Cross-seasonal Experimental Study on the Comprehensive Performance of C-Si PV Window

Abstract

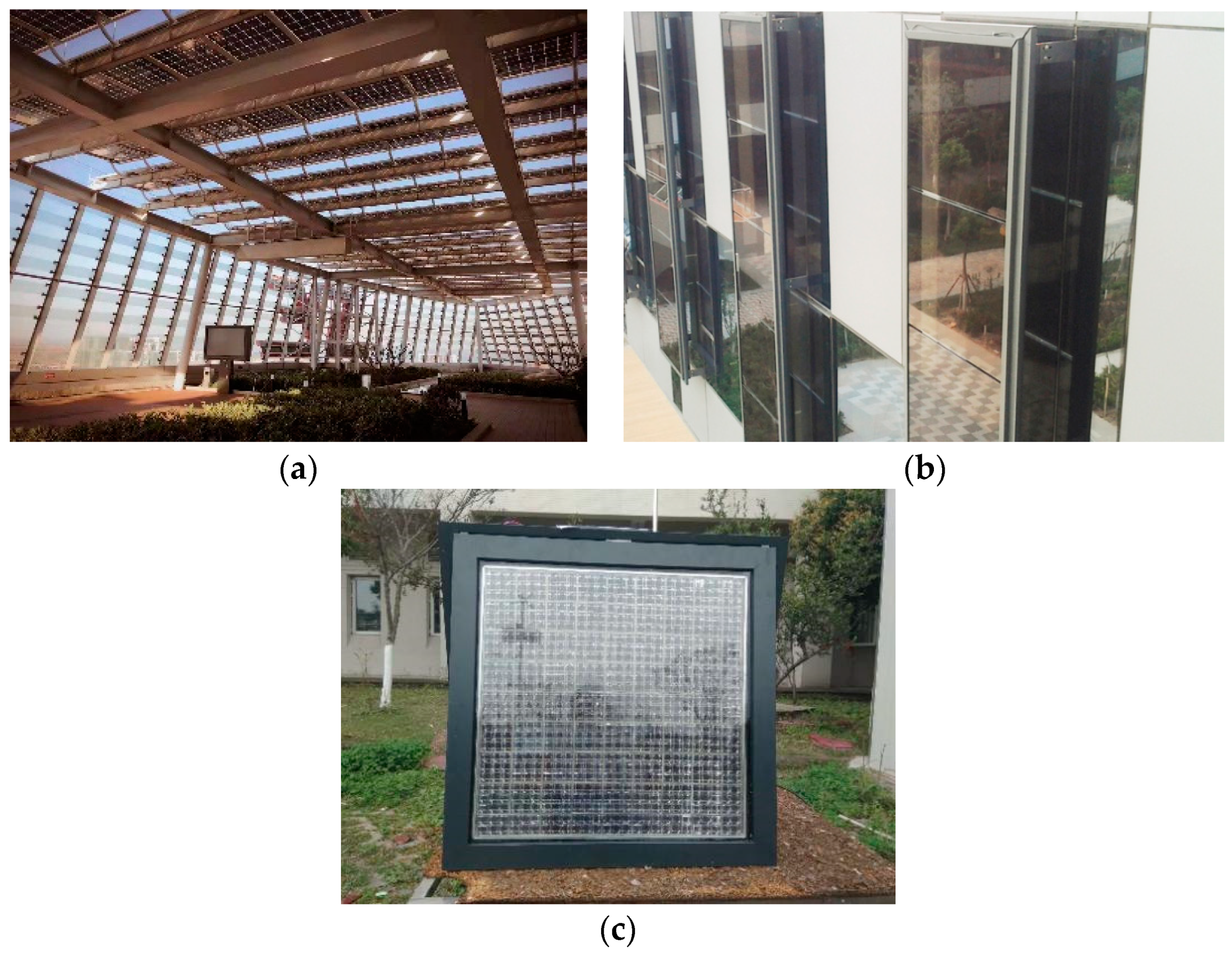

:1. Introduction

2. Theoretical Analysis

2.1. Electricity Performance Analysis of PV Window

