A Review of Energy Management Assessment Models for Industrial Energy Efficiency

Abstract

:1. Introduction

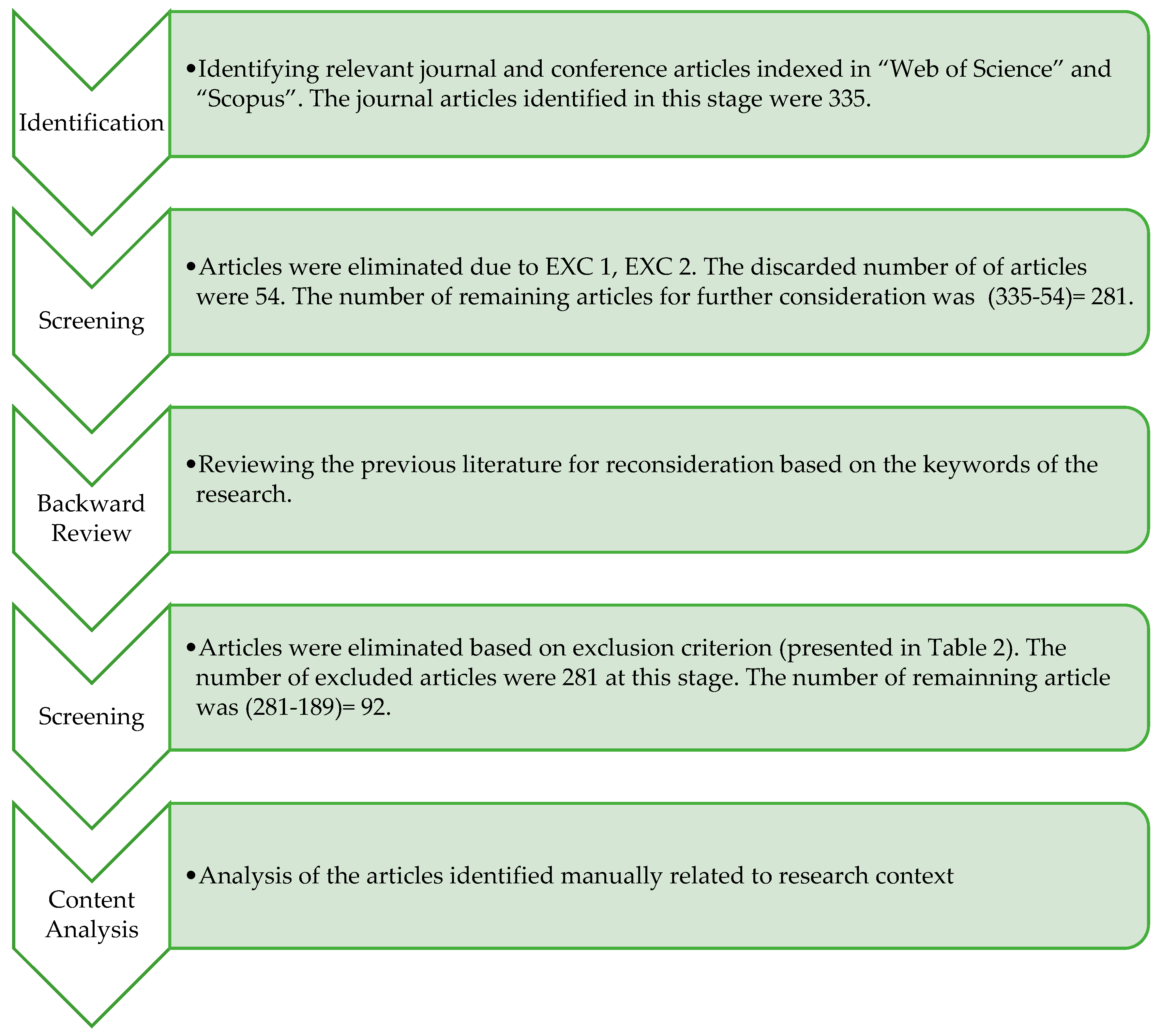

2. Methodology

3. Results and Analysis

3.1. Energy Management Definition

3.2. Approaches to Energy Management Models

3.2.1. Minimum Requirements

3.2.2. Maturity Models

3.2.3. Energy Management Matrixes

3.2.4. Energy Efficiency Measures (EEM) Characterization Framework

4. Discussion

5. Concluding Remarks and Future Research Avenues

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| EMP | Energy Management Practice |

