Soot Particle Size Distribution, Regulated and Unregulated Emissions of a Diesel Engine Fueled with Palm Oil Biodiesel Blends

Abstract

:1. Introduction

2. Experimental Setup and Procedure

2.1. Test Fuels

2.2. Test Engine and Operating Methods

2.3. PM Sampling System and Analysis Method

2.4. Benzene, Toluene, and Xylene (BTX) Emissions Sampling System and Analysis Method

2.5. Trace Metals Sampling System and Analysis Method

3. Results and Discussion

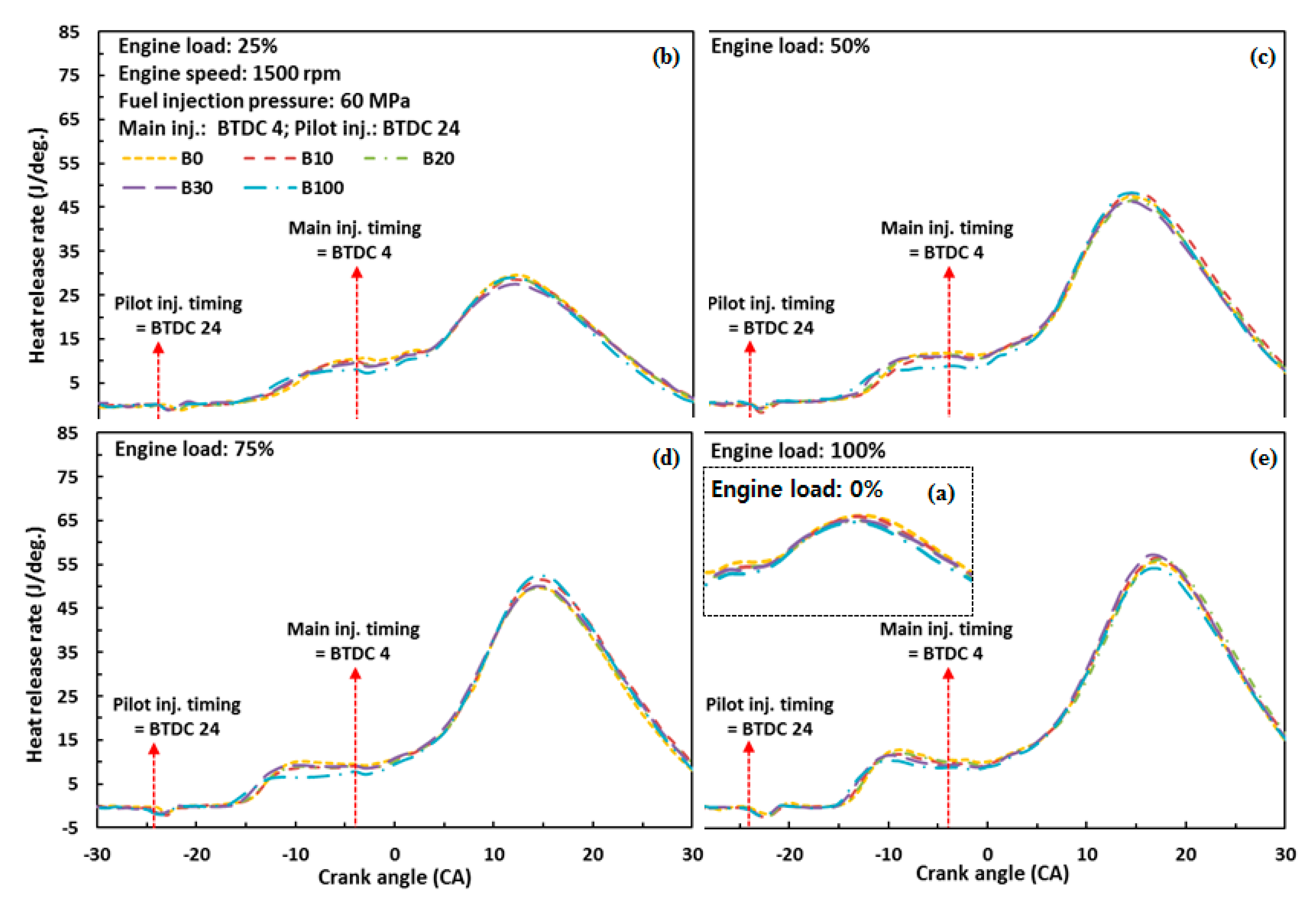

3.1. Combustion Characteristics

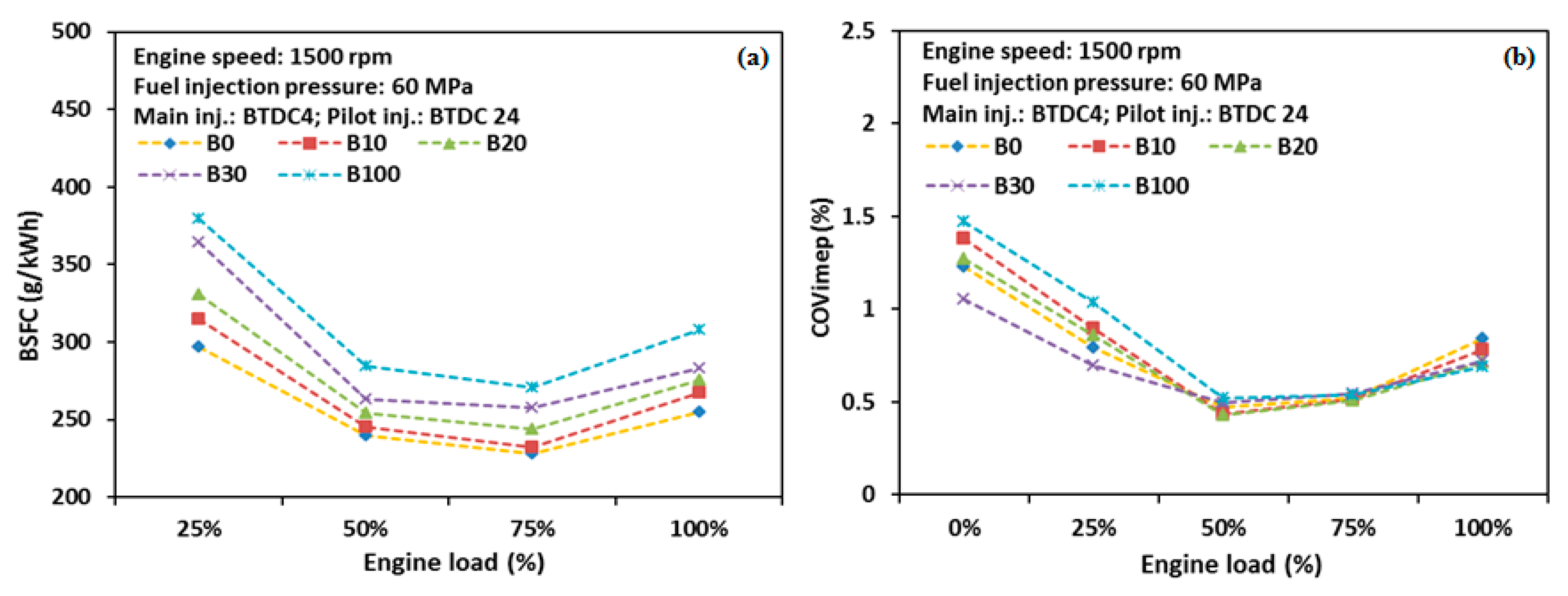

3.2. Engine Performance

3.3. Regulated Emission Characteristics

3.4. Unregulated Emission Characteristics

4. Conclusions

- The influence of biodiesel blends on in-cylinder pressure and HRR has little change compared with pure diesel. The low calorific value and high viscosity of palm oil biodiesel results in higher brake specific fuel consumption (BSFC) than diesel, with an average of about 11.96% higher for all biodiesel blends under all engine operating loads. The COVimep for all biodiesel blends is much lower than 10%, which shows that the CRDI diesel engine without any modification can run very stably under all operating conditions.

