an actual day-ahead scheduling (particularly a day-ahead scheduling for NII systems), like the technical characteristics of conventional units, are missing from those studies.

Moreover, none of the aforementioned studies, [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15], or similar studies concerning simple unit commitment problems [

16], take into account a detailed overview of the desalination system. In particular, all the water storage reservoirs that a desalination system comprises, alongside all the pumps filling or emptying those reservoirs, shall be taken into account when considering modifications in the desalination system’s demand. Unlike [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16], this paper proposes a detailed representation of the desalination system, taking into account all the relevant constraints for the system’s operation. The mathematical representation of the aforementioned operation is incorporated in the day-ahead scheduling for the case of Greek NII systems in order to define the optimal management of the examined desalination system.

The Day-Ahead Scheduling in the case of the Greek NII systems, as well as the mathematical modelling of the relevant problem, is presented in

Section 2 of this paper. The mathematical representation of the desalination system’s operation, required to incorporate the management of the desalination demand in the day ahead scheduling problem is presented in

Section 3. The proposed optimisation procedure is applied for the desalination system installed in the Greek island of Kythnos, in order to observe how the optimal management of the desalination demand can affect the day ahead scheduling of the system. The technical characteristics of the desalination system and the production units in Kythnos (conventional—RES) are presented in

Section 4, while the results of the analysis are provided in

Section 5. Conclusions are drawn in

Section 6.

2. Day-Ahead Scheduling in Non-Interconnected Islands

The relatively small size of NII systems makes it quite difficult to support any competition in generation and justify an energy market with an increased number of suppliers. In this respect, according to the Greek Legislation, the unit commitment and load dispatch in Greek NII systems is performed taking into account the operational cost of conventional units, while RES energy is dispatched with priority. Unlike standard electricity markets, the market participants do not submit priced offers in the Greek NII energy markets.

The operation of the Non-Interconnected Islands in Greece is mainly defined according to the NII Operational Code. The targets set in this Code mainly aim to increase the RES penetration in each island while, at the same time, achieving the most economical operation of the participating conventional generation units. Apparently, the aforementioned goals shall be satisfied while ensuring the required power adequacy and the safe system operation.

The NII Code defines that the first operational cycle for the operation of the NII energy market is the “Day-Ahead Scheduling” (DAS), which takes place before the examined dispatch day and concerns the next 24 h. Dispatch Scheduling and Real-Time Dispatch shall be performed within the day, considering small time intervals or the real-time operation of the system, in order to re-evaluate the dispatch and the production scheduling of the production units. Since the scope of this paper is to evaluate the potential benefit of the desalination systems, taking into account time intervals of a whole day or even a whole year, the Day-Ahead Scheduling will be examined.

According to the NII, the System Operator shall perform the Day-Ahead Scheduling, taking into account hourly Power Offers submitted for the generator units in the network. Moreover, the targets set in the Greek NII Code for the Day-Ahead Scheduling mainly aim to increase the RES penetration in each NII system, while also achieving the most economical operation of the relevant conventional generation units. The cost for the operation of the production units can be summarized in (1), where

or

indicates the cost of the conventional unit

, or the RES unit

, respectively, at timeslot

t:

In order to increase the RES penetration, while achieving a minimum conventional production cost, the virtual cost of the RES units in the problem’s objective function, , can be set equal to zero as it is evident in (2). The rest of the terms in (2) indicate the virtual cost of slack parameters

More specifically:

The term indicates the production power of unit g, at timeslot t, that is lower than the relevant technical minimum and is the relevant penalty cost.

The term indicates the power divergence from the ramp-up requirement and is the relevant penalty cost.

The term indicates the power divergence from the ramp-down requirement and is the relevant penalty cost.

The term indicates the power curtailment for unit r at timeslot t, where indicates the relevant maximum available RES energy and denotes the RES energy actually injected in the grid. is the penalty cost in order to ensure a lower RES curtailment .

