Energetic and Economic Analyses of an LCPV/T Solar Hybrid Plant for a Sports Center Building in Mexico

Abstract

:1. Introduction

2. Materials and Methods

2.1. Transient Energy Modeling

2.2. Economic and Environmental Analyses

- The term Eeq denotes the annual equivalent electricity produced by the hybrid plant considering the conversion factor from heat to electricity to be 0.55 [5];

- A commercial electricity price inflation rate of 8%, (average in Mexico [22]);

- A local discount rate d of 5% (reported by the National Bank of Mexico);

- An electricity production annual derate D of 1%.

- The term Qeq represents the annual equivalent heat produced by the hybrid plant considering the conversion factor from electricity to heat to be 1, which resembles the efficiency of an electric resistance (ER) water heater [30];

- A natural gas inflation rate of 12% (average in Mexico [31]);

- A local discount rate d of 5% (reported by the National Bank of Mexico);

- A thermal energy production annual derate D of 1%.

3. Results and Discussion

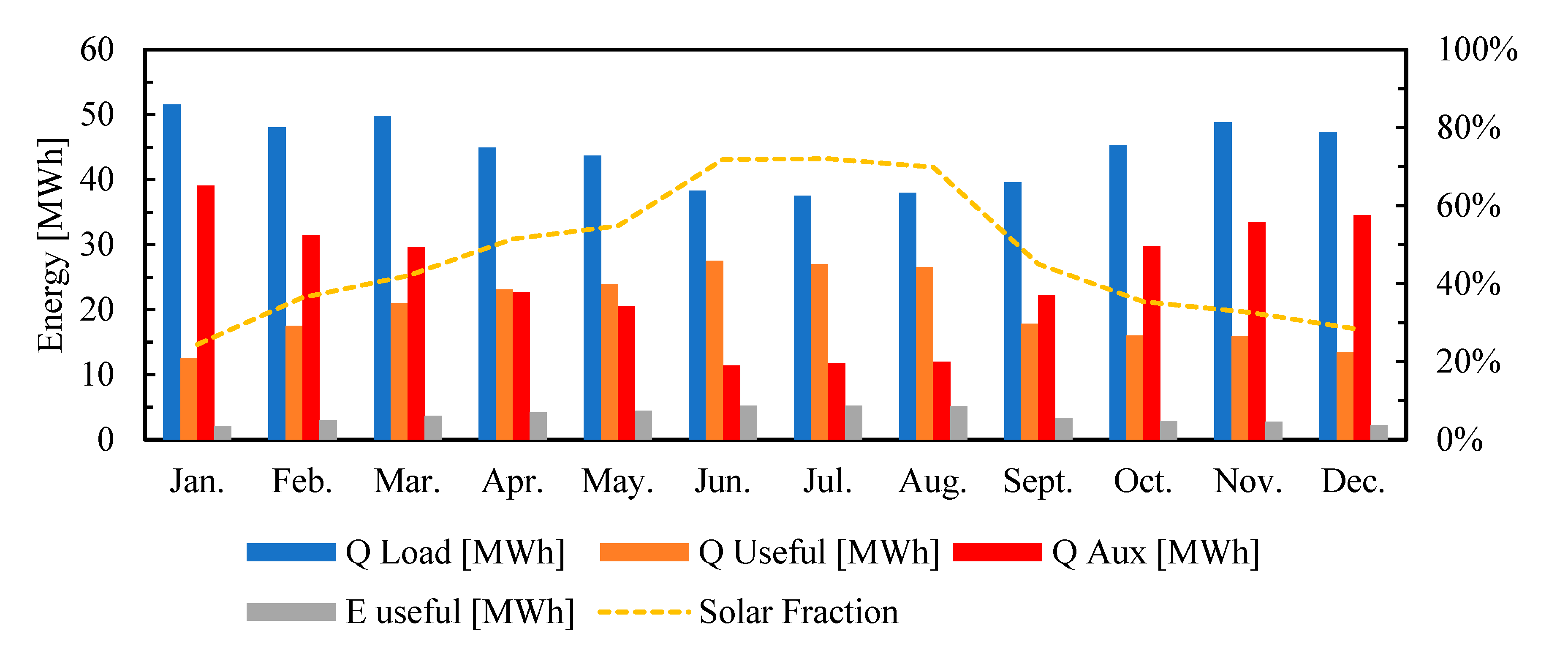

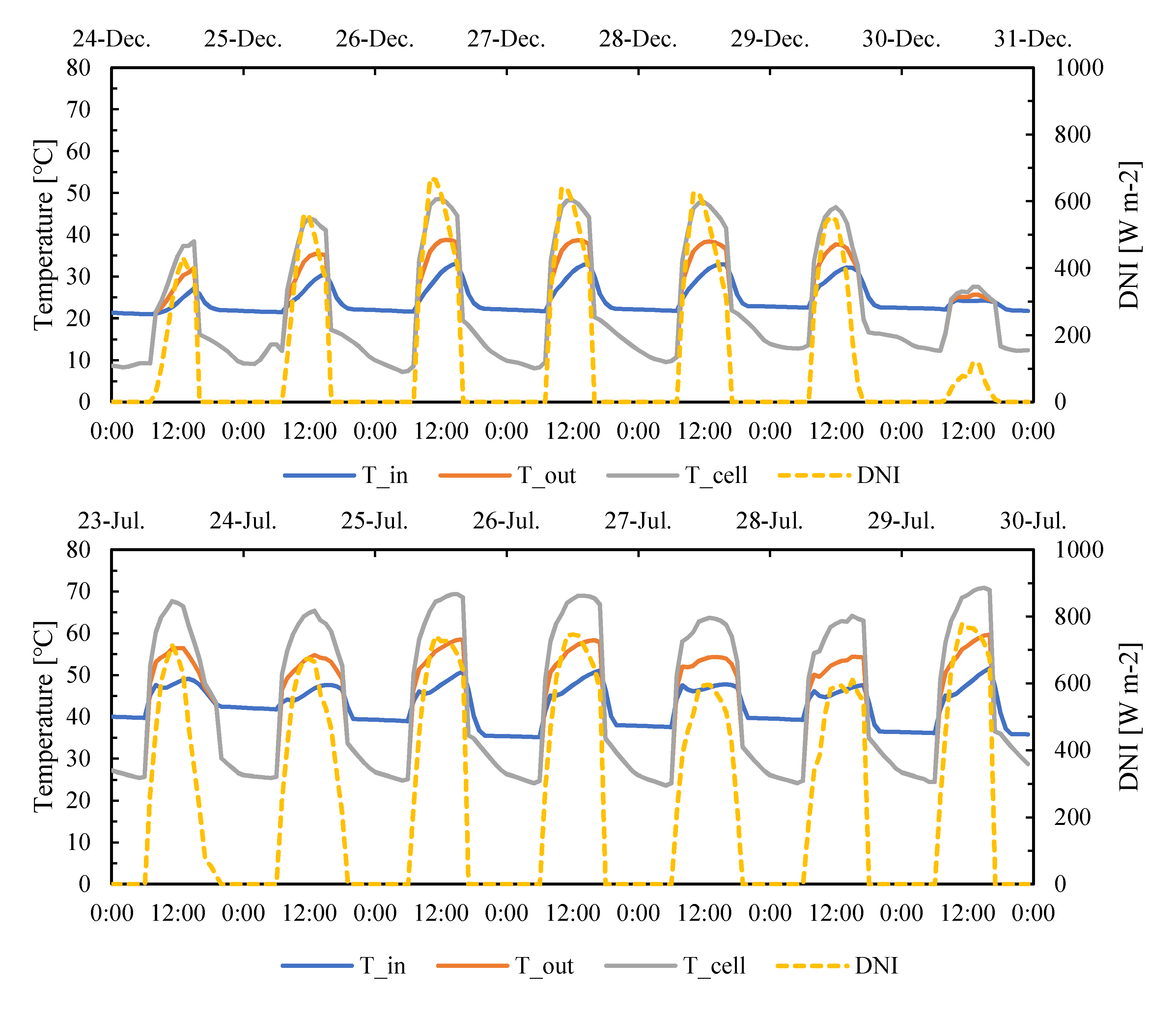

3.1. Technical Performance

3.2. Economic and Environmental Performances

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature and Subscripts

| Nomenclature | Subscripts | ||

| Area | Aperture | ||

| Concentration ratio | Ambient | ||

| Fuel low heating value | Boiler | ||

| Thermal specific capacity | Electrical | ||

| Electricity savings (USD) | Fuel | ||

| Fuel savings (USD) | Intermediate | ||

| Total savings (USD) | Low concentrating PV/T | ||

| Discount rate | Photovoltaic cells | ||

