Experimental Assessment of the Thermal Performance of a Heat Pump Dryer System Based on the Variations in Compressor Discharge Pressure on Oregano Drying

Abstract

:1. Introduction

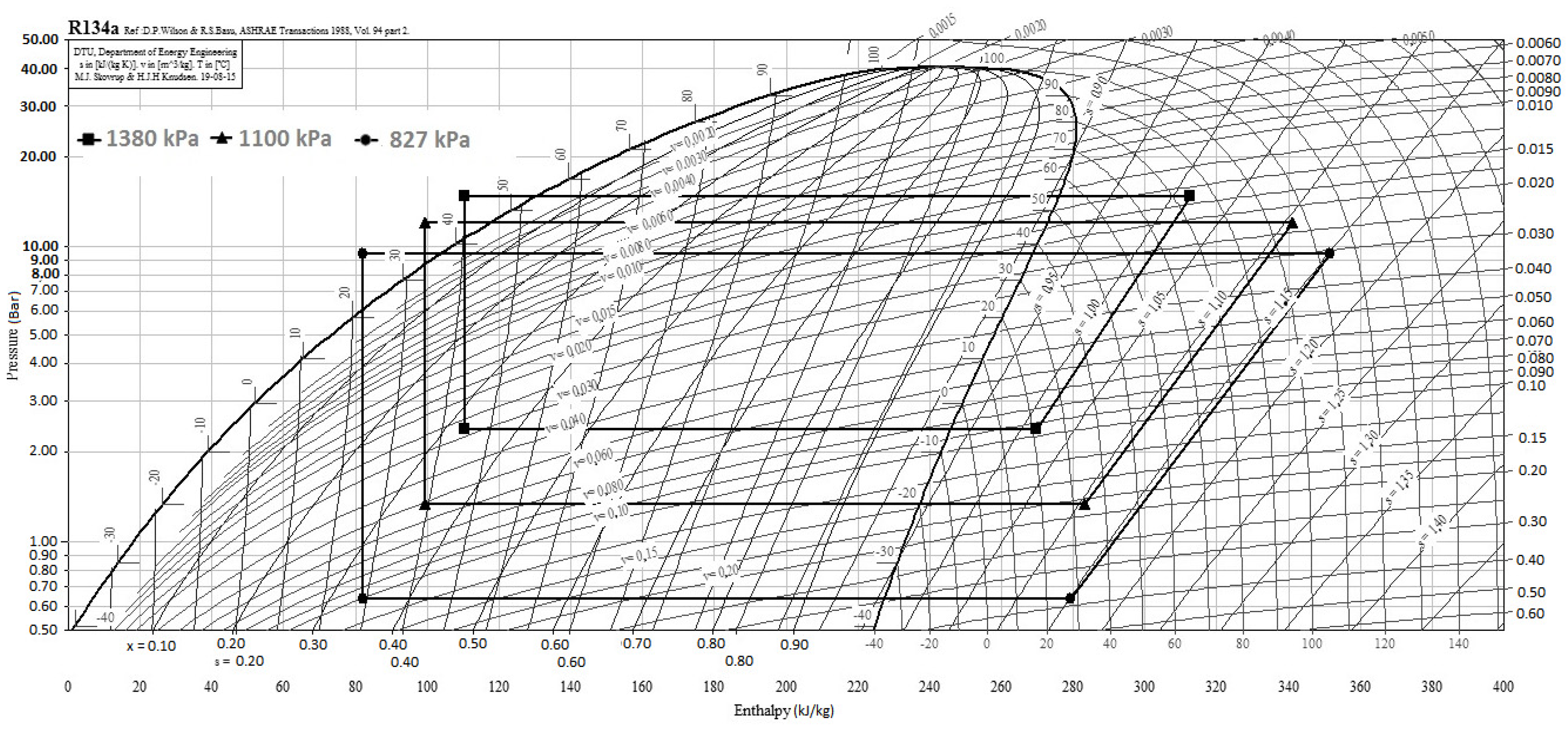

2. Materials and Methods

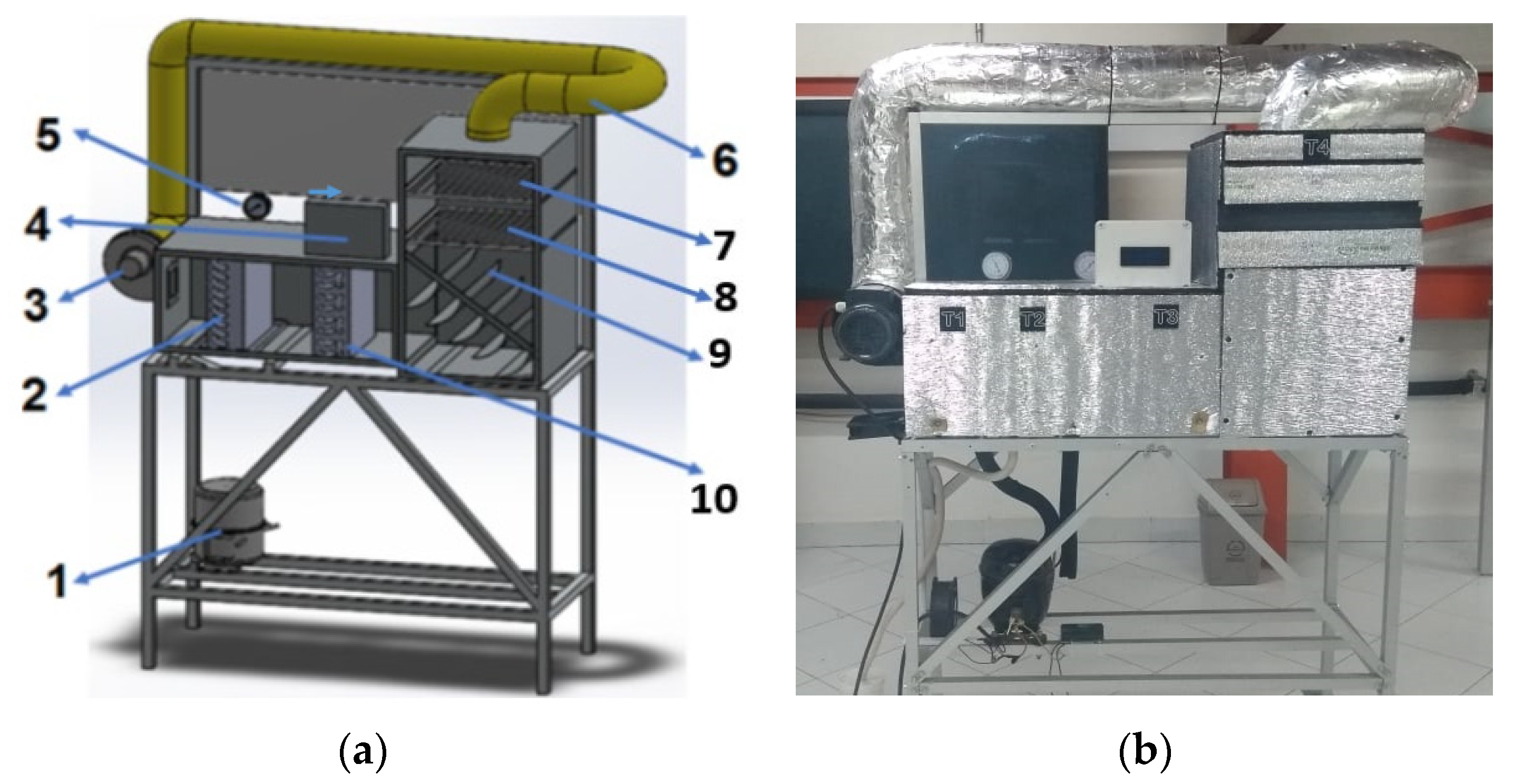

2.1. Experimental Setup

2.2. Experimental Design

2.3. Model Development

- Heating capacity

