Energy Cost-Efficient Task Positioning in Manufacturing Systems

Abstract

1. Introduction

2. Problem Formulation

- A piecewise linear function of time defines the available RES power.

- The variable TOU price component of the energy from a conventional EGS is described by a piecewise constant function of time .

- A set of n positioned tasks is given.

- For each , a respective processing time is defined.

- The task needs a constant electrical power during its execution.

- A directed acyclic graph is given, where . It defines precedence constraints between tasks. If , the task cannot start before the task is completed.

- The planning horizon is defined. All tasks have to complete by the time .

- The objective is to determine start times of all tasks which minimise the total cost of electrical energy:subject to

3. Discrete-Time Linear Programming Model

- the number of the slots ,

- the maximum energy which can be consumed in a slot, i.e., in the time ,

- the processing time of a task expressed in the number of slots , where denotes the nearest integer to x,

- the value of the price of EGS power in the slot t,

- the value of the maximum available renewable energy in the slot t.

- —index of the first slot of the task ,

- —index of the last slot of the task ,

- —total consumption of the EGS energy in the slot t,

- —auxiliary variable equal to 1, if the task is executed in the slot t,

- —auxiliary variable used in constraints related to ,

4. Tabu Search Algorithm for ECETPP

4.1. Neighbourhood

4.2. Calculation of Objective Function Value

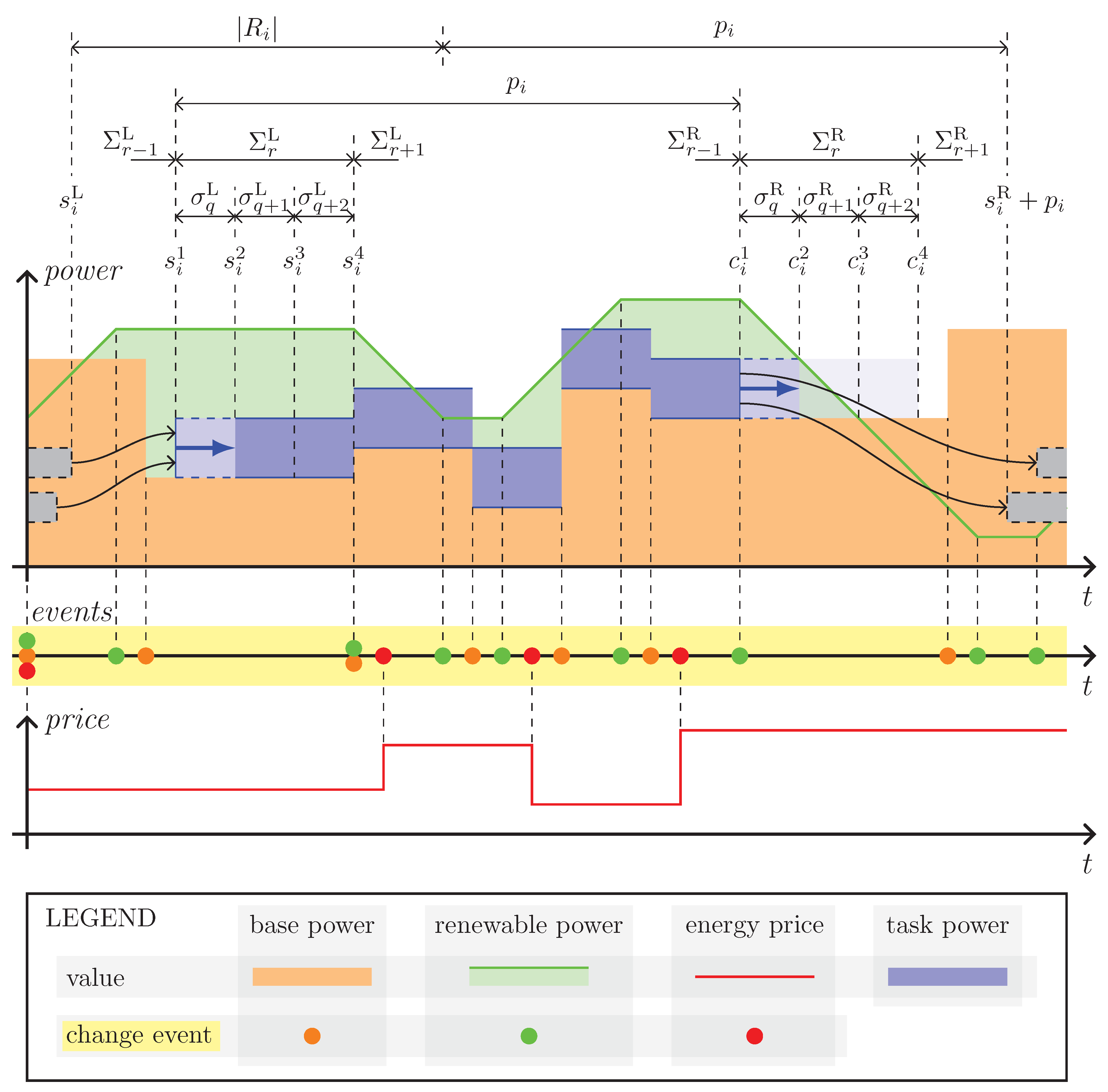

- Range. It is the full interval of the allowable positions of a given task, providing that positions of other tasks are fixed. In the considered example, is the start time of the leftmost position of in the range , because at least one predecessor of completes at . Analogously, is the start time of the rightmost position of in the range , because at least one successor of starts at . In particular, a range is bounded by the time 0 or , according to Equations (11) and (12), if the related task has no predecessor or successor, respectively.

- Section. Let E be the set of all events. A pair , where and are the largest intervals (in the sense of inclusion), such that and , will be called a section. A task is inside a section if and only if and . In general, a range may include many sections , which can be ordered in the natural way, such that for each . As an example, a section is presented in Figure 2. It is left and right bounded by the events at the moments and , respectively.

- Segment. One can notice (Figure 2) that the function which connects positions of and its energy cost changes character in the intervals , and , even though they belong to the same section. Indeed, in , all required power is provided by a free of charge renewable source, in the component of renewable power decreases linearly, and in all energy consumed by the task is for pay. In general, to obtain the intervals on which the cost functions are defined homogeneously, one has to split sections into smaller parts at the points at which or . These parts are referred to as segments. By analogy to a section, the q-th segment of the range is represented by a pair of intervals , such that a task is inside this segment if and only if and .

4.3. Tabu Configuration

5. Computational Experiments

5.1. Organization of Experiments

- Set of tasks, processing times of the tasks and precedence constraints between them—acquired from the related solved JSP instance.

