1. Introduction

The industrial sector, being one of the largest entities for consuming energy [

1], is responsible for 30% of total carbon emission [

2]. Further, the up-rising of energy expenses, stringent environmental restrictions, and fossil fuel depletion have shaped increased demand to the reduction of energy consumption and its associated costs in the industries [

3]. In this context, ensuring energy efficiency is one of the significant mainstays of the industrial processes that must be addressed as a priority. Energy efficiency gains through the implementation of energy management practices can provide multiple benefits to an organization ensuring the optimum usage of energy resources maintaining the desired energy productivity level and reduce the energy costs [

4,

5,

6].

The energy management programs are being developed to endorse energy efficiency in the industries for facilitating energy savings, reduction of greenhouse gas emissions, and productivity benefits [

7,

8]. However, industrial energy efficiency still remains unattained [

9,

10]; with low implementation rates of energy efficiency measures [

11,

12] because of certain barriers [

13,

14], although research has shown its immense potential. There are multiple studies conducted at local, regional, national, and multinational focusing the barriers to adopt energy efficiency in the industries [

15,

16,

17,

18,

19]. On the contrary, the drivers are also found towards energy-efficient technology adoption by several studies [

20,

21,

22]. The energy efficiency gap has been conferred, keeping the relevance on technical aspects and appliances [

23], whilst it has also incorporated behavioral issues [

24].

Energy management and energy services are mostly studied through theoretically or conceptually, whilst energy management practices are studied in an empiric way [

25]. Academic studies have been conducted regionally and beyond by many researchers about energy management practices and their characterization [

15,

26,

27,

28]. Energy management practices, as well as energy services, are perceived as significant explanations, and few efforts are paid to depict them including the assessment model to facilitate industrial think tank focusing particular set of actions for improved energy management [

24]. It is notable to mention that research mainly acquainted the idea of an “extended energy efficiency gap”, expressing the gap abide by technical as well as managerial components. In addition, a vast portion of unexplored market potential namely “energy service gap” exists because of high operating cost at the industrial application phase [

29], even though energy services speak for a favorable market-centric resolution for improved energy efficiency [

30]. So far, the avenues between integration of energy management with production systems are unexplored. Further, energy management into industrial decision-making process is not discussed thoroughly till now. Therefore, it is imperative to explore the domain of energy management to support industrial decision-makers pointing to the specified actions which are required to minimize the energy management lagging aspects, still keeping mind the multi-dimensional context and complexity of industrial energy management systems [

31,

32].

Given the introductory context, the paper aims to methodologically review the energy management assessment models that facilitate the assessment of industrial energy management. Notably, this study does not consider energy generation part and confines its focus to energy management framework only to help the industrial decision-making process covering energy consumption aspects in the industries.

This study is novel considering the fact that there has not been any study focusing on energy management 4.0 in the industrial decision-making process and comprehends the energy management framework to the best of authors’ knowledge. In this study, we have worked to synthesize this gap in the greater interest of academia. By doing the review, we want to highlight future research avenues having nexus with energy management and industrial energy efficiency. Interestingly, all of the present research gaps fall into the big area, which is energy management 4.0 in industrial decision making. On another note, this study would help the industrial managers and engineers by figuring out improvement options in their energy management activities and supply chain system. In addition, the available options for policymakers to address energy management regulations are also incorporated in this study.

The rest of this paper is designed as follows: an introduction to the energy management concept is presented in

Section 1.

Section 2 describes the methodology.

Section 3 provides the descriptive results of reviewing the literature on energy management assessment model. Subsequently, this paper concludes with explaining and incorporating the results in

Section 4.

Section 5 presents the concluding remarks.

2. Methodology

A systematic and rigorous review process was conducted in this paper. The primary focus of such reviews is to point out the related available studies established on pre-formulated research queries to synthesize the conclusion based on the evidence [

33]. It is notable to mention that the systematic review features substantial leverages contrast to conventional narrative approaches of literature work. The conventional review does not apprehend formal methodological approaches, whilst the systematic review incites to minimize research biases through the adoption of search strategies, preordained inquiry string, and inclusion and elimination criterion [

33]. Moreover, the comprehensive documentation nature of review enhances the clarity of review as well as facilitates subsequent replication [

34].