- Refrigerant mass flow rate

- Drying and energy parameter

3. Results and Discussion

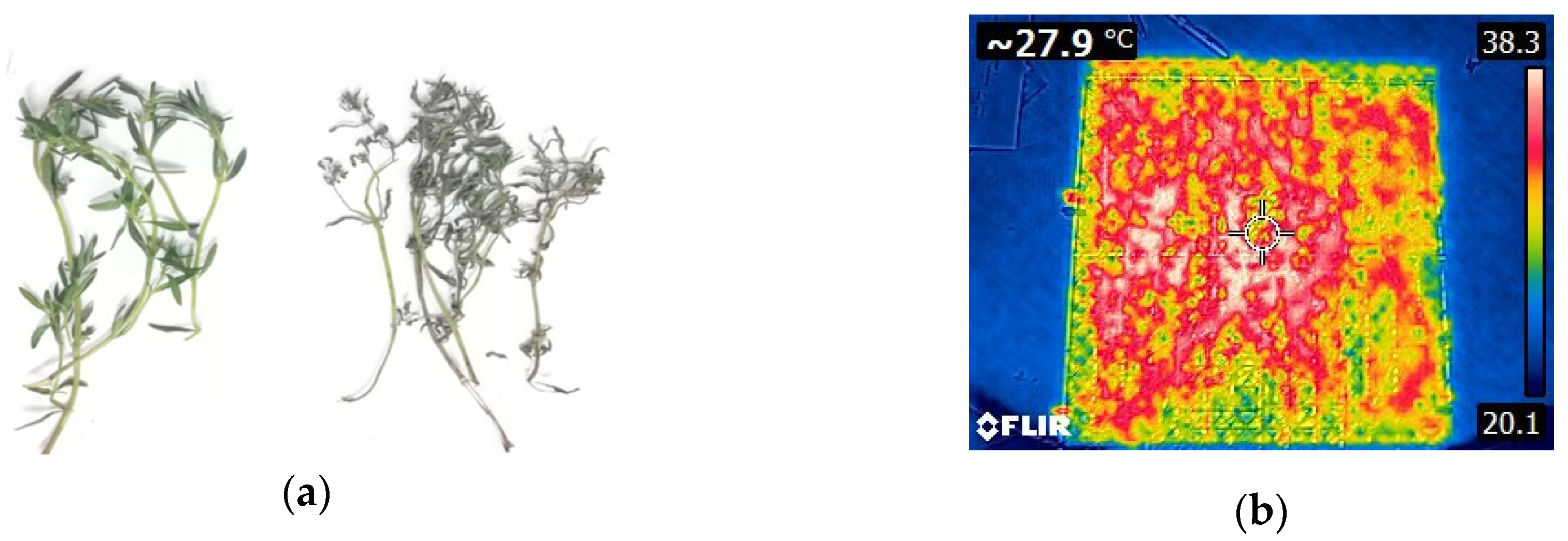

3.1. Subsection Impact of Variation in Compressor Pressure Discharge on Oregano Drying Characteristics

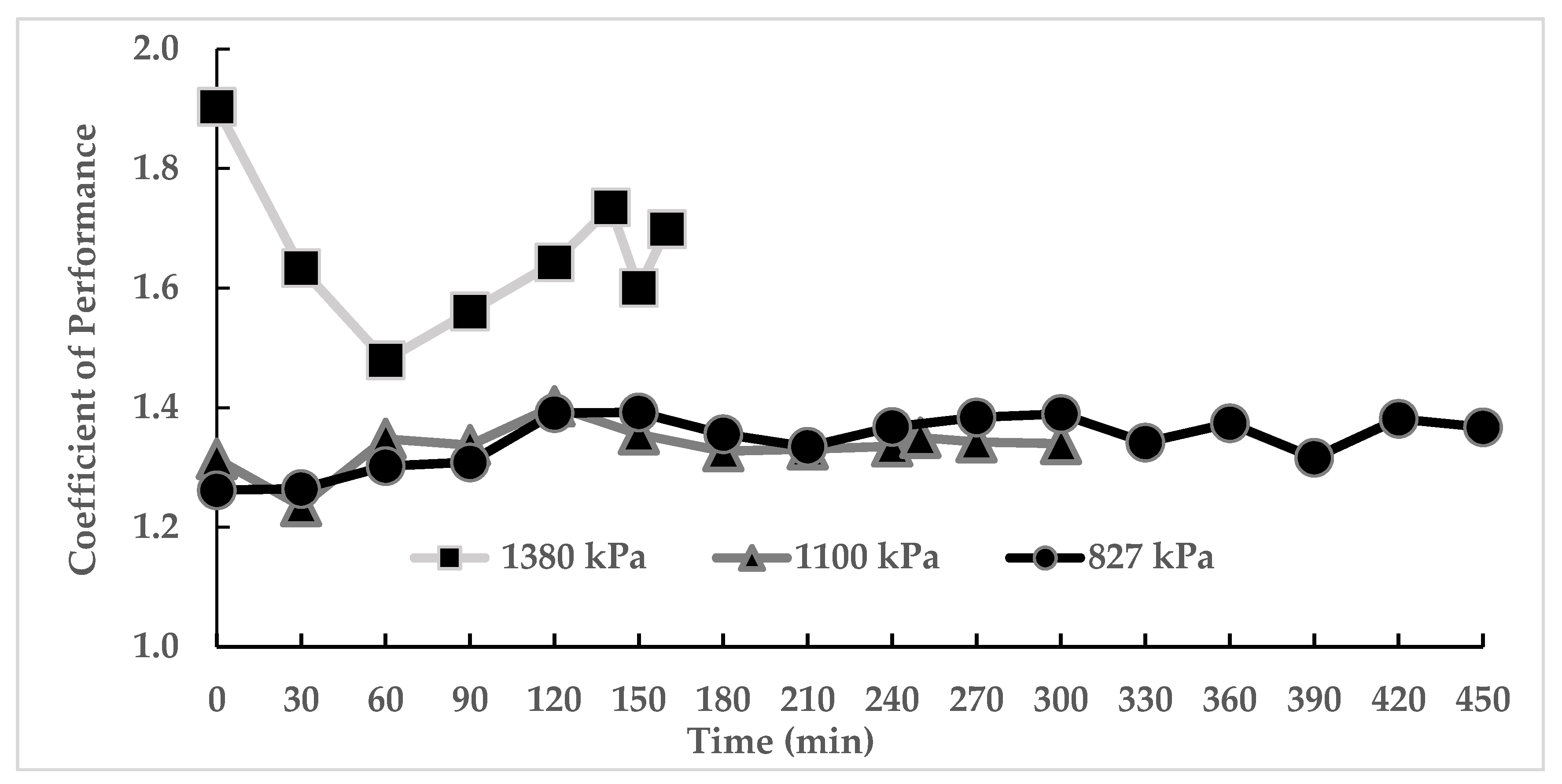

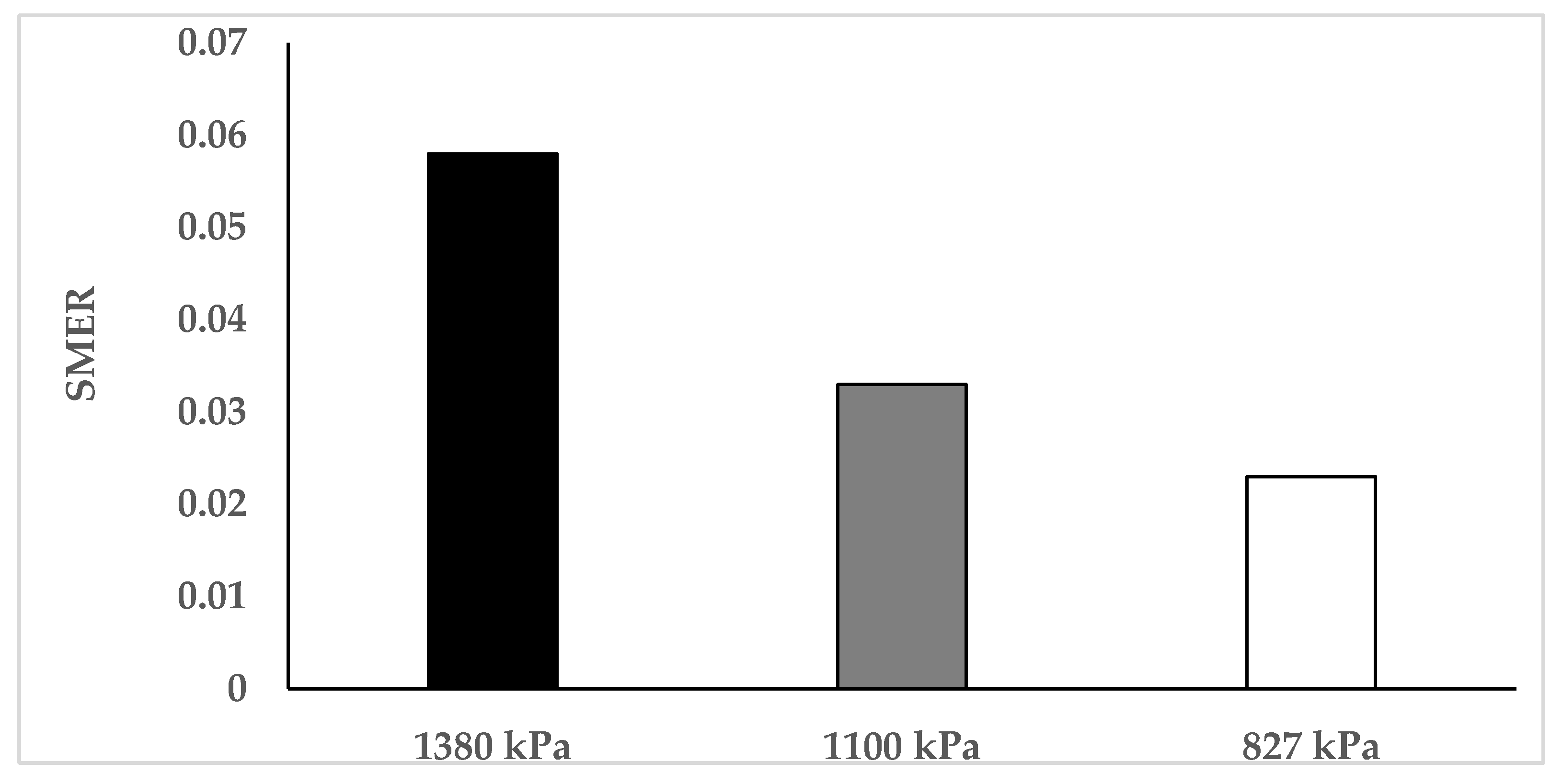

3.2. Efficiency of Oregano Drying Process in HPDs

