Heat Transfer Enhancement of Plate-Fin Heat Sinks with Different Types of Winglet Vortex Generators

Abstract

1. Introduction

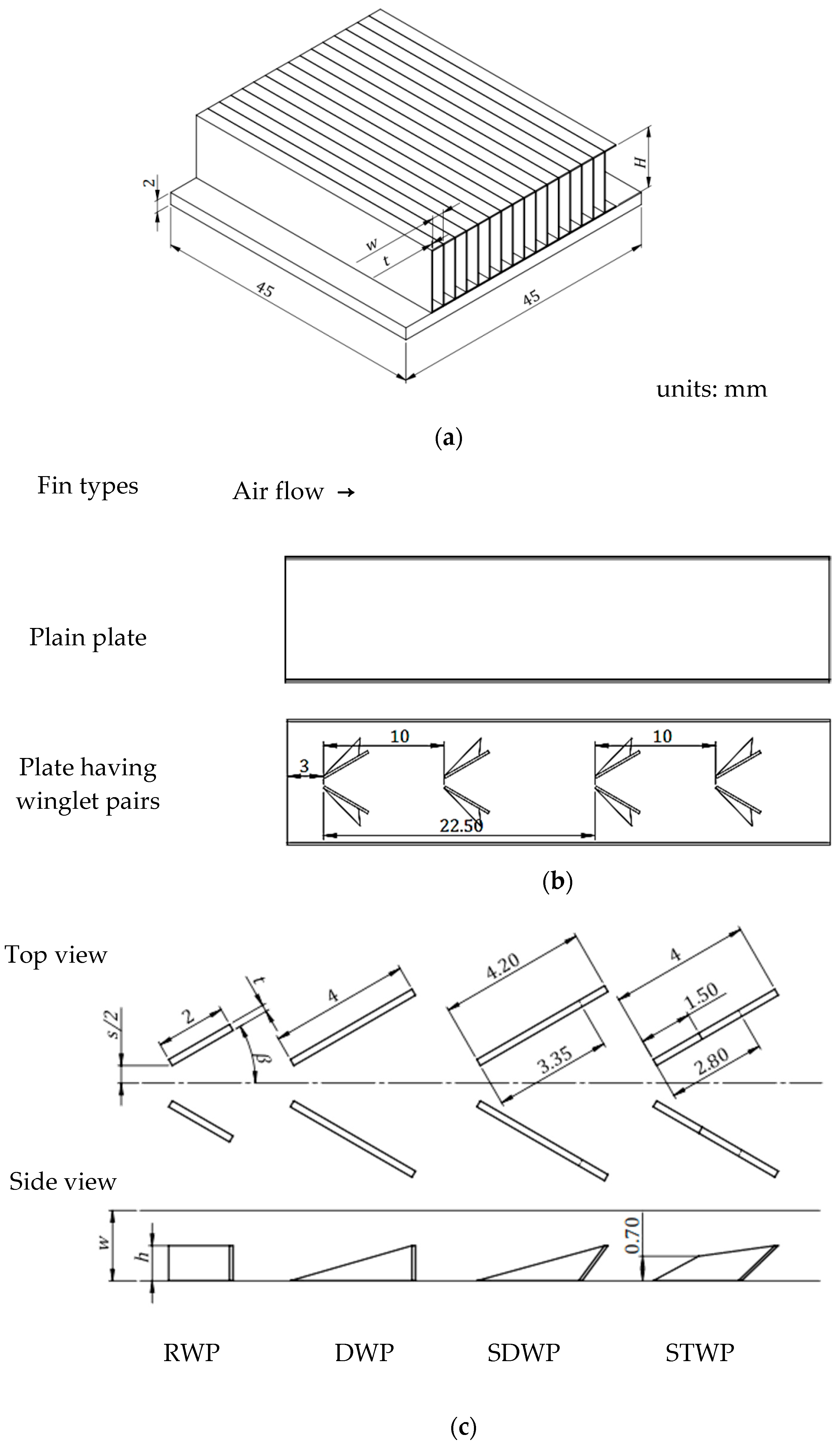

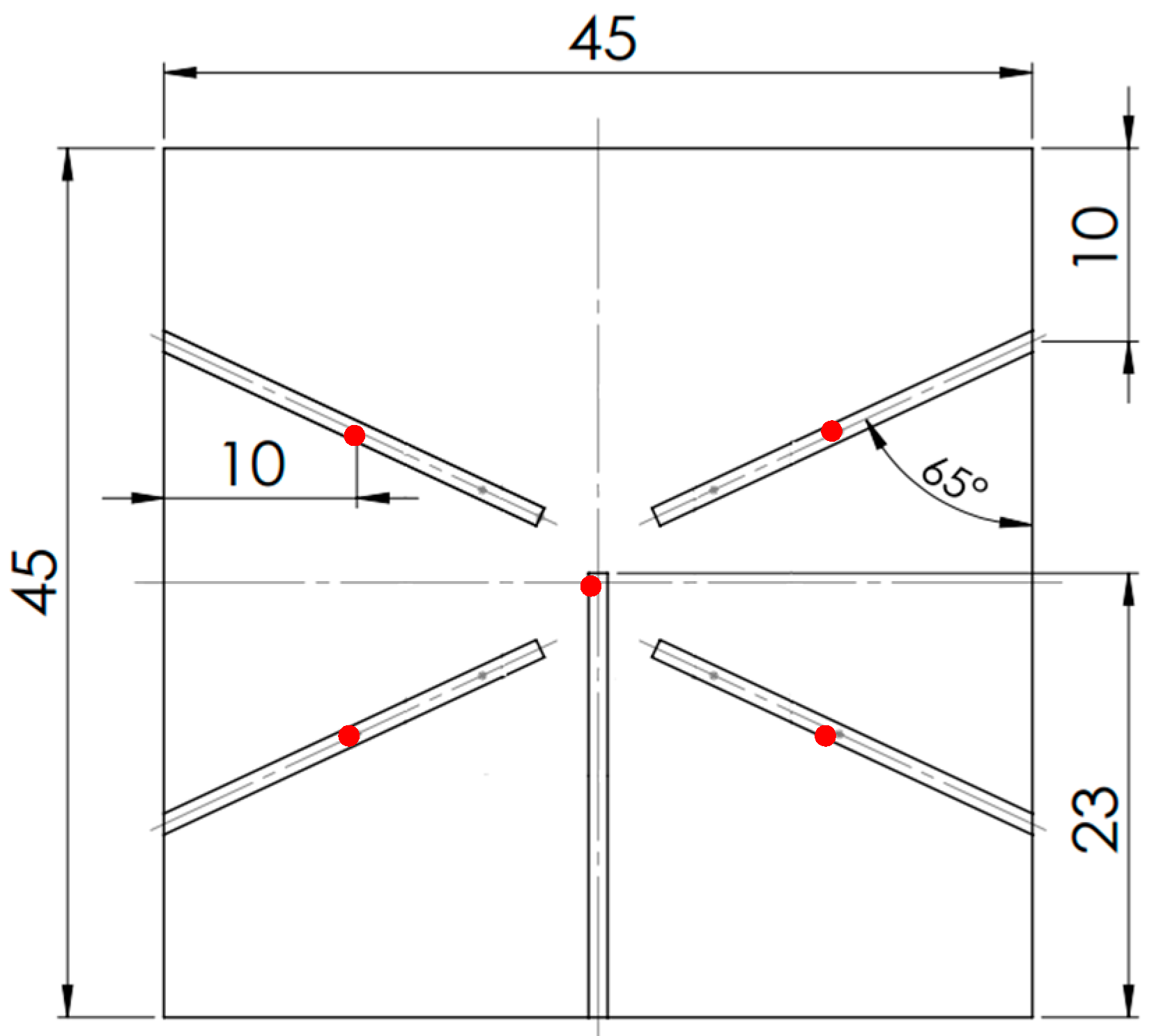

2. Experimental Setup

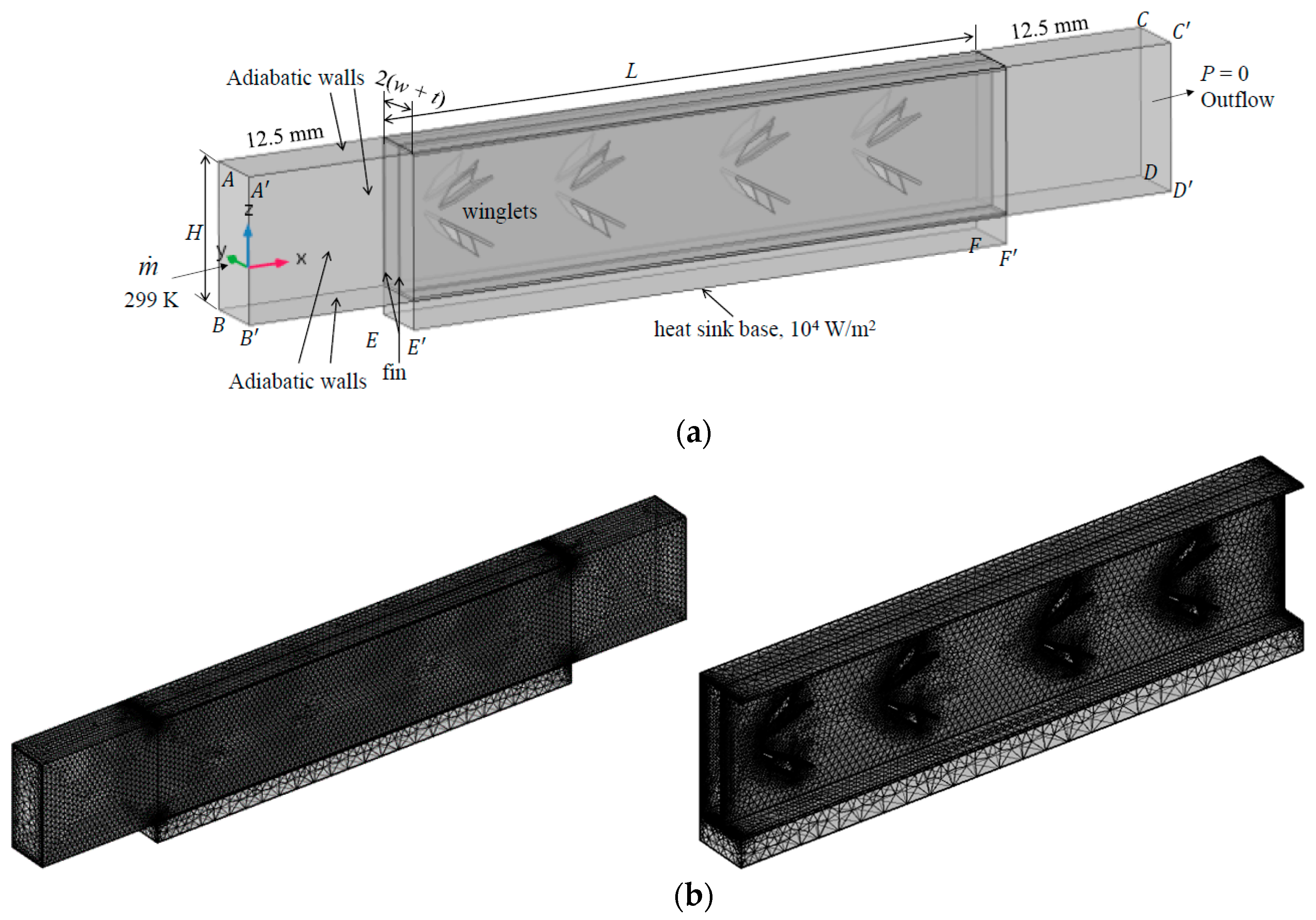

3. Numerical Simulation

4. Result and Discussion

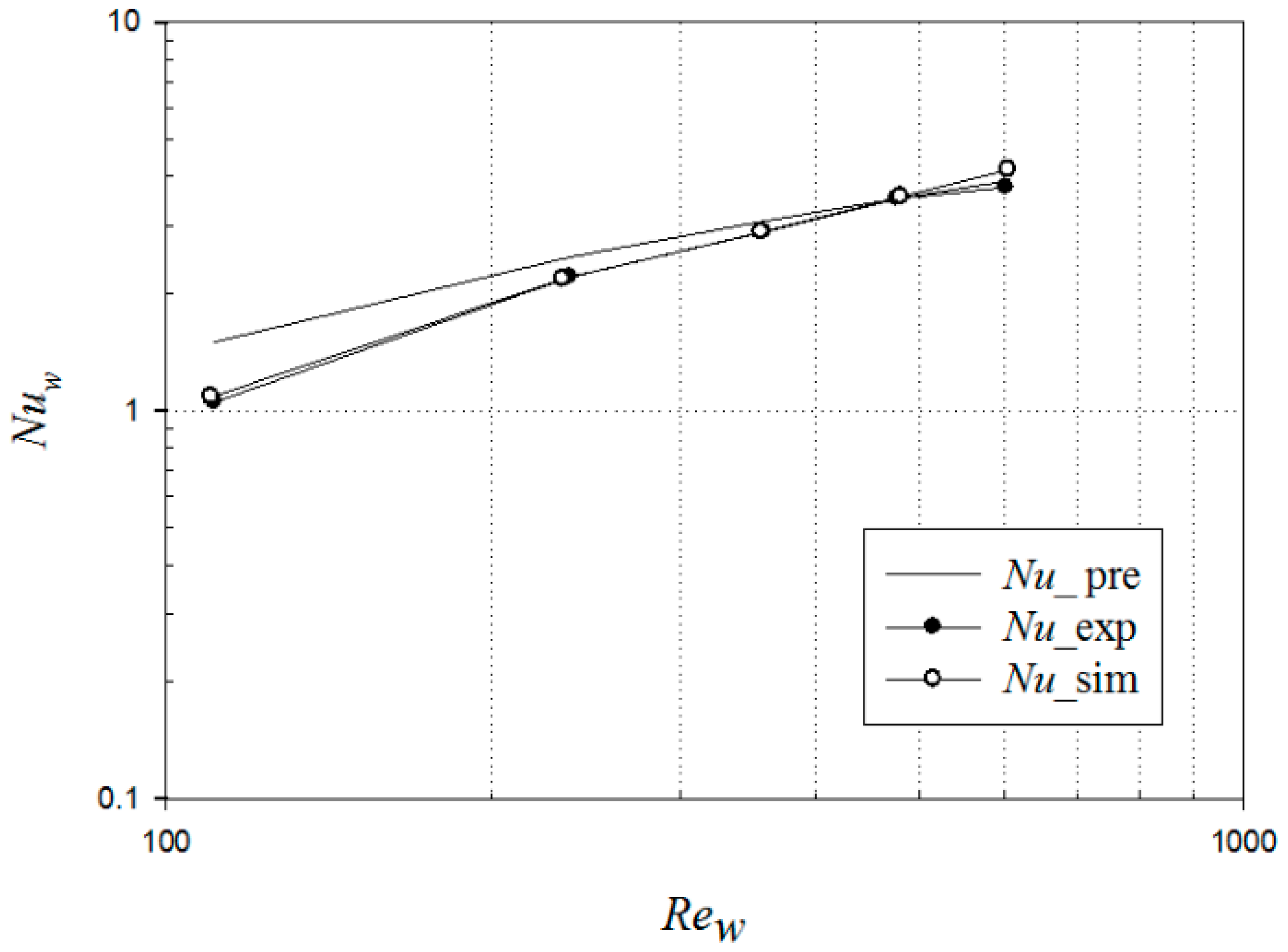

4.1. Validation of Experimental Results