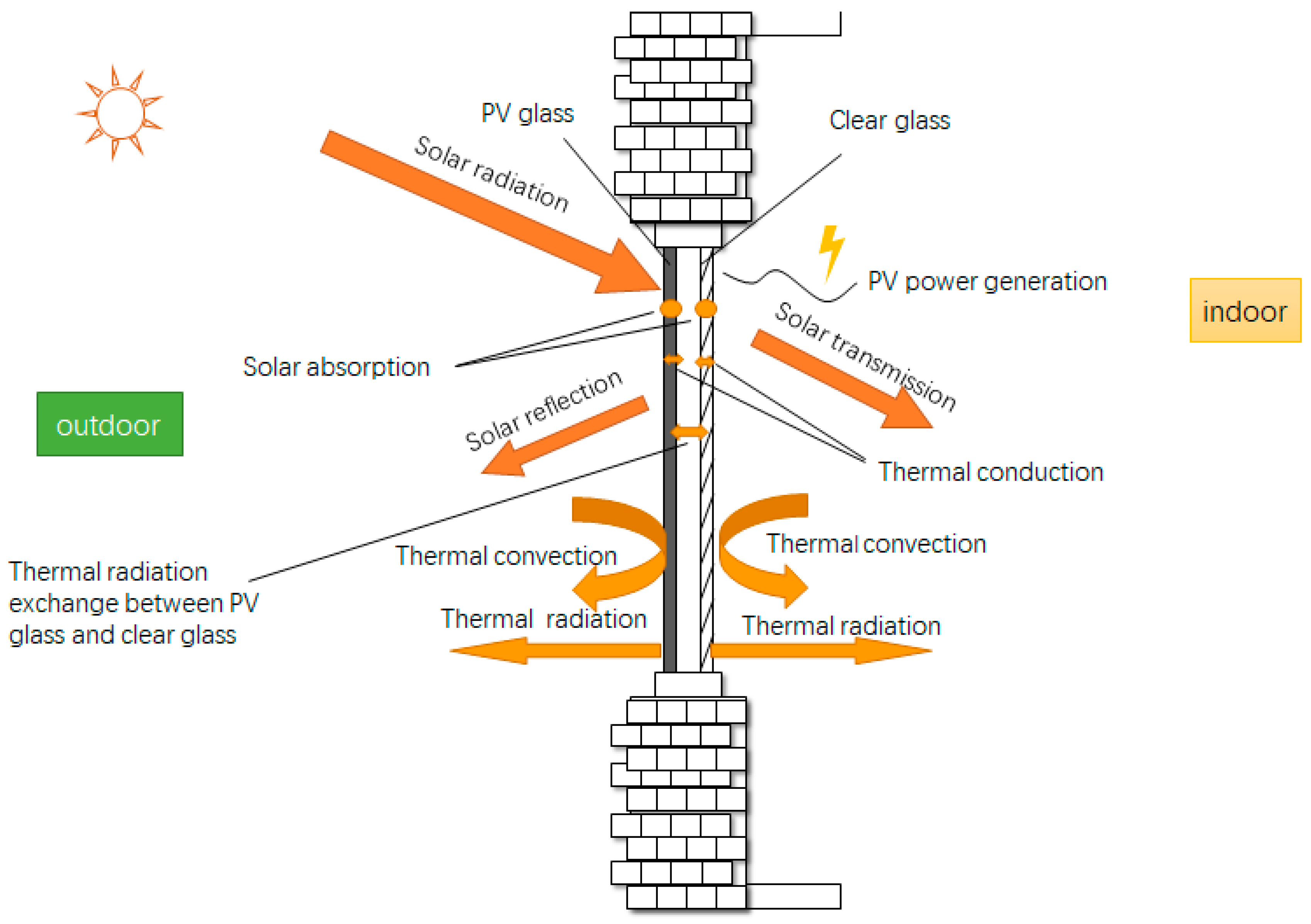

2.2. Thermal Performance Analysis of PV Window

2.3. Lighting Performance Analysis of PV Window

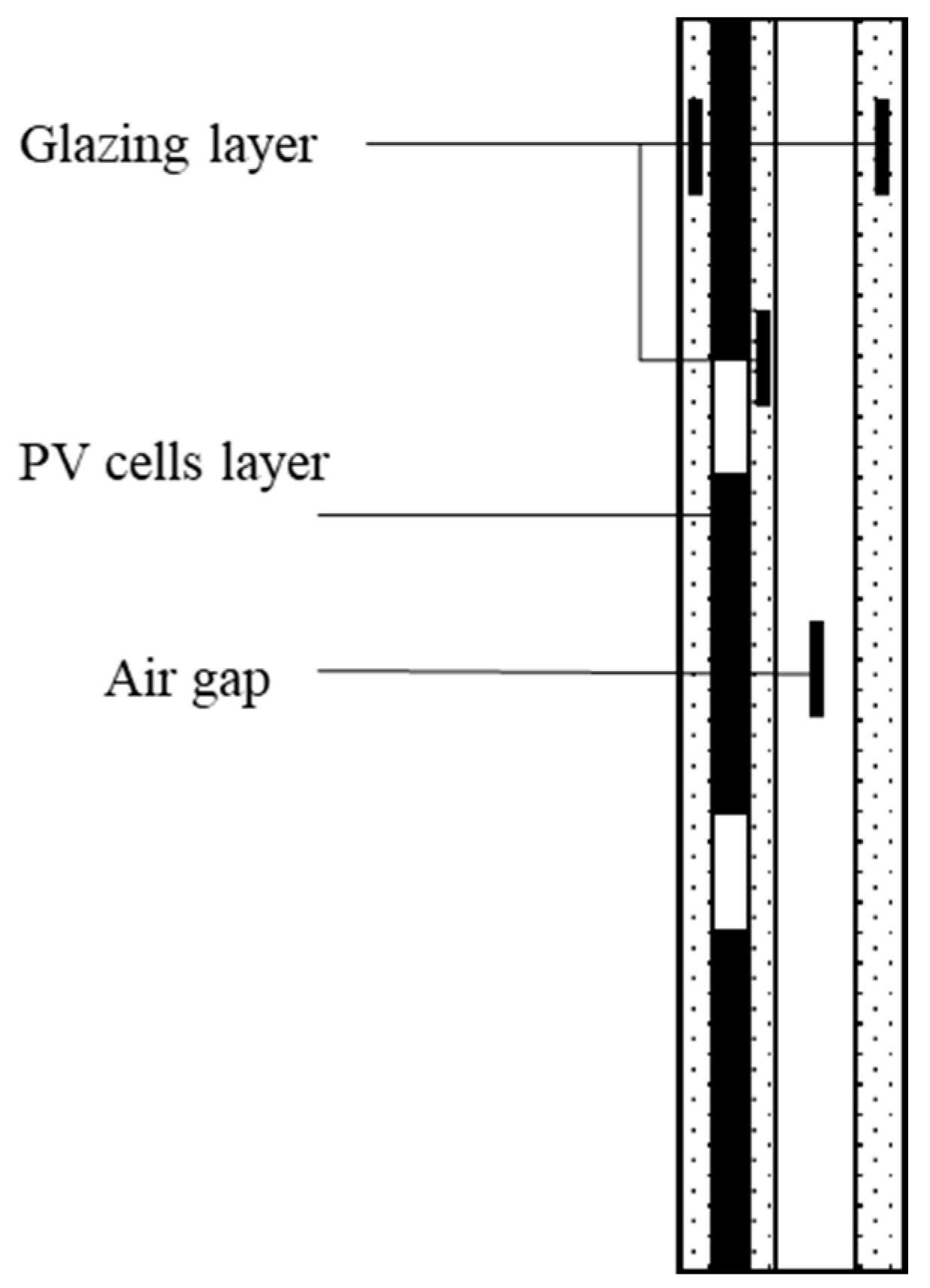

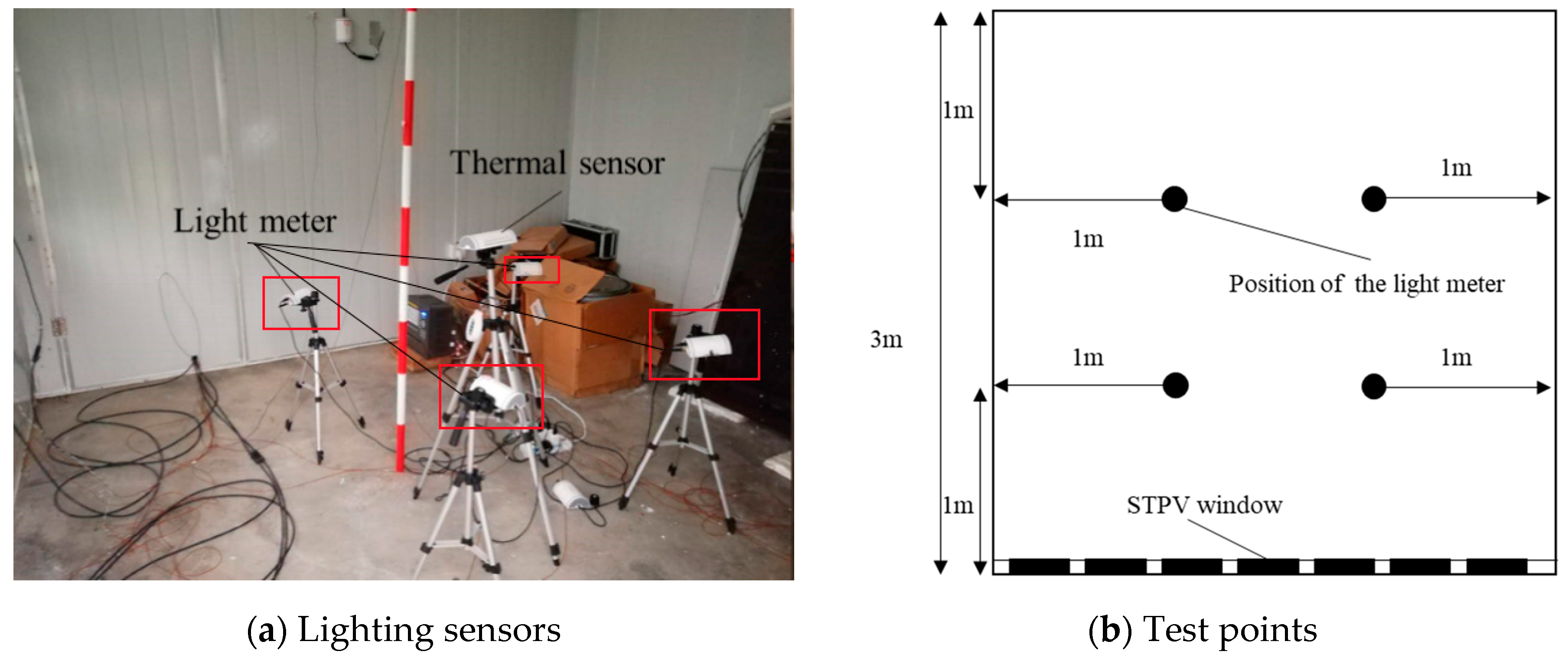

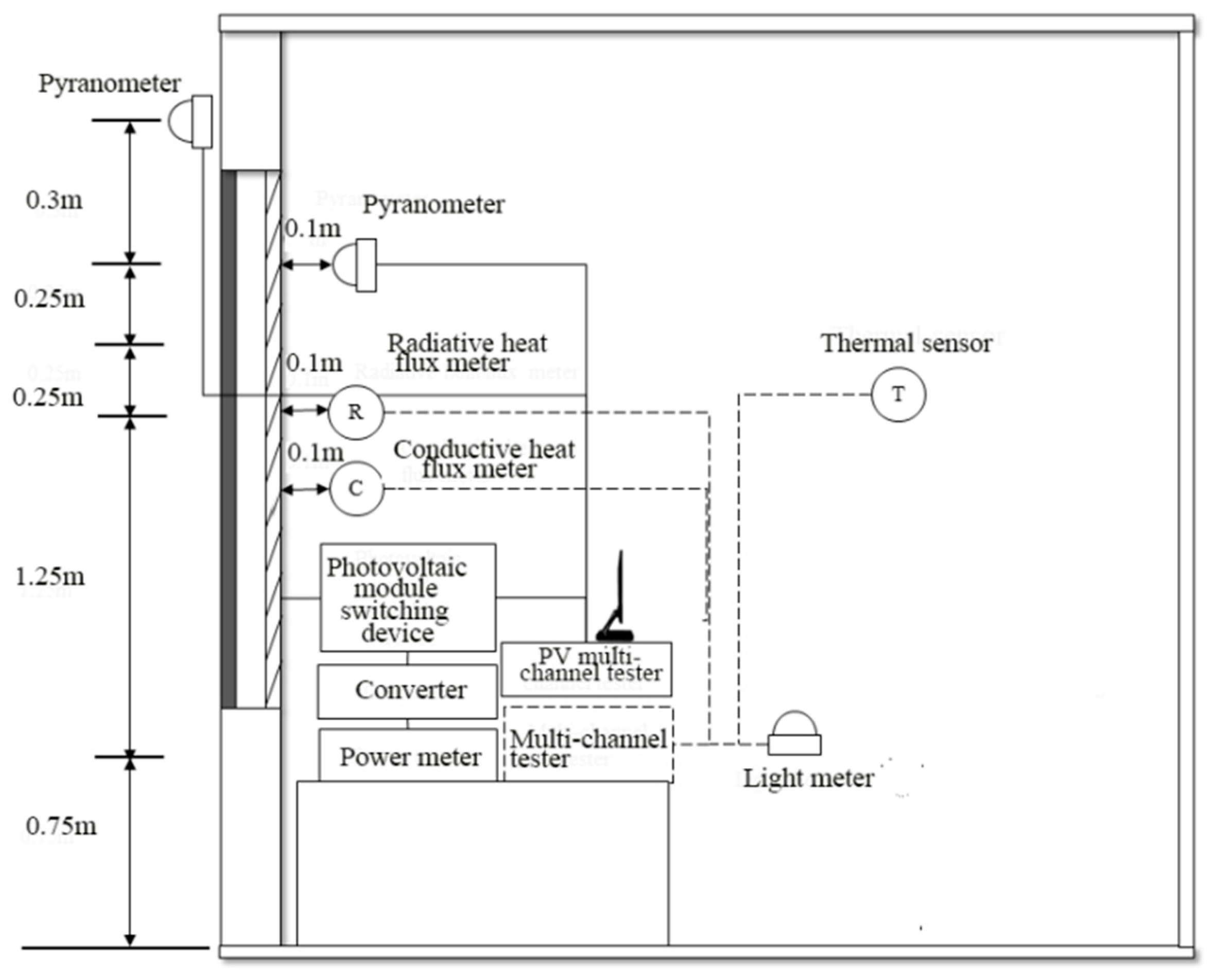