| EEM | Energy Efficiency Measure |

| ESM | Energy Saving Measure |

| SME | Small- and Medium-sized Enterprise |

| GHG | Greenhouse Gases |

| CMM | Capability Maturity Model |

| PDCA | Plan-Do-Check-Act |

| CMMI | Capability Maturity Model Integration |

| EMMM50001 | ISO 50001-based Energy Management Maturity Model |

| ISO | International Organization for Standardization |

| EnMS | Energy Management System |

| EUMMM | Energy and Utility Management Maturity Model |

References

- Faheem, M.; Gungor, V.C. Energy efficient and QoS-aware routing protocol for wireless sensor network-based smart grid applications in the context of industry 4.0. Appl. Soft Comput. J. 2018, 68, 910–922. [Google Scholar] [CrossRef]

- Tesch da Silva, F.S.; da Costa, C.A.; Paredes Crovato, C.D.; da Rosa Righi, R. Looking at energy through the lens of Industry 4.0: A systematic literature review of concerns and challenges. Comput. Ind. Eng. 2020, 143, 106426. [Google Scholar] [CrossRef]

- König, W. Energy efficiency in industrial organizations—A cultural-institutional framework of decision making. Energy Res. Soc. Sci. 2020, 60, 101314. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Trianni, A. Broadening to sustainability the perspective of industrial decision-makers on the energy efficiency measures adoption: Some empirical evidence. Energy Effic. 2018, 11, 1193–1210. [Google Scholar] [CrossRef] [Green Version]

- Pye, M.; McKane, A. Making a stronger case for industrial energy efficiency by quantifying non-energy benefits. Resour. Conserv. Recycl. 2000, 28, 171–183. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management—Gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Sola, A.V.H.; Mota, C.M.M. Influencing factors on energy management in industries. J. Clean. Prod. 2020, 248, 119263. [Google Scholar] [CrossRef]

- Introna, V.; Cesarotti, V.; Benedetti, M.; Biagiotti, S.; Rotunno, R. Energy Management Maturity Model: An organizational tool to foster the continuous reduction of energy consumption in companies. J. Clean. Prod. 2014, 83, 108–117. [Google Scholar] [CrossRef]

- Hirst, E.; Brown, M. Closing the efficiency gap: Barriers to the efficient use of energy. Resour. Conserv. Recycl. 1990, 3, 267–281. [Google Scholar] [CrossRef]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Anderson, S.T.; Newell, R.G. Information programs for technology adoption: The case of energy-efficiency audits. Resour. Energy Econ. 2004, 26, 27–50. [Google Scholar]

- Cagno, E.; Trianni, A. Analysis of the Most Effective Energy Efficiency Opportunities in Manufacturing Primary Metals, Plastics, and Textiles Small- and Medium-Sized Enterprises. J. Energy Resour. Technol. 2012, 134. [Google Scholar] [CrossRef]

- Jaffe, A.B.; Stavins, R.N. The energy-efficiency gap What does it mean? Energy Policy 1994, 22, 804–810. [Google Scholar]

- Johansson, M.T. Improved energy efficiency within the Swedish steel industry—The importance of energy management and networking. Energy Effic. 2015, 8, 713–744. [Google Scholar]

- Brunke, J.C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef] [Green Version]

- Hasan, A.S.M.M.; Rokonuzzaman, M.; Tuhin, R.A.; Salimullah, S.M.; Ullah, M.; Sakib, T.H.; Thollander, P. Drivers and Barriers to Industrial Energy Efficiency in Textile Industries of Bangladesh. Energies 2019, 12, 1775. [Google Scholar] [CrossRef] [Green Version]

- Soepardi, A.; Thollander, P. Analysis of Relationships among Organizational Barriers to Energy Efficiency Improvement: A Case Study in Indonesia’s Steel Industry. Sustainability 2018, 10, 216. [Google Scholar]

- Trianni, A.; Cagno, E.; Thollander, P.; Backlund, S. Barriers to industrial energy efficiency in foundries: A European comparison. J. Clean. Prod. 2013, 40, 161–176. [Google Scholar]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar]

- Cagno, E.; Trianni, A.; Spallina, G.; Marchesani, F. Erratum to: Drivers for energy efficiency and their effect on barriers: Empirical evidence from Italian manufacturing enterprises. Energy Effic. 2017, 10. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Marchesani, F.; Spallina, G. Classification of drivers for industrial energy efficiency and their effect on the barriers affecting the investment decision-making process. Energy Effic. 2017, 10, 199–215. [Google Scholar] [CrossRef]