A more detailed explanation on the slack parameters is provided later, when the relevant requirements are explained thoroughly

The production cost of a conventional unit is usually expressed in a quadratic form. In order to consider this cost in a mixed integer linear programming model (MILP),

linear segments may be taken into account [

14,

15]. The production power

of each conventional unit can be expressed as in (3), while constraints (5)–(9) shall be taken into account in order to define the operation in each production scale.

denotes the maximum production power in each segment

,

indicates the technical minimum power of unit

g,

is a binary variable indicating whether unit

g operates at the production segment

and

is the power production in each segment. Specific conditions when resolving the DAS problem may require that the production power

is lower than the technical minimum. Thus the term

is introduced in (3), alongside the constraint in (4), indicating that the production power of unit g, at timeslot t, is lower than the relevant technical minimum. In order to avoid such situations, the term

is included in the objective function (2). The relevant penalty cost

shall be considerably high in order to avoid a production power lower than the technical minimum:

The production cost

for a unit g operating with a power

at timeslot t is provided according to (10). In particular, the cost is equal to the cost for producing a power equal to the technical minimum

plus the relevant cost for the production of power

at each segment

k. The production cost in each segment can be linearly approximated by the term

[

1], where

indicates the production cost for a power equal to

. Apparently,

indicates the cost for the production of a power equal to the technical minimum

:

The ramp-up requirement for a conventional unit indicates that the increase in the power between two examined timeslots cannot be greater than the relevant limit

as expressed in (14). If the unit is required to be put in operation after a timeslot where it is idle (i.e.,

), the power of the unit in timeslot t shall be equal to

. This can be expressed by including the relevant term in (14). In case the ramp-up requirement cannot be satisfied, the term

shall be introduced in (14), indicating the relevant power divergence. The relevant slack variable shall also be introduced in the objective function (2), where the relevant penalty cost

shall be quite large in order to avoid conditions where the ramp-up condition is not met. For the first timeslot of the examined day the state of the conventional unit g at the last timeslot of the previous day,

as well as the relevant production power

shall be taken into account, as it can be seen in (15). Similar constraints shall be considered for the ramp-down requirements of the conventional units (indicating that the decrease in power among two examined timeslots cannot be greater than the relevant limit

), as it can be seen in equations (16)–(17).

If a unit

shall remain connected to the grid for a specific amount of timeslots equal to

within the day (or for all the timeslots of the examined day,

Nt), then (18) shall be taken into account:

The constraints for the minimum up time,

, of each conventional unit, g, are indicated in Equations (19)–(22). In particular (19) and (20) concern the minimum up time requirement for the first hours of the examined day, taking into account the number of hours the unit has been operating,

, up until the last timeslot, of the previous day. The requirement for the last hours of the scheduling day is expressed in (22), while the relevant requirement for the rest of the day’s timeslots is expressed in (21). Similar constraints are defined for the minimum down time requirement,

, of each unit g, as expressed in (23)–(26):

When considering a RES unit,

r, with a controllable output power, the power

injected in the grid, cannot be greater than the relevant maximum available produced power

from this unit, in the examined timeslot t, as indicated in (27). Moreover, for safety reasons related to the uncertainty in the forecasted RES production, it is important that significantly increased amounts of RES power compared to the system’s load,

, shall not be considered when resolving the DAS. Thus a limit equal to

is considered in the relevant injected power in Equation (28):

In order to ensure that the energy balance constraint is satisfied for every timeslot of the Dispatch Day, the total sum of the energy produced from all the production units (conventional and RES) at the examined timeslot, t, shall be equal to the system load

, as indicated in Equation (29):

3. Operation of a Desalination System

An overview of the desalination system installed in Kythnos, a NII island in Greece, is depicted in

Figure 1. The desalination units are providing clear water to the community of Merichas in the island.

The operation of each desalination unit in

Figure 1 lies in removing the salt from the sea water (which is referred to as

feed in the desalination process) while producing clear water (or

permeate) [

1,

10,

17]. The desalination units have a specific performance concerning the amount of clear water that can be produced from a certain amount of sea water. This performance is usually called

Recovery Ratio and is calculated according to (30). During the process of desalination a part of the sea water turns into a mixture with a high salt concentration, called

brine. Potential disturbances in the marine ecosystem shall be taken into account when considering the brine disposal in the sea [

18], however ways are proposed in literature [

2,

19,

20] in order to reduce the relevant environmental impact:

Initially, the sea water is transferred to two feed reservoirs (Reservoirs 1 and 2 in

Figure 1) by employing the relevant pumps (Pump

sf1 & Pump

sf2 in). Additional pumps (Pump

fd1 & Pump

fd2 in

Figure 1) are employed in order to provide sea water to the desalination units. After the desalination process is completed (by one or both of the desalination units in

Figure 1), clear water is provided to the relevant Permeate Reservoirs. These reservoirs are in the same location with the desalination units, yet the water is required to be transferred to a higher altitude in order to finally be provided to Mericha’s population. The relevant task is performed with Pump

pcw1 & Pump

pcw2 in

Figure 1 that transfer clear water to the relevant reservoirs.

