Numerical Simulation of the Solid Particle Sedimentation and Bed Formation Behaviors Using a Hybrid Method

Abstract

:1. Introduction

2. Mathematical Treatment

3. Verification Experiment and Numerical Simulations

3.1. Particle Sedimentation Experiments

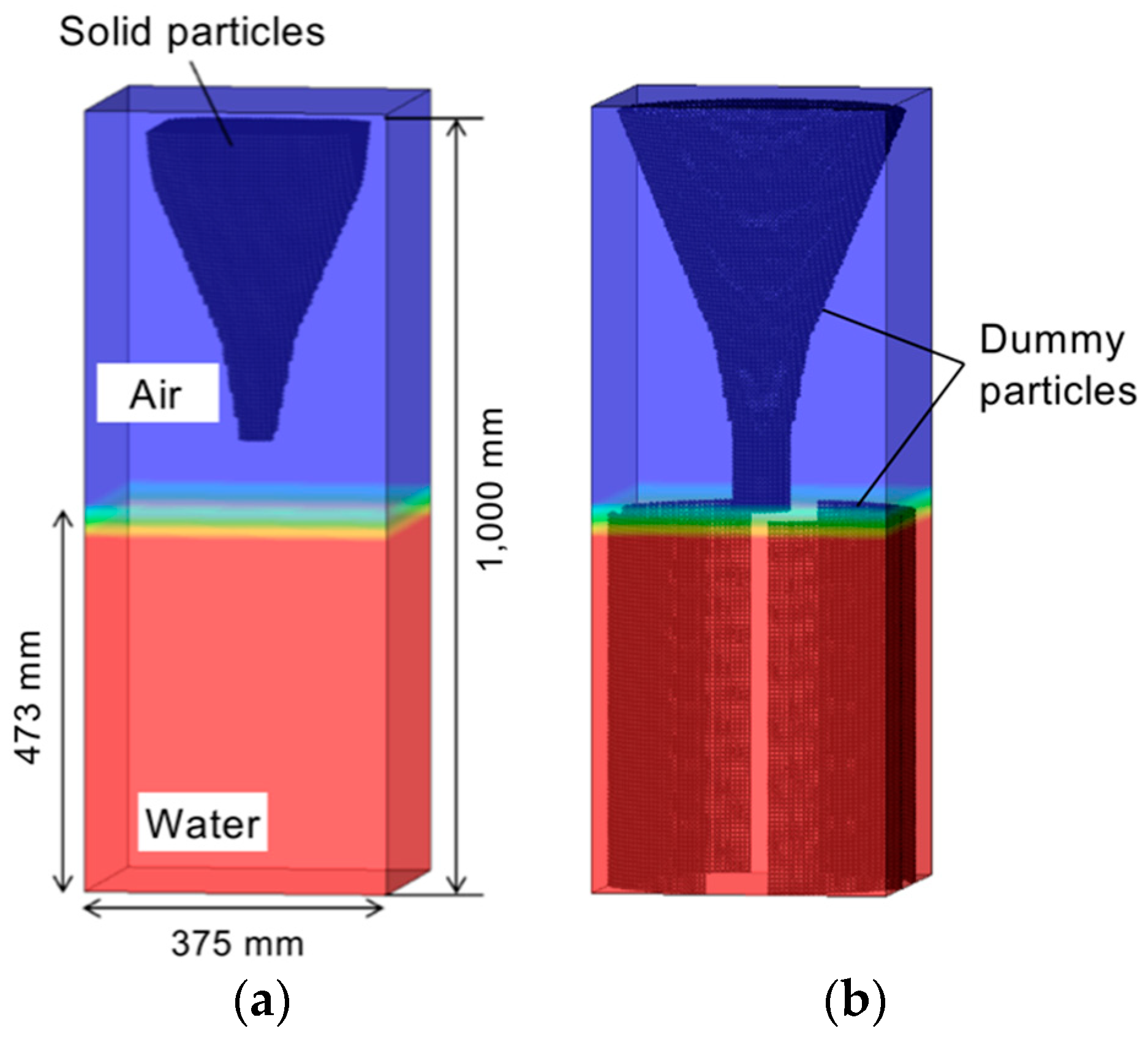

3.2. Simulation Conditions

4. Results and Comparisons

4.1. Homogeneous Particles

4.2. Mixed Particles

4.3. Analysis of Particles Distributions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Magallon, D.; Hohmann, H.; Schins, H. Pouring of 100-kg-Scale Molten UO2 into sodium. Nucl. Technol. 1991, 98, 79–90. [Google Scholar] [CrossRef]