3.3. Analysis of Variance for the HPDS Drying Process

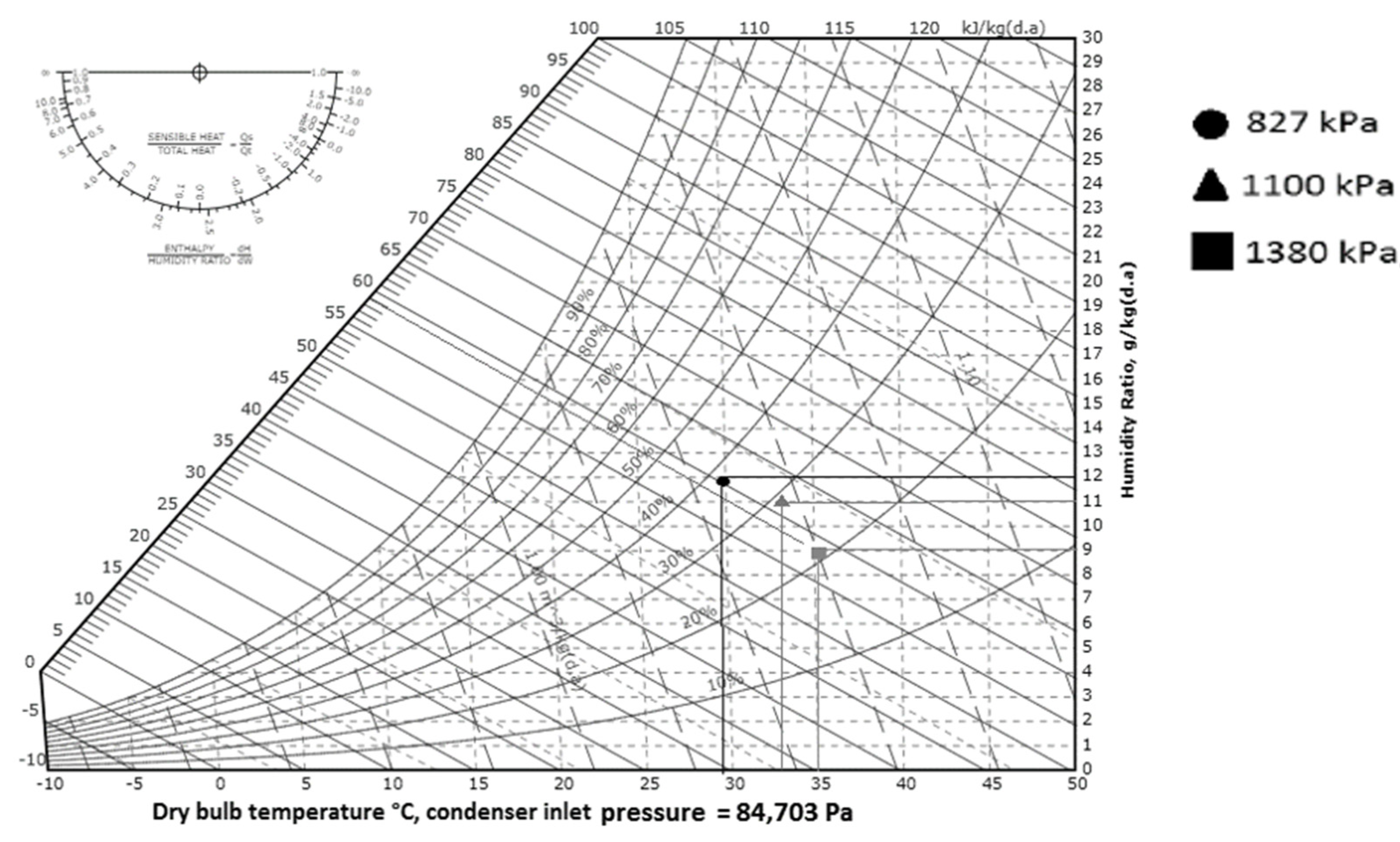

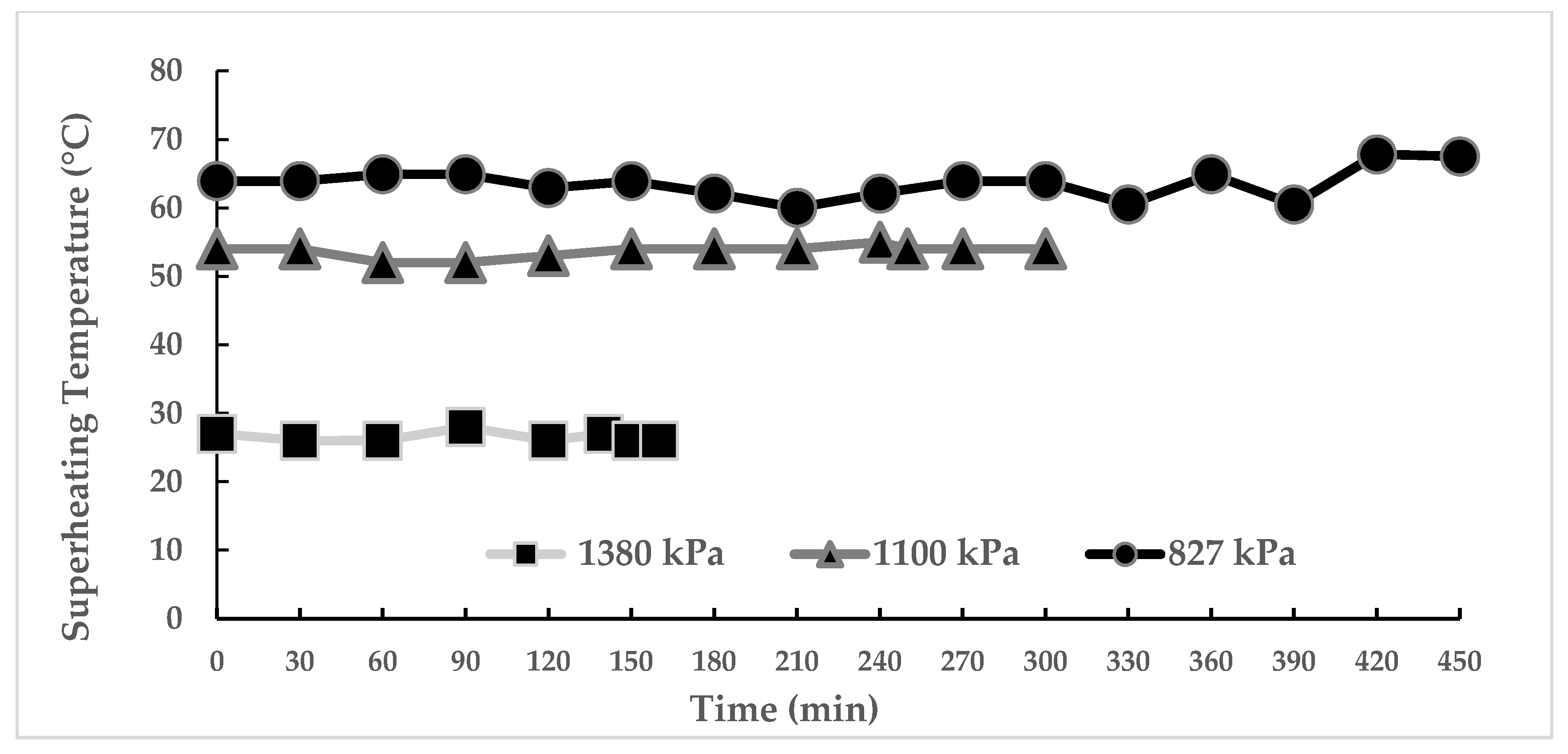

3.4. Behavior of Superheating with the Variation of the Compressor Discharge Pressure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Drabova, L.; Alvarez-Rivera, G.; Suchanova, M.; Schusterova, D.; Pulkrabova, J.; Tomaniova, M.; Kocourek, V.; Chevallier, O.; Elliott, C.; Hajslova, J. Food