The high salt concentration mixture that is created during the desalination process is disposed in the Brine Reservoir depicted in

Figure 1, and is finally transferred to the sea with the relevant pumps (Pump

bs1 and Pump

bs2).

The desalination system in Kythnos currently operates according to the level of water in each reservoir, as indicated in

Figure 2. More specifically, when the water is lower than a specific level (L

low) the relevant pump or desalination system is activated in order for the reservoir to be filled up until a specific high level (L

high). In this respect, the power required for the operation of the desalination system does not take into account any specific requirement (for instance available RES production) but merely depends on the relevant reservoir levels. It is evident, however, that the available volume capacity in all the system’s reservoirs could be exploited in order to schedule the system’s energy consumption during the day and offer demand response services towards the system operator.

In order to exploit the demand-response capabilities that can be provided by the desalination system, specific constraints shall be taken into account in order to define the relevant mathematical model that will allow the incorporation of the desalination operation in the DAS scheduling, as specified in

Section 2. In particular the exact demand of the desalination system at each timeslot

, shall be calculated by the defined optimisation problem and shall be added to the system’s load without the desalination demand,

, (which can be considered constant in the Day-Ahead Scheduling problem) as indicated in Equation (31):

The water volume of each reservoir , at each timeslot t, will be equal to the volume of the reservoir in the previous timeslot, , plus the water flowing towards the reservoir, . The water flowing out of the reservoir, , shall be subtracted from the relevant result, as indicated in (32). Concerning the first timeslot of the day the volume of the reservoir, , at the last timeslot of the previous day shall be taken into account, as it is evident in (33). Physical Constraints shall be considered for the minimum and maximum limit of each reservoir as noted in (34).

The water flowing towards each reservoir

,

, shall be limited according to the relevant limit established by the relevant pump. In particular, if

is the water flow in m

3/h indicated for each pump

pu = {

sf1,

sf2,

fp1,

fp2,

bs1,

bs2,

pcw1,

pcw2}, then the maximum water flowing through the pump at the timeslot examined will be equal to

, where

is the duration of the timeslot examined and is the power requirements of the pump (in kW). The relevant limits for the water flowing through the pumps are defined according to (35) and (36). Particularly concerning the 7th reservoir in

Figure 1 and the brine produced from the desalination units, it can be observed in

Figure 1 that two pumps are pumping brine towards the sea, thus Equation (37) shall be taken into account. The relevant limit for the water flowing through the pumps are expressed in equations (38) and (39):

It can be observed in

Figure 1 that pumps are providing water to the desalination units, thus the relevant limits in (40) and (41) shall be taken into account. Moreover, the water flowing out from reservoirs 3 & 4 is equal to the water flowing towards reservoirs 5 and 6 as noted in equations (42) and (43):

Concerning the operation of the desalination units, according to Equation (30) the produced clear water at each timeslot t will be equal to the sea water provided to the desalination unit multiplied by the Recovery Ratio R, as indicated in Equations (44) and (45). The water flowing out of the desalination units,

and

in

Figure 1, is also limited by the Recovery Ratio as indicated in (36). Moreover, it is evident in

Figure 1 that both desalination systems share a common reservoir for the brine produced from each one of them (

and

), thus constraints (46)–(48) shall be taken into account. The maximum flow rate of brine towards the Brine Reservoir (Reservoir No. 7 in

Figure 1) is defined according to the Recovery Ratio of the desalination units as expressed in (49) and (50):

The water flowing out of the Clear Water reservoirs (Reservoirs No. 5 and 6 in

Figure 1) shall be equal to the population’s water demand at the specific timeslot examined as it is evident in (51). The Volume of the Clear Water Reservoirs in the end of each timeslot shall be equal to, or greater than, the water demand of the next timeslot as noted in (52). (53) indicates that in the last timeslot of the examined day,

