The Effect of Fracturing Fluid Saturation on Natural Gas Flow Behavior in Tight Reservoirs

Abstract

:1. Introduction

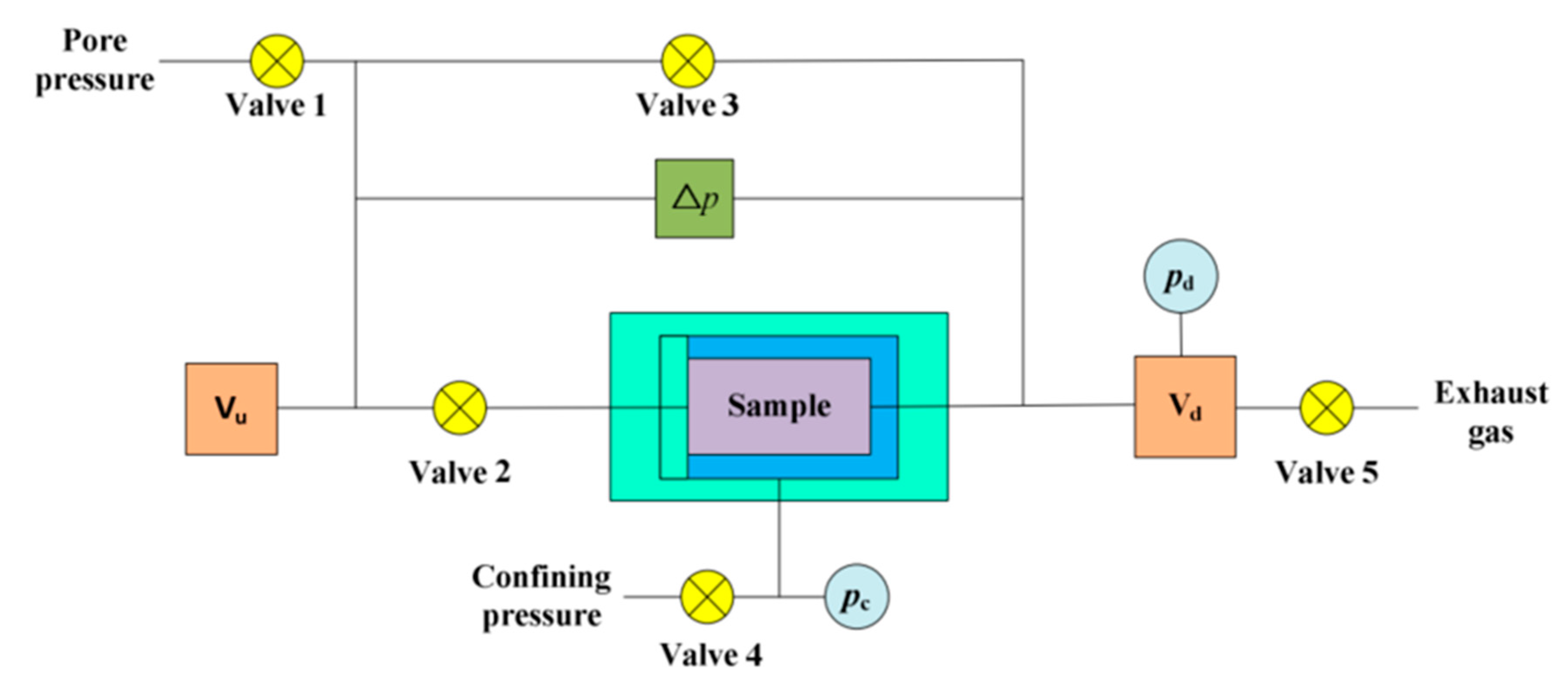

2. Samples and Experimental Methods

3. Results and Discussion

3.1. Some Basic Properties of Samples

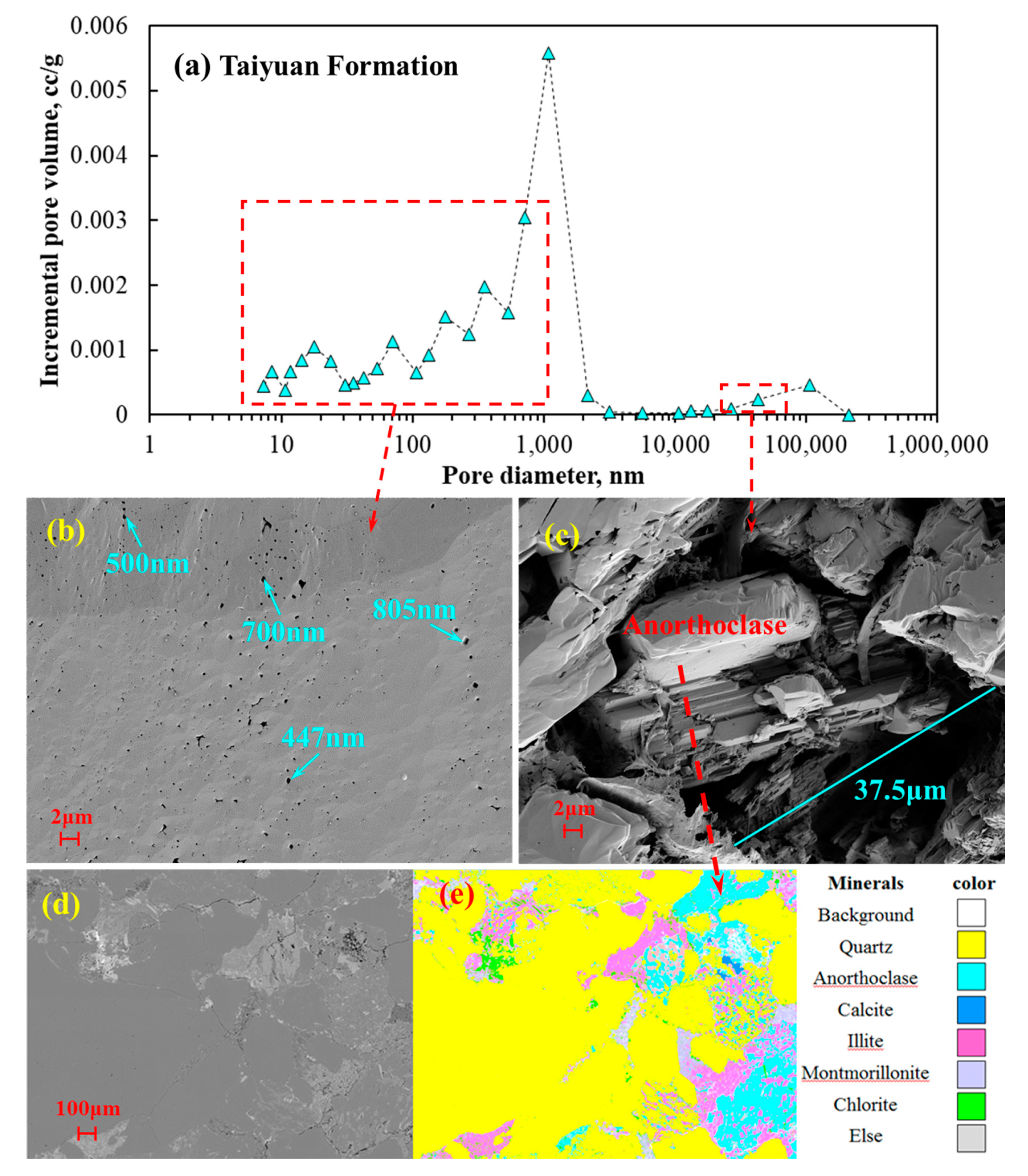

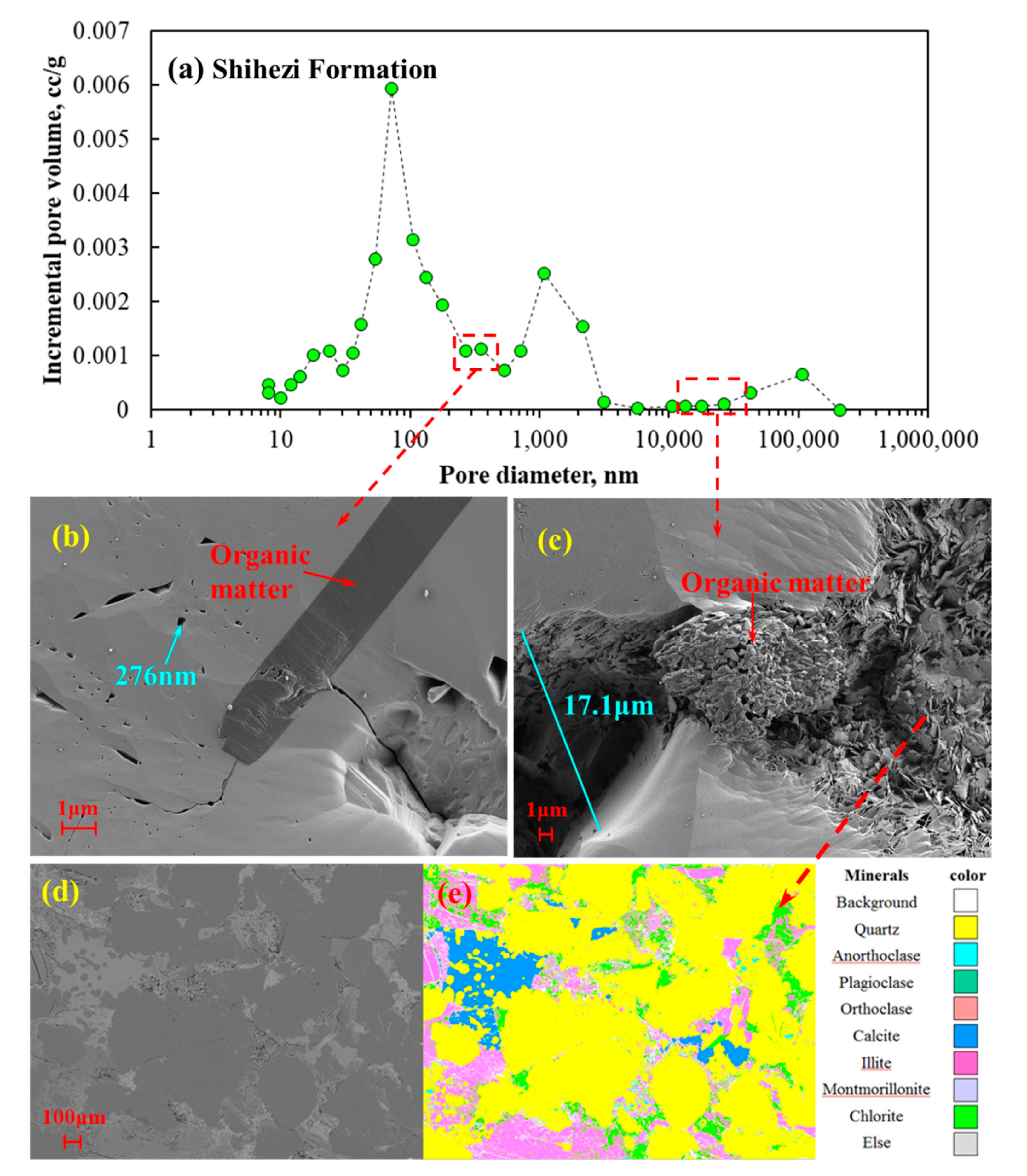

3.2. Pore Throat Size Distribution, SEM and QEMSCAN Analysis

3.3. Seepage Pore Size Distribution

3.4. Irreducible Water Saturation

3.5. Gas Relative Permeability

3.6. Flow Rate with Gradient Pressure at Different Water Saturations

3.6.1. Taiyuan Formation

3.6.2. Shihezi Formation

3.6.3. Comparison between These Two Formations

3.7. Comparison of Tight Sand Formation with Other Unconventional Formations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kang, Y.; Xu, C.; You, L.; Yu, H.; Zhang, B. Comprehensive evaluation of formation damage induced by working fluid loss in fractured tight gas reservoir. J. Nat. Gas Sci. Eng. 2014, 18, 353–359. [Google Scholar] [CrossRef]

