The Identification of Hotspots in the Bioenergy Production Chain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and the Scope of the Study

2.2. Allocation

2.3. Description of Scenarios

3. Results and Discussion

3.1. Identification of Environmental Hotspots in the Bioenergy Production Chain Based on Literature Data

3.2. Life Cycle Impact Assessment

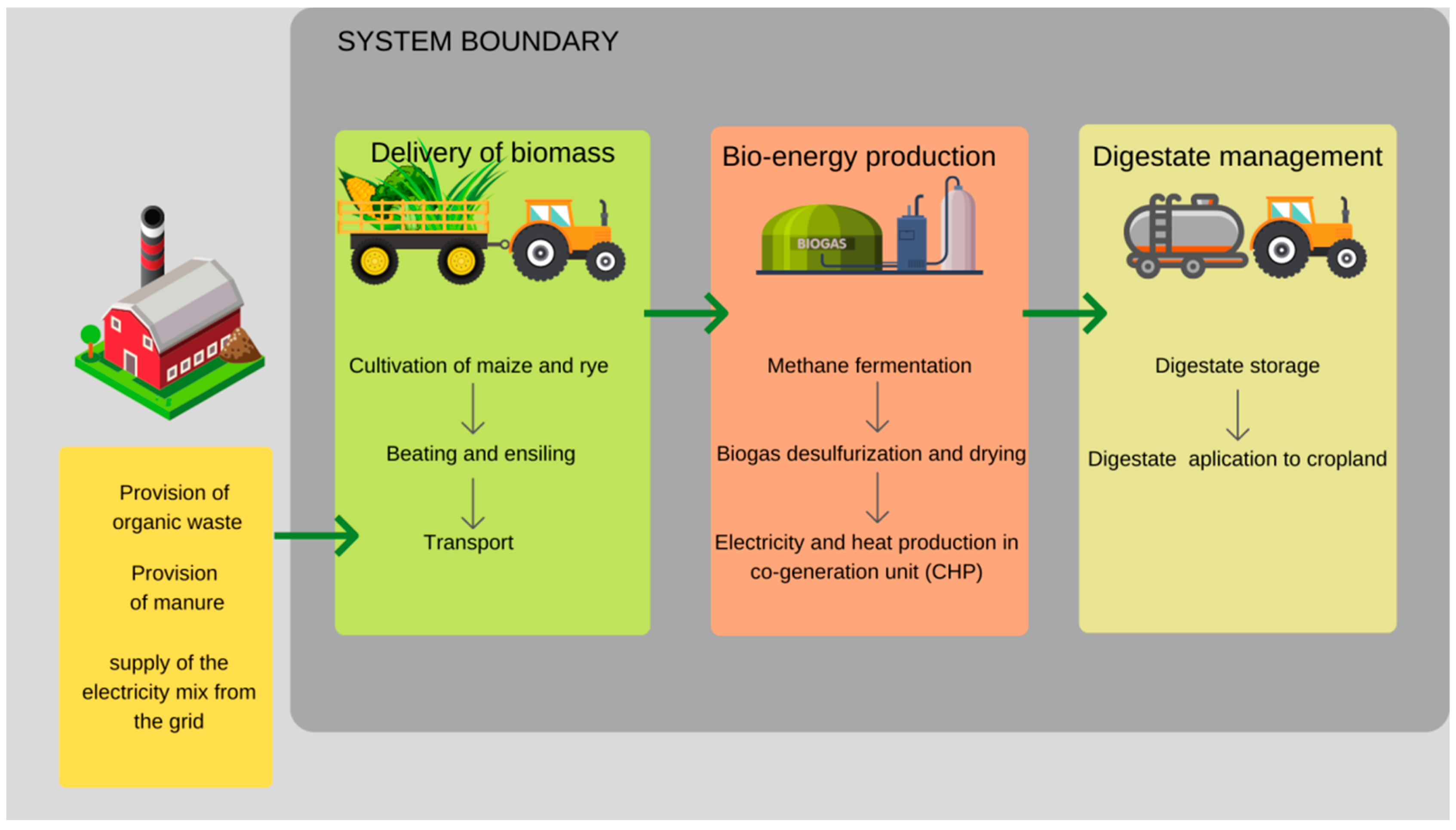

- Crop cultivation;

- Delivery of biomass;

- Energy production/plant operation;

- Digestate management (storage and application).

