Investigating the Width of Isolated Coal Pillars in Deep Hard-Strata Mines for Prevention of Mine Seismicity and Rockburst

Abstract

1. Introduction

2. Case Study of Mining-Induced Seismicity on Both Sides of an ICP

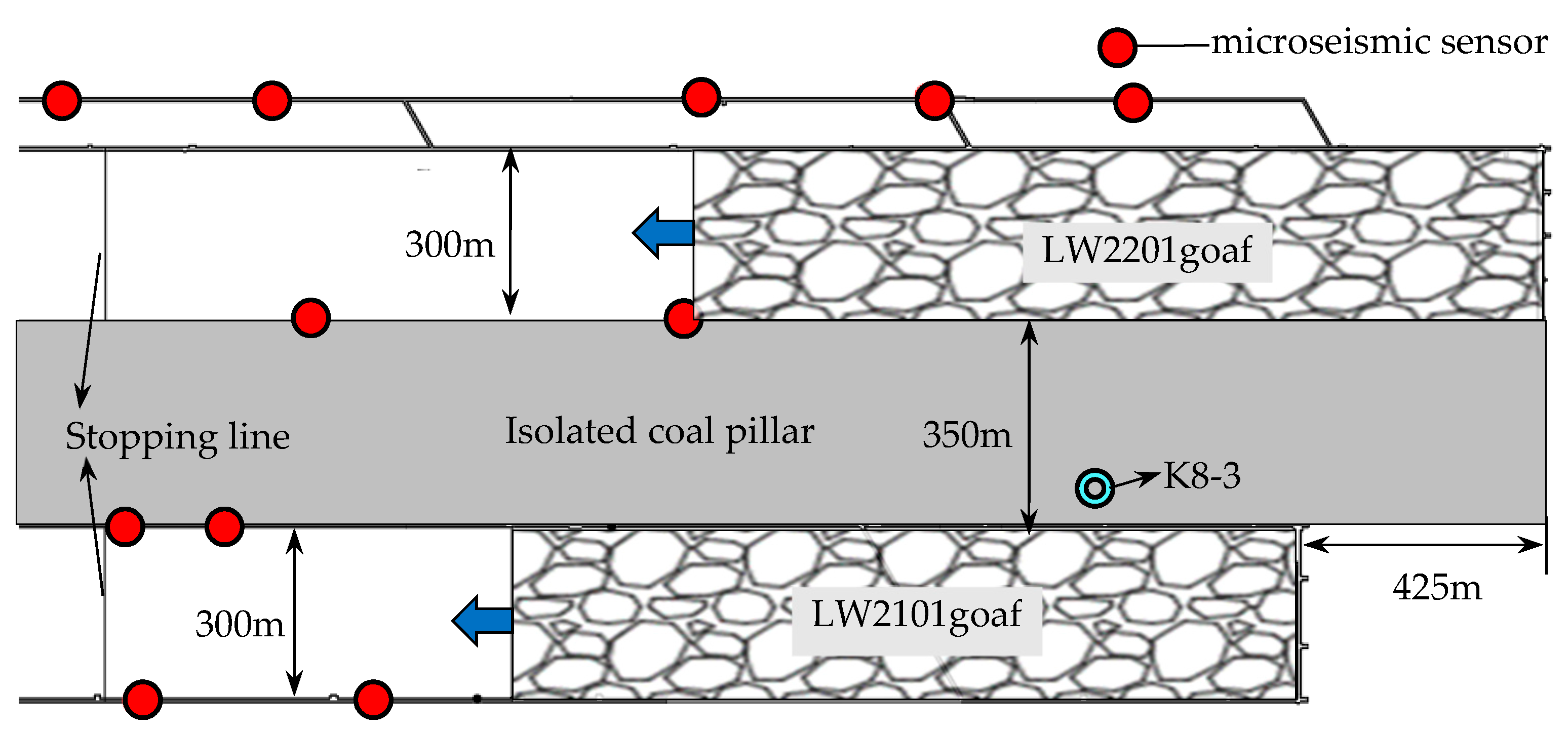

2.1. Field Conditions of Yingpanhao Coal Mine in Inner Mongolia

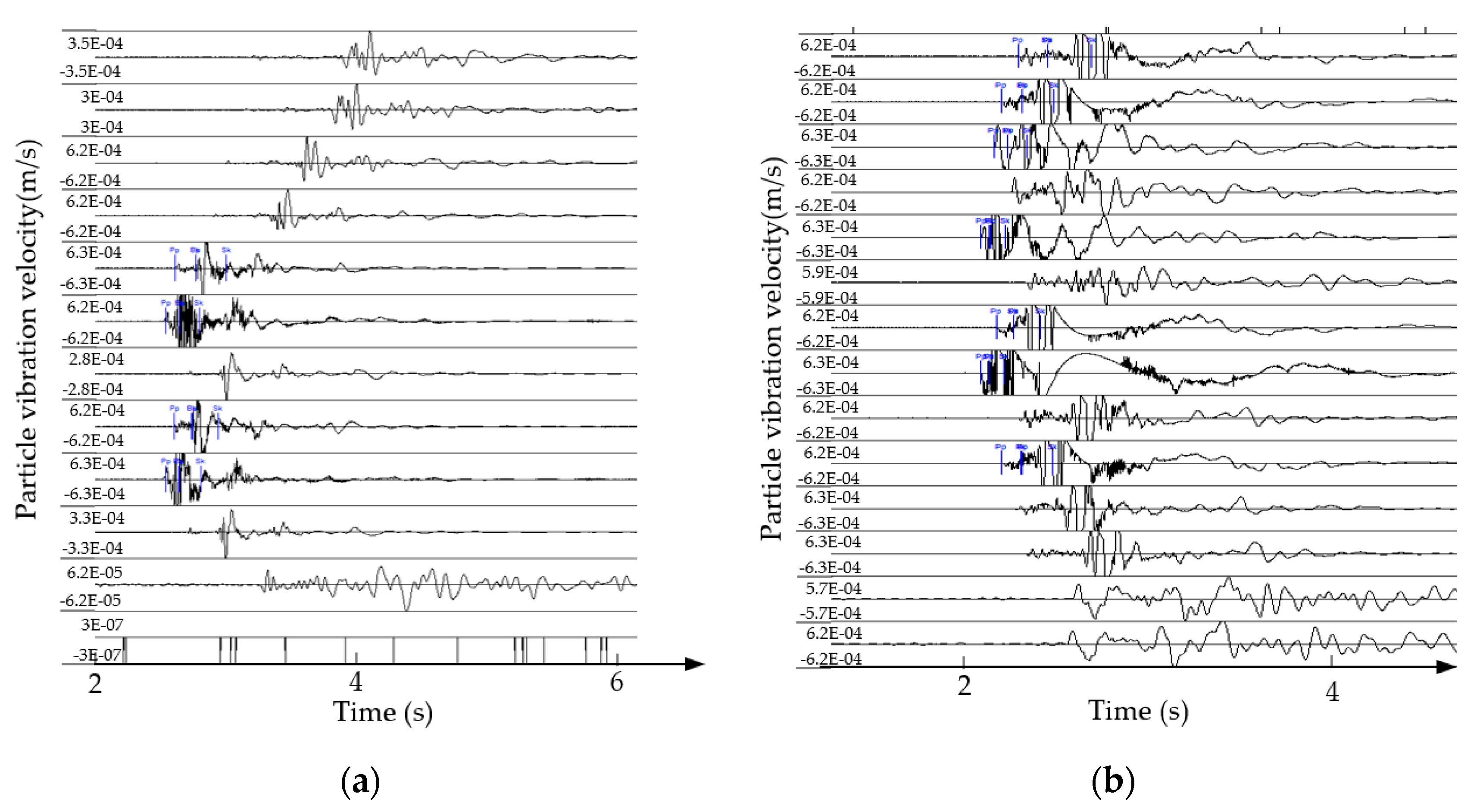

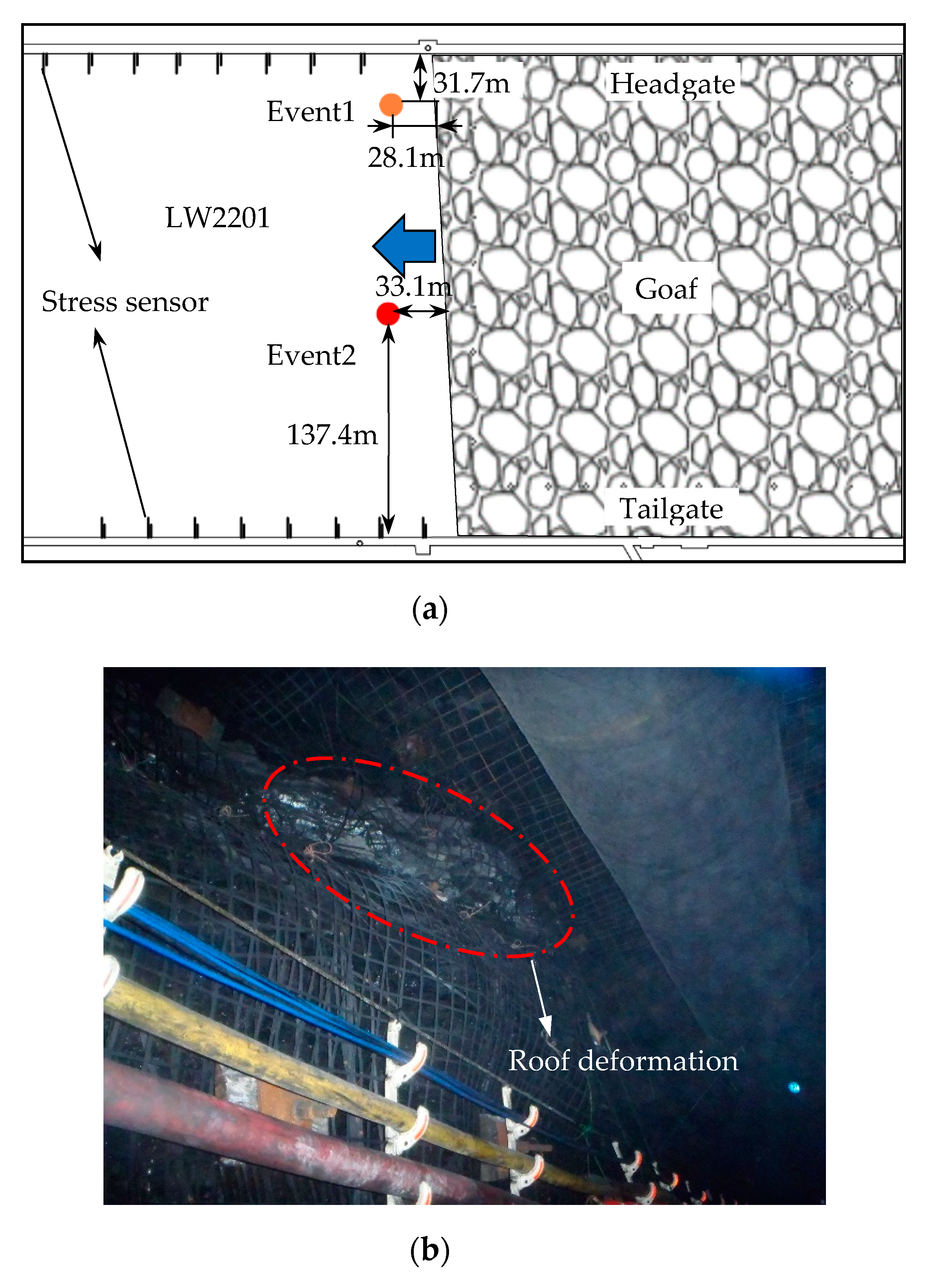

2.2. Description of Mine Seismicity on the Working Face