- Power consumption of each task—randomly determined using the probability distribution [Watts].

- Time profile of renewable power—based on the function presented in Figure 1 plot B, scaled according to the average power consumption.

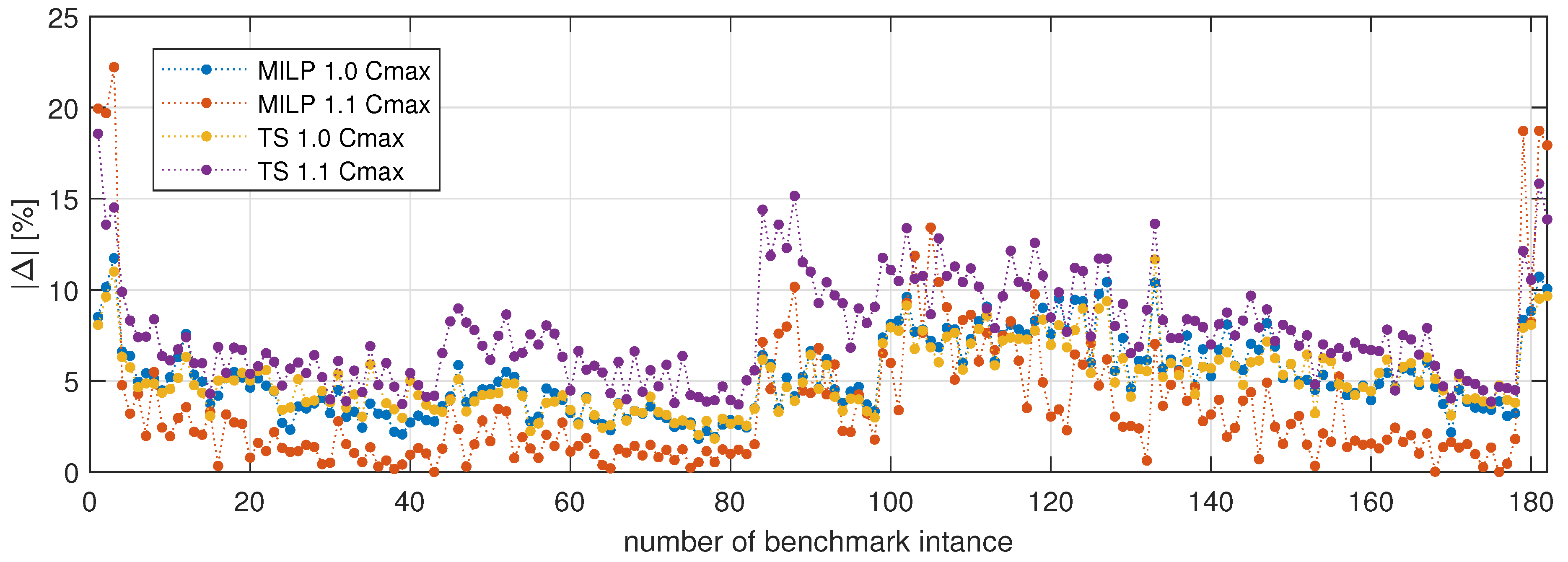

5.2. Overview of Results

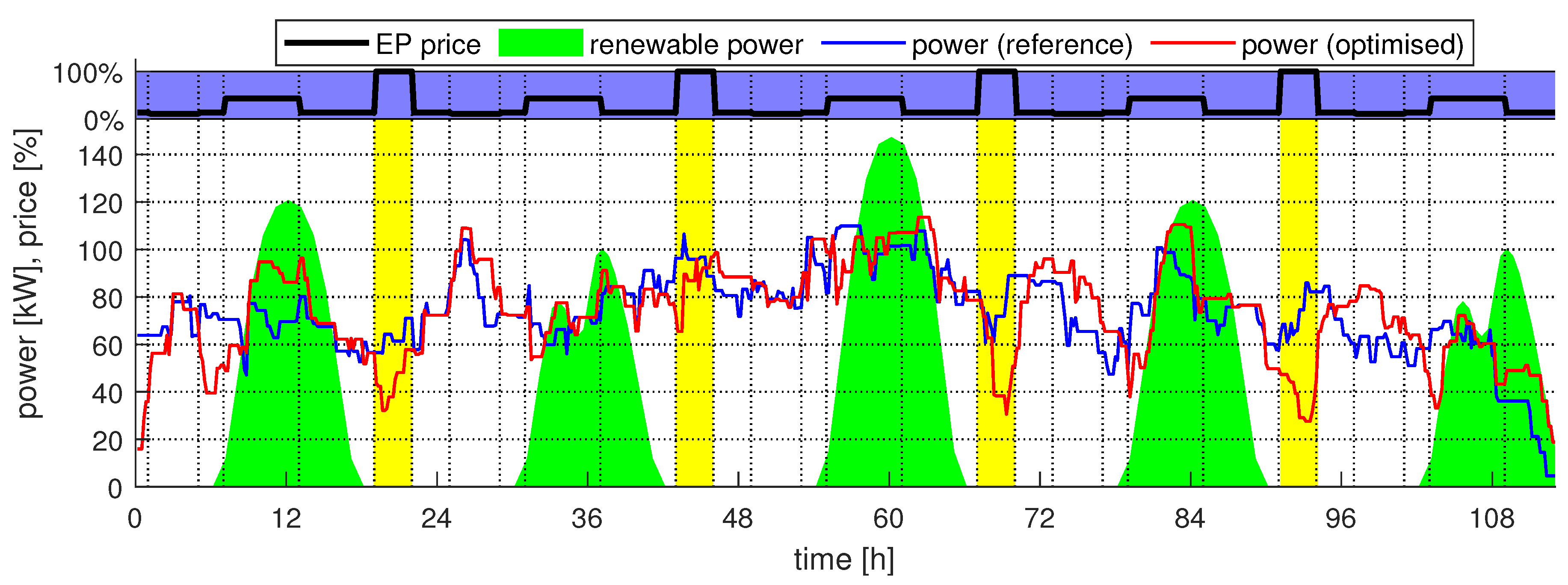

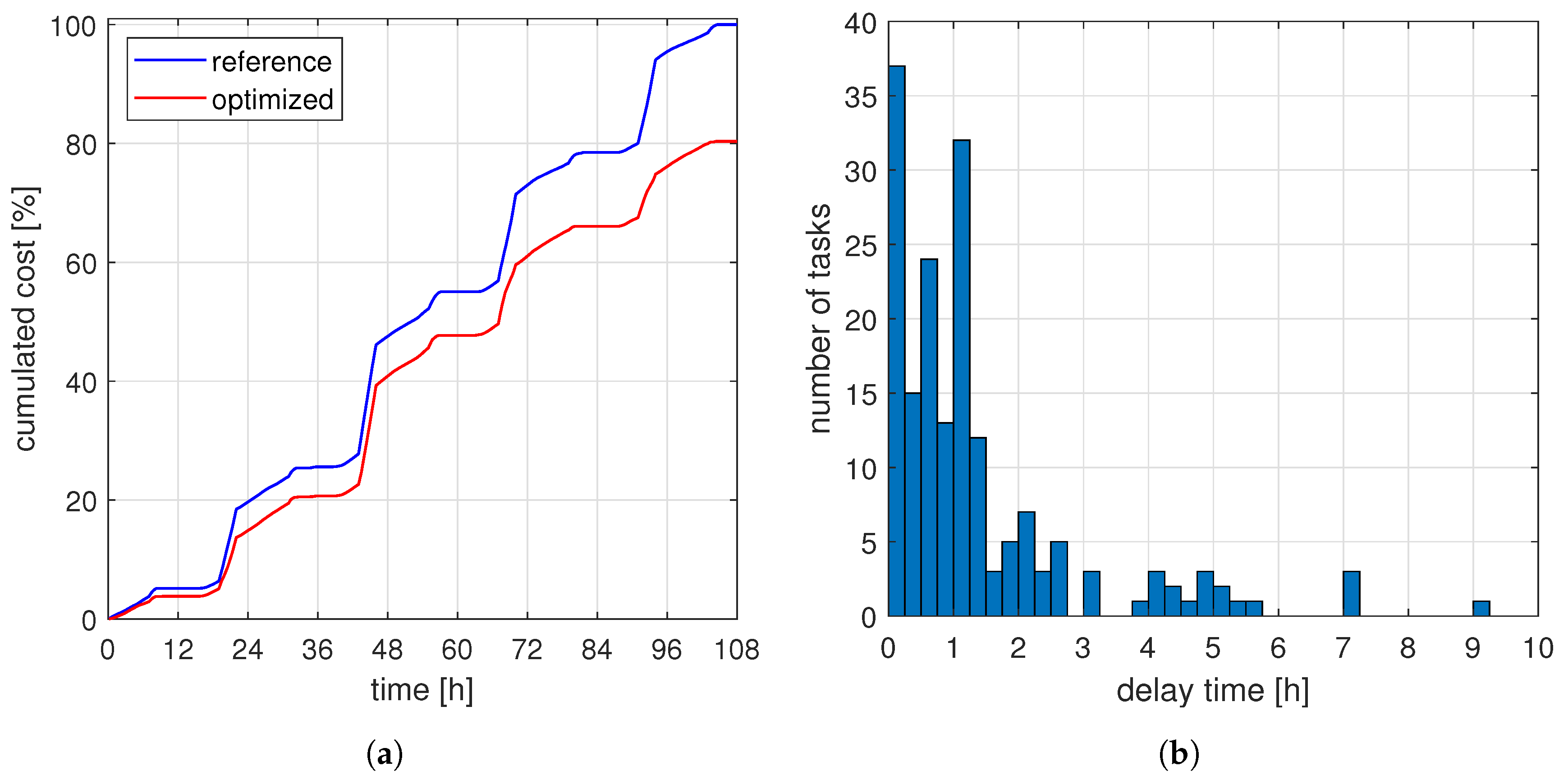

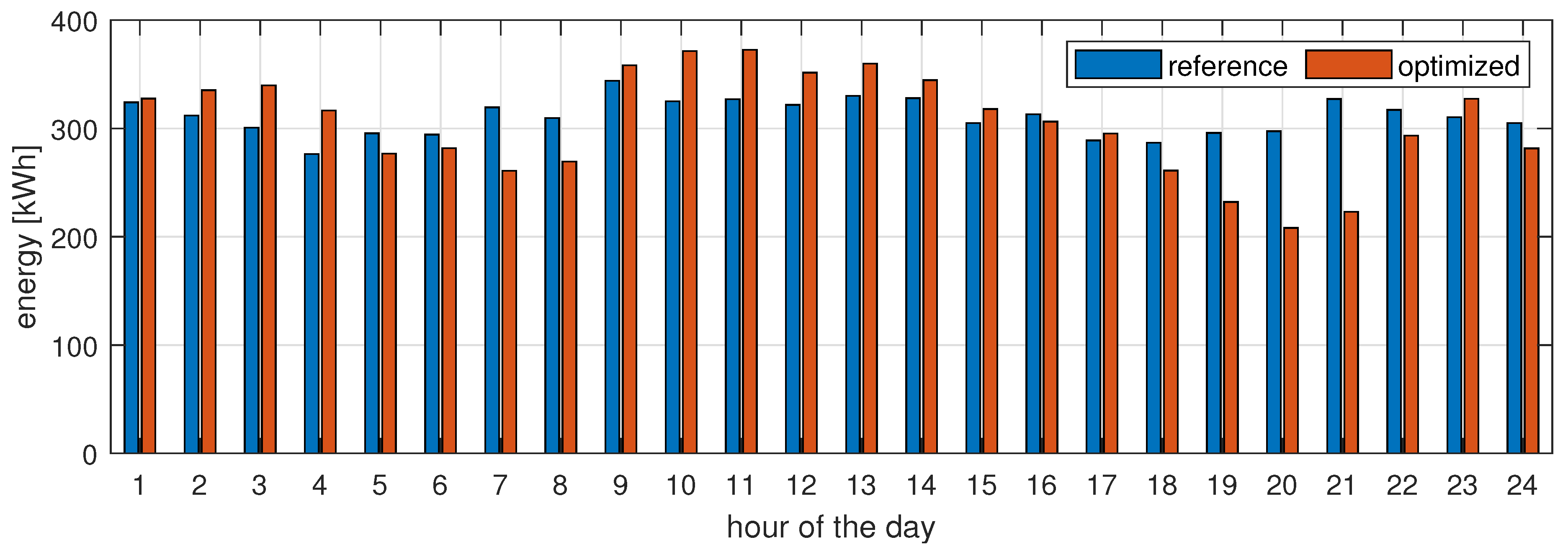

5.3. Selected Instance

6. Discussion

7. Conclusions

Supplementary Materials

Funding

Conflicts of Interest

Abbreviations

| APS | advanced planning and scheduling |

| EGS | electrical grid system |

| ECETPP | energy cost-efficient task positioning problem |

| JSP | job shop problem |

| MILP | mixed-integer linear programming |

| RES | renewable energy source |

| TOU | time-of-use |

| TS | tabu search |

References

- Gahm, C.; Denz, F.; Dirr, M.; Tuma, A. Energy-efficient scheduling in manufacturing companies: A review and research framework. Eur. J. Oper. Res. 2016, 248, 744–757. [Google Scholar]

