Available Energy in Cars’ Exhaust System for IoT Remote Exhaust Gas Sensor and Piezoelectric Harvesting

Abstract

:1. Introduction

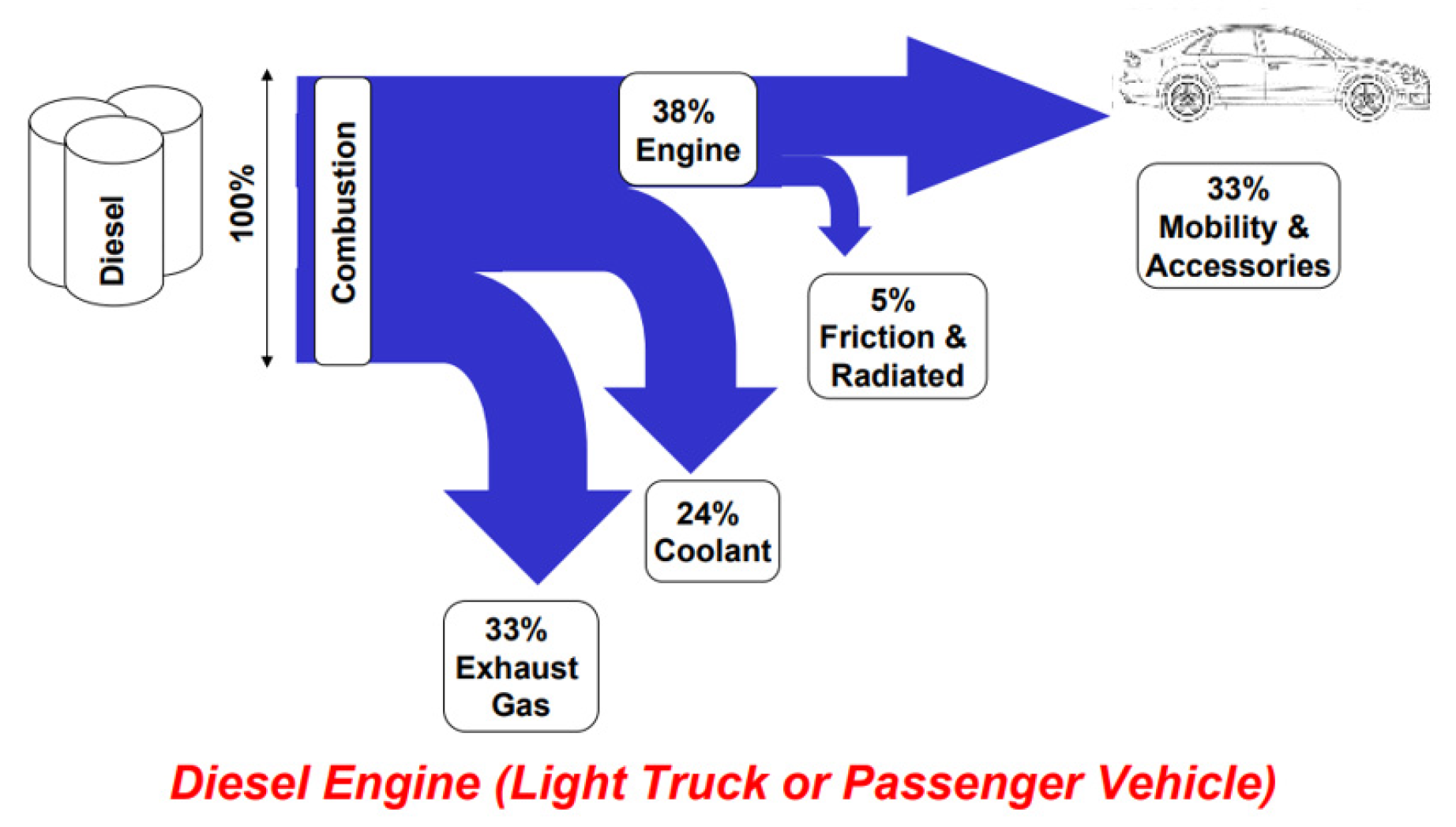

Thoretical Model for Evaluating Exhaust Gas Energy

2. Materials and Methods

2.1. Tests at the Engine Bench

2.2. Test Cycles

2.3. Measurement Systems

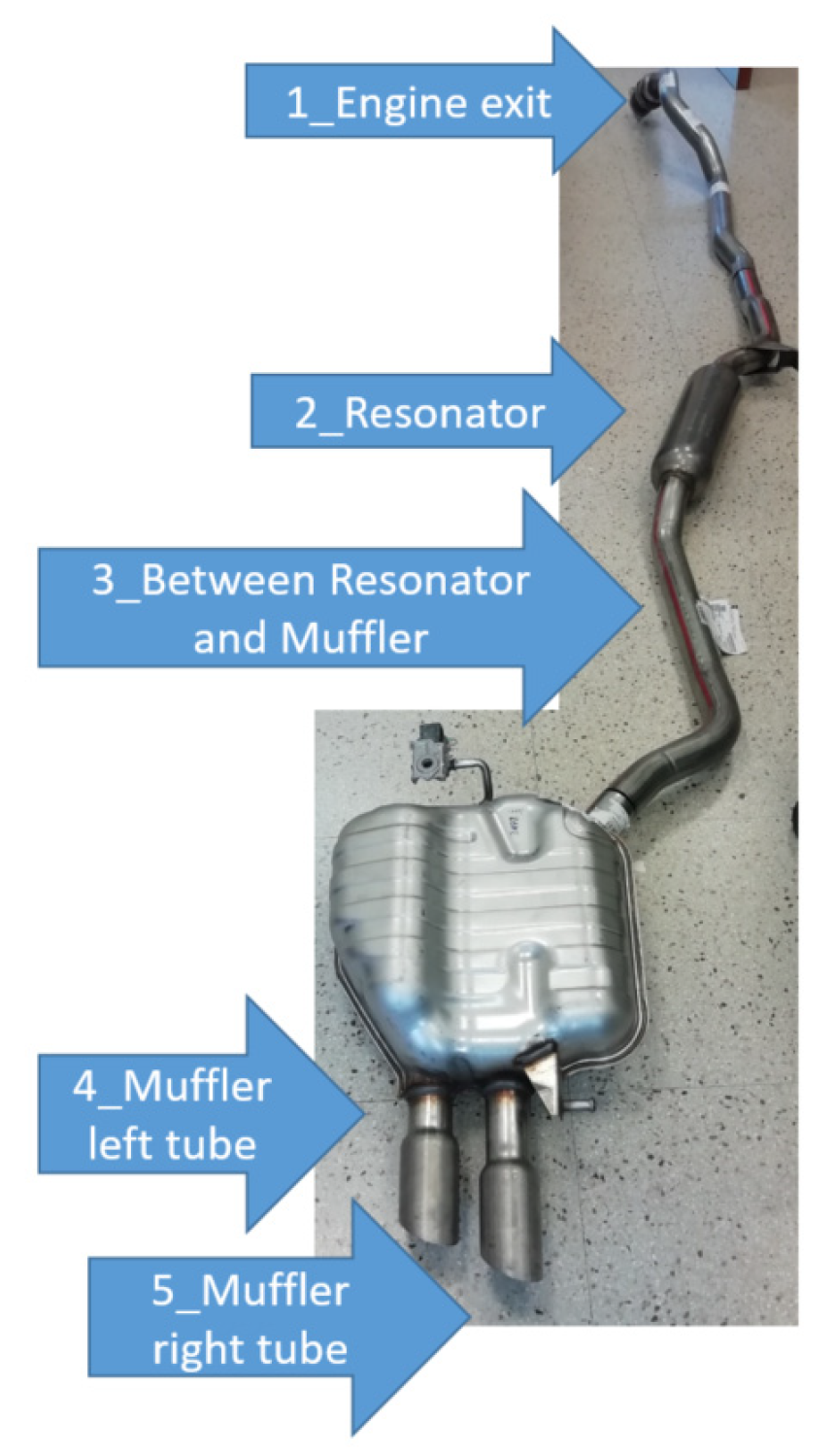

2.4. Exhaust Gas Positions

2.5. Piezoelectric Conversion

3. Results

Detailed Results Relative to the Exhaust Gas for Each Exhaust Position

4. Discussion

4.1. Validation of Gas Speed Measured by Pitot Tube

4.2. Estimation of Power at the Engine Exhaust for the Bench Engine

4.3. Piezoelectric Conversion from the Exhaust Pipe under Real Driving Conditions

4.4. Efficiency of Piezoelectric Harvester

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Engine Regime Rpm Torque | Engine Exit | Resonator | Between Resonator/Muffler | Muffler Right Tube | Muffler Left Tube | |

