The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock

2.2. Feedstock Characterization

2.3. Pressure Agglomeration Process

2.4. Combustion of Pellets

3. Results and Discussion

3.1. Physicochemical Properties of the Feedstock

3.2. Pressure Agglomeration Tests

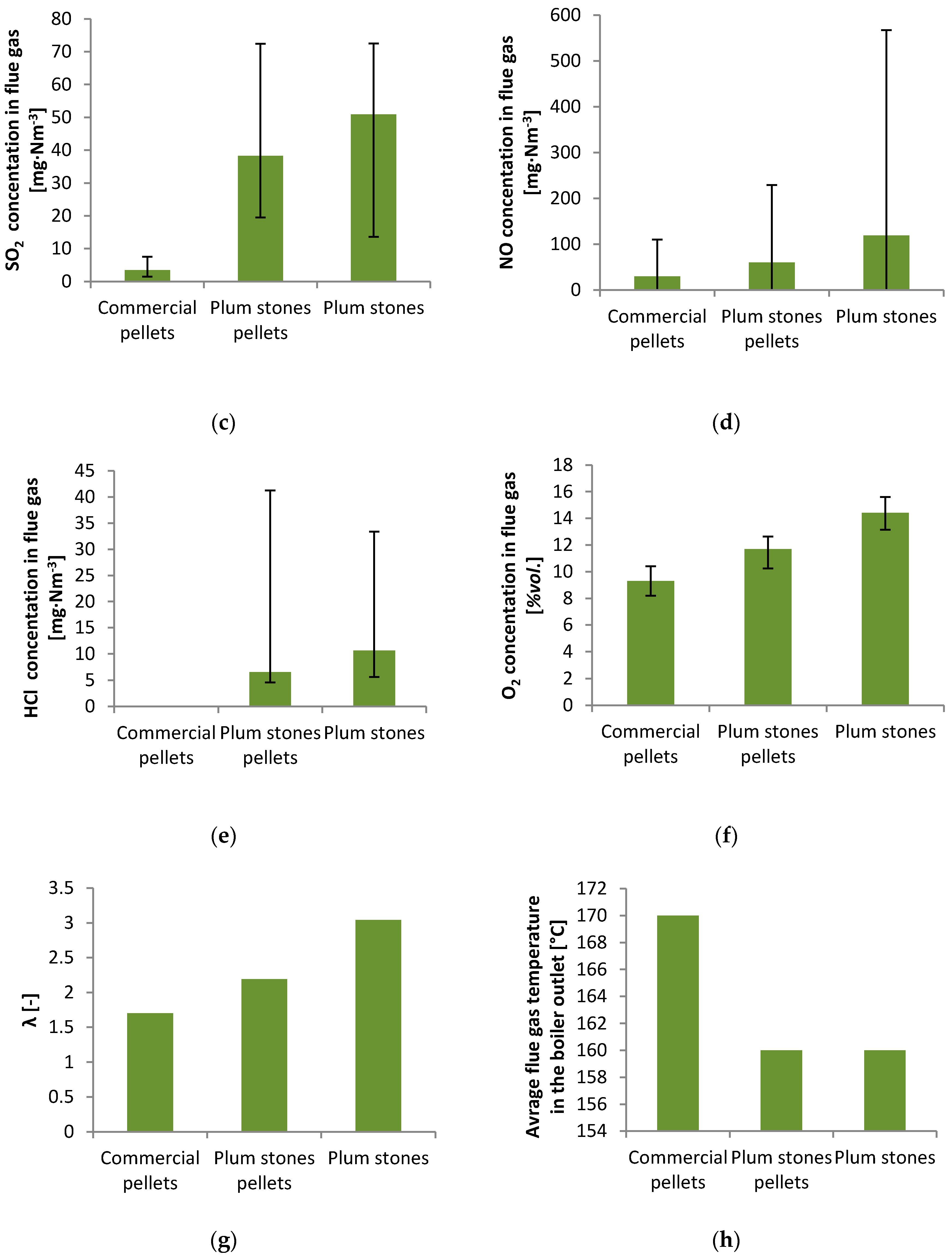

3.3. Combustion Tests

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Description |

| LHV | lower heating value (MJ·kg−1) |

| HHV | higher heating value (MJ·kg−1) |

| w | moisture content (wt.%) |

| Zs1 | the actual chemical content in the exhaust gas (%,mg·Nm−3) |

| Zs2 | content of the chemical compounds in the exhaust gas for a given oxygen content (%, mg·Nm−3) |