3.3. The Energy Efficiency Indicator

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; European Commission: Brussel, Belgium, 2018. [Google Scholar]

- European Parliament. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources; European Parliament: Strasbourg/Paris, France, 2018. [Google Scholar]

- Woźniak, E.; Twardowski, T. The bioeconomy in Poland within the context of the European Union. New Biotechnol. 2018, 40, 96–102. [Google Scholar] [CrossRef]

- Tullin, C. Heat Generation from Biomass in Sweden; Elsevier BV: Amsterdam, The Netherlands, 2016; pp. 241–265. [Google Scholar]

- Searcy, E.; Lamers, P.; Deutmeyer, M.; Ranta, T.; Hektor, B.; Heinimö, J.; Trømborg, E.; Wild, M. Commodity-Scale Biomass Trade and Integration with Other Supply Chains; Elsevier BV: Amsterdam, The Netherlands, 2016; pp. 115–137. [Google Scholar]

- Darda, S.; Papalas, T.; Zabaniotou, A. Biofuels journey in Europe: Currently the way to low carbon economy sustainability is still a challenge. J. Clean. Prod. 2019, 208, 575–588. [Google Scholar] [CrossRef]

- Moriarty, P.; Yan, X.; Wang, S.J. Liquid biofuels: Not a long-term transport solution. Energy Proc. 2019, 158, 3265–3270. [Google Scholar] [CrossRef]

- Moula, M.E.; Nyári, J.; Bartel, A. Public acceptance of biofuels in the transport sector in Finland. Int. J. Sustain. Built Environ. 2017, 6, 434–441. [Google Scholar] [CrossRef]

- Karytsas, S.; Theodoropoulou, H. Socioeconomic and demographic factors that influence publics’ awareness on the different forms of renewable energy sources. Renew. Energy 2014, 71, 480–485. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, The Council, The European Economic and Social Committee and the Committee of the Regions a New Circular Economy Action Plan for a Cleaner and More Competitive Europe COM/2020/98 Final; European Commission: Brussel, Belgium, 2020; p. 98. [Google Scholar]

- European Commission. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; European Commission: Brussel, Belgium, 2009; p. 28/EC. [Google Scholar]

- Forsberg, G. Biomass energy transport. Biomass Bioenergy 2000, 19, 17–30. [Google Scholar] [CrossRef]

- Chary, K.; Aubin, J.; Guindé, L.; Sierra, J.; Blazy, J.-M. Cultivating biomass locally or importing it? LCA of biomass provision scenarios for cleaner electricity production in a small tropical island. Biomass Bioenergy 2018, 110, 1–12. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency CO2 Emissions from Fuel Combustion 2019. CO2 Emiss. Fuel Combust. 2019. [CrossRef]

- Hannula, I.; Reiner, D.M. Near-Term Potential of Biofuels, Electrofuels, and Battery Electric Vehicles in Decarbonizing Road Transport. Joule 2019, 3, 2390–2402. [Google Scholar] [CrossRef]

- Arodudu, O.; Voinov, A.; van Duren, I. Assessing bioenergy potential in rural areas—A NEG-EROEI approach. Biomass Bioenergy 2013, 58, 350–364. [Google Scholar] [CrossRef] [Green Version]

- Arodudu, O.; Holmatov, B.; Voinov, A. Ecological impacts and limits of biomass use: A critical review. Clean Technol. Environ. Policy 2020, 22, 1591–1611. [Google Scholar] [CrossRef]

- Piotrowski, S.; Carus, M.; Essel, R. Global Bioeconomy in the Conflict Between Biomass Supply and Demand. Ind. Biotechnol. 2015, 11, 308–315. [Google Scholar] [CrossRef]

- D’Adamo, I.; Rosa, P. Current state of renewable energies performances in the European Union: A new reference framework. Energy Conver. Manag. 2020, 121, 84–92. [Google Scholar] [CrossRef]

- Muscat, A.; de Olde, E.; de Boer, I.; Ripoll-Bosch, R. The battle for biomass: A systematic review of food-feed-fuel competition. Glob. Food Secur. 2020, 25, 100330. [Google Scholar] [CrossRef]

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.-H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Ministry of State Assets. Poland’s National Energy and Climate Plan for the Years 2021–2030; Ministry of State Assets: Warsaw, Poland, 2019; In Polish. [Google Scholar]

