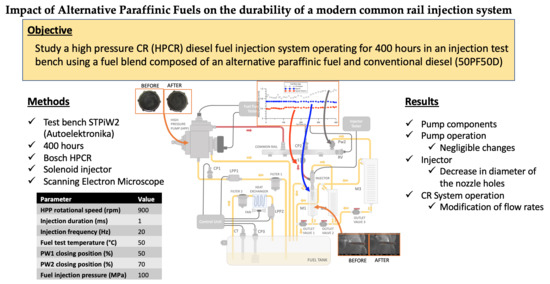

Impact of Alternative Paraffinic Fuels on the Durability of a Modern Common Rail Injection System

Abstract

:1. Introduction

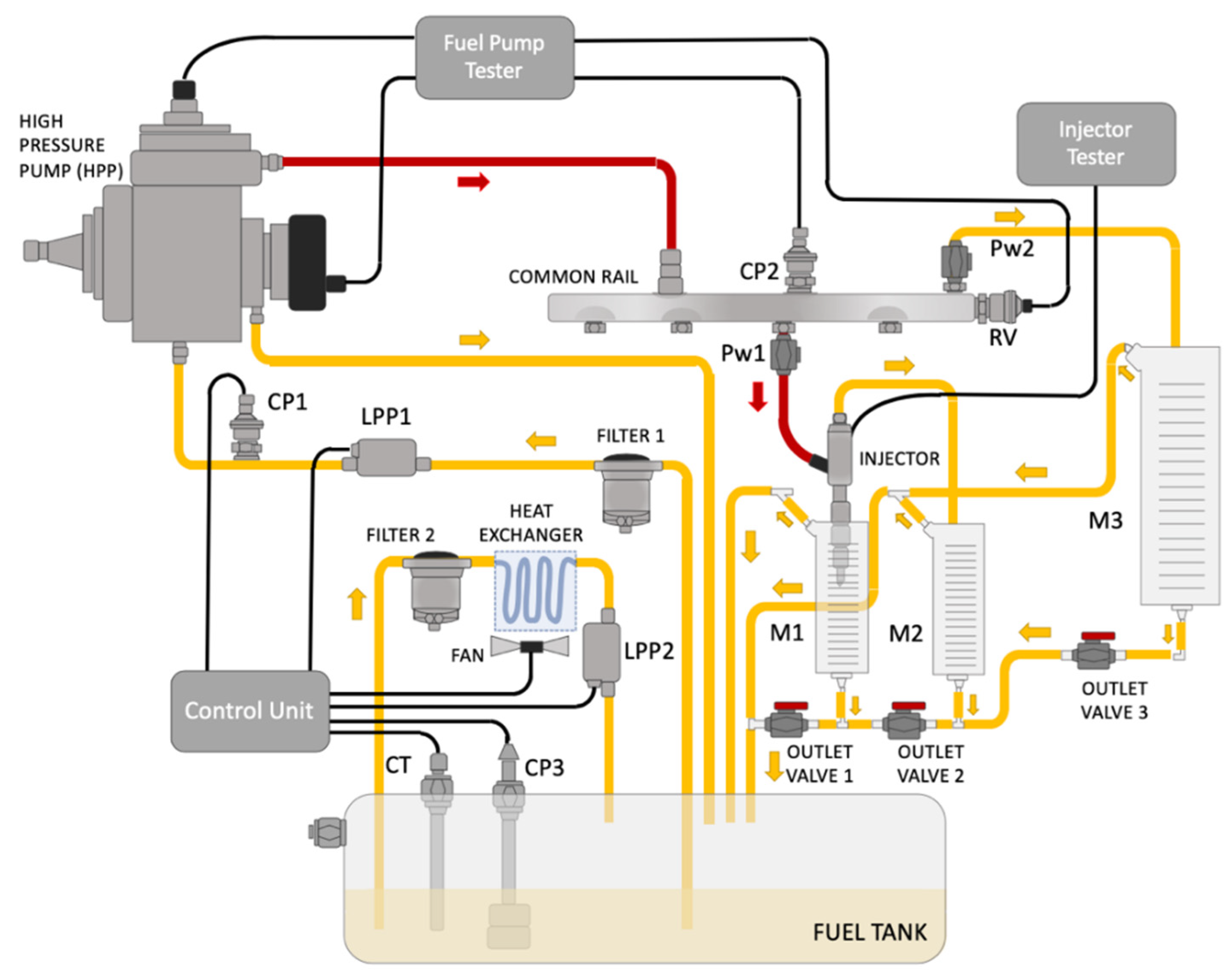

2. Materials and Methods

2.1. Materials

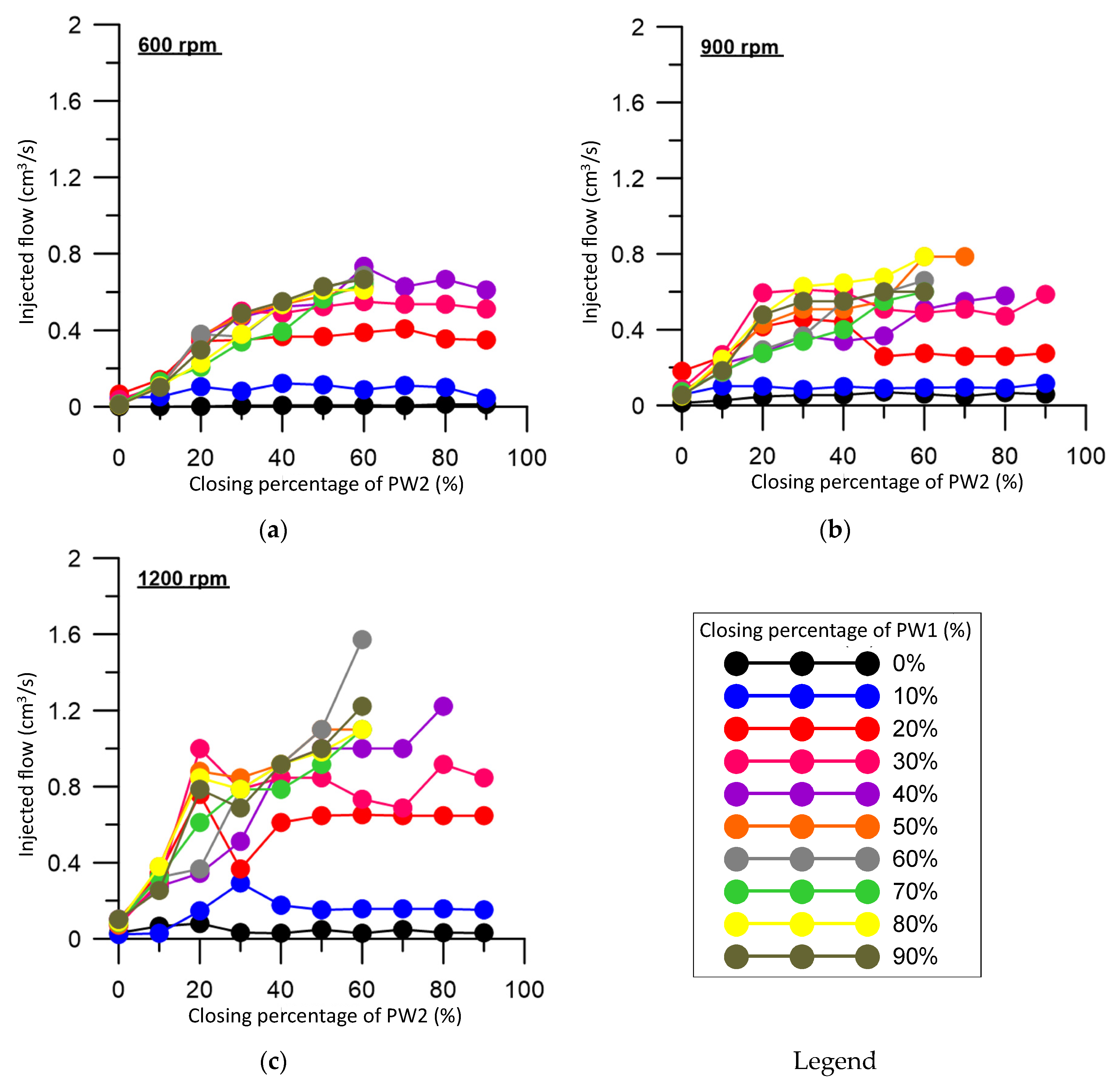

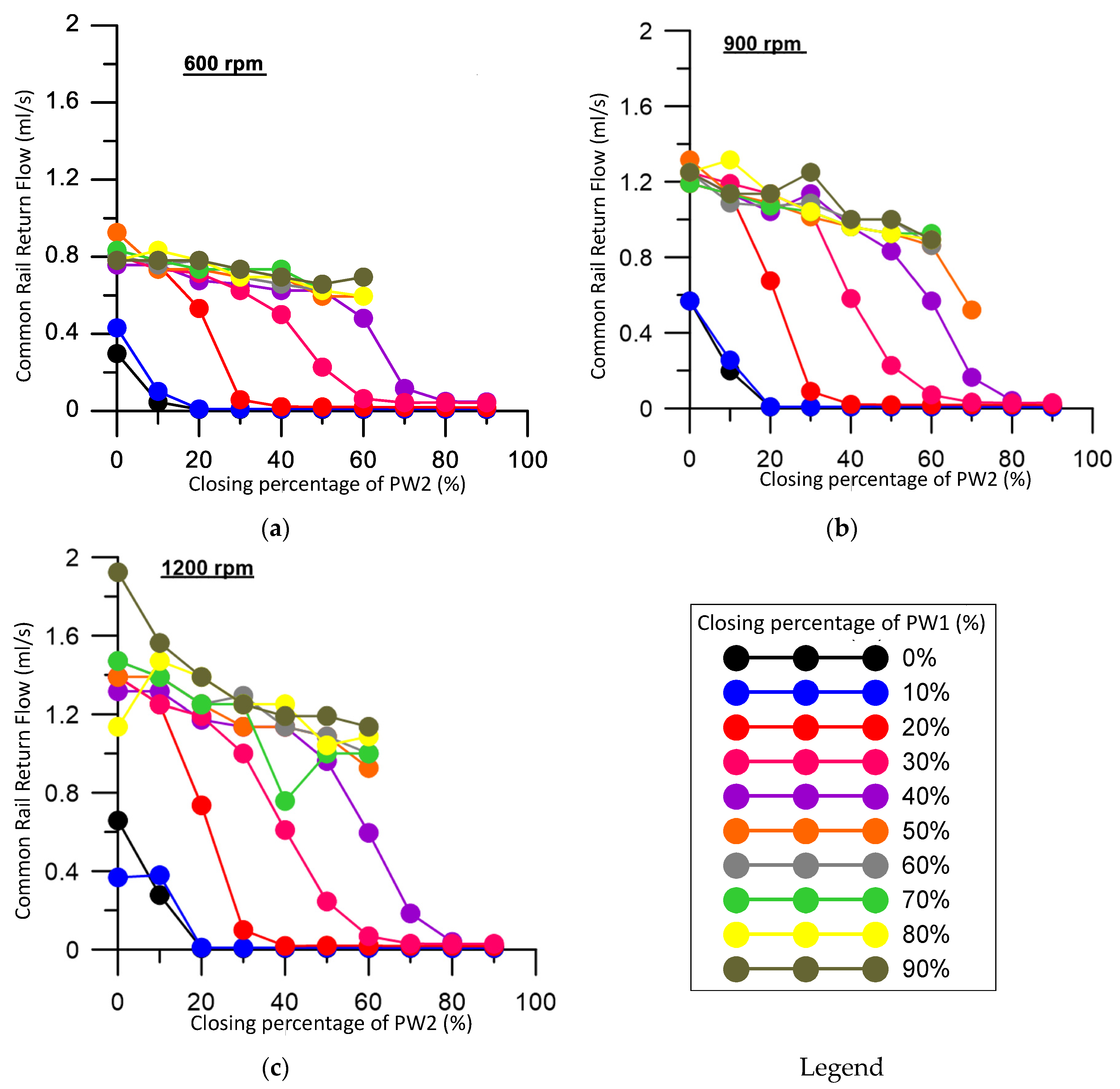