- Lai, F.; Li, Z.; Wang, Y. Impact of water blocking in fractures on the performance of hydraulically fractured horizontal wells in tight gas reservoir. J. Pet. Sci. Eng. 2017, 156, 134–141. [Google Scholar] [CrossRef]

- Liang, X.; Zhou, F.; Liang, T.; Su, H.; Yuan, S.; Li, Y. Impacts of pore structure and wettability on distribution of residual fossil hydrogen energy after imbibition. Int. J. Hydrog. Energy 2020, 45, 14779–14789. [Google Scholar] [CrossRef]

- Li, C.; Singh, H.; Cai, J. Spontaneous imbibition in shale: A review of recent advances. Capilarity 2019, 2, 17–32. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Ge, H.; Zhang, X.; Chang, L.; Liu, D.; Liu, J. Impact of fracturing liquid absorption on the production and water-block unlocking for shale gas reservoir. Adv. Geo Energy Res. 2018, 2, 163–172. [Google Scholar] [CrossRef] [Green Version]

- Shen, W.; Li, X.; Cihan, A.; Lu, X.; Liu, X. Experimental and numerical simulation of water adsorption and diffusion in shale gas reservoir rocks. Adv. Geo Energy Res. 2019, 3, 165–174. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B.; Bennion, D.W.; Bietz, R.F. Mechanisms of Formation Damage and Permeability Impairment Associated With the Drilling, Completion and Production of Low API Gravity Oil Reservoirs. In Proceedings of the SPE International Heavy Oil Symposium, Society of Petroleum Engineers, Calgary, AB, Canada, 19–21 June 1995; pp. 689–707. [Google Scholar]

- Bennion, D.; Bietz, R.; Thomas, F.; Cimolai, M. Reductions in the Productivity of Oil And Low Permeability Gas Reservoirs Due to Aqueous Phase Trapping. J. Can. Pet. Technol. 1994, 33, 33. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B.; Ma, T. Formation Damage Processes Reducing Productivity of Low Permeability Gas Reservoirs. In Proceedings of the SPE Rocky Mountain Regional/Low-Permeability Reservoirs Symposium and Exhibition, Society of Petroleum Engineers, Denver, CO, USA, 12–15 March 2000; pp. 1–19. [Google Scholar]

- Kewen, L.; Abbas, F. Experimental Study of Wettability Alteration to Preferential Gas-Wetting in Porous Media and Its Effects. SPE Reserv. Evaluation Eng. 2000, 3, 139–149. [Google Scholar] [CrossRef]

- Tang, G.Q.; Firoozabadi, A. Wettability Alteration to Intermediate Gas-Wetting in Porous Media at Elevated Temperatures. Transp. Porous Media 2003, 52, 185–211. [Google Scholar] [CrossRef]

- Fahes, M.M.; Firoozabadi, A. Wettability Alteration ro Intermediate Gas-Wetting in Gas-Condensate Reservoirs at High Temperatures. In Proceedings of the SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers (SPE), Dallas, TX, USA, 9–12 October 2005; p. 14. [Google Scholar]

- Kim, J.; Gomaa, A.M.; Nelson, S.G.; Hudson, H.G. Engineering Hydraulic Fracturing Chemical Treatment to Minimize Water Blocks: A Simulated Reservoir-on-a-Chip Approach. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control; Society of Petroleum Engineers (SPE), Lafayette, LA, USA, 24–26 February 2016; p. 16. [Google Scholar]

- Liu, X.; Kang, Y.; Luo, P.; You, L.; Tang, Y.; Kong, L. Wettability modification by fluoride and its application in aqueous phase trapping damage removal in tight sandstone reservoirs. J. Pet. Sci. Eng. 2015, 133, 201–207. [Google Scholar] [CrossRef]