- Arodudu, O.; Helming, K.; Voinov, A.; Wiggering, H. Integrating agronomic factors into energy efficiency assessment of agro-bioenergy production—A case study of ethanol and biogas production from maize feedstock. Appl. Energy 2017, 198, 426–439. [Google Scholar] [CrossRef] [Green Version]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef]

- Tsapekos, P.; Khoshnevisan, B.; Alvarado-Morales, M.; Symeonidis, A.; Kougias, P.; Angelidaki, I. Environmental impacts of biogas production from grass: Role of co-digestion and pretreatment at harvesting time. Appl. Energy 2019, 252, 113467. [Google Scholar] [CrossRef]

- Weißbach, D.; Ruprecht, G.; Huke, A.; Czerski, K.; Gottlieb, S.; Hussein, A. Energy intensities, EROIs (energy returned on invested), and energy payback times of electricity generating power plants. Energy 2013, 52, 210–221. [Google Scholar] [CrossRef]

- Hall, C.A.; Lambert, J.G.; Balogh, S.B. EROI of different fuels and the implications for society. Energy Policy 2014, 64, 141–152. [Google Scholar] [CrossRef] [Green Version]

- Murphy, D.J.; Hall, C.A.S. Year in review-EROI or energy return on (energy) invested. Ann. N. Y. Acad. Sci. 2010, 1185, 102–118. [Google Scholar] [CrossRef]

- de Vries, J.; Vinken, T.; Hamelin, L.; de Boer, I.J.M. Comparing environmental consequences of anaerobic mono- and co-digestion of pig manure to produce bio-energy—A life cycle perspective. Bioresour. Technol. 2012, 125, 239–248. [Google Scholar] [CrossRef] [Green Version]

- Lijó, L.; Lorenzo-Toja, Y.; González-García, S.; Bacenetti, J.; Negri, M.; Feijoo, G. Eco-efficiency assessment of farm-scaled biogas plants. Bioresour. Technol. 2017, 237, 146–155. [Google Scholar] [CrossRef]

- Fantin, V.; Giuliano, A.; Manfredi, M.; Ottaviano, G.; Stefanova, M.; Masoni, P. Environmental assessment of electricity generation from an Italian anaerobic digestion plant. Biomass Bioenergy 2015, 83, 422–435. [Google Scholar] [CrossRef]

- Hartmann, J.K. Life-Cycle-Assessment of Industrial Scale Biogas Plants. Ph.D. Thesis, Georg-August-Universitat Gottingen, Gottingen, Germany, 2006. Available online: https://d-nb.info/982240473/34 (accessed on 21 October 2020).

- de Vries, J.; Groenestein, C.; de Boer, I. Environmental consequences of processing manure to produce mineral fertilizer and bio-energy. J. Environ. Manag. 2012, 102, 173–183. [Google Scholar] [CrossRef] [Green Version]

- Gold, S.; Seuring, S. Supply chain and logistics issues of bio-energy production. J. Clean. Prod. 2011, 19, 32–42. [Google Scholar] [CrossRef]

- Fazio, S.; Monti, A. Life cycle assessment of different bioenergy production systems including perennial and annual crops. Biomass Bioenergy 2011, 35, 4868–4878. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Negri, M.; Fiala, M.; Feijoo, G.; Feijoo, G. Environmental assessment of farm-scaled anaerobic co-digestion for bioenergy production. Waste Manag. 2015, 41, 50–59. [Google Scholar] [CrossRef]

- Secchi, S.; Kurkalova, L.; Gassman, P.W.; Hart, C. Land use change in a biofuels hotspot: The case of Iowa, USA. Biomass Bioenergy 2011, 35, 2391–2400. [Google Scholar] [CrossRef]

- Shabani, N.; Akhtari, S.; Sowlati, T. Value chain optimization of forest biomass for bioenergy production: A review. Renew. Sustain. Energy Rev. 2013, 23, 299–311. [Google Scholar] [CrossRef]

- Paolotti, L.; Martino, G.; Marchini, A.; Pascolini, R.; Boggia, A. Economic and environmental evaluation of transporting imported pellet: A case study. Biomass Bioenergy 2015, 83, 340–353. [Google Scholar] [CrossRef]

- González-García, S.; Bacenetti, J. Exploring the production of bio-energy from wood biomass. Italian case study. Sci. Total. Environ. 2019, 647, 158–168. [Google Scholar] [CrossRef] [PubMed]