|---|---|---|---|---|---|---|

| Position # | 1 | 2 | 3 | 4 | 5 | |

| 1500 rpm | 30 Nm | 12 m/s | 2 m/s | 13 m/s | 4 m/s | 9 m/s |

| 1500 rpm | 320 Nm | 17 m/s | 3 m/s | 17 m/s | 9 m/s | 11 m/s |

| 2000 rpm | 50 Nm | 7 m/s | 3 m/s | 9 m/s | 2 m/s | 5 m/s |

| 2000 rpm | 320 Nm | 26 m/s | 6 m/s | 25 m/s | 14 m/s | 16 m/s |

| 3000 rpm | 40 Nm | 23 m/s | 5 m/s | 30 m/s | 12 m/s | 15 m/s |

| 3000 rpm | 320 Nm | 37 m/s | 8 m/s | 41 m/s | 22 m/s | 23 m/s |

| Engine Regime Rpm Torque | Engine Exit | Resonator | Between Resonator/Muffler | Muffler Right Tube | Muffler Left Tube | |

|---|---|---|---|---|---|---|

| Position # | 1 | 2 | 3 | 4 | 5 | |

| 1500 rpm | 30 Nm | 485 °C | 450 °C | 280 °C | 100 °C | 165 °C |

| 1500 rpm | 320 Nm | 630 °C | 550 °C | 320 °C | 110 °C | 175 °C |

| 2000 rpm | 50 Nm | 340 °C | 370 °C | 300 °C | 115 °C | 183 °C |

| 2000 rpm | 320 Nm | 640 °C | 380 °C | 300 °C | 125 °C | 195 °C |

| 3000 rpm | 40 Nm | 645 °C | 370 °C | 310 °C | 160 °C | 220 °C |

| 3000 rpm | 320 Nm | 740 °C | 400 °C | 300 °C | 190 °C | 220 °C |

| Engine Regime Rpm Torque | Engine Exit | Resonator | Between Resonator/Muffler | Muffler Right Tube | Muffler Left Tube | |

|---|---|---|---|---|---|---|

| Position # | 1 | 2 | 3 | 4 | 5 | |

| 1500 rpm | 30 Nm | 164 | 167 | 162 | 101 | 101 |

| 1500 rpm | 320 Nm | 182 | 200 | 190 | 101 | 101 |

| 2000 rpm | 50 Nm | 116 | 120 | 117 | 101 | 101 |

| 2000 rpm | 320 Nm | 225 | 225 | 225 | 101 | 101 |

| 3000 rpm | 40 Nm | 137 | 133 | 135 | 101 | 101 |

| 3000 rpm | 320 Nm | 225 | 225 | 225 | 101 | 101 |

References

- Hooftman, N.; Messagie, M.; Van Mierlo, J.; Coosemans, T. A review of the European passenger car regulations—Real driving emissions vs. local air quality. Renew. Sustain. Energy Rev. 2018, 86, 1–21. [Google Scholar] [CrossRef]

- Williams, M.; Minjares, R. A technical summary of Euro 6/VI vehicle emission standards. The International Council on Clean Transportation. Available online: http://www.indiaenvironmentportal.org.in/files/file/ICCT_Euro6-VI_briefing.pdf (accessed on 2 May 2020).