fraud in oregano: Pesticide residues as adulteration markers. Food Chem. 2019, 276, 726–734. [Google Scholar] [CrossRef] [PubMed]

- Vital, A.C.P.; Guerrero, A.; Kempinski, E.M.B.C.; Monteschio, J.D.O.; Sary, C.; Ramos, T.R.; Campo, M.D.M.; Prado, I.N. Consumer profile and acceptability of cooked beef steaks with edible and active coating containing oregano and rosemary essential oils. Meat Sci. 2018, 143, 153–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Babu, A.; Kumaresan, G.; Raj, V.A.A.; Velraj, R. Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 2018, 90, 536–556. [Google Scholar] [CrossRef]

- Song, X.; Hu, H.; Zhang, B.; Xiaoyong, S.; Hao, H.; Baoling, Z. Drying characteristics of Chinese Yam (Dioscorea opposita Thunb.) by far-infrared radiation and heat pump. J. Saudi Soc. Agric. Sci. 2018, 17, 290–296. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Lin, W.; Mao, X.; Li, W.; Yang, L.; Wei, J.; Xiao, B. Performance Analysis of Heat Pump Dryer with Unit-Room in Cold Climate Regions. Energies 2019, 12, 3125. [Google Scholar] [CrossRef] [Green Version]