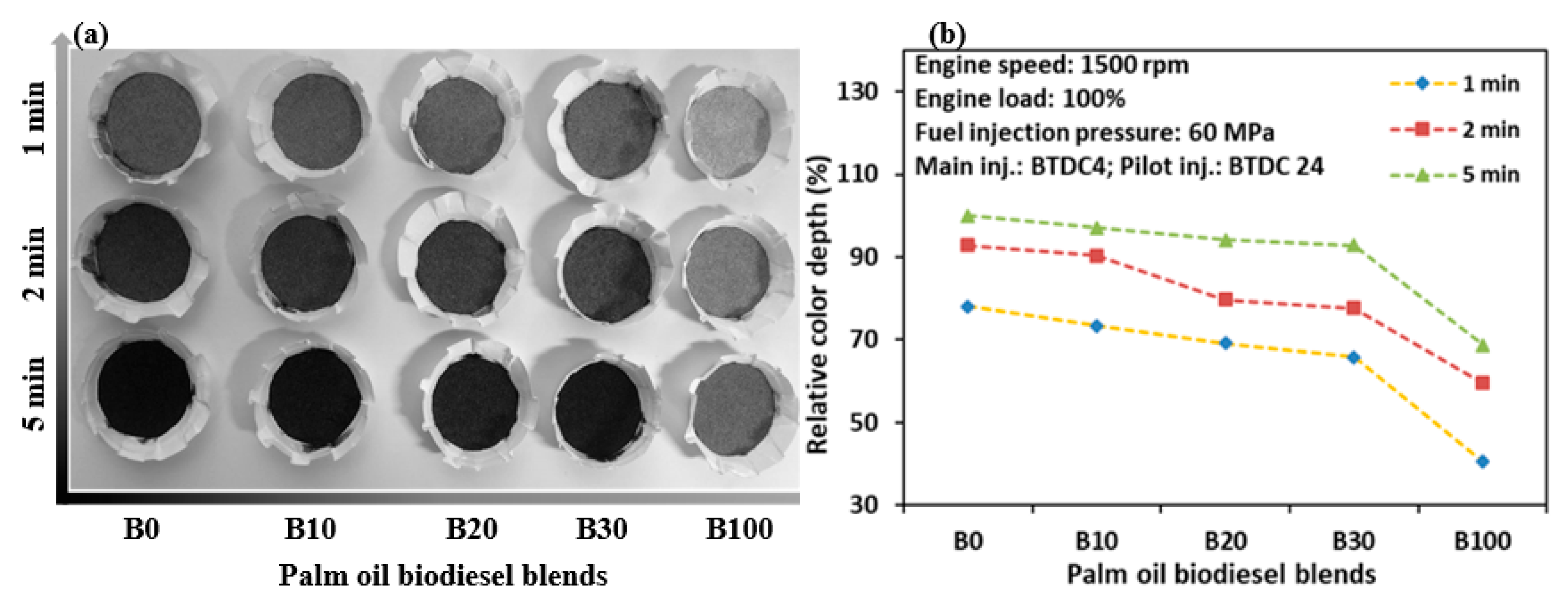

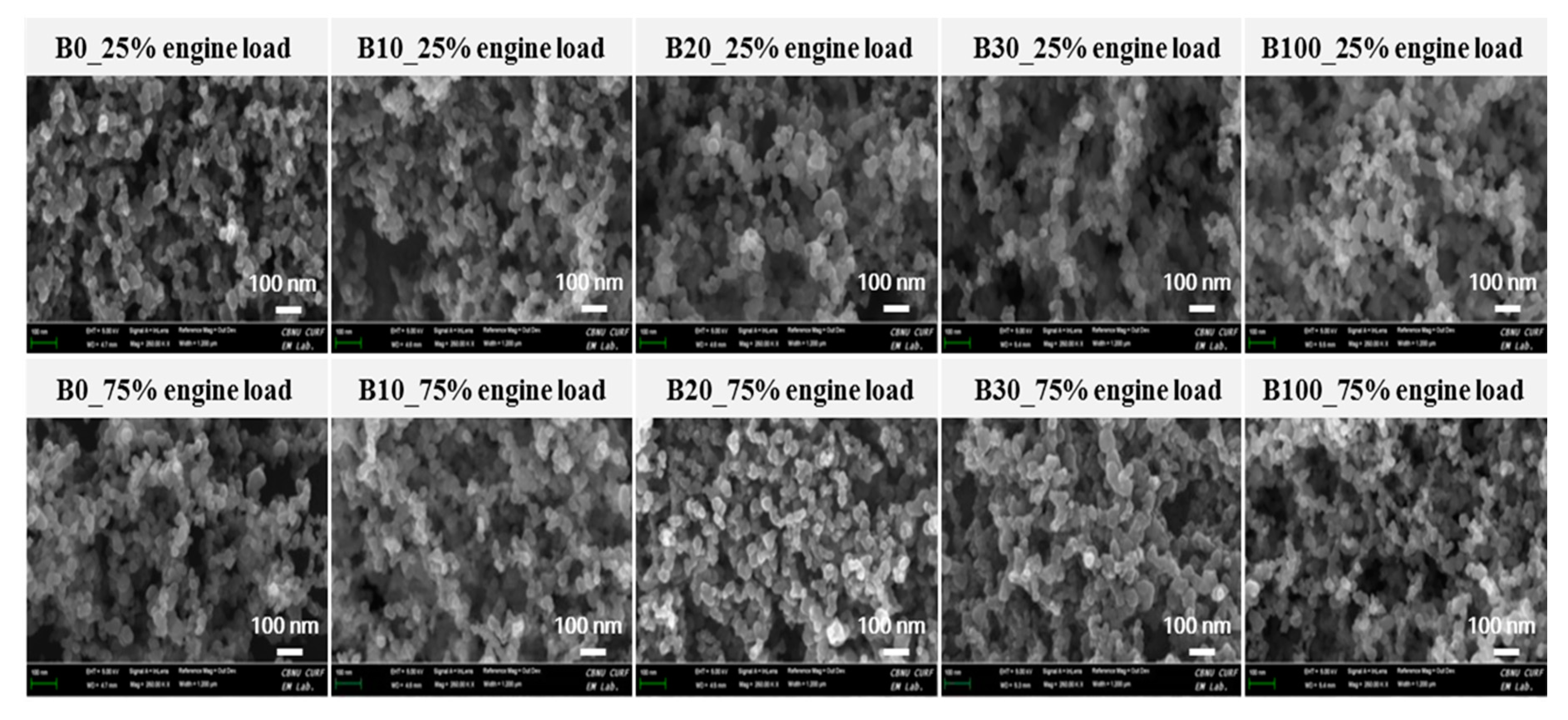

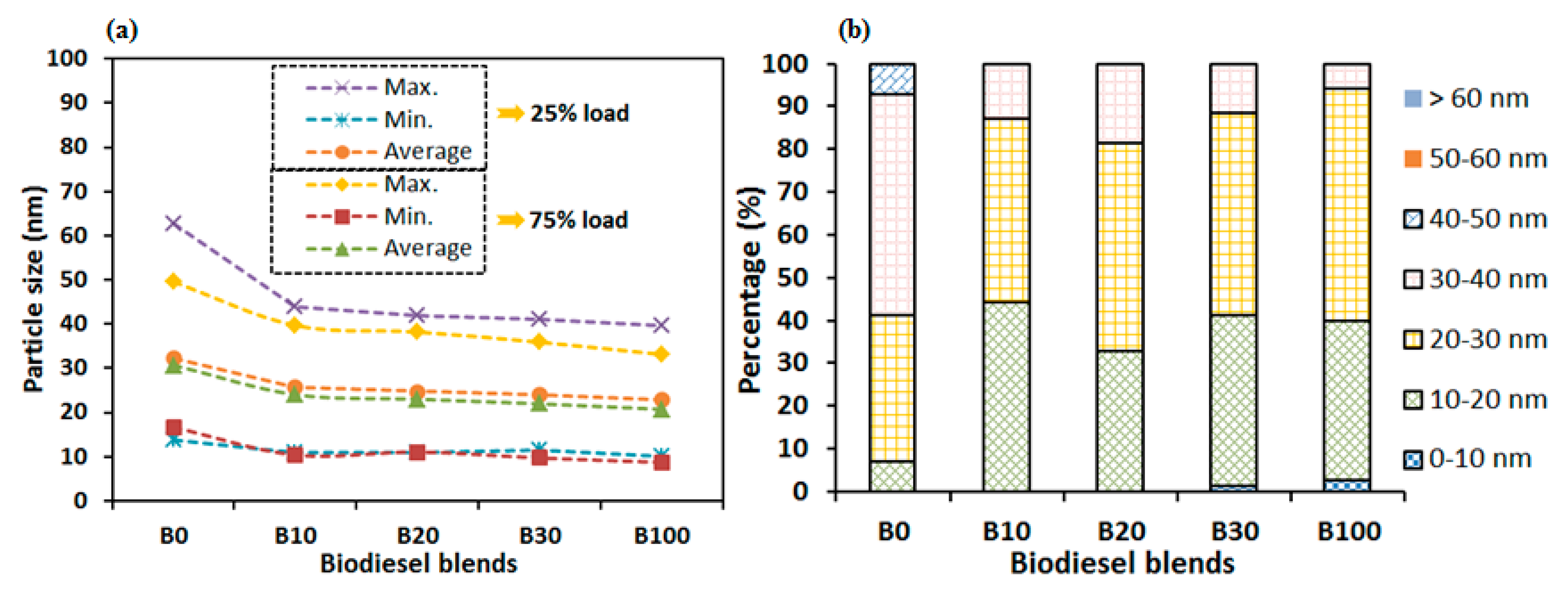

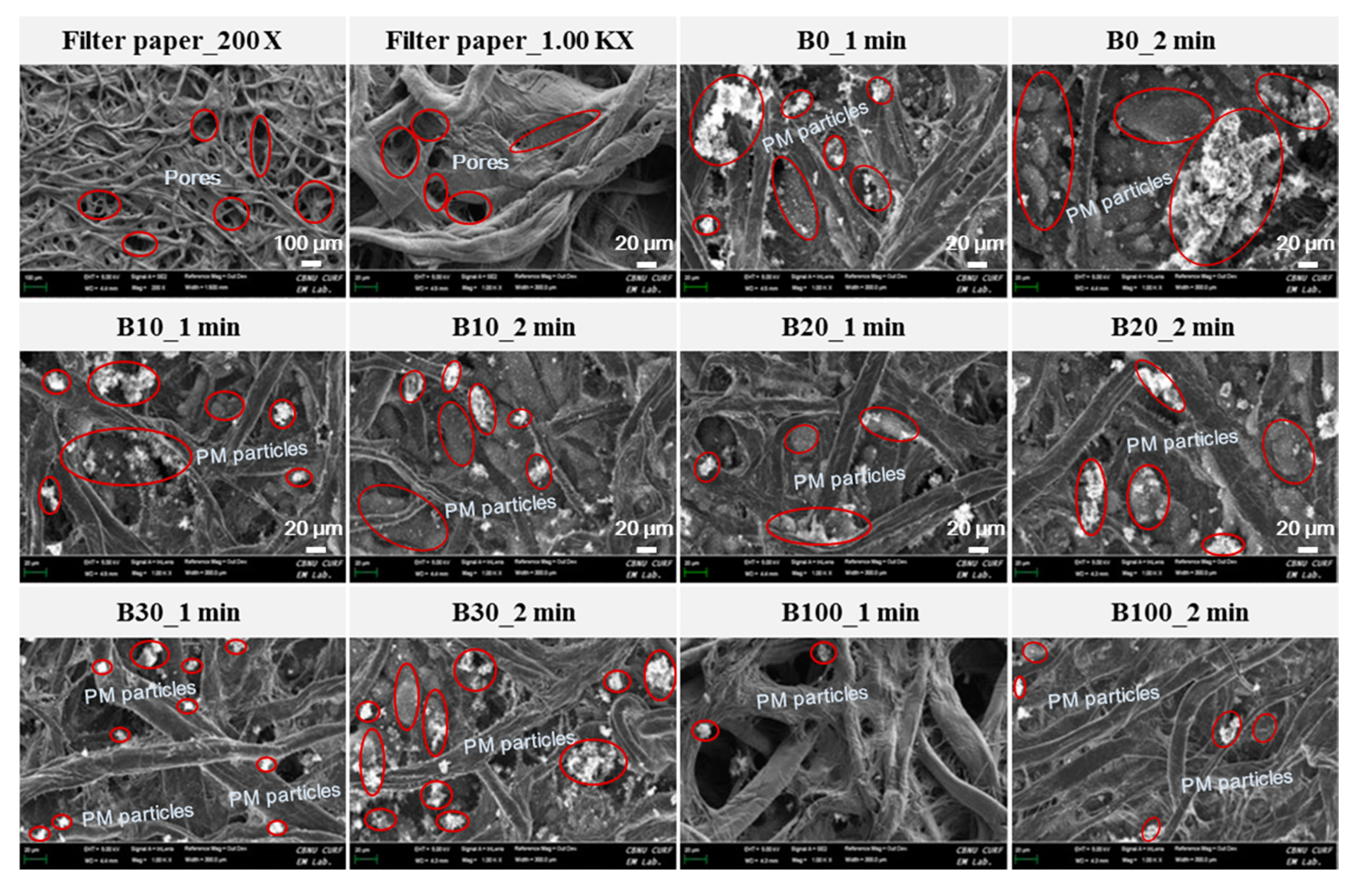

- Compared to B0 fuel, the CO, HC, and smoke opacity are significantly reduced, while the NOx emissions are increased slightly under all engine loads in the CRDI diesel engine fueled with B10, B20, B30, and B100, respectively. Moreover, the PM primary particles for all test fuels are much smaller than 100 nm in diameter. The diameter of these particles further decreases with the increases in engine load and the biodiesel mixture ratio. At 75% load, the average diameters of the PM primary particles for B0, B10, B20, B30, and B100 are 30.70, 24.02, 23.01, 