- Fontaras, G.; Ciuffo, B.; Zacharof, N.; Tsiakmakis, S.; Marotta, A.; Pavlovic, J.; Anagnostopoulos, K. The difference between reported and real-world CO2 emissions: How much improvement can be expected by WLTP introduction? Transp. Res. Procedia 2017, 25, 3933–3943. [Google Scholar] [CrossRef]

- Varella, R.; Giechaskiel, B.; Sousa, L.; Duarte, G.; Weiss, M.; Bonnel, P.; Hummel, R.; Steininger, N.; Djoric, V.; Jovic, J.; et al. Comparison of Portable Emissions Measurement Systems (PEMS) with Laboratory Grade Equipment. Appl. Sci. 2018, 8, 1633. [Google Scholar] [CrossRef] [Green Version]

- Djoric, V.; Jovic, J.; Vukanovic, S. Collection and assessment of instantaneous vehicle emissions on street network. In Proceedings of the Transport Research Arena (TRA) 5th Conference: Transport Solutions from Research to Deployment European Commission, Paris, Italy, 14–17 April 2014. [Google Scholar]

- Hossain, S.N.; Bari, S. Waste heat recovery from exhaust of a diesel generator set using organic fluids. Procedia Eng. 2014, 90, 439–444. [Google Scholar] [CrossRef] [Green Version]

- Hossain, S.N.; Bari, S. Additional power generation from waste energy of diesel engine using parallel flow shell and tube heat exchanger. J. Eng. Gas Turbines Power 2014, 136, 100–104. [Google Scholar] [CrossRef]

- Fern, P.; Armas, O.; Gil, A. Developing Computational Fluid Dynamics (CFD) Models to Evaluate Available Energy in Exhaust Systems of Diesel Light-Duty Vehicles. Appl. Sci. 2017, 7, 590. [Google Scholar] [CrossRef] [Green Version]

- Jadhao, J.S.; Thombare, D.G.; Student, P.G.; Sangali, D. Review on Exhaust Gas Heat Recovery for IC engine. Int. J. Eng. Innov. Technol. (IJEIT) Vol. 2013, 2, 93–100. [Google Scholar]

- Orido, G.; Ngunjiri, P.G.; Njue, D.M. Exhaust Gases Energy Recovered from Internal Combustion Engine for Useful Applications. IOSR J. Mech. Civ. Eng. 2017, 14, 01–07. [Google Scholar] [CrossRef]

- Guduru, K.K. Power Generation by using Kinetic Energy of Exhaust Gases from an Internal Combustion Engine. Int. J. Res. Comput. Technol. 2019, 7, 1–5. [Google Scholar]

- Alshammari, M.; Alshammari, F.; Pesyridis, A. Electric boosting and energy recovery systems for engine downsizing. Energies 2019, 12, 4636. [Google Scholar] [CrossRef] [Green Version]

- Ismail, B.I. Automotive exhaust gas waste-heat recovery for green electrical power generation using Thermoelectric technology. Recent Pat. Electr. Electron. Eng. 2012, 5, 185–197. [Google Scholar] [CrossRef]

- Weiss, M.; Bonnel, P.; Hummel, R.; Steininger, N. A Complementary Emissions Test for Light-Duty Vehicles: Assessing the Technical Feasibility of Candidate Procedures; Conclusions of the Real-Driving Emissions-Light-Duty Vehicles (RDE-LDV) working group; Publications Office of the European Union: Brussels, Belgium, 2013. [Google Scholar] [CrossRef]

- Valencia, G.; Fontalvo, A.; Cárdenas, Y.; Duarte, J.; Isaza, C. Energy and exergy analysis of different exhaust waste heat recovery systems for natural gas engine based on ORC. Energies 2019, 12, 2378. [Google Scholar] [CrossRef] [Green Version]

- Fu, J.; Liu, J.; Yang, Y.; Yang, H. A Study on the Prospect of Engine Exhaust Gas Energy Recovery. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering, Wuhan, China, 15–17 April 2011; IEEE: Miami, FL, USA, 2011; pp. 1960–1963. [Google Scholar] [CrossRef]

- Gomes, J.B.A.; Rodrigues, J.J.P.C.; Rabêlo, R.A.L.; Kumar, N.; Kozlov, S. IoT-enabled gas sensors: Technologies, applications, and opportunities. J. Sens. Actuator Netw. 2019, 8, 57. [Google Scholar] [CrossRef] [Green Version]

- Todaro, M.T.; Guido, F.; Mastronardi, V.; Desmaele, D.; Epifani, G.; Algieri, L.; De Vittorio, M. Piezoelectric MEMS vibrational energy harvesters: Advances and outlook. Microelectron. Eng. 2017, 183–184, 23–36. [Google Scholar] [CrossRef]

