1. Introduction

Heat driven thermodynamic cycle is as an alternative to the common mechanical vapour compression cycle, where an abundance of waste heat or low potential heat (low-temperature difference) is available. Adsorption cycles can work with minimum consumption of electricity provided sufficient heat source such as solar thermal [

1] or co-generation [

2,

3,

4] providing heat or cold from renewable sources or waste, based on the application. The adsorption phenomena works as a driving force for these systems, and adsorption isotherm models are an essential tool to describe and predict their behaviour. The adsorption models are readily used in simulations of adsorption heat storage (AHS) [

5,

6] and adsorption heat pump (AHP) [

7,

8,

9,

10,

11] systems. The advantage of such an approach is a low necessary amount of the actual sample and faster evaluation of the key properties of the adsorption system.

Majority of the research of the adsorption heat-based technologies involves AHP thanks to their more efficient performance and significantly less mass of the deployed system as well as the lower amount for the expensive adsorption materials. However, both the AHP and the AHS systems can be modelled based on the isothermal data with good accuracy and analysis results of the key performance points. The most common models are then deployed based on the adsorption material characteristics and their practicality. Dubinin-Astakhov [

8,

9] and Tóth [

5,

11] adsorption models are usually used to describe materials with high adsorption potential such as silica gel, which generally shows high water affinity as Type I isotherm. Helaly et al. [

5] used Tóth adsorption model for performance analysis of water adsorption on silica gel and zeolite 13X-based adsorption storage systems and achieved a good agreement with the actual experimental data. Likewise, Schmidt et al. [

6] showed on the example of zeolite 13x/water adsorption pair that a proper system analysis of its performance can be obtained just from the adsorption model considering its physical validity. [

11] used in their work uncommon Mahle’s isotherm model [

12] to fit the data of a Type V isotherm. However, because the Mahle’s model does not properly consider the surface adsorption and focuses mainly on the capillary condensation part, it can be technically successfully deployable only on Type V isotherms. Hence, to jointly describe also the adsorption characteristics of silica gel, ferroaluminophosphates FAM Z01 and FAM Z02, and metal-organic frameworks MIL 101(Cr) and NH

-MIL 125(Ti) they used Tóth isotherm [

13] next to the Mahle’s model. For more complex isotherm showing Type IV isotherm some unorthodox high polynomial functions have been documented as well [

10]. The problematic of current isotherm models used to describe the adsorption uptake in the adsorption cooling applications were also identified by Mohammed et al. [

14] with the introduction of some corrections to the most common adsorption material, silica gel. That is, however, mostly for microporous materials or materials with high water affinity showing uncomplicated isotherms curves of Type I.

Accordingly, the mathematical models describing the water adsorption isotherms on mesoporous materials are a subject of many research publications [

15,

16,

17,

18,

19]. However, on the contrary to the classical models which exhibit simple parabolic or hyperbolic curvature of the adsorption isotherms based on the pure surface adsorption, porous materials display frequently complex adsorption behaviour which can be described by those models only partially. That means that these can provide us only with a limited precision or can be applied only to a specific region of the isotherm [

20]. The sigmoidal (or S-shaped) adsorption isotherm, typical for the mesoporous materials, is usually identified by the International Union of Pure and Applied Chemistry (UIPAC) as Type IV or Type V, plus subtypes (a) and (b), depending on the immediate surface characteristics [