3. Experimental Test Method

4. Experimental Analysis of the Performance of PV Window

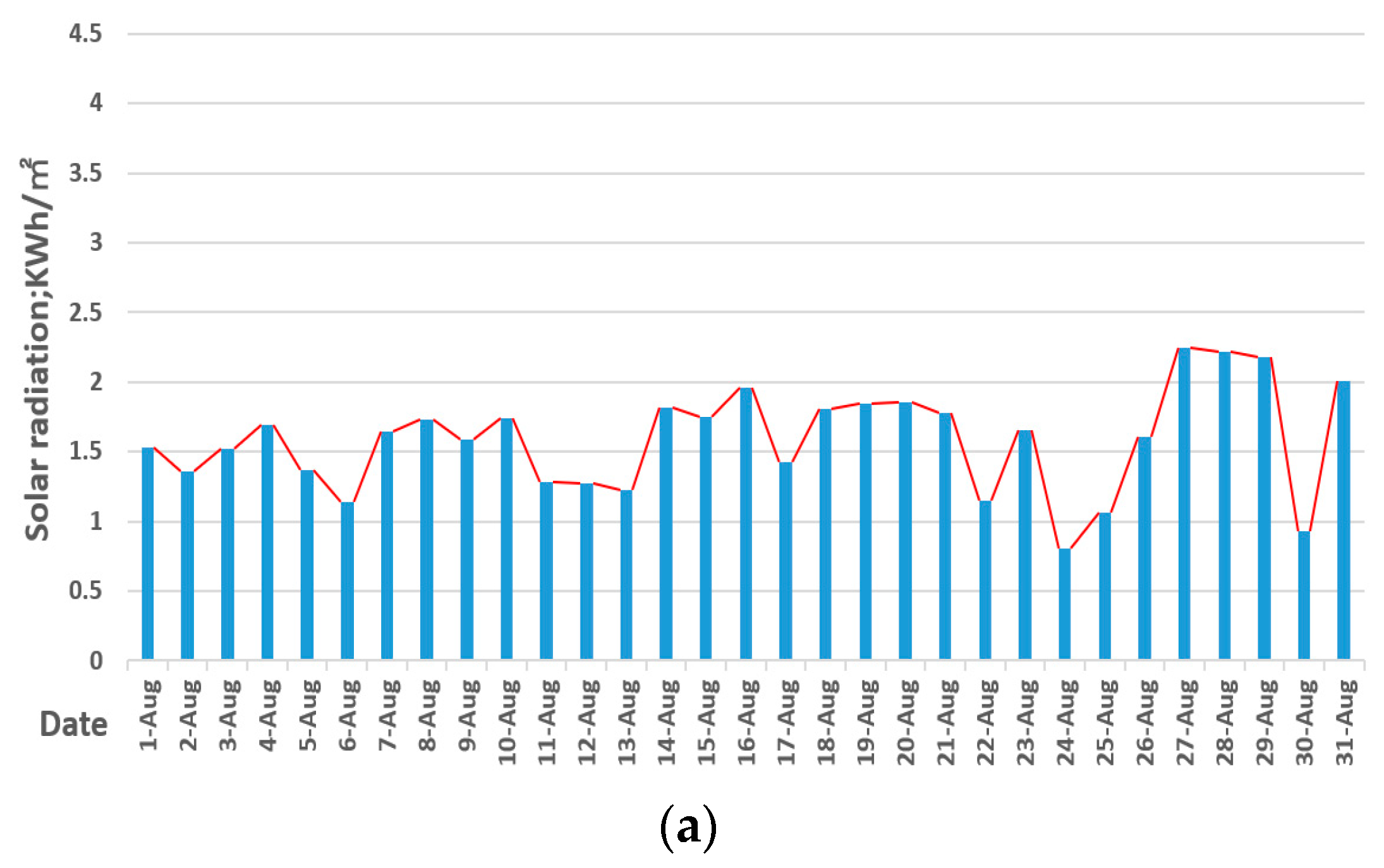

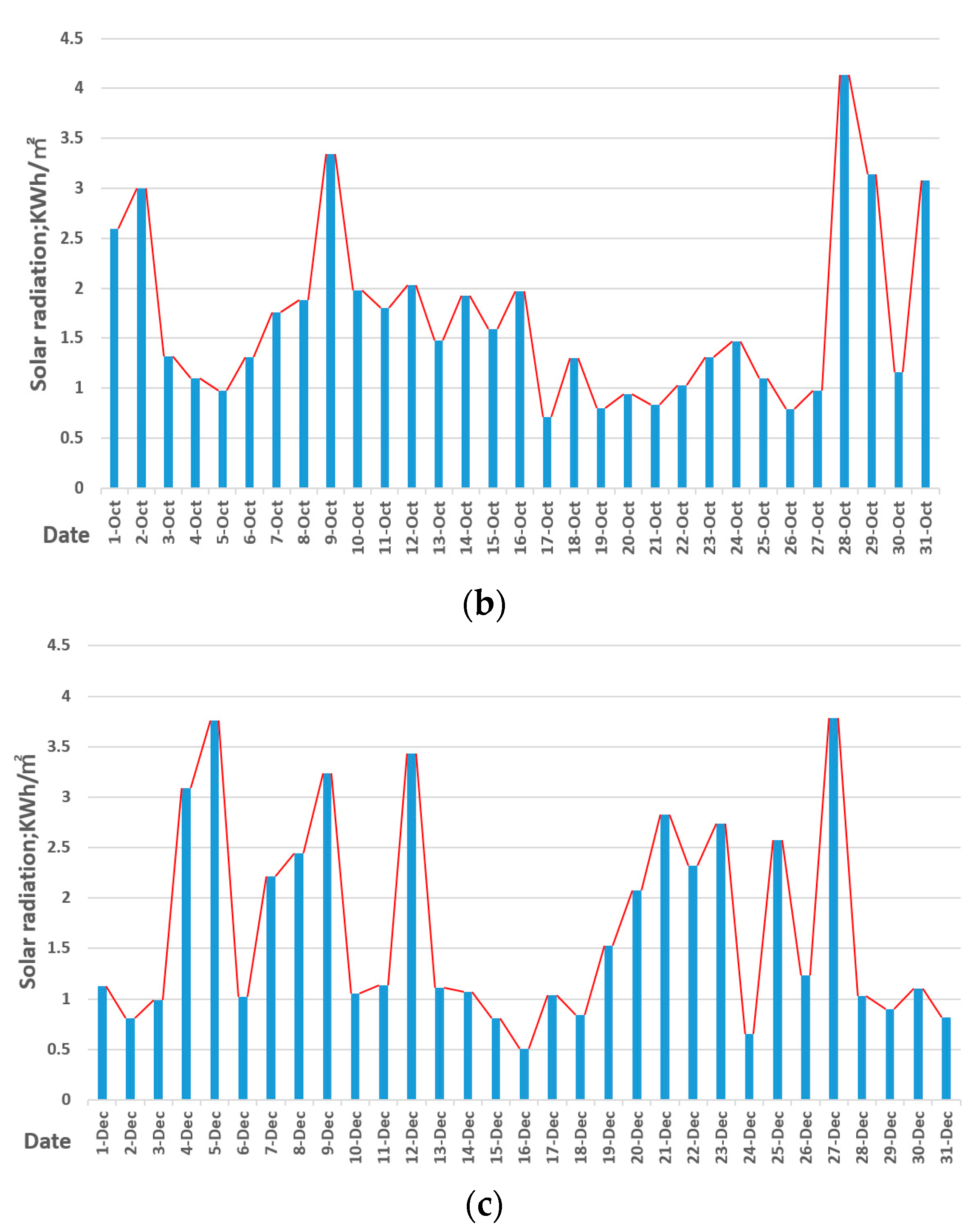

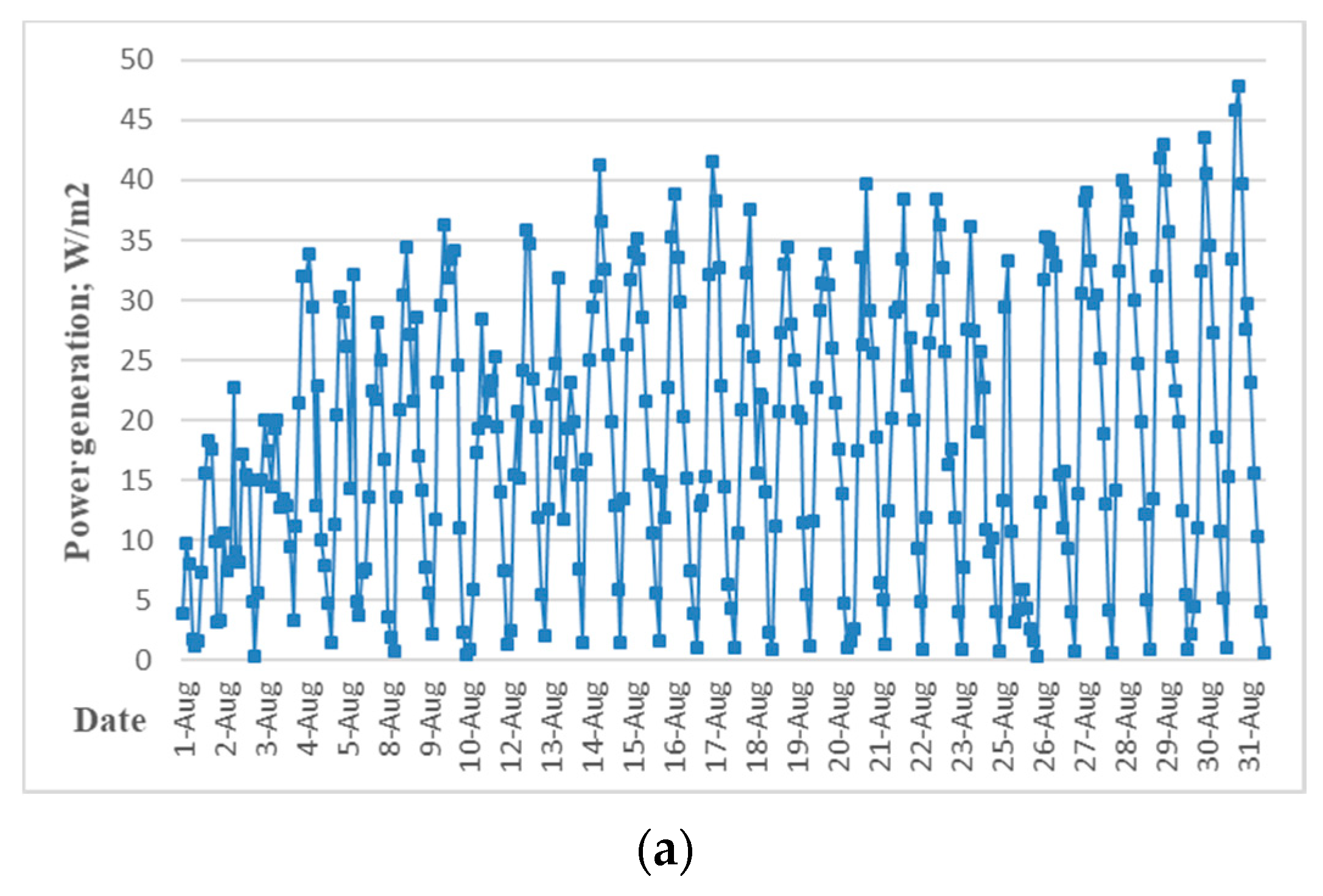

4.1. Analysis of the Electrical Performance