21.96, and 20.71 nm, respectively, which are 5.10%, 6.39%, 6.88%, 8.16%, and 9.13% lower than those at 25% load.

- Unregulated emissions such as trace metals (TMs) including Pb, Mn, and Ba are found in the engine emissions, and the Pb content is the highest, followed by Mn and Ba. The TM changes are affected by a variety of complex factors such as fuel composition, lubricating oil composition, and engine operating conditions. Of the BTX hydrocarbons, benzene is the highest in the emissions from all fuels, followed by xylene and benzene. BTX emissions are decreased by increased engine load and biodiesel content in diesel fuel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, H.; Huang, R.; Guo, X.; Pan, M.; Teng, W.; Chen, Y.; Li, Z. Effects of pine oil additive and pilot injection strategies on energy distribution, combustion and emissions in a diesel engine at low-load condition. Appl. Energy 2019, 250, 185–197. [Google Scholar] [CrossRef]

- Chen, H.; Wang, M.; Wang, X.; Li, D.; Pan, Z.; Bae, C. Experimental investigation of particulate matter structures under partially premixed combustion in a compression ignition engine. Fuel 2020, 259, 116286. [Google Scholar] [CrossRef]

- Chen, H.; Huang, R.; Huang, H.; Pan, M.; Teng, W. Potential improvement in particulate matter’s emissions reduction from diesel engine by addition of PODE and injection parameters. Appl. Therm. Eng. 2019, 150, 591–604. [Google Scholar] [CrossRef]