- Apeaning, R.W.; Thollander, P. Barriers to and driving forces for industrial energy efficiency improvements in African industries—A case study of Ghana’s largest industrial area. J. Clean. Prod. 2013, 53, 204–213. [Google Scholar] [CrossRef] [Green Version]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M.; Giretti, A. Environmental impacts related to the commissioning and usage phase of an intelligent energy management system. Appl. Energy 2015, 138, 216–223. [Google Scholar]

- Sa, A.; Paramonova, S.; Thollander, P.; Cagno, E. Classification of Industrial Energy Management Practices: A Case Study of a Swedish Foundry. Energy Procedia 2015, 75, 2581–2588. [Google Scholar]

- Trianni, A.; Cagno, E.; Bertolotti, M.; Thollander, P.; Andersson, E. Energy management: A practice-based assessment model. Appl. Energy 2019, 235, 1614–1636. [Google Scholar]

- Hasan, A.S.M.M.; Hoq, M.T.; Thollander, P. Energy management practices in Bangladesh’s iron and steel industries. Energy Strateg. Rev. 2018, 22, 230–236. [Google Scholar]

- Thollander, P.; Ottosson, M. Energy management practices in Swedish energy-intensive industries. J. Clean. Prod. 2010, 18, 1125–1133. [Google Scholar]

- Hasan, A.S.M.M.; Hossain, R.; Tuhin, R.A.; Sakib, T.H.; Thollander, P. Empirical Investigation of Barriers and Driving Forces for Efficient Energy Management Practices in Non-Energy-Intensive Manufacturing Industries of Bangladesh. Sustainability 2019, 11, 2671. [Google Scholar]

- Backlund, S.; Thollander, P. Thollander the energy-service gap. What does it mean? In Proceedings of the ECEEE 2011 Summer Study, Hyères, France, 6–11 June 2011; pp. 649–656. [Google Scholar]

- Good, N.; Martínez Ceseña, E.A.; Zhang, L.; Mancarella, P. Techno-economic and business case assessment of low carbon technologies in distributed multi-energy systems. Appl. Energy 2016, 167, 158–172. [Google Scholar]

- Kannan, R.; Boie, W. Energy management practices in SME—Case study of a bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef] [Green Version]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The SAGE Handbook of Organizational Research Methods; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. ISBN 9781412931182. [Google Scholar]

- Higgins, J.P.; Green, S. Cochrane Handbook for Systematic Reviews of Interventions: Cochrane Book Series; John Wiley and Sons: Hoboken, NJ, USA, 2008; ISBN 9780470699515. [Google Scholar]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; Delgado López-Cózar, E. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Informetr. 2018, 12, 1160–1177. [Google Scholar] [CrossRef] [Green Version]

- Podsakoff, P.M.; MacKenzie, S.B.; Bachrach, D.G.; Podsakoff, N.P. The influence of management journals in the 1980s and 1990s. Strateg. Manag. J. 2005, 26, 473–488. [Google Scholar] [CrossRef]

- Kahlenborn, W.; Kabisch, S.; Klein, J.; Ina Richter, S.S. Energy Management–Systems in Practice: A Guide for Companies and Organisations; Federal Ministry for the Environment, Nature Conservation and Nuclear Safety: Bonn, Germany, 2010; p. 12. [Google Scholar]

- Capehart, B.L.; Turner, W.C.; Kennedy, W.J. Guide to Energy Management, 5th ed.; The Fairmont Press: Lilburn, GA, USA, 2006; ISBN 0881734772. [Google Scholar]

- O’Callaghan, P.W.; Probert, S.D. Energy management. Appl. Energy 1977, 3, 127–138. [Google Scholar] [CrossRef]

- Ates, S.A.; Durakbasa, N.M. Evaluation of corporate energy management practices of energy intensive industries in Turkey. Energy 2012, 45, 81–91. [Google Scholar] [CrossRef]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Rasmussen, J. The additional benefits of energy efficiency investments—A systematic literature review and a framework for categorisation. Energy Effic. 2017, 10, 1401–1418. [Google Scholar] [CrossRef] [Green Version]

- Mckane, A.; Williams, R.; Perry, W. Setting the Standard for Industrial Energy Efficiency Permalink. In Proceedings of the Conference on Energy Efficiency in Motor Driven Systems, Beijing, China, 10–13 June 2007. [Google Scholar]

- Christoffersen, L.B.; Larsen, A.; Togeby, M. Empirical analysis of energy management in Danish industry. J. Clean. Prod. 2006, 14, 516–526. [Google Scholar] [CrossRef]

- ISO 50001:2018(en), Energy Management Systems—Requirements with Guidance for Use. Available online: https://www.iso.org/obp/ui/#iso:std:iso:50001:ed-2:v1:en (accessed on 18 October 2020).