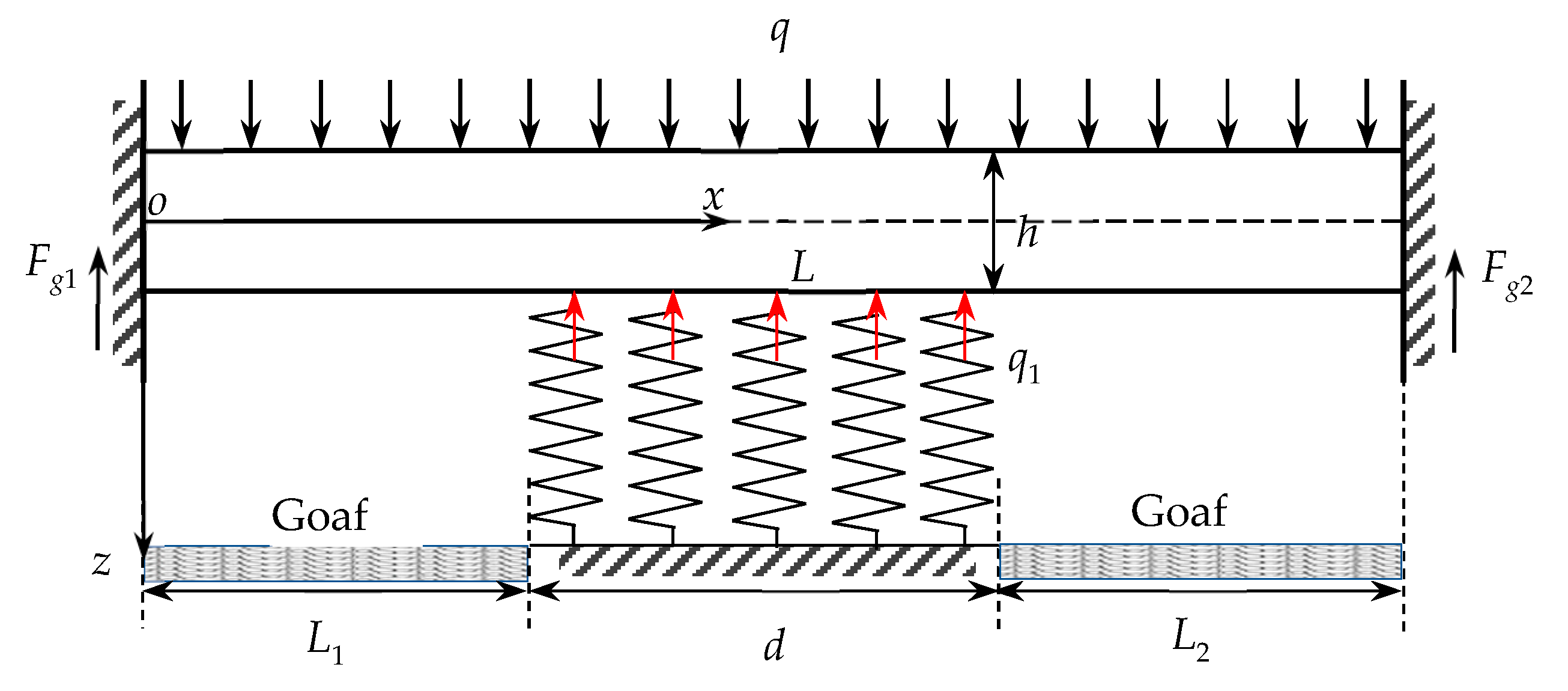

3. Occurrence Mechanism of MS on Both Sides of an ICP

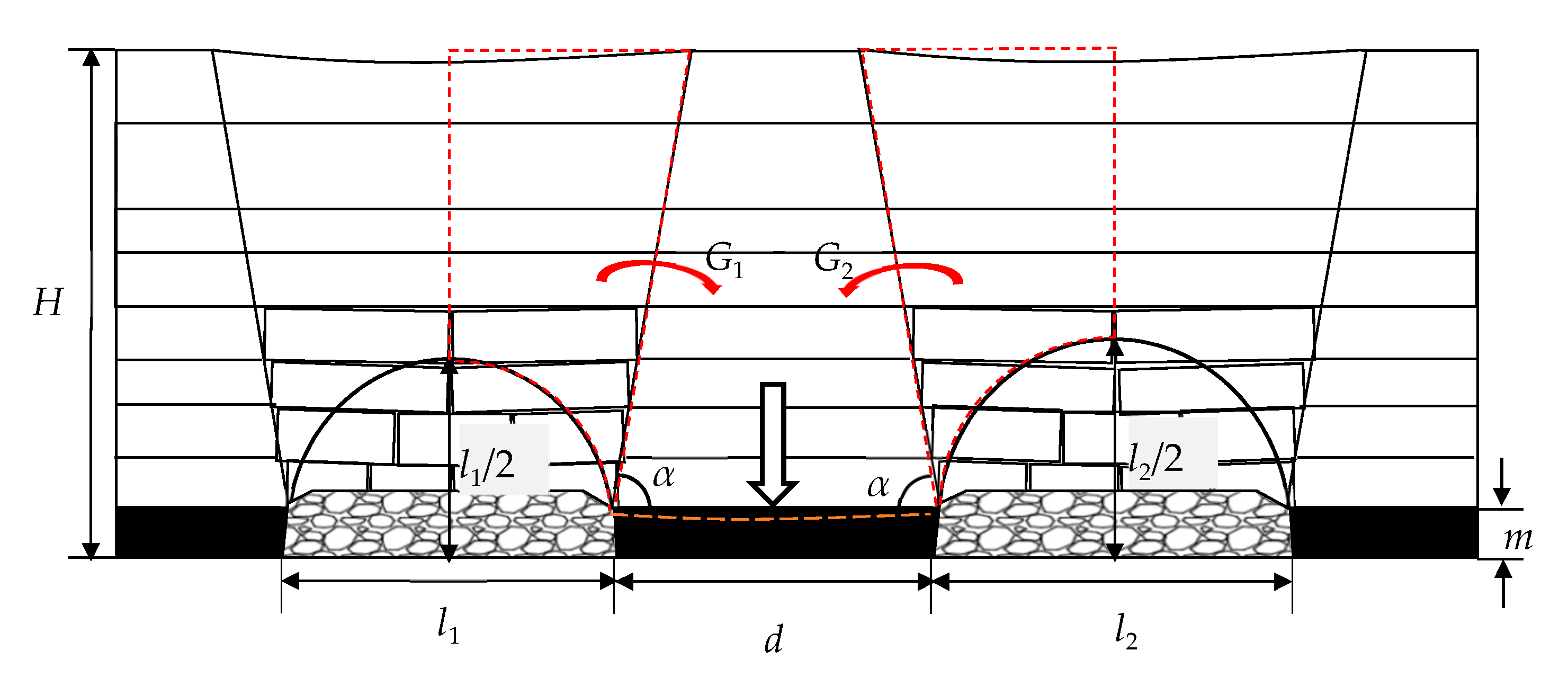

3.1. Flexural Deformation of the MKS

3.2. Mining-Induced Compression Amount of the ICP

3.3. Analysis of the Relationship Between the Compression of the ICP and the Flexural Deformation of the MKS

- (1)

- When wmax ≥ s, the overlying high hard MKS undergoes a flexural deformation, but it still keeps full contact with the lower rock strata, supported by the ICP. This means that its flexural deformation does not reach the limited deflection and breaks will not arise.

- (2)

- When wmax < s, after ICP experiences a compressive deformation, the soft rock stratum breaks and dips down, MKS reaches its limited deflection, and a separated stratum with a large amount of elastic energy appears. Influenced by other disturbances, it easily breaks down, releases a great amount of energy, and leads to MS, which greatly affects the safety of underground production and the stability of ground buildings.

4. ICP Width Design Based on the Collaborative Control of MS and Rockburst

4.1. Width of the ICP Calculated Based on the Nonoccurrence of OII Rockbursts

4.2. ICP Width Calculated Based on MS Prevention

4.3. ICP Width Design Basis

- (1)

- If , both OII rockbursts and MS may be induced;

- (2)

- If , either OII rockbursts or MS may be induced;

- (3)

- If , neither OII rockbursts nor MS will take place.