2.2. Development of the Durability Testing Method

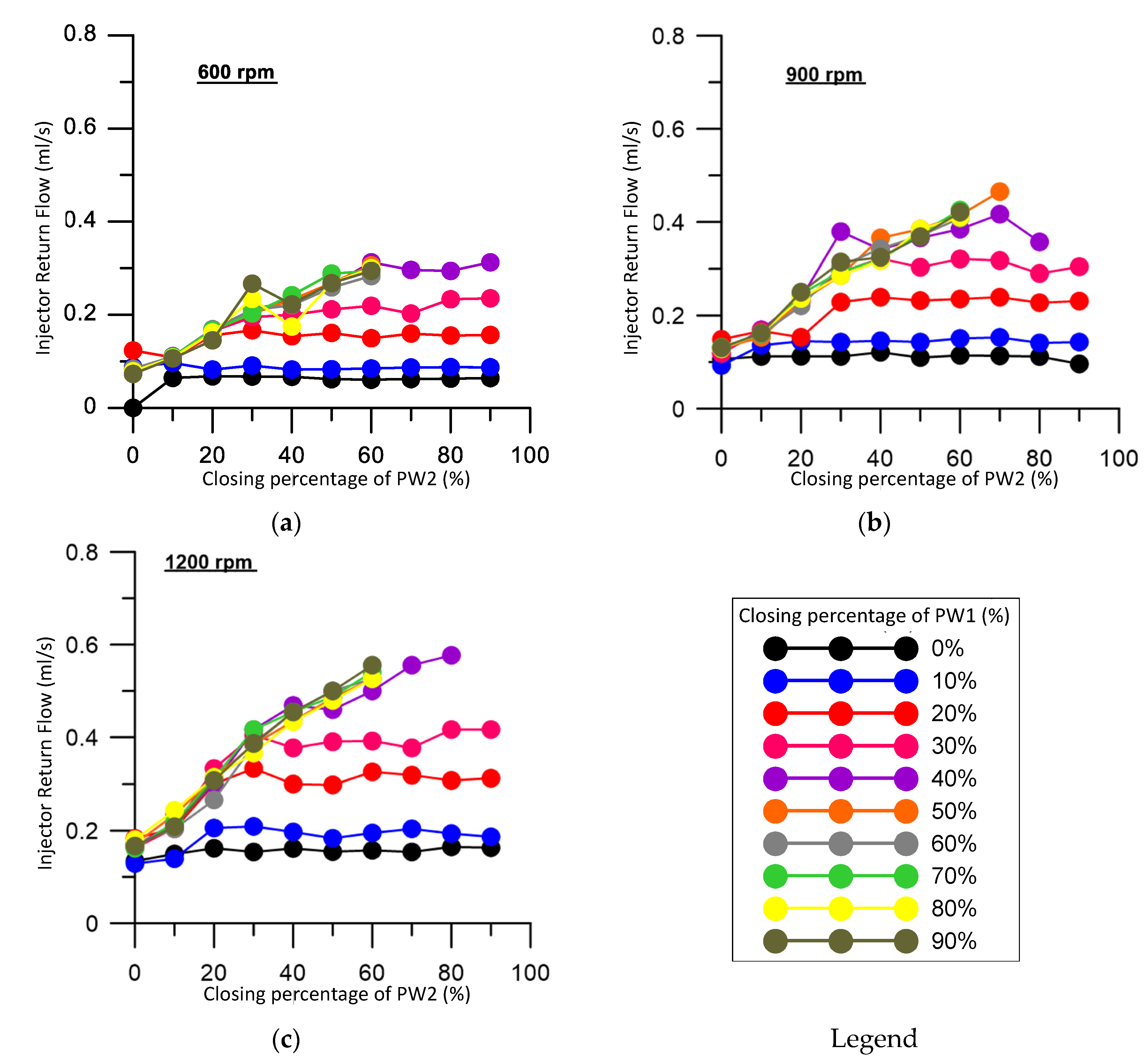

- (a)

- the rotational speed of the high-pressure pump (HPP); and

- (b)

- the opening/closing percentage of the valves PW1 and PW2 controlling the fuel flow rates to obtain the maximum achievable rail pressure and flow rates.

- (a)

- For 600 rpm pump speed, the closing percentage of PW1 is higher than or equal to 40%, and closing percentages of PW2 of 60%;

- (b)

- For 900 rpm, the PW1 shutdown percentage of 50% with PW2 shutdown percentages of 70%;

- (c)

- For 1200 rpm, closing rates of PW1 of 50% with closing percentages of PW2 of 70%.

- (a)

- The injection pressure ranges from 100 to 120 MPa, these being the highest fuel pressures which provide a large number of combinations for PW1 and PW2;

- (b)

- The chosen rotational speed is 900 rpm, as the fuel flow rate is not repeatable for higher rotational speeds leading to unstable tests.

- (1)

- PW1 50% and PW2 70%;

- (2)

- PW1 60% and PW2 50%;

- (3)

- PW1 70% and PW2 50%.