In this paper, the relevant literature search methodology comprised of scientific literature sources, mainly the “Scopus” and “Web of Science” as both of the sources are well accepted in academia for their research quality and reliability [

35]. We checked the online databases indexed in “Scopus” and “Web of Science” to identify the articles based on our keyword. In this research, the selected keywords to sort out the literature are “Energy Management”, “Industry”, “Energy Management Model”, “Energy Management Practices”, and “Energy Efficiency”. Nonetheless, there was no specific starting timeframe for searching the literature in the database, though attempts were made to consider the recent researches.

Table 1 presents the selection basis of the literature review.

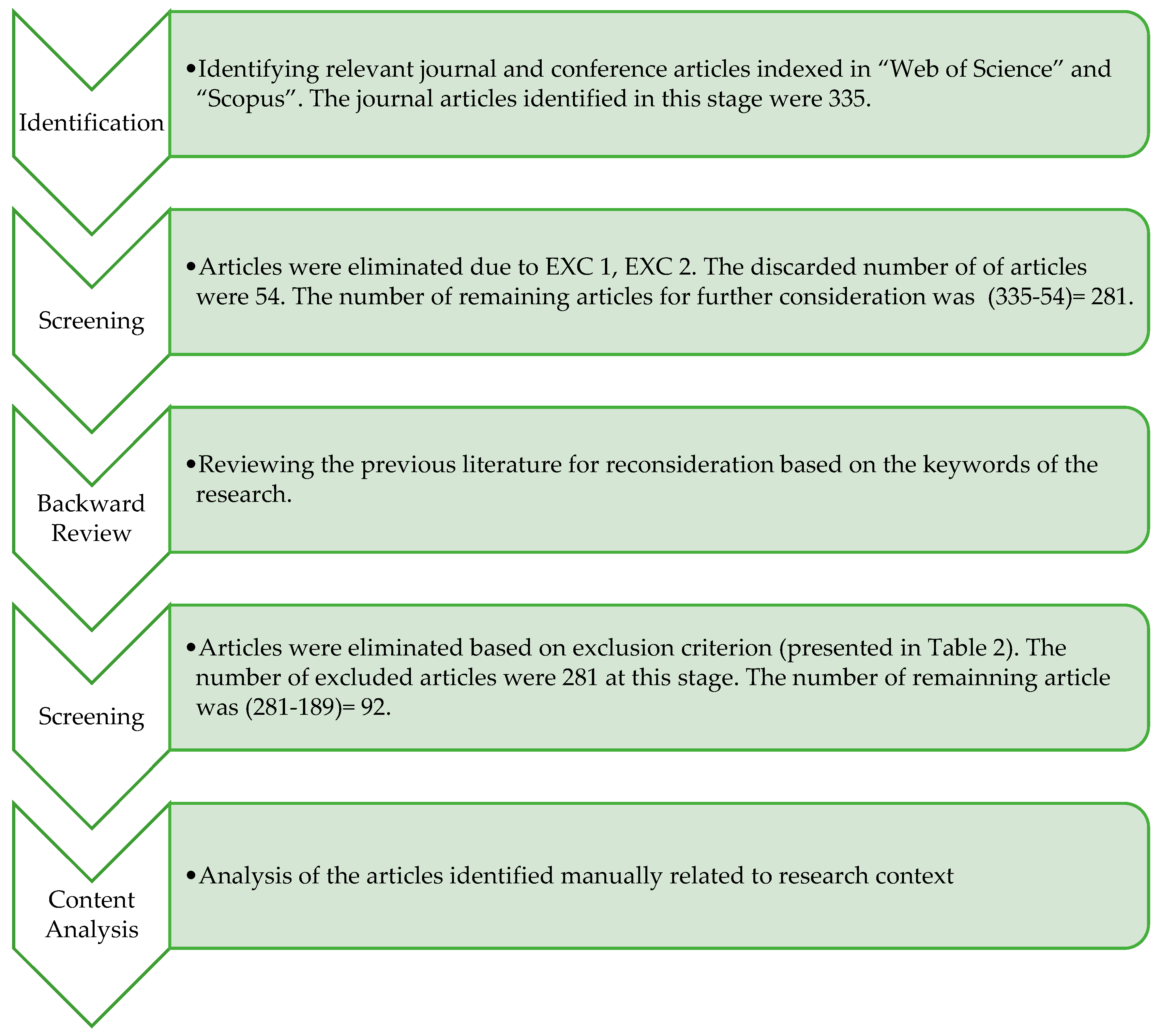

Each of the selected articles has been checked manually for content analysis in stage 2, the “screening” process. During the screening process, expulsion criteria that are followed in this research are presented in

Table 2. Articles were discarded in this stage based on the criterion EXC 1, EXC 2. In stage 3, a backward review was conducted to reconsider relevant articles based on our selected keywords. The following stage consists of the exclusion of articles based on the criterion EXC 2, EXC 3, EXC 4, EXC 5, EXC 6, and EXC 7. Finally, the last step of methodology replicates the content analysis of selected articles. The entire methodological steps are illustrated in

Figure 1.

In the phase of analyzing the content, it was essential to distinguish between energy management and energy management assessment framework/model. Therefore, the situation was very critical and decisive to the inclusion of such specification in this study. Nonetheless, discarding any concept related to energy management and its framework additional resolutions and aspects were also introduced that were not considered in the initial phase.

4. Discussion

The energy management frameworks were mainly researched to adopt energy management practices at the technical levels in the industries. However, the reviewed papers emphasized the energy management system, ISO 50001, and PDCA cycle, while some studies suggested holistic approaches towards industrial energy efficiency.

The framework proposed by Christoffersen et al. was stood out on the Danish industries and emphasized on multiple factors, mostly energy policy, goals and capstone projects aimed at energy savings. Regulation, external relations, company characteristics, and organizational internal condition are the main out-layers of the model to frame the energy management. However, the company size and energy intensity are two factors that can be considered to categorize the industries to apply or analyze the model [