5. Verification by Theoretical Solution, Numerical Simulation Analysis, and Microseismic Monitoring

5.1. Verification by Theoretical Solution

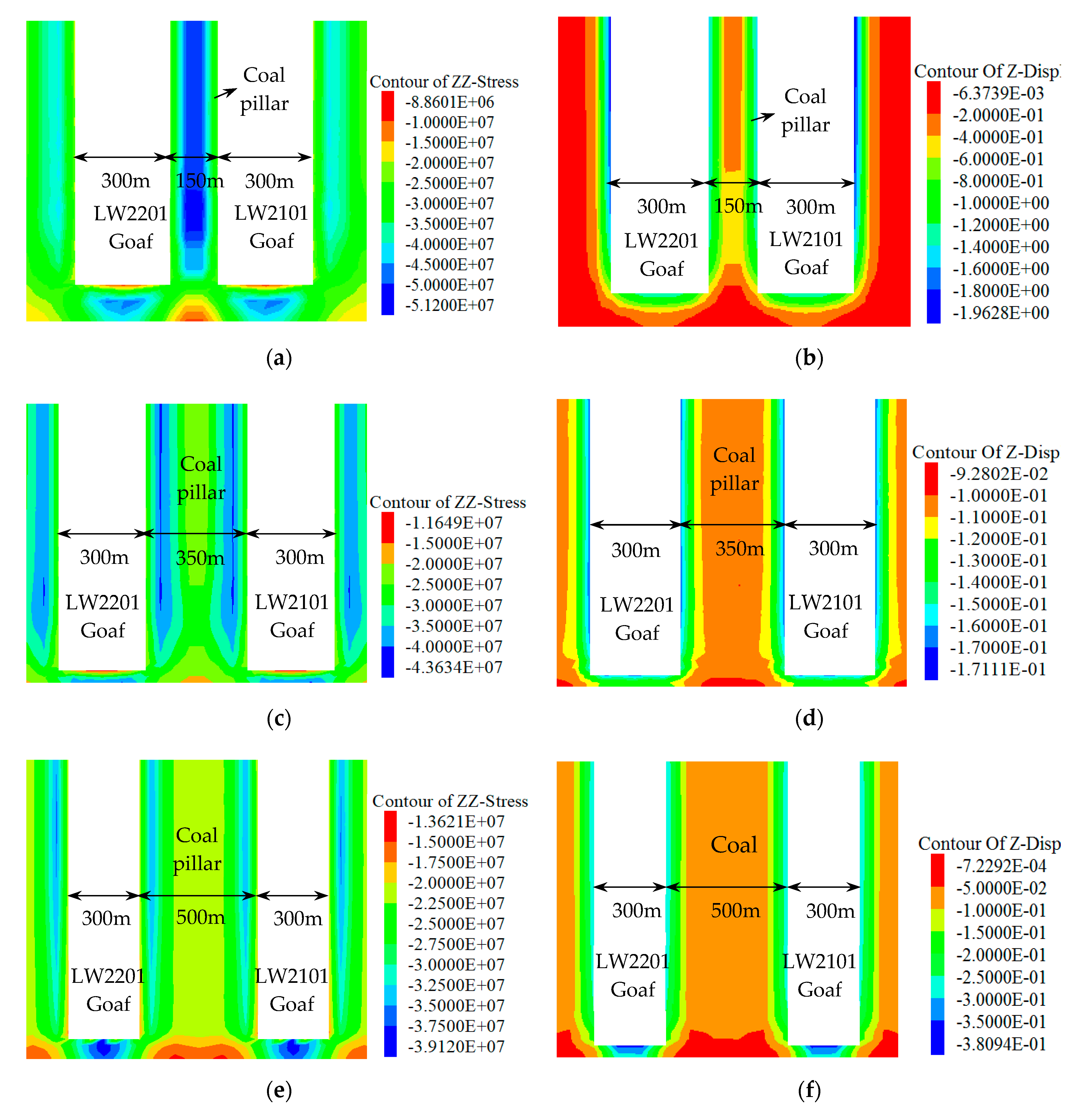

5.2. Verification by Numerical Simulation Analysis

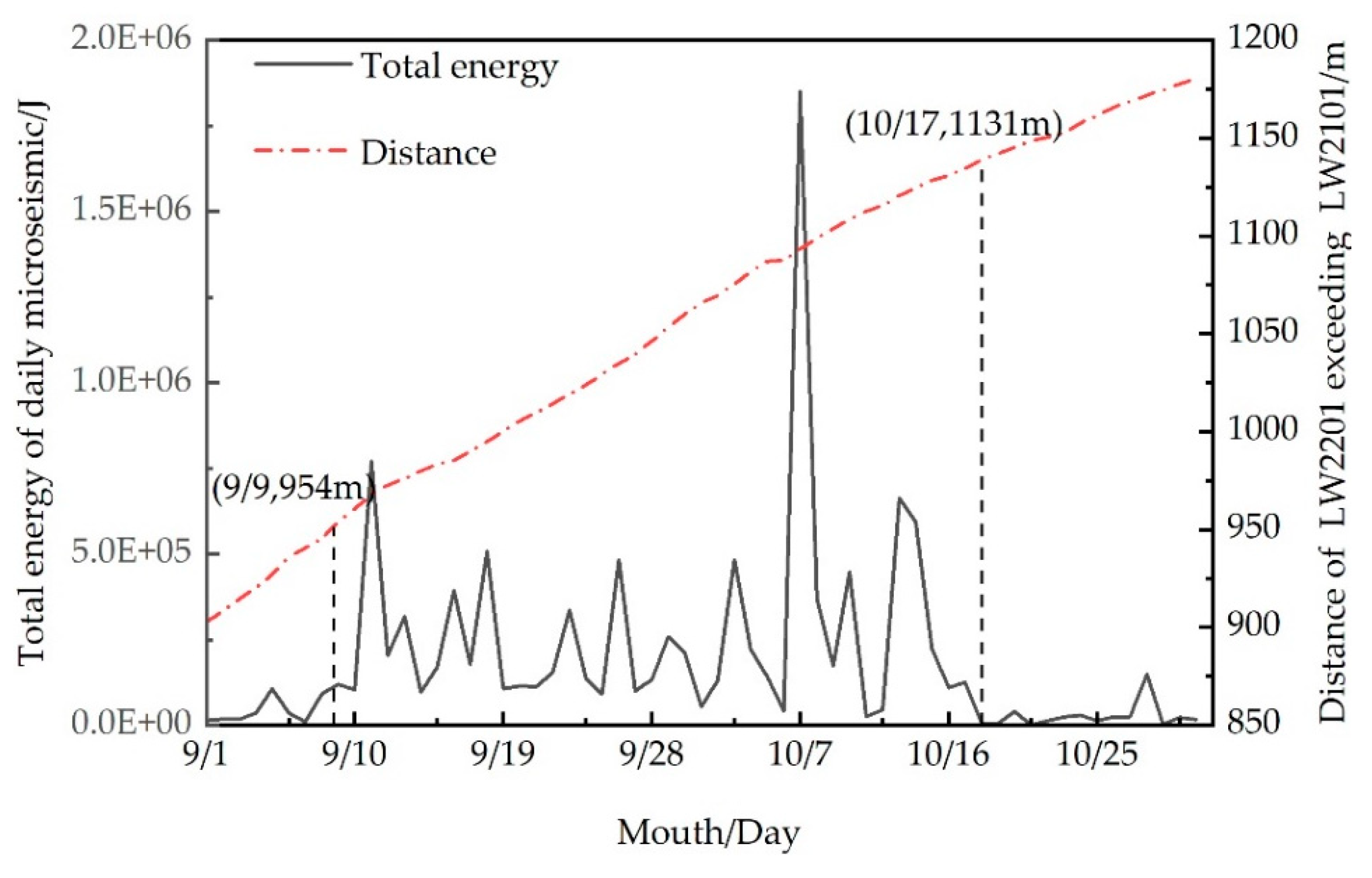

5.3. Verification by Microseismic Monitoring Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, M.C.; Zhao, F.; Cai, M.; Du, S. A novel experimental technique to simulate pillar burst in laboratory. Rock Mech. Rock Eng. 2015, 48, 1833–1848. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, N.; Xue, J.H.; Zhang, L. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- He, S.Q.; Song, D.Z.; Li, Z.L.; He, X.Q.; Chen, J.Q.; Zhong, T.P.; Lou, Q. Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions. Energies 2020, 13, 1362. [Google Scholar] [CrossRef]

