The Identification and Rebound Effect Evaluation of Equipment Energy Efficiency Improvement Policy: A Case Study on Japan’s Top Runner Policy

Abstract

:1. Introduction

1.1. Review on Impact Analysis of Energy Efficiency Improvement and Carbon Emission Reduction at National Level

1.2. Content and Contribution

- (1)

- The energy and environmental contribution evaluation method of equipment energy efficiency improvement policy is proposed and verified by the case study of Japan (Top Runner Policy, TRP).

- (2)

- The CO2 rebound effect of energy efficiency improvement of passenger cars, air conditioning and lighting equipment are analyzed, and the emission reduction effects of short-term and life cycle are compared.

- (3)

- It provides a theoretical reference for the energy and environmental impact analysis of equipment energy efficiency at the national level.

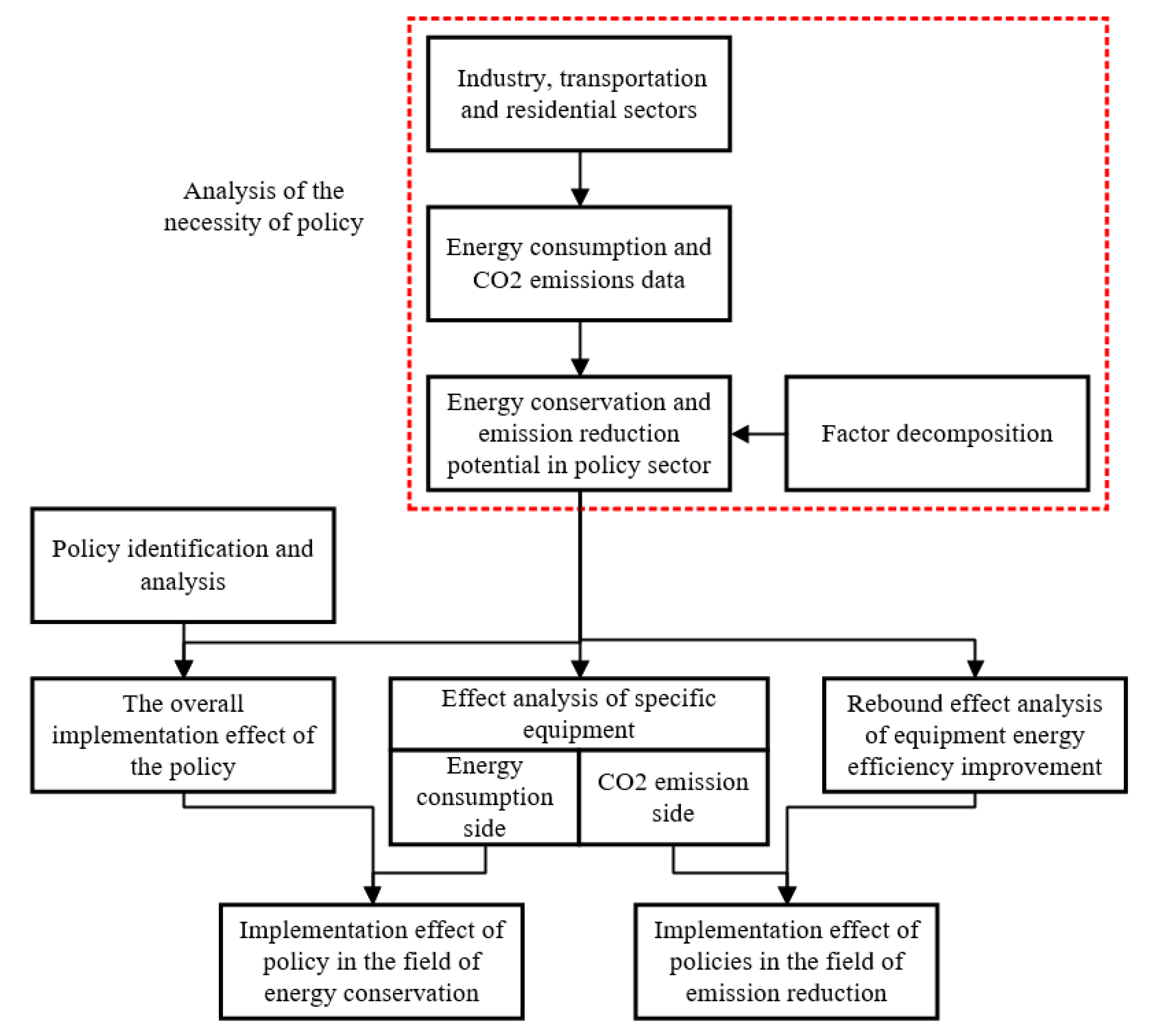

2. Methodology

2.1. Factor Decomposition

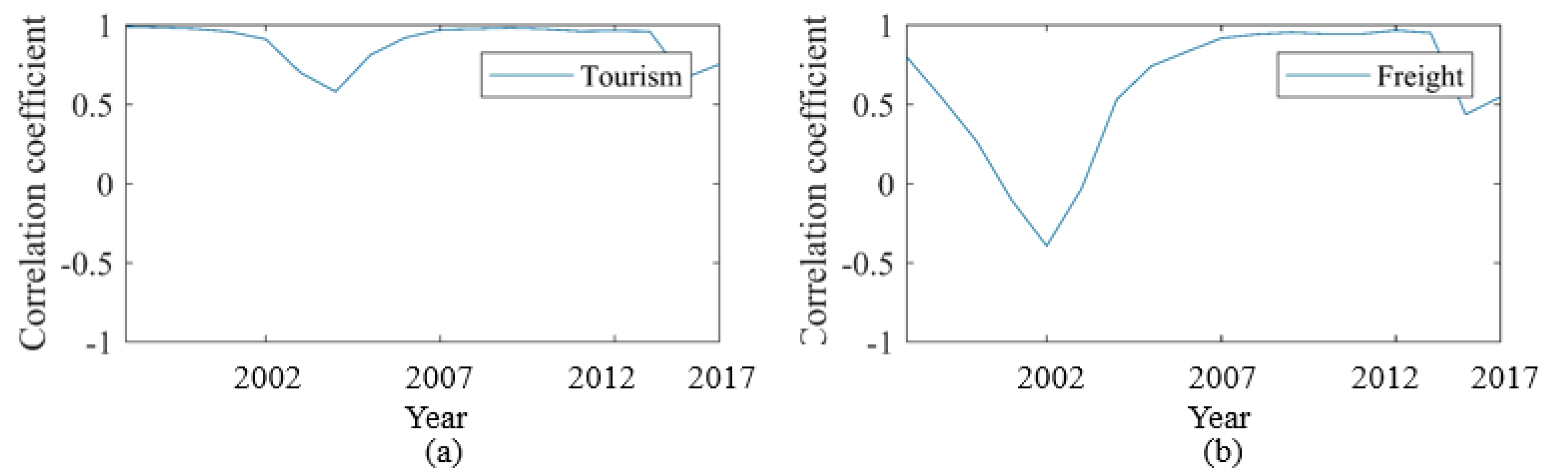

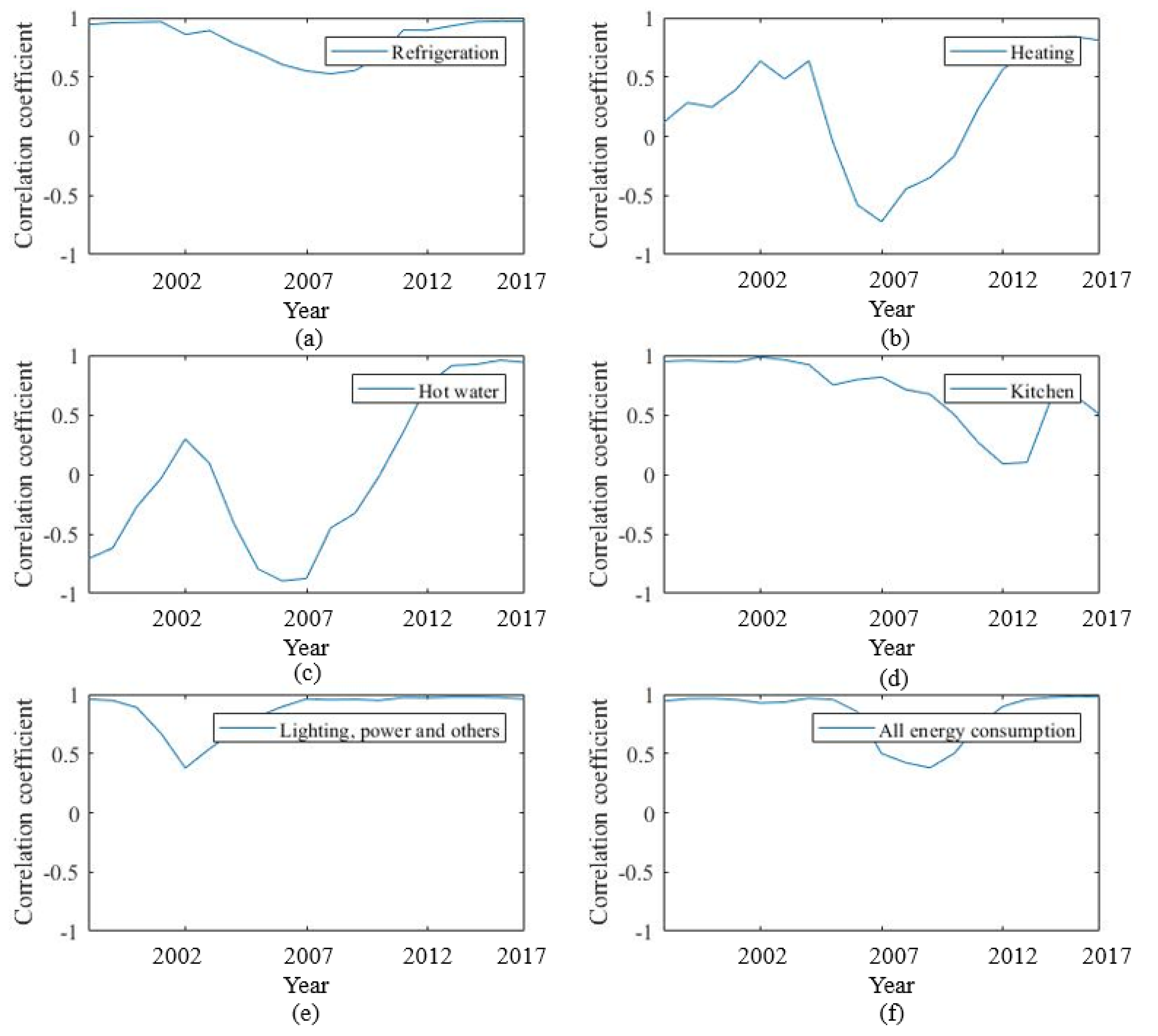

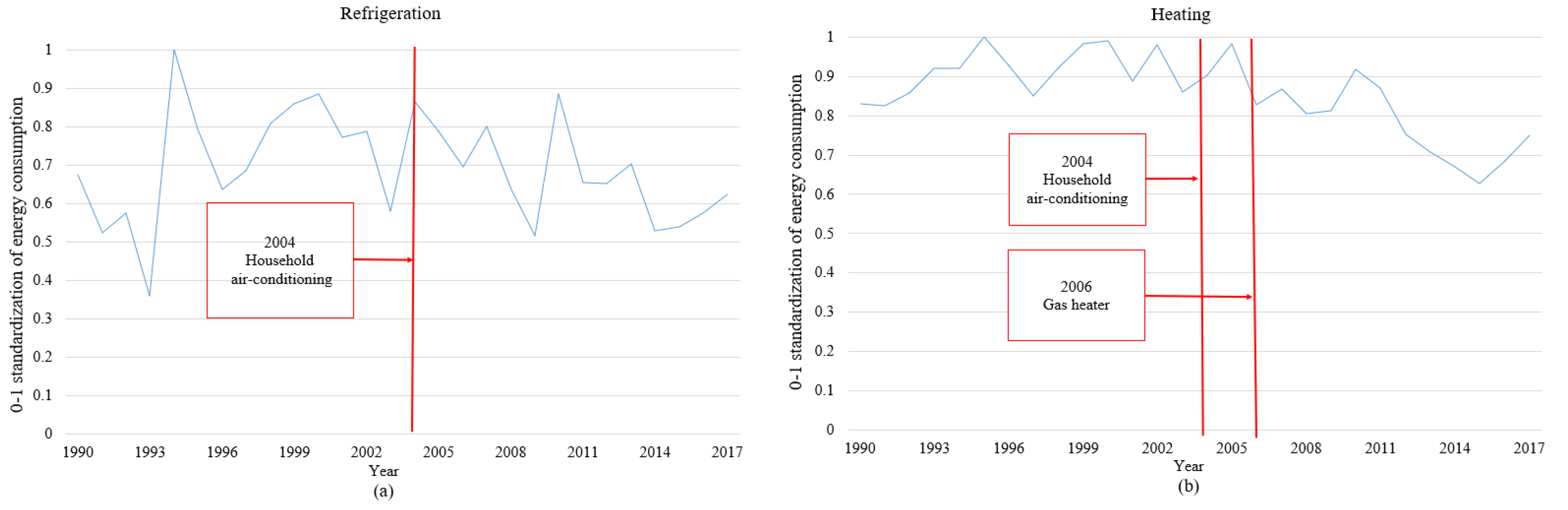

2.2. Moving Windows and Correlation Analysis

2.3. Life Cycle Rebound Effect

3. Research Objects and Analysis

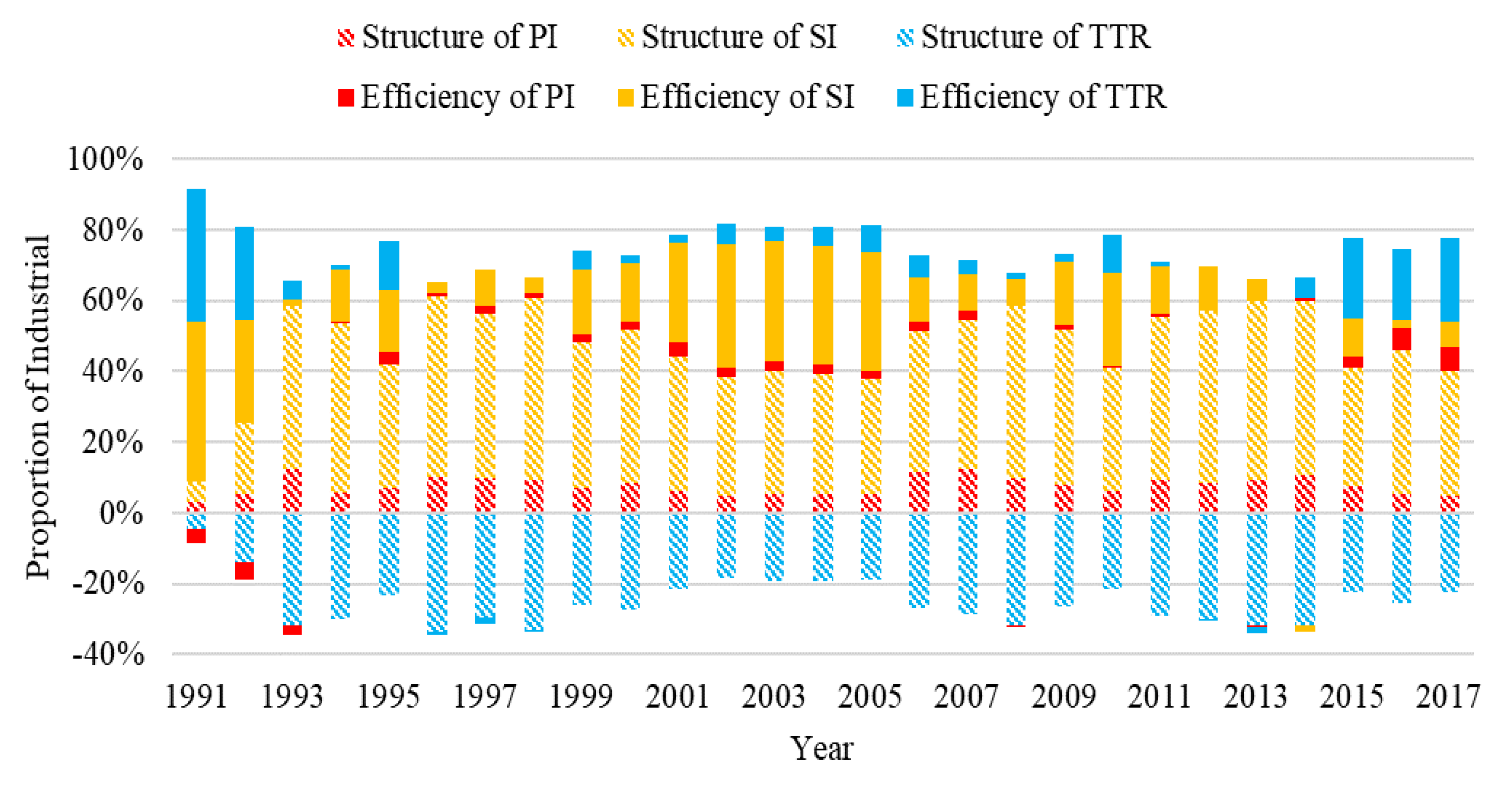

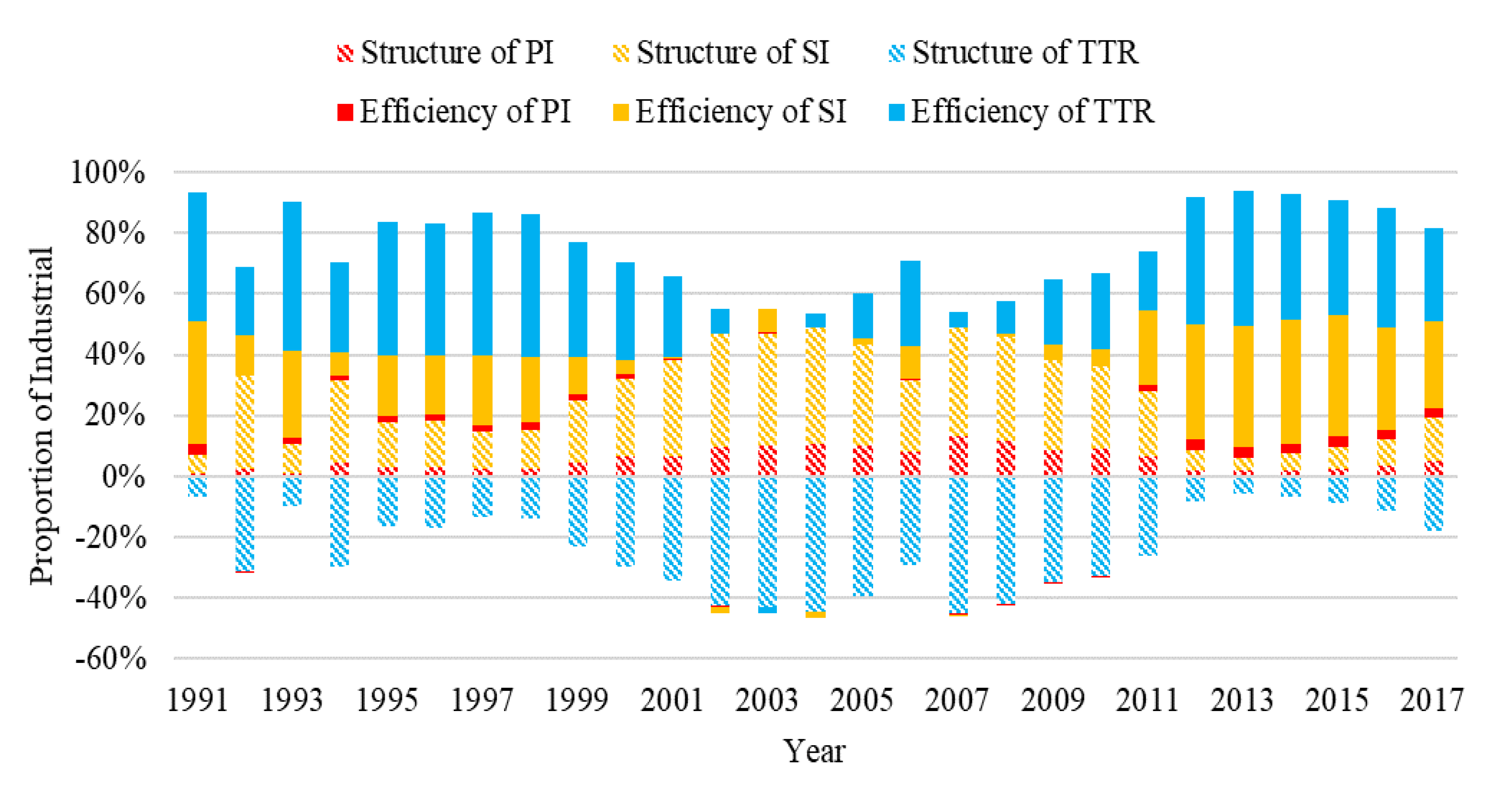

3.1. Factor Decomposition of Energy Saving and Emission Reduction Potential

3.2. Identification of Top Runner Policy (TRP) and Analysis of Its Influence Lag

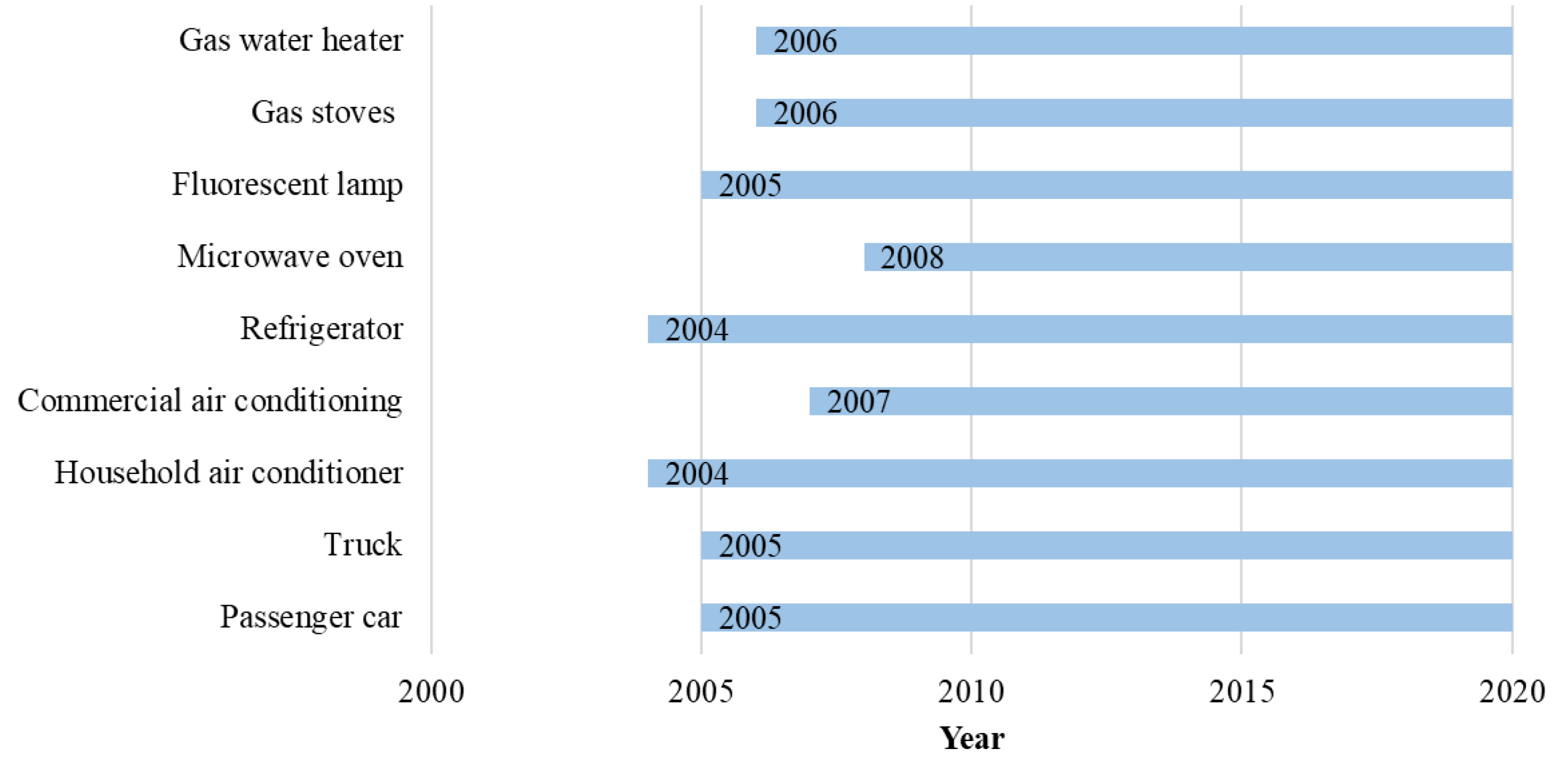

3.2.1. Overview of TRP

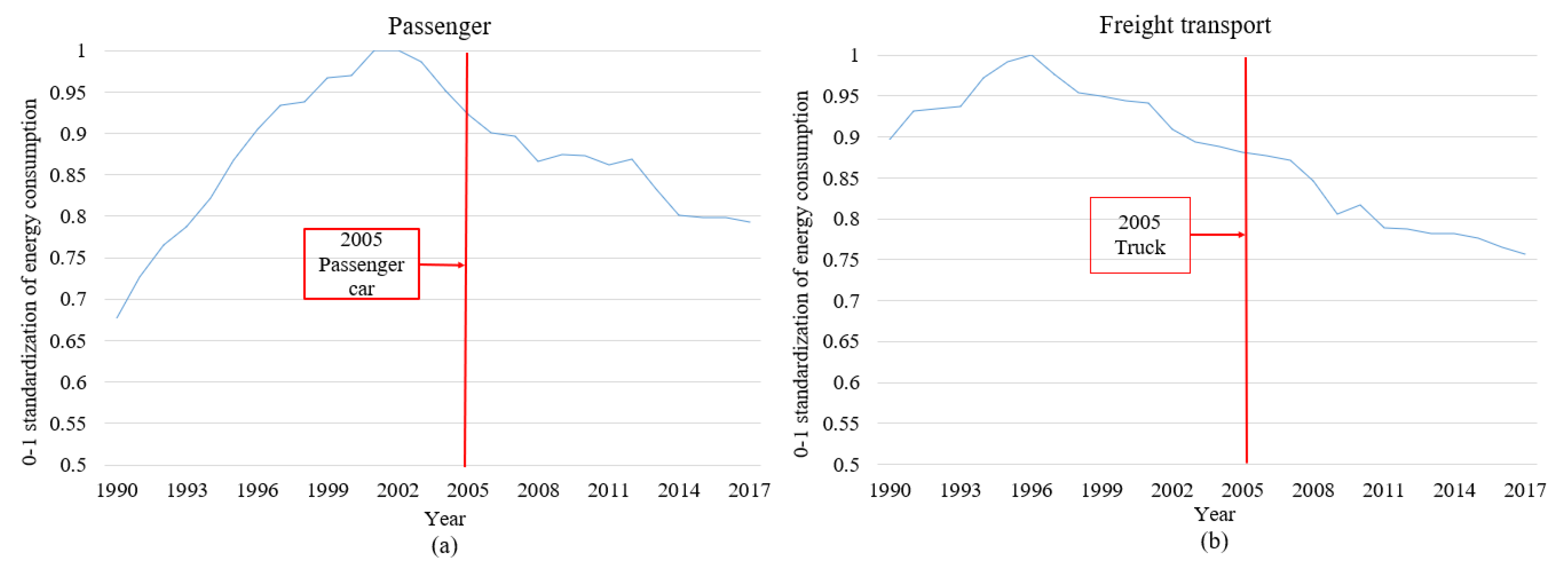

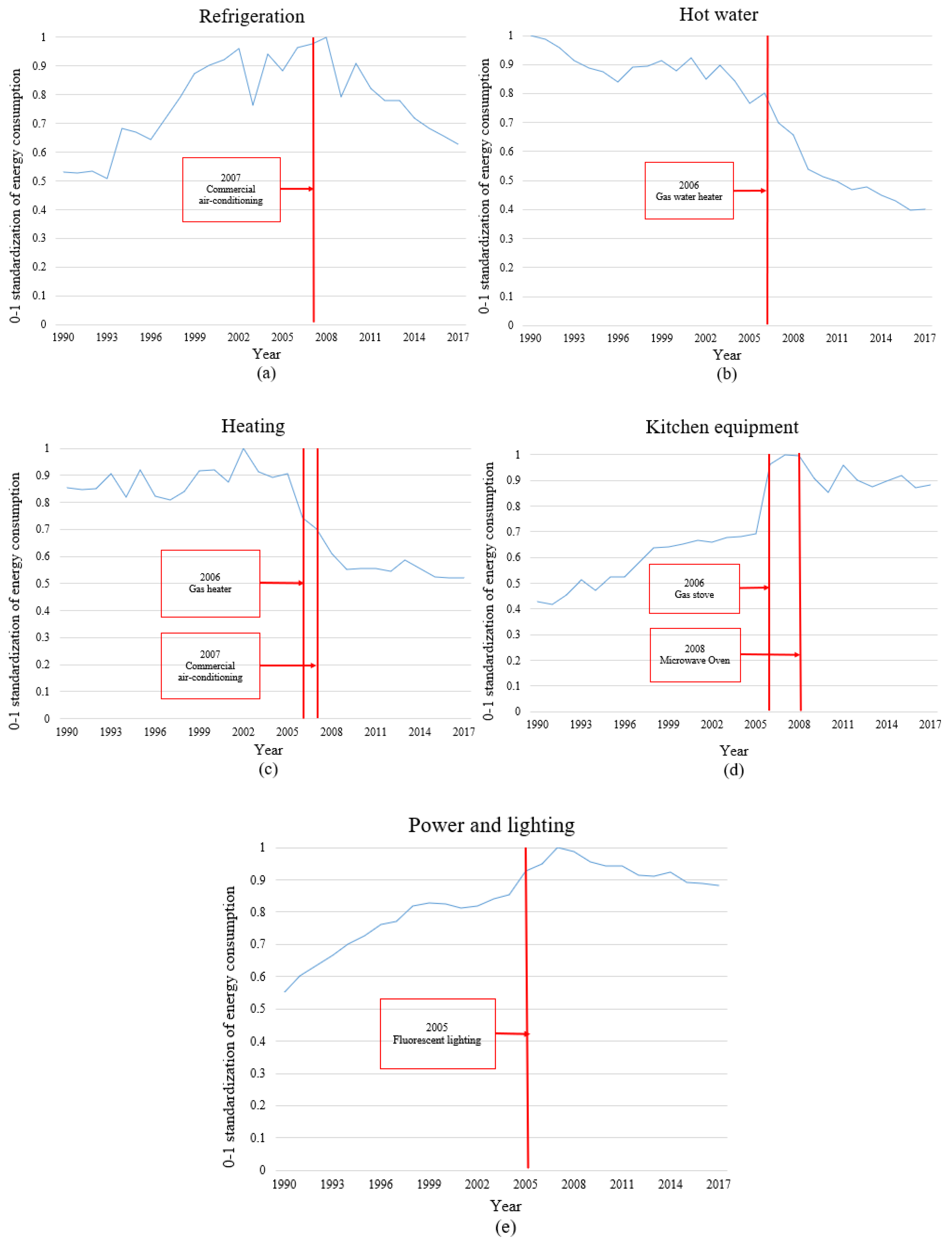

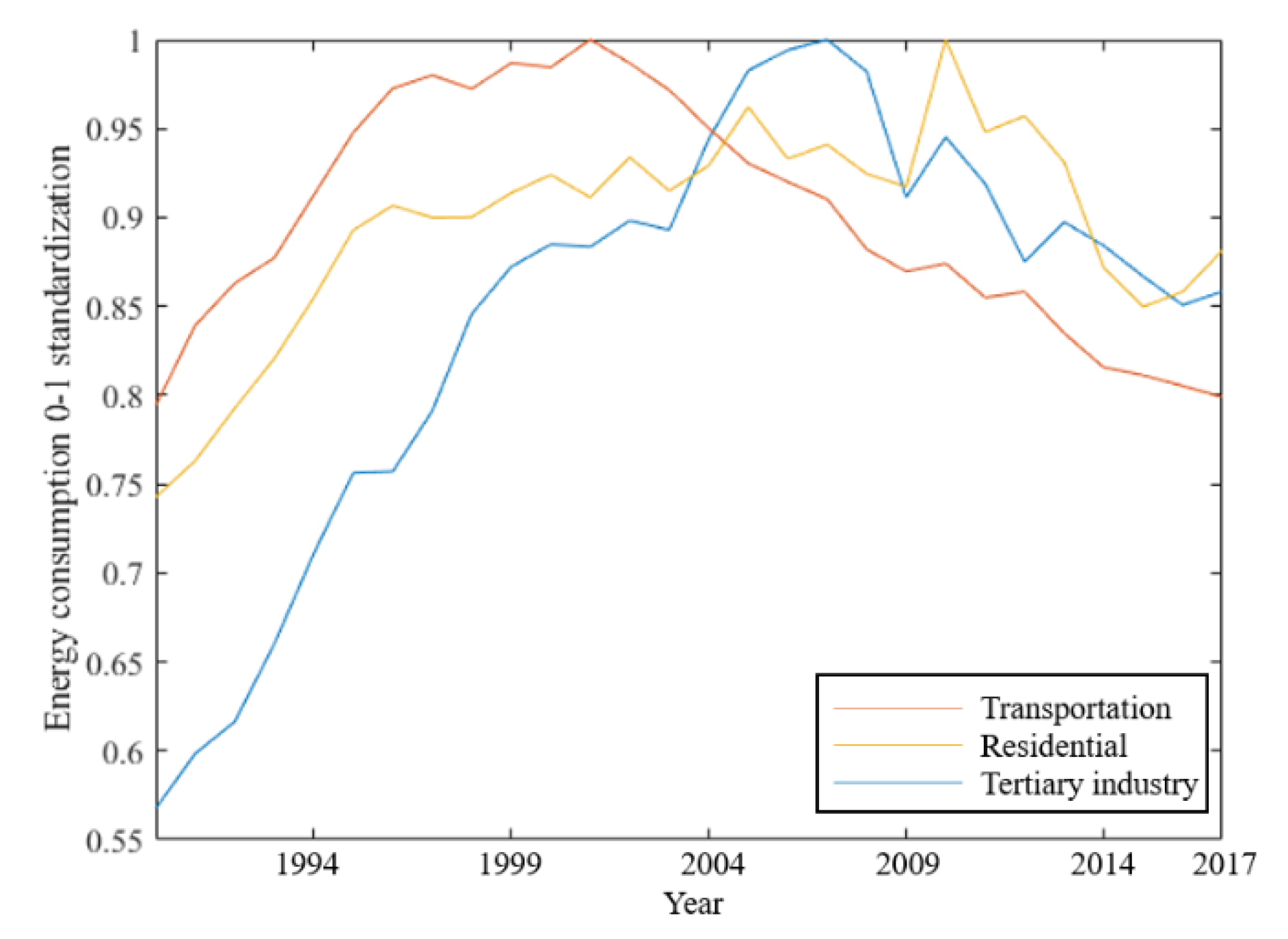

3.2.2. Policy Identification and Impact Lag Analysis

4. Comprehensive Evaluation of Specific Equipment in TRP

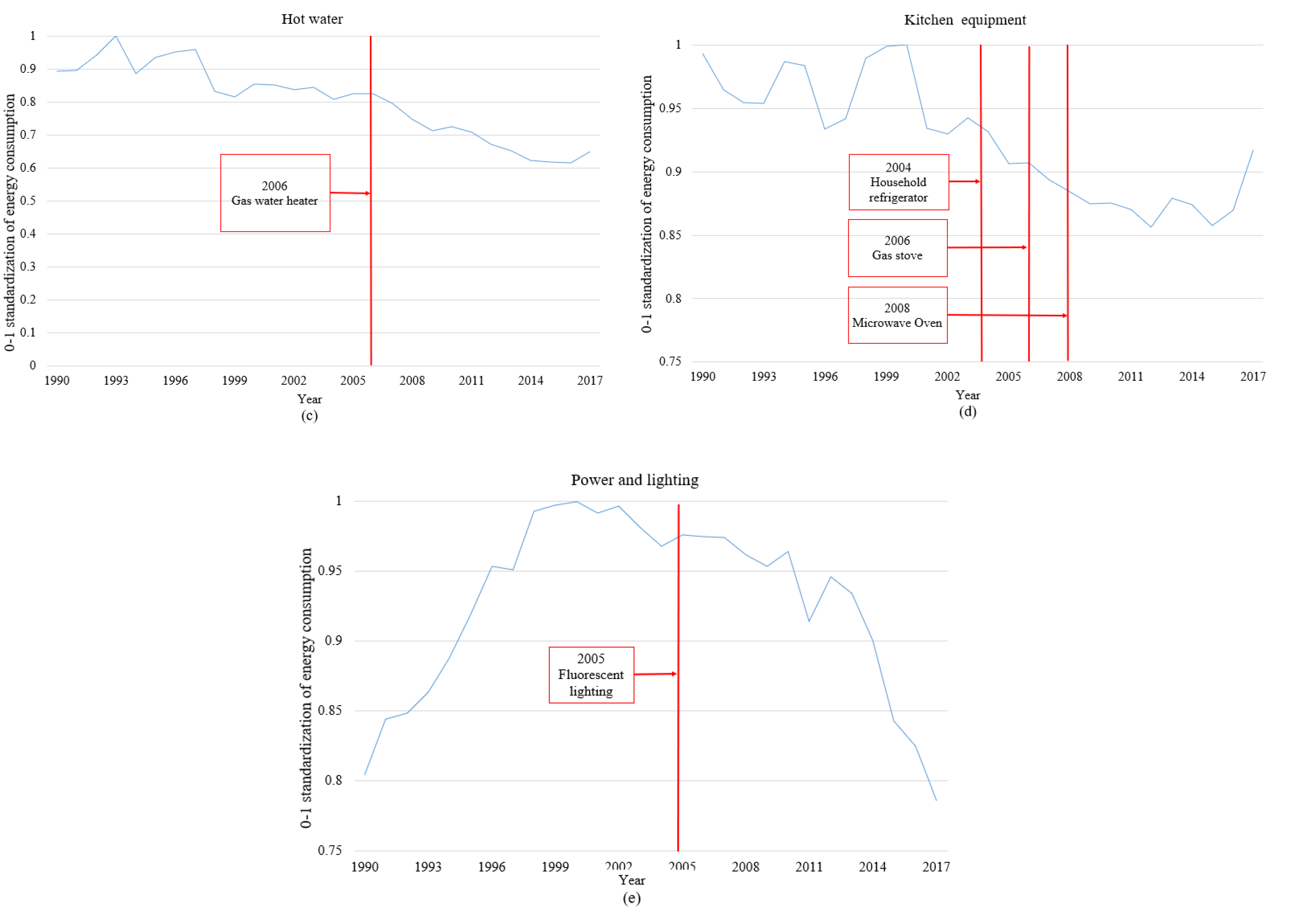