- Caserini, S.; Livio, S.; Giugliano, M.; Grosso, M.; Rigamonti, L. LCA of domestic and centralized biomass combustion: The case of Lombardy (Italy). Biomass Bioenergy 2010, 34, 474–482. [Google Scholar] [CrossRef]

- Gao, C.-K.; Na, H.-M.; Song, K.-H.; Dyer, N.; Tian, F.; Xu, Q.-J.; Xing, Y.-H. Environmental impact analysis of power generation from biomass and wind farms in different locations. Renew. Sustain. Energy Rev. 2019, 102, 307–317. [Google Scholar] [CrossRef]

- Montemayor, E.; Bonmatí, A.; Torrellas, M.; Camps, F.; Ortiz, C.; Domingo, F.; Riau-Arenas, V.; Antón, A. Environmental accounting of closed-loop maize production scenarios: Manure as fertilizer and inclusion of catch crops. Resour. Conserv. Recycl. 2019, 146, 395–404. [Google Scholar] [CrossRef]

- Poeschl, M.; Ward, S.; Owende, P. Environmental impacts of biogas deployment—Part II: Life cycle assessment of multiple production and utilization pathways. J. Clean. Prod. 2012, 24, 184–201. [Google Scholar] [CrossRef]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of Eco-Efficiency of Two Alternative Agricultural Biogas Plants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef] [Green Version]

- Uusitalo, V.; Havukainen, J.; Manninen, K.; Höhn, J.; Lehtonen, E.; Rasi, S.; Soukka, R.; Horttanainen, M. Carbon footprint of selected biomass to biogas production chains and GHG reduction potential in transportation use. Renew. Energy 2014, 66, 90–98. [Google Scholar] [CrossRef]

- Rana, R.; Ingrao, C.; Lombardi, M.; Tricase, C. Greenhouse gas emissions of an agro-biogas energy system: Estimation under the Renewable Energy Directive. Sci. Total Environ. 2016, 550, 1182–1195. [Google Scholar] [CrossRef] [Green Version]

- González-García, S.; Dias, A.C.; Clermidy, S.; Benoist, A.; Bellon-Maurel, V.; Gasol, C.M.; Gabarrell, X.; Arroja, L. Comparative environmental and energy profiles of potential bioenergy production chains in Southern Europe. J. Clean. Prod. 2014, 76, 42–54. [Google Scholar] [CrossRef]

- Miguel, G.S.; Corona, B.; Ruiz, D.; Landholm, D.M.; Laina, R.; Tolosana, E.; Sixto, H.; Cañellas, I. Environmental, energy and economic analysis of a biomass supply chain based on a poplar short rotation coppice in Spain. J. Clean. Prod. 2015, 94, 93–101. [Google Scholar] [CrossRef]

- Bacenetti, J.; Lovarelli, D.; Ingrao, C.; Tricase, C.; Negri, M.; Fiala, M. Assessment of the influence of energy density and feedstock transport distance on the environmental performance of methane from maize silages. Bioresour. Technol. 2015, 193, 256–265. [Google Scholar] [CrossRef]

- Paolotti, L.; Martino, G.; Marchini, A.; Boggia, A. Economic and environmental assessment of agro-energy wood biomass supply chains. Biomass Bioenergy 2017, 97, 172–185. [Google Scholar] [CrossRef]

- Qin, Z.; Zhuang, Q.; Cai, X.; He, Y.; Huang, Y.; Jiang, D.; Lin, E.; Liu, Y.; Tang, Y.; Wang, M.Q. Biomass and biofuels in China: Toward bioenergy resource potentials and their impacts on the environment. Renew. Sustain. Energy Rev. 2018, 82, 2387–2400. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental impact assessment of olive pomace oil biodiesel production and consumption: A comparative lifecycle assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Tabatabaei, M.; Ghanavati, H.; Mohtasebi, S.S.; Rahimi, V.; Shafiei, M.; Angelidaki, I.; Karimi, K. Life cycle assessment of castor-based biorefinery: A well to wheel LCA. Int. J. Life Cycle Assess. 2017, 23, 1788–1805. [Google Scholar] [CrossRef]

- Styles, D.; Adams, P.; Thelin, G.; Vaneeckhaute, C.; Chadwick, D.; Withers, P.J.A. Life Cycle Assessment of Biofertilizer Production and Use Compared with Conventional Liquid Digestate Management. Environ. Sci. Technol. 2018, 52, 7468–7476. [Google Scholar] [CrossRef]

