Analysing the Effect of Substrate Properties on Building Envelope Thermal Performance in Various Climates

Abstract

:1. Introduction

2. Methodology

3. Results and Discussion

3.1. Validating the Model for Equivalent Thermal Resistance

3.2. Daily Performance of Different Roof Substrate Properties

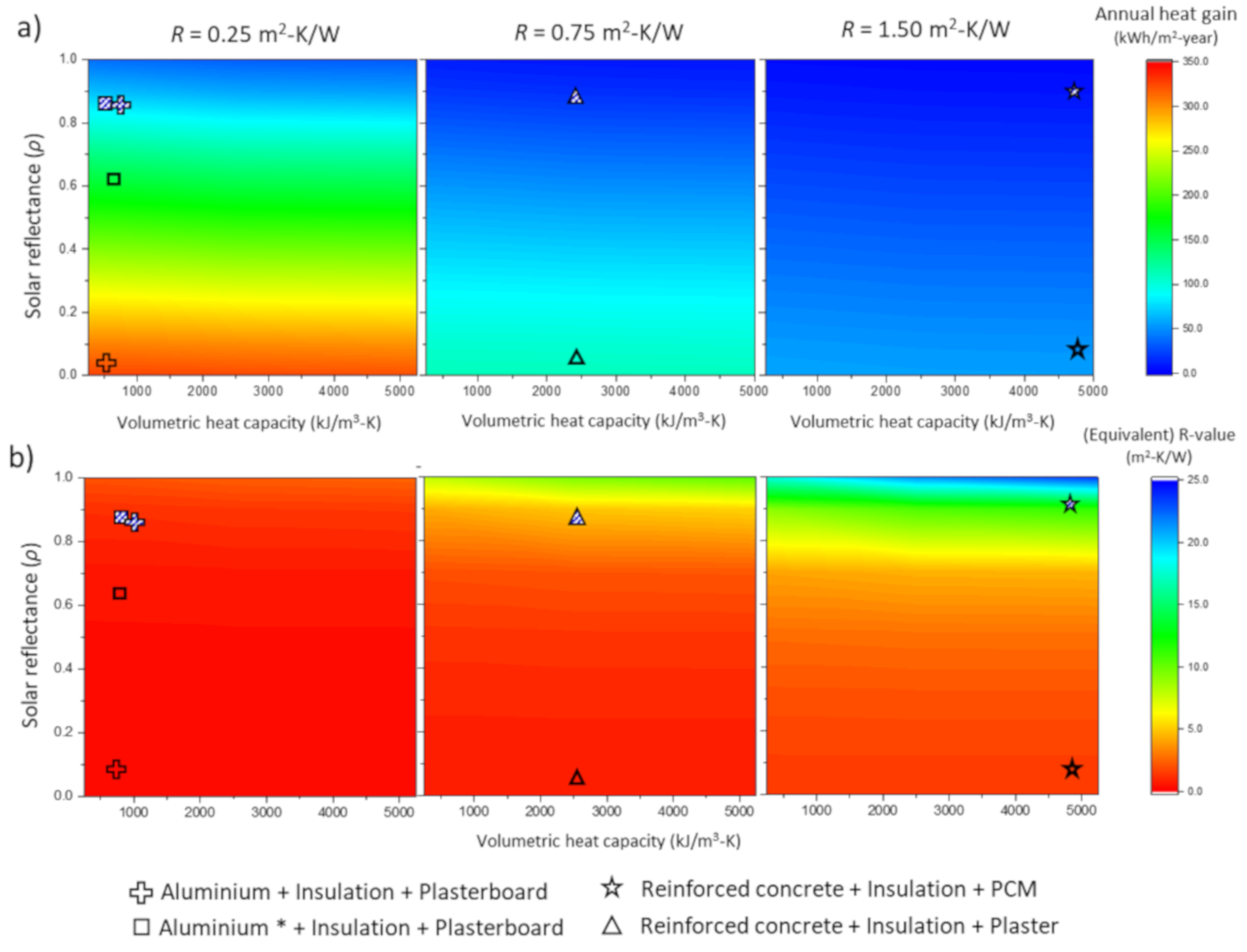

3.3. Annual Performance of Different Roof Substrate Properties

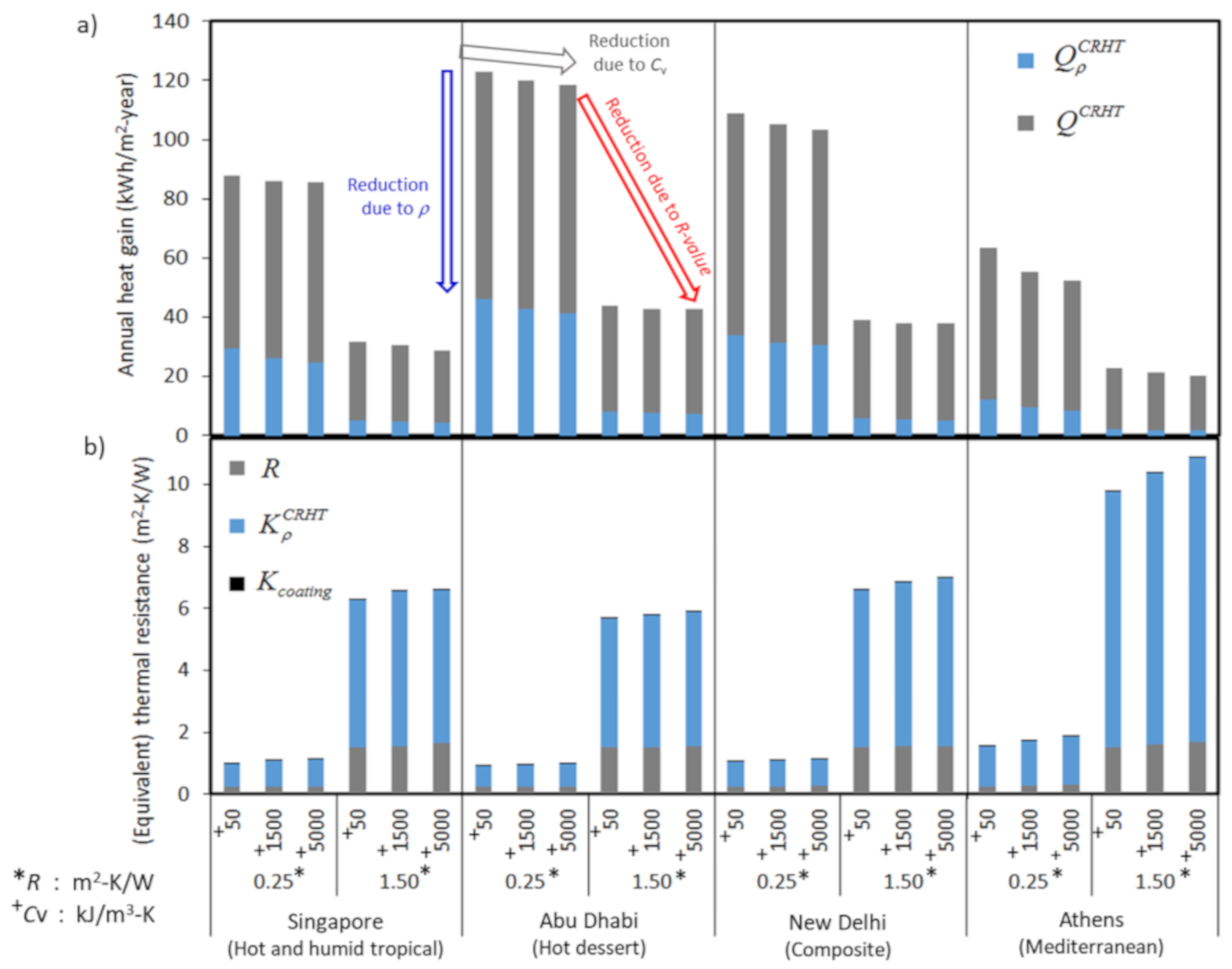

3.4. Substrate Performance in Various Climates

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Al-Sanea, S.A.; Zedan, M.F.; Al-Hussain, S.N. Effect of masonry material and surface absorptivity on critical thermal mass in insulated building walls. Appl. Energy 2013, 102, 1063–1070. [Google Scholar] [CrossRef]

- Zingre, K.T.; Wan, M.P.; Tong, S.; Li, H.; Chang, V.W.-C.; Wong, S.K.; Toh, W.B.T.; Lee, I.Y.L. Modeling of cool roof heat transfer in tropical climate. Renew. Energy 2015, 75, 210–223. [Google Scholar] [CrossRef]

- Zingre, K.T.; Yang, X.; Wan, M.P. Performance Analysis of Cool Roof, Green Roof and Thermal Insulation on a Concrete Flat Roof in Tropical Climate. Evergreen 2015, 2, 34–43. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance assessment of phase change material integrated cementitious composites in buildings: Experimental and numerical approach. Appl. Energy 2017, 207, 654–664. [Google Scholar] [CrossRef]

- Alam, M.; Zou, P.X.; Sanjayan, J.; Ramakrishnan, S. Energy saving performance assessment and lessons learned from the operation of an active phase change materials system in a multi-storey building in Melbourne. Appl. Energy 2019, 238, 1582–1595. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Inamuddin; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance of buildings integrated with phase change materials to reduce heat stress risks during extreme heatwave events. Appl. Energy 2017, 194, 410–421. [Google Scholar] [CrossRef]

- Lei, J.; Kumarasamy, K.; Zingre, K.T.; Yang, J.; Wan, M.P.; Yang, E.-H. Cool colored coating and phase change materials as complementary cooling strategies for building cooling load reduction in tropics. Appl. Energy 2017, 190, 57–63. [Google Scholar] [CrossRef]