- Guido, F.; Qualtieri, A.; Algieri, L.; Lemma, E.D.; De Vittorio, M.; Todaro, M.T. AlN-based flexible piezoelectric skin for energy harvesting from human motion. Microelectron. Eng. 2016, 159, 174–178. [Google Scholar] [CrossRef]

- Lee, Y.J.; Qi, Y.; Zhou, G.; Lua, K.B. Vortex-induced vibration wind energy harvesting by piezoelectric MEMS device in formation. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Boulahlib, M.S.; Boukebbab, S.; Gaci, F.; Kholai, O. Experimental study of energy balance for air-cooled di diesel engines operating in hot climates. SAE Tech. Pap. 2009. [Google Scholar] [CrossRef]

- Taymaz, I. An experimental study of energy balance in low heat rejection diesel engine. Energy 2006, 31, 364–371. [Google Scholar] [CrossRef]

- Fairbanks, J.W. The 60 Percent Efficient Diesel Engine; Probable, Possible, or Just A Fantasy? In Proceedings of the 2005 Diesel Engine Emissions Reduction (DEER) Conference Presentations, US Department of Energy Chicago, Chicago, IL, USA, 24 August 2005. [Google Scholar]

- Gopal, K.N.; Subbarao, R.; Pandiyarajan, V.; Velraj, R. Thermodynamic analysis of a diesel engine integrated with a PCM based energy storage system. Int. J. Thermodyn. 2010, 13, 15–21. [Google Scholar] [CrossRef]

- Kyle, B.G. Chemical and Process Thermodynamics; Englewood Cliffs/Prentice Hall: Upper Saddle River, NJ, USA, 1984. [Google Scholar]

- Dubois, E.; Mercier, A. Design and Optimization of an Integrated Turbo-Generator and Thermoelectric Generator for Vehicle Exhaust Electrical Energy Recovery. Energy Recover. 2009, 1–329. [Google Scholar] [CrossRef]

- Koshy, A.P.; Jose, B.K.; Johnson, J.E.; Krishnan, K.N. Exhaust Gas Waste Heat Recovery and Utilization System in ICEngine. Int. J. Innov. Res. Sci. Technol. 2015, 1, 392–400. [Google Scholar]

- Testo. Tubo di Pitot Diritto 360 mm. Available online: https://www.testo.com/it-IT/tubo-di-pitot-diritto-360-mm/p/0635-2043 (accessed on 1 April 2020).

- Testo 480 Data Logger. Available online: https://www.testo.com/en-US/testo-480/p/0563-4800 (accessed on 1 April 2020).

- Saleh, J.M. Fluid Flow Handbook; McGraw-Hill Professional: New York, NY, USA, 2002. [Google Scholar]

- Von Karman, T. Aerodynamics; McGraw-Hill: New York, NY, USA, 1963; ISBN 978-0-486-43485-8. [Google Scholar]

- Townley, A. Vibrational Energy Harvesting Using Mems Piezoelectric Generators. Available online: https://sunfest.seas.upenn.edu/wp-content/uploads/2018/07/TownleyAndrew09.pdf (accessed on 7 June 2020).

- Fonseca González, N.; Casanova Kindelán, J.; López Martínez, J.M. Methodology for instantaneous average exhaust gas mass flow rate measurement. Flow Meas. Instrum. 2016, 49, 52–62. [Google Scholar] [CrossRef] [Green Version]

- Petroni, S.; Rizzi, F.; Guido, F.; Cannavale, A.; Donateo, T.; Ingrosso, F.; Mastronardi, V.M.; Cingolani, R.; De Vittorio, M. Flexible AlN flags for efficient wind energy harvesting at ultralow cut-in wind speed. RSC Adv. 2015, 5, 14047–14052. [Google Scholar] [CrossRef]

- Arroyo, E.; Jia, Y.; Du, S.; Chen, S.T.; Seshia, A.A. Experimental and theoretical study of a piezoelectric vibration energy harvester under high temperature. J. Microelectromechanical Syst. 2017, 26, 1216–1225. [Google Scholar] [CrossRef] [Green Version]