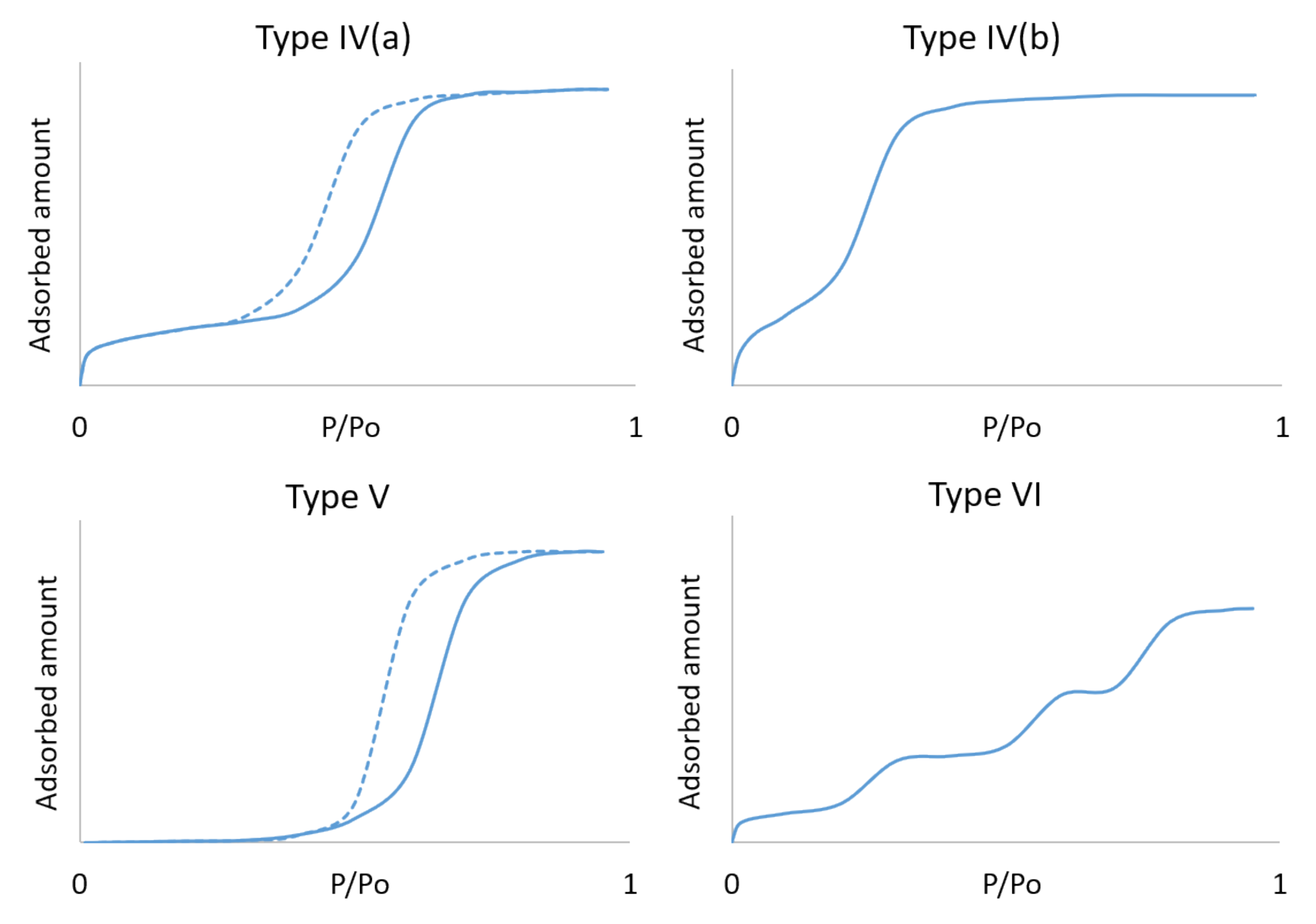

21]. The sigmoidal shape shown in

Figure 1 is typically caused by secondary adsorbate–adsorbate interactions such as capillary condensation in mesopores. Different shapes of the individual types are then given by their specific adsorbent–adsorbate relation characteristics. Type IV corresponds to materials with a surface more susceptible or accessible to adsorption of a given adsorbate, while Type V describes adsorption processes burdened by certain constraints. Those constraints can be of chemical characteristics, such as lower affinity towards the selected adsorbate (e.g., silica without hydroxyl groups with water), or of physical characteristics in case of a small opening window to the pores of some zeolite materials [

22,

23,

24,

25] resulting in higher activation energy. The Type IV isotherm is further divided to Type IV(a) with an adsorption/desorption hysteresis, and Type IV(b) without hysteresis [

21]. A particular case represents the stepwise Type VI isotherm typical for some layer-by-layer adsorption on highly uniform nonporous surfaces [

16]. However, we can also observe similar behaviour at significantly higher relative pressures for water adsorption on some mesoporous materials with a particular pore size distribution like the TMPS-2.7A reported in our previous findings [

26].

While the simplest of this selection is possibly the Type V isotherm with only one rising edge in the small range of the relative pressure, the most complicated adsorption systems are described by Type VI. Although the adsorption systems of Type IV and Type V isotherms are well known and abundant, thanks to the nature of the adsorption process on mesoporous material, the theoretical models are still difficult to universally apply and new models are continuously developed. The modelling attempts of the isotherm adsorption curves on mesoporous materials based only on the simple empirical expressions and fundamental adsorption models such as Henry’s [

27], Langmuir’s [

28], Freundlich’s [

29], Temkin’s [

30], BET [

31] and their algebraic combinations [

15] usually fail due to the complicated shape of the actual isotherm or insufficient accuracy; or can be used only on selected examples of adsorbent–adsorbate pairs.

3. Materials and Methods

The experimental data in this work were obtained from industrially manufactured mesoporous silica materials from Taiyo Kagaku Co., Ltd. (Yokkaichi, Mie, Japan) and laboratory prepared samples of MCM-41 and SBA-15 mesoporous silica. The manufactured materials belong to the TMPS group and the selected five samples are specified by different pore size ranging from 1.8

to 4.2

and with or without aluminium doping. The aluminium doped samples are signed with a capital latter

A at the end of the sample name. For a comparison, laboratory prepared MCM-41 and SBA-15 mesoporous silica were examined for the water adsorption as well. The MCM-41 was prepared by cationic surfactant CTMABr in ammonia solution as described by Grün et al. [

58] and by adjusting the method to create a smaller pore size comparable to the studied TMPS specimens by decreasing the ammonia volume to 3

. The results are spherical cells with diameter spanning from 100

up to 2

on average with pore diameter approximately

. The SBA-15 was synthesised according to Sayari et al. [

59] with the Pluronic P123 template. To adjust the pore size, we chose the first micelle stabilisation phase to 20 h at

35

and the subsequent growing phase to

100

for 24 h. The result was standard rod-like cells with a diameter of 200

–300

and length around 1

. The pore size was found out as

. Similarly to the TMPS materials, both the SBA-15 and the MCM-41 were used without any modifications. The properties of all used materials are summarised in

Table 1. The detailed investigation on the physical properties of the used mesoporous silica materials is provided elsewhere Mikšík et al. [

60].

