Sliding Mode Self-Sensing Control of Synchronous Machine Using Super Twisting Interconnected Observers

Abstract

:1. Introduction

2. Problem Statement

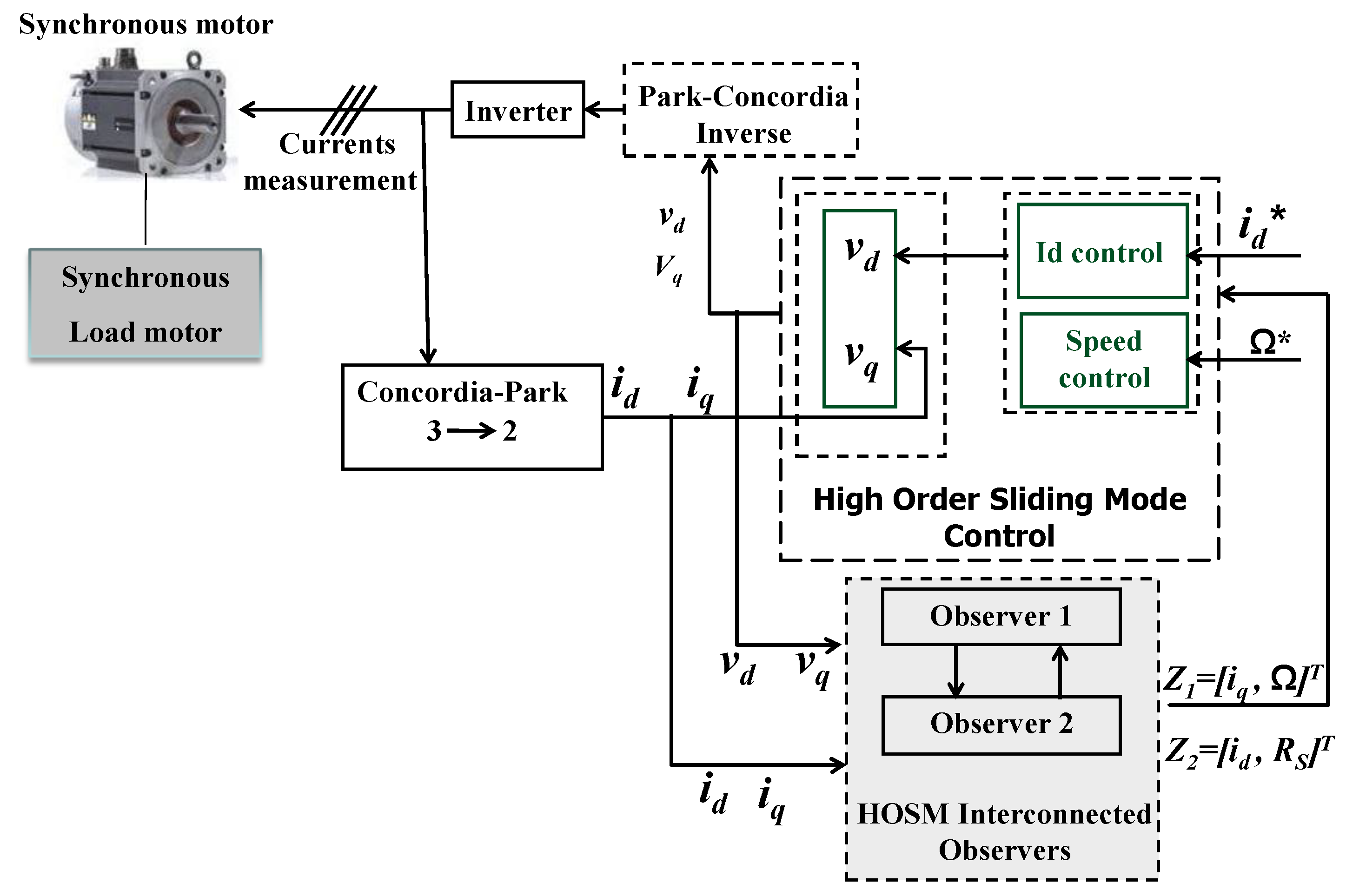

3. MTPA QC HOSM Control

3.1. Quasi-Continuous Higher Order Sliding Mode Controller

3.2. IPMSM Controller Design

4. Interconnected Observer Based HOSM Design for IPMSM

4.1. The Super Twisting Algorithm

4.2. HOSM Rotor Position Observer

- , , , ,

- , , , .

