Thermochemical Conversion of Biomass and Municipal Waste into Useful Energy Using Advanced HiTAG/HiTSG Technology

Abstract

:1. Introduction

2. Experimental Set-Up and Feedstock Characteristic

2.1. Batch Type Updraft Gasifier

2.2. Continuous HTAG/HTSG Test Facility

- Cylindrical-type reactor;

- Afterburning combustion chamber (shortly called afterburner) to burn fuel gas;

- Electrical heater to preheat feed gas in the lower range of temperatures (below 600 °C);

- Highly preheated air or air/stem regenerator;

- Feedstock supplier system;

- Electrical steam boiler;

- Air blower supplying air into heaters and next to the gasifier;

- Flue gas fan;

- Set of flow meters and pressure measurements devices;

- Gas Chromatograph (GC) and data acquisition system.

3. Experimental Results

3.1. Results of Fixed-Bed Gasifier Experiments

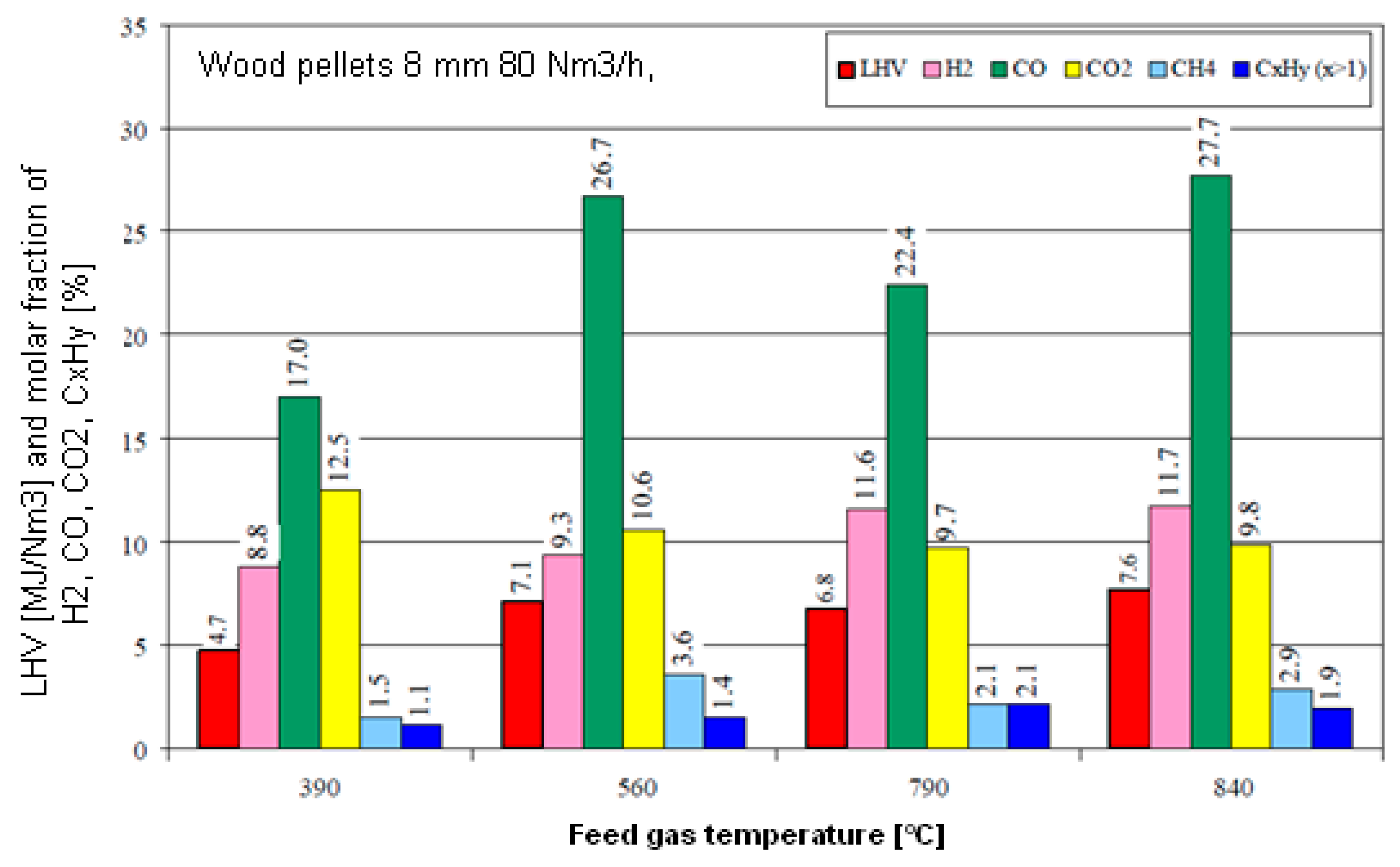

3.2. Results of HiTAG Experiments

3.3. Results of HTAG/HTSG Investigations

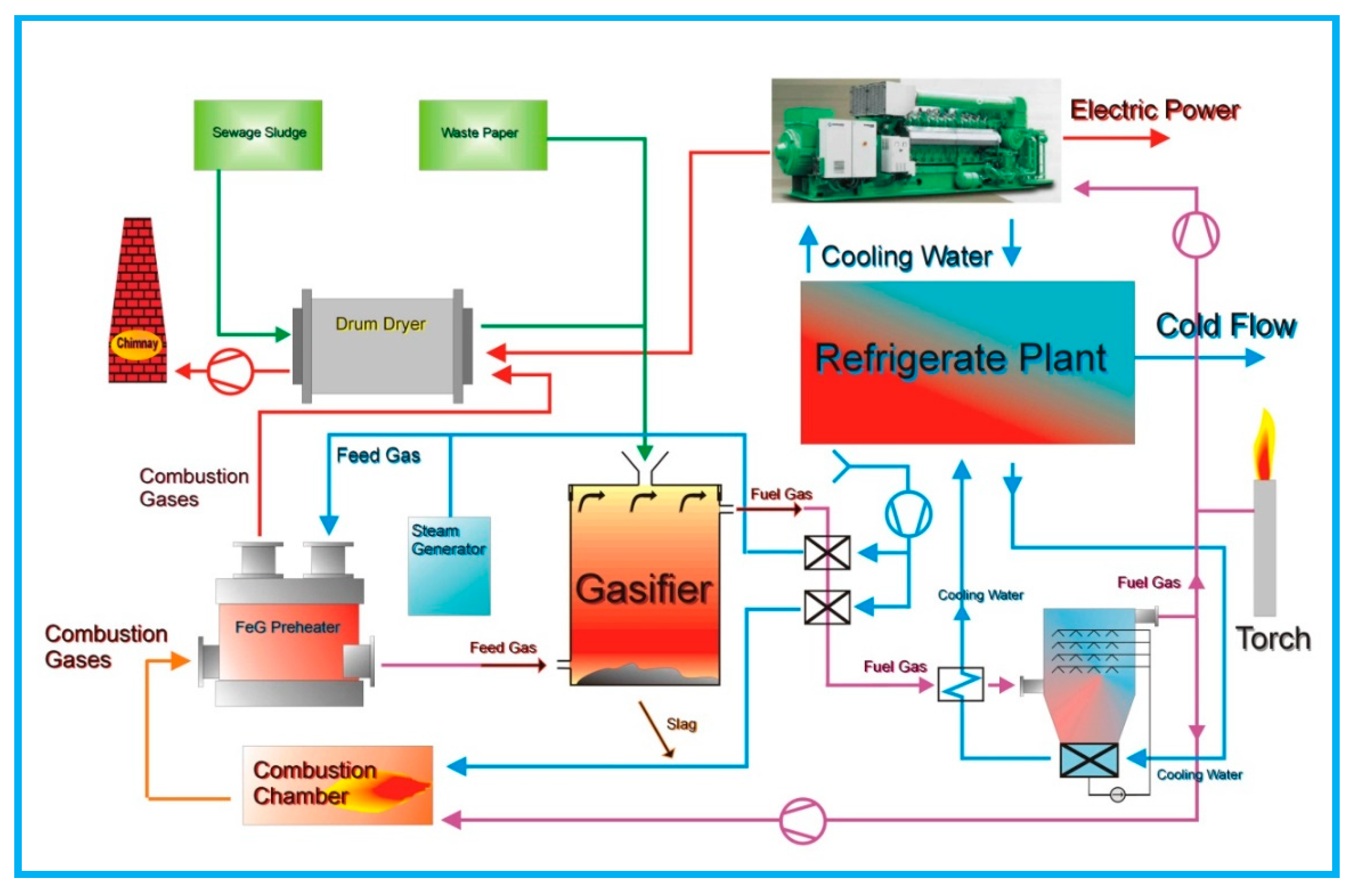

4. Technoeconomic Study of HTAG/HTSG Energy Conversion

- Feedstocks: waste paper (40 t/d), sewage sludge (0–10 t/d);

- Prices: waste paper 10 Euro/t, sewage sludge −10 Euro/t;

- Electricity selling price: 0.1 Euro/kWh;

- Labor costs per 7.5 h shift: 40 Euro/worker, 50 Euro/engineer;

- Four engineers and four workers per day (1 shift on leave);

- Operating time: 200 days/y;

- LHV of waste paper (12–17 MJ/kg).