- Moon, G.; Lee, Y.; Choi, K.; Jeong, D. Emission characteristics of diesel, gas to liquid, and biodiesel-blended fuels in a diesel engine for passenger cars. Fuel 2010, 89, 3840–3846. [Google Scholar] [CrossRef]

- Rao, Z.; Chen, Z.; Liang, H.; Huang, L.; Huang, D. Carbonyl compounds over urban Beijing: Concentrations on haze and non-haze days and effects on radical chemistry. Atmospheric Environ. 2016, 124, 207–216. [Google Scholar] [CrossRef]

- Pesant, L.; Forti, L.; Jeuland, N. Effect of Fuel Characteristics on the Performances and Emissions of an Early-injection LTC / Diesel Engine. SAE Technical Paper Series 2008. [Google Scholar] [CrossRef]

- Reşitoğlu, İ.A.; Altinişik, K.; Keskin, A. The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean Technol. Environ. Policy 2014, 17, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Kwon, E.E.; Seo, J.; Yi, H. Transforming animal fats into biodiesel using charcoal and CO2. Green Chem. 2012, 14, 1799. [Google Scholar] [CrossRef]

- Demirbaş, A. Biodiesel from vegetable oils via transesterification in supercritical methanol. Energy Convers. Manag. 2002, 43, 2349–2356. [Google Scholar] [CrossRef]

- Levine, R.B.; Pinnarat, T.; Savage, P.E. Biodiesel Production from Wet Algal Biomass through in Situ Lipid Hydrolysis and Supercritical Transesterification. Energy Fuels 2010, 24, 5235–5243. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel from waste cooking oil via base-catalytic and supercritical methanol transesterification. Energy Convers. Manag. 2009, 50, 923–927. [Google Scholar] [CrossRef]

- Wang, W.G.; Lyons, D.W.; Clark, A.N.N.; Gautam, M.; Norton, P.M. Emissions from Nine Heavy Trucks Fueled by Diesel and Biodiesel Blend without Engine Modification. Environ. Sci. Technol. 2000, 34, 933–939. [Google Scholar] [CrossRef]

- Qi, D.; Chen, H.; Matthews, R.; Bian, Y. Combustion and emission characteristics of ethanol–biodiesel–water micro-emulsions used in a direct injection compression ignition engine. Fuel 2010, 89, 958–964. [Google Scholar] [CrossRef]

- Enweremadu, C.; Rutto, H. Combustion, emission and engine performance characteristics of used cooking oil biodiesel—A review. Renew. Sustain. Energy Rev. 2010, 14, 2863–2873. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Rajamanoharan, K. Experimental investigations of performance and emissions of Karanja oil and its blends in a single cylinder agricultural diesel engine. Appl. Energy 2009, 86, 106–112. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel–diesel and canola oil–diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Canakci, M.; Van Gerpen, J.H. Comparison of engine performance and emissions for petroleum diesel fuel, yellow grease biodiesel, and soybean oil biodiesel. Trans. ASAE 2003, 46, 937. [Google Scholar] [CrossRef]

- Ng, H.K.; Gan, S. Combustion performance and exhaust emissions from the non-pressurised combustion of palm oil biodiesel blends. Appl. Therm. Eng. 2010, 30, 2476–2484. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.; Kalam, M.; Fattah, I.R.; Ashraful, A.; Mobarak, H. Biodiesel production and performance evaluation of coconut, palm and their combined blend with diesel in a single-cylinder diesel engine. Energy Convers. Manag. 2014, 87, 250–257. [Google Scholar] [CrossRef]

- An, H.; Yang, W.; Chou, S.; Chua, K. Combustion and emissions characteristics of diesel engine fueled by biodiesel at partial load conditions. Appl. Energy 2012, 99, 363–371. [Google Scholar] [CrossRef]

- Salamanca, M.; Mondragón, F.; Agudelo, J.R.; Santamaría, A. Influence of palm oil biodiesel on the chemical and morphological characteristics of particulate matter emitted by a diesel engine. Atmospheric Environ. 2012, 62, 220–227. [Google Scholar] [CrossRef]

- Bourrous, S.; Ribeyre, Q.; Lintis, L.; Yon, J.; Bau, S.; Thomas, D.; Vallières, C.; Ouf, F.-X. A semi-automatic analysis tool for the determination of primary particle size, overlap coefficient and specific surface area of nanoparticles aggregates. J. Aerosol Sci. 2018, 126, 122–132. [Google Scholar] [CrossRef] [Green Version]

- Anderson, P.M.; Guo, H.; Sunderland, P.B. Repeatability and reproducibility of TEM soot primary particle size measurements and comparison of automated methods. J. Aerosol Sci. 2017, 114, 317–326. [Google Scholar] [CrossRef]