| Electricity | Photovoltaic reference | ||

| Electricity price | Receiver | ||

| Derate | Thermal | ||

| Collector heat removal factor | Operation and maintenance | ||

| Collector efficiency factor | Greek Symbols | ||

| Fuel price | absorptance | ||

| Fuel volume | Efficiency | ||

| Inflation rate | Incidence angle | ||

| Temperature coefficient | |||

| Incidence angle modifier | |||

| Mass flow rate | |||

| Electric power | |||

| Thermal power | |||

| Heat | |||

| Collector thermal loss | |||

| Incident solar irradiance | |||

| Temperature | |||

| Time | |||

| Internal heat transfer coefficient | |||

| Collector heat loss coefficient | |||

| Volume | |||

References

- Sotehi, O.; Chaker, A.; Maalouf, C. Hybrid PV/T water solar collector for net zero energy building and fresh water production: A theoretical approach. Desalination 2016, 385, 1–11. [Google Scholar] [CrossRef]

- Fuentes, M.; Vivar, M.; de la Casa, J.; Aguilera, J. An experimental comparison between commercial hybrid PV-T and simple PV systems intended for BIPV. Renew. Sustain. Energy Rev. 2018, 93, 110–120. [Google Scholar] [CrossRef]

- Yang, L.; Heng, Z.; Haiping, C.; Han, Y.; Fei, Y. Simulating and experimental research on a low-concentrating PV/T triple-generation system. Energy Convers. Manag. 2019, 199, 111942. [Google Scholar] [CrossRef]

- Herrando, M.; Pantaleo, A.M.; Wang, K.; Markides, C.N. Solar combined cooling, heating and power systems based on hybrid PVT, PV or solar-thermal collectors for building applications. Renew. Energy 2019, 143, 637–647. [Google Scholar] [CrossRef]