| O2′ | set value of the oxygen content in the exhaust (%) |

| O2” | actual oxygen content in the exhaust gas (%) |

| λ | excess air factor (-) |

| rb% | rye bran content (%) |

| mrs | matrix rotational speed (rpm) |

| ρ | pellet’s density (kg·m−3) |

| Px | pellet’s kinetic durability (%) |

| Ng | granulator’s power demand (kW) |

| wt.% | weight percent |

| vol.% | volume percent |

| a.r. | as received |

| d.b. | dry basis |

| n.d. | not determined |

References

- Geng, Y.; Fujita, T.; Park, H.-S.; Chiu, A.S.F.; Huisingh, D. Recent progress on innovative eco-industrial development. J. Clean. Prod. 2016, 114, 1–10. [Google Scholar] [CrossRef]

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef] [PubMed]

- Krajowy Ośrodek Bilansowania i Zarządzania Emisjami = Polish National Center for Emissions Balancing and Management. Available online: https://www.kobize.pldate06.02.2019 (accessed on 6 February 2019).

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The use of lignocellulosic waste in the production of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Central Statistical Office, Poland. Available online: https://stat.gov.pl/10.06.2020 (accessed on 8 February 2019).

- Skoczko, I.; Szatyłowicz, E. Analysis and assessment of air quality in the city of Białystok in 2012–2017. Econ. Environ. 2018, 2, 142–153. [Google Scholar]

- Vershinina, K.; Nyashina, G.; Dorokhov, V.; Shlegel, N. The prospects of burning coal and oil processing waste in slurry, gel, and solid state. Appl. Therm. Eng. 2019, 156, 51–62. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental impacts of food waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jozwiakowski, K.; Waliszewska, H. Digestate management in polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Stenmarck, Å.; Jensen, C.; Quested, T.; Moates, G. Estimates of European Food Waste Levels; Report of the project FUSIONS (contract number: 311972) grantem by the European Commission (FP7); IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2016. [Google Scholar]

- Nayaka, A.; Bhushan, B. An overview of the recent trends on the waste valorization techniques for food waste. J. Environ. Manag. 2019, 233, 352–370. [Google Scholar] [CrossRef]

- Banaszuk, P.; Wysocka-Czubaszek, A.; Czubaszek, R.; Roj-Rojewski, S. Skutki energetycznego wykorzystania biomasy = Effects of the biomass energy use. Wieś I Rol. 2015, 4, 139–152. [Google Scholar]

- Motghare, K.A.; Rathod, A.P.; Wasewar, K.L.; Labhsetwar, N.K. Comparative study of different waste biomass for energy application. Waste Manag. 2016, 47, 40–45. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef] [Green Version]

- González-García, E.; Marina, M.L.; García, M.C. Plum(Prunus domestica L.) by-product as a new and cheap source of bioactive peptides: Extraction method and peptides characterization. J. Funct. Foods 2014, 11, 428–437. [Google Scholar] [CrossRef]

- Nowicki, P.; Skrzypczak, M.; Pietrzak, R. Effect of activation method on the physicochemical properties and NO2 removal abilities of sorbents obtained from plum stones (Prunus domestica). Chem. Eng. J. 2010, 162, 723–729. [Google Scholar] [CrossRef]