- van Stappen, F.; Mathot, M.; Decruyenaere, V.; Loriers, A.; Delcour, A.; Planchon, V.; Goffart, J.-P.; Stilmant, D. Consequential environmental life cycle assessment of a farm-scale biogas plant. J. Environ. Manag. 2016, 175, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Röder, M.; Whittaker, C.; Thornley, P. How certain are greenhouse gas reductions from bioenergy? Life cycle assessment and uncertainty analysis of wood pellet-to-electricity supply chains from forest residues. Biomass Bioenergy 2015, 79, 50–63. [Google Scholar] [CrossRef]

- Damen, K.; Faaij, A. A Greenhouse Gas Balance of two Existing International Biomass Import Chains. Mitig. Adapt. Strat. Glob. Chang. 2006, 11, 1023–1050. [Google Scholar] [CrossRef]

- Dwivedi, P.; Johnson, E.; Greene, D.; Baker, S. Tracking Economic and Environmental Indicators of Exported Wood Pellets to the United Kingdom from the Southern United States: Lessons for Policy? BioEnergy Res. 2016, 9, 907–916. [Google Scholar] [CrossRef]

- Beagle, E.; Belmont, E. Comparative life cycle assessment of biomass utilization for electricity generation in the European Union and the United States. Energy Policy 2019, 128, 267–275. [Google Scholar] [CrossRef]

- Huopana, T.; Song, H.; Kolehmainen, M.; Niska, H. A regional model for sustainable biogas electricity production: A case study from a Finnish province. Appl. Energy 2013, 102, 676–686. [Google Scholar] [CrossRef]

- Boulamanti, A.K.; Maglio, S.D.; Giuntoli, J.; Agostini, A. Influence of different practices on biogas sustainability. Biomass Bioenergy 2013, 53, 149–161. [Google Scholar] [CrossRef]

- Garbs, M.; Geldermann, J. Analysis of selected economic and environmental impacts of long distance manure transports to biogas plants. Biomass Bioenergy 2018, 109, 71–84. [Google Scholar] [CrossRef]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural anaerobic digestion plants: What LCA studies pointed out and what can be done to make them more environmentally sustainable. Appl. Energy 2016, 179, 669–686. [Google Scholar] [CrossRef] [Green Version]

- Hall, C.A.S.; Balogh, S.; Murphy, D.J.R. What is the Minimum EROI that a Sustainable Society Must Have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Yazan, D.M.; Fraccascia, L.; Mes, M.; Zijm, H. Cooperation in manure-based biogas production networks: An agent-based modeling approach. Appl. Energy 2018, 212, 820–833. [Google Scholar] [CrossRef]

- Chiriboga, G.; ve la Rosa, A.; Molina, C.; Velarde, S. Energy Return on Investment (EROI) and Life Cycle Analysis (LCA) of biofuels in Ecuador. Heliyon 2020, 6, e04213. [Google Scholar] [CrossRef]

- Fraccascia, L.; Yazan, D.M. The role of online information-sharing platforms on the performance of industrial symbiosis networks. Resour. Conserv. Recycl. 2018, 136, 473–485. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal; European Commission: Brussel, Belgium, 2019; p. 640. [Google Scholar]

- von der Leyen, U. Mission Letter to Timmermans Responsible for the Green Deal; European Commission: Brussels, Belgium, September 2019. [Google Scholar]

- European Commission. National Energy and Climate Plans (NECPs). Available online: https://ec.europa.eu/energy/topics/energy-strategy/national-energy-climate-plans_en#national-long-term-strategies (accessed on 4 October 2020).

- European Commission. A Framework Strategy for a Resilient Energy Union with a Forward-Looking Climate Change Policy; European Commission: Brussel, Belgium, 2015; p. 80. [Google Scholar]

- EU Funding Possibilities in the Energy Sector. Available online: https://ec.europa.eu/energy/funding-and-contracts/eu-funding-possibilities-in-the-energy-sector_en (accessed on 4 October 2020).