, the volume of the clear water reservoirs shall be equal to the demand of the 1st timeslot of the next day,

:

The energy required for the operation of a pump pu (where

with the relevant indices referring to the pumps in

Figure 1) can be calculated according to (54), taking into account the water flowing through the pump

(in m

3), the nominal water flow supported by the pump,

, (in m

3/h) and the nominal power of the pump,

, in kW. The exact calculation for the energy of each pump can be provided according to (55). Similarly the energy,

, required for the operation of each desalination unit

can be calculated according to (56), taking into account the nominal power of the unit

(in kW) and the nominal clear water production

(in m

3/h). Thus the total amount of energy for the operation of the desalination system,

, can be calculated according to (57). This amount of energy is added to the system load without the desalination demand, as indicated in (31), in order to define the system’s total load:

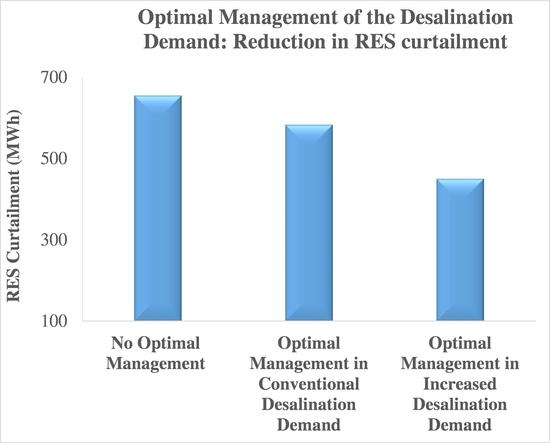

It shall be noted that resolving the DAS problem (i.e., minimise the objective function in (2), taking into account constraints (3)–(29)), while also considering the demand flexibility that can be offered by the desalination system (constraints (31)–(57)) will result in the grid absorbing the maximum amount of RES energy in order to serve the daily water demand. However, in order to further increase the RES produced energy injected in the grid, the RES energy within the day may be exploited in order to further increase the volume of water in the reservoirs of the desalination system. Thus additional clear water may be available in the end of the day that can potentially cover the water demand of the following days. This can be achieved by introducing the term in the objective function (2), where indicates the maximum available RES energy and denotes the RES energy actually injected in the grid. A large penalty cost will result in a lower RES curtailment, .

4. Study Case

In order to observe the potential benefits that can arise by managing the desalination system’s demand, the load for the year 2019 in the island of Kythnos is taken into account, as depicted in

Figure 3. It is evident that significant variations are observed in the system load during the year. In particular, the tourism activity in the summer months significantly increases the system load, introducing a peak of 3.42 MW. A peak of 2.56 MW is also noted during April, denoting the Easter vacations in Greece when an increased tourism activity is observed.

In order to cover the island’s demand during the winter and summer days, while also ensuring the safe operation of the system, four conventional generators of a nominal power equal to 1.1 ΜW are installed in Kythnos Island. The four generators are identical, with the characteristics provided in

Table 1. It is evident that two scales can be distinguished for the production of these generators (i.e.,

). The technical minimum power for the relevant units is equal to 637 kW, while the Ramp-up and Ramp-down requirements demand that the power between two hours cannot be increased (or decreased) more than 600 kW.

A wind generator of a nominal power equal to 600 kW is considered to be installed in Kythnos, with the production (P

max,t in (27)) as depicted in

Figure 4. The limit

Rl for the RES injected power in (28) is considered equal to 30%.

Concerning the desalination system in Kythnos, depicted in

Figure 1, the maximum volume

of the reservoirs is equal to

. It is evident that the Clear Water Reservoirs (Reservoirs No. 5 and 6) have quite an increased capacity for clear water (

), indicating significant demand response capabilities. The nominal flow rate of the pumps and desalination units, as well as the relevant nominal power is indicated in

Table 2.

The high and low limits in the reservoirs indicating the simple operation of the desalination system, not considering any smart demand response scheme to be applied, are presented in

Table 3Taking into account data provided for NIIs in Greece (

https://www.deya-parou.gr/), the estimation of the yearly water demand in Merichas (the area in Kythnos where clear water from the desalination system is provided) is presented in

Figure 5a. The distribution of the demand during the day is depicted in

Figure 5b, according to data provided in [

21].