- Wang, K.; Herrando, M.; Pantaleo, A.M.; Markides, C.N. Technoeconomic assessments of hybrid photovoltaic-thermal vs. conventional solar-energy systems: Case studies in heat and power provision to sports centres. Appl. Energy 2019, 254, 113657. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A.; Yang, Y. Optimization and dynamic techno-economic analysis of a novel PVT-based smart building energy system. Appl. Therm. Eng. 2020, 181, 115926. [Google Scholar] [CrossRef]

- Brottier, L.; Bennacer, R. Thermal performance analysis of 28 PVT solar domestic hot water installations in Western Europe. Renew. Energy 2020, 160, 196–210. [Google Scholar] [CrossRef]

- Braun, R.; Haag, M.; Stave, J.; Abdelnour, N.; Eicker, U. System design and feasibility of trigeneration systems with hybrid photovoltaic-thermal (PVT) collectors for zero energy office buildings in different climates. Sol. Energy 2019, 196, 39–48. [Google Scholar] [CrossRef]

- Zhou, C.; Ruobing, L.; Jili, Z. Optimization Design Method and Experimental Validation of a Solar PVT Cogeneration System. Energies 2017, 10, 1281. [Google Scholar] [CrossRef] [Green Version]

- Obalanlege, M.A.; Mahmoudi, Y.; Douglas, R.; Ebrahimnia-Bajestan, E.; Davidson, J.; Bailie, D. Performance assessment of a hybrid photovoltaic-thermal and heat pump system for solar heating and electricity. Renew. Energy 2020, 148, 558–572. [Google Scholar] [CrossRef]

- Del Amo, A.; Martínez-gracia, A.; Pintanel, T.; Bayod-rújula, A.A.; Torné, S. Analysis and optimization of a heat pump system coupled to an installation of PVT panels and a seasonal storage tank on an educational building. Energy Build. 2020, 226, 110373. [Google Scholar] [CrossRef]