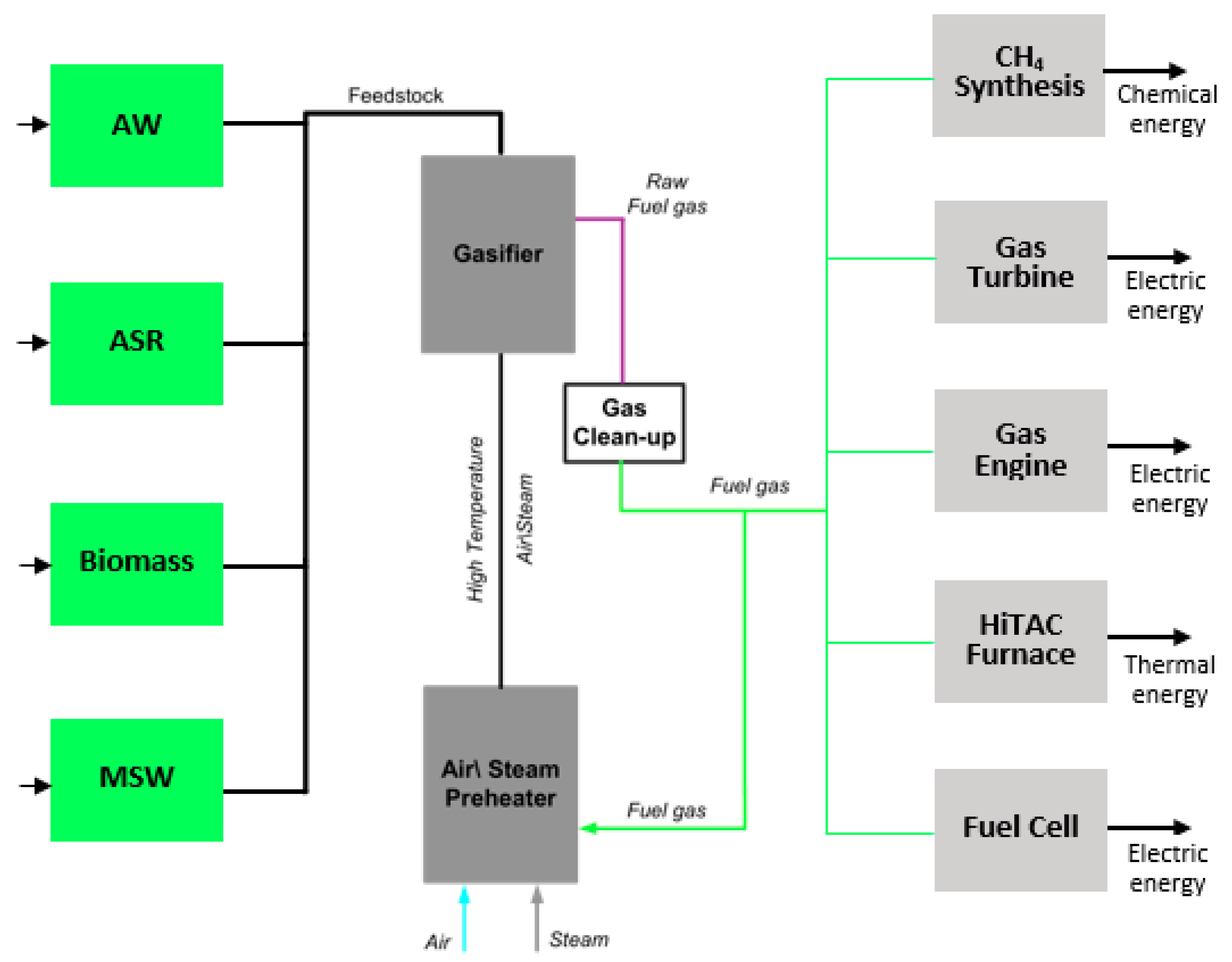

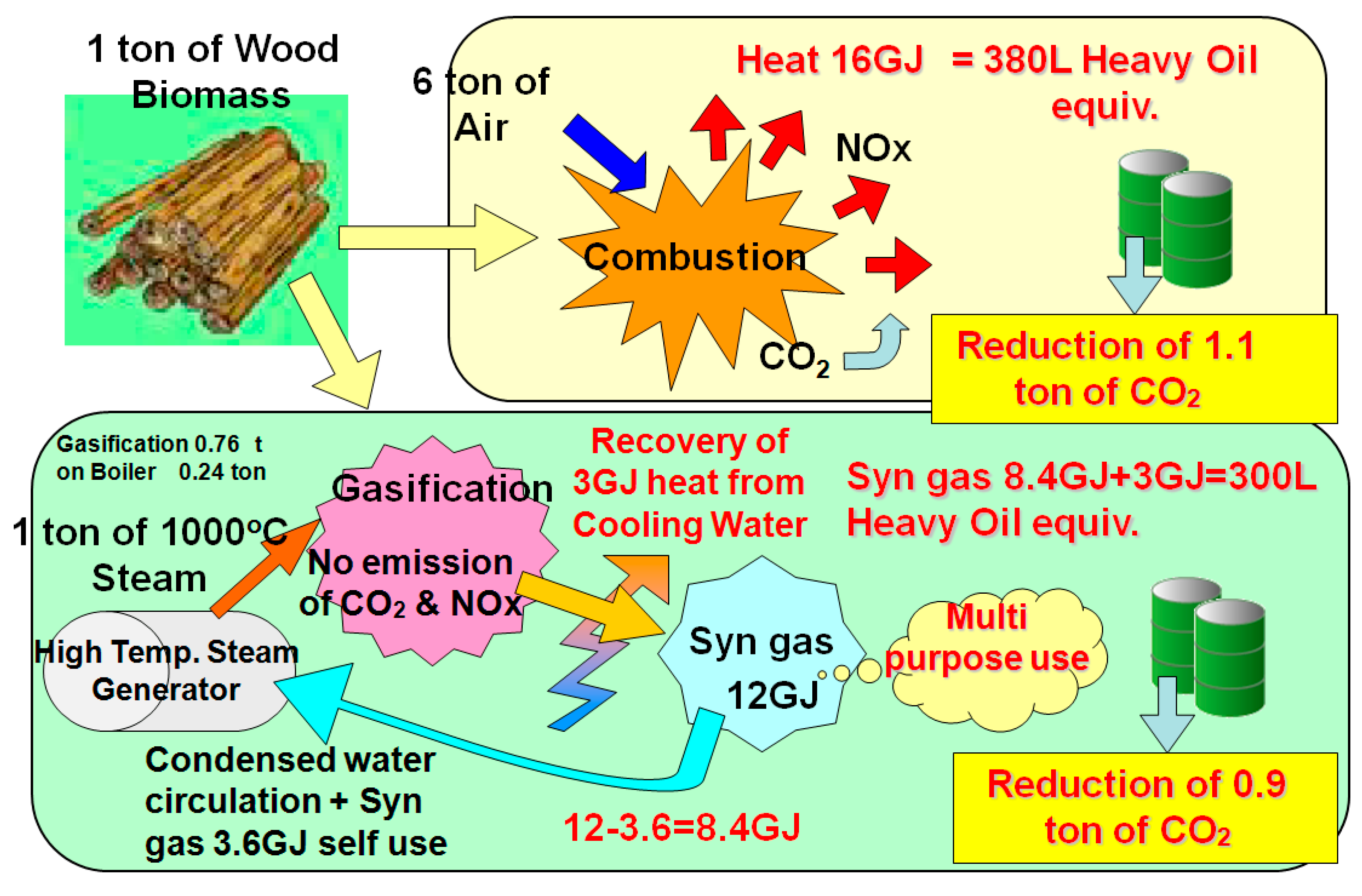

5. Examples of Typical Commercial Biomass Gasification Systems

- Woodchips are loaded in the bunker from trucks;

- Screw conveyors load the woodchips into the drying conveyor;

- Drying conveyor removes nearly all water out of the woodchips;

- Pyrolysis conveyor is dividing the woodchips in solids and gas;

- TAR is removed in the gasification unit;

- Larger parts are removed from gas in the cyclone;

- The remaining smaller parts are removed in the bag filter;