- Giret, A.; Trentesaux, D.; Prabhu, V. Sustainability in manufacturing operations scheduling: A state of the art review. J. Manuf. Syst. 2015, 37, 126–140. [Google Scholar] [CrossRef]

- Dai, M.; Tang, D.; Xu, Y.; Li, W. Energy-aware integrated process planning and scheduling for job shops. J. Eng. Manuf. 2015, 229, 13–26. [Google Scholar] [CrossRef]

- Liu, M.; An, L.; Zhang, J.; Chu, F.; Chu, C. Energy-oriented bi-objective optimisation for a multi-module reconfigurable manufacturing system. Int. J. Prod. Res. 2019, 57, 5974–5995. [Google Scholar]

- Pach, C.; Berger, T.; Sallez, Y.; Bonte, T.; Adam, E.; Trentesaux, D. Reactive and energy-aware scheduling of flexible manufacturing systems using potential fields. Comput. Ind. 2014, 65, 434–448. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R.; Lacan, F.; Jiang, Z. Deep learning-driven particle swarm optimisation for additive manufacturing energy optimisation. J. Clean. Prod. 2020, 245. [Google Scholar] [CrossRef]

- Touzout, F.A.; Benyoucef, L. Multi-objective sustainable process plan generation in a reconfigurable manufacturing environment: Exact and adapted evolutionary approaches. Int. J. Prod. Res. 2019, 57, 2531–2547. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Aktas, E.; Besikci, U. Green scheduling of a two-machine flowshop: Trade-off between makespan and energy consumption. Eur. J. Oper. Res. 2016, 248, 772–788. [Google Scholar] [CrossRef]

- Salido, M.A.; Escamilla, J.; Giret, A.; Barber, F. A genetic algorithm for energy-efficiency in job-shop scheduling. Int. J. Adv. Manuf. Technol. 2016, 85, 1303–1314. [Google Scholar]

- Aghelinejad, M.M.; Ouazene, Y.; Yalaoui, A. Production scheduling optimisation with machine state and time-dependent energy costs. Int. J. Prod. Res. 2018, 56, 5558–5575. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres-Meré, J.; García-Sánchez, A.; Ortega-Mier, M. Optimizing the production scheduling of a single machine to minimize total energy consumption costs. J. Clean. Prod. 2014, 67, 197–207. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Chu, F.; Yu, J. An energy-efficient two-stage hybrid flow shop scheduling problem in a glass production. Int. J. Prod. Res. 2020, 58, 2283–2314. [Google Scholar] [CrossRef]

- Yildirim, M.B.; Mouzon, G. Single-Machine Sustainable Production Planning to Minimize Total Energy Consumption and Total Completion Time Using a Multiple Objective Genetic Algorithm. IEEE Trans. Eng. Manag. 2012, 59, 585–597. [Google Scholar] [CrossRef]

- Che, A.; Zhang, S.; Wu, X. Energy-conscious unrelated parallel machine scheduling under time-of-use electricity tariffs. J. Clean. Prod. 2017, 156, 688–697. [Google Scholar] [CrossRef]

- Ho, M.H.; Hnaien, F.; Dugardin, F. Electricity cost minimisation for optimal makespan solution in flow shop scheduling under time-of-use tariffs. Int. J. Prod. Res. 2020. [Google Scholar] [CrossRef]

- Moon, J.Y.; Shin, K.; Park, J. Optimization of production scheduling with time-dependent and machine-dependent electricity cost for industrial energy efficiency. Int. J. Adv. Manuf. Technol. 2013, 68, 523–535. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, S. Models and optimisation approaches for scheduling steelmaking–refining–continuous casting production under variable electricity price. Int. J. Prod. Res. 2014, 54, 1032–1049. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, F.; Fang, K.; Sutherland, J.W. Energy-conscious flow shop scheduling under time-of-use electricity tariffs. CIRP Ann. 2014, 63, 37–40. [Google Scholar] [CrossRef]

- Mitra, S.; Grossmann, I.E.; Pinto, J.M.; Arora, N. Optimal production planning under time-sensitive electricity prices for continuous power-intensive processes. Comput. Chem. Eng. 2012, 38, 171–184. [Google Scholar] [CrossRef]

- Sin, I.H.; Chung, B.D. Bi-objective optimization approach for energy aware scheduling considering electricity cost and preventive maintenance using genetic algorithm. J. Clean. Prod. 2020, 244. [Google Scholar] [CrossRef]

- Materi, S.; D’Angola, A.; Renna, P. A dynamic decision model for energy-efficient scheduling of manufacturing system with renewable energy supply. J. Clean. Prod. 2020, 270. [Google Scholar] [CrossRef]

- Wu, X.; Shen, X.; Cui, Q. Multi-Objective Flexible Flow Shop Scheduling Problem Considering Variable Processing Time due to Renewable Energy. Sustainability 2018, 10, 841. [Google Scholar] [CrossRef]

- Cui, W.; Li, L.; Lu, Z. Energy-efficient scheduling for sustainable manufacturing systems with renewable energy resources. Nav. Res. Logist. 2019, 66, 154–173. [Google Scholar] [CrossRef]

- Golari, M.; Fan, N.; Jin, T. Multistage Stochastic Optimization for Production-Inventory Planning with Intermittent Renewable Energy. Prod. Oper. Manag. 2017, 26, 409–425. [Google Scholar] [CrossRef]

- Küster, T.; Lützenberger, M.; Freund, D.; Albayrak, S. Distributed Evolutionary Optimisation for Electricity Price Responsive Manufacturing using Multi-Agent System Technology. Int. J. Adv. Intell. Syst. 2013, 6, 27–40. [Google Scholar]

- Bożek, A.; Werner, F. Flexible job shop scheduling with lot streaming and sublot size optimisation. Int. J. Prod. Res. 2018, 56, 6391–6411. [Google Scholar] [CrossRef]

- Bożek, A.; Wysocki, M. Flexible job shop with continuous material flow. Int. J. Prod. Res. 2015, 53, 1273–1290. [Google Scholar] [CrossRef]

- Glover, F. Tabu search—Part I. Orsa J. Comput. 1989, 1, 190–206. [Google Scholar] [CrossRef]

- Glover, F.; Laguna, M.; Martí, R. Principles and Strategies of Tabu Search. In Handbook of Approximation Algorithms and Metaheuristics, 2nd ed.; Gonzalez, T.F., Ed.; Methologies and Traditional Applications; Chapman and Hall/CRC: New York, NY, USA, 2018; pp. 361–377. [Google Scholar]