- Fauske, H.K.; Koyama, K. Assessment of Fuel Coolant Interactions (FCIs) in the FBR Core Disruptive Accident (CDA). J. Nucl. Sci. Technol. 2002, 39, 608–614. [Google Scholar] [CrossRef]

- Nakai, R.; Suzuki, T.; Kamiyama, K.; Seino, H.; Koyama, K.; Morita, K. Development of Level 2 PSA methodology for sodium-cooled fast reactors. (1) Overview of evaluation technology development. In Proceedings of the 8th International Topical Meeting on Nuclear Thermal Hydraulics, Operation and Safety (NUTHOS-8), Shanghai, China, 10–14 October 2010. N8P0095. [Google Scholar]

- Yakush, S.; Kudinov, P.; Dinh, T.N. Modeling of two-phase natural convection flows in a water pool with a decay-heated debris bed. In Proceedings of the International Congress on Advances in Nuclear Power Plants (ICAPP 2008), Anaheim, CA, USA, 8–12 June 2008; pp. 1141–1150. [Google Scholar]

- Ma, W.; Dinh, T.N.; Buck, M.; Burger, M. Analysis of the effect of bed inhomogeneity on debris coolability. In Proceedings of the 15th International Conference on Nuclear Engineering (ICONE15), Nagoya, Japan, 22–26 April 2007. ICONE15-10752. [Google Scholar]

- Burger, M.; Buck, M.; Schmidt, W.; Walter, W. Validation and application of the WABE Code: Investigation of Constitutive Laws and 2D effects on Debris Coolability. Nucl. Eng. Des. 2006, 236, 2164–2188. [Google Scholar] [CrossRef]

- Yakush, S.; Kudninov, P. Simulation of ex-vessel debris bed formation and coolability in a LWR severe accident. In Proceedings of the Implementation of Severe Accident Management Measures (ISAMM 2009), Schloss Böttstein, Switzerland, 26–28 October 2009. [Google Scholar]

- Karbojian, A.; Ma, W.M.; Kudinov, P.; Dinh, T.N. A scoping study of debris bed formation in the DEFOR test facility. Nucl. Eng. Des. 2009, 239, 1653–1659. [Google Scholar] [CrossRef]

- Weimin, M.A.; Truc-Nam, D. The effects of debris bed’s prototypical characteristics on corium coolability in a LWR severe accident. Nucl. Eng. Des. 2010, 240, 598–608. [Google Scholar]

- Zhang, B.; Harada, T.; Hirahara, D.; Matsumoto, T.; Morita, K.; Fukuda, K.; Yamano, H.; Suzuki, T.; Tobita, Y. Self-leveling onset criteria in debris bed. J. Nucl. Sci. Technol. 2010, 47, 384–395. [Google Scholar] [CrossRef]

- Alvarez, D.; Amblard, M. Fuel levelling. In Proceedings of the 5th Information Exchange Mtg. on Post Accident Debris Cooling, Karlsruhe, Germany, 28–30 July 1982; pp. 9–12. [Google Scholar]

- Shamsuzzaman, M.; Horie, T.; Fuke, F.; Kai, T.; Zhang, B.; Matsumoto, T.; Morita, K.; Tagami, H.; Suzuki, T.; Tobita, Y. Experimental evaluation of debris bed characteristics in particulate debris sedimentation behaviour. In Proceedings of the 21st International Conference on Nuclear Engineering (ICONE21), Chengdu, China, 29 July–2 August 2013. [Google Scholar]

- Shamsuzzaman, M.; Horie, T.; Fuke, F.; Kai, T.; Zhang, B.; Matsumoto, T.; Morita, K.; Tagami, H.; Suzuki, T.; Tobita, Y. Experimental study on debris bed characteristics for the sedimentation behavior of solid particles used as simulant debris. Ann. Nucl. Energy 2018, 111, 474–486. [Google Scholar] [CrossRef]

- Sheikh, M.A.R.; Son, E.; Kamiyama, M.; Morioka, T.; Matsumoto, T.; Morita, K.; Matsuba, K.; Kamiyama, K.; Suzuki, T. Experimental investigation on characteristics of mixed particle debris in sedimentation and bed formation behavior. In Proceedings of the 11th International Topical Mtg. on Nuclear Reactor Thermal Hydraulics, Operation and Safety (NUTHOS-11), Gyeongju, Korea, 9–13 October 2016. [Google Scholar]