- Ash is continuously conveyed away from the gasification unit;

- Heat from heat-exchanger can be connected to the district heating grid;

- Purified gas is led into the gas-generator producing electric power;

- Heat-exchanger is connected to the gas-generator;

- The electric power is connected to the residential power grid.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, S.; Zheng, H.; Zheng, Y.; Tian, J.; Jing, T.; Chang, J.-S.; Ho, S.-H. Recent advances in hydrogen production by thermo-catalytic conversion of biomass. Int. J. Hydrogen Energy 2019, 44, 14266–14278. [Google Scholar] [CrossRef]

- Oumer, A.N.; Hasan, M.M.; Baheta, A.T.; Mamat, R.; Abdullah, A.A. Bio-based liquid fuels as a source of renewable energy: A review. Renew. Sustain. Energy Rev. 2018, 88, 82–98. [Google Scholar] [CrossRef]

- Fasolini, A.; Cucciniello, R.; Paone, E.; Mauriello, F.; Tabanelli, T. A Short Overview on the Hydrogen Production Via Aqueous Phase Reforming (APR) of Cellulose, C6-C5 Sugars and Polyols. Catalysts 2019, 9, 917. [Google Scholar] [CrossRef] [Green Version]

- 2nd International Seminar on High Temperature Combustion in Industrial Furnaces; KTH: Stockholm, Sweden, 2000.