- Arshad, A.; Muhannad Talib, S.; Khalil, R.; Hassan, B.; Muhammad Khan, M. Reducing Mechanical Formation Damage by Minimizing Interfacial Tension and Capillary Pressure in Tight Gas. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2013; Volume 50, p. 12019. [Google Scholar]

- Bennion, D.; Thomas, F.; Bietz, R.; Bennion, D. Water and Hydrocarbon Phase Trapping In Porous Media-Diagnosis, Prevention And Treatment. J. Can. Pet. Technol. 1996, 35, 29–36. [Google Scholar] [CrossRef]

- Cimolai, M.P.; Gies, R.M.; Bennion, D.B.; Myers, D.L. Mitigating Horizontal Well Formation Damage in a Low-Permeability Conglomerate Gas Reservoir. In Proceedings of the SPE Gas Technology Symposium, Society of Petroleum Engineers, Calgary, AB, Canada, 28–30 June 1993; p. 11. [Google Scholar]

- Davis, B.B.J.; Wood, W.D. Maximizing Economic Return by Minimizing or Preventing Aqueous Phase Trapping During Completion and Stimulation Operations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers, New Orleans, LA, USA, 4–7 October 2004; pp. 1–8. [Google Scholar]

- You, L.; Kang, Y. Integrated Evaluation of Water Phase Trapping Damage Potential in Tight Gas Reservoirs. In Proceedings of the 8th European Formation Damage Conference; Society of Petroleum Engineers (SPE), Scheveningen, The Netherlands, 27–29 May 2009; pp. 1–10. [Google Scholar]

- Tian, J.; Kang, Y.; Luo, P.; You, L.; Zhang, D. A new method of water phase trapping damage evaluation on tight oil reservoirs. J. Pet. Sci. Eng. 2019, 172, 32–39. [Google Scholar] [CrossRef]

- Liu, N.; Yao, Y.; Junxiang, N.; Yin, P. Characteristics and low yield factors of H8 and Taiyuan Formation tight sandstone reservoir in the east of Ordos Basin, China. J. Chengdu Univ. Technol. Sci. Technol. Ed. 2015, 42, 435–443. (In Chinese) [Google Scholar]

- Xie, X.; Tang, H.; Meng, Y.; Li, G.; Zhao, F. The Application of Gas Bubble-pressure Method in the Study on Reservoir Pore Structures (Chinese Edition). J. Southwest Pet. Univ. Sci. Technol. Ed. 2009, 31, 17–20. [Google Scholar]

- McGuire, K.S.; Lawson, K.W.; Lloyd, D.R. Pore size distribution determination from liquid permeation through microporous membranes. J. Membr. Sci. 1995, 99, 127–137. [Google Scholar] [CrossRef]

- Jones, S. A Technique for Faster Pulse-Decay Permeability Measurements in Tight Rocks. SPE Form. Eval. 1997, 12, 19–26. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, A.M.M.; Bustin, R.M. Measurements of gas permeability and diffusivity of tight reservoir rocks: Different approaches and their applications. Geofluids 2009, 9, 208–223. [Google Scholar] [CrossRef]

- Brace, W.F.; Walsh, J.B.; Frangos, W.T. Permeability of granite under high pressure. J. Geophys. Res. 1968, 73, 2225–2236. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Li, L.; Tian, T.; Chao, J. The effect of clay-swelling induced cracks on shale permeability during liquid imbibition and diffusion. J. Nat. Gas Sci. Eng. 2020, 83, 103514. [Google Scholar] [CrossRef]

- Sheng, G.; Zhao, H.; Su, Y.; Javadpour, F.; Wang, C.; Zhou, Y.; Liu, J.; Wang, H. An analytical model to couple gas storage and transport capacity in organic matter with noncircular pores. Fuel 2020, 268, 117288. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Ji, W.; Wu, Y.; Xu, X.; Huang, W.; Li, Q.; Yu, J. Analyzing Tight Sand Characteristics and Its Influence on Aqueous Phase Removal by Gas Displacement. Geofluids 2019, 2019, 1–18. [Google Scholar] [CrossRef]