| Biogas Plant Scenario | Type of Biomass | Annual Amount of Biomass (tonnes/Year) | Maximum Transportation Distance (km) One Direction | Type of Transport | Methane Efficiency 1 (m3/t of Input) |

|---|---|---|---|---|---|

| S01 | pig slurry | 14,824 | 5.0 | tractor with a barrel | 8.6 |

| maize silage | 21,693 | 0.87 | tractor with trailer | 123.0 | |

| S02 | chicken manure | 1536 | 0.1 | tractor with a barrel | 182.0 |

| maize silage | 10,743 | 0.03 | telescopic handler | 123.1 | |

| raw maize | 11,937 | 0.9 | tractor with trailer | - | |

| potato pulp | 273 | 5.0 | tractor with trailer | 51.7 | |

| distillery residues | 3917 | 20.0 | tractor with a barrel | 30.8 | |

| slaughterhouse waste | 1347 | 80.0 | lorry 16–32 t, Euro 4 | 225.1 | |

| sludges | 550 | 100.0 | tanker 16–32 t, Euro 4 | 62.9 | |

| pig slurry | 5652 | 10.0 | tractor with a barrel | 8.6 | |

| animal fats | 552 | 100.0 | tanker 16–32 t, Euro 4 | 540.6 | |

| organic food waste | 854 | 100.0 | lorry 3.5–7.5 t, Euro 4 | 71.5 | |

| S03 | raw maize | 2250 | 0.4 | tractor with trailer | - |

| maize silage | 2025 | 45.0 | lorry 16–32 t, Euro 4 | 121.9 | |

| distillery residues | 11,490 | 0.1 | gravity pipeline | 17.1 | |

| potato pulp | 5920 | 11.3 | lorry 16–32 t, Euro 4 | 51.7 | |

| vegetables and fruit pomaces | 1596 | 22.5 | lorry 16–32 t, Euro 4 | 44.8 | |

| pig slurry | 590 | 3.8 | tractor with a barrel | 5.4 | |

| protein residues | 403 | 172.5 | lorry 16–32 t, Euro 4 | 497.0 | |

| S04 | cattle manure | 12,837 | 0.3 | telescopic handler | 46.8 |

| maize silage (as residues from a household) | 936 | 0.3 | tractor with trailer | 123.0 | |

| distillery residues | 10,835 | 0.1 | gravity pipeline | 30.6 | |

| cattle slurry | 1107 | 0.3 | gravity pipeline | 17.1 | |

| raw rye | 2433 | 0.2 | telescopic handler | - | |

| rye silage | 2190 | 0.2 | tractor with trailer | 97.0 |

| Type of Energy | S01 | S02 | S03 | S04 |

|---|---|---|---|---|

| electricity produced | 7862 | 6224 | 3007 | 3746 |

| electricity used | 1020 | 1727 | 598 | 446 |

| heat waste obtained | 7769 | 7951 | 3193 | 4224 |

| heat used (own purposes) | 1470 | 876 | 417 | 1232 |

| heat sold | - | 7951 | 1804 | 2253 |

| Authors | Type of Biomass | Distance | Share of Transport in Environmental Impact of a Production Chain 1 | Type of Transport | LCA Method |

|---|---|---|---|---|---|

| [24] | pig manure | 20 km | 37% of total impact in baseline scenario | road transport, lorry 7.5–16.0 metric tons | Impact 2002+ |

| [45] | energy crops, pig manure, agri-food residues | up to 3 km | 81% | road transport, tractor with a barrel 16.0–22.0 metric tons | Impact 2002+ |

| local transport on site of the farm | 3% | pipeline, local transport on site from farm | |||

| up to 100 km | 84% | road transport | |||

| up to 100 km | 67% | road transport and pipeline | |||

| [46] | biowaste | 13 km/tonne for biowaste | ~27% | road truck | GHG |

| agricultural biomass | within 10 km of the plant | 8% | tractor | ||

| [25] | grass | 100 km from grassland to biogas plant and 25 km to farmland | 69% reduction of ecosystem quality and 21% of climate change from baseline scenario to minimal distance | n.a. | Impact 2002+ |

| [39] | pellets | Cross-border distances 1000–2000 km | n.a. | lorry 26–32 | Eco indicator 99 |

| from USA to Italy | n.a. | freight ship | |||

| [47] | maize | max 17 km | 4% | Euro5 3.5–16.0 lorry | GWP100 |

| triticale | 6% | ||||

| tritello | 1% | ||||

| animal effluents | 6% | ||||

| [48] | eucalyptus logging | 108 km | third contributor in all categories from 5 to 10% | truck | CML method |

| vineyard pruning residues | 9.5 km | second contributor in all categories from 5 to 20% | tractor | ||

| 66 km | truck | ||||

| poplar plantation SRC | 107 km | third contributor in all categories from 2 to 10% | truck | ||