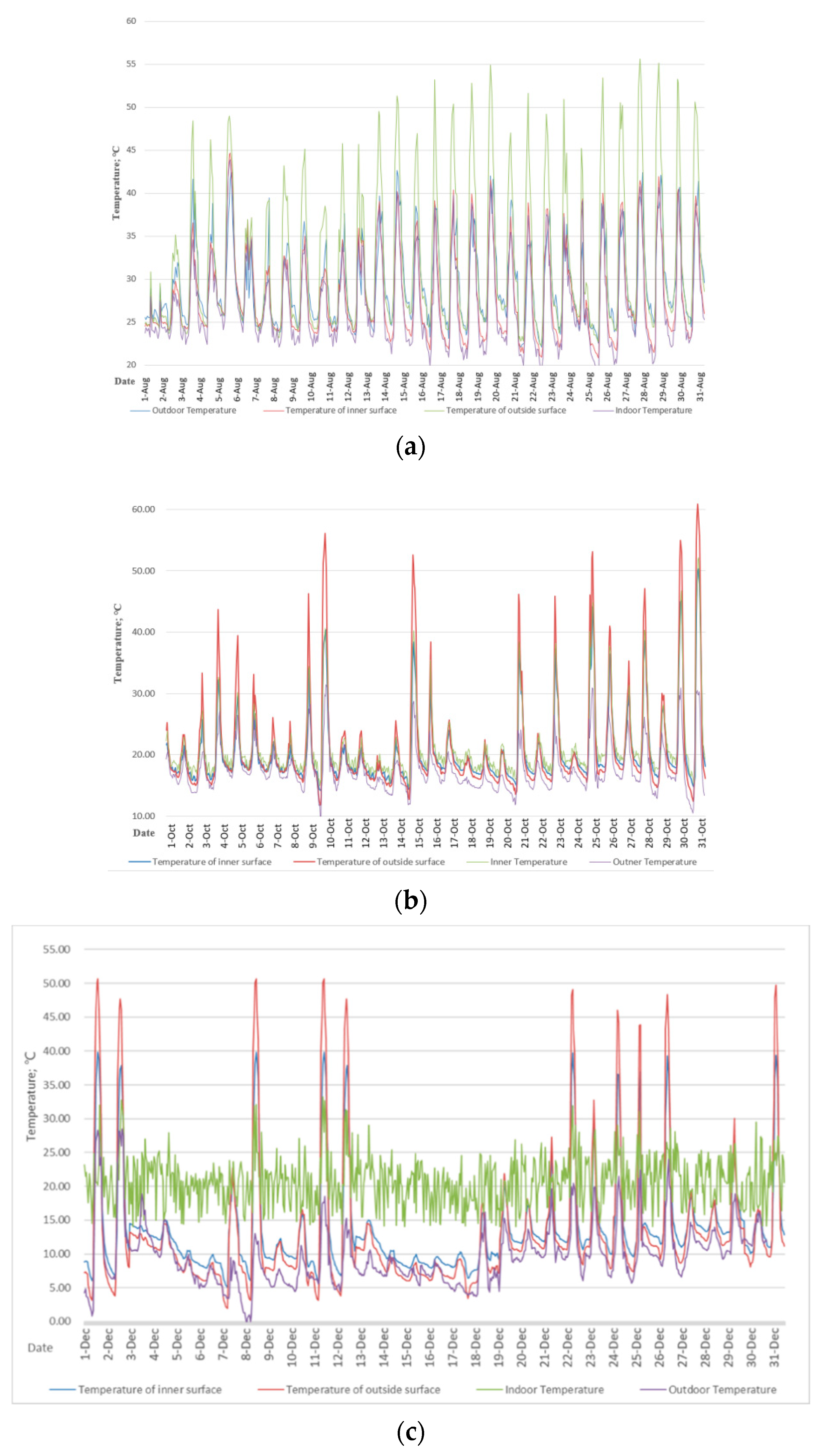

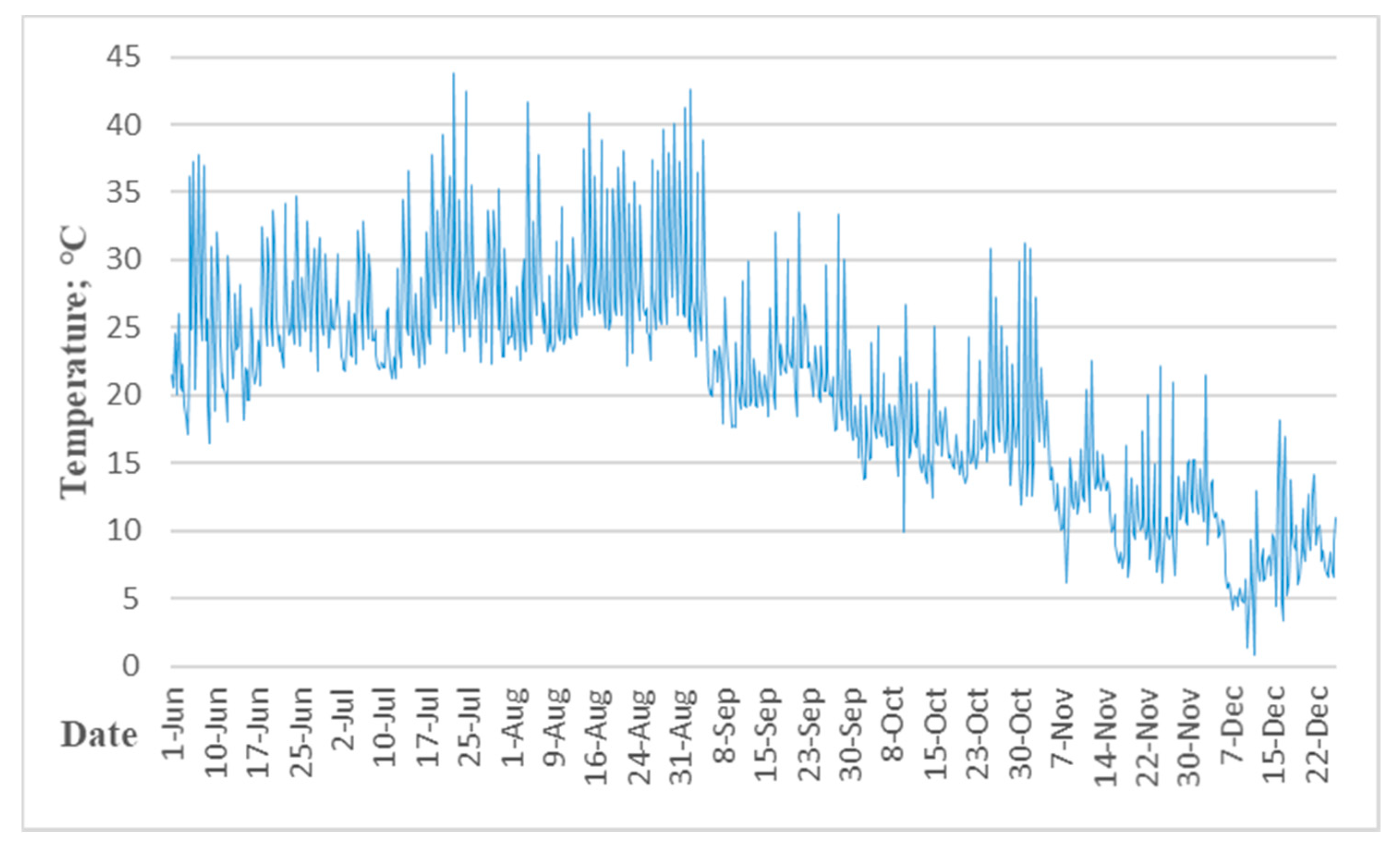

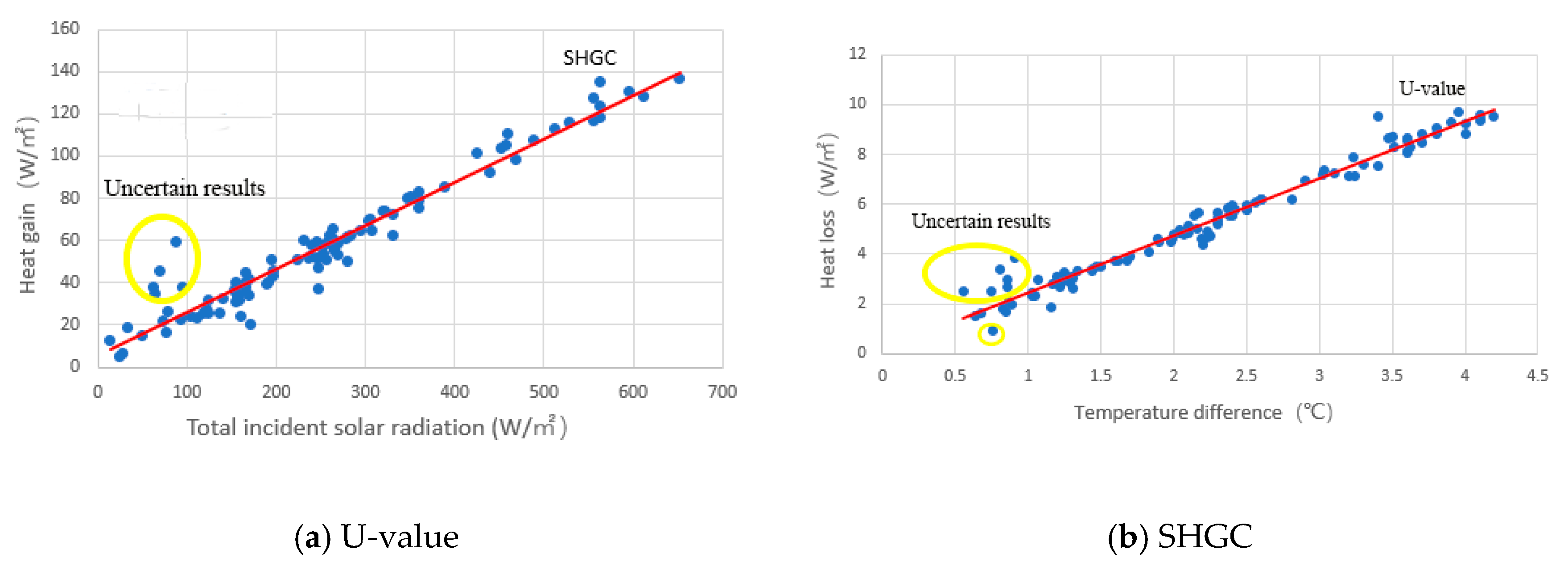

4.2. Analysis of the Thermal Performance

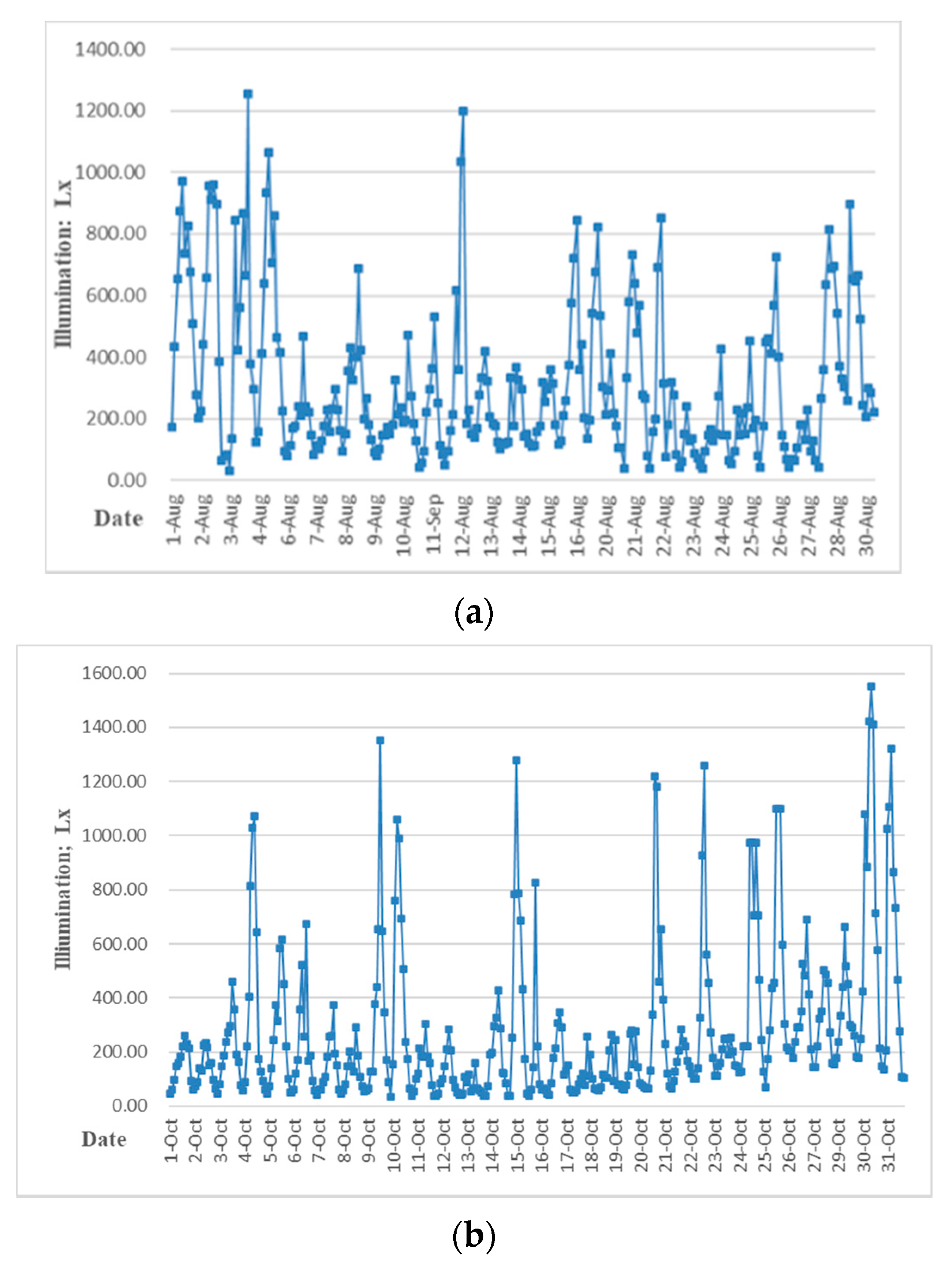

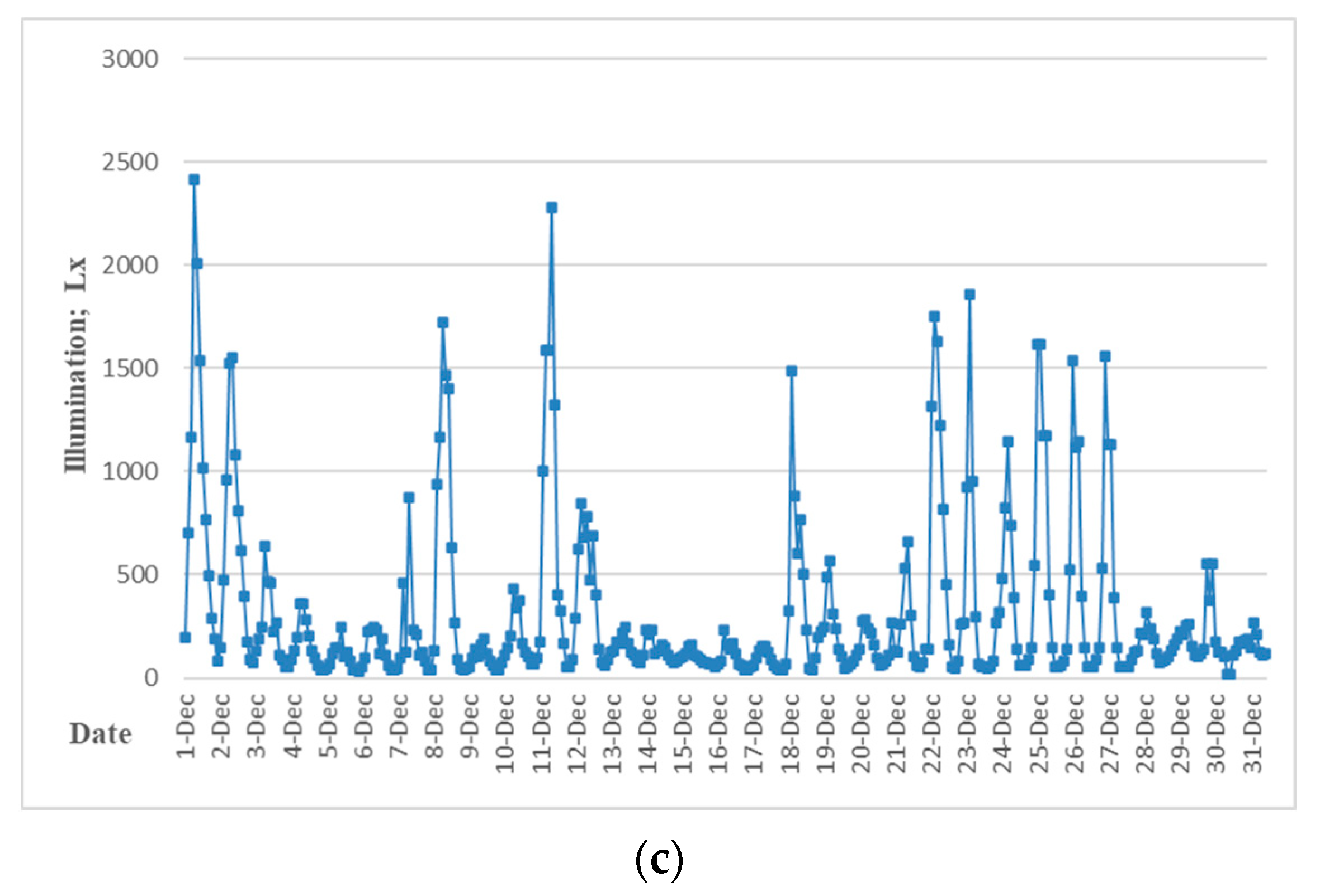