4.2. Measured Results of the Heat Sinks

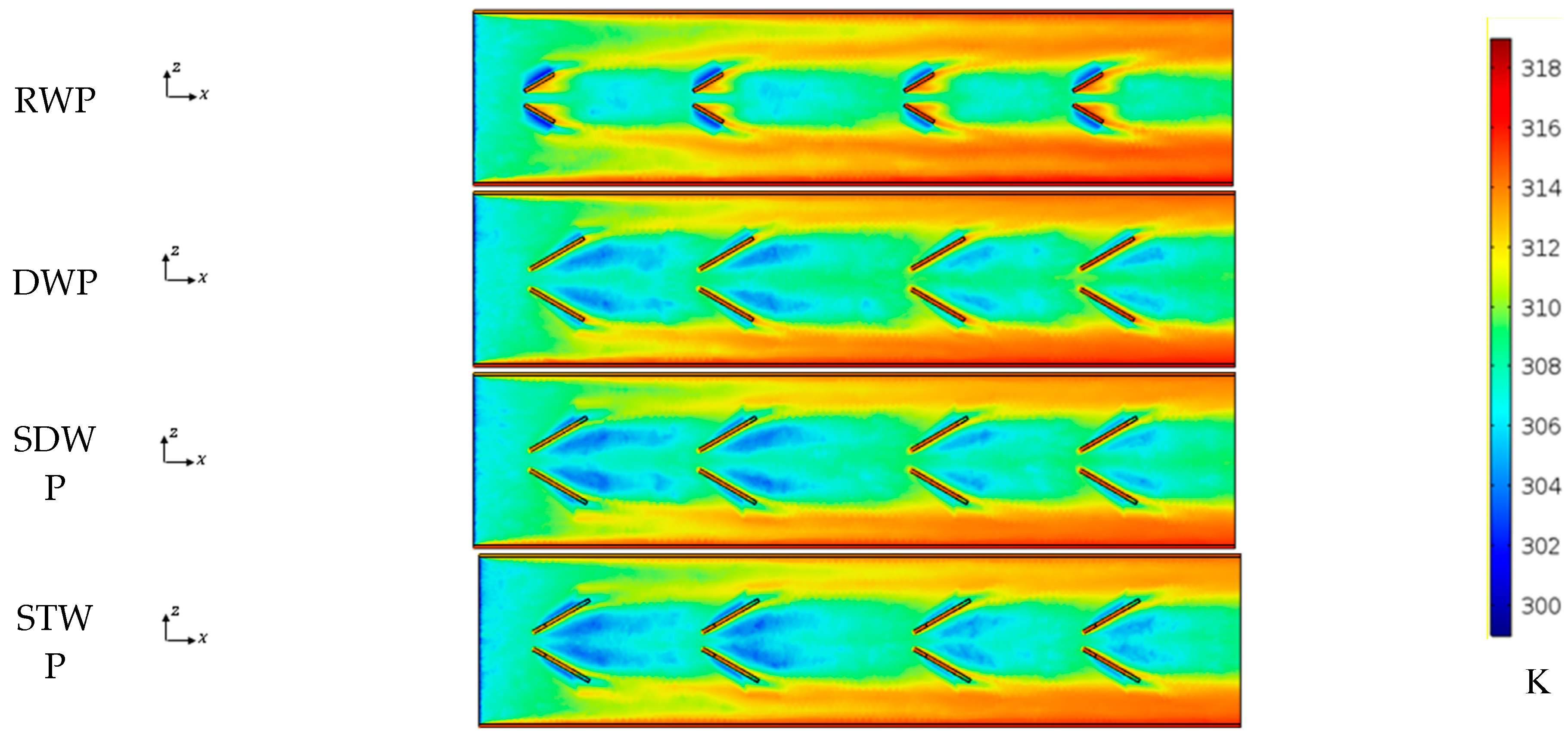

4.3. Simulation Results

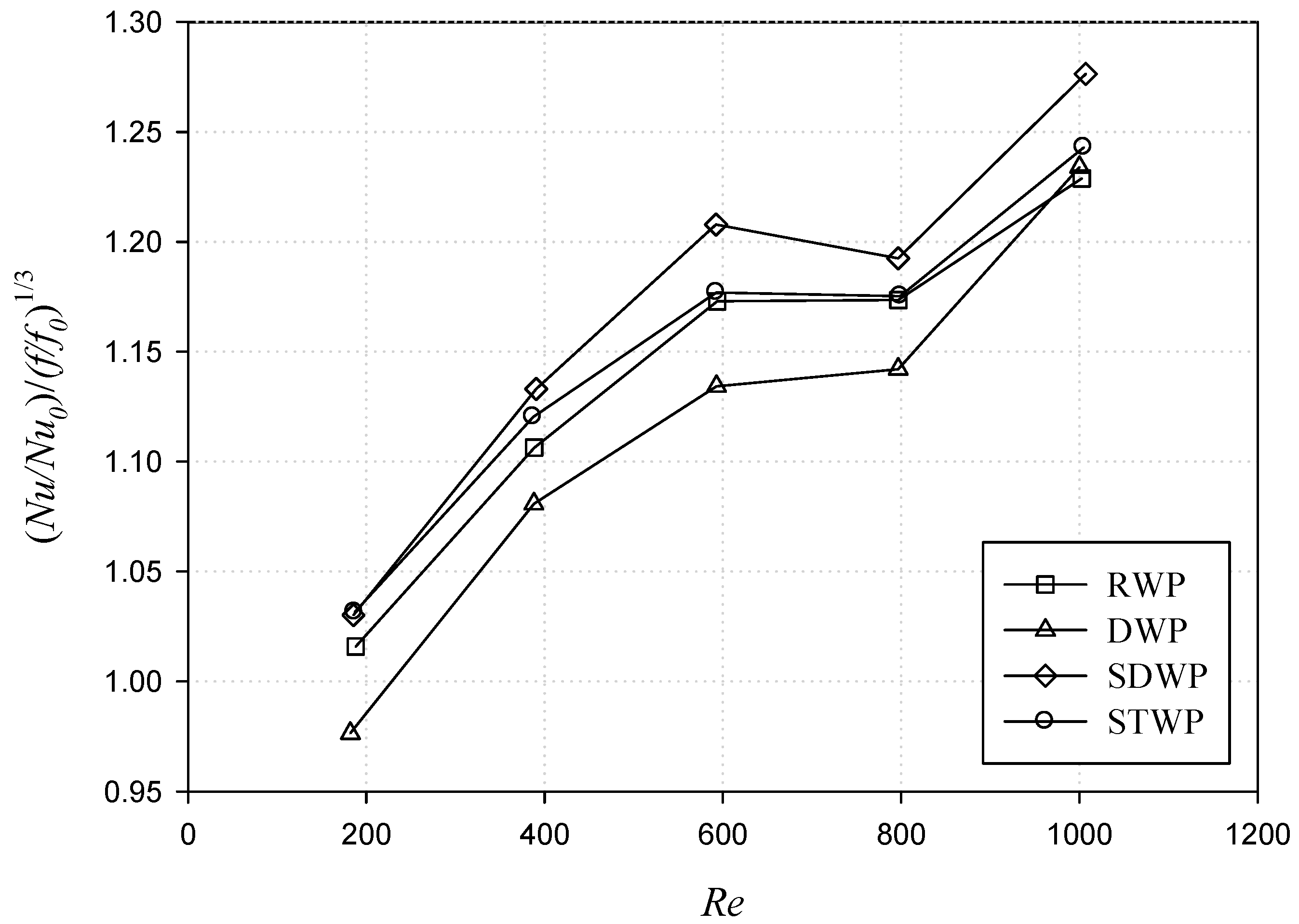

4.4. Performance Evaluation of the Heat Sinks

5. Conclusions

- Both the pressure drop and heat transfer coefficient of those heat sinks having winglet VGs were augmented, compared to those of the plain plate-fin heat sink. At air velocity of 5 