- Sa, A.; Thollander, P.; Cagno, E. Assessing the driving factors for energy management program adoption. Renew. Sustain. Energy Rev. 2017, 74, 538–547. [Google Scholar] [CrossRef]

- Weber, C.V.; Curtis, B.; Chrissis, M.B. Capability Maturity Model, Version 1.1. IEEE Softw. 1993, 10, 18–27. [Google Scholar]

- Becker, J.; Knackstedt, R.; Pöppelbuß, J. Developing Maturity Models for IT Management. Bus. Inf. Syst. Eng. 2009, 1, 213–222. [Google Scholar] [CrossRef]

- Scott, J.E. Mobility, business process management, software sourcing, and maturity model trends: Propositions for the IS organization of the future. Inf. Syst. Manag. 2007, 24, 139–145. [Google Scholar] [CrossRef]

- Lahrmann, G.; Marx, F.; Mettler, T.; Winter, R.; Wortmann, F. Inductive Design of Maturity Models: Applying the Rasch Algorithm for Design Science Research; Springer: Berlin/Heidelberg, Germany, 2011; Volume 6629, ISBN 9783642206320. [Google Scholar]

- CMMI Product Team. CMMI for Development, Version 1.3; Software Engineering Institute, Carnegie Mellon University: Pittsburgh, PA, USA, 2010. [Google Scholar]

- Proença, D.; Borbinha, J. Maturity Models for Information Systems—A State of the Art. In Proceedings of the Procedia Computer Science; Elsevier: Amsterdam, The Netherlands, 2016; Volume 100, pp. 1042–1049. [Google Scholar]

- Jovanović, B.; Filipović, J. ISO 50001 standard-based energy management maturity model—Proposal and validation in industry. J. Clean. Prod. 2016, 112, 2744–2755. [Google Scholar] [CrossRef]

- Ngai, E.W.T.; Chau, D.C.K.; Poon, J.K.L.; To, C.K.M. Energy and utility management maturity model for sustainable manufacturing process. Int. J. Prod. Econ. 2013, 146, 453–464. [Google Scholar] [CrossRef]

- Gordić, D.; Babić, M.; Jovičić, N.; Šušteršič, V.; Končalović, D.; Jelić, D. Development of energy management system-Case study of Serbian car manufacturer. Energy Convers. Manag. 2010, 51, 2783–2790. [Google Scholar] [CrossRef]

- Carbon Trust. Energy Management—A Comprehensive Guide to Controlling Energy Use; Carbon Trust: London, UK, 2011. [Google Scholar]

- ENERGY STAR. Guidelines for Energy Management; ENERGY STAR: Oakland, CA, USA, 2012. [Google Scholar]

- Fleiter, T.; Hirzel, S.; Worrell, E. The characteristics of energy-efficiency measures—A neglected dimension. Energy Policy 2012, 51, 502–513. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; De Donatis, A. A framework to characterize energy efficiency measures. Appl. Energy 2014, 118, 207–220. [Google Scholar] [CrossRef]

- Worrell, E.; Laitner, J.A.; Ruth, M.; Finman, H. Productivity benefits of industrial energy efficiency measures. Energy 2003, 28, 1081–1098. [Google Scholar] [CrossRef] [Green Version]

- Lung, R.B.; McKane, A.; Leach, R.; Marsh, D. Ancillary Savings and Production Benefits in the Evaluation of Industrial Energy Efficiency Measures. In Proceedings of the 2005 American Council for an Energy-Efficient Economy Summer Study on Energy Efficiency in Industry; ACEEE: Washington, DC, USA, 2005; pp. 103–114. [Google Scholar]

- Sorrell, S. The economics of energy service contracts. Energy Policy 2007, 35, 507–521. [Google Scholar] [CrossRef]

- Benedetti, M.; Cesarotti, V.; Holgado, M.; Introna, V.; Macchi, M. A proposal for energy services’ classification including a product service systems perspective. In Proceedings of the Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2015; Volume 30, pp. 251–256. [Google Scholar]