- Wang, J.C.; Jiang, F.X.; Meng, X.J.; Wang, X.Y.; Zhu, S.T.; Feng, Y. Mechanism of Rock Burst Occurrence in Specially Thick Coal Seam with Rock Parting. Rock Mech. Rock Eng. 2016, 49, 1953–1965. [Google Scholar] [CrossRef]

- Li, Z.L.; He, X.Q.; Dou, L.M.; Song, D.Z.; Wang, G.F.; Xu, X.L. Investigating the mechanism and prevention of coal mine dynamic disasters by using dynamic cyclic loading tests. Saf. Sci. 2019, 115, 215–228. [Google Scholar] [CrossRef]

- Bräuner, G. Rockbursts in Coal Mines and Their Prevention; Routledge: London, UK, 2017. [Google Scholar]

- He, M.C.; Gao, Y.B.; Yang, J.; Gong, W.L. An innovative approach for gob-side entry retaining in thick coal seam longwall mining. Energies 2017, 10, 1785. [Google Scholar] [CrossRef]

- Wang, S.L.; Hao, S.P.; Chen, Y.; Bai, J.B.; Wang, X.Y.; Xu, Y. Numerical investigation of coal pillar failure under simultaneous static and dynamic loading. Int. J. Rock Mech. Min. Sci. 2016, 84, 59–68. [Google Scholar] [CrossRef]