3. Results

3.1. Fuel Effect on the Components of the HPCR Fuel Injection System

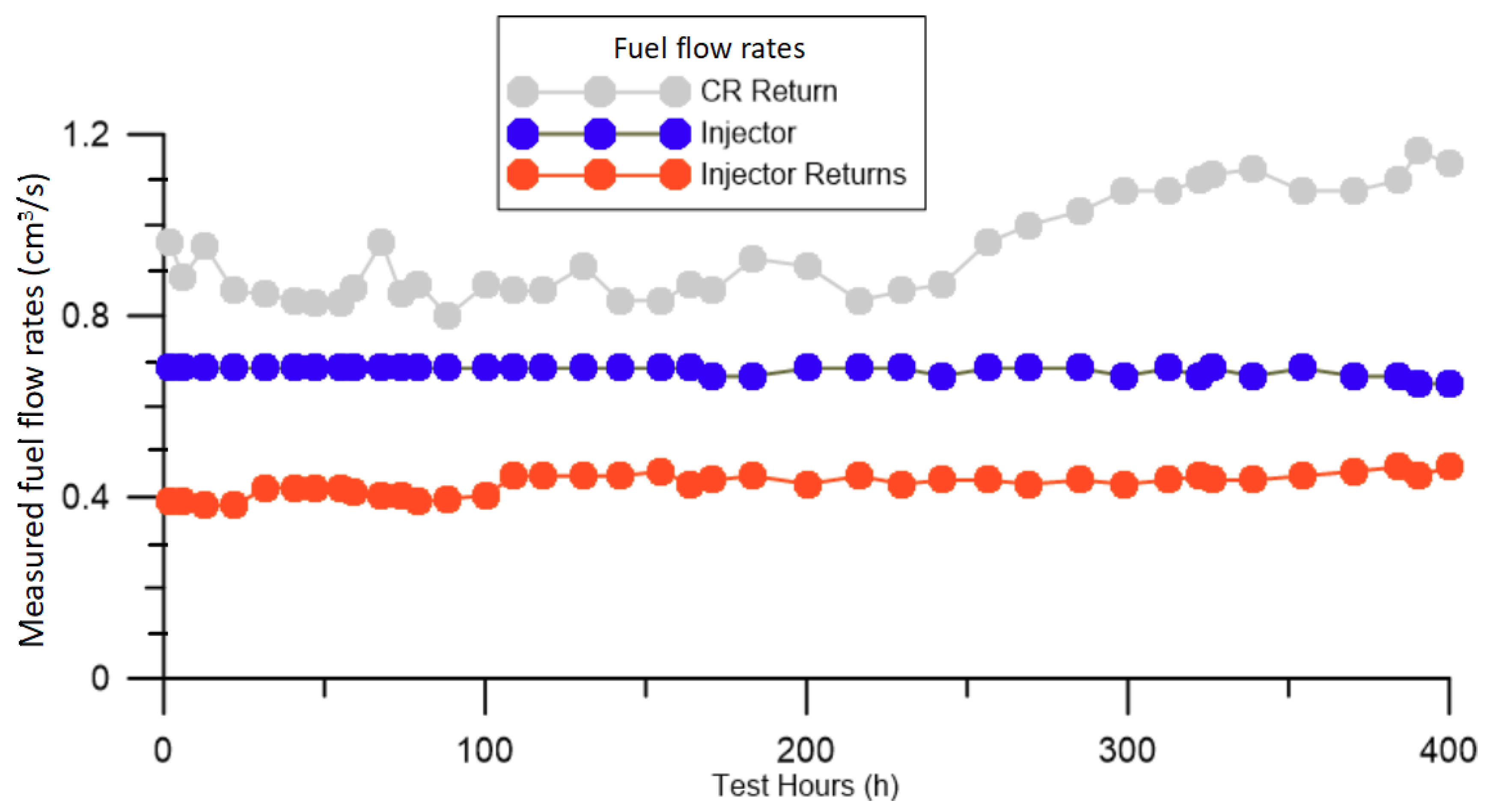

3.2. Fuel Effect on Fuel Flow Rates of the HPCR Fuel Injection System

- (1)

- The flow that needs to be accumulated in the rail to reach the set pressure is lower (probably since the operation of the common rail has changed, or that its dimensions have changed); and

- (2)

- The injector injects less fuel because the holes are smaller and the leftover fuel increased the injector return flow.

3.3. Effect of Durability Experiment on Fuel Stability and Aging

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Herfatmanesh, M.R.; Peng, Z.; Ihracska, A.; Lin, Y.; Lu, L.; Zhang, C. Characteristics of pressure wave in common rail fuel injection system of high-speed direct injection diesel engines. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Huang, X.; Xie, Z.; Zhou, M. Design and optimization of a novel electrically controlled high pressure fuel injection system for heavy fuel aircraft piston engine. Chin. J. Aeronaut. 2018, 31, 1920–1928. [Google Scholar] [CrossRef]

- Guangxin, G.; Zhulin, Y.; Apeng, Z.; Shenghua, L.; Yanju, W. Effects of Fuel Temperature on Injection Process and Combustion of Dimethyl Ether Engine. J. Energy Resour. Technol. 2013, 135, 042202. [Google Scholar] [CrossRef] [PubMed]

- Maeda, Y.; Murayama, T.; Fukazawa, S. Influence of Fuel Properties on the Injection Characteristics of Fuel Injection Systen in Diesel Engines. Bull. JSME 1975, 18, 411–418. [Google Scholar] [CrossRef]

- Schaschke, C.; Fletcher, I.; Glen, N. Density and Viscosity Measurement of Diesel Fuels at Combined High Pressure and Elevated Temperature. Processes 2013, 1, 30–48. [Google Scholar] [CrossRef]

- Caprotti, R.; Breakspear, A.; Graupner, O. Diesel injector deposits potential in future fueling systems. In Proceedings of the Powertrain & Fluid Systems Conference and Exhibition, Toronto, ON, Canada, 16–19 October 2006. SAE Technical Paper No: 2006-01-3359. [Google Scholar] [CrossRef]

- Barker, J.; Richards, P.; Goodwin, M.; Wooler, J. Influence of High Injection Pressure on Diesel Fuel Stability: A Study of Resultant Deposits. SAE Int. J. Fuels Lubr. 2009, 2, 877–884. [Google Scholar] [CrossRef]

- Matzke, M.; Litzow, U.; Jess, A.; Caprotti, R.; Balfour, G. Diesel Lubricity Requirements of Future Fuel Injection Equipment. SAE Int. J. Fuels Lubr. 2009, 2, 273–286. [Google Scholar] [CrossRef]

- Gill, S.S.; Tsolakis, A.; Dearn, K.D.; Rodríguez-Fernández, J. Combustion characteristics and emissions of Fischer–Tropsch diesel fuels in IC engines. Prog. Energy Combust. Sci. 2011, 37, 503–523. [Google Scholar] [CrossRef]