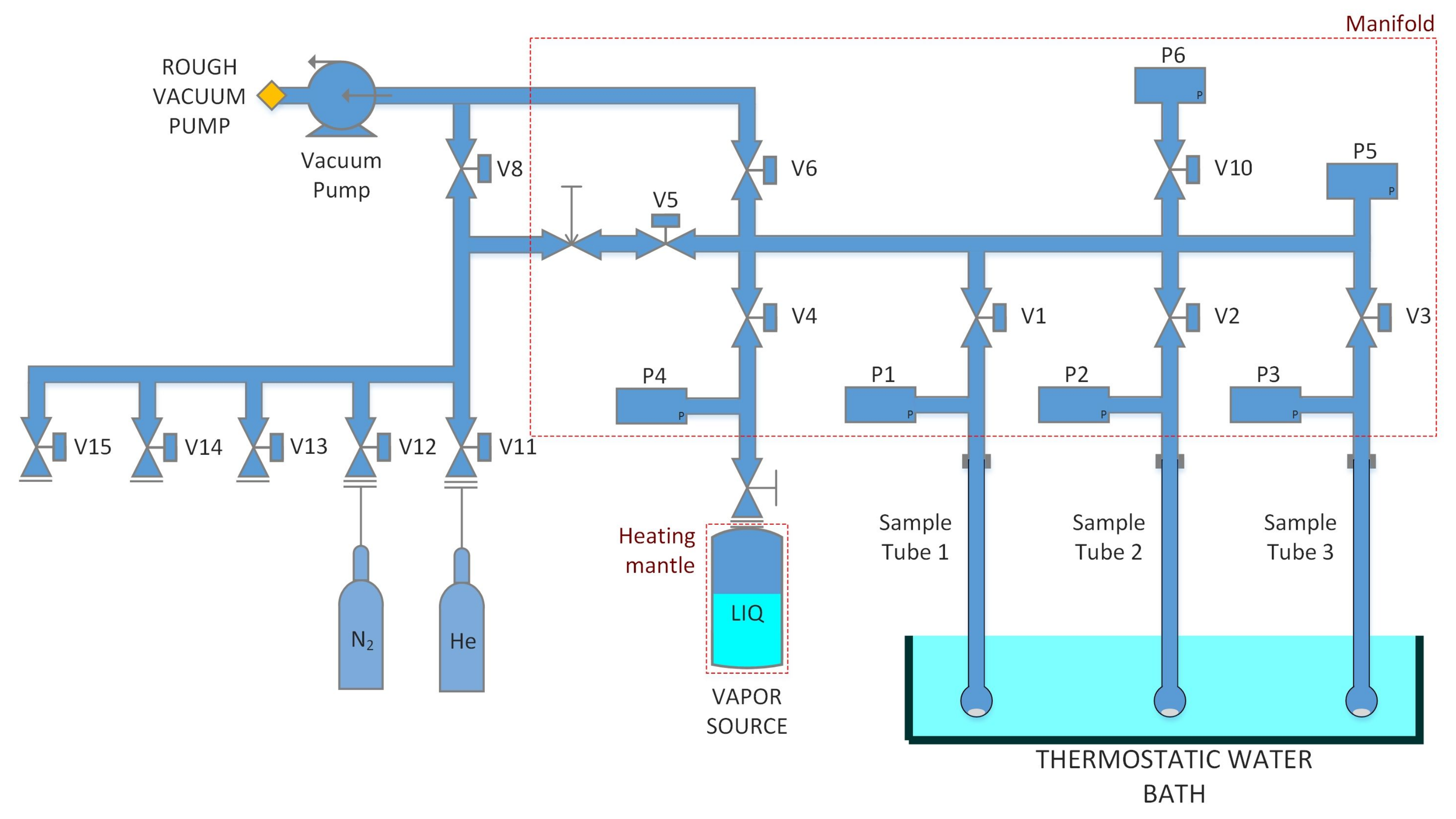

The adsorption isotherms were measured on high accuracy surface characterisation analyser 3Flex (Micromeritics, Norcross, GA, USA). The schematic of the measurement device is provided in

Figure 2. The 3Flex analyser is a constant volume analyser and uses volumetric method to establish the adsorption amount. The standard measurement process follows a set routine based on sampling certain amount of the adsorbate vapour into the closed manifold space (closed by V1-6 valves) with known volume. In the second step the valve to the desired sample tube is opened (one of V1-3 valves) and the adsorbate is introduced to the sample. The sampling time is typically couple of seconds after which the valves is closed and the sampled vapour amount is calculated on the bases of the pressure difference before and after the introduction. The final adsorbed amount is then calculated based on introduced amount of adsorbed vapour and the residual pressure inside the sample tube after equilibrium is reached. The equilibrium time was set to 10 s with less than 0.01% change of the adsorption amount. The relative error of the measurement based on the reference material provided by the manufacturer was less than

u <

. However, repeated measurements showed relative error of up to

u =

on the adsopriton amount and

u =

on the relative pressure as a joint error of weighting and vapour source preparation. However, with careful weight measurement the repeatability was typically 98. The relative deviation of the adsorption amount was also confirmed by an absolute thermogravimetric (TG) instrument MSB-TG (MicrotracBEL, Osaka, Japan) equipped with a magnetic suspension balance (MSB) (Rubotherm GmbH, Bochum, Germany). The high precision pressure transducer’s relative error was

of the reading accuracy allowing a negligible increase of the error through the measurement. The free volume of the experimental vessel and the sample was established through introducing a known amount of helium from the manifold to the fully evacuated sample tube. The volume of the sample tube containing the sample was then automatically calculated based on the pressure difference of the manifold and compared to the pressure increase inside of the sample tube before and after introducing the gas. Considering the size of the water molecules and the helium molecules, the deviation caused by the inaccessible space (very small crevices) is further on assumed as negligible.

Prior to the measurement, the samples were thoroughly degassed at 200

and high vacuum (

) for 5 h before weighting. Nitrogen gas was used to fill the manifold and sample tube to avoid unnecessary contamination during the manipulation between the measurements and weighting. After weighting, the samples were degassed once more at 200

for another 5 h. The residual pressure over the samples in the sample cell was confirmed to be

in all cases at the room temperature of 25

at the end of the degassing process. The drying temperature of 200

was selected with regards to the water adsorption properties of the possible presence of silanol (-Si-OH) groups [

56]. Furthermore, to sustain high reproducibility, each measurement was conducted with a fresh sample every time. The TMPS samples were measured at five different temperatures

5, 15, 25, 35 and 40

. The MCM-41 and SBA-15 were measured at four different temperatures 10, 20, 30 and 40

. The vapour source was prepared from ultra-pure deionised water with standard resistivity of

. The vapour source was degassed by regular procedure employing liquid nitrogen and high vacuum source. The degassing cycle was repeated until the pressure of vapour source at the room temperature (25

) was equal to the referenced values (REFPROP).