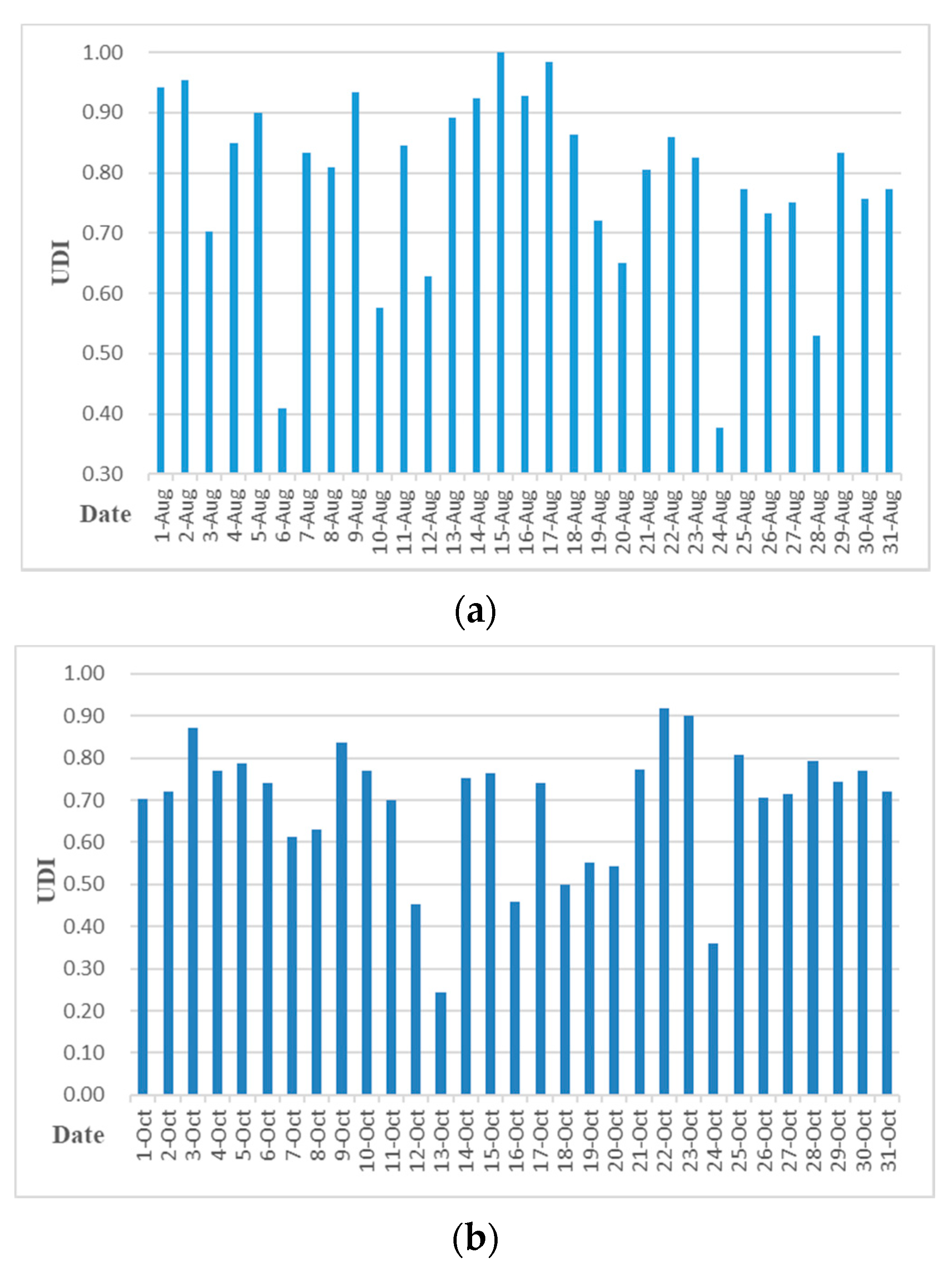

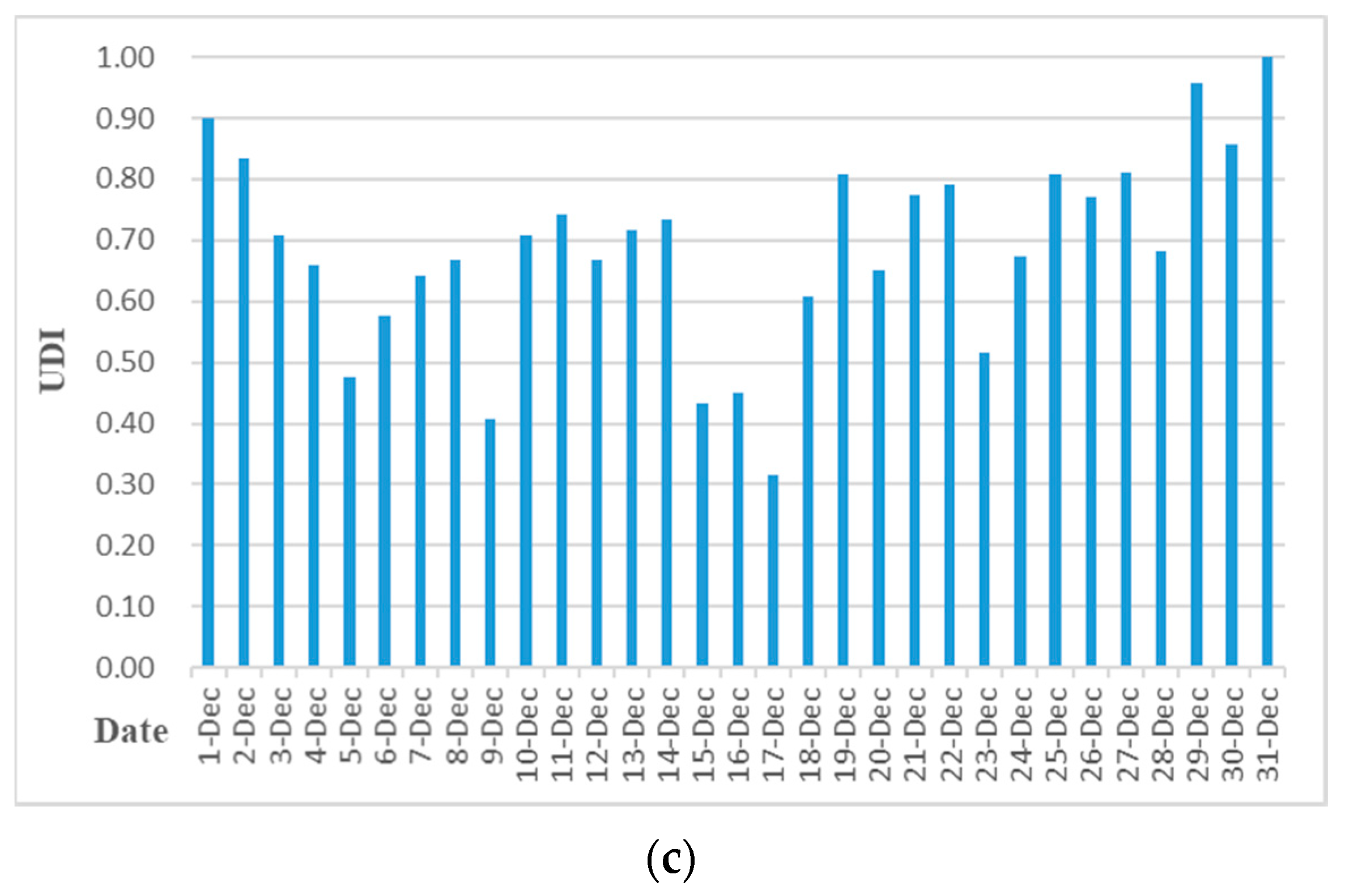

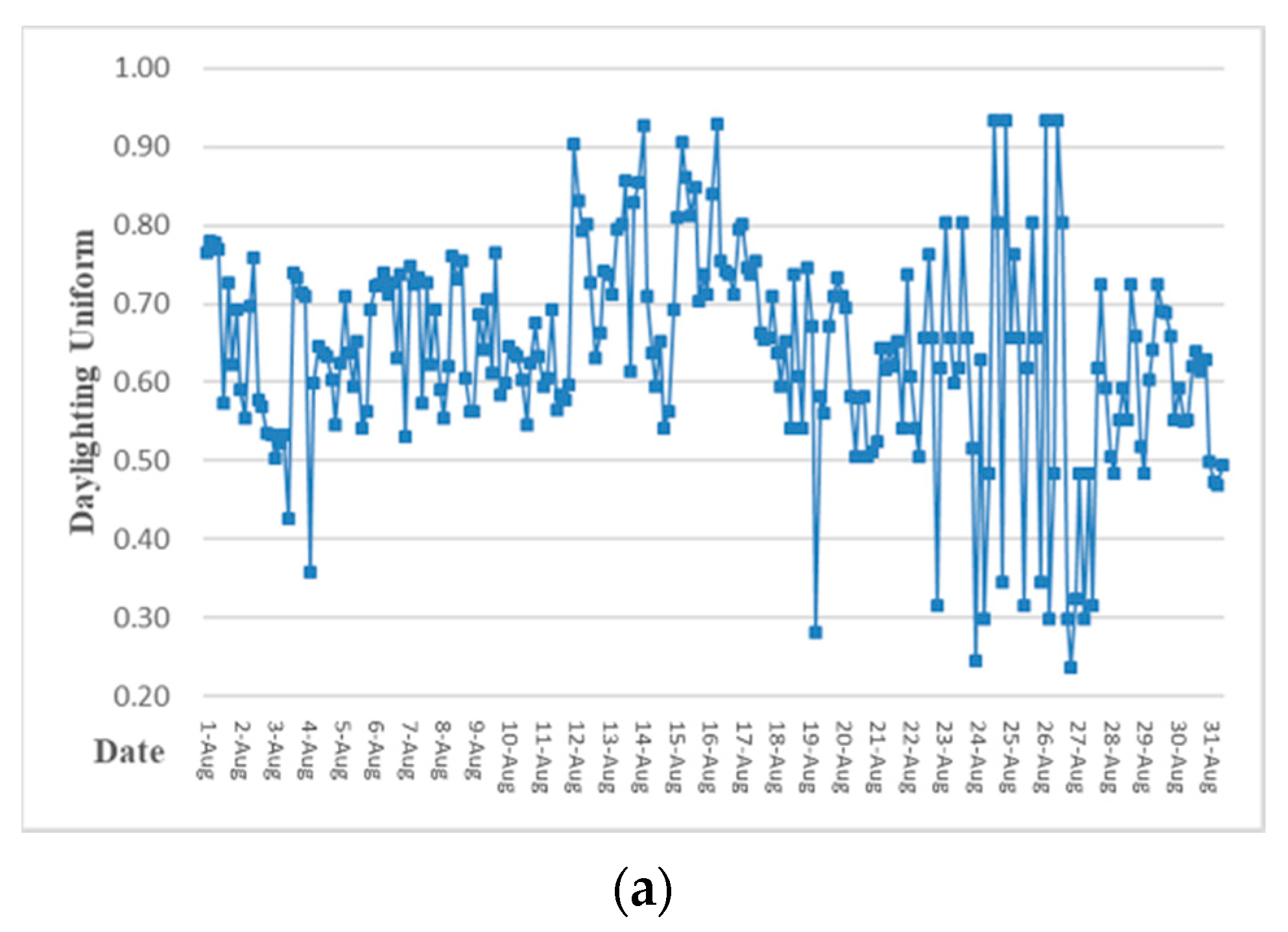

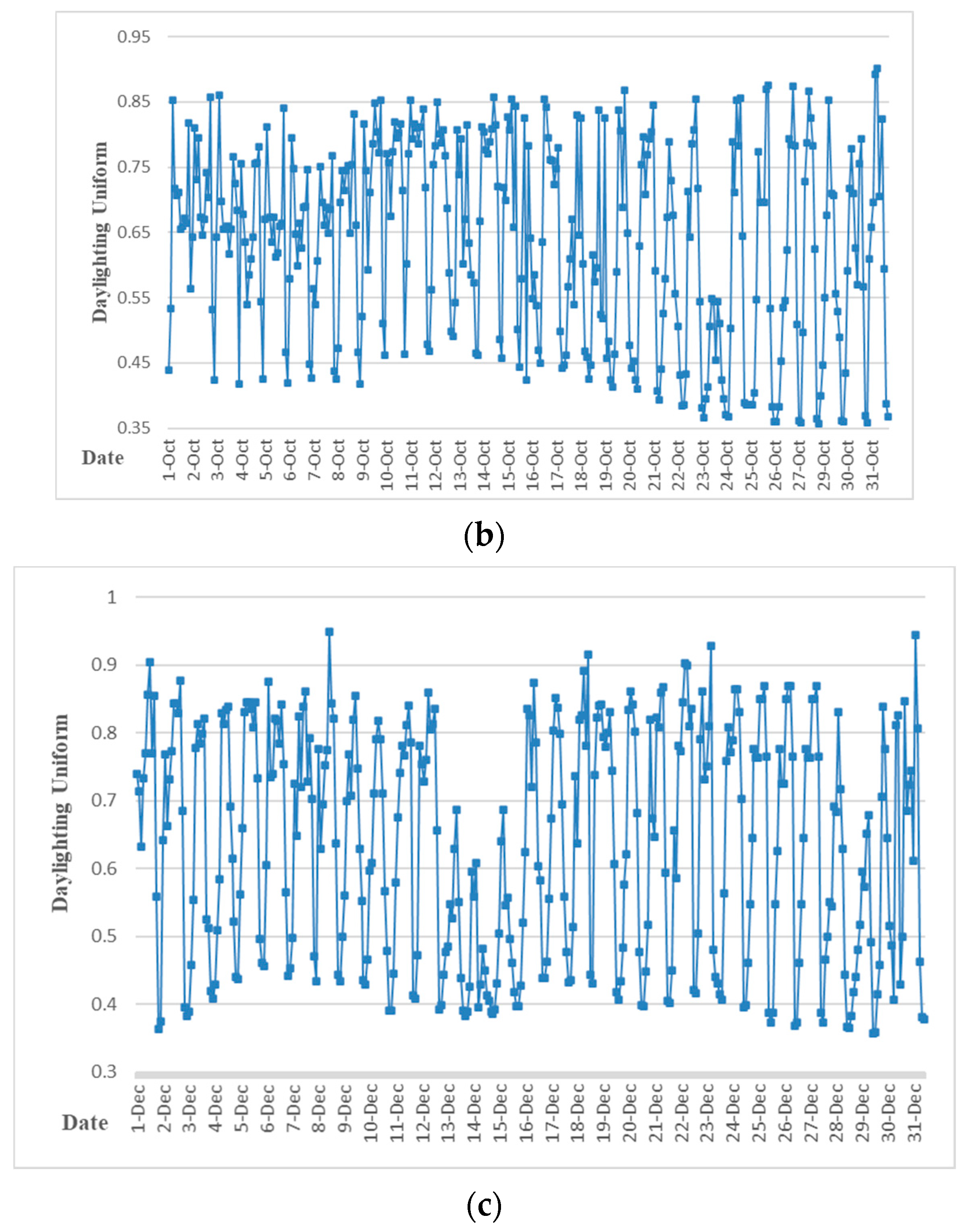

4.3. Analysis of the Daylighting Performance