- Armas, O.; Gómez, A.; Ramos, Á. Comparative study of pollutant emissions from engine starting with animal fat biodiesel and GTL fuels. Fuel 2013, 113, 560–570. [Google Scholar] [CrossRef]

- Wu, T.; Huang, Z.; Zhang, W.G.; Fang, J.H.; Yin, Q. Physical and chemical properties of GTL-Diesel fuel blends and their effects on performance and emissions of a multicylinder DI compression ignition engine. Energy Fuels 2007, 21, 1908–1914. [Google Scholar] [CrossRef]

- Ezzitouni, S.; Soriano, J.A.; Gómez, A.; Armas, O. Impact of injection strategy and GTL fuels on combustion process and performance under diesel engine start. Fuel 2017, 200, 529–544. [Google Scholar] [CrossRef]

- Sajjad, H.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Arbab, M.I.; Imtenan, S.; Rahman, S.M.A. Engine combustion, performance and emission characteristics of gas to liquid (GTL) fuels and its blends with diesel and bio-diesel. Renew. Sustain. Energy Rev. 2014, 30, 961–986. [Google Scholar] [CrossRef] [Green Version]

- Schaberg, P.; Wattrus, M. Comparative Emissions Performance of Blends of GTL Diesel and FAME. In Proceedings of the SAE 2014 International Powertrain, Fuels & Lubricants Meeting, Birmingham, UK, 20–23 October 2014. Paper No: 2014-01-2769. [Google Scholar] [CrossRef]

- Christensen, E.; McCormick, R.L.; Sigelko, J.; Johnson, S.; Zickmann, S.; Lopes, S.; Slade, D. Impact of a Diesel High Pressure Common Rail Fuel System and Onboard Vehicle Storage on B20 Biodiesel Blend Stability. SAE Int. J. Fuels Lubr. 2016. [Google Scholar] [CrossRef] [Green Version]

- Fazal, M.A.; Haseeb, A.S.M.A.; Masjuki, H.H. Comparative corrosive characteristics of petroleum diesel and palm biodiesel for automotive materials. Fuel Process. Technol. 2010, 91, 1308–1315. [Google Scholar] [CrossRef]

- Mallick, P.K. Advanced materials for automotive applications: An overview. Adv. Mater. Automot. Eng. 2012, 5–27. [Google Scholar] [CrossRef]

- Sundus, F.; Fazal, M.A.; Masjuki, H.H. Tribology with biodiesel: A study on enhancing biodiesel stability and its fuel properties. Renew. Sustain. Energy Rev. 2017, 70, 399–412. [Google Scholar] [CrossRef]

- Haseeb, A.S.M.A.; Masjuki, H.H.; Ann, L.J.; Fazal, M.A. Corrosion characteristics of copper and leaded bronze in palm biodiesel. Fuel Process. Technol. 2010, 91, 329–334. [Google Scholar] [CrossRef]

- Kaul, S.; Saxena, R.C.; Kumar, A.; Negi, M.S.; Bhatnagar, A.K.; Goyal, H.B.; Gupta, A.K. Corrosion behavior of biodiesel from seed oils of Indian origin on diesel engine parts. Fuel Process. Technol. 2007, 88, 303–307. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Koo, B.C.P.; Guo, Y. Degradation of biodiesel under different storage conditions. Bioresour. Technol. 2006, 97, 250–256. [Google Scholar] [CrossRef]

- Bouaid, A.; Martinez, M.; Aracil, J. Long storage stability of biodiesel from vegetable and used frying oils. Fuel 2007, 86, 2596–2602. [Google Scholar] [CrossRef]

- Floweday, G. Potential for Reduced Wear Rates in Diesel Engines Running on Fischer-Tropsch Diesel. In Proceedings of the SAE Technical Papers Powertrains, Fuels and Lubricants Meeting, Florence, Italy, 15–17 June 2009; Volume 15. Paper No: 2009-01–1959. [Google Scholar] [CrossRef]

- Swarts, A.; Bell, A.; Mokheseng, K.; Pretorius, M.; Schaberg, P. Comprehensive applications testing of diesel from a commercial scale gas-to-liquids plant. SAE Int. J. Fuels Lubr. 2010, 3, 280–291. [Google Scholar] [CrossRef]

- Sajjad, H.; Masjuki, H.H.; Varman, M.; Khan, M.M.R.; Arbab, M.I.; Imtenan, S.; Sanjid, A. Comparative Study of Biodiesel, GTL Fuel and Their Blends in Context of Engine Performance and Exhaust Emission. Procedia Eng. 2014, 90, 466–471. [Google Scholar] [CrossRef] [Green Version]

- Velaers, A.J.; de Goede, S. The Properties and Injector Nozzle Fouling Performance of Neat GTL and GTL/EN590 Diesel Blends in Various Diesel Engines. SAE Int. J. Fuels Lubr. 2012, 5. [Google Scholar] [CrossRef]

- ASTM D6468-08(2019), Standard Test Method for High Temperature Stability of Middle Distillate Fuels; ASTM International: West Conshohocken, PA, USA, 2019.