- Nabavi, S.; Zhang, L. Design and Optimization of a Low-Resonant-Frequency Piezoelectric MEMS Energy Harvester Based on Artificial Intelligence. Proceedings 2018, 2, 930. [Google Scholar] [CrossRef] [Green Version]

- Weinstein, L.A.; Cacan, M.R.; So, P.M.; Wright, P.K. Vortex shedding induced energy harvesting from piezoelectric materials in heating, ventilation and air conditioning flows. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

| Point 1 | Point 2 | Point 3 | Point 4 | Point 5 | Point 6 | |

|---|---|---|---|---|---|---|

| RPM | 1500 | 1500 | 2000 | 2000 | 3000 | 3000 |

| Torque | 200 | 320 | 50 | 320 | 40 | 320 |

| Equivalent gear | 1 | 2 | 5 | 3 | 6 | 6 |

| Engine Operating Point Speed_Torque | Fuel Gas Flow | Fuel Mass Flow 1 | Total Mass Flow |

|---|---|---|---|

| (rpm)_(Nm) | (mg/stroke) | (g/s) | (g/s) |

| 1500_200 | 38.8 | 37 | 38.2 |

| 1500_320 | 55.0 | 43 | 45.8 |

| 2000_50 | 11.4 | 22 | 22 |

| 2000_320 | 57.2 | 68 | 64.9 |

| 3000_40 | 11.9 | 63 | 63 |

| 3000_320 | 55.1 | 100 | 100.5 |

| Engine Point Rpm_Torque | Total Mass Flow | Gas Density | Volume Flow | Cross Section | Calculated Speed | Measured Speed | Error |

|---|---|---|---|---|---|---|---|

| (g/s) | (kg/m3) | (m3/s) × 10−3 | (cm2) | (m/s) | (m/s) | % | |

| 1500_200 | 38.2 | 0.81 | 47.2 | 56 | 8.4 | 9 | 6.4 |

| 1500_320 | 45.8 | 0.79 | 58.0 | 56 | 10.4 | 11 | 5.9 |

| 2000_50 | 22 | 0.77 | 28.6 | 56 | 5.1 | 5 | 2.0 |

| 2000_320 | 69.4 | 0.75 | 92.5 | 56 | 16.5 | 16 | 3.3 |

| 3000_40 | 63 | 0.72 | 87.5 | 56 | 15.6 | 15 | 4.2 |

| 3000_320 | 100.5 | 0.72 | 139.6 | 56 | 24.9 | 23 | 8.4 |

| Voltage Average | Voltage Max | Energy | Power Average | Power Max |

|---|---|---|---|---|

| 74 mV | 6.5 V | 21 µJ | 33 nW | 42 µW |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madaro, F.; Mehdipour, I.; Caricato, A.; Guido, F.; Rizzi, F.; Carlucci, A.P.; De Vittorio, M. Available Energy in Cars’ Exhaust System for IoT Remote Exhaust Gas Sensor and Piezoelectric Harvesting. Energies 2020, 13, 4169. https://doi.org/10.3390/en13164169

Madaro F, Mehdipour I, Caricato A, Guido F, Rizzi F, Carlucci AP, De Vittorio M. Available Energy in Cars’ Exhaust System for IoT Remote Exhaust Gas Sensor and Piezoelectric Harvesting. Energies. 2020; 13(16):4169. https://doi.org/10.3390/en13164169

Chicago/Turabian StyleMadaro, Francesco, Iman Mehdipour, Antonio Caricato, Francesco Guido, Francesco Rizzi, Antonio Paolo Carlucci, and Massimo De Vittorio. 2020. "Available Energy in Cars’ Exhaust System for IoT Remote Exhaust Gas Sensor and Piezoelectric Harvesting" Energies 13, no. 16: 4169. https://doi.org/10.3390/en13164169

APA StyleMadaro, F., Mehdipour, I., Caricato, A., Guido, F., Rizzi, F., Carlucci, A. P., & De Vittorio, M. (2020). Available Energy in Cars’ Exhaust System for IoT Remote Exhaust Gas Sensor and Piezoelectric Harvesting. Energies, 13(16), 4169. https://doi.org/10.3390/en13164169