Adaptive Control of Fuel Cell and Supercapacitor Based Hybrid Electric Vehicles

Abstract

:1. Introduction

- Efficient power distribution between the fuel cell and supercapacitor is done in order to improve the efficiency of the HEV under varying load conditions.

- Slowly-varying converter model parameters are estimated using adaptive update laws such thatthe controller updates itself by keeping in mind parametric variations.

- Proposed nonlinear controllers, including the Lyapunov-based adaptive controller and adaptive backstepping controller, do not need exact model parameters. These controllers can cater to slowly-varying parametric variations and uncertainties.

- The proposed system has been tested on experimental data from the Extra Urban Driving Cycle (EUDC). The physical effectiveness of the proposed system was validated using real-time controller hardware in the loop experiments.

- The proposed nonlinear controllers converge tracking errors to zero.

- HESS was proven to be globally asymptotically stable using a Lyapunov-based stability criterion.

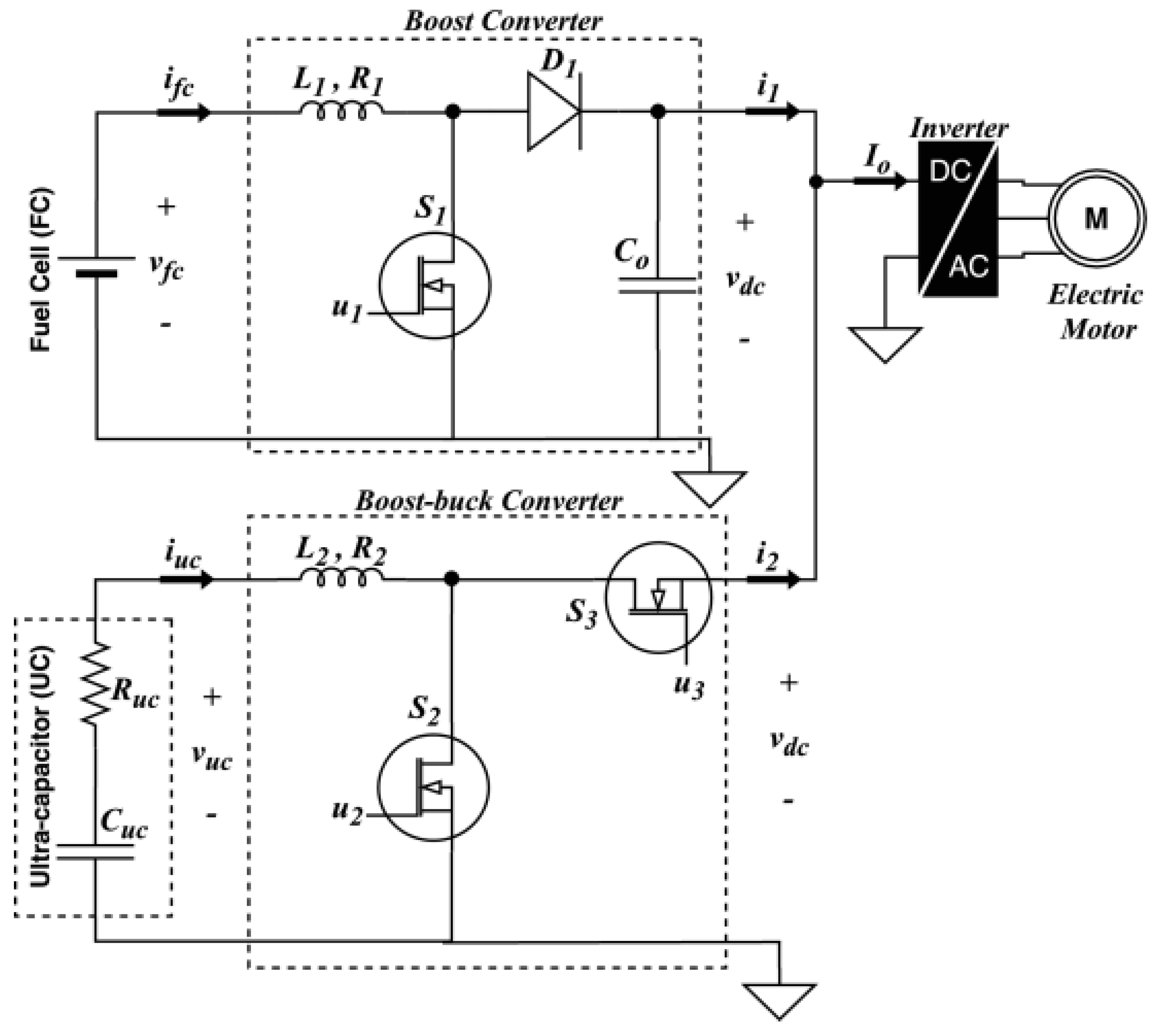

2. The Hybrid Energy Storage System Modeling

2.1. Fuel Cell—Boost Converter Model

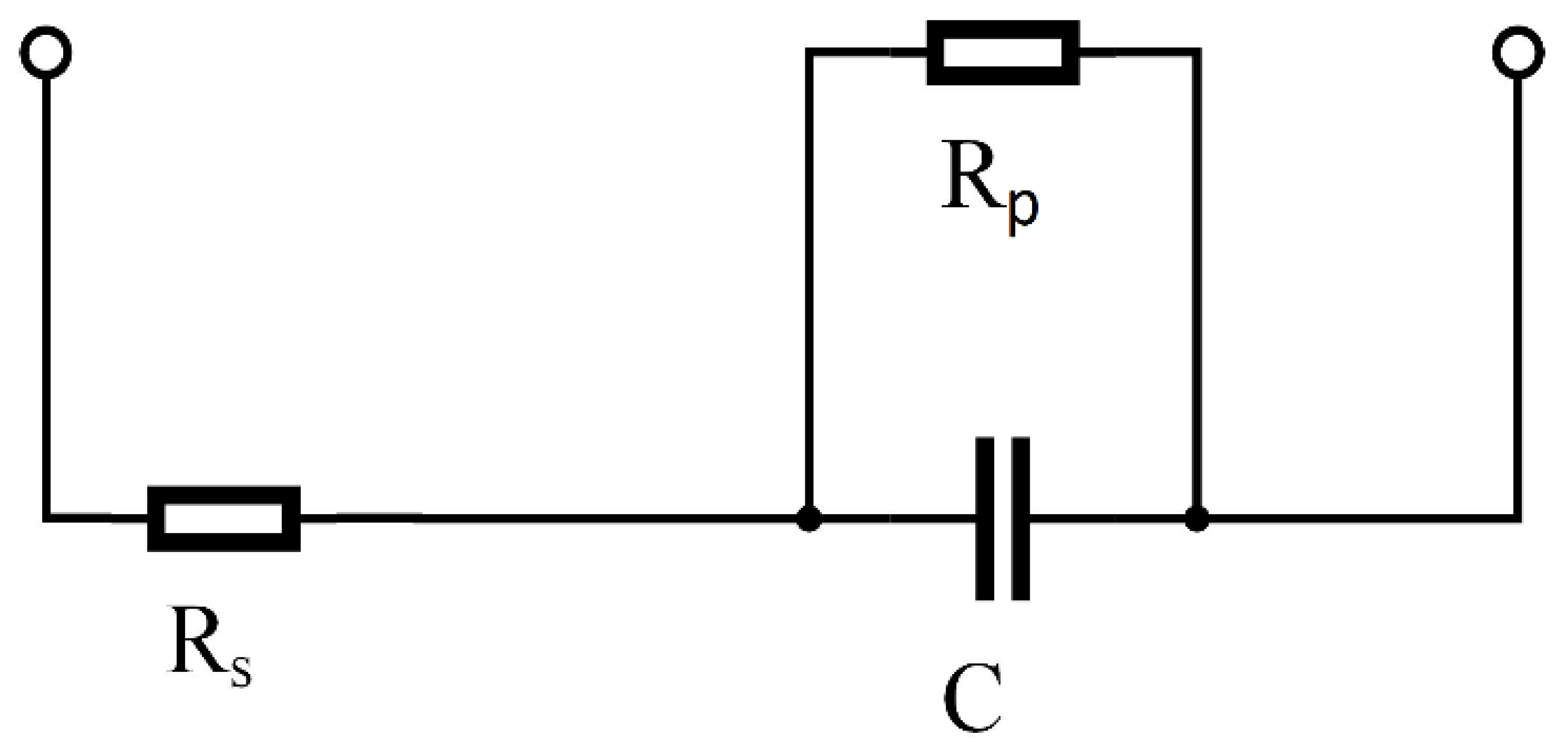

2.2. Supercapacitor—Boost-Buck Converter Model

2.3. Combined Dynamical Model for HEV

3. Controller Design for HEV

3.1. The Power Distribution Strategy for HEV

- = required load power (kW);

- = reference power of fuel cell (kW);

- = reference power of supercapacitor (kW);

- comes from remaining load power required (kW);

- reference current for fuel cell (A);

- reference current for supercapacitor (A).