- Mochida, S.; Hasegawa, T. Development of highly preheated turbulent-jet generator. In Proceedings of the 3rd International Symposium on Advanced Energy Conversion System and Related Technologies, RAN2001, Nagoya, Japan, 15–17 December 2001. [Google Scholar]

- Donaj, P.; Blasiak, W.; Yang, W.; Forsgren, C. Conversion of microwave pyrolysed ASR’s char using high temperature agents. J. Hazard. Mater. 2011, 185, 472–481. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Stuermer, T.; Gunarathne, R.; Yang, W.; Blasiak, W. Effect of calcium oxide on high-temperature steam gasification of municipal solid waste. Fuel 2014, 122, 36–46. [Google Scholar] [CrossRef]

- Yang, W.; Ponzio, A.; Lucas, C.; Blasiak, W. Performance analysis of a fixed-bed biomass gasifier using high-temperature air. Fuel Process. Technol. 2006, 87, 235–245. [Google Scholar] [CrossRef]

- Blasiak, W.; Kalisz, S.; Szewczyk, D.; Lucas, C.; Abeyweera, R. High Temperature Air/Steam Gasification of Biomass and Wastes; Stage 2, Technical Report No.2, ISRN KTH/MSE–03/61-SE+ENERGY/TR; Publishing House of KTH University: Stockholm, Sweden, 2003. [Google Scholar]

- Ponzio, A.; Yang, W.; Blasiak, W.; Stasiek, J. Hydrogen generation from biomass using high temperature agent gasification from biomass using high temperature agent gasification. In Proceedings of the 16th European Biomass Conference and Exhibition, Feria Valencia, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- Mikielewicz, D.; Stasiek, J.; Blasiak, W.; Ponzio, A.; Yang, W. Advanced Technology for Thermo-chemical Conversion of Biomass and Solid Municipal Wastes for Hydrogen-Rich Gas Production. In Proceedings of the 8th European Conference on Industrial Furnaces and Boilers, Vilamura, Portugal, 25–28 March 2008. [Google Scholar]

- Lucas, C.; Szewczyk, D.; Blasiak, W.; Mochida, S. High-temperature air and steam gasification of densified biofuels. Biomass Bioenergy 2004, 27, 563–575. [Google Scholar] [CrossRef]

- Ponzio, A.; Kalisz, S.; Blasiak, W. Effect of operating conditions on tar and gas composition in high temperature air/steam gasification (HTAG) of plastic containing waste. Fuel Process. Technol. 2006, 87, 223–233. [Google Scholar] [CrossRef]

- Wilson, L.; John, G.R.; Mhilu, C.F.; Yang, W.; Blasiak, W. Coffee husks gasification using high temperature air/steam agent. Fuel Process. Technol. 2010, 91, 1330–1337. [Google Scholar] [CrossRef]

- Donaj, P.; Yang, W.; Blasiak, W.; Forsgren, C. Recycling of automobile shredder residue with a microwave pyrolysis combined with high temperature steam gasification. J. Hazard. Mater. 2010, 182, 80–89. [Google Scholar] [CrossRef] [PubMed]

- Tsuji, H.; Gupta, G.K.; Hasegawa, T.; Katsuki, M.; Kishimoto, K.; Morita, M. High Temperature Air Combustion: From Energy Conservation to Pollution Reduction; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Lucas, C.; Szewczyk, D.; Blasiak, W. Fuel gas production from High Temperature Air and Steam gasification of biomass wastes. In Proceedings of the International Conference on Incineration and Thermal Treatment Technologies (IT3), Orlando, FL, USA, 12–16 May 2003. [Google Scholar]

- Blasiak, W.; Szewczyk, D.; Lucas, C.; Abeyweera, N.R.; Jansson, A.; Bjorkman, E. High Temperature Air/steam Gasification; STAGE 1 Technical Report Nr1. ISRN KTH/MSE–03/01 SE+ ENERGY/TR; Publishing House of KTH University: Stockholm, Sweden, 2003. [Google Scholar]

- Abeyweera, R. Energy Balance of the High Temperature Air/Steam Gasification of Biomass in Heat and Power Generation Process. Master’s Thesis, KTH, Stockholm, Sweden, 2003. [Google Scholar]

- Stasiek, J.; Jewartowski, M.; Yang, W. Small scale gasification of biomass and municipal wastes for heat and electricity production using HTAG technology. E3S Web Conf. 2017. [Google Scholar] [CrossRef] [Green Version]