- Nowicki, P.; Wachowska, H.; Pietrzak, R. Active carbons prepared by chemical activation of plum stones and their application in removal of NO2. J. Hazard. Mater. 2010, 181, 1088–1094. [Google Scholar] [CrossRef] [PubMed]

- Górnaś, P.; Rudzinska, M.; Soliven, A. Industrial by-products of plum Prunus domestica L. and Prunus cerasifera Ehrh. as potential biodiesel feedstock: Impact of variety. Ind. Crop. Prod. 2017, 100, 77–84. [Google Scholar] [CrossRef]

- Ceylan, S. Kinetic analysis on the non-isothermal degradation of plum stone waste by thermogravimetric analysis and integraf Master-Plots metod. Waste Manag. Res. 2015, 33, 345–352. [Google Scholar] [CrossRef]

- Kostic, M.D.; Velickovic, A.V.; Jokovic, N.M.; Stamenkovic, O.S.; Veljkovic, V.B. Optimization and kinetic modeling of esterification of the oil obtained from waste plum stones as a pretreatment step in biodiesel production. Waste Manag. 2016, 48, 619–629. [Google Scholar] [CrossRef]

- Cagnon, B.; Py, X.; Guillot, A.; Stoeckli, F.; Chambat, G. Contributions of hemicellulose, cellulose and lignin to the mass and the porous properties of chars and steam activated carbons from various lignocellulosic precursors. Bioresour. Technol. 2009, 100, 292–298. [Google Scholar] [CrossRef] [Green Version]

- Kamel, B.S.; Kakuda, Y. Characterization of the seed oil and meal from apricot, cherry, nectarine, peach and plum. JAOCS 1992, 69. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: http://www.fao.org/faostat/en/ (accessed on 8 February 2019).

- Arendt, E.K.; Zannini, E. Rye Cereal Grains for the Food and Beverage Industries, 1st ed.; Wood Head Publishing Series in Food Science, Technology and Nutrition; Wood Head Publishing: Cambridge, UK, 2013; pp. 220–243. [Google Scholar]

- Bushuk, W. Rye. In Encyclopedia of Grain Science; Wrigley: Chicago, IL, USA; Elsevier: Oxford, UK, 2004. [Google Scholar]

- Shewry, P.R.; Bechtel, D.B. Morphology and Chemistry of the Rye Grain. Rye: Production, Chemistry and Technology, 2nd ed.; AACC International, Inc.: St. Paul, MN, USA, 2001. [Google Scholar]

- Śmiechowska, M.; Jurasz, M. Zawartość włókna surowego w wybranych produktach zbożowych = The content of crude fiber in selected cereal products. Probl. Hig. I Epidemiol. 2014, 95, 429–432. [Google Scholar]

- Obidziński, S.; Dołżyńska, M.; Stasiełuk, W. Production of fuel pellets from a mixture of sawdust and rye bran. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/214/1/012073/pdf (accessed on 29 September 2020).

- Allesina, G.; Pedrazzi, S.; Allegretti, F.; Tartarini, P. Spent coffee grounds ash eat source for coffee roasting plants: Experimental validation and case study. Appl. Eng. 2017, 126, 730–736. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Piekarski, W.; Słowik, T.; Zając, G.; Krzaczek, P.; Sobczak, P. Właściwości mechaniczne peletów z biomasy ślazowca pensylwańskiego = Mechanical properties of pellets from syllabus moths. Autobusy Tech. Eksploat. Syst. Transp. 2011, 12, 420–424. [Google Scholar]

- Yub Harun, N.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef] [Green Version]

- Czekała, W. Agricultural Biogas Plants as a Chance for the Development of theAgri-Food Sector. J. Ecol. Eng. 2018, 19, 179–183. [Google Scholar] [CrossRef]

- Cengiz, N.Ü.; Yıldız, G.; Sert, M.; Gokkaya, D.S.; Saglam, M.; Yüksel, M.; Ballice, L. Hydrothermal gasification of a biodiesel by-product crude glycerol in the presence of phosphate based catalysts. Int. J. Hydrogen Energy 2015, 40, 14806–14815. [Google Scholar] [CrossRef]