- The fuel cell works most of the time during low power demands. The remaining power is used to charge the supercapacitor. The charging and discharging of supercapacitor are done according to load requirements.

- During high power demands, the fuel cell is supported by the supercapacitor, for a short period of time, in order to meet high power requirements.

3.1.1. Lyapunov-Based Adaptive Controller Design

3.1.2. Backstepping-Based Adaptive Controller Design

4. Results and Discussion

4.1. MATLAB Simulation Results

4.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heydari, S.; Fajri, P.; Rasheduzzaman, M.; Sabzehgar, R. Maximizing Regenerative Braking Energy Recovery of Electric Vehicles Through Dynamic Low-Speed Cutoff Point Detection. IEEE Trans. Transp. Electrif. 2019, 5, 262–270. [Google Scholar] [CrossRef]

- Reimers, J.; Dorn-Gomba, L.; Mak, C.; Emadi, A. Automotive Traction Inverters: Current Status and Future Trends. IEEE Trans. Veh. Technol. 2019, 68, 3337–3350. [Google Scholar] [CrossRef]

- Sumathi, P.; Azhagumurugan, R. Novel modular multiple input bi-directional dc-dc power converter using fuzzy network for HEV/FCV application. In Proceedings of the 2016 International Conference on Computation of Power, Energy Information and Commuincation (ICCPEIC), Chennai, India, 20–21 April 2016; pp. 439–444. [Google Scholar]

- Joshi, M.C.; Samanta, S.; Srungavarapu, G. Battery ultracapacitor based DC motor drive for electric vehicles. In Proceedings of the 2017 IEEE Region 10 Symposium (TENSYMP), Cochin, India, 14–16 July 2017; pp. 1–5. [Google Scholar]

- Fadil, H.E.; Giri, F.; Guerrero, J.M.; Tahri, A. Modeling and Nonlinear Control of a Fuel Cell/Supercapacitor Hybrid Energy Storage System for Electric Vehicles. IEEE Trans. Veh. Technol. 2014, 63, 3011–3018. [Google Scholar] [CrossRef] [Green Version]

- Lai, C.M.; Lee, D.; Cheng, Y.H.; Cheng, C.C. An integrated two-input three-output DC/DC boost converter with fuel-cell/battery energy resources for HEV and DC-distribution system. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Busan, Korea, 1–4 June 2016; pp. 370–374. [Google Scholar]

- Li, Y.; Yang, D.; Ruan, X. A systematic method for generating multiple-input dc/dc converters. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar]

- Zhang, R.; Tao, J.; Zhou, H. Fuzzy Optimal Energy Management for Fuel Cell and Supercapacitor Systems Using Neural Network Based Driving Pattern Recognition. IEEE Trans. Fuzzy Syst. 2019, 27, 45–57. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Yufit, V.; Campbell, J.; Offer, G.J.; Martinez-Botas, R.F.; Brandon, N.P. Simulated and experimental validation of a fuel cell-supercapacitor passive hybrid system for electric vehicles. In Proceedings of the IET Hybrid and Electric Vehicles Conference 2013 (HEVC 2013), London, UK, 6–7 November 2013; pp. 1–6. [Google Scholar]

- Kim, Y.; Raghunathan, V.; Raghunathan, A. Design and Management of Battery-Supercapacitor Hybrid Electrical Energy Storage Systems for Regulation Services. IEEE Trans. Multi Scale Comput. Syst. 2017, 3, 12–24. [Google Scholar] [CrossRef]

- Xu, D.; Liu, Q.; Yan, W.; Yang, W. Adaptive Terminal Sliding Mode Control for Hybrid Energy Storage Systems of Fuel Cell, Battery and Supercapacitor. IEEE Access 2019, 7, 29295–29303. [Google Scholar] [CrossRef]

- Ahrabi, R.R.; Ardi, H.; Elmi, M.; Ajami, A. A Novel Step-Up Multiinput DC–DC Converter for Hybrid Electric Vehicles Application. IEEE Trans. Power Electron. 2017, 32, 3549–3561. [Google Scholar] [CrossRef]