- Antunes, P.; Carreira, P.; Mira da Silva, M. Towards an energy management maturity model. Energy Policy 2014, 73, 803–814. [Google Scholar] [CrossRef]

- O’Sullivan, J. Energy Management Maturity Model (EM3)—A Strategy to Maximize the Potential for Energy Savings through EnMS. 2012. [Google Scholar]

- Finnerty, N.; Sterling, R.; Coakley, D.; Keane, M.M. An energy management maturity model for multi-site industrial organisations with a global presence. J. Clean. Prod. 2017, 167, 1232–1250. [Google Scholar] [CrossRef] [Green Version]

- Prashar, A. Energy efficiency maturity (EEM) assessment framework for energy-intensive SMEs: Proposal and evaluation. J. Clean. Prod. 2017, 166, 1187–1201. [Google Scholar] [CrossRef]

- Ashford, C.J. Energy Efficiency: A Managed Resource. Facilities 1993, 11, 24–27. [Google Scholar] [CrossRef]

- ISO 50001:2011(en), Energy Management Systems—Requirements with Guidance for Use. Available online: https://www.iso.org/obp/ui/#iso:std:iso:50001:ed-1:v1:en (accessed on 11 April 2020).

- Mao, M.; Jin, P.; Hatziargyriou, N.D.; Chang, L. Multiagent-based hybrid energy management system for microgrids. IEEE Trans. Sustain. Energy 2014, 5, 938–946. [Google Scholar] [CrossRef]

- Blaauwbroek, N.; Nguyen, P.H.; Konsman, M.J.; Shi, H.; Kamphuis, R.I.G.; Kling, W.L. Decentralized Resource Allocation and Load Scheduling for Multicommodity Smart Energy Systems. IEEE Trans. Sustain. Energy 2015, 6, 1506–1514. [Google Scholar] [CrossRef] [Green Version]

- Jokela, T.; Siponen, M.; Hirasawa, N.; Earthy, J. A survey of usability capability maturity models: Implications for practice and research. Behav. Inf. Technol. 2006, 25, 263–282. [Google Scholar] [CrossRef]

- Krishnan, M.S.; Kriebel, C.H.; Kekre, S.; Mukhopadhyay, T. An Empirical Analysis of Productivity and Quality in Software Products. Manag. Sci. 2000, 46, 745–759. [Google Scholar] [CrossRef]

- Fawcett, T.; Hampton, S. Why & how energy efficiency policy should address SMEs. Energy Policy 2020, 140, 111337. [Google Scholar]

- Skumatz, L.A.; Dickerson, C.A. Extra! Extra! Non-Energy Benefits Swamp Load Impacts For PG&E Program! In Proceedings of the 1998 ACEEE Summer Study, Panel 8, Pacific Grove, CA, USA, 25–31 August 1998; pp. 301–312. [Google Scholar]

- Skumatz, L.A.; Gardner, J. Methods and results for measuring non-energy benefits in the commercial and industrial sectors. In Proceedings of the Proceedings ACEEE Summer Study on Energy Efficiency in Industry, Washington, DC, USA, 2005; pp. 163–176. [Google Scholar]

- Mills, E.; Rosenfeld, A. Consumer non-energy benefits as a motivation for making energy-efficiency improvements. Energy 1996, 21, 707–720. [Google Scholar] [CrossRef]

- Gilchrist, A. Industrial Internet Use-Cases; Apress: Berkeley, CA, USA, 2016. [Google Scholar]

- Tortorella, G.L.; Fettermann, D. Implementation of industry 4.0 and lean production in brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Fleiter, T.; Worrell, E.; Eichhammer, W. Barriers to energy efficiency in industrial bottom-up energy demand models—A review. Renew. Sustain. Energy Rev. 2011, 15, 3099–3111. [Google Scholar] [CrossRef]

- Walsh, C.; Thornley, P. Barriers to improving energy efficiency within the process industries with a focus on low grade heat utilisation. J. Clean. Prod. 2012, 23, 138–146. [Google Scholar] [CrossRef]

- De Groot, H.L.F.; Verhoef, E.T.; Nijkamp, P. Energy saving by firms: Decision-making, barriers and policies. Energy Econ. 2001, 23, 717–740. [Google Scholar] [CrossRef] [Green Version]

- Harris, J.; Anderson, J.; Shafron, W. Investment in energy efficiency: A survey of Australian firms. Energy Policy 2000, 28, 867–876. [Google Scholar] [CrossRef]