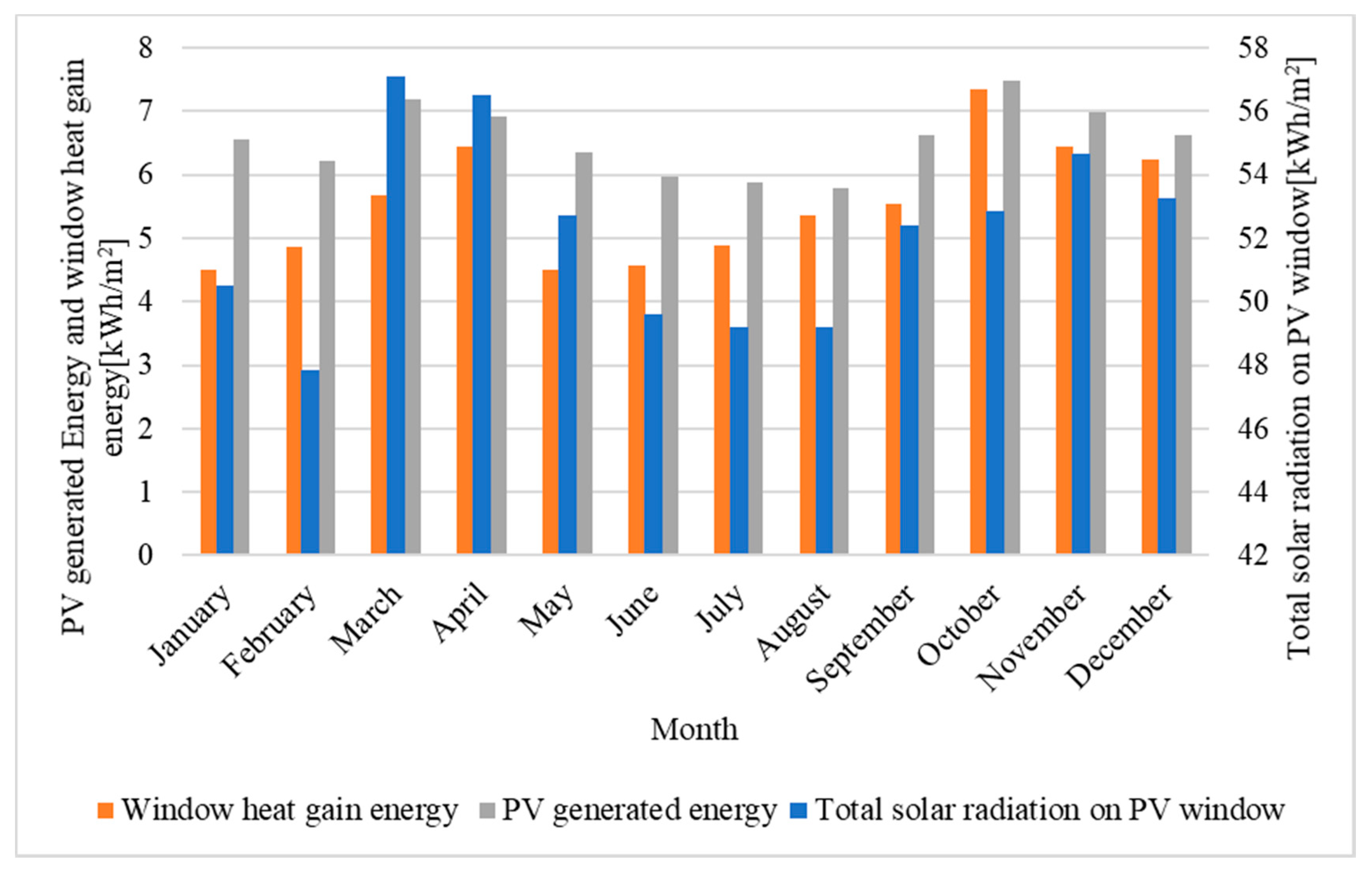

4.4. Cross-Seasonal Performance Analysis of PV Window

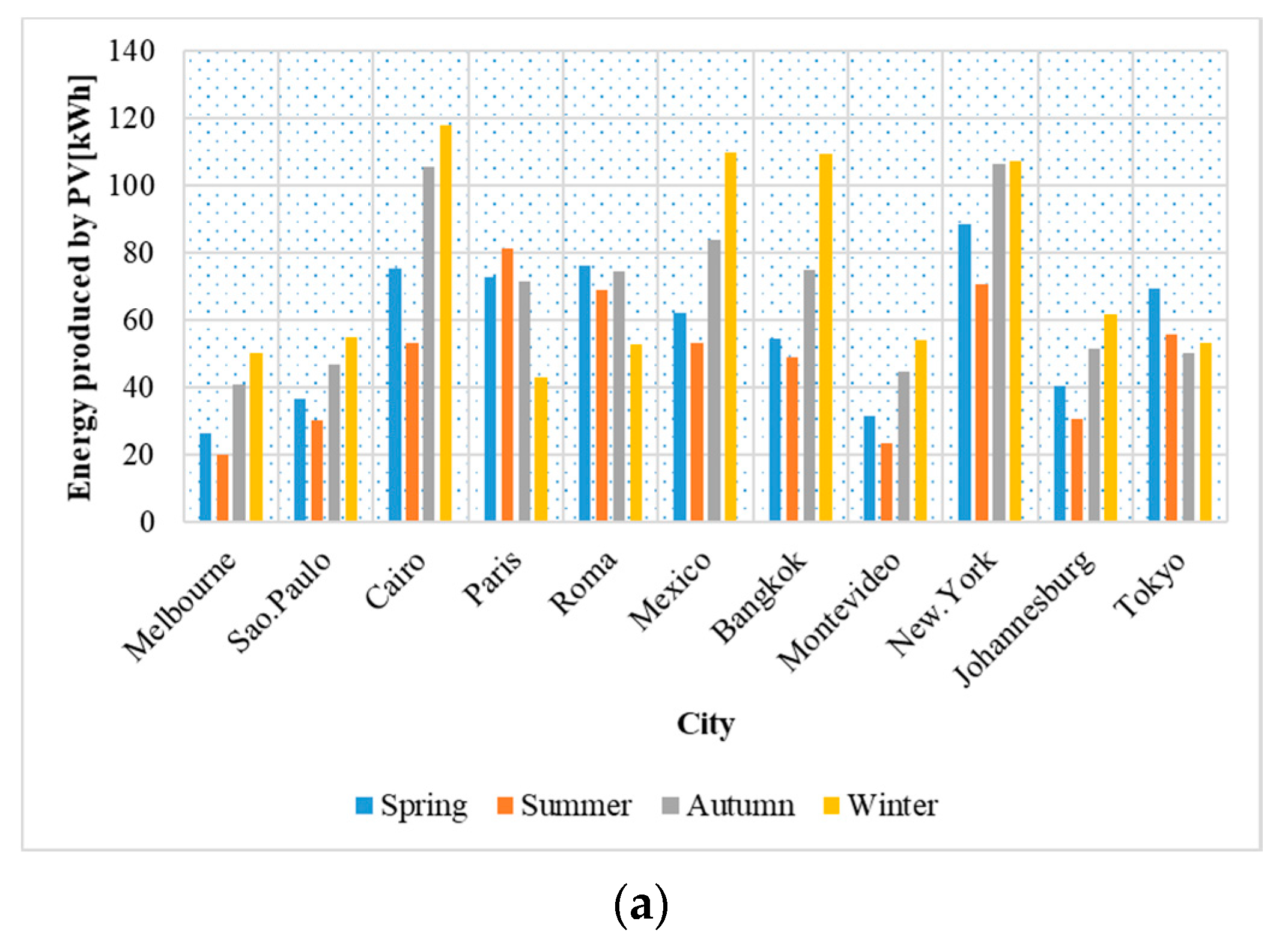

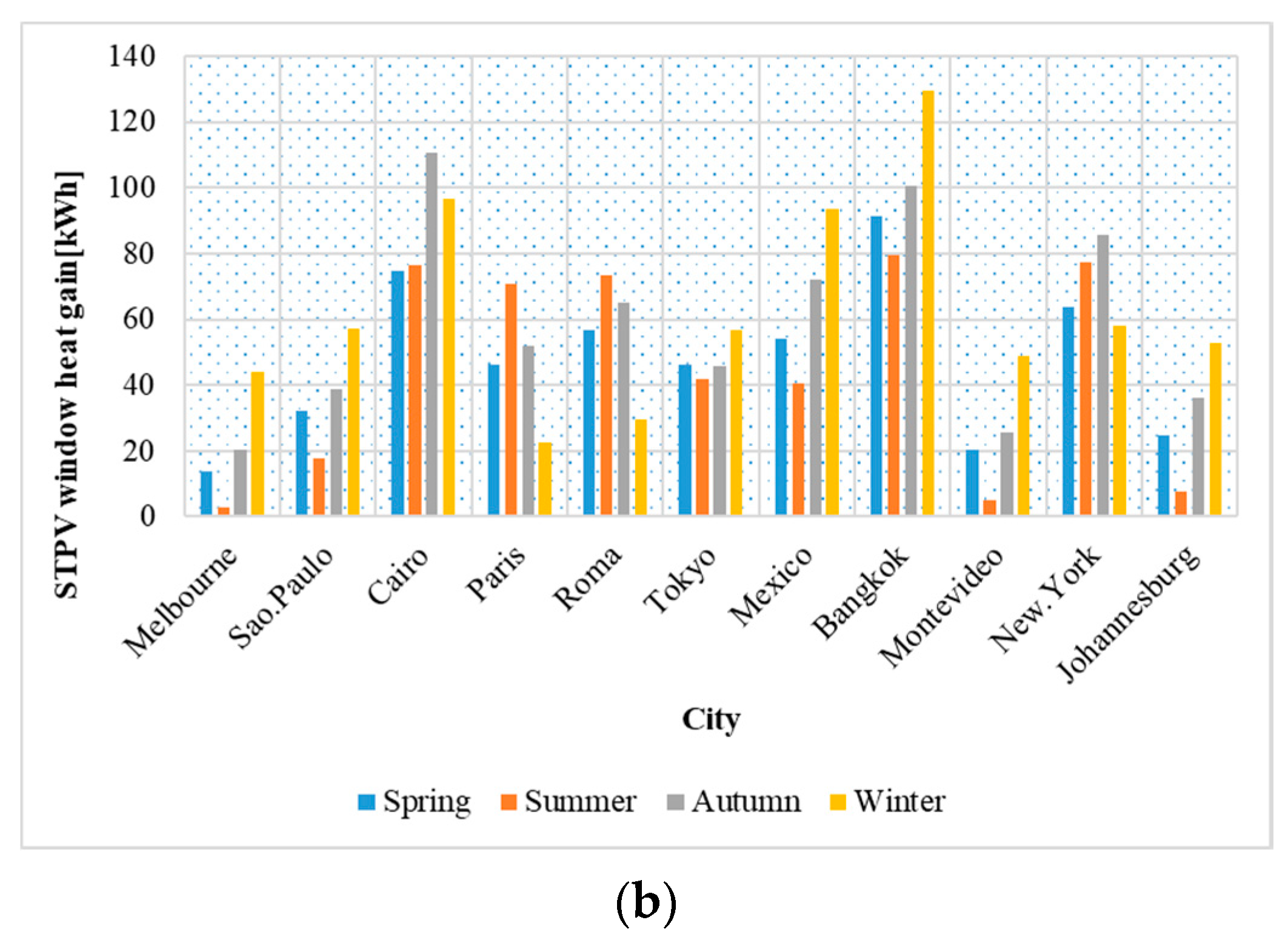

5. Application Potential Analysis of STPV Window in the World

6. Conclusions

- (1)