m/s, the heat transfer coefficient of the plain plate-fin heat sink was about 50 W/m2K, while that of the heat sinks having winglet VGs was between 67 W/m2K and 70 W/m2K.

- Whatever the type of winglets tested, the simulation result showed that the heat transfer enhancement attributed to the VGs was gradually weakened as the air flowed downstream. It suggests that optimizing the number and arrangement of the winglets might result in similar or higher heat transfer coefficient with lower pressure drop.

- The heat sink having SDWP yielded the best heat transfer performance among other types of VGs in this study. Its Nusselt number was increased by a factor of 40% compared to that of the heat sink without VGs. The normalized Nusselt number versus Reynolds number showed a local minimum at Re = 800 for all types of heat sinks, indicating a transition between thermally fully developed flow and developing flow.

- The thermal enhancement factor which considers Nusselt number together with friction factor of the tested heat sinks indicated that the best VGs were SDWP with TEF of 1.28 at Reynolds number of 1000, followed by RWP and STWP, and DWP was the worst in this study, in the range 200 ≤ Re ≤ 1000.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Remsburg, R.; Hager, J. Direct Integration of IGBT Power Modules to Liquid Cooling Arrays; Electric Vehicle Symposium: Los Angeles, CA, USA, 2007. [Google Scholar]

- Rajashekara, K. Present status and future trends in electric vehicle propulsion technologies. IEEE Trans. Emerg. Sel. Top. Power Electron. 2013, 1, 3–10. [Google Scholar] [CrossRef]