44]. The main features proposed by Christofferen et al. align with ISO 50001: 2011 standard though this model has been replaced by ISO 50001: 2018 [

58]. The earlier model encompassed energy management system implementation based on PDCA cycle and enlisted few prerequisites that include mainly management liability, policy, energy audit, energy performance indexing, energy management blueprint, documentation, and so forth. One of the major changes in the recent model is the PDCA cycle modification. “Checking” was the center in the earlier version, whilst “Leadership” became the focus of all cycle components.

Figure 3 represents the revised PDCA cycle of ISO 50001:2018. In the minimum requirement segment, the model proposed by Ates et al. comprehended conventional streams towards energy management. One of the significant features is the inclusion of energy manager, whilst ISO 40001 (environmental permit) also act as an enabling feature along with ISO 50001 [

40].

Looking at the minimum requirement focused model, it is observed that all the energy management initiatives are not integrated into the frameworks. Christoffersen et al. [

44] considered energy management as a comprehensive management system. However, the model does not integrate the energy manager concept. Furthermore, there is no clear guideline about top or mid-level management support to achieve energy savings. Though, the involvement of employee to energy-saving related works are suggested. Nonetheless, The ISO 50001 model is a significant protocol [

69] along with the proposition by Ates and Durakbasa [

40], manifold aspects are still to be explored regards of operational activities in the industrial energy management domain. For instance, the principles of sustainability and integral management need to be presented at the protocol. In addition, there is very little contribution on the risk management and opportunities of energy efficiency from an integral and strategic point of view, including the planning and control of product lines, process design, projects, and business approaches [

69]. Notably, the fruitful operation of the energy management system requires the integrated deployment of planned, tactical, and operational levels that align the business culture with sustainable attainment. In this context, the vision that the organization plans to form should be linked to energy efficiency strategy with organization’s survival plan in the market. Additionally, it is necessary to make explicit reference to newly adapted technical features through peer to peer energy management platform for optimizing the integration of energy management system component with the variable energy demand [

70,

71]. Moreover, an integrated perspective to control of operational features of each process are required to explore linked to energy efficiency [

69].