- Sheikh, M.A.R.; Son, E.; Kamiyama, M.; Morioka, T.; Matsumoto, T.; Morita, K.; Matsuba, K.; Kamiyama, K.; Suzuki, T. Sedimentation behavior of mixed solid particles. J. Nucl. Sci. Technol. 2018, 55, 623–633. [Google Scholar] [CrossRef]

- Bohl, W.R.; Luck, L.B. SIMMER-II: A Computer Program for LMFBR Disrupted Core Analysis; LA-11415-MS; Los Alamos National Laboratory: Los Alamos, NM, USA, 1990. [Google Scholar]

- Smith, L.L.; Bell, C.R.; Bohl, W.R.; Luck, L.B.; Wehner, T.R.; DeVault, G.P.; Parker, F.R. The SIMMER Program: Its Accomplishment. In Proceedings of the International Top. Mtg. on Fast Reactor Safety, Knoxville, TN, USA, 21–25 April 1985. [Google Scholar]

- Tobita, Y.; Kondo, S.; Yamano, H.; Morita, K.; Maschek, W.; Coste, P.; Cadiou, T. The development of SIMMER-III, an advanced computer program for LMFR safety analysis and its application to sodium experiments. Nucl. Technol. 2006, 153, 245–255. [Google Scholar] [CrossRef]

- Yamano, H.; Fujita, S.; Tobita, Y.; Sato, I.; Niwa, H. Development of a three-dimensional CDA analysis code: SIMMER-IV and its first application to reactor case. Nucl. Eng. Des. 2008, 283, 67–73. [Google Scholar] [CrossRef]

- Yamano, H.; Tobita, Y.; Fujita, S.; Maschek, W. First 3-D calculation of core disruptive accident in a large-scale sodium-cooled fast reactor. Ann. Nucl. Energy 2009, 36, 337–343. [Google Scholar] [CrossRef]

- Yamano, H.; Tobita, Y. Experimental analyses by SIMMER-III on duct-wall failure and fuel discharge/relocation behavior. Mech. Eng. J. 2014, 1, TEP0028. [Google Scholar] [CrossRef] [Green Version]

- Yamano, H.; Suzuki, T.; Tobita, Y.; Matsumoto, T.; Morita, K. Validation of the SIMMER-IV severe accident computer code on three-dimensional sloshing behavior. In Proceedings of the 8th Japan-Korea Symposium on Nuclear Thermal Hydraulics and Safety (NTHAS-8), Beppu, Japan, 9–12 December 2012. [Google Scholar]

- Onoda, Y.; Matsuba, K.; Tobita, Y.; Suzuki, T. Preliminary analysis of the post-disassembly expansion phase and structural response under unprotected loss of flow accident in prototype sodium cooled fast reactor. Mech. Eng. J. 2017, 4. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 2007, 62, 3378–3396. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Tsuji, Y.; Kawaguchi, T.; Tanaka, T. Discrete particle simulation of two dimensional fluidized bed. Powder Technol. 1993, 77, 79–87. [Google Scholar] [CrossRef]

- Tagami, H.; Cheng, S.; Tobita, Y.; Morita, K. Model for particle behavior in debris bed. Nucl. Eng. Des. 2018, 328, 95–106. [Google Scholar] [CrossRef]

- Guo, L.; Morita, K.; Tobita, Y. Numerical simulation of gas-solid fluidized beds by coupling a fluid-dynamics model with the discrete element method. Ann. Nucl. Energy 2014, 72, 31–38. [Google Scholar] [CrossRef]

- Guo, L.; Morita, K.; Tagami, H.; Tobita, Y. Numerical simulation of a self-leveling experiment using a hybrid method. Mech. Eng. J. 2014, 1. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.; Morita, K.; Tobita, Y. Numerical simulations of gas-liquid-particle three-phase flows using a hybrid method. J. Nucl. Sci. Technol. 2016, 53, 271–280. [Google Scholar] [CrossRef]

- Guo, L.; Morita, K.; Tobita, Y. Numerical simulations on self-leveling behaviors with cylindrical debris bed. Nucl. Eng. Des. 2017, 315, 61–68. [Google Scholar] [CrossRef]

- Shamsuzzaman, M.; Zhang, B.; Horie, T.; Fuke, F.; Matsumoto, T.; Morita, K.; Tagami, H.; Suzuki, T.; Tobita, Y. Numerical simulation on sedimentation of solid particles used as simulant fuel debris. J. Nucl. Sci. Technol. 2014, 51, 681–699. [Google Scholar] [CrossRef]