- Morozumi, A.; Gohara, H.; Momose, F.; Saito, T.; Nishimura, Y.; Mochizuki, E.; Takahashi, Y. Next-generation IGBT module structure for hybrid vehicle with high cooling performance and high temperature operation. In Proceedings of the 2014 International Power Electronics Conference, Hiroshima, Japan, 18–21 May 2014. [Google Scholar]

- Hussein, K.; Ishihara, M.; Miyamoto, N.; Nakata, Y.; Nakano, T. New compact, high performance 7th Generation IGBT module with direct liquid cooling for EV/HEV inverters. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Qian, C.; Gheitaghy, A.M.; Fan, J.J.; Tang, H.Y.; Sun, B.; Ye, H.Y.; Zhang, G.Q. Thermal Management on IGBT Power Electronic Devices and Modules. IEEE Access 2018, 6, 12868–12884. [Google Scholar] [CrossRef]

- Nonneman, J.; T’Jollyn, I.; Clarie, N.; Weckx, S.; Sergeant, P.; De Paepe, M. Model-Based Comparison of Thermo-Hydraulic Performance of Various Cooling Methods for Power Electronics of Electric Vehicles. In Proceedings of the 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018. [Google Scholar]

- Wang, C.C. A quick overview of compact air-cooled heat sinks applicable for electronic cooling—Recent progress. Inventions 2017, 2, 5. [Google Scholar] [CrossRef]

- Johnson, T.; Joubert, P. The influence of vortex generators on the drag and heat transfer from a circular cylinder normal to an airstream. J. Heat Transf. 1969, 91, 91–99. [Google Scholar] [CrossRef]

- Patankar, S.V.; Prakash, C. An analysis of the effect of plate thickness on laminar flow and heat transfer in interrupted-plate passages. Int. J. Heat Mass Transf. 1981, 24, 1801–1810. [Google Scholar] [CrossRef]

- Biswas, G.; Chattopadhyay, H. Heat transfer in a channel with built in wing type of vortex generators. Int. J. Heat Mass Transf. 1992, 35, 803–814. [Google Scholar] [CrossRef]

- Tiggelbeck, S.; Mitra, N.K.; Fiebig, M. Experimental investigation of heat transfer enhancement and flow losses in a channel with double rows of longitudinal vortex generators. Int. J. Heat Mass Transf. 1993, 36, 2327–2337. [Google Scholar] [CrossRef]

- Tiggelbeck, S.; Mitra, N.; Fiebig, M. Comparison of wing-type vortex generators for heat transfer enhancement in channel flows. J. Heat Transf. 1994, 116, 880–885. [Google Scholar] [CrossRef]

- Biswas, G.; Torri, K.; Fujji, D.; Nishino, K. Numerical and Experimental determination of flow structure and heat transfer effects of longitudinal vortices in a channel flow. Int. J. Heat Mass Transf. 1996, 39, 3441–3451. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Numerical study on laminar convection heat transfer in a channel with longitudinal vortex generator. Part B: Parametric study of major influence factors. Int. J. Heat Mass Transf. 2008, 51, 3683–3692. [Google Scholar] [CrossRef]

- Tian, L.; He, Y.; Lei, Y. Numerical study of fluid flow and heat transfer in a flat plate channel with longitudinal vortex generators by applying field synergy principle analysis. Int. Commun. Heat Mass Transf. 2009, 36, 111–120. [Google Scholar] [CrossRef]

- Violato, D.; Ianiro, A.; Cardone, G.; Scarano, F. Three-dimensional vortex dynamics and convective heat transfer in circular and chevron impinging jets. Int. J. Heat Fluid Flow 2012, 37, 22–36. [Google Scholar] [CrossRef]

- Li, L.; Du, X.; Zhang, Y.; Yang, L.; Yang, Y. Numerical simulation on flow and heat transfer of fin-and-tube heat exchanger with longitudinal vortex generators. Int. J. Therm. Sci. 2015, 92, 85–96. [Google Scholar] [CrossRef]

- Oneissi, M.; Habchi, C.; Russeil, S.; Bougeard, D.; Lemenand, T. Novel design of delta winglet pair vortex generator for heat transfer enhancement. Int. J. Therm. Sci. 2016, 109, 1–9. [Google Scholar] [CrossRef]