- Hossain, S.R.; Ahmed, I.; Azad, F.S.; Monjurul Hasan, A.S.M. Empirical investigation of energy management practices in cement industries of Bangladesh. Energy 2020, 212, 118741. [Google Scholar] [CrossRef]

- Palm, J.; Thollander, P. An interdisciplinary perspective on industrial energy efficiency. Appl. Energy 2010, 87, 3255–3261. [Google Scholar] [CrossRef] [Green Version]

- Nesticò, A.; Somma, P. Comparative Analysis of Multi-Criteria Methods for the Enhancement of Historical Buildings. Sustainability 2019, 11, 4526. [Google Scholar] [CrossRef] [Green Version]

- Thiede, S. Energy Efficiency in Manufacturing Systems; Sustainable Production, Life Cycle Engineering and Management; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-25913-5. [Google Scholar]

- André, J.-C. Industry 4.0: Paradoxes and Conflicts; Wiley-ISTE: Hoboken, NJ, USA, 2019; ISBN 978-1-786-30482-7. [Google Scholar]

- Backlund, S.; Thollander, P.; Palm, J.; Ottosson, M. Extending the energy efficiency gap. Energy Policy 2012, 51, 392–396. [Google Scholar] [CrossRef] [Green Version]

- Stephan, A.; Roosa, W.C.T.; Doty, S. Energy Management Handbook, 9th ed.; Fairmont Press: Lilburn, GA, USA, 2018; ISBN 9781138666979. [Google Scholar]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

| Heading | Remark |

|---|---|

| Research domain | Energy; Engineering; Management |

| Search string | Industrial Energy Management; Energy management Practice; Energy Management Framework |

| Publication Type | The academic journals, conference proceedings, and book chapters. Working papers are not considered due to their review process state and reliability issue [36]. The included publications are Elsevier, Springer, IEEE Xplore, MDPI, Taylor & Francis, John Wiley & Sons, and Emerald. |

| Availability | Available online |

| Area | Industry |

| Relevance | Articles articulate energy management; energy efficiency proceedings at the institutional perspective |

| Time | Focus on the recent researches |

| Exclusion Heading | Remark |

|---|---|

| EXC 1 | The article published not in English |

| EXC 2 | The article uses “Energy management” term only in title and does not incorporate in any energy management framework or model in an elaborated form |

| EXC 3 | The article uses “Energy management” only as a part of the future research direction or future perspective |

| EXC 4 | The article uses “Energy Management” just as a cited term |

| EXC 5 | Articles deals only with drivers, barriers to energy management practices in the industries |

| EXC 6 | Availability of full texts |

| EXC 7 | Working papers |

| Minimum Prerequisite | Abdelaziz et al. [41] | Christoffersen et al. [44] | Thollander and Ottosson [27] | McKane et al. [43] | Ates and Durakbasa [40] |

|---|---|---|---|---|---|

| Long-term strategic plan; inclusion of energy policy; energy saving targets. | ✓✓ | ✓ | ✓✓ | ✓ | ✓ |

| Energy activities by dedicated responsibilities and actions | ✓ | ✓ | ⨯ | ⨯ | ⨯ |

| Acquaintance of energy management team led by the energy manager | ✓✓ | ⨯ | ⨯ | ✓✓ | ✓ |

| Policies and proceedings | ⨯ | ✓ | ⨯ | ✓✓ | ✓ |

| Energy audit to explore energy-saving features | ✓✓ | ⨯ | ✓✓ | ⨯ | ⨯ |

| Planning and implementation of an explicit energy-saving program | ✓ | ✓✓ | ✓✓ | ✓✓ | ✓✓ |

| Identification of key performance indicators | ⨯ | ⨯ | ⨯ | ✓✓ | ⨯ |

| Meter and monitoring of energy consumption | ✓ | ⨯ | ✓✓ | ⨯ | ✓ |

| Energy reporting | ✓✓ | ⨯ | ⨯ | ✓✓ | ⨯ |

| Top management commitment | ⨯ | ⨯ | ✓✓ | ⨯ | ⨯ |

| Employee engagement in energy management activities | ✓ | ✓ | ✓ | ⨯ | ✓ |

| Phase | Remark |

|---|---|

| Plan | To apprehend the organizational context; incorporation of energy policy; incorporation of energy management team; consideration of actions towards risks and opportunities; conduct of energy review; identification of significant energy uses and establishment of energy performance indicators; energy baseline; objectives and energy targets; necessary action plans to improve energy performance in accordance with the organization’s energy policy. |