3.1. New Type IV and Type V Adsorption Isotherm Model

Through the theoretical approaches to accommodate different adsorption processes described in the introduction in one model is deemed practically impossible. Especially challenging is the adsorption on mesoporous materials and those materials on the microporous and mesoporous boundary, as mentioned above as well. This problematic stands on the perspective of two synergic effects with different physical explanation and therefore governed by different properties. While the direct adsorption on the surface can be properly described by the standard adsorption theories such as Langmuir, BET or GAB, the limits of the capillary condensation in the mesoporous space lies in the mesopore volume distribution which roughly corresponds to the pore size distribution. As the condensation cannot be described simply by the empty adsorption sites nor through multilayer adsorption, as the limits are more of a geometrical constitution rather than chemical, a different approach should be considered for the mesoporous materials. In this work, an approach for the modelling was, therefore, taken from the perspective of the dependency of capillary condensation relative pressure directly on the pore size distribution. Such system was also briefly mentioned in the work of Do and Do [

46] without further explanation per se. This approach, however, should require the identification of the pore size distribution beforehand or at least the adequate distribution model. Previously [

60], the TMPS materials were analysed on their volumetric-based pore size distribution according to the Density Functional Theory (DFT) method, and a surprisingly good fit was observed with a modified standard distribution function:

where

x is the pore size,

is a dimensional coefficient and

and

are regular coefficients for the standard distribution function, where

correlates to the range and

is the position factor. Considering that the adsorption process for mesoporous materials is a combination of adsorption and capillary condensation, we can write:

where the adsorption amount at equilibrium

is a sum of the regular adsorption

and capillary condensation

. By further developing this dependency it is possible to deduce a combination of standard adsorption model and condensation process based on the pore distribution. Firstly, it is necessary to rewrite the Equation (

29) into an integral form while

:

The boundary conditions of the Equation (

31) are logically stated for the states in which the isotherm is defined from

= 0 to

=

, while the upper limit is unity at full system saturation where

. The integration of this modified standard distribution then leads naturally to error function and after some algebraic manipulation, we will get the cumulative condensation amount:

As the adsorption on hydrophilic materials is multilayer in principle, the selection of the surface adsorption part was obvious with respect to the BET theory. We selected two well-known models based on the assumption of the practicality of the new model; the multilayer BET (Equation (

7)) and the modified BET model known as the GAB model. The main difference between these models would be, therefore, the expectation of the finite number of adsorbed layers (i.e., confined space) in opposition to the reduced relative pressure

to compensate for the saturation pressure deviation in case of the GAB model. The multilayer BET model extended by the mesopore condensation distribution function defined by Equation (

32) and the final equation takes the following form (further on only as mBET+G):

where the variable

x is the standard relative pressure

. Above that, we can describe the individual constants from Equation (

33) by the temperature dimension

T, which will be demonstrated in the following parts.

The combination of the condensation distribution function of Equation (

32) part with the GAB model will take a similar route giving the final form:

In Equation (

34) (further on referred as GAB+G)

x is the standard relative pressure substituted by the reduced relative pressure from Equation (

8). As mentioned before, the two new models have two parts describing individual processes during the adsorption. The GAB modification has been proven as a valid model for many systems surpassing the original BET model especially at higher relative pressures; however, it is derived from the assumption of infinite adsorption layers, which can lead to significant overestimation in adsorption. On the other hand, it is simpler than the second model based on the finite-layer derivation of the BET theory. Similarly to BET model the

constant represents the affinity of the adsorbate to the adsorbent.

The and (first layer adsorbed volume), are properties of the system and should be independent on the temperature. However, in the case of , it is more appropriate to talk about apparent first layer capacity, as it is not necessarily an exact value, but rather an approximation of the model itself.

3.2. Modelling, Error Analysis and Goodness of Fit

To assess the quality of the model and the goodness of fit, several methods have been employed. As the standard method for the goodness of fit was used the non-linear Chi-Square Test (

) in the following form:

where

is the calculated value and

is the experimentally measured value. (

) method also has its shortcomings as it is supposed to be fit to data with a certain distribution. In case that the model fits well and the distribution of the points is too small, the results are small as well and a direct comparison can prove to be impractical. Hence, for standard comparison of dependencies, the usual coefficient of determination

is used as well to assess the correlation between the models and experimental data. The equation is used in the form:

where the parameters are the same as in Equation (

35), while

is the average value of the adsorbed amount. As a result that the coefficient of determination does not provide adequate information when the data range spans through several orders of magnitude, to assess the absolute fit of the calculated model on the experimental data an average absolute deviation (AAD) and average relative deviation (ARD%) were used as a direct measure for the data fitting. The ARD% was used in its natural form:

The average absolute deviation was then calculated similarly without the scaling normalization by the effective experimental data

:

The parameters of the function are again identical to Equation (

35) of the

test.

The model simulation was conducted through a repeated non-linear regression fitting using Trust Region Reflective (TRR) algorithm. An important criterion was an introduction of a weighting factor to compensate for the scalability of the adsorption amount at low relative pressure with optimization of the absolute average deviation fitting parameter. The fundamental fitting (preliminary fitting) of the models was executed with a different constant weighting factor according to distribution, where N is the number of the data points. This method was selected to better compensate for the imbalance in the input data, giving the beginning of the adsorption higher priority on a more local level. This way, a good fit for the basic model could be ascertained, providing us with meaningful results in terms of the BET adsorption theory and very good fit with experimental data. The same approach was applied to the other models as well. All the calculations and modelling of the isotherm curves were executed by original Python scripts.

4. Results

From the explanation above, it is evident that simple models would be difficult to apply to mesoporous materials as materials with strong duality (or triality) in their adsorption mechanisms. For the comparison of the new isotherm model, we have chosen the Rutherford model [

42], Henry–Sips model [

24] and Ng’s model [

18] with two nominal peaks (

) (Ng-2f) as suggested in their work for the isotherm types IV and V. The selection of the comparison models was done based on the best fit out of the regular models described previously in this work. Although the goodness of fit of these models somehow lacks certain aspects, the results of the selected models prove to provide sufficient fit with the present mesoporous silica materials and the results are comparable to the new models. A full summary of the final form, at which all the models were used, is provided in

Table 2.