- Obidziński, S. Analysis of usability of potato pulp as solid fuel. Fuel Process. Technol. 2012, 94, 67–74. [Google Scholar] [CrossRef]

- Obidziński, S.; Joka, M.; Fijoł, O. Two-stage agglomeration of fine-grained herbal nettle waste. Int. Agrophysics 2017, 31, 515–523. [Google Scholar] [CrossRef]

- Hejft, R. Ciśnieniowa Aglomeracja Materiałów Roślinnych = Pressure Agglomeration of Plant Materials; Biblioteka Problemów Eksploatacji: Białystok, Poland, 2002. [Google Scholar]

- Bonassa, G.; Schneider, L.T.; Canever, V.B.; Cremonez, P.A.; Frigo, E.P.; Dieter, J.; Teleken, J.G. Scenarios and prospects of solid biofuel use in Brazil. Renew. Sustain. Energy Rev. 2018, 82, 2365–2378. [Google Scholar] [CrossRef]

- European Biomass Association Raport 2017. Available online: https://epc.bioenergyeurope.org/ (accessed on 20 January 2019).

- Cincinelli, A.; Guerranti, C.; Martellini, T.; Scodellini, R. Residential wood combustion and its impact on urban air quality in Europe. Curr. Opin. Environ. Sci. Health 2019, 8, 10–14. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalao, J.P.S. Wood pellets as a sustainable energy alternative in Portugal. Renew. Energy 2016, 85, 1011–1016. [Google Scholar] [CrossRef]

- Sandroa, N.; Agis, P.; Gojmir, R.; Vlasta, Z.; Müslüm, A. Using pellet fuels for residential heating: A field study on its efficiency and the users’ satisfaction. Energy Build. 2019, 184, 193–204. [Google Scholar] [CrossRef]

- Yilmaz, E.; Wzorek, M.; Akçay, S. Co-pelletization of sewage sludge and agricultural waste. J. Environ. Manag. 2018, 216, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Agar, D.A.; Rudolfsson, M.; Kalén, G.; Campargue, M.; DaSilva Perez, D.; Larsson, S.H. A systematic study of ring-die pellet production from fore stand agricultural biomass. Fuel Process. Technol. 2018, 180, 47–55. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Moya, R.; Tenorio, C.; Oporto, G. Short Rotation Wood Crops in Latin American: A Review on Status and Potential Uses as Biofuel. Energies 2019, 12, 705. [Google Scholar] [CrossRef] [Green Version]

- EU Commission Regulation 2015/1189of28/04/2015 Ecodesign Directive. Available online: http://ec.europa.eu (accessed on 20 January 2019).

- PN-ENISO16994:2016.Solid biofuels—Determination of total sulfur and chlorine content.

- PN-ENISO16948:2016.Solid biofuels—Determination of total carbon, hydrogen and nitrogen content.

- PN-ENISO18134:2017.Solid biofuels—Determination of moisture content—Drying method—Part 2: Total moisture—Simplified method.

- PN-ENISO18123:2016.Solid biofuels—Determination of volatile matter.

- PN-ENISO18122:2016.Solid biofuels—Determination of ash content.

- PN-ISO1928:2002.Solid fuels—Determination of heat of combustion by calorimetric bomb method and calorific value calculation.

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and Fuel Properties of Onion Husks. Energies 2019, 12, 4687. [Google Scholar] [CrossRef] [Green Version]

- Obidziński, S.; Hejft, R.; Dołżyńska, M. Badanie procesu granulowania odpadów zbożowych = Research on the granulation process of cereal waste. Przemysł Chem. 2017, 96, 2360–2363. [Google Scholar] [CrossRef]

- Obidziński, S.; Hejft, R. Influence of technical and technological factors of the fodders pelleting process on the quality of obtained product. J. Res. Appl. Agric. Eng. 2012, 57, 94–99. [Google Scholar]

- Obidziński, S.; Hejft, R. The influence of potato pulp addition to the oat bran on the energy consumption of the pelletisation process and pellets quality. J. Res. Appl. Agric. Eng. 2013, 58, 133–138. [Google Scholar]

- PN-R-64834:1998. Feed—Study of kinetic strength of granules.