| Do | Implementation of the action plans; operation and maintenance controls, and communication; ensuring competence in energy domain i.e., energy performance in design and procurement. |

| Check | Monitor; quantify; analyzation; evaluation; audit and conducting management review of energy performance as well as energy management system. |

| Act | Activities to address non-conformities and continuation for improving energy performance. |

| Category | Model Narration | Remark | Reference |

|---|---|---|---|

| Minimum requirements | Significant features: energy policy, energy saving goals (quantitative) or aspirations regarding energy-saving projects and their implementation. Energy efficient purchases, specific allotment of energy responsibility and tasks. Functioning engagement of stakeholders, specially the employees by apprising, persuading, and educating. | This model consider the energy management as a comprehensive management system. Focused on policy, energy saving goals and specific energy saving projects. However, the model does not integrate the energy manager concept. Furthermore, there is no clear guideline about top or mid-level management support to achieve energy savings. Though, involvement of employee to energy saving related work are suggested. | [44] |

| “Plan-Do-Check-Act” cycle is the basis for instructions. Preconditions: management liability; policy; legitimate concern and obligations; energy audit; energy performance index; energy baseline; energy targets, and energy management blueprint; proficiency, training and consciousness; communication; archiving; energy services acquisition; operation and control; monitoring, measurement and analysis; compliance evaluation maintaining the legal necessities; in-house audit of the energy management system; aberration, corrective as well as precautionary action; archive governance; management review. | ISO 50001 incorporates nineteen characteristics in the framework. Precisely, management commitment and energy manager are also inclined to the model. Moreover, the framework integrates the employee involvements and documentation and records for further assessment. | [45] | |

| Alteration of the merest requirements from the (27)’s set by adding the metering of major proceedings; inclusion of dedicated energy manager at the industry. | This model is an extended version of Christoffersen et al. [44]. The model integrates energy metering, energy policy, energy manager, saving target and saving projects focusing on energy. | [40] | |

| Maturity Models | Five stages: preliminary, arrange, delineate, managed in quantitative form and reformed; Novel process avenues are regulated towards progress focusing on environmental aspect; Four maturity phases: practice enactment, standardization of practice, performance management and recurring phase for improvement. | The model used Capability Maturity Model Integration (CMMI) as a reference framework and extended to environmental management context. It comprised of particular procedures for energy as well as resource management. No clear guideline about dedicated energy manager. | [54] |

| Instructions to attain improved energy efficiency and amenability with energy management standards especially ISO 50001. Energy management actions are categorized into five maturity phases subsequent to the PDCA cycle. | The framework adapts manifold energy management practices based on PDCA cycle. Notably, top management support is incorporated in the framework. Energy management roles are characterized. However, no clear indication about energy manager inclusion in the process. | [64] | |

| Five levels: Emerging, Define, Integration, Optimization and Novelty; four sections on the basis of PDCA cycle, 16 pillars, and 63 sub-pillars. The model allows 5 attribution promulgation for each sub-pillar to evaluate the maturity. | Energy management review along with action plan are integrated to the framework. In addition, competence building feature is also included. | [65] | |

| Primary features for the energy consumption management keeping alignment to ISO 50001. Five phases: initial, intermittent, planning, supervisory and optimal. 5 dimensions that are portrayed as requisite for success: consciousness, information, and expertise (utmost significant); methodological proposition; energy performance management and archiving system; institutional architecture; alignment with strategy. | The tool is not incorporated with inclusion of energy manager. | [8] | |

| Incorporation with ISO 50001; knowledge base creation for self-assessment along with monitoring and improvement. The levels are depicted for each ISO 50001 process instilled by Eric et al. [54]. | The assessment tool includes top management commitment, and energy manager appointment with other manifold energy management practices. | [53] | |

| Salient features are the assessment of compelling factors for energy management adoption, contribution towards a better understanding of suitable energy management configuration with the help of evaluation of maturity level. | The model considers inclusion of energy manger, precisely a dedicated energy management team. In addition, top management support is integrated with the considered attributes in the model. | [46] | |

| Incorporation of qualitative metrics; assessment model implies on PDCA cycle; inclusion of SWOT analysis tool, incorporation of global energy management team and external peers. | Incorporates their application specific purposes which are descriptive, prescriptive, and comparative. Features with manifold energy management practices along with energy manager. | [66] | |