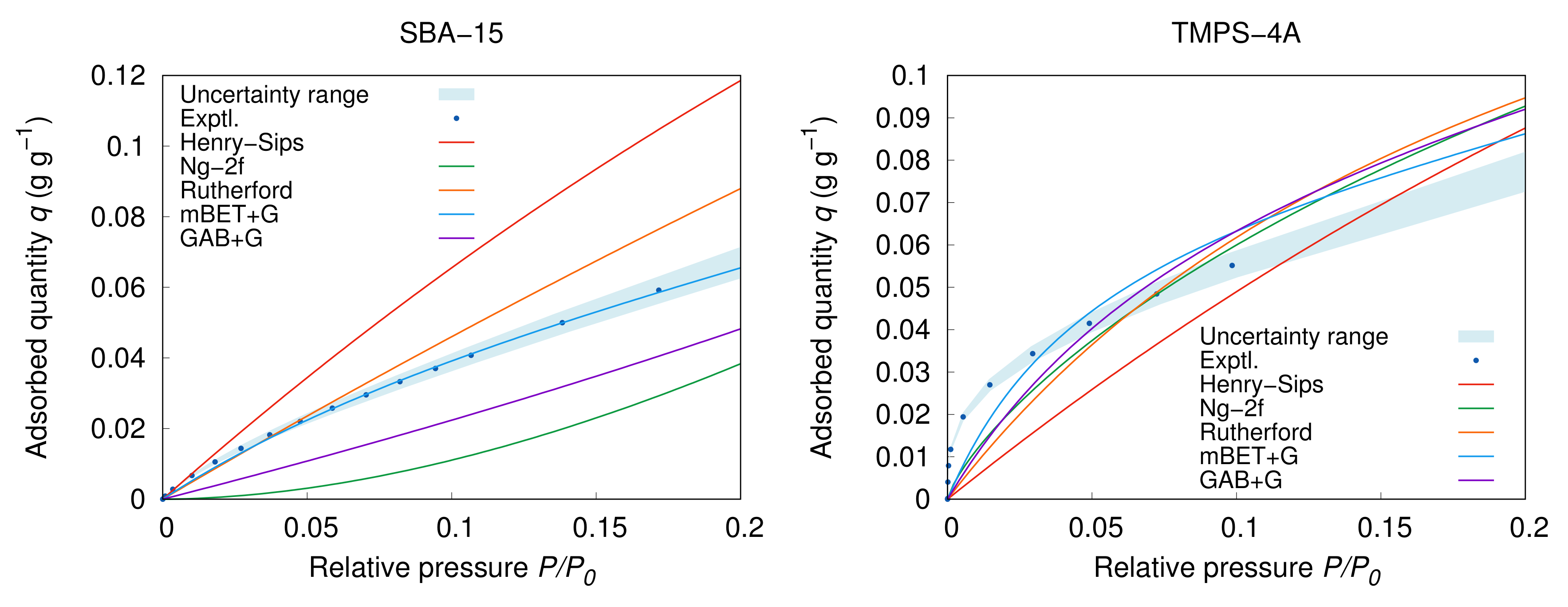

The graphical representation of the new mBET+G and GAB+G models compared to the experimental data and literature models is provided in

Figure 3 on the example of TMPS-2A and SBA-15. It is visible that all the selected models perform well except for the Henry–Sips model which cannot properly describe and follow the two modes of the adsorption process which is even more apparent given the respective examples in

Figure 3 which are representatives of both Type V (SBA-15) and Type IV (TMPS-2A) isotherms. To objectively compare the fitting of the models, a numerical comparison is provided by the means of

and ARD% for all tested samples. The statistical parameters are summarized in

Table 3.

The best fit from the regular models based on the

and ARD% values shows Rutherford’s model following the CMMS approach; moreover, this model works with only five constants making it more statistically significant. The visible improvement of the fitting is apparent from the ARD% values, which had been decreased in almost all cases. The better fitting can also be observed directly from the graphical output of the residual analysis in

Figure 4. However, when comparing the individual models, we have to evaluate all of the statistical factors.

Even if the relative deviations are rather high (mostly > 10%) the average absolute deviations listed in the

Table 4, together with the full summary of the models’ constants parameters, are relatively small for all the models. The implications are clear when we directly confront these two values. If the AAD is small, the overall fit is acceptable, however, if the ARD% value is also small, even the fitting at lower relative pressures fits the experimental data. Then again, with ARD% values too high, the fit at the lower relative pressures is typically poor as it is apparent in

Figure 5 showing detail fitting in the relative pressure

region of 0 to 0.2. This comparison is indeed crucial if fitting the whole adsorption pressure range by physically meaningful parameters of the used models.