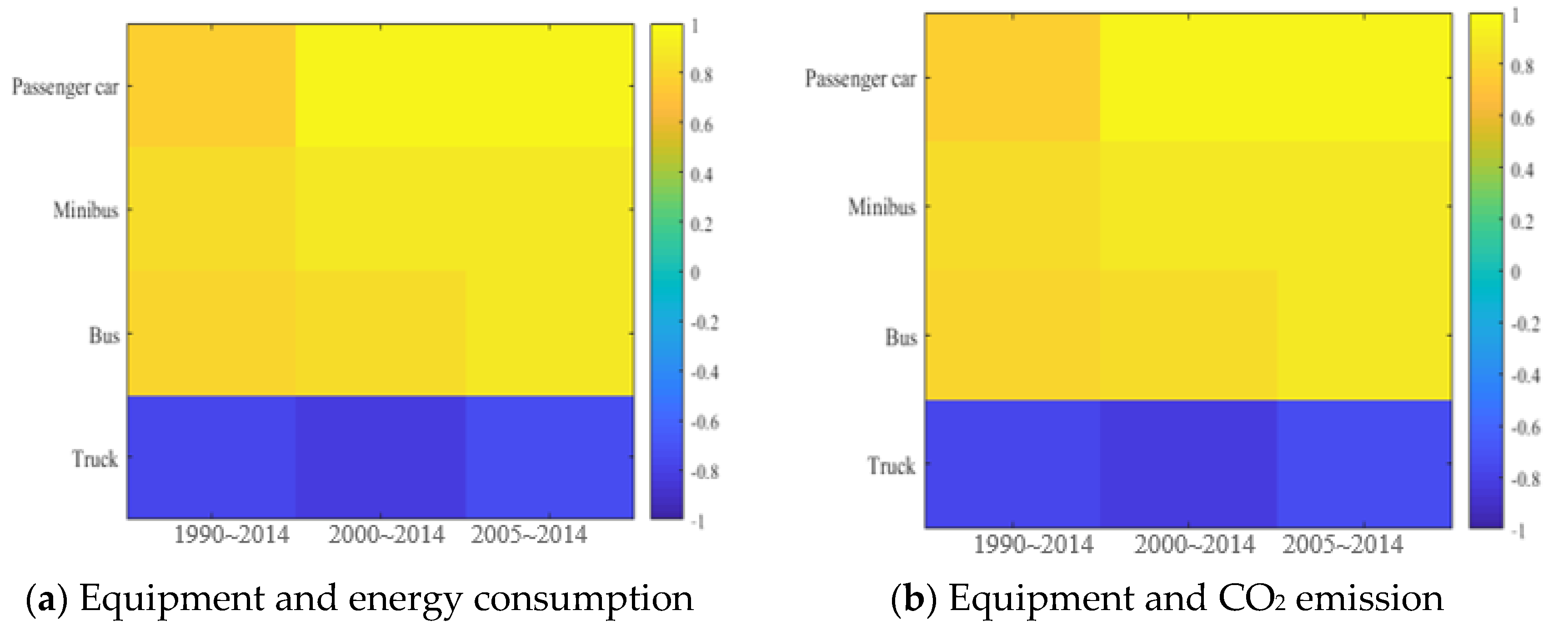

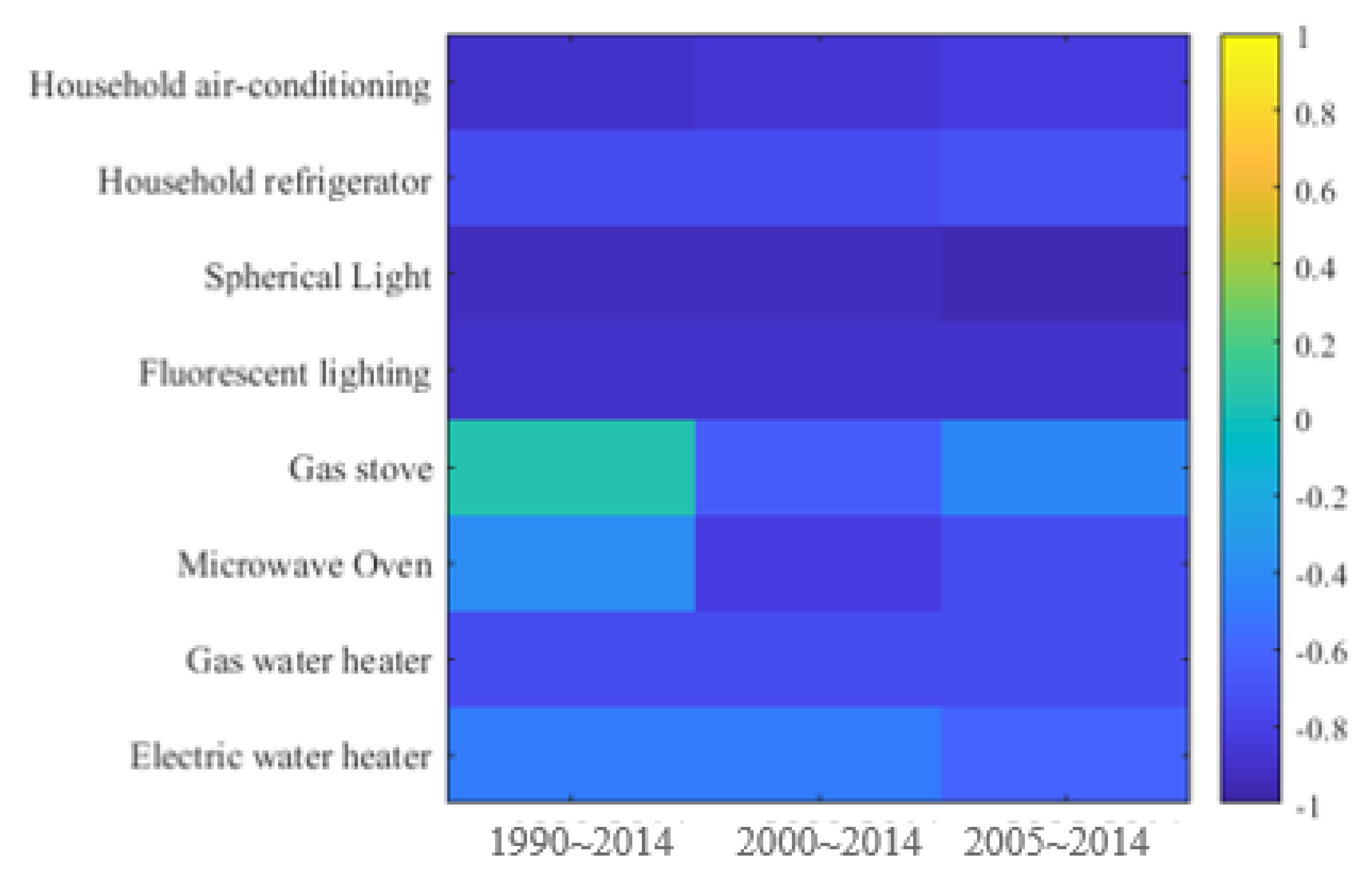

4.1. Impact Analysis of Equipment Energy Efficiency Improvement

4.2. CO2 Rebound Effect Analysis

5. Conclusions

- (1)

- In terms of the overall effect of the policy, through moving window and correlation analysis, the effects of TRP in the tertiary industry, transportation and residential were identified and analyzed. Among them, the effect in the tertiary industry was the best. In the field of transportation and family, although affected by other earlier energy-saving policies, it still had a certain effect.

- (2)

- In terms of specific equipment, the energy and environmental impacts of the specific equipment involved in the TRP were analyzed through correlation analysis in different stages. For energy saving, most of the equipment had a positive impact, especially