- Ferreira, S.L.; Dos Santos, A.; De Souza, G.R.; Polito, W. Analysis of the emissions of volatile organic compounds from the compression ignition engine fueled by diesel–biodiesel blend and diesel oil using gas chromatography. Energy 2008, 33, 1801–1806. [Google Scholar] [CrossRef]

- Shukla, P.C.; Gupta, T.; Labhsetwar, N.K.; Agarwal, A.K. Trace metals and ions in particulates emitted by biodiesel fuelled engine. Fuel 2017, 188, 603–609. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.Y.; Yoon, S.K.; Choi, N.J. Reducing volatile organic compound emissions from diesel engines using canola oil biodiesel fuel and blends. Fuel 2018, 218, 266–274. [Google Scholar] [CrossRef]

- Som, S.; Ramirez, A.I.; Longman, D.E.; Aggarwal, S.K. Effect of nozzle orifice geometry on spray, combustion, and emission characteristics under diesel engine conditions. Fuel 2011, 90, 1267–1276. [Google Scholar] [CrossRef]

- Sahoo, P.; Das, L. Combustion analysis of Jatropha, Karanja and Polanga based biodiesel as fuel in a diesel engine. Fuel 2009, 88, 994–999. [Google Scholar] [CrossRef]

- Wu, Y.; Huang, R.; Lee, C.F.; Huang, C. Effects of the exhaust gas recirculation rate and ambient gas temperature on the spray and combustion characteristics of soybean biodiesel and diesel. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2011, 226, 372–384. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Raheman, H.; Ghadge, S. Performance of compression ignition engine with mahua (Madhuca indica) biodiesel. Fuel 2007, 86, 2568–2573. [Google Scholar] [CrossRef]

- Suresh, M.; Jawahar, C.; Richard, A. A review on biodiesel production, combustion, performance, and emission characteristics of non-edible oils in variable compression ratio diesel engine using biodiesel and its blends. Renew. Sustain. Energy Rev. 2018, 92, 38–49. [Google Scholar] [CrossRef]

- Uyumaz, A.; Solmaz, H.; Yılmaz, E.; Yamık, H.; Polat, S. Experimental examination of the effects of military aviation fuel JP-8 and biodiesel fuel blends on the engine performance, exhaust emissions and combustion in a direct injection engine. Fuel Process. Technol. 2014, 128, 158–165. [Google Scholar] [CrossRef]

- Shirneshan, A.; Almassi, M.; Ghobadian, B.; Borghei, A.; Najafi, G. Effects of Biodiesel and Engine Load on Some Emission Characteristics of a Direct Injection Diesel Engine. Curr. World Environ. 2012, 7, 207–212. [Google Scholar] [CrossRef] [Green Version]

- Monyem, A.; Van Gerpen, J.H. The effect of biodiesel oxidation on engine performance and emissions. Biomass- Bioenergy 2001, 20, 317–325. [Google Scholar] [CrossRef] [Green Version]

- Kwanchareon, P.; Luengnaruemitchai, A.; Jai-In, S. Solubility of a diesel–biodiesel–ethanol blend, its fuel properties, and its emission characteristics from diesel engine. Fuel 2007, 86, 1053–1061. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Robbins, C. Review of the effects of biodiesel on NOx emissions. Fuel Process. Technol. 2012, 96, 237–249. [Google Scholar] [CrossRef]

- Wang, X.; Cheung, C.; Di, Y.; Huang, Z. Diesel engine gaseous and particle emissions fueled with diesel–oxygenate blends. Fuel 2012, 94, 317–323. [Google Scholar] [CrossRef]

- Mangesh, V.; Padmanabhan, S.; Tamizhdurai, P.; Ramesh, A. Experimental investigation to identify the type of waste plastic pyrolysis oil suitable for conversion to diesel engine fuel. J. Clean. Prod. 2020, 246, 119066. [Google Scholar] [CrossRef]

- Ghadikolaei, M.A.; Wei, L.; Cheung, C.S.; Yung, K.-F. Effects of engine load and biodiesel content on performance and regulated and unregulated emissions of a diesel engine using contour-plot map. Sci. Total. Environ. 2019, 658, 1117–1130. [Google Scholar] [CrossRef] [PubMed]

- Chong, C.T.; Tian, B.; Ng, J.-H.; Fan, L.; Ni, S.; Wong, K.Y.; Hochgreb, S. Quantification of carbon particulates produced under open liquid pool and prevaporised flame conditions: Waste cooking oil biodiesel and diesel blends. Fuel 2020, 270, 117469. [Google Scholar] [CrossRef]