In the energy management maturity model segment, the model proposed by Ngai et al. based on capability maturity model integration (CMMI), an extension of capability maturity model incorporated five levels according to the behavioral exhibition of the industries [

54]. The levels are determined by performance area of key processes [

72]. The achievement goals of key process areas must be specified for individual level for further actions. Notably, the propositions of CMM framework has been applied at multiple process enhancement programs in order to achieve the desired quality in the production system [

73]. One limitation of this model is inadequate implementation time, having only one factory for consideration. However, the authors have affirmed the acceptability of the model because of prior implementation of management practices. On the contrary, Antunes et al. emphasized the PDCA cycle to design the energy management framework [

64]. Additionally, the authors implied the model with ISO 50001 and incorporated energy management practices also. Notable to mention that Finnerty et al. also designed the framework based on the PDCA cycle, keeping on focus on energy management practices [

66].

The model proposed by Introna et al. is comprised of five dimensions and enables the feature of self-evaluation for the industries towards energy management practices. The dimensions are characterized by identifying the necessary elements in energy management consumption segment of the industries [

8]. On the contrary, Jovanović et al. focused on ISO 50001 processes as well as PDCA phases, keeping the knowledge base in the model EMMM50001 [

53]. The EMMM50001 establishes the relation to EUMMM maturity levels, maintaining ISO 50001 specifications and PDCA phases. Notably to mention that EMMM50001 links the CMMI criteria, also maintaining the ISO 50001.

It can be observed that the majority of the maturity models emphasized on similar type of characteristics and areas to evaluate the energy management in an organization by a systematic set of commendations. However, the narrated models demand more time and resources to perform as per their characterization. In addition, looking at the scientific literature, all of the frameworks studied to see the requirements for providing a continuous development path following the PDCA approach and ISO 50001. Notably, few of the maturity models incorporate the implication of dedicated energy manager and top management support. In contrast, Antunes et al. [

64] affirm on top management support whilst not integrating the energy manager in the framework. The framework by Introna et al. [

8] also did not complied with the energy manager. Nonetheless, Jovanović and Filipović [

53] and Finnerty et al. [

66] considered top management support along with the energy manager in their framework.

Gordic’ et al. applied the energy management matrixes model in the Serbian car manufacturer industries and critically analyzed the existing energy management system with the model [

55]. Notably to mention that the energy management matrixes models proposed by Gordic’ et al., Carbon Trust and Energy Star encompass all key areas to assess the energy management practices in the model, with having few modifications at the individual version.

On the contrary, Fleiter et al. [

58] and Trianni et al. [

52] emphasized on a characterization based model where both of the models are incorporated with specific attributes. The characterization scheme has some implications on policy design and assessment. However, formalization of the groups with categorized attributes enables the option towards relevant aspects identifying the energy efficiency measures. In addition, Trianni et al. contend a comprehensive scenario on EEMs focusing on the relevant aspects of industrial energy management [

52]. One of the critical factors, “corporate involvement” for industrial decision-makers is also implied, hence allowing additional feature and an increase in the applicability of the model. In another proposed framework, Trianni et al. incorporated energy management practice-based approach. However, the authors acknowledge more compatible space for the SMEs within the model, as SMEs are sought to be entitled to more attention, considering their cumulative energy consumption percentile [

74]. In a recent study, Tina et al. persuade the significance of SMEs and the policy implications in the peripheral of the industrial energy sector [

74]. Referring to the SMEs, Prashar [

67] proposes an energy efficiency maturity assessment framework that emphasizes SMEs. Notably, the author argues that the common energy efficiency framework approach does not facilitate fully to the SMEs; hence, a customized maturity framework is significant. The author considered steel re-rolling mill sector of India as the contextual sphere for the proposed framework.