- Available online: https://phyllis.nl/Home/Help20.07.2020 (accessed on 20 July 2020).

- Kaczmarczyk, J. Analiza Techniczna Węgla i Biomasy = Technical Analysis of Coal and Biomass; Laboratorium Politechnika Wrocławska: Wrocław, Poland, 2012. [Google Scholar]

- Saxena, S.C. Devolatization and combustion characteristics of coal particles. Prog. Energy Combust. Sci. 1990, 16, 55–94. [Google Scholar] [CrossRef]

- Chmielniak, T.; Chmielniak, T.; Hycnar, J.J.; Karcz, A.; Kotowski, W.; Kowalik, P.; Kubica, K.; Ney, R.; Ściążko, M.; Tramer, A.; et al. Termochemiczne Przetwórstwo Węgla I Biomasy = Thermochemical Processing of Coal and Biomass; Wyd. Instytutu Chemicznej Przeróbki Węgla i Instytutu Gospodarki Surowcami Mineralnymi i Energią PAN: Zabrze, Poland; Kraków, Poland, 2003. [Google Scholar]

- Obernberger, I. Nutzung Fester Biomasse in Verbrennungsanlagenunter Besonderer Berü Cksichtigung des Verhaltens Aschebildender Elemente. Schriftenreihe Thermische Biomassenutzung, Band 1; Graz, Osterreichdbv-Verlagder Technischen Universitat Graz: Graz, Germany, 1997. [Google Scholar]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part1. Phase–mineral and chemical composition and classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Teixeira, P.; Lopes, H.; Gulyurtlu, I.; Lapa, N. Use of chemical fractionation to understand partitioning of biomass ash constituents during co-firing in fluidized bed combustion. Fuel 2012, 101, 215–227. [Google Scholar] [CrossRef] [Green Version]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical properties of solid biofuels—Significance andi mpast. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Dubiński, J.; Turek, M.; Aleksa, H. Węgiel kamienny dla energetyki zawodowej w aspekcie wymogów ekologicznych = Hard coal for commercial power engineering in the aspect of ecological requirements. Górnictwo I Środowisko 2005, 2, 5–21. [Google Scholar]

- Eriksson, J.-E.; Khazraie, T.; Hupa, L. Different Methods for the Characterization of Ash Compositions in Co-Firing Boilers; Energy Technology, The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2018; pp. 253–263. [Google Scholar] [CrossRef]

- Hansen, U.E.; Nygaard, I. Sustainable energy transitions in emerging economies: The formation of a palm oil biomass waste-to-energy in Malaysia 1990–2011. Energy Policy 2014, 66, 666–676. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and co-combustion of biomass. In Proceedings of the 12th European Biomass Conference 2002, Amsterdam, The Netherlands, 17–21 June 2002. [Google Scholar] [CrossRef]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef] [Green Version]

- Glarborg, P. Hidden interactions-trace species governing combustion and emissions. Proc. Combust. Inst. 2007, 31, 77–98. [Google Scholar] [CrossRef]

- Glarborg, P.; Jensen, A.D.; Johnsson, J.E. Fuel nitrogen conversion in solid fuel fired systems. Prog. Energy Combust. Sci. 2003, 29, 89–113. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 12, 3042. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Buksa, K. Extraction and characterization of rye grain starch and its susceptibility to resistant starch formation. Carbohydr. Polym. 2018, 194, 184–192. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production–A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G. Grinding performance and physical properties of non-treated and steam exploded barley, canola, oat and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Obidziński, S.; Joka, M.; Bieńczak, A.; Jadwisieńczak, K. Tests of the process of post-production onion waste pelleting. J. Res. Appl. Agric. Eng. 2017, 2, 89–92. [Google Scholar]

- Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T. Badanie emisji wybranych zanieczyszczeń gazowych podczas spalania peletów z agrobiomasy w kotle małej mocy = Research on the emission of selected gaseous pollutants during the combustion of pellets from agrobiomass in a low-power boiler. Rocz. Ochr. Środowiska 2017, 19, 715–730. [Google Scholar]

- Menghini, D.; Marra, F.S.; Allouis, C.; Beretta, F. Effect of excess air on the optimization of heating appliances for biomass combustion. Exp. Fluid Sci. 2008, 32, 1371–1380. [Google Scholar] [CrossRef]

- Pudlik, W. Termiczna Przeróbka Odpadów. Podstawy Teoretyczne = Thermal Waste Treatment. Theoretical Basics; Wydawnictwo Politechniki Gdańskiej: Gdańsk, Poland, 2014. [Google Scholar]

- Kubica, K. Efektywne I Przyjazne Środowisku Źródła Ciepła–Ograniczenie Niskiej Emisji = Efficient and Environmentally Friendly Heat Sources-Reduction of Low Emissions; Guide: Katowice, Poland, 2010. [Google Scholar]

- Mitchell, E.J.S.; Lea-Langton, A.R.; Jones, J.M.; Williams, A.; Layden, P.; Johnson, R. The impact of fuel properties on the emissions from the combustion of biomass and other solid fuels in a fixed bedd omestic stove. Fuel Process. Technol. 2016, 142, 115–123. [Google Scholar] [CrossRef]

- Oleniacz, R. Czynniki wpływające na skład spalin I wielkość emisji zanieczyszczeń z procesów termicznego przekształcania odpadów niebezpiecznych = Factors affecting exhaust gas composition and the amount of pollutant emissions from hazardous waste thermal conversion processes. Paliwa z Odpadów 2001, 3, 181–191. [Google Scholar]

- Szkarowski, A.; Janta-Lipińska, S. Improving of boiler efficiency by controlling the harmful substances concentration in the combustion products. Environment 2018, 367–375. [Google Scholar] [CrossRef]

- Wandrasz, J.W.; Wandrasz, A.J. Paliwa Formowane Biopaliwa I Paliwa z Odpadów w Procesach Termicznych = Formed Fuels Biofuels and Waste Fuels in Thermal Processes; Wyd. Seidel-Przywecki: Warszawa, Poland, 2006. [Google Scholar]

- PNEN-303-5:2012.Heating boilers—Part 5: Heating boilers for solid fuels with manual and automatic fuel hopper of nominal power up to 500 kW—Terminology, Requirements, Testing and Marking. Available online: https://standards.globalspec.com/std/1539323/EN%20303-5 (accessed on 30 September 2020).

- Szatyłowicz, E.; Skoczko, I. Evaluation of the PAH Contentin Soot from Solid Fuels Combustion in Low Power Boilers. Energies 2019, 12, 4254. [Google Scholar] [CrossRef] [Green Version]

- Khodaei, H.; Guzzomi, F.; Patiño, D.; Rashidian, B.; Yeohb, G.H. Air staging strategies in biomass combustion-gaseous and particulate emission reduction potentials. Fuel Process. Technol. 2017, 157, 29–41. [Google Scholar] [CrossRef]

- Wielgosiński, G.; Łechtańska, P.; Namiecińska, O. Emission of some pollutants from biomass combustion in comparison to hard coal combustion. J. Energy Inst. 2017, 90, 787–796. [Google Scholar] [CrossRef]

- Miller, J.A.; Bowman, C.T. Mechanism and modeling of nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 1989, 15, 287–338. [Google Scholar] [CrossRef]

- Fenimore, C.P. Formation of Nitric Oxide in Premixed Hydrocarbon Flames. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0082078471800401 (accessed on 29 September 2020).