| Consists of three features: (1) energy efficiency features (2) energy efficiency maturity levels; (3) implementation method which is accustomed from ZED scheme especially for SMEs. Seven dimensions: management obligation, arrangement and procedure, compliance of regulation and fiscal enticements, archiving system, product and procedure innovation, in-house communication, and ethos. Consists of nineteen characteristics. | Total number of nineteen energy efficiency characteristics are integrated in the model. In addition, management commitment is segregated into two sections in the form of strategic priority and energy policy. | [67] | |

| Energy Management Matrixes | Five levels of energy management matrixes to address six institutional aspects that are policy, organization, motivation, information scheme, marketing, and financing. | Top management support is fully integrated into the framework under policy section. Energy managerial role included in organizational structure. | [68] |

| Five levels of energy management matrixes to assess six institutional issues that are energy management scheme; organization; staff inspiration; tracking, supervision and reporting systems; staff consciousness/training and promotion, and financing. | Energy manager feature is integrated with a proposition of organizational structure. Moreover, energy management is considered comprehensively in this framework. | [55] | |

| Five levels of energy management matrixes to assess six institutional issues which are policy or specific guidelines, coordinating, training, evaluation of performance, communication, and financing. Valuation model exploring the subsequent aspects reflected as energy management practice: policy and legislation, energy blueprint, organizational formation; regulation; acquisition strategy, financing scheme, observation, and analysis of energy consumption, setting of goal; identification of possible options; staff involvement and training; operational process; communications. | The Carbon Trust guidelines comprised of five aspects. Inclusion of dedicated energy manager is not integrated to this model. However, the model incorporates senior management commitment to enhance energy efficiency related initiatives. | [56] | |

| Model exploring the succeeding features considered as energy management practice: energy director appointment, incorporation of energy team, apply of energy policy; collection of information and management, establishment of yardstick or threshold, analysis, assessing from technical perspective and energy audits; exploring and setting the scope, improvement option estimation, goal setting; define technical procedures and targets, roles and resources determination; formation of a communication plan, awareness raising, capacity building, inspire, trail and monitor; measurement of result, recapitulation of action plan; maintain internal recognition, and receiving external appreciation. | The ENERGY STAR guideline clearly emphasizes on appointment of energy director with dedicated energy team. In addition, the model looks to establish baselines for measuring energy performance. | [57] | |

| EEMs characterization framework | Three main characteristics are considered. Each characteristic are divided into sub-divisions. The first character “Relative advantage” is attributed by internal rate of return, introductory expenses, reimbursement time, and benefits of non-energy. “Technical context” the second character is attributed by modification type, impact opportunity, gap among core processes, and Lifetime. The last character “Information context” is attributed by transaction expenses, planning and execution knowledge, Dissemination progress, and field wise applicableness. | One of the salient features of this framework is inclusion of non-energy benefits. Energy manager is not integrated into the framework. | [58] |

| Economic characterization consists of payback time, application costs. Energy is attributed with resource stream and energy saving. Environmental characterization is attributed by waste minimization and emission contraction. Production is attributed by productivity, working environment, and operation and maintenance. Implementation related attributes are energy saving strategy, types of action, implementation easiness, success probability, community engagement in corporate level, distance among key processes, and audit regularity. Interaction-related characterization is attributed by indirect effects. | Corporate involvement is one of the notable attributes and considered as significant for industrial decision-makers. The need for analyzing energy efficiency measures as per different perspectives is highlighted; precisely having the aspects in grouped for providing more inclusive view on the pertinent outlooks distinguishing the energy efficiency measures. | [59] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, A.S.M.M.; Trianni, A. A Review of Energy Management Assessment Models for Industrial Energy Efficiency. Energies 2020, 13, 5713. https://doi.org/10.3390/en13215713

Hasan ASMM, Trianni A. A Review of Energy Management Assessment Models for Industrial Energy Efficiency. Energies. 2020; 13(21):5713. https://doi.org/10.3390/en13215713

Chicago/Turabian StyleHasan, A S M Monjurul, and Andrea Trianni. 2020. "A Review of Energy Management Assessment Models for Industrial Energy Efficiency" Energies 13, no. 21: 5713. https://doi.org/10.3390/en13215713

APA StyleHasan, A. S. M. M., & Trianni, A. (2020). A Review of Energy Management Assessment Models for Industrial Energy Efficiency. Energies, 13(21), 5713. https://doi.org/10.3390/en13215713