Few of the studies on characterization the energy efficiency measure focuses on financial features. Notably to mention that these models do not frame the energy efficiency measures comprehensively, rather offer some framework without characterizing the energy efficiency measures in-depth. In one of the studies by Pye and McKane, they state that quantification of the accumulated benefits of energy efficiency scheme supports the enterprises perceive the monetary opportunities of EEMs financing [

5]. The energy savings features act not as the singular primary driver for the industrial decision process; hence, the authors persuade that energy savings be viewed as a factor of the holistic approach towards energy efficiency programs. Skumatz studied the methods to find out the attributes of EEMs and established the scheme to measure both of the positive and negative secondary benefits stemming from industrial energy efficiency schemes [

75,

76]. On the contrary, Mills and Rosenfeld provided a framework to understand multiple benefits of energy efficiency initiatives and grouped the attributes into the better interior environment, noise lessening, savings of labor and time, improved supervision of procedure, convenience, water savings and waste reduction, and benefits due to downsizing of equipment [

77].

The majority of studies on energy efficiency measures, benefits, and initial characterization frameworks propose few interesting reflections. However, a lack of consistency on the attributes grouping within existing categories from the methodological perspective is observed. It is found that the same attributes are grouped in different categories by different researchers. Moreover, the attributes are categorized and then aggregated again within other segments by different researcher. For instance, “reduced noise” and “improved indoor environment” are framed in two different categories in [

77], whereas “reduced noise level” as categorized in “working environment” segment. On the other note, the decision-making process is a grey area keeping mind about the stakeholders. Nonetheless, the earlier characterization framework did not incorporate the energy efficiency measure implications in a comprehensive way. To be precise, the inclusion of non-energy benefits is not incorporated into the characterization framework. Notably, the inclusion of non-energy features in the modeling factors would double the cost-effective potential for energy-efficiency enhancement, likened to an analysis eliminating those benefit [

60]. However, few attributes (e.g., improved air quality, better worker safety, reduction of noise level, and improved working situation) are there in the characterization framework, which are difficult to quantify [

76]. Therefore, speculation is required to articulate the benefits into a comparable cost figure, and hence the assessment turns out to be rather subjective [

60].

The study by Ngai et al. [

54] features energy management with particular process areas in the manufacturing industries. In this study, few guidelines are offered to conduct analysis for organizational maturity improvement in terms of energy along with the management of utility resources. However, the integration of energy management into production process has not been complied comprehensively. This is a significant avenue that needs be to address with utmost attention in future studies considering the technical implications offered by Industry 4.0. Notable to mention here, is that increasing the efficiency at the production processes is one of the salient features of Industry 4.0 [

78]. The deployment of smart machinery offers diverse benefits which primarily includes manufacturing productivity and waste reduction [

79]. Therefore, it is worth observing the energy management characteristics linked with production process through the lens of Industry 4.0.

Nonetheless, energy management towards industrial energy efficiency has been widely discussed in academia, and several barriers are still persistent in the energy management domain. The identification of barriers is important because it hampers or slows down the adoption of energy efficiency measures [

80]. Several studies have addressed the barriers which cover energy-intensive industries to SMEs and include regional, national, and transnational perspectives [

15,

26,

27,

81,

82,

83,

84]. However, most comprehensive studies focusing on energy management have been discussed without really looking at the integration of energy management into production and operation management. An imperative avenue, therefore, lies to be further explored in future within this research domain.

5. Concluding Remarks and Future Research Avenues

The paper attributes a review of research works on the energy management model for energy management practices in the industries. Multiple models have been compiled and structured, maintaining the narrations. Moreover, the energy management frameworks were synthesized emanate from the findings in order to facilitate energy management in the industries by offering necessary benchmarks to the industrial experts. The review findings show that the narrated models can support an organization to assess energy management and incorporate insightful contribution to energy efficiency initiatives. Nonetheless, some of the studies did not comply with a full methodological description and exhibited shorter model validation. In addition, a gap exists between the theoretical concept and practical implementation of energy management and its practices. Precisely, majority approaches remain unsuccessful in replicating and scope of actions distinct in energy management due to the certain barriers [

27,

66,

85].