- Armas, O.; Martínez-Martínez, S.; Mata, C. Effect of an ethanol–biodiesel–diesel blend on a common rail injection system. Fuel Process. Technol. 2011, 92, 2145–2153. [Google Scholar] [CrossRef]

- Armas, O.; Mata, C.; Martínez-Martínez, S. Effect of an ethanol–diesel blend on a common-rail injection system. Int. J. Engine Res. 2012, 13, 417–428. [Google Scholar] [CrossRef]

- Kegl, B.; Hribernik, A. Experimental analysis of injection characteristics using biodiesel fuel. Energy Fuels 2006, 20, 2239–2248. [Google Scholar] [CrossRef]

- Gondal, A.K.; Nautiyal, P.C. Wear investigations of injector nozzle using radionuclide technique. Wear 1991, 147, 375–384. [Google Scholar] [CrossRef]

- Lindholm, P.; Björklund, S.; Calvo-Cortes, M. Characterisation of wear on a cam follower system in a diesel engine. Wear 2003, 254, 1199–1207. [Google Scholar] [CrossRef]

- Macian, V.; Bermudez, V.; Payri, R.; Gimeno, J. New technique for determination of internal geometry of a diesel nozzle with the use of silicone methodology. Exp. Tech. 2003, 27, 39–43. [Google Scholar] [CrossRef]

- Soriano, J.A.; Mata, C.; Armas, O.; Ávila, C. A zero-dimensional model to simulate injection rate from first generation common rail diesel injectors under thermodynamic diagnosis. Energy 2018, 158, 845–858. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Armas, O.; Gómez, A.; Gil, A. Developing computational fluid dynamics (CFD) models to evaluate available energy in exhaust systems of diesel light-duty vehicles. Appl. Sci. 2017, 7, 590. [Google Scholar] [CrossRef] [Green Version]

- Celik, I.; Sensogut, C.; Aydin, O. Usage of biodiesel as fuel and examining its effects on an engine. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 1857–1865. [Google Scholar] [CrossRef]

- Celik, I.; Aydin, O. Effects of B100 Biodiesel on Injector and Pump Piston. Tribol. Trans. 2011, 54, 424–431. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, D.T. The Impact of Injector Hole Diameter on SprayBehaviour for Butanol-Diesel Blends. Energies 2018, 11, 1298. [Google Scholar] [CrossRef] [Green Version]

- Reddy, M.S.; Sharma, N.; Agarwal, A.K. Effect of straight vegetable oil blends and biodiesel blends on wear of mechanical fuel injection equipment of a constant speed diesel engine. Renew. Energy 2016, 99, 1008–1018. [Google Scholar] [CrossRef]

- Salvador, F.J.; Gimeno, J.; Carreres, M.; Crialesi-Esposito, M. Fuel temperature influence on the performance of a last generation common-rail diesel ballistic injector. Part I: Experimental mass flow rate measurements and discussion. Energy Convers. Manag. 2016, 114, 364–375. [Google Scholar] [CrossRef] [Green Version]

- O’Rear, D.J.; Bacha, J.D.; Tiedemann, A.N. Thermally stable blends of Fischer Tropsch and LCO diesel fuel components. Energy Fuels 2004, 18, 682–684. [Google Scholar] [CrossRef]

- Hu, E.; Xu, Y.; Hu, X.; Pan, L.; Jiang, S. Corrosion behaviors of metals in biodiesel from rapeseed oil and methanol. Renew. Energy 2012, 37, 371–378. [Google Scholar] [CrossRef]