- Liu, J.H.; Jiang, F.X.; Wang, N.G.; Li, Z.S.; Zhang, Z.G. Research on reasonable width of segment pillar of fully mechanized caving face in extra-thick coal seam of deep shaft. Chin. J. Rock. Mech. Eng. 2012, 31, 921–927. [Google Scholar]

- Cao, A.Y.; Dou, L.M.; Wang, C.B.; Yao, X.X.; Dong, J.Y.; Gu, Y. Microseismic precursory characteristics of rock burst hazard in mining areas near a large residual coal pillar: A case study from xu zhuang coal mine, Xuzhou, China. Rock Mech. Rock Eng. 2016, 49, 1943–1952. [Google Scholar] [CrossRef]

- Liu, G.J.; Mu, Z.L.; Chen, J.J.; Yang, J.; Cao, J.L. Rock burst risk in an island longwall coal face by stress field. Geosci. J. 2018, 22, 609–622. [Google Scholar] [CrossRef]

- Li, D.; Jiang, F.X.; Chen, Y.; Gai, D.C.; Wang, Y.; Wang, W.B. Study on impact mechanism and prevention technology of drainage lane of large coal pillars near deep wells. J. Min. Saf. Eng. 2019, 36, 265–271. [Google Scholar]

- Zhu, S.T.; Feng, Y.; Jiang, F.X. Determination of abutment pressure in coal mines with extremely thick alluvium stratum: A typical kind of rock burst mines in china. Rock Mech. Rock Eng. 2016, 49, 1943–1952. [Google Scholar] [CrossRef]

- Vizintin, G.; Kocjancic, M.; Vulic, M. Study of coal burst source locations in the velenje colliery. Energies 2016, 9, 507. [Google Scholar] [CrossRef]

- Cai, M.F.; He, M.C.; Liu, D.Y. Rock Mechanics and Engineering; Science Press: Beijing, China, 2002. [Google Scholar]

- Ju, Y.; Wang, Y.L.; Su, C.S.; Zhang, D.S.; Ren, Z.Y. Numerical analysis of the dynamic evolution of mining-induced stresses and fractures in multilayered rock strata using continuum-based discrete element methods. Int. J. Rock Mech. Min. Sci. 2019, 113, 191–210. [Google Scholar] [CrossRef]

- Zhang, C.; Canbulat, I.; Bruce, H.; Ward, C.R. Assessing coal burst phenomena in mining and insights into directions for future research. Int. J. Coal Geol. 2017, 179, 28–44. [Google Scholar] [CrossRef]

- Qian, M.G.; Miao, X.X. Theory research of critical layer in strata control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Pan, Y.S. Disturbance response instability theory of rockburst in coal mine. J. China Coal Soc. 2018, 43, 2091–2098. [Google Scholar]

- Zhang, T.K.; Pan, Y.S.; Xiao, Y.H.; Wang, A.W. Analytic solutions of a reducible strain gradient elasticity model for solid cylinder with a cavity and its application in zonal failure. Appl. Math. Model. 2019, 72, 663–681. [Google Scholar] [CrossRef]

- Jiang, F.X.; Zhang, X.M.; YANG, S.H.; Xun, L.; Ma, Q.H.; Wang, H.J. Discussion on overlying strata spatial structures of longwall in coal mine. Chin. J. Rock Mech. Eng. 2006, 25, 979–984. [Google Scholar]

- Jiang, F.X.; Liu, Y.; Zhang, Y.C.; Wen, J.L.; Yang, W.L.; An, J. A three-zone structure loading model of overlying strata and its application on rockburst prevention. Chin. J. Rock Mech. Eng. 2016, 35, 2398–2408. [Google Scholar]

- Hosseini, N. Evaluation of the rockburst potential in longwall coal mining using passive seismic velocity tomography and image subtraction technique. J. Seismol. 2017, 21, 1101–1110. [Google Scholar] [CrossRef]

- Cao, A.Y.; Zhu, L.L.; Li, F.C.; Dou, L.M.; Zhao, Y.L.; Zhang, Z.L. Characteristics of T-type overburden structure and tremor activity in isolated face mining under thick-hard strata. J. China Coal Soc. 2014, 39, 328–335. [Google Scholar]

- Cao, A.Y.; Jing, G.C.; Dou, L.M.; Gong, S.Y.; Zhao, Y.L.; Zhang, Z.L. Seismic hazard assessment in complex island coalface by computed tomography. J. Min. Saf. Eng. 2015, 32, 20–27. [Google Scholar]

- Li, Z.L.; He, X.Q.; Dou, L.M. Control measures and practice for rock burst induced by overburden fracture in top coal caving mining. J. China Univ. Min. Technol. 2018, 47, 162–171. [Google Scholar]

- Zhang, M.; Jiang, F.X.; Li, K.Q.; Wang, C.W.; Wu, X.G.; Gao, H.J.; Ji, S.H. Study of the compatible deformation and stability of the system of super thick strata and coal pillars. Chin. J. Rock Mech. Eng. 2017, 36, 326–334. [Google Scholar]