- Marchesoni, M.; Vacca, C. New DC–DC Converter for Energy Storage System Interfacing in Fuel Cell Hybrid Electric Vehicles. IEEE Trans. Power Electron. 2007, 22, 301–308. [Google Scholar] [CrossRef]

- Lu, X.; Chen, Y.; Fu, M.; Wang, H. Multi-Objective Optimization-Based Real-Time Control Strategy for Battery/Ultracapacitor Hybrid Energy Management Systems. IEEE Access 2019, 7, 11640–11650. [Google Scholar] [CrossRef]

- Nguyen, B.; German, R.; Trovão, J.P.F.; Bouscayrol, A. Real-Time Energy Management of Battery/Supercapacitor Electric Vehicles Based on an Adaptation of Pontryagin’s Minimum Principle. IEEE Trans. Veh. Technol. 2019, 68, 203–212. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.; Wang, J.; Shen, W.; Shi, D.; Huang, Y. Controllable regenerative braking process for hybrid battery–ultracapacitor electric drive systems. IET Power Electron. 2018, 11, 2507–2514. [Google Scholar] [CrossRef]

- Olama, A.; Mendes, P.R.C.; Camacho, E.F. Lyapunov-based hybrid model predictive control for energy management of microgrids. Transm. Distrib. IET Gener. 2018, 12, 5770–5780. [Google Scholar] [CrossRef]

- López-Pérez, M.; Claudio-Sánchez, A.; Cano-Castillo, U.; Loyola-Morales, F. Hybrid electric power plant sizing strategy based on ab-initio fuel cell design for weight minimization. Int. J. Hydrog. Energy 2020, 45, 21738–21753. [Google Scholar] [CrossRef]

- Lai, C.M.; Lin, Y.J.; Hsieh, M.H.; Li, J.T. A newly-designed multiport bidirectional power converter with battery/supercapacitor for hybrid electric/fuel-cell vehicle system. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Busan, Korea, 1–4 June 2016; pp. 163–166. [Google Scholar]

- Boulon, L.; Pera, M.C.; Hissel, D.; Bouscayrol, A.; Delarue, P. Energetic Macroscopic Representation of a Fuel Cell-Supercapacitor System. In Proceedings of the 2007 IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 290–297. [Google Scholar]

- Tani, A.; Camara, M.B.; Dakyo, B.; Azzouz, Y. DC/DC and DC/AC Converters Control for Hybrid Electric Vehicles Energy Management-Ultracapacitors and Fuel Cell. IEEE Trans. Ind. Informa. 2013, 9, 686–696. [Google Scholar] [CrossRef]

- Burke, A.F. Batteries and Ultracapacitors for Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 806–820. [Google Scholar] [CrossRef]

- Tani, A.; Camara, M.B.; Dakyo, B.; Azzouz, Y. Embedded energy management based on DC/DC converters—Ultracapacitors and Fuel Cell. In Proceedings of the 2012 IEEE International Conference on Industrial Technology, Athens, Greece, 19–21 March 2012; pp. 198–204. [Google Scholar]

- Armghan, H.; Ahmad, I.; Ali, N.; Munir, M.F.; Khan, S.; Armghan, A. Nonlinear Controller Analysis of Fuel Cell–Battery–Ultracapacitor-based Hybrid Energy Storage Systems in Electric Vehicles. Arab. J. Sci. Eng. 2018, 43, 3123–3133. [Google Scholar] [CrossRef]

- Khan, M.S.; Ahmad, I.; Armaghan, H.; Ali, N. Backstepping sliding mode control of FC-UC based hybrid electric vehicle. IEEE Access 2018, 6, 77202–77211. [Google Scholar] [CrossRef]

- Rahman, A.U.; Ahmad, I.; Malik, A.S. Variable structure-based control of fuel cell-supercapacitor-battery based hybrid electric vehicle. J. Energy Storage 2020, 29, 101365. [Google Scholar] [CrossRef]

- Redman-White, W.; Kennedy, H.; Bodnar, R.; Lee, T. Adaptive Tuning of Large-Signal Resonant Circuits Using Phase-Switched Fractional Capacitance. IEEE Trans. Circuits Syst. II Express Briefs 2017, 64, 1072–1076. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Deng, W.; Li, G. Stochastic Control of Predictive Power Management for Battery/Supercapacitor Hybrid Energy Storage Systems of Electric Vehicles. IEEE Trans. Ind. Inform. 2018, 14, 3023–3030. [Google Scholar] [CrossRef]