- Zhou, G.; Feng, Z. Experimental investigations of heat transfer enhancement by plane and curved winglet type vortex generators with punched holes. Int. J. Therm. Sci. 2014, 78, 26–35. [Google Scholar] [CrossRef]

- Esmaeilzadeh, A.; Amanifard, N.; Deylami, H. Comparison of simple and curved trapezoidal longitudinal vortex generators for optimum flow characteristics and heat transfer augmentation in a heat exchanger. Appl. Therm. Eng. 2017, 125, 1414–1425. [Google Scholar] [CrossRef]

- Kashyap, U.; Das, K.; Debnath, B.K. Effect of surface modification of a rectangular vortex generator on heat transfer rate from a surface to fluid: An extended study. Int. J. Therm. Sci. 2018, 134, 269–281. [Google Scholar] [CrossRef]

- Lu, G.; Zhai, X. Effects of curved vortex generators on the air-side performance of fin-and-tube heat exchangers. Int. J. Therm. Sci. 2019, 136, 509–518. [Google Scholar] [CrossRef]

- Han, H.; Wang, S.; Sun, L.; Li, Y.; Wang, S. Numerical study of thermal and flow characteristics for a fin-and-tube heat exchanger with arc winglet type vortex generators. Int. J. Refrig. 2019, 98, 61–69. [Google Scholar] [CrossRef]

- ASHRAE Handbook Fundamental; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 1993; pp. 13.14–13.15.

- ASHRAE Standard 41.2-1987, Standard Methods for Laboratory Air-Flow Measurement; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 1987.

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Teertstra, P.; Yovanovich, M.M.; Culham, J.R. Analytical forced convection modeling of plate-fin heat sinks. J. Electron. Manuf. 2000, 10, 253–261. [Google Scholar] [CrossRef]

- Muzychka, Y.S.; Yovanovich, M.M. Laminar forced convection heat transfer in the combined entry region of non-circular ducts. J. Heat Transf. 2004, 126, 54–61. [Google Scholar] [CrossRef]

| fin pitch, w | 2 mm | |||

| fin height, H | 10 mm | |||

| fin thickness, t | 0.2 mm | |||

| fin length, L | 45 mm | |||

| number of rectangular channel, n | 16 | |||

| winglet type | RWP | DWP | SDWP | STWP |

| angle of attack, β | 30° | |||

| winglet height, h (mm) | 1 | |||

| vortex generator area, AVG (mm2) | 4 | |||

| transverse distance between the tip of the winglet pair, s (mm) | 1 | |||

| RWP: Rectangular Winglet Pair, DWP: Delta Winglet Pair, SDWP: Swept Delta Winglet Pair, STWP: Swept Trapezoid Winglet Pair | ||||

| Parameter | Uncertainty | |

|---|---|---|

| 1 m/s | 5 m/s | |

| 0.23% | 0.36% | |

| 0.15% | 0.27% | |

| V | 1.09% | 1.09% |

| 0.71% | 0.94% | |

| 2.42% | 2.43% | |

| 1.50% | 1.49% | |

| 1.00% | 1.32% | |

| 3.43% | 3.44% | |

| 1.15% | 1.15% | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shyu, J.-C.; Jheng, J.-S. Heat Transfer Enhancement of Plate-Fin Heat Sinks with Different Types of Winglet Vortex Generators. Energies 2020, 13, 5219. https://doi.org/10.3390/en13195219

Shyu J-C, Jheng J-S. Heat Transfer Enhancement of Plate-Fin Heat Sinks with Different Types of Winglet Vortex Generators. Energies. 2020; 13(19):5219. https://doi.org/10.3390/en13195219

Chicago/Turabian StyleShyu, Jin-Cherng, and Jhao-Siang Jheng. 2020. "Heat Transfer Enhancement of Plate-Fin Heat Sinks with Different Types of Winglet Vortex Generators" Energies 13, no. 19: 5219. https://doi.org/10.3390/en13195219

APA StyleShyu, J.-C., & Jheng, J.-S. (2020). Heat Transfer Enhancement of Plate-Fin Heat Sinks with Different Types of Winglet Vortex Generators. Energies, 13(19), 5219. https://doi.org/10.3390/en13195219