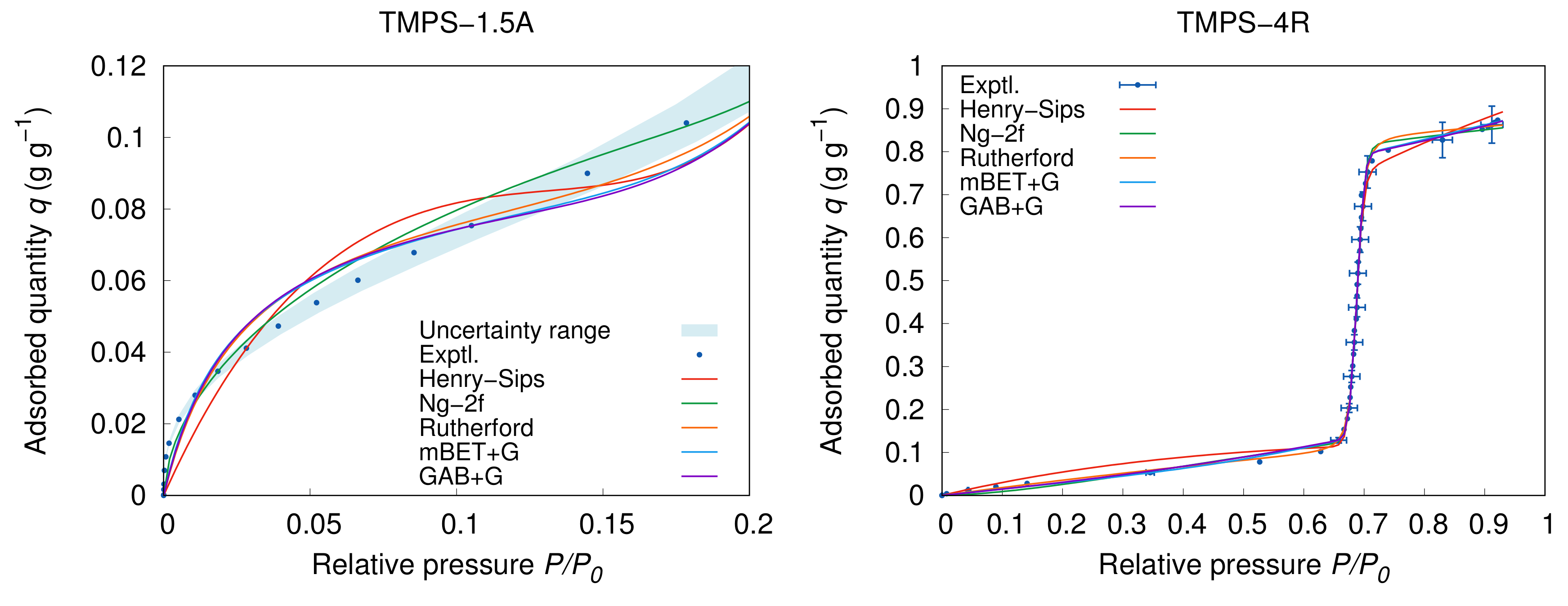

The new models are easily comparable to the recent models and in several aspects, they outperform them. The direct comparison based on ARD% reveals that far best results are reached by the mBET+G, which reaches the best ARD% values and

parameters on average. That is, some of the materials show better fitting parameters for different individual models, however, the overall universal applicability is in favour of the mBET+G model. As an example can serve the material TMPS-4R which fits the mBET+G model with ARD% =

%, however, Rutherford’s model shows ARD% =

%, which is clearly better value. Similar results are also in case of the absolute deviation AAD of the TMPS-4R where Rutherford’s model performs the best among all the models with AAD =

−1 while the mBET+G is the second best with AAD =

−1. Afterwards, the mBET+G model shows better results and fitting parameters in all other materials compared to Rutherford’s model. The same situation is in case of TMPS-1.5A where the best performing model is Ng’s two-part model (Ng-2f) reaching very low AAD =

−1. The mBET+G and GAB+G then show slightly higher values of AAD =

−1 and AAD =

−1, respectively. The fitting example of the TMPS-4R and TMPS-1.5A is available in

Figure 6. The results are therefore strongly in favour of mBET+G and the GAB+G model is used mainly for demonstration and comparison.

A strong point of the proposed combination is the complementarity of the two models; multilayer BET model and capillary condensation distribution function model. Comparing the fitting parameters of the individual models, the newly proposed model systems, especially the mBET+G, provide the most regular parameters in relation to the properties of the adsorbents. Looking at the Henry–Sips model, the proportionality factor

almost completely separates the individual parts of Henry contribution and Sips contribution at a certain point. That is not necessarily wrong for many of the materials which exhibit a strong Henry region, however, the applicability is strongly limited and, as shown in this work, the fitting is mostly insufficient. Different situation is in case of the Ng-2f’s model where the energy distribution functions are designed to overlap each other to create the resulting isotherm. Even though that the fitting is improved, the fitting parameters are not following the individual adsorption phases. That is apparent from irregular values of the parameters (very high or very small values of

) for different adsorbents regardless the properties. The best fit in comparison to the proposed mBET+G, therefore, provides the Rutherford’s model. Rutherford’s model is technically a combination of Langmuir isotherm and modified (simplified) CMMS model. However, it is important to note that Rutherford’s model is not primarily intended to cover the capillary condensation as was explained in the

Section 2.2. Thus, the parameters of the model have limited meaning for materials with capillary condensation. As a result of this, the Rutherford’s model tends to overestimate the adsorption quantity at lower relative pressure for materials with low affinity to the adsorbate (SBA-15) or underestimate it for materials with high affinity (TMPS-4A) as clearly visible in

Figure 5. From this perspective is clear that the proposed model has superior properties when considering materials with certain amount of capillary condensation. It would be possible to argue that a very good fit can be reached by expanding the Ng’s multipart model [

18] or Yahia’s multipart model [

16], however, this fitting would be achieved on the expenses of increased amount of necessary parameters and complexity.

From the

Figure 5 and

Figure 6 on the examples TMPS-4A and TMPS-1.5A, it is notable that most of the models underestimate the adsorbed quantity at low

, and therefore, underestimates the adsorption potential. This situation is most apparent in the case of material with high affinity to water and strong adsorbent–adsorbate interaction of the adsorption isotherm Type IV. Furthermore, at the end of the adsorption at high relative pressure, all of the samples show a continuous increase in the adsorption amount associated with progressing multilayer adsorption and at the further end with inter-particle condensation. This part is also very well described by the extended BET combined models as the multilayer formation is usually considered to continue through the whole pressure span. However, because the BET theory does not account for the inter-particle condensation, it may lead to inevitable compensation error, as shown in detail in

Figure 4. The same problems, naturally, concerns other models as well as they do not explicitly deal with the physical properties of the system such as the shape and size of the adsorbent particles. Nevertheless, this region is seldom a concern during modelling or simulation of the adsorption systems and it is primarily used for the material analysis only.