- Adams, J.; Balas, E.; Zawack, D. The shifting bottleneck procedure for job shop scheduling. Manag. Sci. 1988, 34, 391–401. [Google Scholar] [CrossRef]

- Demirkol, E.; Mehta, S.; Uzsoy, R. Benchmarks for shop scheduling problems. Eur. J. Oper. Res. 1998, 109, 137–141. [Google Scholar] [CrossRef]

- Taillard, E. Benchmarks for basic scheduling problems. Eur. J. Oper. Res. 1993, 64, 278–285. [Google Scholar]

- Storer, R.H.; Wu, S.D.; Vaccari, R. New search spaces for sequencing problems with application to job shop scheduling. Manag. Sci. 1992, 38, 1495–1509. [Google Scholar]

- Yamada, T.; Nakano, R. A Genetic Algorithm Applicable to Large-Scale Job-Shop Problems. In Proceedings of the Parallel Problem Solving from Nature 2, Brussels, Belgium, 28–30 September 1992; pp. 281–290. [Google Scholar]

- Shylo, O. Reasearch Homepage. 2019. Available online: http://optimizizer.com/research.php (accessed on 14 August 2020).

| Tariff | Hours | Price [PLN/kWh] |

|---|---|---|

| morning peak | 7:00–13:00 | 49.40 |

| afternoon peak | 19:00–22:00 | 115.36 |

| load valley | 1:00–5:00 | 12.78 |

| other hours | others | 15.87 |

| Inst. | [days] | [s] | gap [%] | Comparison [%] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| R | |||||||||||

| Abz09 | 4.7 | 142 | 0 | 12.16 | −2.18 | −42.68 | −27.98 | 8.69 | −19.64 | −19.53 | |

| Ta35 | 13.9 | 3603 | 3.41 | 9.88 | −1.78 | −14.12 | −29.71 | 9.4 | −19.01 | −19.05 | |

| Yn03 | 6.2 | 169 | 0 | 8.18 | 2.57 | −35.05 | −25.29 | 7.15 | −17.38 | −17.34 | |

| Abz08 | 4.6 | 71 | 0 | 10.25 | −2.01 | −25.64 | −27.23 | 7.47 | −17.27 | −17.31 | |

| Ta26 | 11.4 | 603 | 0.01 | 4.86 | −3.9 | −7.74 | −26.06 | 11.39 | −16.96 | −17.01 | |

| Ta03 | 8.5 | 142 | 0.01 | 2.12 | −6.23 | −2.6 | −25.82 | 14.44 | −16.78 | −16.86 | |

| Ta23 | 10.8 | 856 | 0.01 | 5.35 | −1.77 | −24.68 | −24.45 | 9.68 | −16.60 | −16.59 | |

| Ta29 | 11.3 | 805 | 0.01 | 6.52 | −2.08 | −0.01 | −26.27 | 8.89 | −16.43 | −16.47 | |

| Ta28 | 11.1 | 1021 | 0.01 | 7.36 | −5.62 | 9.09 | −25.67 | 10.47 | −16.04 | −16.1 | |

| Ta04 | 8.2 | 246 | 0.01 | 5.13 | 1.14 | −33.94 | −22.75 | 8.34 | −15.97 | −15.94 | |

| Ta25 | 11.1 | 1000 | 0.01 | 6.27 | −2.13 | −2.35 | −24.81 | 8.78 | −15.57 | −15.67 | |

| Ta10 | 8.6 | 325 | 0.01 | −1.95 | −8.32 | −1.54 | −22 | 17 | −15.44 | −15.54 | |

| Ta79 | 39.9 | 3619 | 18.18 | 0.91 | −0.65 | −4.41 | −4.45 | 2.12 | −3.14 | −3.14 | |

| Ta80 | 39 | 3601 | 11.05 | 0.41 | −0.4 | −8.05 | −3.94 | 2.37 | −3.1 | −3.09 | |

| Ta74 | 40.6 | 3609 | 20.61 | 0.6 | −0.82 | −8.12 | −3.82 | 2.57 | −3.1 | −3.09 | |

| Ta76 | 37.8 | 3662 | 17.89 | −0.11 | −0.93 | −2.09 | −4.39 | 2.6 −3.09 | −3.09 | ||

| Ta72 | 38.7 | 3651 | 23.5 | 0.76 | −1.16 | −6.17 | −3.75 | 2.59 | −2.97 | −2.98 | |

| Dmu72 | 37.9 | 3614 | 17.41 | 0.77 | −0.85 | −2.97 | −4.02 | 2.06 | −2.82 | −2.83 | |

| Ta71 | 44.9 | 1572 | 8.51 | 0.71 | −0.3 | −2.68 | −3.84 | 1.58 | −2.57 | −2.58 | |

| Ta73 | 36 | 3681 | 31.24 | −0.37 | −0.29 | −0.67 | −0.54 | 0.69 | −0.48 | −0.48 | |

| Ta77 | 37.1 | 3723 | 33.87 | −0.42 | −0.22 | −1.29 | −0.27 | 0.62 | −0.35 | −0.34 | |

| Dmu37 | 37.1 | 3675 | 26.5 | −0.18 | −0.22 | −0.53 | −0.32 | 0.45 | −0.3 | −0.3 | |

| Dmu36 | 36 | 3705 | 37.33 | −0.22 | −0.27 | −0.56 | −0.27 | 0.49 | −0.29 | −0.29 | |

| Dmu39 | 37.2 | 3691 | 30.54 | −0.37 | −0.26 | −0.69 | −0.12 | 0.52 | −0.21 | −0.21 | |