- Ma, L.; Ning, H.; Wu, J.; Cheong, K.-P.; Ren, W. Characterization of Temperature and Soot Volume Fraction in Laminar Premixed Flames: Laser Absorption/Extinction Measurement and Two-Dimensional Computational Fluid Dynamics Modeling. Energy Fuels 2018, 32, 12962–12970. [Google Scholar] [CrossRef]

- Twigg, M.V.; Phillips, P.R. Cleaning the Air We Breathe - Controlling Diesel Particulate Emissions from Passenger Cars. Platin. Met. Rev. 2009, 53, 27–34. [Google Scholar] [CrossRef]

- Li, R.; Wang, Z. Study on status characteristics and oxidation reactivity of biodiesel particulate matter. Fuel 2018, 218, 218–226. [Google Scholar] [CrossRef]

- Patel, C.; Chandra, K.; Hwang, J.; Agarwal, R.A.; Gupta, N.; Bae, C.; Gupta, T.; Agarwal, A.K. Comparative compression ignition engine performance, combustion, and emission characteristics, and trace metals in particulates from Waste cooking oil, Jatropha and Karanja oil derived biodiesels. Fuel 2019, 236, 1366–1376. [Google Scholar] [CrossRef]

- Cheung, C.; Zhu, L.; Huang, Z. Regulated and unregulated emissions from a diesel engine fueled with biodiesel and biodiesel blended with methanol. Atmospheric Environ. 2009, 43, 4865–4872. [Google Scholar] [CrossRef]

- Zhou, J.; Cheung, C.; Zhao, W.; Leung, C. Diesel–hydrogen dual-fuel combustion and its impact on unregulated gaseous emissions and particulate emissions under different engine loads and engine speeds. Energy 2016, 94, 110–123. [Google Scholar] [CrossRef]

- Di, Y.; Cheung, C.; Huang, Z. Experimental investigation on regulated and unregulated emissions of a diesel engine fueled with ultra-low sulfur diesel fuel blended with biodiesel from waste cooking oil. Sci. Total. Environ. 2009, 407, 835–846. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, P.; Liu, X.; Chen, B.; Geng, C.; Li, B.; Wang, H.; Li, Z.; Yao, M. Laser diagnostics and chemical kinetic analysis of PAHs and soot in co-flow partially premixed flames using diesel surrogate and oxygenated additives of n-butanol and DMF. Combust. Flame 2018, 188, 129–141. [Google Scholar] [CrossRef]

| Properties (Units) | B0 | B10 | B20 | B30 | B100 |

|---|---|---|---|---|---|

| Density (kg/m3 at 15 °C) | 836.8 | 841 | 845 | 849 | 877 |

| Viscosity (mm2/s at 40 °C) | 2.719 | 2.893 | 2.991 | 3.173 | 4.56 |

| Calorific value (MJ/kg) | 43.96 | 43.43 | 42.83 | 42.31 | 39.72 |

| Cetane index | 55.8 | - | - | - | 57.3 |

| Flash point (°C) | 55 | - | - | - | 196.0 |

| Oxidation stability (h/110 °C) | 25 | - | - | - | 9.24 |

| Oxygen content (%) | 0 | - | - | - | 11.26 |

| Engine Parameter | Units | Specifications |

|---|---|---|

| Type | - | turbocharged CRDI diesel engine |

| Number of cylinders | - | 4 |

| Bore × stroke | mm | 83 × 92 |

| Injector hole diameter | mm | 0.17 |

| Compression ratio | - | 17.7:1 |

| Max. power | kW/rpm | 82/4000 |

| Item | Conditions |

|---|---|

| Test fuels | B0, B10, B20, B30, B100 |

| Engine loads | 0%, 25%, 50%, 75%, 100% |

| Engine speed | 1500 rpm |

| Fuel injection pressure | 60 MPa |

| Pilot injection timing | 24° BTDC |

| Main injection timing | 4° BTDC |

| Intake air temperature | 25 ± 3 °C |

| Cooling water temperature | 85 ± 3 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, J.C.; Choi, N.J. Soot Particle Size Distribution, Regulated and Unregulated Emissions of a Diesel Engine Fueled with Palm Oil Biodiesel Blends. Energies 2020, 13, 5736. https://doi.org/10.3390/en13215736

Ge JC, Choi NJ. Soot Particle Size Distribution, Regulated and Unregulated Emissions of a Diesel Engine Fueled with Palm Oil Biodiesel Blends. Energies. 2020; 13(21):5736. https://doi.org/10.3390/en13215736

Chicago/Turabian StyleGe, Jun Cong, and Nag Jung Choi. 2020. "Soot Particle Size Distribution, Regulated and Unregulated Emissions of a Diesel Engine Fueled with Palm Oil Biodiesel Blends" Energies 13, no. 21: 5736. https://doi.org/10.3390/en13215736