- Liu, Y.; Xian, C.; Li, Z.; Wang, J.; Ren, F. A new classification system of lithic-rich tight sandstone and its application to diagnosis high-quality reservoirs. Adv. Geo Energy Res. 2020, 4, 286–295. [Google Scholar] [CrossRef]

- Li, W.; Lu, S.; Xue, H.; Zhang, P.; Hu, Y. Microscopic pore structure in shale reservoir in the argillaceous dolomite from the Jianghan Basin. Fuel 2016, 181, 1041–1049. [Google Scholar] [CrossRef]

- Ji, W.; Song, Y.; Rui, Z.; Meng, M.; Huang, H. Pore characterization of isolated organic matter from high matured gas shale reservoir. Int. J. Coal Geol. 2017, 174, 31–40. [Google Scholar] [CrossRef]

- Huang, H.; Li, R.; Xiong, F.; Hu, H.; Sun, W.; Jiang, Z.; Chen, L.; Wu, L. A method to probe the pore-throat structure of tight reservoirs based on low-field NMR: Insights from a cylindrical pore model. Mar. Pet. Geol. 2020, 117, 104344. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, S.; Li, J.; Chang, X. 1D and 2D Nuclear magnetic resonance (NMR) relaxation behaviors of protons in clay, kerogen and oil-bearing shale rocks. Mar. Pet. Geol. 2020, 114, 104210. [Google Scholar] [CrossRef]

- Ji, W.; Hao, F.; Schulz, H.-M.; Song, Y.; Tian, J. The architecture of organic matter and its pores in highly mature gas shales of the lower Silurian Longmaxi Formation in the upper Yangtze platform, south China. AAPG Bull. 2019, 103, 2909–2942. [Google Scholar] [CrossRef]

- Hassanpouryouzband, A.; Joonaki, E.; Taghikhani, V.; Boozarjomehry, R.B.; Chapoy, A.; Tohidi, B. New Two-Dimensional Particle-Scale Model to Simulate Asphaltene Deposition in Wellbores and Pipelines. Energy Fuels 2018, 32, 2661–2672. [Google Scholar] [CrossRef]

- Goetz, D.; Knight, R.; Tercier, P. A Laboratory Procedure for Estimating Irreducible Water Saturation From Cuttings; SPWLA-1997-v38n2a4; Society of Petrophysicists and Well-Log Analysts: Houston, TX, USA, 1996; Volume 37, p. 7. [Google Scholar]

- Yang, Y.; Birmingham, T.J. Irreducible Water Saturation Has Been Determined as the Key Factor Governing Hydrocarbon Production From Low Permeability Carbonate at the Wattenberg Field in the Denver Julesburg Basin. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), Denver, CO, USA, 21–24 September 2008; p. 7. [Google Scholar]

- Bourdet, J.; Kempton, R. Novel Approach to Measuring Irreducible Water Salinity in Gas Reservoirs. In Proceedings of the Offshore Technology Conference-Asia, Kuala Lumpur, Malaysia, 25–28 March 2014; p. 8. [Google Scholar]

- Shanley, K.W.; Cluff, R.M.; Robinson, J.W. Factors controlling prolific gas production from low-permeability sandstone reservoirs: Implications for resource assessment, prospect development, and risk analysis. AAPG Bull. 2004, 88, 1083–1121. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Zhou, F.; Liang, T.; Wang, C.; Wang, J.; Yuan, S. Impacts of low harm fracturing fluid on fossil hydrogen energy production in tight reservoirs. Int. J. Hydrogen Energy 2020, 45, 21195–21204. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Hu, Q.; Li, L.; Gao, Z.; Tian, T.; Chao, J. The effect of clay-swelling induced cracks on imbibition behavior of marine shale reservoirs. J. Nat. Gas Sci. Eng. 2020, 83, 103525. [Google Scholar] [CrossRef]

| Samples | Length, mm | Diameter, mm | Porosity, % | Permeability, mD | Formation | Depth, m |