- Stasiek, J.; Yang, W.; Yueshi, W. Modelling of biomass and municipal wastes conversion into heat, electricity and/or hydrogen using HTAG. In Proceedings of the 15th UK Heat Transfer Conference, Brunel University, London, UK, 4–5 September 2017. [Google Scholar]

- Stasiek, J.; Jewartowski, M. Conversion of biomass and municipal wastes into syngas and hydrogen using highly preheated agent (HTAG). In Proceedings of the 36th UIT Heat Transfer Conference, Sicily, Catania, Italy, 25–27 June 2018. [Google Scholar]

- Garcia, L.; Sjavador, M.; Araujo, J.; Bilbao, R. Catalytic Steam Gasification of Pine Sawdust. Effect of Catalyst Weight/Biomass Flow Rate and Steam/Biomass Ratios on Gas Production and Composition. Energy Fuels 1999, 13, 851–859. [Google Scholar] [CrossRef]

- Available online: http://www.gasifiers.bioenergylists.org/files/weiss_combined_heat_and_power.pdf (accessed on 1 April 2020).

- Available online: https://www.holz-kraft.com/en/products/biomass-chp.html (accessed on 1 May 2020).

- Wu, Y. Computational Fluid Dynamics Modelling of Biomass Gasification in Fixed-Bed Reactors Using Highly Preheated Agent. Ph.D. Thesis, KTH, Stockholm, Sweden, 2014. [Google Scholar]

- Zaini, I.N.; Yang, W.; Jonsson, P.G. Steam gasification of solid recovered fuel char derived from landfill waste: A kinetic study. Energy Procedia 2017, 142, 723–729. [Google Scholar] [CrossRef]

- Kabalina, N.; Costa, M.; Yang, W.; Martin, A. Energy and economic assessment of a polygeneration district heating and cooling system based on gasification of refuse derived fuels. Energy 2017, 137, 696–705. [Google Scholar] [CrossRef]

- Pan, Z.; Chan, W.P.; Veksha, A.; Giannis, A.; Dou, X.; Vang, H.; Lisak, G.; Lim, T.-T. Thermodynamic analyses of synthetic natural gas production via municipal solid waste gasification, high-temperature water electrolysis and methanation. Energy Convers. Manag. 2019, 202, 112160. [Google Scholar] [CrossRef]

| Item | Price (Euro) |

|---|---|

| Gasifier | 174,500 |

| Air preheater | 40,000 |

| Power generator | 798,750 |

| Gas conditioning and cleaning system | 335,000 |

| Fuel preparation unit | 145,000 |

| Control system | 135,000 |

| Measurement equipment | 75,000 |

| Start-up fuel system | 57,000 |

| Design cost | 205,000 |

| Flare | 57,000 |

| Chimney | 57,000 |

| Assembling | 1,033,000 |

| Refrigeration unit | 1,024,680 |

| Total: | 3,772,930 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stąsiek, J.; Szkodo, M. Thermochemical Conversion of Biomass and Municipal Waste into Useful Energy Using Advanced HiTAG/HiTSG Technology. Energies 2020, 13, 4218. https://doi.org/10.3390/en13164218

Stąsiek J, Szkodo M. Thermochemical Conversion of Biomass and Municipal Waste into Useful Energy Using Advanced HiTAG/HiTSG Technology. Energies. 2020; 13(16):4218. https://doi.org/10.3390/en13164218

Chicago/Turabian StyleStąsiek, Jan, and Marek Szkodo. 2020. "Thermochemical Conversion of Biomass and Municipal Waste into Useful Energy Using Advanced HiTAG/HiTSG Technology" Energies 13, no. 16: 4218. https://doi.org/10.3390/en13164218

APA StyleStąsiek, J., & Szkodo, M. (2020). Thermochemical Conversion of Biomass and Municipal Waste into Useful Energy Using Advanced HiTAG/HiTSG Technology. Energies, 13(16), 4218. https://doi.org/10.3390/en13164218