4.3. Convergence of High-Order Sliding-Mode Observers

4.4. Hosm Speed and Resistance Observer

5. Simulation Results

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Athavale, A.; Sasaki, K.; Gagas, B.S.; Kato, T.; Lorenz, R.D. Variable Flux Permanent Magnet Synchronous Machine (VF-PMSM) Design Methodologies to Meet Electric Vehicle Traction Requirements with Reduced Losses. IEEE Trans. Ind. Appl. 2017, 53, 4318–4326. [Google Scholar] [CrossRef]

- Liu, F.; Xu, L.; Li, Y.; Kang, Y.; Wu, Z. Permanent magnet synchronous machine starter/generators based high-voltage DC parallel electric power system for the more electric aircraft. J. Eng. 2018, 2018, 565–569. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, Z. Improved Sensorless Control of Permanent-Magnet Synchronous Machine Based on Third-Harmonic Back EMF. IEEE Trans. Ind. Appl. 2014, 50, 1861–1870. [Google Scholar] [CrossRef]

- Divandari, M.; Rezaie, B.; Noei, A.R. Speed control of switched reluctance motor via fuzzy fast terminal sliding-mode control. Comput. Electr. Eng. 2019, 80, 106472. [Google Scholar] [CrossRef]

- Zhan, H.; Zhu, Z.Q.; Odavic, M. Nonparametric Sensorless Drive Method for Open-Winding PMSM Based on Zero-Sequence Back EMF With Circulating Current Suppression. IEEE Trans. Power Electron. 2017, 32, 3808–3817. [Google Scholar] [CrossRef]

- Genduso, F.; Miceli, R.; Rando, C.; Galluzzo, G.R. Back EMF Sensorless-Control Algorithm for High-Dynamic Performance PMSM. IEEE Trans. Ind. Electron. 2010, 57, 2092–2100. [Google Scholar] [CrossRef]

- Bolognani, S.; Ortombina, L.; Tinazzi, F.; Zigliotto, M. Model sensitivity of fundamental-frequency-based position estimators for sensorless pm and reluctance synchronous motor drives. IEEE Trans. Ind. Electron. 2018, 65, 77–85. [Google Scholar] [CrossRef]

- Dian, R.; Xu, W.; Zhu, J.; Hu, D.; Liu, Y. An Improved Speed Sensorless Control Strategy for Linear Induction Machines Based on Extended State Observer for Linear Metro Drives. IEEE Trans. Veh. Technol. 2018, 67, 9198–9210. [Google Scholar] [CrossRef]

- Hamida, M.A.; De Leon, J.; Glumineau, A.; Boisliveau, R. An Adaptive Interconnected Observer for Sensorless Control of PM Synchronous Motors with Online Parameter Identification. IEEE Trans. Ind. Electron. 2013, 60, 739–748. [Google Scholar] [CrossRef]

- Taherzaheh, M.; Hamida, M.; Ghanes, M.; Koteich, M. A New Torque Observation Technique for a PMSM Considering Unknown magnetic Conditions. IEEE Trans. Ind. Electron. 2020, 1. [Google Scholar] [CrossRef]

- Saïd, S.H.; M’Sahli, F.; Mimouni, M.; Farza, M. Adaptive high gain observer based output feedback predictive controller for induction motors. Comput. Electr. Eng. 2013, 39, 151–163. [Google Scholar] [CrossRef] [Green Version]

- Kadrine, A.; Tir, Z.; Malik, O.P.; Hamida, M.A.; Reatti, A.; Houari, A. Adaptive non-linear high gain observer based sensorless speed estimation of an induction motor. J. Frankl. Inst. 2020. [Google Scholar] [CrossRef]

- Senanayaka, J.S.L.; Karimi, H.R.; Robbersmyr, K.G. Sensorless small wind turbine with a sliding-mode observer for water heating applications. In Proceedings of the IECON 2015-41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 000863–000868. [Google Scholar]

- Shtessel, Y.; Taleb, M.; Plestan, F. A novel adaptive-gain supertwisting sliding mode controller: Methodology and application. Automatica 2012, 48, 759–769. [Google Scholar] [CrossRef]

- Davila, J.; Fridman, L.; Levant, A. Second-order sliding-mode observer for mechanical systems. IEEE Trans. Autom. Control 2005, 50, 1785–1789. [Google Scholar] [CrossRef]

- Zerdali, E.; Barut, M. The Comparisons of Optimized Extended Kalman Filters for Speed-Sensorless Control of Induction Motors. IEEE Trans. Ind. Electron. 2017, 64, 4340–4351. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, H.; Xu, S.; Yang, S. Four-quadrant sensorless control in switched reluctance machine drive using pulse injection based on special flux linkage curves. IET Electr. Power Appl. 2017, 11, 1566–1574. [Google Scholar] [CrossRef]

- Hamida, M.A.; Glumineau, A.; De Leon, J. Robust Integral Backstepping Control for Sensorless IPM Synchronous Motor Controller. J. Frankl. Inst. 2012, 349, 1734–1757. [Google Scholar] [CrossRef]

- Wang, G.; Yang, L.; Zhang, G.; Zhang, X.; Xu, D. Comparative Investigation of Pseudorandom High-Frequency Signal Injection Schemes for Sensorless IPMSM Drives. IEEE Trans. Power Electron. 2017, 32, 2123–2132. [Google Scholar] [CrossRef]