| [42] | straw | 20 km | 15% | diesel tractor | GW |

| Impact Category | Unit | S01 | S02 | S03 | S04 |

|---|---|---|---|---|---|

| Carcinogens | kg C2H3Cl eq | 7.72 × 104 | 3.92 × 104 | 3.55 × 104 | 1.13 × 103 |

| Noncarcinogens | kg C2H3Cl eq | 1.54 × 105 | 7.12 × 104 | 5.87 × 104 | 2.41 × 103 |

| Respiratory inorganics | kg PM2.5 eq | 6.79 × 103 | 3.65 × 103 | 5.24 × 103 | 7.80 × 102 |

| Ionizing radiation | Bq C-14 eq | 1.59 × 108 | 7.67 × 107 | 5.13 × 107 | 1.97 × 106 |

| Ozone layer depletion | kg CFC-11 eq | 7.24 × 10-1 | 6.01 × 10-1 | 7.75 × 10-1 | 7.38 × 10-3 |

| Respiratory organics | kg C2H4 eq | 6.71 × 103 | 3.48 × 103 | 3.17 × 103 | 1.36 × 102 |

| Aquatic ecotoxicity | kg TEG water | 4.42 × 108 | 2.82 × 108 | 3.35 × 108 | 5.82 × 106 |

| Terrestrial ecotoxicity | kg TEG soil | 1.62 × 108 | 1.21 × 108 | 2.17 × 108 | 2.68 × 106 |

| Terrestrial acid/nutri | kg SO2 eq | 1.85 × 105 | 1.01 × 105 | 1.69 × 105 | 4.12 × 104 |

| Land occupation | m2org.arable | 8.56 × 105 | 4.85 × 105 | 2.13 × 105 | 9.22 × 103 |

| Aquatic acidification | kg SO2 eq | 3.36 × 104 | 1.86 × 104 | 2.74 × 104 | 5.36 × 103 |

| Aquatic eutrophication | kg PO4 P-lim | 1.47 × 103 | 7.83 × 102 | 6.60 × 102 | 3.84 × 101 |

| Global warming | kg CO2 eq | 6.81 × 106 | 3.80 × 106 | 5.11 × 106 | 1.02 × 105 |

| Nonrenewable energy | MJ primary | 1.08 × 108 | 7.37 × 107 | 8.43 × 107 | 1.19 × 106 |

| Mineral extraction | MJ surplus | 6.57 × 105 | 2.45 × 105 | 5.60 × 104 | 1.04 × 104 |

| Biogas Plant Scenario | S01 | S02 | S03 | S04 | |

|---|---|---|---|---|---|

| energy input (GJ) | crop cultivation | 374 | 271 | 51 | 79 |

| feedstock delivery | 271 | 861 | 499 | 137 | |

| energy input/plant operation | 3672 | 6217 | 2153 | 1606 | |

| heat input/plant operation | 5292 | 3154 | 1498 | 4435 | |

| digestate storage | 0 | 925 | 0 | 0 | |

| digestate application | 6429 | 3079 | 2331 | 3517 | |

| man work | 181 | 382 | 382 | 181 | |

| sum | 16,219 | 14,890 | 6913 | 9955 | |

| energy output (GJ) | energy production | 28,303 | 22,406 | 10,825 | 13,486 |

| heat production | 5292 | 31,777 | 7996 | 12,546 | |

| energy in digestate | 6549 | 4810 | 3646 | 4799 | |

| sum | 40,144 | 58,993 | 22,467 | 30,831 | |

| EROI | 2.48 | 3.96 | 3.25 | 3.10 | |

| EROI without energy for transportation | 2.50 | 4.17 | 3.37 | 3.13 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muradin, M.; Kulczycka, J. The Identification of Hotspots in the Bioenergy Production Chain. Energies 2020, 13, 5757. https://doi.org/10.3390/en13215757

Muradin M, Kulczycka J. The Identification of Hotspots in the Bioenergy Production Chain. Energies. 2020; 13(21):5757. https://doi.org/10.3390/en13215757

Chicago/Turabian StyleMuradin, Magdalena, and Joanna Kulczycka. 2020. "The Identification of Hotspots in the Bioenergy Production Chain" Energies 13, no. 21: 5757. https://doi.org/10.3390/en13215757

APA StyleMuradin, M., & Kulczycka, J. (2020). The Identification of Hotspots in the Bioenergy Production Chain. Energies, 13(21), 5757. https://doi.org/10.3390/en13215757