Adaptive Takagi–Sugeno Fuzzy Model Predictive Control for Permanent Magnet Synchronous Generator-Based Hydrokinetic Turbine Systems

Abstract

:1. Introduction

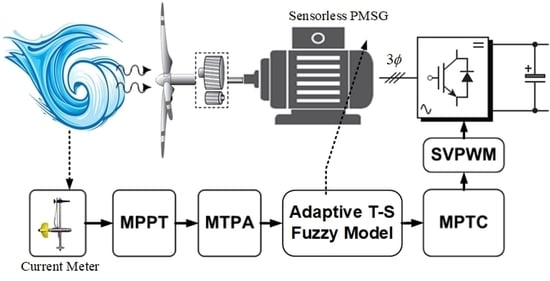

2. Problem Formulation

2.1. Tidal Turbine Model

2.2. Permanent Magnet Synchronous Generator Model

3. Adaptive Takagi–Sugeno Fuzzy Model Predictive Controller Design

3.1. Stator Flux Reference Value Estimation

3.2. Adaptive Takagi–Sugeno Fuzzy Model

3.3. Model Predictive Torque Control

4. Simulation Results and Discussion

4.1. Case 1. Northwest European Shelf Tidal Current Speed Profile

4.2. Case 2. Pentland Firth Tidal Current Speed Profile

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Definition |

| Hydrokinetic power (W) | |

| Ocean density | |

| Cross sectional area of the turbine through water flows | |

| Blade radius | |

| Tidal current speed | |

| Power coefficient | |

| Tip speed ratio | |

| Pitch angle of the turbine (deg) | |

| Generator mechanical rotation speed | |

| Electrical generator rotation speed | |

| Mechanical reference rotation speed | |

| Optimal blade tip speed ratio | |

| Maximum power coefficient | |

| d-axis and q-axis voltages (V) | |

| d-axis and q-axis currents (A) | |

| d-axis and q-axis reference currents by MTPA (A) | |

| , | d-axis and q-axis stator flux linkages |

| Stator reference flux linkage | |

| d-axis and q-axis stator inductances (H) | |

| Overall rotor inertia | |

| Viscous friction coefficient | |

| Mechanical torque | |

| Electromagnetic torque | |

| PI control gains | |

| T–S fuzzy model | |

| Estimated error of adaptive T–S fuzzy model | |

| Switching state of phase | |

| Switching vector | |

| Inverter voltage vectors | |

| Number of pole pairs |

References

- Sönnichsen, N. Global Outlook on Electricity Generation by Energy Source 2018–2050. In Statista—The Statistics Portal; UNH Library: Durham, NH, USA, 2020. [Google Scholar]

- International Renewable Energy Agency (IRENA). Renewable Capacity Highlights. In IRENA’s Renewable Energy Statistics; IRENA: Abu Dhabi, UAE, 2020; ISBN 978-92-9260-246-8. [Google Scholar]

- Boretti, A. State-of-the-Art of MW-Level Capacity Oceanic Current Turbines. In Nonlinear Engineering; De Gruyter: Berlin, Germany, 2020; Volume 9, pp. 361–369. [Google Scholar]

- Ministry of Economic Affairs (MOEA). Renewable Energy Development Act. Available online: https://law.moj.gov.tw/ENG/LawClass/LawAll.aspx?pcode=J0130032 (accessed on 25 September 2020).

- Taiwan Power Company. Sustainable Power, Caring Forever. In Taiwan Power Company Sustainability Report; Taiwan Power Company: Taipei, Taiwan, 2018. [Google Scholar]

- Hsing, H.C.; Lee, H.I. Comprehensive Overview of Renewable Energy Development in Taiwan. Renew. Sustain. Energy Rev. 2014, 37, 215–228. [Google Scholar]

- Wong, S. Annual Electricity Generation from Pumped Storage and Conventional Hydropower in Taiwan from 2008 to 2018. In Statista—The Statistics Portal; UNH Library: Durham, NH, USA, 2020. [Google Scholar]

- Guner, F.; Zenk, H. Experimental, Numerical and Application Analysis of Hydrokinetic Turbine Performance with Fixed Rotating Blades. Energies 2020, 13, 766. [Google Scholar] [CrossRef] [Green Version]

- Rajabpour, L.; Shasadeghi, M.; Barzegar, A. Design of Robust H∞ Fuzzy Output Feedback Controller for Affine Nonlinear Systems: Fuzzy Lyapunov Function Approach. Int. J. Adv. Intell. Parad. 2019, 14, 328–344. [Google Scholar]

- Casadei, D.; Profumo, F.; Serra, G.; Tani, A. FOC and DTC: Two Viable Schemes for Induction Motors Torque Control. IEEE Trans. Power Electron. 2002, 17, 779–787. [Google Scholar] [CrossRef] [Green Version]