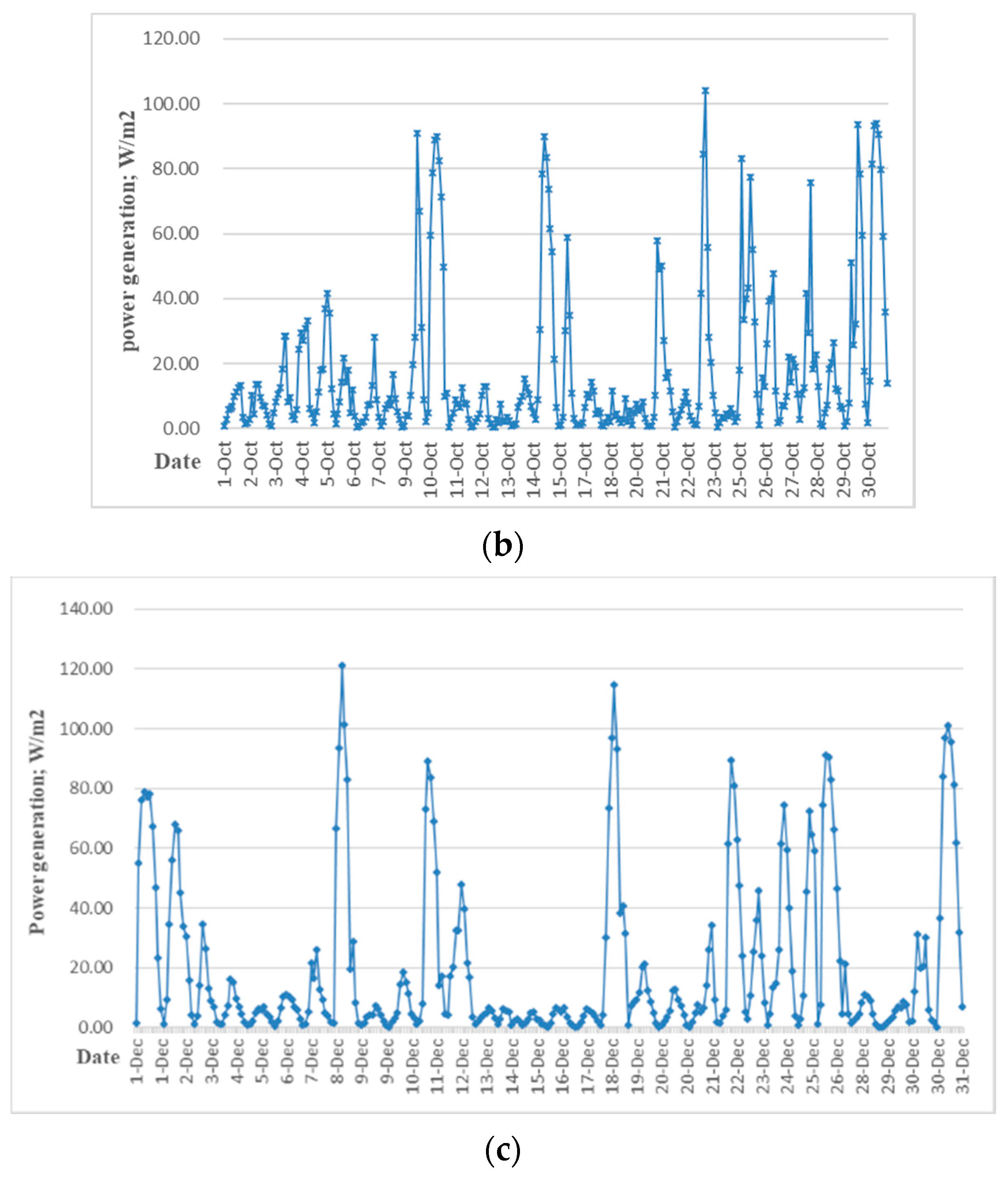

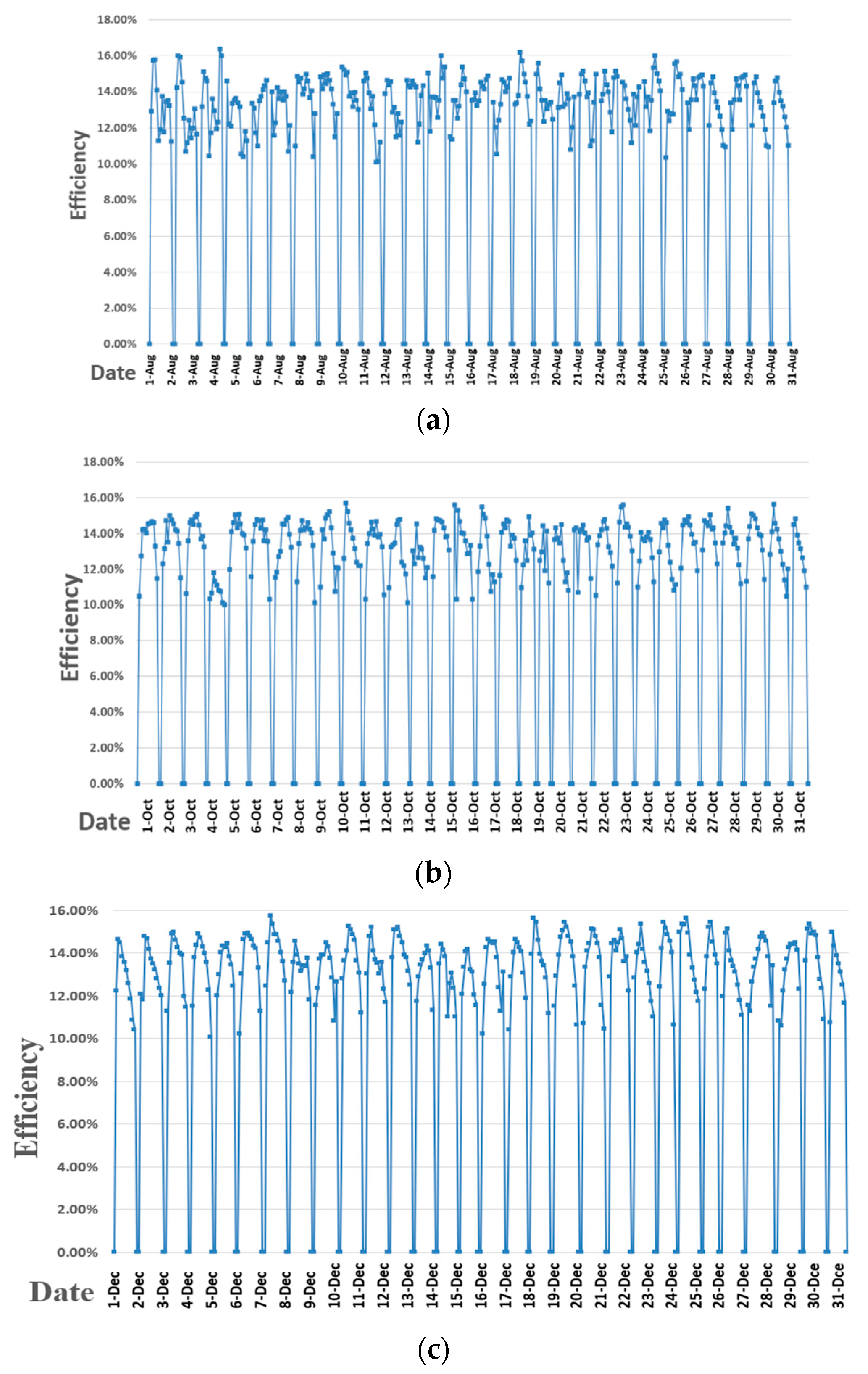

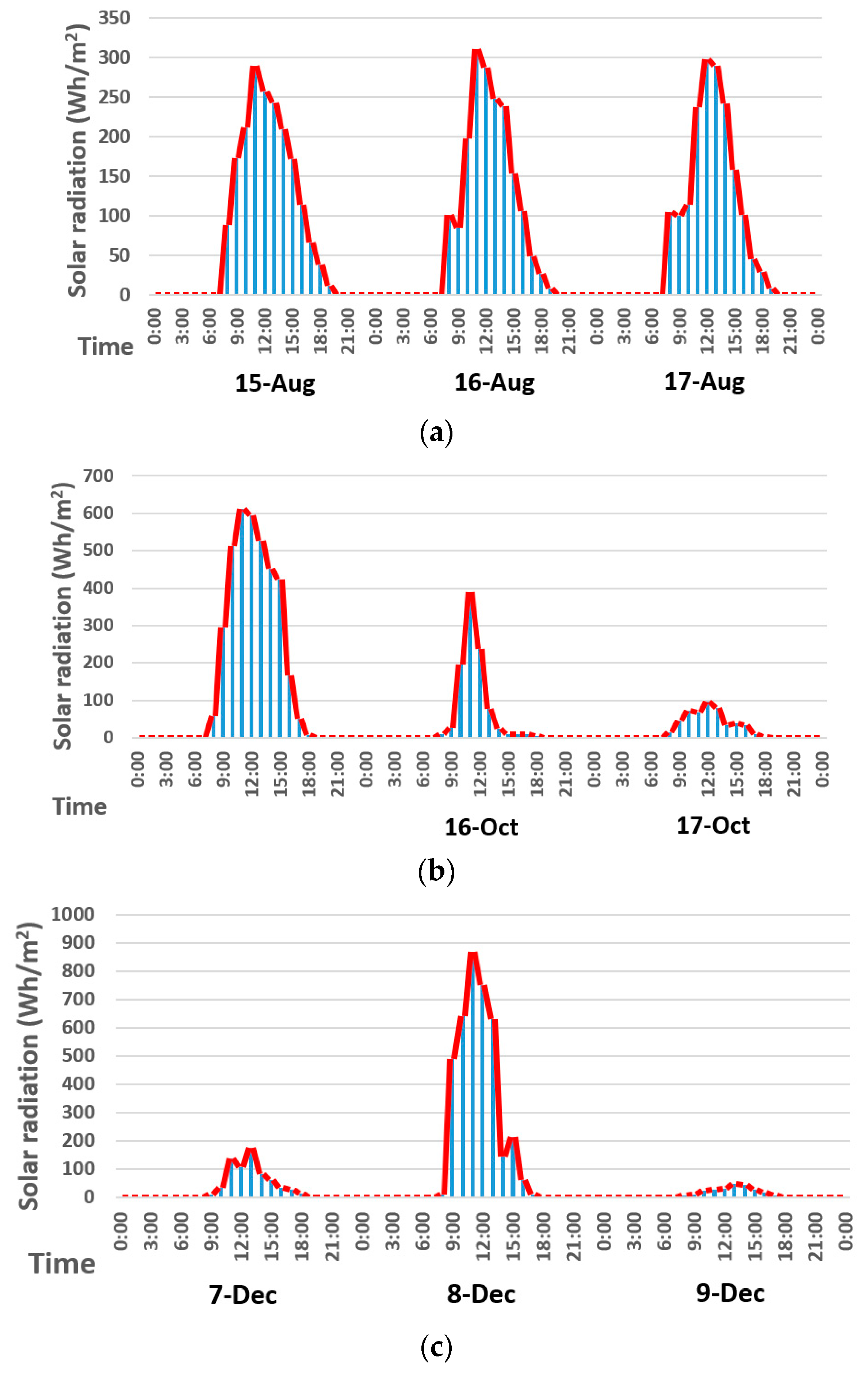

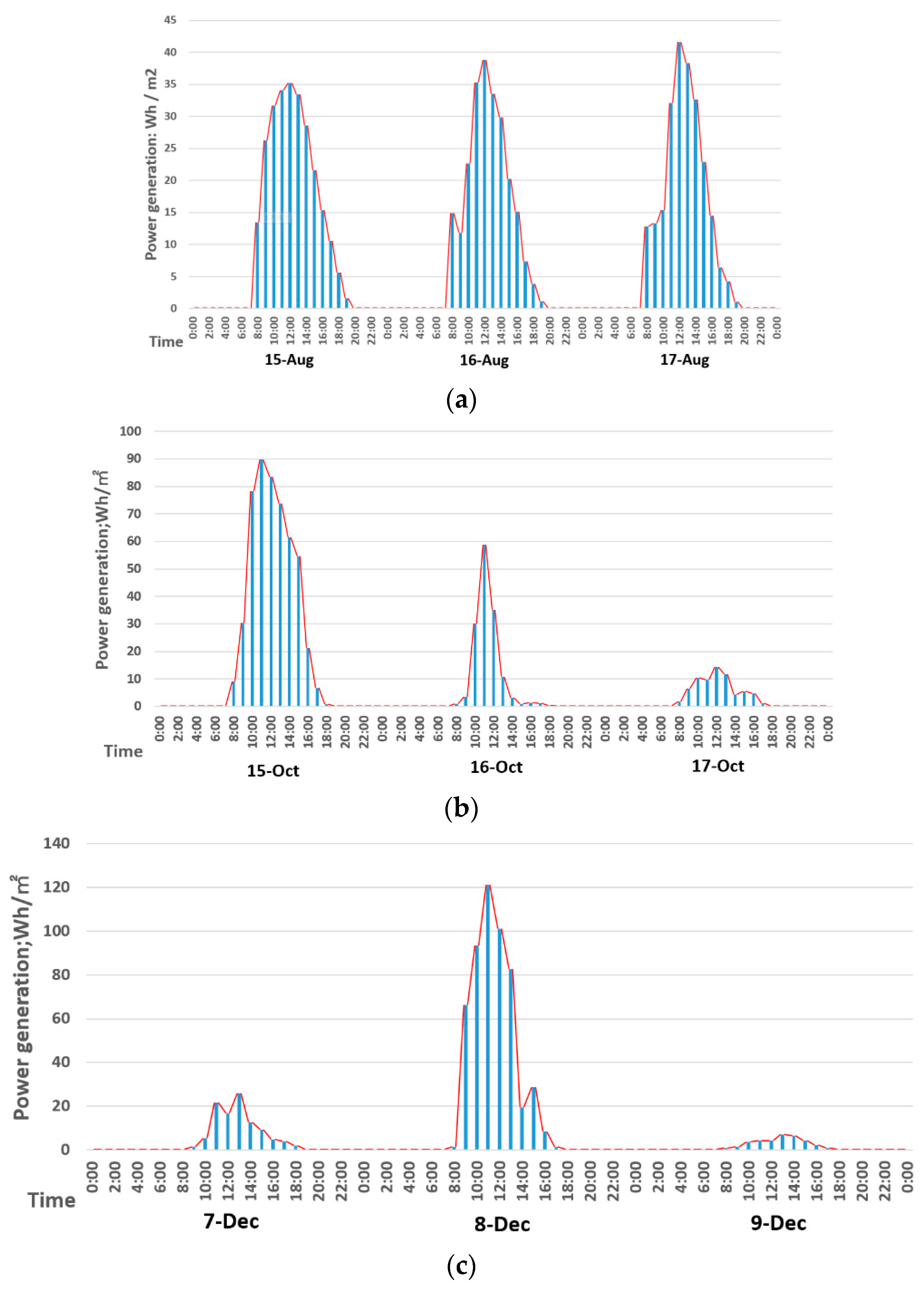

- In terms of electrical performance, because the average irradiance on the south facade wall in autumn was much greater than the other two seasons, the electricity generation of PV window in autumn was the highest with 50 W/m2 among the three seasons. The average electricity efficiency was 14.4%, 13.63%, and 13.47% in summer, autumn, and winter, respectively. This indicates that the innovation designed C-Si PV windows could work normally across different seasons. For the further typical day analysis, it has the same trend.