Temperature Dependent Fitting and Analysis

For the purpose of a combination with a simulated environment, the model parameters should be fitted into a temperature function series. Hence, the creation of a universal model applicable for the whole temperature region was attempted in this work as well. Considering the best fit of the experimental data and the purpose of this study, we have selected only the mBET+G model for this procedure as it gives better overall performance over the GAB+G model. The approximation of the model’s parameters dependence on the temperature can be expressed as a linear function of temperature:

where

T is the variable temperature, and

and

are the individual parameter’s temperature change rate and temperature-independent constant component, respectively. The linear approximation was selected for its simplicity and with the focus on sustainable accuracy which was validated in comparison for the individual isothermal data fitting. However, we need to emphasise that the linear approximation used specifically in this temperature range will not be necessarily also applicable beyond the scope of the presented experimental data. Hence, extrapolation of the data outside of the experimentally acquired temperature range should be validated.

The full approximation can be simply made based on the results of the individual isotherm analyses and their linear estimation. That gives, however, rather crude results with fitting errors far surpassing the original fitting parameters and a further optimization has to be applied. With the fundamental estimation taken from the simple linear regression of the individual parameters, the whole model was optimized on the whole data set at once through a continuous non-linear regression using the ARD% results as the weighting factors. This approach allowed us to have good agreement with the original fitting focusing on the sustainable fit at lower relative pressure and at the same time, we could partially compensate for the differences of the separate isotherm measurements. The final and optimized fitting is presented in

Figure 7 on the example of TMPS-1.5 and TMPS-2A, which have different surface characteristics and mean pore size. The average relative deviation is typically higher than in case of the individual isotherm modelling and reaches AAD

% for TMPS-2A compared to AAD

% of the one isotherm fitting at 25

. Somewhat atypical is the fitting of TMPS-1.5 which shows overall deviation decrease in the temperature approximation over the one isotherm fitting dropping from the original AAD

% at 25

to the overall AAD

%. This is caused by the slightly deficient fit at 25

while the average of all isotherms of TMPS-1.5 was in fact

%. The fitting parameters of the temperature approximation for the whole sample set are summarized in

Table 5.

Based on the linear expression, we can distinguish two separate patterns within the parameters. The first group describing the adsorbent–adsorbate interactions consists of highly and partially temperature-dependent parameters

C and

n. These parameters decrease with temperature in all cases, which follows the general adsorption theory that higher adsorption temperature negatively influences the adsorbent–adsorbate adsorption energy resulting in weaker bonding. The second group consists of parameters which are directly dependent on the physical properties of the adsorbent and mostly influences by the adsorbate–adsorbate interactions, such as capillary condensation. Into this group also belongs the maximum surface uptake

as it does describe the unchanging surface area of the adsorbent even though it is affected by the adsorbate-adsorbent to a certain degree. The values of

for most of the tested materials are well below

−1 −1 of the slope making it practically constant in the selected temperature range. Similar observations were noted for the parameters describing the capillary condensation region in the form of the distribution function consisting of

,

and

parameters, here with respective linear coefficients denoted as sub

and intercept constant denoted as sub

. If we look closely to the effective values of those parameters, we can see that the linear coefficients are typically two to three orders smaller than the intercept constants. This mean that within the selected temperature range 5

to 40

the temperature dependence is limited to less than 10% on the final values. Furthermore, individual changes can be explained by the governing processes during the adsorption giving them physical meaning, although the explanation is not that straightforward as we would expect. For example, the change with temperature of the

parameter, which describes the mean value of the capillary condensation relative pressure, is connected to the change of the surface tension from the Kelvin Equation (

16). The increase in the surface tension caused by the temperature rise also causes the increase of the Kelvin radius leading to shifting of the condensation in the pores to higher relative pressure values. However, at the same, the density of the adsorbed layers decreases, causing an opposing force to this process as the adsorbed layer thickness increases on the surface of the adsorbent. Although this effect may be small in comparison, many of these processes affect the final value requiring further insight.

5. Discussion

Despite the similar origins, the materials presented in this work have different properties and behaviour arising from their chemical and geometrical structure. The typical and pure mesoporous silica usually exhibit limited adsorption at lower relative pressures as shown in

Figure 3 on the typical representative SBA-15. A similar situation is in case of TMPS-4R and MCM-41, which have unaltered simple silica structure. These low hydrophilic properties of their surface are adequately described by the low

C constants values from the mBET+G and GAB+G models. The

C constant in the BET theory describes the intensity of the adsorbent–adsorbate interaction, and it is typically given by the following formula:

where

and

are the average adsorption heat of the first layer and heat of liquefaction, respectively. The gas constant

R is then used together with the thermodynamic temperature

T. However, even though that the

C and

constants of GAB and BET models share the same origins, the values significantly vary as shown in

Table 4 when the GAB+G model is showing considerably higher values, even several times higher than the mBET+G model. If we look further into the meaning of the

C constant and its relation to other constants in the GAB and BET models as was explained before, we come to the realisation that in case of the GAB model the

constant is practically co-dependent on the

constant while in the BET model the relation is clearer from the original expression of Equation (

7) where

. That means while in the GAB+G model the

constant requires a more careful approach, in case of the mBET+G model Equation (

40) can be applied directly provided the capillary condensation expression part does not interfere with the BET contribution to the model. Truly, in

Figure 8 is clearly visible that the distribution function applies only in a very narrow window corresponding neatly to the capillary condensation region. At the same time, the multilayer adsorption following the BET model is undisturbed and continues to add to the adsorbed quantity. A certain flaw in this model can be perceived the sudden change in the surface area after the full pore filling making the inner surface of the pores completely inaccessible which is not accounted for in either part of the equation. However, despite that, the model continues without significant deviation from the experimental data until high relative pressure where the inter-particle condensation takes place. The inter-particle condensation is characterised by a sudden rise in the adsorption quantity beyond the

mark and it depends on the particle size and shape. As a result that the inter-particle condensation is of low importance in the practical meaning, we tried to avoid this region in the experimental setup actively and only trace evidence of this process can be observed in

Figure 6 on the example of TMPS-4R.