| Inst. | [days] | [s] | gap [%] | Comparison [%] | ||||

|---|---|---|---|---|---|---|---|---|

| Abz09 | 4.7 | 230 | 0.01 | 16.12 | 8 | −11.96 | −27.09 | −11.73 |

| Yn03 | 6.2 | 369 | 0.01 | 11.78 | 7.74 | −9 | −24.77 | −10.72 |

| Ta29 | 11.3 | 1035 | 0.01 | 13.43 | 3.69 | −2.45 | −26.64 | −10.41 |

| Ta35 | 13.9 | 3606 | 8.79 | 15.7 | 3.46 | −2.63 | −27.55 | −10.39 |

| Abz08 | 4.6 | 91 | 0 | 1 2.08 | 6.36 | −7.84 | −27.25 | −10.14 |

| Yn04 | 6.7 | 131 | 0.01 | 12.94 | 7.13 | −11.31 | −21.57 | −10.06 |

| Ta28 | 11.1 | 1438 | 0.01 | 18.65 | 0.87 | −1.99 | −25.3 | −9.77 |

| Ta04 | 8.2 | 208 | 0.01 | 13.4 | 5.34 | −8.26 | −22.29 | −9.6 |

| Ta23 | 10.8 | 1583 | 0.01 | 10.86 | 6.01 | −7.02 | −24.05 | −9.51 |

| Ta25 | 11.1 | 725 | 0.01 | 14.93 | 2.49 | −1.66 | −24.63 | −9.44 |

| Ta26 | 11.4 | 1081 | 0.01 | 15.09 | 2.78 | −3.09 | −24.55 | −9.38 |

| Ta14 | 9.3 | 1041 | 0.01 | 9.21 | 5.15 | −5.48 | −23.57 | −9.07 |

| Dmu73 | 43.1 | 3605 | 2.11 | 3.77 | 1.33 | −1.91 | −6.12 | −2.58 |

| Dmu75 | 40.8 | 3866 | 3.86 | 3.51 | 0.89 | −0.71 | −6.62 | −2.47 |

| Dmu36 | 48 | 3786 | 3.82 | 3.14 | 1.47 | −1.89 | −5.68 | −2.44 |

| Ta72 | 39.2 | 3796 | 7.79 | 4.4 | 1.06 | −2.25 | −5.42 | −2.43 |

| Dmu35 | 32.8 | 3669 | 8.44 | 1.58 | 1.62 | −1.1 | −6.06 | −2.31 |

| Dmu74 | 36.4 | 3600 | 2.38 | 4.17 | 1.47 | −3.38 | −4.28 | −2.3 |

| Dmu62 | 43 | 3649 | 4.52 | 3.42 | 1.21 | −2.01 | −5.04 | −2.24 |

| Dmu22 | 39.1 | 3680 | 7.9 | 0.92 | 2.34 | −2.63 | −4.67 | −2.2 |

| Dmu31 | 36 | 3587 | 8.57 | 1.49 | 1.03 | 0.35 | −6.41 | −2.17 |

| Dmu79 | 39 | 3636 | 8.57 | 1.37 | 1.68 | −1.58 | −4.93 | −2.06 |

| Dmu70 | 43 | 3753 | 0.84 | 1.15 | 1.92 | −2.41 | −3.89 | −1.9 |

| Dmu71 | 42.6 | 3696 | 3.38 | 1.89 | 1.2 | −1.33 | −4.38 | −1.82 |

| Inst. | [days] | [s] | gap [%] | Comparison [%] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | ||||||||||

| Abz07 | 4.8 | 3601 | 70.61 | 5.06 | −2.97 | −34.69 | −28.38 | 12.29 | −19.97 | −19.87 |

| Abz08 | 5.1 | 3601 | 86.26 | 6.61 | −1.86 | −26.54 | −30.95 | 10.28 | −19.78 | −19.81 |

| Abz09 | 5.2 | 3601 | 89.66 | 15.2 | −1.42 | −63.09 | −18.9 | 6.23 | −15.67 | −15.41 |

| Yn01 | 6.8 | 3602 | 94.43 | −0.06 | −4.53 | −25.5 | −16.33 | 12.51 | −12.92 | −12.85 |

| Yn03 | 6.8 | 3602 | 95.15 | 2.29 | −0.28 | −54.26 | −9.76 | 9.66 | −11 | −10.84 |

| Ta25 | 12.2 | 3602 | 95.85 | 8.83 | −6.9 | −6.89 | −14.63 | 8.55 | −10.34 | −10.47 |

| Ta17 | 11.2 | 3601 | 92.08 | 1.49 | −8.02 | 1.05 | −12.12 | 11.55 | −9.07 | −9.17 |

| Ta29 | 12.4 | 3603 | 95.39 | 5.55 | −6.9 | 41.45 | −16.38 | 6.45 | −8.75 | −8.87 |

| Yn04 | 7.4 | 3601 | 92.26 | 6.71 | −1.64 | 3.55 | −15.09 | 2.85 | −8.7 | −8.83 |

| Ta21 | 12.5 | 3601 | 95.28 | −1.76 | −8.35 | −15.07 | −7.26 | 13.38 | −7.66 | −7.78 |

| Ta13 | 10.3 | 3602 | 89.27 | −0.4 | −5.65 | 6.68 | −11.27 | 8.79 | −7.63 | −7.66 |

| Ta28 | 12.2 | 3601 | 95.84 | 2.24 | −6.14 | 37.68 | −13.32 | 6.49 | −7.15 | −7.23 |

| Ta70 | 20.5 | 3603 | 99.5 | −3.14 | 1.89 | −17.3 | 3.91 | 0.65 | 0.82 | 0.82 |

| Ta30 | 28.1 | 3608 | 97.75 | −4.64 | −0.55 | −12.67 | 4.01 | 2.63 | 0.86 | 0.88 |

| Dmu22 | 33.5 | 3603 | 98.63 | −1.46 | −1.34 | −7.13 | 3.16 | 1.59 | 0.89 | 0.89 |

| Dmu06 | 21.9 | 3602 | 99.98 | −1.44 | −0.15 | 2.16 | 1.67 | 0.03 | 1.02 | 1.04 |

| Dmu14 | 14 | 3602 | 97.81 | −3.49 | −2.99 | −15.26 | 6.1 | 3.83 | 1.4 | 1.39 |

| Ta41 | 37 | 3603 | 99.52 | −0.46 | 0.9 | −7.82 | 4.01 | −1.08 | 1.96 | 2 |

| Dmu27 | 15.3 | 3603 | 99.08 | 4.65 | 1.95 | −12.22 | 3.88 | −3.73 | 2.12 | 2.12 |

| Ta34 | 25.9 | 3602 | 97.51 | 4.31 | −0.77 | −6.22 | 4.17 | −2.04 | 2.31 | 2.35 |

| Ta62 | 24.8 | 3603 | 96.99 | −4.69 | 1 | −13.56 | 6.63 | 0.89 | 2.41 | 2.48 |

| Dmu21 | 36.1 | 3603 | 99.36 | 1.06 | 0.44 | −6.85 | 5.01 | −1.85 | 2.71 | 2.75 |

| Dmu13 | 12.1 | 3601 | 95.95 | 0.62 | −1.13 | −26.84 | 8.91 | 0.87 | 2.73 | 2.81 |

| Ta55 | 22.9 | 3602 | 99.9 | −6.7 | −0.64 | −15.85 | 8.13 | 2.77 | 2.82 | 2.83 |