business air conditioning, business cold storage, microwave oven and passenger cars. For emission reduction, the tertiary industry and transportation had a positive impact, but the effect in the family area was not obvious.

- (3)

- In terms of short-term and long-term impacts, the short-term and long-term rebound effects of CO2 emissions were analyzed from use stage, whole stage and life cycle perspectives. The REC of fluorescent lamp lighting was only 0.15 in both short-term and long-term, and the effect of energy-saving and emission reduction was basically offset. Air conditioning and passenger cars had better short-term effect, and the index REC of rebound effect was 1.16 and 1.24, respectively. For long-term effect, air conditioning had the best effect. Therefore, although the effect of TRP in the field of emission reduction was not obvious at present, the effect of equipment will gradually appear over time.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- International Energy Agency; Birol, F. World Energy Outlook 2019; International Energy Agency: Paris, French, 2019. [Google Scholar]

- British Petroleum. Outlook, BP Energy, 2019 ed.; British Petroleum: London, UK, 2019. [Google Scholar]

- Locmelis, K.; Blumberga, D.; Blumberga, A.; Kubule, A. Benchmarking of industrial energy efficiency. Outcomes of an energy audit policy program. Energies 2020, 13, 2210. [Google Scholar] [CrossRef]

- Lee, C.Y.; Lotsu, S.; Islam, M.; Yoshida, Y.; Kaneko, S. The impact of an energy efficiency improvement policy on the economic performance of electricity-intensive firms in Ghana. Energies 2019, 12, 3684. [Google Scholar] [CrossRef] [Green Version]

- Nahla, S. Energy intensity and its determinants in OPEC countries. Energy 2019, 186, 115803. [Google Scholar]