- (2)

- For the thermal performance analysis, the average heat daily flux density through PV window was up to 60 W/m2 due to the high outdoor ambient temperature in summer. In Autumn, the average heat gain of the PV window was 80 W/m2, which was significantly higher than that of the two seasons. Some measures could be considered such as shading and ventilation in order to reduce the building cooling load. In winter, the heat generation could be strengthened and reduce the building heating load.

- (3)

- Although the PV window blocks the daylighting partially, the daylighting requirement was still met on most of the days. Furthermore, the average of the UDI in summer was the highest up to 0.79, and the average illumination uniform among the all seasons may achieve a higher level. It indicates that the PV window can improve the indoor lighting environment of the BIPV building.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| PV | Photovoltaic |

| C-Si | Crystalline silicon PV cells |

| a-Si | Thin film PV cells |

| PVB-DSF | Double-layer photovoltaic shutters |

| SHGC | The fraction of incident solar radiation admitted through a window, both directly transmitted and absorbed and subsequently released inward |

| U value | Heat transfer coefficient |

| UDI | The useful daylight illuminance |

| Symbols | |

| The solar radiation direct transferred into the room through the PV window, W/m2 | |

| Gr | The radiation heat transfer, W/m2 |

| Gc | The conductive heat transfer, W/m2 |

| η | The PV window power generation efficiency, W/m2 |

| P | The output of PV window, W |

| Aw | The area of PV window, m2 |

| To | The outdoor ambient temperature, °C |

| Ti | The indoor temperature, °C |

| Cav | The average indoor daylighting coefficient on the working surface |

| Duni | The uniformity ratio of daylighting |

| Cmin | The minimum indoor lighting coefficient |

| tud | The useful daylighting time |

| tT | The total daytime, s |

References

- U.S. Energy Information Administration. International Energy Outlook 2016—EIA. 2016. Available online: http://www.iea.org/etp/buildings/ (accessed on 15 May 2020).

- Myong, S.Y.; Jeon, S.W. Efficient outdoor performance of esthetic bifacial a-Si: H semi-transparent PV modules. Appl. Energy 2016, 164, 312–320. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, W.; Xie, L.; Ni, Z.; Wei, Q.; Wang, W.; Tian, H. Experimental and numerical evaluation of the crystalline silicon PV window under the climatic conditions in southwest China. Energy 2019, 183, 584–598. [Google Scholar] [CrossRef]

- Yoon, J.H.; Shim, S.R.; An, Y.S.; Lee, K.H. An experimental study on the annual surface temperature characteristics of amorphous silicon BIPV window. Energy Build. 2013, 62, 166–175. [Google Scholar] [CrossRef]

- Song, J.H.; An, Y.S.; Kim, S.G.; Leea, S.J.; Yoonb, J.H.; Choung, Y.K. Power output analysis of transparent thin-film module in building integrated photovoltaic system (BIPV). Energy Build. 2008, 40, 2067–2075. [Google Scholar] [CrossRef]

- McCormick, P.G.; Suehrcke, H. The effect of intermittent solar radiation on the performance of PV systems. Sol. Energy 2018, 171, 667–674. [Google Scholar] [CrossRef]

- Park, K.E.; Kang, G.H.; Kim, H.I.; Yu, G.J.; Kim, J.T. Analysis of thermal and electrical performance of semi-transparent photovoltaic (PV) module. Energy 2010, 35, 2681–2687. [Google Scholar] [CrossRef]

- Li DH, W.; Lam TN, T.; Cheung, K.L. Energy and cost studies of semi-transparent photovoltaic skylight. Energy Convers. Manag. 2009, 50, 1981–1990. [Google Scholar]

- Wang, M.; Peng, J.; Li, N.; Lu, L.; Yang, H. Experimental study on thermal performance of semi-transparent PV window in winter in Hong Kong. Energy Procedia 2017, 105, 864–868. [Google Scholar] [CrossRef]

- Zhang, Y.; He, W.; Ji, J. CFD simulation analysis of thermal performance of photovoltaic double window. Build. Technol. 2009, 24, 48–51. [Google Scholar]

- Chen, H.; Cai, B.; Guo, J.; Wang, C.; Chen, F.; Yang, J. Air-cooled Photovoltaic Blinds with Automatic Sun Tracking System. Build. Energy Effic. 2017, 2, 29–34. [Google Scholar]

- Luo, Y.; Zhang, L.; Liu, Z.; Xie, L.; Wang, X.; Wu, J. Experimental study and performance evaluation of a PV-blind embedded double skin façade in winter season. Energy 2018, 165, 326–342. [Google Scholar] [CrossRef]

- Urraca, R.; Huld, T.; Lindfors, A.V.; Riiheläc, A.; Martinez-de-Pison, F.J.; Sanz-Garcia, A. Quantifying the amplified bias of PV system simulations due to uncertainties in solar radiation estimates. Sol. Energy 2018, 176, 663–677. [Google Scholar] [CrossRef] [Green Version]

- Lv, X. The Strategy of Energy Saving Design of Office Building Windows in Hot-Summer and Cold-Winter Area. Master’s Thesis, Hefei University of Technology, Hefei, China, 2010. [Google Scholar]

- Nie, J.; Weng, Z.; Liu, B.; Zhang, G.; Zhang, M.; Wei, S.; Chen, D. The Influence of Different Wavelength Light on the Characteristics of Flexible Solar Cell. Phys. Bull. 2015, 3, 118–121. [Google Scholar]

- Chow, T.T.; Li, C.; Lin, Z. Innovative solar windows for cooling-demand climate. Sol. Energy Mater. Sol. Cells 2010, 94, 212–220. [Google Scholar] [CrossRef]

- Marinoski, D.L.; Güths, S.; Pereira, F.O.R.; Lamberts, R. Improvement of a measurement system for solar heat gain through fenestrations. Energy Build. 2007, 39, 478–487. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Kalogirou, S.A. Application of infrared thermography for the determination of the overall heat transfer coefficient (U-Value) in building envelopes. Appl. Energy 2011, 88, 4358–4365. [Google Scholar] [CrossRef]

- Tina, G.M.; Gagliano, A. An improved multi-layer thermal model for photovoltaic modules. In Proceedings of the 2016 International Multidisciplinary Conference on Computer and Energy Science (SpliTech), Split, Croatia, 13–15 July 2016; pp. 1–6. [Google Scholar]

- Method of Daylighting Measurement; Standardization Administration of China: Beijing, China, 2017.

- Wei, W.; Kunpeng, L. An Introduction of New Daylighting Evaluation Criteria: A Replacement for Daylight Factor. China Illum. Eng. J. 2012, 2, 3. [Google Scholar]

- Nabil, A.; Mardaljevic, J. Useful daylight illuminances: A replacement for daylight factors. Energy Build. 2006, 38, 905–913. [Google Scholar] [CrossRef]

- Code for Thermal Design of Building (GB 50176-2016); China Architecture and Building Press: Beijing, China, 2016.

- Lu, L.; Law, K.M. Overall energy performance of semi-transparent single-glazed photovoltaic (PV) window for a typical office in Hong Kong. Renew. Energy 2013, 49, 250–254. [Google Scholar] [CrossRef]

- Methods of Daylighting Mersurements (GB/T 5699-2017); China Academy of Building Research: Beijing, China, 2017.

- Wang, W.; Zhang, W.; Xie, L.; Wu, Y.; Tian, H.; Zheng, L. Experimental Assessment of the Energy Performance of a Double-Skin Semi-Transparent PV Window in the Hot-Summer and Cold-Winter Zone of China. Energies 2018, 11, 1700. [Google Scholar] [CrossRef] [Green Version]

- Manual for Outdoor PV Test SYSTEM. 2018. Available online: http://www.ei41.com/Home/JSZC_Search? openPartTypeName=jishuzhichi_chanpinziliao (accessed on 15 March 2018).

- National Standard of the People’s Republic of China. GB 50736-2012: Design Code for Heating Ventilation and Air Conditioning of Civil Buildings; China Architecture and Building Press: Beijing, China, 2012. [Google Scholar]

- Standard for Daylighting Design of Buildings (GB/T 50033-2013); Ministry of Housing and Urban-Rural Development of the People’s Republic of China and General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2013.

- Gagliano, A.; Aneli, S.; Nocera, F. Analysis of the performance of a building solar thermal facade (BSTF) for domestic hot water production. Renew. Energy 2019, 142, 511–526. [Google Scholar] [CrossRef]

- Tina, G.M.; Gagliano, A.; Nocera, F.; Patania, F. Photovoltaic glazing: Analysis of thermal behavior and indoor comfort. Energy Procedia 2013, 42, 367–376. [Google Scholar] [CrossRef] [Green Version]

| a. The Properties of Double-Skin C-Si STPV Window | |

|---|---|

| Layer/Property | thickness (mm) |

| Conventional glass | 6 |

| Air gap | 9 |

| PV module | 2 |

| Coverage ratio of the PV window | 80% |

| b. The Parameters of C-Si Component | |

| Size (mm) | 156.2 × 156.2 |

| Efficiency (%) | 18.8 |

| P max under STC (W) | 4.62 |

| U oc under STC (V) | 0.641 |

| I sc under STC (A) | 9.025 |

| c. The Parameters of Glazing | |

| Size (mm) | 156.2 × 156.2 |

| SHGC | 0.72 |

| U value ()) | 2.83 |

| Visible transmittance | 0.723 |

| Equipment | Manufacture | Function | Accuracy/Sensitivity |

|---|---|---|---|

| Outdoor multi-channel PV | CETC | PV testing | 0 W–10 kW |

| Pyranometer | JianTongtech | Testing the solar radiation | 0~1800 W/m2; ±3% |

| Weather station | JianTongtech | Weather condition recorder | Temperature: ±0.5 °C, humidity: 0.1%, ±2%; atmospheric pressure: 1 mbar; wind rate: 0.1 m/s; wind direction: ±5% |

| T-type Thermocouples | JianTongtech | Temperature test | −20 °C–100 °C; 0.1 °C; ±0.5 °C |

| Conductive heat flux meters | JianTongtech | Conductive heat flux test | −2000 W/m2–2000 W/m2; 5% |

| Radiant heat flux sensor | JianTongtech | Radiant heat flux test | −2000 W/m2–2000 W/m2; DC5V; 0.3 μm–50 μm; ±5% |

| Light meter | JianTongtech | Illuminance measurement | 0–100,000 lux; 1 lux; ±4% |

| Multi-channel data recorder | JianTongtech | Data collector | The minimum resolutions are 1 μV and 0.1 °C |

| Spring | Summer | Autumn | Winter | |

|---|---|---|---|---|

| Maximum illumination of the test room; lx | 1500 | 1200 | 1600 | 2500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wang, W.; Xie, L.; Tian, H.; Chen, M.; Li, Z.; Li, J. Cross-seasonal Experimental Study on the Comprehensive Performance of C-Si PV Window. Energies 2020, 13, 5684. https://doi.org/10.3390/en13215684

Zhang W, Wang W, Xie L, Tian H, Chen M, Li Z, Li J. Cross-seasonal Experimental Study on the Comprehensive Performance of C-Si PV Window. Energies. 2020; 13(21):5684. https://doi.org/10.3390/en13215684

Chicago/Turabian StyleZhang, Wei, Wei Wang, Lingzhi Xie, Hao Tian, Mo Chen, Zihao Li, and Jianhui Li. 2020. "Cross-seasonal Experimental Study on the Comprehensive Performance of C-Si PV Window" Energies 13, no. 21: 5684. https://doi.org/10.3390/en13215684