- Nasr, A.; Gu, C.; Bozhko, S.; Gerada, C. Performance Enhancement of Direct Torque-Controlled Permanent Magnet Synchronous Motor with a Flexible Switching Table. Energies 2020, 13, 1907. [Google Scholar] [CrossRef] [Green Version]

- Morales-Caporal, R.; Bonilla-Huerta, M.E.; Arjona, A.; Hernandez, C. Sensorless Predictive DTC of a Surface-Mounted Permanent-Magnet Synchronous Machine Based on Its Magnetic Anisotropy. IEEE Trans. Ind. Electron. 2013, 60, 3016–3024. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, L. Modeling and Control of the PMSG Wind Generation System with A Novel Controller. In Proceedings of the 3th IEEE International Conference on Intelligent System Design and Engineering Applications, Hong Kong, China, 16–18 January 2013; pp. 946–949. [Google Scholar]

- Kim, Y.S.; Chung, I.Y.; Moon, S.I. Tuning of the PI Controller Parameters of a PMSG Wind Turbine to Improve Control Performance under Various Wind Speeds. Energies 2015, 8, 1406–1425. [Google Scholar] [CrossRef] [Green Version]

- Errouissi, R.; AI-Durra, A.; Debouza, M. A Novel Design of PI Current Controller for PMSG-Based Wind Turbine Considering Transient Performance Specifications and Control Saturation. IEEE Trans. Ind. Electron. 2018, 65, 8624–8634. [Google Scholar] [CrossRef]

- Yang, B.; Yu, T.; Shu, H.; Han, Y.; Cao, P.; Jiang, L. Adaptive Fractional-Order PID Control of PMSG-Based Wind Energy Conversion System for MPPT Using Linear Observers. Int. Trans. Electr. Energy Syst. 2019, 29, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Benelghali, S. Experimental Validation of a Marine Current Turbine Simulator: Application to a Permanent Magnet Synchronous Generator-Based System Second-Order Sliding Mode Control. IEEE Trans. Ind. Electr. 2011, 58, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Pourebrahim, R.; Tohidi, S.; Younesi, A. Sensorless Model Reference Adaptive Control of DFIG by Using High Frequency Signal Injection and Fuzzy Logic Control. Iran. J. Electr. Electr. Eng. 2018, 14, 11–21. [Google Scholar]

- Pathak, K.B.; Adhyaru, D.M. Performance Analysis of Lyapunov Stability-Based and ANFIS-Based MRAC. Int. J. Comput. Syst. Eng. 2019, 5, 119–127. [Google Scholar] [CrossRef]

- M’zoughi, F.; Garrido, I.; Garrido, A.J.; De La Sen, M. Self-Adaptive Global-Best Harmony Search Algorithm-Based Airflow Control of a Wells-Turbine-Based Oscillating-Water Column. Appl. Sci. 2020, 10, 4628. [Google Scholar] [CrossRef]

- Song, S.K.; Park, J.B. Control Strategy of an Impulse Turbine for an Oscillating Water Column-Wave Energy Converter in Time-Domain Using Lyapunov Stability Method. Appl. Sci. 2016, 6, 281. [Google Scholar] [CrossRef] [Green Version]

- Geyer, T.; Papafotiou, G.; Morari, M. Model Predictive Direct Torque Control-Part I: Concept, Algorithm, and Analysis. IEEE Trans. Ind. Electr. 2009, 56, 1894–1905. [Google Scholar] [CrossRef]

- Singh, M.; Chandra, A. Application of Adaptive Network-Based Fuzzy Inference System for Sensorless Control of PMSG-Based Wind Turbine with Nonlinear-Load-Compensation Capabilities. IEEE Trans. Power Electr. 2011, 26, 165–175. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, W.; Jiang, Z.; Pan, L.; Lei, M. Adaptive Backstepping Control for Maximizing Marine Current Power Generation Based on Uncertainty and Disturbance Estimation. Electr. Power Energy Syst. 2020, 117, 1–11. [Google Scholar] [CrossRef]

- Hussain, S.; Bazaz, M.A. Modified SVPWM Technique for a Sensorless Controlled Induction Motor Drive Using Neural Network Observer and Predictive Controller. Int. J. Adv. Intell. Parad. 2020, 16, 172–189. [Google Scholar] [CrossRef]

- Boldea, I. The Electric Generators Handbook: Synchronous Generators; Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2006. [Google Scholar]

- Abdelrahem, M.; Hackl, C.M.; Kennel, R. Implementation and Experimental Investigation of a Sensorless Field-Oriented Control Scheme for Permanent-Magnet Synchronous Generato. Electr. Eng. 2018, 100, 849–856. [Google Scholar] [CrossRef]