- Fang, G.; Tian, L.; Fu, M.; Sun, M.; Du, R. The impacts of energy construction adjustment on energy intensity and economic growth—A case study of China. Energy Procedia 2016, 104, 239–244. [Google Scholar] [CrossRef]

- Soni, A.; Mittal, A.; Kapshe, M. Energy intensity analysis of indian manufacturing industries. Resour. Effic. Technol. 2017, 3, 353–357. [Google Scholar] [CrossRef]

- Guang, F.; He, Y.; Wen, L.; Sharp, B. Energy intensity and its differences across China’s regions: Combining econometric and decomposition analysis. Energy 2019, 180, 989–1000. [Google Scholar] [CrossRef]

- Calcagnini, G.; Giombini, G.; Travaglini, G. Modelling energy intensity, pollution per capita and productivity in Italy: A structural VAR approach. Renew. Sustain. Energy Rev. 2016, 59, 1482–1492. [Google Scholar] [CrossRef]

- Silva, F.I.A.; Guerra, S.M.G. Analysis of the energy intensity evolution in the Brazilian industrial sector—1995 to 2005. Renew. Sustain. Energy Rev. 2009, 13, 2589–2596. [Google Scholar] [CrossRef]

- De Jesus, D.O.; Paulo, M. Effect of generation capacity factors on carbon emission intensity of electricity of Latin America & the Caribbean, a temporal IDA-LMDI analysis. Renew. Sustain. Energy Rev. 2019, 101, 516–526. [Google Scholar]

- Okajima, S.; Okajima, H. Analysis of energy intensity in Japan. Energy Policy 2013, 61, 574–586. [Google Scholar] [CrossRef]

- Huang, J.; Du, D.; Tao, Q. An analysis of technological factors and energy intensity in China. Energy Policy 2017, 109, 1–9. [Google Scholar] [CrossRef]

- Petrović, P.; Filipović, S.; Radovanović, M. Underlying causal factors of the European Union energy intensity: Econometric evidence. Renew. Sustain. Energy Rev. 2018, 89, 216–227. [Google Scholar] [CrossRef]