| Property | Diesel | Paraffinic Fuel |

|---|---|---|

| Density at 15 °C (kg/m3) | 827.1 | 784.6 |

| Viscosity at 40 °C (cSt) | 2.467 | 3.497 |

| Low heating value (LCV) (MJ/kg) | 42.7 | 43.9 |

| Sulphur (mg/kg) | 46 | <10 |

| H/C ratio (molar) | 1.88 | 2.10 |

| Duct | Dimensions |

|---|---|

| HPCR-CR duct length from HPCR to CR (mm) | 540 |

| CR-injector duct length (mm) | 160 |

| Duct internal diameter (mm) | 2 |

| Parameter | Value |

|---|---|

| HPP rotational speed (rpm) | 600, 900 and 1200 |

| PW1 closing (%) | From 0 to 90 |

| PW2 closing (%) | From 0 to 90 |

| Parameter | Value |

|---|---|

| HPP rotational speed (rpm) | 900 |

| Injection duration (ms) | 1 |

| Injection frequency (Hz) | 20 |

| Fuel test temperature (°C) | 50 |

| PW1 closing position (%) | 50 |

| PW2 closing position (%) | 70 |

| Fuel injection pressure (MPa) | 100 |

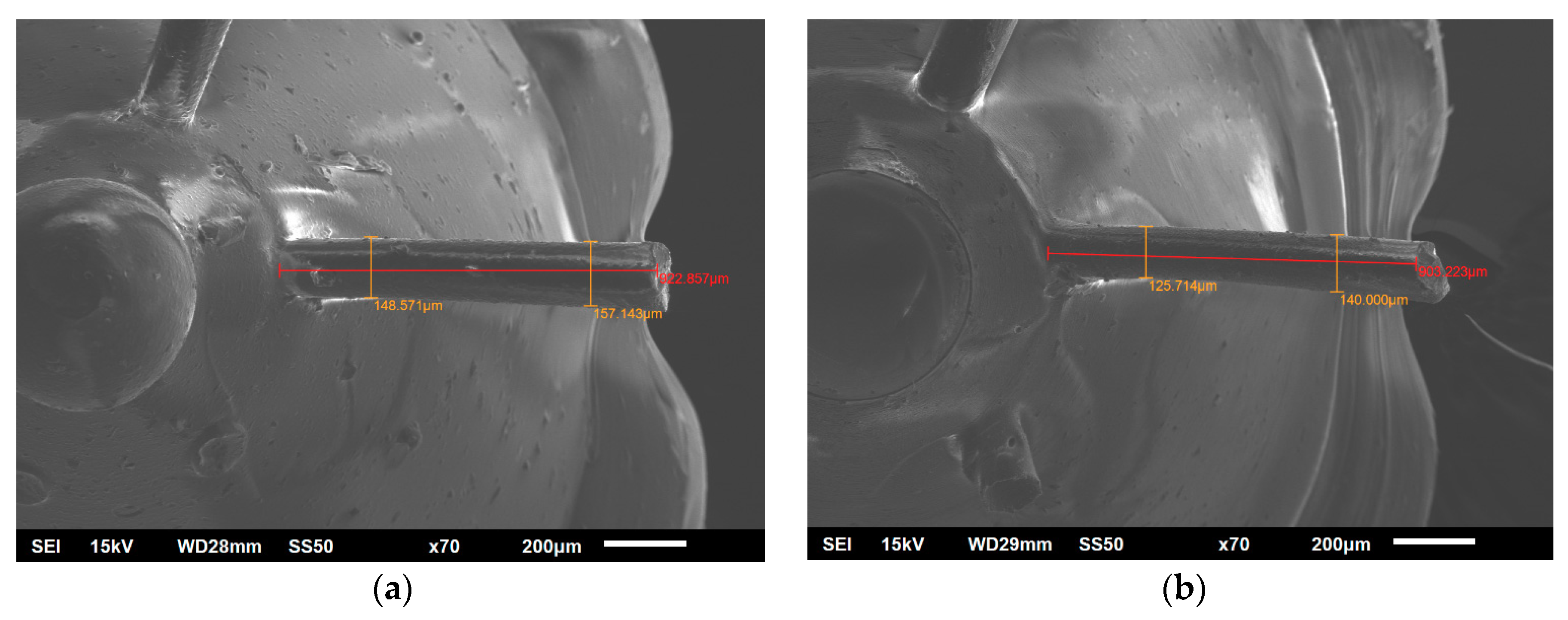

| Hole Number | d μm (0 h) | d μm (400 h) | ||

|---|---|---|---|---|

| d1 | d2 | d1 | d2 | |

| 1 | 148.6 | 157.1 | 125.7 | 140.0 |

| 2 | 149.2 | 158.0 | 126.9 | 141.7 |

| 3 | 148.3 | 157.5 | 125.9 | 142.7 |

| 4 | 147.9 | 158.2 | 126.2 | 141.4 |

| Mean | 148.5 | 157.7 | 126.2 | 141.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mata, C.; Piaszyk, J.; Soriano, J.A.; Herreros, J.M.; Tsolakis, A.; Dearn, K. Impact of Alternative Paraffinic Fuels on the Durability of a Modern Common Rail Injection System. Energies 2020, 13, 4166. https://doi.org/10.3390/en13164166

Mata C, Piaszyk J, Soriano JA, Herreros JM, Tsolakis A, Dearn K. Impact of Alternative Paraffinic Fuels on the Durability of a Modern Common Rail Injection System. Energies. 2020; 13(16):4166. https://doi.org/10.3390/en13164166

Chicago/Turabian StyleMata, Carmen, Jakub Piaszyk, José Antonio Soriano, José Martín Herreros, Athanasios Tsolakis, and Karl Dearn. 2020. "Impact of Alternative Paraffinic Fuels on the Durability of a Modern Common Rail Injection System" Energies 13, no. 16: 4166. https://doi.org/10.3390/en13164166

APA StyleMata, C., Piaszyk, J., Soriano, J. A., Herreros, J. M., Tsolakis, A., & Dearn, K. (2020). Impact of Alternative Paraffinic Fuels on the Durability of a Modern Common Rail Injection System. Energies, 13(16), 4166. https://doi.org/10.3390/en13164166