- Balevičiusa, R.; Kačianauskas, R.; Mróz, Z.; Sielamowicz, I. Discrete particle investigation of friction effect in filling and unsteady/steady discharge in three-dimensional wedge-shaped hopper. Powder Technol. 2008, 187, 159–174. [Google Scholar] [CrossRef]

- Dziugys, A.; Peters, B. An approach to simulate the motion of spherical and non-spherical fuel particles in combustion chambers. Granul. Matter. 2001, 3, 231–265. [Google Scholar] [CrossRef]

| Homogeneous Particles (Bulk Volume Is 5.0 L) | ||

|---|---|---|

| Particle Type | ||

| Case 1 | SS ( = 7800 kg/m3; = 6 mm) | |

| Case 2 | Al2O3 ( = 3600 kg/m3; = 6 mm) | |

| Binary Mixture of Particles (Equal Volume Mixing Ratio) | ||

| Particle type | SS ( = 8050 kg/m3), Al2O3 ( = 3720 kg/m3) | |

| Case M1 | Al2O3 and SS particles with = 6 mm | |

| Case M2 | Al2O3 particles with = 4 and 6 mm | |

| Case M3 | SS particles with = 4 and 6 mm | |

| Binary Mixture of Particles (Different Volume Mixing Ratio) | ||

| Case M4 | Al2O3 and SS particles with = 6 mm with volume mixing ratio of 1:3 | |

| Case M5 | Al2O3 and SS particles with = 6 mm with volume mixing ratio of 3:1 | |

| Model Parameters | SS Particles | Al2O3 Particles | Dummy Particles |

|---|---|---|---|

| Poisson’s ratio [-] | 0.305 (Cases 1, M1, M2, M4, M5) | 0.21 | 0.305 (Cases 1, M1, M2, M4, M5) |

| 0.21 (Case M3) | 0.21 (Case M3) | ||

| Young’s modulus [Pa] | 5.4 106 (Cases 1, M1) | 9.0 106 (Cases 2, M1) | 5.0 105 |

| 5.0 105 (Case M3) | 5.0 105 Case M2 | ||

| 5.4 105 Cases M4, M5 | 9.0 105 Cases M4, M5 | ||

| Modulus of rigidity [Pa] | 1.8 106 Cases 1, M1 | 3.0 106 Cases 2, M1 | 5.0 105 |

| 5.0 105 (Case M3) | 5.0 105 (Case M2) | ||

| 1.8 105 (Cases M4, M5) | 3.0 105 (Cases M4, M5) | ||

| Dynamic friction coefficient [-] | 0.25 (Cases 1, M1, M4, M5) | 0.25 (Cases 2, M1, M4, M5) | 0.20 |

| 0.30 (Case M3) | 0.30 (Case M2) | ||

| Viscous damping coefficient (normal direction) [s−1] | 1100 (Cases 1, M1, M4, M5) | 1100 | 14,000 |

| 7000 (Case M3) | |||

| Viscous damping coefficient (tangential direction) [s−1] | 1100 (Cases 1, M1, M4, M5) | 1100 | 14,000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheikh, M.A.R.; Liu, X.; Matsumoto, T.; Morita, K.; Guo, L.; Suzuki, T.; Kamiyama, K. Numerical Simulation of the Solid Particle Sedimentation and Bed Formation Behaviors Using a Hybrid Method. Energies 2020, 13, 5018. https://doi.org/10.3390/en13195018

Sheikh MAR, Liu X, Matsumoto T, Morita K, Guo L, Suzuki T, Kamiyama K. Numerical Simulation of the Solid Particle Sedimentation and Bed Formation Behaviors Using a Hybrid Method. Energies. 2020; 13(19):5018. https://doi.org/10.3390/en13195018

Chicago/Turabian StyleSheikh, Md Abdur Rob, Xiaoxing Liu, Tatsuya Matsumoto, Koji Morita, Liancheng Guo, Tohru Suzuki, and Kenji Kamiyama. 2020. "Numerical Simulation of the Solid Particle Sedimentation and Bed Formation Behaviors Using a Hybrid Method" Energies 13, no. 19: 5018. https://doi.org/10.3390/en13195018

APA StyleSheikh, M. A. R., Liu, X., Matsumoto, T., Morita, K., Guo, L., Suzuki, T., & Kamiyama, K. (2020). Numerical Simulation of the Solid Particle Sedimentation and Bed Formation Behaviors Using a Hybrid Method. Energies, 13(19), 5018. https://doi.org/10.3390/en13195018