- Zingre, K.T.; Yang, E.H.; Wan, M.P. Dynamic thermal perfomance of inclined double-skin roof: Modeling and experimental investigation. Energy 2017, 133, 900–912. [Google Scholar] [CrossRef]

- Kumar, D.K.; Puranik, S. Thermal performance evaluation of a mineral-based cement tile as roofing material. Indoor Built Environ. 2016, 26, 409–421. [Google Scholar] [CrossRef]

- Kosny, J.; Christian, J.E.; Desjarlais, A.O.; Kossecka, E.; Berrenberg, L. The performance check between whole building thermal performance criteria and exterior wall; Measured clear wall R-value, thermal bridging, thermal bass, and air-\tightness. ASHRAE Transactions 1998, 104. [Google Scholar]

- Long, L.; Ye, H. The roles of thermal insulation and heat storage in the energy performance of the wall materials: A simulation study. Sci. Rep. 2016, 6, 24181. [Google Scholar] [CrossRef] [PubMed]

- Muscio, A.; Akbari, H. An index for the overall performance of opaque building elements subjected to solar radiation. Energy Build. 2017, 157, 184–194. [Google Scholar] [CrossRef]

- Zingre, K.T.; Wan, M.P.; Yang, X. A new RTTV (Roof thermal transfer value) model for cool roofs. Energy 2015, 81, 222–232. [Google Scholar] [CrossRef]

- Zingre, K.T.; Wan, M.P.; Wong, S.K.; Toh, W.B.T.; Lee, I.Y.L. Modelling of cool roof performance for double-skin roofs in tropical climate. Energy 2015, 82, 813–826. [Google Scholar] [CrossRef]

- EnergyPlus Weather Dataset. Typical Meteorological Year Weather Data Files for EnergyPlus Simulations, U.S; Department of Energy, University of Illinois: Chicago, IL, USA, 2013. [Google Scholar]

- Tong, S.; Li, H.; Zingre, K.T.; Wan, M.P.; Chang, V.W.-C.; Wong, S.K.; Toh, W.B.T.; Lee, I.Y.L. Thermal performance of concrete-based roofs in tropical climate. Energy Build. 2014, 76, 392–401. [Google Scholar] [CrossRef]

| Parameter | Daily Heat Gain | Daily Heat Loss | ||

|---|---|---|---|---|

| Sunny Day | Cloudy Day | Sunny Day | Cloudy Day | |

| Increasing ρ only (from 10% to 80%) | −68% | −60% | +50% | +43% |

| Increasing Cv only (from 500 to 5000 kJ/m3-K) | −8% | −1% | −100% | −100% |

| Increasing R only (from 0.25 to 1.50 m2-K/W) | −82% | −80% | −50% | −60% |

| No. | Roof Assembly Layers | R (m2-K/W) | ρ of Outside Exposed Surface (%) | Cv (kJ/m3-K) | ||

|---|---|---|---|---|---|---|

| Outside Layer | Middle Layer | Inside Layer | ||||

| 1 | Aluminum (5 mm) | Polyurethane (5 mm) | Plasterboard (20 mm) | 0.25 | 10 | 500 |

| 2 | Aluminum (5 mm) | Polyurethane (5 mm) | Plasterboard (20 mm) | 0.25 | 60 | 500 |

| 3 | Reinforced concrete (100 mm) | Polyurethane (20 mm) | Plaster (15 mm) | 0.75 | 10 | 2300 |

| 4 | Reinforced concrete (100 mm) | Polyurethane (75 mm) | PCM (5 mm) | 1.50 | 10 | 5000 |

| Location (Climate) | ×Ko (m2-K/W) | ×Ki (m2-K/W) | ××Io (kWh/m2-Year) | ×To (°C) | ×Tsky (°C) | × ΔT (°C) |

|---|---|---|---|---|---|---|

| Singapore (Hot and humid tropical) | 0.031 | 0.234 | 1831 | 27.5 | 18.1 | 5.7 |

| Abu Dhabi (Hot dessert) | 0.032 | 0.237 | 2896 | 27.1 | 14.9 | 11.9 |

| New Delhi (Composite) | 0.033 | 0.240 | 2572 | 24.5 | 12.3 | 11.5 |

| Athens (Mediterranean) | 0.031 | 0.228 | 1938 | 15.7 | 3.7 | 7.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zingre, K.T.; Kumar D. E. V. S., K.; Wan, M.P. Analysing the Effect of Substrate Properties on Building Envelope Thermal Performance in Various Climates. Energies 2020, 13, 5119. https://doi.org/10.3390/en13195119

Zingre KT, Kumar D. E. V. S. K, Wan MP. Analysing the Effect of Substrate Properties on Building Envelope Thermal Performance in Various Climates. Energies. 2020; 13(19):5119. https://doi.org/10.3390/en13195119

Chicago/Turabian StyleZingre, Kishor T., Kiran Kumar D. E. V. S., and Man Pun Wan. 2020. "Analysing the Effect of Substrate Properties on Building Envelope Thermal Performance in Various Climates" Energies 13, no. 19: 5119. https://doi.org/10.3390/en13195119