| Inst. | [days] | [s] | gap [%] | Comparison [%] | |||||

|---|---|---|---|---|---|---|---|---|---|

| Abz09 | 5.2 | 3602 | 47.71 | 35.53 | 15.06 | −27.28 | −47.15 | −22.22 | |

| Abz07 | 5 | 3601 | 54.44 | 20.17 | 17.51 | −22.59 | −43.8 | −19.95 | |

| Abz08 | 5.1 | 3602 | 50.88 | 15.34 | 18.26 | −20.68 | −48.17 | −19.69 | |

| Yn03 | 6.8 | 3603 | 92.09 | 12.41 | 18.09 | −18.23 | −41.82 | −18.73 | |

| Yn01 | 6.8 | 3603 | 91.88 | 21.28 | 8.91 | −6.97 | −50.05 | −18.72 | |

| Yn04 | 7.4 | 3603 | 92.53 | 37.56 | 5.97 | −16.73 | −40.28 | −17.93 | |

| Ta07 | 9.3 | 3602 | 49.48 | 26.33 | 3.08 | −6.53 | −34.19 | −13.42 | |

| Ta05 | 9.4 | 3604 | 77.11 | 16.19 | 6.07 | −8.14 | −28.81 | −11.87 | |

| Ta08 | 9.3 | 3604 | 72.33 | 22.94 | 5.52 | −15.71 | −19.46 | −10.42 | |

| Swv05 | 10.8 | 3603 | 65.23 | 23.97 | 1.21 | −2.41 | −26.78 | −10.16 | |

| Ta20 | 10.3 | 3604 | 81.84 | 12.76 | 4.59 | −5.29 | −23.86 | −9.75 | |

| Ta04 | 9 | 3602 | 73.27 | 12.32 | 3.52 | −2.96 | −25.18 | −9.28 | |

| Ta78 | 39.5 | 3603 | 99.39 | 1.91 | −0.14 | −0.78 | −0.48 | −0.37 | |

| Dmu40 | 20.5 | 3603 | 98 | 0.05 | 1.91 | −4.3 | 2.33 | −0.33 | |

| Ta70 | 27.3 | 3605 | 97.48 | −0.47 | 1.31 | −2.37 | 0.67 | −0.33 | |

| Dmu35 | 43.8 | 3605 | 99.76 | −0.46 | 0.78 | −1.04 | −0.17 | −0.29 | |

| Dmu62 | 26.5 | 3602 | 92.23 | 0.75 | 0.37 | −1.19 | −0.01 | −0.29 | |

| Dmu72 | 40.8 | 3605 | 100 | 0.87 | 0.87 | −2.74 | 1.11 | −0.27 | |

| Ta76 | 49.4 | 4201 | 99.56 | 1.11 | −0.42 | 0.54 | −0.98 | −0.23 | |

| Dmu44 | 40.1 | 3603 | 99.78 | 1.43 | 0.33 | −1.97 | 0.86 | −0.2 | |

| Dmu33 | 43 | 3602 | 100 | 0.58 | 0.93 | −281 | 1.52 | −0.16 | |

| Dmu13 | 22.9 | 3665 | 99.76 | −1.66 | 1.71 | −2.88 | 1.93 | −0.01 | |

| Ta55 | 42.6 | 3605 | 99.87 | −0.02 | 0.11 | −0.41 | 0.44 | 0.05 | |

| Dmu61 | 41.2 | 3605 | 100 | −0.84 | 0.59 | −1.25 | 1.53 | 0.24 | |

| Inst. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| n | iter | [%] | [%] | [%] | [%] | n | iter | [%] | [%] | [%] | [%] | |

| Yn03 | 38 | 4.29 | −16.31 | 0.23 | −15.51 | 1.51 | 2 | 1.93 | −40.93 | 10.01 | −33.85 | 29.56 |

| Abz07 | 35 | 6.81 | −13.92 | 0.3 | −13.43 | 2.26 | 2 | 3.11 | −33.01 | 5.78 | −28.92 | 19.98 |

| Abz08 | 52 | 6.2 | −17.53 | 0.22 | −17.09 | 1.31 | 5 | 3.07 | −32.7 | 4.64 | −28.42 | 16.32 |

| Yn01 | 34 | 4.49 | −12.36 | 0.34 | −11.95 | 2.84 | 2 | 2.02 | −31.8 | 3.76 | −29.15 | 12.88 |

| Yn02 | 49 | 3.79 | −10.65 | 0.15 | −10.32 | 1.42 | 1 | 1.82 | −31.73 | 0 | −31.73 | 0 |

| Ta02 | 47 | 5.21 | −14.34 | 0.23 | −13.95 | 1.64 | 6 | 2.7 | −31.12 | 5.3 | −26.14 | 20.27 |

| Ta06 | 60 | 4.33 | −14.62 | 0.12 | −14.39 | 0.81 | 5 | 2.42 | −29.93 | 5.65 | −23.66 | 23.87 |

| Ta10 | 53 | 4.24 | −15.02 | 0.3 | −14.29 | 2.11 | 3 | 2.3 | −28.91 | 0.55 | −28.42 | 1.93 |

| Ta03 | 43 | 4.85 | −16.57 | 0.29 | −16.12 | 1.78 | 11 | 2.78 | −27.99 | 2.99 | −24.31 | 12.29 |

| Ta20 | 43 | 4.39 | −12.51 | 0.13 | −12.27 | 1.07 | 6 | 2.14 | −27.93 | 2.55 | −23.24 | 10.98 |

| Ta01 | 30 | 4.62 | -12.53 | 0.52 | -11.23 | 4.6 | 9 | 2.75 | -27.41 | 3.34 | -19.7 | 16.93 |

| Ta04 | 59 | 5.13 | −15.66 | 0.18 | −15.26 | 1.2 | 21 | 2.92 | −26.89 | 1.1 | −25.02 | 4.41 |

| Dmu80 | 16 | 1.75 | −5.61 | 0.21 | −5.08 | 4.12 | 1 | 0.91 | −7.13 | 0 | −7.13 | 0 |

| Dmu78 | 36 | 2.14 | −4.74 | 0.06 | −4.61 | 1.37 | 6 | 1.13 | −7.11 | 0.51 | −6.27 | 8.09 |

| Dmu64 | 19 | 3.76 | −4.66 | 0.16 | −4.42 | 3.58 | 7 | 1.89 | −6.9 | 0.43 | −6.44 | 6.71 |

| Dmu57 | 7 | 2.61 | −5.65 | 0.32 | −5.2 | 6.09 | 36 | 1.7 | −6.83 | 0.33 | −5.92 | 5.66 |

| Dmu77 | 1 | 1.51 | −5.44 | 0 | −5.44 | 0 | 6 | 1.04 | −6.41 | 0.46 | −5.76 | 8.03 |