- Kwon, Y.; Sul, S. Reduction of Injection Voltage in Signal Injection Sensorless Drives Using a Capacitor-Integrated Inverter. IEEE Trans. Power Electron. 2017, 32, 6261–6274. [Google Scholar] [CrossRef]

- Lu, K.; Lei, X.; Blaabjerg, F. Artificial Inductance Concept to Compensate Nonlinear Inductance Effects in the Back EMF-Based Sensorless Control Method for PMSM. IEEE Trans. Energy Convers. 2013, 28, 593–600. [Google Scholar] [CrossRef]

- Qiao, Z.; Shi, T.; Wang, Y.; Yan, Y.; Xia, C.; He, X. New Sliding-Mode Observer for Position Sensorless Control of Permanent-Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2013, 60, 710–719. [Google Scholar] [CrossRef]

- Hamida, M.; Leon, J.D.; Glumineau, A. High-order sliding mode observers and integral backstepping sensorless control of IPMS motor. Int. J. Control 2014, 87, 2176–2193. [Google Scholar] [CrossRef]

- Mystkowski, A. Lyapunov sliding-mode observers with application for active magnetic bearing operated with zero-bias flux. J. Dyn. Syst. Meas. Control 2019, 141, 041006. [Google Scholar] [CrossRef]

- Liang, D.; Li, J.; Qu, R.; Kong, W. Adaptive Second-Order Sliding-Mode Observer for PMSM Sensorless Control Considering VSI Nonlinearity. IEEE Trans. Power Electron. 2018, 33, 8994–9004. [Google Scholar] [CrossRef]

- Liang, D.; Li, J.; Qu, R. Sensorless Control of Permanent Magnet Synchronous Machine Based on Second-Order Sliding-Mode Observer With Online Resistance Estimation. IEEE Trans. Ind. Appl. 2017, 53, 3672–3682. [Google Scholar] [CrossRef]

- Pillay, P.; Krishnan, R. Modeling, simulation, and analysis of permanent-magnet motor drives. II. The brushless DC motor drive. IEEE Trans. Ind. Appl. 1989, 25, 274–279. [Google Scholar] [CrossRef]

- Estrada, A.; Fridman, L.; Iriarte, R. Combined backstepping and HOSM control design for a class of nonlinear MIMO systems. Int. J. Robust Nonlinear Control 2017, 27, 566–581. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, C.A.; Rodriguez-Resendiz, J.; Mota-Valtierra, G.; Rivas-Araiza, E.A.; Mendiola-Santibanez, J.D.; Luna-Rubio, R. A PC-based architecture for parameter analysis of vector-controlled induction motor drive. Comput. Electr. Eng. 2011, 37, 858–868. [Google Scholar] [CrossRef]

- Inoue, T.; Inoue, Y.; Morimoto, S.; Sanada, M. Mathematical Model for MTPA Control of Permanent-Magnet Synchronous Motor in Stator Flux Linkage Synchronous Frame. IEEE Trans. Ind. Appl. 2015, 51, 3620–3628. [Google Scholar] [CrossRef]

- Filippov, A.F. Differential Equations with Discontinuous Right-Hand Sides; Kluwer: Dortrecht, The Netherlands, 1998. [Google Scholar]

- Hamida, M.; de Leon, J.; Glumineau, A. Experimental sensorless control for IPMSM by using integral backstepping strategy and adaptive high gain observer. Control Eng. Pract. 2017, 59, 64–76. [Google Scholar] [CrossRef]

| Rated power | 2.3 kW | rated phase to phase voltage | 380 V |

| Rated phase current | 6 A | Torque | 5.3 Nm |

| Speed | 3000 rpm | 0.341 Wb | |

| Rated frequency | 100 Hz | Windings connection | start connection |

| 3.25 | p | 3 | |

| 18 mH | 34 mH | ||

| J | 0.00417 kg·m | 0.0034 kg·ms |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kafi, M.R.; Hamida, M.A.; Chaoui, H.; Belkacemi, R. Sliding Mode Self-Sensing Control of Synchronous Machine Using Super Twisting Interconnected Observers. Energies 2020, 13, 4199. https://doi.org/10.3390/en13164199

Kafi MR, Hamida MA, Chaoui H, Belkacemi R. Sliding Mode Self-Sensing Control of Synchronous Machine Using Super Twisting Interconnected Observers. Energies. 2020; 13(16):4199. https://doi.org/10.3390/en13164199

Chicago/Turabian StyleKafi, Mohamed R., Mohamed A. Hamida, Hicham Chaoui, and Rabie Belkacemi. 2020. "Sliding Mode Self-Sensing Control of Synchronous Machine Using Super Twisting Interconnected Observers" Energies 13, no. 16: 4199. https://doi.org/10.3390/en13164199