- Aktaş, M.; Khanlari, A.; Aktekeli, B.; Amini, A. Analysis of a new drying chamber for heat pump mint leaves dryer. Int. J. Hydrogen Energy 2017, 42, 18034–18044. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, S.; Chu, W.; He, W.; Yu, C.; Yu, H. Numerical Analysis and Preliminary Experiment of a Solar Assisted Heat Pump Drying System for Chinese Wolfberry. Energies 2020, 13, 4306. [Google Scholar] [CrossRef]

- Zambonin, G.; Altinier, F.; Beghi, A.; Coelho, L.D.S.; Fiorella, N.; Girotto, T.; Rampazzo, M.; Reynoso-Meza, G.; Susto, G.A. Machine Learning-Based Soft Sensors for the Estimation of Laundry Moisture Content in Household Dryer Appliances. Energies 2019, 12, 3843. [Google Scholar] [CrossRef] [Green Version]

- Erbay, Z.; Hepbasli, A. Assessment of cost sources and improvement potentials of a ground-source heat pump food drying system through advanced exergoeconomic analysis method. Energy 2017, 127, 502–515. [Google Scholar] [CrossRef]

- Liu, H.; Yousaf, K.; Chen, K.; Fan, R.; Liu, J.; Soomro, S.A. Design and Thermal Analysis of an Air Source Heat Pump Dryer for Food Drying. Sustainability 2018, 10, 3216. [Google Scholar] [CrossRef] [Green Version]

- Colak, N.; Hepbasli, A. A review of heat-pump drying (HPD): Part 2—Applications and performance assessments. Energy Convers. Manag. 2009, 50, 2187–2199. [Google Scholar] [CrossRef]

- Mohanraj, M. Performance of a solar-ambient hybrid source heat pump drier for copra drying under hot-humid weather conditions. Energy Sustain. Dev. 2014, 23, 165–169. [Google Scholar] [CrossRef]

- Minea, V. Drying heat pumps—Part II: Agro-food, biological and wood products. Int. J. Refrig. 2013, 36, 659–673. [Google Scholar] [CrossRef]

- Morshedloo, M.R.; Salami, S.A.; Nazeri, V.; Maggi, F.; Craker, L. Essential oil profile of oregano (Origanum vulgare L.) populations grown under similar soil and climate conditions. Ind. Crop. Prod. 2018, 119, 183–190. [Google Scholar] [CrossRef]

- Fatouh, M.; Metwally, M.N.; Helali, A.B.; Shedid, M.H. Herbs drying using a heat pump dryer. Energy Convers. Manag. 2006, 47, 2629–2643. [Google Scholar] [CrossRef]

- Chapchaimoh, K.; Poomsa-Ad, N.; Wiset, L.; Morris, J. Thermal characteristics of heat pump dryer for ginger drying. Appl. Therm. Eng. 2016, 95, 491–498. [Google Scholar] [CrossRef]

- Taşeri, L.; Aktaş, M.; Arslan, E.; Gülcü, M.; Seçkin, G.U.; Aktekeli, B. Determination of drying kinetics and quality parameters of grape pomace dried with a heat pump dryer. Food Chem. 2018, 260, 152–159. [Google Scholar] [CrossRef]

- Aktaş, M.; Arslan, E.; Özdemir, M.B.; Gönen, E. Performance analysis and modeling of a closed-loop heat pump dryer for bay leaves using artificial neural network. Appl. Therm. Eng. 2015, 87, 714–723. [Google Scholar] [CrossRef]

- Harchegani, M.T.; Sadeghi, M.; Emami, M.D.; Moheb, A. Investigating energy consumption and quality of rough rice drying process using a grain heat pump dryer. Aust. J. Crop Sci. 2012, 6, 592. [Google Scholar]

- Shen, J.; Guo, T.; Tian, Y.; Xing, Z. Design and experimental study of an air source heat pump for drying with dual modes of single stage and cascade cycle. Appl. Therm. Eng. 2018, 129, 280–289. [Google Scholar] [CrossRef]

- Mohammadi, I.; Tabatabaekoloor, R.; Motevali, A. Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 2019, 170, 149–158. [Google Scholar] [CrossRef]

- Ong, S.P.; Law, C.L. Drying Kinetics and Antioxidant Phytochemicals Retention of Salak Fruit under Different Drying and Pretreatment Conditions. Dry. Technol. 2011, 29, 429–441. [Google Scholar] [CrossRef]