- Lee, H.; Fu, L.; Lian, F. Sensorless Adaptive Backstepping Speed Control of Induction Motor. In Proceedings of the 45th IEEE Conference on Decision and Control, San Diego, CA, USA, 13–15 December 2006; pp. 1252–1257. [Google Scholar]

- Chavan, S.L.; Talange, D.B. Electrical equivalent circuit modeling and parameter estimation for PEM fuel cell. In Proceedings of the 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 21–22 April 2017; pp. 1–6. [Google Scholar]

- Khan, S.S.; Rafiq, M.A.; Shareef, H.; Sultan, M.K. Parameter optimization of PEMFC model using backtracking search algorithm. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (ICREGA), Al Ain, United Arab Emirates, 25–28 February 2018; pp. 323–326. [Google Scholar]

- Sahu, P.; Verma, D.; Nema, S. Physical design and modelling of boost converter for maximum power point tracking in solar PV systems. In Proceedings of the 2016 International Conference on Electrical Power and Energy Systems (ICEPES), Bhopal, India, 14–16 December 2016; pp. 10–15. [Google Scholar]

- Kai, W.; Baosen, R.; Liwei, L.; Yuhao, L.; Hongwei, Z.; Zongqiang, S. A review of modeling research on supercapacitor. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; pp. 5998–6001. [Google Scholar]

- Zhang, L.; Ye, X.; Xia, X.; Barzegar, F. A real-time energy management and speed controller for an electric vehicle powered by a hybrid energy storage system. IEEE Trans. Ind. Inform. 2020, 16, 6272–6280. [Google Scholar] [CrossRef]

- Jiang, B.; Xu, D.; Shi, P.; Lim, C.C. Adaptive neural observer-based backstepping fault tolerant control for near space vehicle under control effector damage. IET Control. Theory Appl. 2014, 8, 658–666. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.; Huang, Y.; Gao, H.; Kaynak, O. Transient-Performance-Guaranteed Robust Adaptive Control and Its Application to Precision Motion Control Systems. IEEE Trans. Ind. Electron. 2016, 63, 6510–6518. [Google Scholar] [CrossRef]

- Xu, D.; Jiang, B.; Shi, P. Adaptive Observer Based Data-Driven Control for Nonlinear Discrete-Time Processes. IEEE Trans. Autom. Sci. Eng. 2014, 11, 1037–1045. [Google Scholar] [CrossRef] [Green Version]

- Krstić, M.; Kanellakopoulos, I.; Kokotović, P.V. Nonlinear and Adaptive Control Design Volume 7 of Adaptive and Learning Systems for Signal Processing, Communications, and Control; Wiley: Hoboken, NJ, USA, 1995. [Google Scholar]

- Rosa, A.H.; Silva, M.B.; Campos, M.F.; Santana, R.A.; Rodrigues, W.A.; Morais, L.M. Shil and dhil simulations of nonlinear control methods applied for power converters using embedded systems. Electronics 2018, 7, 241. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazir, M.S.; Ahmad, I.; Khan, M.J.; Ayaz, Y.; Armghan, H. Adaptive Control of Fuel Cell and Supercapacitor Based Hybrid Electric Vehicles. Energies 2020, 13, 5587. https://doi.org/10.3390/en13215587

Nazir MS, Ahmad I, Khan MJ, Ayaz Y, Armghan H. Adaptive Control of Fuel Cell and Supercapacitor Based Hybrid Electric Vehicles. Energies. 2020; 13(21):5587. https://doi.org/10.3390/en13215587

Chicago/Turabian StyleNazir, Muhammad Saqib, Iftikhar Ahmad, Muhammad Jawad Khan, Yasar Ayaz, and Hammad Armghan. 2020. "Adaptive Control of Fuel Cell and Supercapacitor Based Hybrid Electric Vehicles" Energies 13, no. 21: 5587. https://doi.org/10.3390/en13215587

APA StyleNazir, M. S., Ahmad, I., Khan, M. J., Ayaz, Y., & Armghan, H. (2020). Adaptive Control of Fuel Cell and Supercapacitor Based Hybrid Electric Vehicles. Energies, 13(21), 5587. https://doi.org/10.3390/en13215587