- Abdul-ganiyu, S.; Quansah, D.A.; Ramde, E.W.; Seidu, R.; Adaramola, M.S. Investigation of Solar Photovoltaic-Thermal ( PVT ) and Solar Photovoltaic ( PV ) Performance: A Case Study in Ghana. Energies 2020, 13, 2701. [Google Scholar] [CrossRef]

- Guarini, M.R.; Morano, P.; Sica, F. Integrated ecosystem design: An evaluation model to support the choice of eco-compatible technological solutions for residential building. Energies 2019, 12, 2659. [Google Scholar] [CrossRef] [Green Version]

- U.S. Energy Information Administration. International Energy Outlook 2019; U.S. Energy Information Administration: Washington, DC, USA, 2019.

- Knaack, J.; Oropeza, M.; Potowski, K.; Quiñones, A. Calor Solar Para la Industria México. Available online: https://www.solar-payback.com/wp-content/uploads/2017/07/Solar-Heat-for-Industry-Solar-Payback-April-2017.pdf (accessed on 26 September 2019).

- Acosta, P.I.P. Caracterización y Evaluación de un Sistema Híbrido Fotovoltaico/Térmico Basado en un Concentrador Parabólico Lineal; Tecnológico de Monterrey: Monterrey, Mexico, 2016. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley: Hoboken, NJ, USA, 2013; ISBN 9780470873663. [Google Scholar]

- Florschuetz, L.W. Extension of the Hottel-Whillier model to the analysis of combined photovoltaic/thermal flat plate collectors. Sol. Energy 1979, 22, 361–366. [Google Scholar] [CrossRef]

- Gaul, H.; Rabl, A. Incidence-Angle Modifier and Average Optical Efficiency of Parabolic Trough Collectors. J. Sol. Energy Eng. 1980, 102, 16–21. [Google Scholar] [CrossRef]

- Bernardo, L.R.; Perers, B.; Håkansson, H.; Karlsson, B. Performance evaluation of low concentrating photovoltaic/thermal systems: A case study from Sweden. Sol. Energy 2011, 85, 1499–1510. [Google Scholar] [CrossRef] [Green Version]

- Comisión Reguladora de Energía Índice de Referencia Nacional de Precios de Gas Natural al Mayoreo (IPGN). Available online: https://www.cre.gob.mx//IPGN/index.html (accessed on 9 May 2020).

- Comisión Federal de Electricidad. Tarifas Gran Demanda Media Tensión Horaria (GDMTH). Available online: https://app.cfe.mx/Aplicaciones/CCFE/Tarifas/TarifasCRENegocio/Tarifas/GranDemandaMTH.aspx (accessed on 9 May 2020).

- IEA International Energy Agency. Industrial Combustion Boilers; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems, 2nd ed.; EBSCO Publishing: Ipswich, MA, USA, 2014; ISBN 9780123972705. [Google Scholar]

- Kassem, Y. Solar Energy Potential and Feasibility Study of a 10MW Grid-connected Solar Plant in Libya. Eng. Technol. Appl. Sci. Res. 2020, 10, 5358–5366. [Google Scholar]

- Trading Economics Mexico Interest Rate|2005–2020 Data. Available online: https://tradingeconomics.com/mexico/interest-rate (accessed on 12 October 2020).

- Riggs, B.C.; Biedenharn, R.; Dougher, C.; Ji, Y.V.; Xu, Q.; Romanin, V.; Codd, D.S.; Zahler, J.M.; Escarra, M.D. Techno-economic analysis of hybrid PV/T systems for process heat using electricity to subsidize the cost of heat. Appl. Energy 2017, 208, 1370–1378. [Google Scholar] [CrossRef]

- Wang, K.; Pantaleo, A.M.; Herrando, M.; Faccia, M.; Pesmazoglou, I.; Franchetti, B.M.; Markides, C.N. Spectral-splitting hybrid PV-thermal (PVT) systems for combined heat and power provision to dairy farms. Renew. Energy 2020, 159, 1047–1065. [Google Scholar] [CrossRef]

- Ramos, A.; Chatzopoulou, M.A.; Guarracino, I.; Freeman, J.; Markides, C.N. Hybrid photovoltaic-thermal solar systems for combined heating, cooling and power provision in the urban environment. Energy Convers. Manag. 2017, 150, 838–850. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Electric Resistance Heating. Available online: https://www.energy.gov/energysaver/home-heating-systems/electric-resistance-heating (accessed on 14 September 2020).