- Mladenović, M.; Paprika, M.; Marinković, A. Denitrification techniques for biomass combustion. Renew. Sustain. Energy Rev. 2018, 82, 3350–3364. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Wasilewski, J.; Kuranc, A. Emission characteristics of biomass combustion in a domestic heating boiler fed with Wood and virginia mallow pellets. Fresenius Environ. Bull. 2017, 26, 4663–4670. [Google Scholar]

- Ren, X.; Sun, R.; Chi, H.-H.; Meng, X.; Li, Y.; Levendis, Y.A. Hydrogen chloride emissions from combustion of raw and torrefied biomass. Fuel 2017, 200, 37–46. [Google Scholar] [CrossRef]

- Enestam, S.; Bankiewicz, D.; Tuiremo, J.; Mäkelä, K.; Hupa, M. Are Na Cl and KCl equally corrosive on super heater materials of steam boilers? Fuel 2013, 104, 294–306. [Google Scholar] [CrossRef]

- Wasilewski, R.; Hrabak, J. Influence of chlorine, sulfur and alkalis content in waste biomass on its use in power production. Arch. Gospod. Odpadami I Ochr. Środowiska 2015, 17, 1–8. [Google Scholar]

- Liu, K.; Gao, Y.; Riley, J.T.; Pan, W.-P. An investigation of mercury emission from FBC systems fired with high-chlorine coals. Energy Fuels 2001, 15, 1173–1180. [Google Scholar] [CrossRef]

- Szczepaniak, W. Frakcjonowanie Metali w Procesach Termicznego Przetwarzania Biomasy I Stałych Odpadów Komunalnych = Metal Fractionation in the Processes of Thermal Processing of Biomass and Solid Municipal Waste; Wyd. Ossolineum: Wrocław, Poland, 2005. [Google Scholar]

| Parameter | Plum Stones | Rye Bran |

|---|---|---|

| Proximate analysis (a.r.) (wt.%) | ||

| Volatile matter (PN-EN ISO 18123: 2016) | 70.4 | 69.7 |

| Moisture(PN-EN ISO 18134: 2017) | 10.7 | 10.5 |

| Ash (PN-EN ISO 18122: 2016) | 0.9 | 3.77 |

| Ultimate analysis (d.b.) (wt.%) | ||

| C | 54.2 | 46.3 |

| H | 6.4 | 6.0 |

| O † | 38.2 | 55.1 |

| N | 0.73 | 2.42 |

| S | 0.103 | 0.095 |

| Cl | 0.002 | 0.002 |

| AAEMs †† (d.b.) (wt.%) | ||

| K | 0.151 | n.d. |

| Na | 0.004 | n.d. |

| Mg | 0.045 | n.d. |

| Ca | 0.057 | n.d. |

| Ni | 0.003 | n.d. |

| Si (g·kg−1) | 3.56 | n.d. |

| Hg (g·kg−1) | 0.011 | n.d. |

| HHV (a.r.) (MJ/kg) ††† | 22.26 | 16.77 |

| HHV (d.b) (MJ/kg) | 22.46 | 18.86 |

| LHV (d.b) (MJ/kg) | 20.76 | 17.24 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dołżyńska, M.; Obidziński, S.; Piekut, J.; Yildiz, G. The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies 2020, 13, 5107. https://doi.org/10.3390/en13195107

Dołżyńska M, Obidziński S, Piekut J, Yildiz G. The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies. 2020; 13(19):5107. https://doi.org/10.3390/en13195107

Chicago/Turabian StyleDołżyńska, Magdalena, Sławomir Obidziński, Jolanta Piekut, and Güray Yildiz. 2020. "The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions" Energies 13, no. 19: 5107. https://doi.org/10.3390/en13195107

APA StyleDołżyńska, M., Obidziński, S., Piekut, J., & Yildiz, G. (2020). The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies, 13(19), 5107. https://doi.org/10.3390/en13195107