In the case of the aluminium doped samples TMPS-1.5A, TMPS-2A and TMPS-4A, the

C values are significantly higher, showing strong hydrophilic properties. As a result that the aluminium content is similar to all of the augmented samples, the

C should be as well similar. Yet, in fact only the TMPS-2A and TMPS-4A show similar values of

and

, respectively, and the TMPS-1.5A shows

C value as high as

. This significant increase is caused by the boundary conditions of the microporous region to which the TMPS-1.5A belongs with the average pore diameter of

. The closeness of the microporous region also affects the slightly higher value of the TMPS-2A compared to the TMPS-4A. The microporous conditions then also explain the higher values of the TMPS-1.5 compared to the other aluminium-free samples. The seemingly higher value of SBA-15 at

is similarly caused by a certain content of microporous space created by the inter-pore channels as the remnants of the templating [

61] and as found out as well during the detailed analysis of the sample characteristics [

60].

If we attempt to compare the calculated values of the adsorption heat from Equation (

40) of the first layer with the calculated values from experimental data by Clausius–Clapeyron (CC) relation from our previous work [

26] the average values appear to be in agreement with those calculations. The highest value of the adsorption heat for the first layer based on the mBET+G is reached by the TMPS-1.5A with

−1, while the lowest one is TMPS-4R with

−1. The equivalent values from the Clausius-Clapeyron relation [

26] for the first layer (calculated as an average value from

−1 to

) are at

−1 and

−1 for TMPS-1.5A and TMPS-4R, respectively. Considering that the calculated values of the adsorption heat by the CC relation are typically lower than the actual experimental results [

62], the difference between these two samples is similar and equivalent to their respective surface characteristics.

From the fitting parameters of the mBET+G model is evident that the normal distribution works very well for all of the studied material samples. However, the normal distribution function used to describe the capillary condensation is still somehow lacking in terms of the physical meaning of the individual constants. Therefore, in here, we attempt to explain the individual constant using the physicochemical parameters, whereas the comparison in this work was possible thanks to the variety of the samples, varying by the pore size and surface characteristics. While the physical meaning of the C and n constants from the original BET model is clear and was explained above, parameters describing the capillary condensation may have a broader meaning.

The function describing the capillary condensation is built around the physical pore size distribution, which proved to the adjusted normal distribution based on the DFT analysis data. From the mathematical point of view, the normal distribution function is a form of probability function, hence, its cumulative expression takes the values from zero to unity. With this consideration, the

parameter is then the value of directly condensed adsorbate due to the surface curvature as explained by the Kelvin Equation (

16). Therefore, if we compare the

values to the mesopore volume of the individual samples, a simple linear dependence is achieved in

Figure 9, where the linear regression equals to

. This result can also be considered as a secondary proof of the model applicability. The only sample which does not fit to the equation is the SBA-15 sample, which was also excluded from the linear regression. The explanation could be that the different character of the SBA-15 adsorption makes the

parameter more dependent on the chemical properties of the material such as inverse influence on the number of layers described by the

n constant. The SBA-15 has the highest layer number of

, while the other surface characteristics are comparable to the other samples. The SBA-15 also has significantly bigger pore size allowing for more surface coverage before the capillary condensation is in effect. However, to further study this dependence, more samples with larger pore size should be examined in a separate work.

The position of the capillary condensation on the

x axis of the relative pressure

is decided in Equation (

33) by the

constant. Furthermore, it is clear that the capillary condensation is distinguishably decided by the pore diameter. Therefore, considering the fact that from the definition of the Kelvin equation the critical radius, or curvature, is practically dependent on the natural logarithm of the relative pressure, reciprocally, the

, as a function of the relative pressure, will become dependent on the pore radius or diameter in this case. The linearisation through the logarithm function (

) shows a good fit with the data in

Figure 10 for different pore diameters almost regardless the surface characteristics. This is, in fact, surprising as we have expected stronger dependence on the layer thickness, which directly affects the effective critical radius during the capillary condensation. Looking at the adsorption data presented in

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8 it is apparent that the samples with aluminium have significantly higher adsorption uptake prior to the capillary condensation. A reasonable explanation can be provided by the mechanism of the adsorption on the silica surfaces enhanced for higher hydrophilicity by Brönsted acid sites such as the aluminium atoms incorporated in the silica structure. Even though that these atoms increase the adsorption potential of the silica materials, the effect is strongly localised and typical by cluster formations [

63]. Based on this mechanism, the clusters despite significantly increasing the initial adsorption quantity have limited effect on the entire layer thickness, which consequently allows for a mostly undisturbed dependency of the

on the real pore diameter. However, this clustering effect has also other implications which are moreover connected to the

constant.

The

parameter describes the span of pore capillary condensation, in other words, the range of the effective pore diameters associated with the capillary condensation. From the mathematical meaning, the smaller the

is, the narrower the effective pore diameter range will be. Accordingly, considering the clustering effect, which in terms of position is mostly random, the creation of localised water molecular bridges can be expected, broadening the capillary condensation part and increasing the

value. A similar effect of clustering can be observed in the case of microporous space (<

) which moves the equilibrium of adsorption dynamics further from desorption. This is clearly apparent from

Figure 11, where the

value is shown as a function a natural logarithm of the ratio of

C over

n (

). Although, the selection is somehow limited, the materials with aluminium content or in the range of microporous region show notably higher

values. Furthermore considering the cluster formation as a basic process during the early stages of the adsorption, the final layer number

n is not necessarily actual layer count, but rather an approximation of the clustering effect. Then, because the surface characteristics are simultaneously described by the

C and

n constants the function for the

parameter has to take in account both of these constants. From the definition it is clear that the higher is the basic surface affinity expressed by the constant

C, as in the case if TMPS-1.5A, the higher the results are going to be, considering low

n value. It is therefore apparent that the parameter

is dependent on two main factors. One is inherently connected to the porous structure, which is defined as the pore size distribution. The second factor is then the surface characteristics and the adsorption process defined independently by the BET constants and the apparent effect of cluster-like adsorption.