- Secretaría de Energía Sistema de Información Energética. Available online: http://sie.energia.gob.mx/ (accessed on 20 May 2020).

- IPCC. Emission Factor Database. Available online: https://www.ipcc-nggip.iges.or.jp/EFDB/main.php (accessed on 14 August 2020).

- U.S. Department of Energy. Heat Pump Water Heaters. Available online: https://www.energy.gov/energysaver/water-heating/heat-pump-water-heaters (accessed on 14 September 2020).

- Herrando, M.; Ramos, A.; Freeman, J.; Zabalza, I.; Markides, C.N. Technoeconomic modelling and optimisation of solar combined heat and power systems based on flat-box PVT collectors for domestic applications. Energy Convers. Manag. 2018, 175, 67–85. [Google Scholar] [CrossRef]

- Rashid, K.; Safdarnejad, S.M.; Ellingwood, K.; Powell, K.M. Techno-economic evaluation of different hybridization schemes for a solar thermal/gas power plant. Energy 2019, 181, 91–106. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Greenhouse Gas Equivalencies Calculator. Available online: https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator (accessed on 4 August 2020).

| Feature | Value |

|---|---|

| Process and solar field | |

| Daily hot water demand | 30 m3 |

| Temperature demand | 55 °C |

| Solar field azimuth | 16.6 |

| Thermal storage capacity | 30 m3 |

| Heat demand | 94.4 kW |

| Hybrid collector | |

| Optical efficiency, | 0.601 |

| Concentration ratio | 14.8 |

| Internal heat transfer coefficient, | 3838 |

| Heat loss coefficient, | 2.77 |

| Temperature coefficient, | |

| Energy prices | |

| Natural gas, Cf | 0.011 USD/kWh |

| Electricity, Ce | 0.064 USD/kWh |

| Component | Cost |

|---|---|

| Parabolic trough collectors 1, USD (Source: local retailer) | |

| Hybrid receiver, USD | |

| Storage tank, USD (Source: local retailer) | |

| Inverter, USD/kW [28] | 238 |

| Hydraulic system, USD (Source: local retailer) | |

| Controller, USD (Source: local retailer) | 558 |

| Installation cost, USD [28] | |

| Annual O&M cost, USD [28] |

| Parameters | Hybrid Plant | Conventional System |

|---|---|---|

| Initial investment cost (Co), USD | $29,000 | |

| Hybrid receivers cost 1, USD | - | |

| Energetics price ratio, Ce/Cf | 5.68 | |

| Annual savings (Cs), USD | - | |

| Payback time (PBT), years | 19.23 | - |

| Life cycle savings (LCS), USD | - | |

| LCOHeq, USD/kWh | 0.067 | |

| LCOEeq USD/kWh | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta-Pazmiño, I.; Rivera-Solorio, C.; Gijón-Rivera, M. Energetic and Economic Analyses of an LCPV/T Solar Hybrid Plant for a Sports Center Building in Mexico. Energies 2020, 13, 5681. https://doi.org/10.3390/en13215681

Acosta-Pazmiño I, Rivera-Solorio C, Gijón-Rivera M. Energetic and Economic Analyses of an LCPV/T Solar Hybrid Plant for a Sports Center Building in Mexico. Energies. 2020; 13(21):5681. https://doi.org/10.3390/en13215681

Chicago/Turabian StyleAcosta-Pazmiño, Iván, Carlos Rivera-Solorio, and Miguel Gijón-Rivera. 2020. "Energetic and Economic Analyses of an LCPV/T Solar Hybrid Plant for a Sports Center Building in Mexico" Energies 13, no. 21: 5681. https://doi.org/10.3390/en13215681