- Gandhi, O.; Oshiro, A.H.; deMedeiros Costa, H.K.; Santos, E.M. Energy intensity trend explained for Sao Paulo state. Renew. Sustain. Energy Rev. 2017, 77, 1046–1054. [Google Scholar] [CrossRef]

- Li, J.; Lin, B. Inter-factor/inter-fuel substitution, carbon intensity, and energy-related CO2 reduction: Empirical evidence from China. Energy Econ. 2016, 56, 483–494. [Google Scholar] [CrossRef]

- Zhu, L.; He, L.; Shang, P.; Zhang, Y.; Ma, X. Influencing factors and scenario forecasts of carbon emissions of the Chinese power industry: Based on a generalized divisia index model and monte carlo simulation. Energies 2018, 11, 2398. [Google Scholar] [CrossRef] [Green Version]

- Fredrik, N.G.; Andersson, P.K. CO2 emissions and economic activity: Short- and long-run economic determinants of scale, energy intensity and carbon intensity. Energy Policy 2013, 61, 1285–1294. [Google Scholar]

- Moutinho, V.; Robaina-Alves, M.; Mota, J. Carbon dioxide emissions intensity of Portuguese industry and energy sectors: A convergence analysis and econometric approach. Renew. Sustain. Energy Rev. 2014, 40, 438–449. [Google Scholar] [CrossRef]

- Gui, S.; Wu, C.; Qu, Y.; Guo, L. Path analysis of factors impacting China’s CO2 emission intensity: Viewpoint on energy. Energy Policy 2017, 109, 650–658. [Google Scholar] [CrossRef]

- Cruz, L.; Dias, J. Energy and CO2 intensity changes in the EU-27: Decomposition into explanatory effects. Sustain. Cities Soc. 2016, 26, 486–495. [Google Scholar] [CrossRef]

- Kim, H.; Chen, W. Changes in energy and carbon intensity in Seoul’s water sector. Sustain. Cities Soc. 2018, 41, 749–759. [Google Scholar] [CrossRef]

- Rocchi, P.; Rueda-Cantuche, J.M.; Boyano, A.; Villanueva, A. Macroeconomic effects of EU energy efficiency regulations on household dishwashers, washing machines and washer dryers. Energies 2019, 12, 4312. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y. Exploring the relationship between urbanization and energy consumption in China using ARDL (autoregressive distributed lag) and FDM (factor decomposition model). Energy 2009, 34, 1846–1854. [Google Scholar] [CrossRef]

- Liu, H.; Wang, C.; Tian, M.; Wen, F. Analysis of regional difference decomposition of changes in energy consumption in China during 1995–2015. Energy 2019, 171, 1139–1149. [Google Scholar] [CrossRef]

- Sun, M.; Li, J.; Gao, C.; Han, D. Identifying regime shifts in the US electricity market based on price fluctuations. Appl. Energy 2017, 194, 658–666. [Google Scholar] [CrossRef]

- Han, J.; Du, T.; Zhang, C.; Qian, X. Correlation analysis of CO2 emissions, material stocks and economic growth nexus: Evidence from Chinese provinces. J. Clean. Prod. 2018, 180, 395–406. [Google Scholar] [CrossRef]

- Cao, Z.; Wei, J.; Chen, H.-B. CO2 emissions and urbanization correlation in China based on threshold analysis. Ecol. Indic. 2016, 61, 193–201. [Google Scholar]

- Zhou, H.; Lin, B.; Qi, J.; Zheng, L.; Zhang, Z. Analysis of correlation between actual heating energy consumption and building physics, heating system, and room position using data mining approach. Energy Build. 2018, 166, 73–82. [Google Scholar] [CrossRef]

- Liu, J.; Sun, X.; Lu, B.; Zhang, Y.; Sun, R. The life cycle rebound effect of air-conditioner consumption in China. Appl. Energy 2016, 184, 1026–1032. [Google Scholar] [CrossRef]

- Cabinet Office, Japan. National Economic Statistics. Available online: https://www.esri.cao.go.jp/jp/sna/data/data_list/kenmin/files/files_kenmin.html (accessed on 9 March 2020).

- Ministry of Economy. Trade and Industry (MIT). Japan. Comprehensive Energy Statistics. Available online: https://www.enecho.meti.go.jp/statistics/total_energy/results.html (accessed on 14 April 2020).

- Ministry of Economy and Industry, Department of Resources and Energy. Japan "Top Runner Policy"; Ministry of Economy and Industry, Department of Resources and Energy: Tokyo, Japan, 2015.

- Meng, H.; Xie, W.-J.; Jiang, Z.-Q.; Podobnik, B.; Zhou, W.-X.; Stanley, H.E. Systemic risk and spatiotemporal dynamics of the US housing market. Sci. Rep. 2014, 4, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wang, H.; Gao, W.; Wang, F.; Zhou, N.; Kammen, D.M.; Ying, X. A survey of the status and challenges of green building development in various countries. Sustainability 2019, 11, 5385. [Google Scholar] [CrossRef] [Green Version]

- Up, Hydrogen Scaling. A Sustainable Pathway for the Global Energy Transition. Hydrogen Council. Available online: https://hydrogencouncil.com/wp-content/uploads/2017/11/Hydrogen-scaling-up-Hydrogen-Council.pdf (accessed on 26 August 2020).

- Chen, S.; Zhang, J.; Kim, J. Life cycle analysis of greenhouse gas emissions for fluorescent lamps in mainland China. Sci. Total Environ. 2017, 575, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Viñoles-Cebolla, R.; Bastante-Ceca, M.J.; Capuz-Rizo, S.F. An integrated method to calculate an automobile’s emissions throughout its life cycle. Energy 2015, 83, 125–136. [Google Scholar] [CrossRef]

| Type | Manufacture and Transportation (kgCO2) | The End of Use (kgCO2) | Service Life (Year) | Use | |

|---|---|---|---|---|---|

| Energy Type | Carbon Emission | ||||

| Spherical light | 11.525 | 0.89 | 7.5 | electricity | 0.455 kgCO2/kWh |

| Household air-conditioning | 147 | 10 | 15.7 | electricity | 0.455 kgCO2/kWh |

| Passenger car | 6000 | 300 | 13 | gasoline | 2.3 kgCO2/L |

| Type | Rebound Effect of the Carbon Footprint (REC) | |||

|---|---|---|---|---|

| Use Stage | Whole Stage | Life Cycle | Volatility in Life Cycle (Variance) | |

| Spherical light | 0.150 | 0.167 | 0.152 | 0.016 |

| Household air-conditioning | 1.144 | 1.161 | 1.145 | 0.028 |

| Passenger car | 0.414 | 1.235 | 0.448 | 2.182 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, D.; Dewancker, B.; Qian, F. The Identification and Rebound Effect Evaluation of Equipment Energy Efficiency Improvement Policy: A Case Study on Japan’s Top Runner Policy. Energies 2020, 13, 4397. https://doi.org/10.3390/en13174397

Yu D, Dewancker B, Qian F. The Identification and Rebound Effect Evaluation of Equipment Energy Efficiency Improvement Policy: A Case Study on Japan’s Top Runner Policy. Energies. 2020; 13(17):4397. https://doi.org/10.3390/en13174397

Chicago/Turabian StyleYu, Dan, Bart Dewancker, and Fanyue Qian. 2020. "The Identification and Rebound Effect Evaluation of Equipment Energy Efficiency Improvement Policy: A Case Study on Japan’s Top Runner Policy" Energies 13, no. 17: 4397. https://doi.org/10.3390/en13174397