|---|---|---|---|---|---|---|

| TS1 | 54.61 | 25.33 | 9.02 | 0.385 | Taiyuan | 1983.0 |

| TS2 | 68.02 | 25.31 | 6.40 | 0.18 | Taiyuan | 2425.7 |

| TS3 | 66.76 | 25.32 | 3.40 | 0.075 | Taiyuan | 2456.0 |

| TS4 | 20.82 | 25.25 | 9.07 | 0.115 | Taiyuan | 2090.4 |

| TS5 | 13.55 | 25.25 | 5.3 | 0.07 | Taiyuan | 2454.9 |

| HS1 | 65.62 | 25.36 | 8.16 | 0.77 | Shihezi | 1660.2 |

| HS2 | 67.14 | 25.34 | 2.25 | 0.057 | Shihezi | 2519.7 |

| HS3 | 60.17 | 25.28 | 13.56 | 2.147 | Shihezi | 3225.4 |

| HS4 | 20.74 | 25.24 | 9.7 | 0.19 | Shihezi | 2449.5 |

| HS5 | 19.78 | 25.27 | 5.98 | 0.787 | Shihezi | 2522.0 |

| HS6 | 24.92 | 25.26 | 9.11 | 0.244 | Shihezi | 2581.0 |

| HS7 | 23.22 | 25.36 | 13.77 | 0.158 | Shihezi | 3198.2 |

| Taiyuan Formation | Shihezi Formation | |||

|---|---|---|---|---|

| Minerals | Weight (%) | Area (%) | Weight (%) | Area (%) |

| Quartz | 69.94 | 68.71 | 66.45 | 64.66 |

| Anorthoclase | 12.73 | 12.7 | 1.71 | 1.69 |

| Plagioclase | 0.01 | 0.01 | 0 | 0 |

| Orthoclase | 1.07 | 1.08 | 0 | 0 |

| Calcite | 0.2 | 0.19 | 5.72 | 5.39 |

| Illite | 11.16 | 10.44 | 15.28 | 14.16 |

| Montmorillonite | 2.02 | 2.22 | 0.27 | 0.3 |

| Chlorite | 2.67 | 2.15 | 10.02 | 7.98 |

| Else | 0.19 | 2.5 | 0.55 | 5.82 |

| Temperature | Saturated Liquid | Saturated Method | Testing Gas | Gas Pressure | Confining Pressure |

|---|---|---|---|---|---|

| 25 °C | Distilled water | Rolling on a wet cloth | Nitrogen | 5 MPa | 7 MPa |

| Temperature | Saturated Liquid | Saturated Method | Testing Gas | Minimum Displacing Pressure | Maximum Displacing Pressure | Confining Pressure |

|---|---|---|---|---|---|---|

| 25 °C | Distilled water | Rolling on a wet cloth | Nitrogen | 0.1 MPa/cm | 3.6 MPa/cm | 5 MPa/cm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, M.; Shen, Y.; Ge, H.; Xu, X.; Wu, Y. The Effect of Fracturing Fluid Saturation on Natural Gas Flow Behavior in Tight Reservoirs. Energies 2020, 13, 5278. https://doi.org/10.3390/en13205278

Meng M, Shen Y, Ge H, Xu X, Wu Y. The Effect of Fracturing Fluid Saturation on Natural Gas Flow Behavior in Tight Reservoirs. Energies. 2020; 13(20):5278. https://doi.org/10.3390/en13205278

Chicago/Turabian StyleMeng, Mianmo, Yinghao Shen, Hongkui Ge, Xiaosong Xu, and Yang Wu. 2020. "The Effect of Fracturing Fluid Saturation on Natural Gas Flow Behavior in Tight Reservoirs" Energies 13, no. 20: 5278. https://doi.org/10.3390/en13205278

APA StyleMeng, M., Shen, Y., Ge, H., Xu, X., & Wu, Y. (2020). The Effect of Fracturing Fluid Saturation on Natural Gas Flow Behavior in Tight Reservoirs. Energies, 13(20), 5278. https://doi.org/10.3390/en13205278