Moreover, most of the models have looked the energy management as a single unit function, whilst it is a combination of multi-dimensional approaches with the involvement of several functional units in the industries. Let us not forget about the multi-dimensional operational activities in the industries which are conjugal part with energy management. Notably, multi-dimensional approaches are critical to support the process and operational oriented program [

86]. Therefore, a comprehensive operational approach should be considered by integrating all the relevant energy flows. It infers to all forms of energy, including externally supplied energy sources as well as internal energy flows. Interestingly, relating the energy management into the operational framework integrates the resource efficiency also at the manufacturing level. The raw or auxiliary material consumption might be of interest, considering the direct and indirect impact on energy and resource efficiency in the manufacturing process. Moreover, keeping mind about the non-static nature of energy consumption, the dynamic consumption feature might unveil manifold resource optimization aspects [

87].

Unfortunately, the integration of energy management into operational activities have been little explored. It becomes even more imperative while we look to adopt Industry 4.0 keeping in mind about the manifold complex technical features consist of Internet of Things (IoT), big data, cloud computing, and so on in the industrial plants. Many scholars predict that the exponential progress in the promises of manifold technical features offered by Industry 4.0 might affect the production activities in the industries inclusively. In addition, there are high chances of modification in the traditional industrial actions that cover the processing of elements and material, grinding, and assemble/ dismantle. This is emphasized in Industry 4.0 concept and its implementation, where we pursue to pool the common features with the enormous potential of digital technology [

88]. However, it is understood as a necessary incremental approach aimed at further optimizing the energy system without seeking to disrupt it in principle. In the energy efficiency domain, the energy management and its practices have already influenced the production scenario in a broader aspect, and this inclination should remain as long as we allow the nexus between Industry 4.0 and energy efficiency. On the other hand, energy productivity investments in present as well as the recent technologies must be conveyed through the implementation of energy management and its practices [

89]. Energy management practices and energy services are acknowledged as fundamental solutions; the diminutive effort is being paid in characterizing them [

24]. Notably, assessment models for supporting the industrial decision-makers emphasizing detailed activities for better energy management is deficient. Therefore, it is imperative to consider the energy management in multiple aspects keeping mind about the complex nature of industrial energy system [

31].

Interestingly, energy management has implications on asset maintenance, e.g., on maintenance procedures. As energy management includes the control of energy-consuming devices to optimize energy consumption, manual toggling on and off devices depending on requirement is a rudimentary custom of energy management. The initiation of mechanical and electrical equipment (e.g., timers for programmed toggling, bimetallic strip thermostat, pneumatic and electrical transmission system, and so on) provided means for early energy management schemes in the form of automatic temperature control. Nowadays, the inclusion of direct digital control in energy management has retrofit benefits that allow device monitoring linked to maintenance procedure, thanks to energy management and its practices. The comprehensive data recommend that while energy management does improve the accuracy and response of a system in the industries, the energy management routines facilitate partially asset maintenance [

90]. It infers to monitoring or log building equipment performance while consuming the energy resulting increasing magnitude of all benefits covering maintenance and cost avoidance benefit. Unfortunately, much of the energy management studies have bypassed this retrofit fact while focusing on the energy management framework. So far, the integration of energy management with asset management has not been widely explored, and several questions remain unanswered at present. Therefore, more research needs to be undertaken to fit the asset maintenance into energy management framework in a comprehensive way.

In addition, the narrated models have little explored the sustainability feature integrated with energy efficiency, pointing to the optimization of resource utilization [

91]. We must consider the paradigm that allows industrial energy management effective for the companies. In this context, it would be certainly interesting to visualize the energy management through Industry 4.0 technologies and solutions, may contribute to improved sustainability performances of the companies. If Industry 4.0 is expected to unveil enormous directions not only to energy management but also the sustainability field, the challenge definitely lies on the integrational aspects with energy–industry–sustainability nexus. Therefore, the future research avenues should reflect the energy management framework complying the diverse directions and encompassing the operational management, Industry 4.0 along with sustainability features.