- Shahriari, S.A.A.; Raoofat, M.; Dehghani, M.; Mohammadi, M.; Saad, M. Dynamic State Estimation of a Permanent Magnet Synchronous Generator-Based Wind Turbine. IET Renew. Power Gener. 2016, 10, 1278–1286. [Google Scholar] [CrossRef]

- Urbanski, K.; Janiszewski, D. Sensorless Control of the Permanent Magnet Synchronous Motor. Sensors 2019, 19, 3546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koutroulis, E.; Kalaitzakis, K. Design of a Maximum Power Tracking System for Wind-Energy-Conversion Applications. IEEE Trans. Ind. Electr. 2006, 53, 486–494. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Model Predictive Direct Torque Control with Finite Control Set for PMSM Drive Systems, Part 1: Maximum Torque per Ampere Operation. IEEE Trans. Ind. Inf. 2013, 9, 1912–1921. [Google Scholar] [CrossRef]

- Chica, E.; Clemente, A.R. Design of Zero Head Turbines for Power Generation. In Renewable Hydropower Technologies; IntechOpen: London, UK, 2017; pp. 25–52. [Google Scholar] [CrossRef] [Green Version]

- Elzalabani, M.M.; Fahmy, F.H.; Nafeh, A.E.A.; Allam, G. Modelling and Simulation of Tidal Current Turbine with Permanent Magnet Synchronous Generator. Indones. J. Electr. Eng. 2015, 13, 57–64. [Google Scholar] [CrossRef]

- Chica, E.; Perez, F.; Clemente, A.R.; Agudelo, S. Design of a Hydrokinetic Turbine. WIT Trans. Ecol. Environ. 2015, 195, 137–148. [Google Scholar]

- Kumar, R.; Das, S. Model Reference Adaptive System-Based Sensorless Speed Control of Grid-Connected Doubly Fed Induction Generator in Wind Energy Conversion System. Iran. J. Sci. Technol. Trans. Electr. Eng. 2020, 44, 129–140. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B. Model Predictive Control of Wind Energy Conversion Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Robins, P.E.; Neill, S.P.; Lewis, M.J.; Ward, S.L. Characterising the Spatial and Temporal Variability of the Tidal-Stream Energy Resource Over the Nourthwest European Shelf Seas. Appl. Energy 2015, 147, 510–552. [Google Scholar] [CrossRef] [Green Version]

- Molen, J.V.D.; Ruardij, P.; Greenwood, N. Potential Environmental Impact of Tidal Energy Extraction in the Pentland Firth at Latge Spatial Scales: Results of a Biogeochemical Model. Biogeosciences 2016, 13, 2593–2609. [Google Scholar]

| Symbol | Quantity | Value |

|---|---|---|

| Phase resistance | ||

| Stator d-axis and q-axis inductances | H | |

| Number of pole pairs | ||

| Magnet flux linkage | ||

| DC bus voltage | 200 V | |

| Moment of overall inertia | kgm2 | |

| Viscous friction coefficient | N m/s | |

| The distance of blade radius | m | |

| The density of ocean | kg/m3 | |

| Rotor blade area | m2 |

| Item | ATSFMPC | PI |

|---|---|---|

| Average DC-Link Voltage (V) | 199.7241 | 199.6719 |

| Relative Error of DC-Link Voltage (RMS) | 1.0139 | 6.4472 |

| Item | ATSFMPC | PI |

|---|---|---|

| Average DC-Link Voltage (V) | 199.4414 | 199.4224 |

| Relative Error of DC-Link Voltage (RMS) | 0.9120 | 6.0544 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-C.; Balas, V.E.; Yang, J.-F.; Chang, Y.-H. Adaptive Takagi–Sugeno Fuzzy Model Predictive Control for Permanent Magnet Synchronous Generator-Based Hydrokinetic Turbine Systems. Energies 2020, 13, 5296. https://doi.org/10.3390/en13205296

Lin Y-C, Balas VE, Yang J-F, Chang Y-H. Adaptive Takagi–Sugeno Fuzzy Model Predictive Control for Permanent Magnet Synchronous Generator-Based Hydrokinetic Turbine Systems. Energies. 2020; 13(20):5296. https://doi.org/10.3390/en13205296

Chicago/Turabian StyleLin, Yu-Chen, Valentina Emilia Balas, Ji-Fan Yang, and Yu-Heng Chang. 2020. "Adaptive Takagi–Sugeno Fuzzy Model Predictive Control for Permanent Magnet Synchronous Generator-Based Hydrokinetic Turbine Systems" Energies 13, no. 20: 5296. https://doi.org/10.3390/en13205296