- Zhu, S.T.; Feng, Y.; Jiang, F.X.; Liu, J.H. Mechanism and risk assessment of overall-instability-induced rockbursts in deep island longwall panels. Int. J. Rock Mech. Min. Sci. 2018, 106, 342–349. [Google Scholar] [CrossRef]

- Mu, Z.L.; Dou, L.M.; Gong, S.Y.; Cao, A.Y. Networking design of sos micro-seismic monitoring for mine and error analysis of seismic resource orientation. Coal Min. Technol. 2009, 14, 8–14. [Google Scholar]

- Orlecka-Sikora, B.; Lasocki, S.; Lizurek, G.; Rudzinski, L. Response of seismic activity in mines to the stress changes due to mining induced strong seismic events. Int. J. Rock Mech. Min. Sci. 2012, 53, 151–158. [Google Scholar] [CrossRef]

- Reddish, D.J.; Whittaker, B.N. Subsidence: Occurrence, Prediction and Control; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Jiang, F.X.; Wen, J.L.; Bai, W.S.; Wang, G.L.; Li, M. Rock burst risk in surrounding abscission layer of overlying high key strata in deep strip mining mines. J. China Univ. Min. Technol. 2018, 47, 40–47. [Google Scholar]

- Zhang, J.X.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1439–1448. [Google Scholar] [CrossRef]

- Shen, B.T.; Poulsen, B. Investigation of overburden behaviour for grout injection to control mine subsidence. Int. J. Min. Sci. Technol. 2014, 24, 317–323. [Google Scholar] [CrossRef]

- Feng, Y.; Jiang, F.X.; Li, J.D. Evaluation method of rock burst hazard induced by overall instability of island coal face. J. China Coal Soc. 2015, 40, 1001–1007. [Google Scholar]

- Labuz, J.F.; Zang, A. Mohr-Coulomb Failure Criterion. In the ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer: Berlin, Germany, 2014; pp. 227–231. [Google Scholar]

- Zhao, H.C.; Kaunda, R.B. Numerical Assessment of the Influences of Gas Pressure on Coal Burst Liability. Energies 2018, 11, 260. [Google Scholar] [CrossRef]

- Feng, G.R.; Wang, P.F.; Chugh, Y.P. A New Gob-Side Entry Layout for Longwall Top Coal Caving. Energies 2018, 11, 1292. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Paul, P.S.; Sinha, R.K. Generalised Analytical Models for the Strength of the Inclined as well as the Flat Coal Pillars using Rock Mass Failure Criterion. Rock Mech. Rock Eng. 2019, 52, 3921–3946. [Google Scholar] [CrossRef]

- Henryk, G. The Theory of Strata Mechanics; Polish Scientific Publishers: Warszawa, Poland, 1991. [Google Scholar]

- Jiang, F.X.; Yang, S.H.; Xun, L. Spatial fracturing progresses of surrounding rock masses in longwall face monitored by microseismic monitoring techniques. J. China Coal Soc. 2003, 28, 357–360. [Google Scholar]

| Names of the Rocks | Thickness/m | Accumulated Depth/m | Columnar Forms | Note |

|---|---|---|---|---|

| Wind-blown sand | 95.75 | 95.75 | Sand on the surface | |

| Sandstone group | 324.45 | 420.2 |  | (Red layer) MKS |

| Interbedding of sandy mudstone and sandstone | 213.81 | 634.01 |  | Soft rock strata |

| Sandstone group | 38.55 | 672.56 |  | Inferior key stratum |

| Sandy mudstone | 7.52 | 680.08 |  | Soft rock stratum |

| Medium sandstone | 19.47 | 699.55 |  | Basic roof |

| Siltstone | 14.79 | 714.34 |  | |

| 2-2 coal | 6.13 | 720.47 |  | Coal seam |

| Siltstone | 9.21 | 729.68 |  | Basic bottom |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Zhu, S.; Jiang, F.; Liu, J.; Shang, X.; Zhang, X. Investigating the Width of Isolated Coal Pillars in Deep Hard-Strata Mines for Prevention of Mine Seismicity and Rockburst. Energies 2020, 13, 4293. https://doi.org/10.3390/en13174293

Wang B, Zhu S, Jiang F, Liu J, Shang X, Zhang X. Investigating the Width of Isolated Coal Pillars in Deep Hard-Strata Mines for Prevention of Mine Seismicity and Rockburst. Energies. 2020; 13(17):4293. https://doi.org/10.3390/en13174293

Chicago/Turabian StyleWang, Bo, Sitao Zhu, Fuxing Jiang, Jinhai Liu, Xiaoguang Shang, and Xiufeng Zhang. 2020. "Investigating the Width of Isolated Coal Pillars in Deep Hard-Strata Mines for Prevention of Mine Seismicity and Rockburst" Energies 13, no. 17: 4293. https://doi.org/10.3390/en13174293

APA StyleWang, B., Zhu, S., Jiang, F., Liu, J., Shang, X., & Zhang, X. (2020). Investigating the Width of Isolated Coal Pillars in Deep Hard-Strata Mines for Prevention of Mine Seismicity and Rockburst. Energies, 13(17), 4293. https://doi.org/10.3390/en13174293