| Dmu71 | 41 | 3.6 | −4.56 | 0.11 | −4.3 | 2.64 | 26 | 1.71 | −6.4 | 0.18 | −5.68 | 3.2 |

| Dmu74 | 25 | 3.05 | −4.52 | 0.14 | −4.2 | 3.23 | 15 | 1.76 | −6.29 | 0.35 | −5.5 | 6.33 |

| Dmu70 | 57 | 2.56 | −4.46 | 0.04 | −4.33 | 0.99 | 16 | 1.35 | −5.83 | 0.27 | −5.29 | 5.03 |

| Dmu69 | 22 | 1.84 | −5 | 0.12 | −4.85 | 2.45 | 9 | 1.16 | −5.82 | 0.25 | −5.53 | 4.53 |

| Dmu79 | 39 | 2.03 | −4.32 | 0.08 | −4.17 | 1.8 | 23 | 1.17 | −5.64 | 0.1 | −5.42 | 1.87 |

| Dmu73 | 46 | 3.31 | -3.94 | 0.06 | -3.83 | 1.5 | 35 | 1.6 | -5.55 | 0.17 | -5.08 | 3.35 |

| Dmu75 | 57 | 4.02 | −3.11 | 0.05 | −2.98 | 1.64 | 18 | 2.02 | −5.44 | 0.58 | −4.46 | 12.96 |

| Inst. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| n | iter | [%] | [%] | [%] | [%] | n | iter | [%] | [%] | [%] | [%] | |

| Abz07 | 44 | 8.43 | −8.07 | 0.1 | −8 | 1.28 | 3 | 5.21 | −18.57 | 4.39 | −14.86 | 29.54 |

| Yn03 | 42 | 5.93 | −9.51 | 0.22 | −8.73 | 2.51 | 5 | 4.01 | −15.83 | 0.63 | −15.45 | 4.06 |

| Swv05 | 39 | 23 | −3.89 | 0.02 | −3.84 | 0.57 | 32 | 11.22 | −15.15 | 1.12 | −12.69 | 8.8 |

| Abz09 | 17 | 7.11 | −11 | 0.51 | −10.34 | 4.9 | 5 | 5.45 | −14.51 | 0.45 | −14.01 | 3.24 |

| Swv01 | 57 | 17.49 | −6.16 | 0.07 | −6.04 | 1.1 | 22 | 10.76 | −14.39 | 0.82 | −12.79 | 6.44 |

| Yn04 | 11 | 6.43 | −9.65 | 0.29 | −8.82 | 3.28 | 7 | 3.49 | −13.86 | 0.21 | −13.51 | 1.56 |

| Ta35 | 4 | 3.36 | −11.66 | 0.72 | −10.59 | 6.75 | 3 | 2.73 | −13.62 | 1.34 | −12.13 | 11.02 |

| Swv03 | 46 | 17.87 | −3.29 | 0.1 | −3.18 | 3.01 | 13 | 9.35 | −13.58 | 2.1 | −11.91 | 17.61 |

| Abz08 | 42 | 8.75 | −9.62 | 0.15 | −9.27 | 1.67 | 6 | 6.08 | −13.58 | 0.54 | −12.76 | 4.25 |

| Ta04 | 39 | 7.71 | −9.13 | 0.38 | −8.37 | 4.5 | 39 | 5.84 | −13.38 | 0.26 | −12.89 | 2.04 |

| Ta08 | 46 | 8.34 | −6.02 | 0.08 | −5.85 | 1.3 | 21 | 5.5 | −12.82 | 0.84 | −11 | 7.61 |

| Ta20 | 60 | 7.33 | -7.76 | 0.14 | -7.26 | 1.94 | 9 | 4.28 | -12.57 | 0.62 | -11.81 | 5.21 |

| Dmu73 | 47 | 5.05 | −2.03 | 0.05 | −1.9 | 2.47 | 10 | 2.88 | −4.11 | 0.48 | −2.75 | 17.49 |

| Ta72 | 2 | 1.57 | −3.1 | 0.19 | −2.97 | 6.55 | 1 | 1.06 | −4.04 | 0 | −4.04 | 0 |

| Dmu64 | 27 | 6.07 | −2.82 | 0.08 | −2.7 | 2.93 | 17 | 3.72 | −3.99 | 0.24 | −3.6 | 6.59 |

| Dmu27 | 21 | 2.2 | −3.83 | 0.19 | −3.41 | 5.43 | 7 | 1.51 | −3.98 | 0.03 | −3.93 | 0.83 |

| Dmu77 | 48 | 2.67 | −2.64 | 0.05 | −2.5 | 1.82 | 4 | 1.89 | −3.94 | 0.51 | −3.2 | 15.88 |

| Dmu75 | 52 | 6.11 | −1.83 | 0.05 | −1.72 | 2.79 | 13 | 3.32 | −3.93 | 0.65 | −3.05 | 21.25 |

| Dmu29 | 1 | 1.91 | −3.53 | 0 | −3.53 | 0 | 1 | 1.42 | −3.88 | 0 | −3.88 | 0 |

| Dmu74 | 35 | 4.51 | −2.8 | 0.06 | −2.7 | 2.34 | 20 | 3.12 | −3.86 | 0.18 | −3.66 | 4.9 |

| Ta77 | 2 | 1.37 | −3.73 | 0.55 | −3.34 | 16.39 | 1 | 1 | −3.86 | 0 | −3.86 | 0 |

| Dmu70 | 41 | 3.78 | −2.67 | 0.08 | −2.48 | 3.22 | 12 | 2.42 | −3.78 | 0.24 | −3.3 | 7.22 |

| Dmu36 | 30 | 1.95 | -2.97 | 0.09 | -2.81 | 3.17 | 1 | 1.34 | -3.73 | 0 | -3.73 | 0 |

| Dmu78 | 33 | 3.17 | −2.85 | 0.04 | −2.74 | 1.62 | 36 | 2.38 | −3.7 | 0.1 | −3.38 | 3 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bożek, A. Energy Cost-Efficient Task Positioning in Manufacturing Systems. Energies 2020, 13, 5034. https://doi.org/10.3390/en13195034

Bożek A. Energy Cost-Efficient Task Positioning in Manufacturing Systems. Energies. 2020; 13(19):5034. https://doi.org/10.3390/en13195034

Chicago/Turabian StyleBożek, Andrzej. 2020. "Energy Cost-Efficient Task Positioning in Manufacturing Systems" Energies 13, no. 19: 5034. https://doi.org/10.3390/en13195034

APA StyleBożek, A. (2020). Energy Cost-Efficient Task Positioning in Manufacturing Systems. Energies, 13(19), 5034. https://doi.org/10.3390/en13195034