- Doymaz, I.; Ismail, O. Drying characteristics of sweet cherry. Food Bioprod. Process. 2011, 89, 31–38. [Google Scholar] [CrossRef]

| Component | Type | Technical Specifications | |

|---|---|---|---|

| 1 | Compressor | Alternative hermetic piston, Embraco FFU 100HAK model | 248.56 W, 115–127 V, 5 A, 60 Hz |

| 2 | Evaporator | Finned cross-flow heat exchanger | 8 fin/in |

| 3 | Compressor Air Blower | SunFlow centrifugal fan, 172*150*50 mm HBL model | 0.37 kW, 2.1 m3/h |

| 4 | Temperature display and registration unit | Electronic interface made with Arduino | 5 V, 1.5 A |

| 5 | High and low pressure sensor | Bourdon manometer | 0–3447.3 kPa; 0–827 kPa |

| 6 | Pipeline for air recirculation | Thermal isolated pipe | 4″ = 0.10 m, aluminum, fiber glass as isolating system |

| 7 | Tray 1 | Grill | 34 cm × 34.5 cm |

| 8 | Tray 2 | Grill | 34 cm × 34.5 cm |

| 9 | Baffle | Aluminum deflector | degree tilt 45° |

| 10 | Condenser | Finned cross-flow heat exchanger | 8 fin/in |

| Instruments | Properties | Range | Accuracy | Uncertainty |

|---|---|---|---|---|

| Temperature and humidity sensor | Power supply 3–5.5 VDC | −40–80 °C | ||

| 0–99.9% RH | ||||

| Low Pressure | Mechanical manifold gauge | 0–11884.49 kPa | N/A | |

| High pressure | Mechanical manifold gauge | 0–23768.3 kPa | N/A | |

| Velocity | Multifunction vane thermo-anemometer | 0.6–32 m/s | 0.1 m/s | |

| Digital balance | BOECO-3000 g | 0–3000 g | ||

| Thermographic Camera | FLIR E4 | −20–250 °C | 0.15 °C | |

| Superheating and subcooling calculator | 24 preprogrammed refrigerants and a Type K thermocouple | −40–200 °C | ||

| Voltage and current measurement device | Digital clamp multimeter, UT207A | 0–600 VAC | N/A | |

| 0–66 A | ||||

| Thermogravimetric Analyzer | Thermogravimetric analyzer Q6000 SDT | 19 samples with sample weights of up to 5 g | 0.02% | 0.0001 g |

| Data acquisition system | Arduino-based data Acquisition system | 10 points for temperature measurement | N/A | N/A |

| Parameter | Operating Range |

|---|---|

| Air velocity | 1.2 m/s |

| Refrigerant mass flow | 0.0031 kg/s |

| Surrounding air temperature | 25 °C (average) |

| Surrounding relative humidity | 68% (average) |

| Volumetric air flow | 195 m3/h |

| Atmospheric pressure | 85.2 kPa |

| Pressure | |||

|---|---|---|---|

| 1380 kPa | 1100 kPa | 827 kPa | |

| Temperature | 46.3 | 39.2 | 32.9 |

| 46.7 | 39.9 | 34.0 | |

| 46.1 | 39.5 | 34.8 | |

| 46.3 | 39.5 | 33.9 | |

| Source of Variations | Sum of Squares | Degree of Freedom | Mean Squares | F-Value | p-Value | F critical Value |

|---|---|---|---|---|---|---|

| Between groups | 233.76 | 2 | 116.88 | 305.17 | 9.2258×10−7 | 5.14325285 |

| Inside groups | 2.30 | 6 | 0.38 | |||

| Total | 236.06 | 8 |

| Comparison | Result | |

|---|---|---|

| 1380 kPa vs 1100 kPa | 6.8 | >1.2364 |

| 1380 kPa vs 827 kPa | 12.5 | >1.2364 |

| 1100 kPa vs 827 kPa | 5.6 | >1.2364 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar-Hincapié, A.; Delgado-Mejía, A.; Romero-Maya, A.F.; Duque-Grisales, E. Experimental Assessment of the Thermal Performance of a Heat Pump Dryer System Based on the Variations in Compressor Discharge Pressure on Oregano Drying. Energies 2020, 13, 6333. https://doi.org/10.3390/en13236333

Salazar-Hincapié A, Delgado-Mejía A, Romero-Maya AF, Duque-Grisales E. Experimental Assessment of the Thermal Performance of a Heat Pump Dryer System Based on the Variations in Compressor Discharge Pressure on Oregano Drying. Energies. 2020; 13(23):6333. https://doi.org/10.3390/en13236333

Chicago/Turabian StyleSalazar-Hincapié, Arley, Alvaro Delgado-Mejía, Andrés Felipe Romero-Maya, and Eduardo Duque-Grisales. 2020. "Experimental Assessment of the Thermal Performance of a Heat Pump Dryer System Based on the Variations in Compressor Discharge Pressure on Oregano Drying" Energies 13, no. 23: 6333. https://doi.org/10.3390/en13236333