An Effective Operation Strategy for CCHP System Integrated with Photovoltaic/Thermal Panels and Thermal Energy Storage

Abstract

:1. Introduction

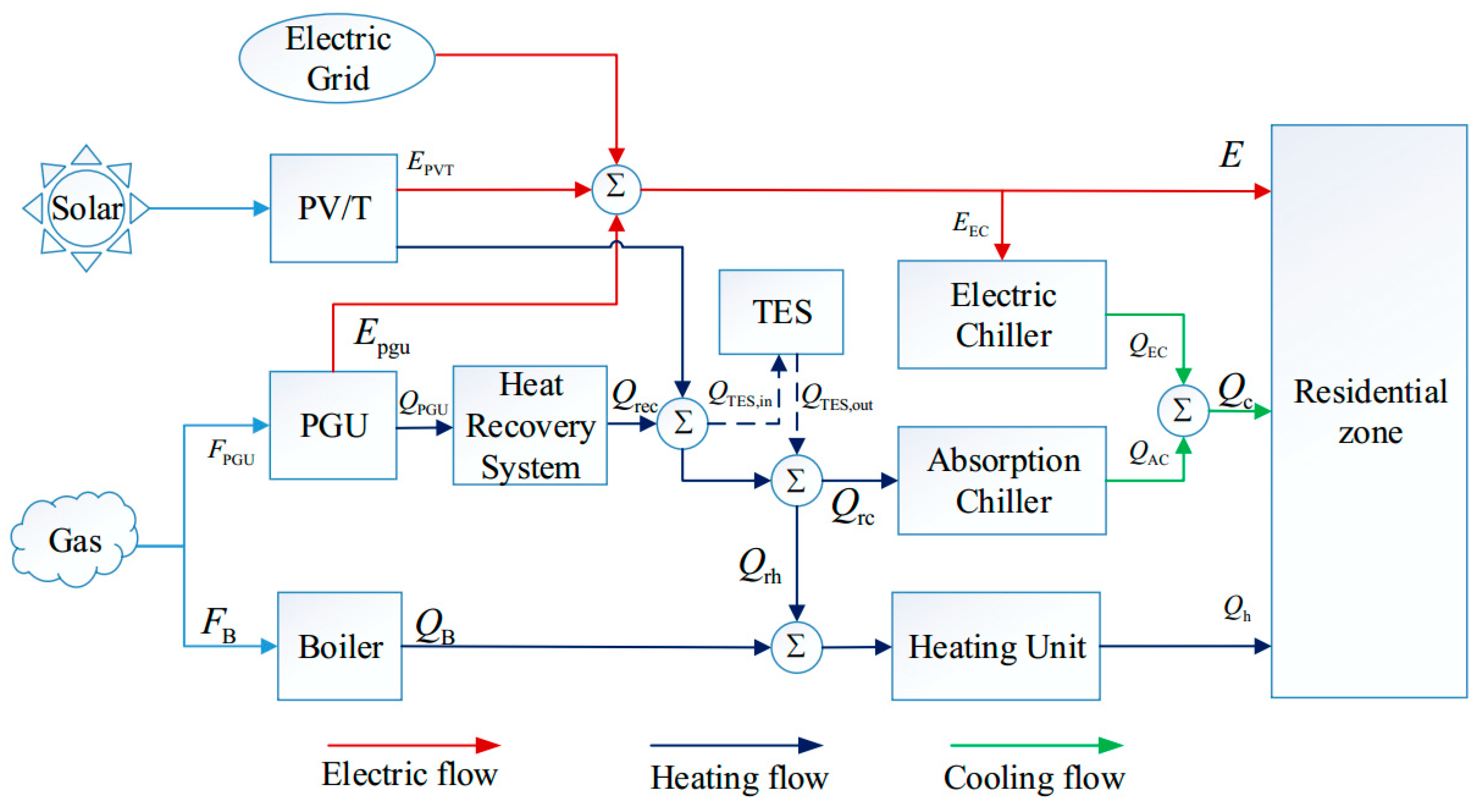

- A CCHP system with the integration of PV/T panels and thermal energy storage is established. The interactions between various energy demands side and energy supply side under different system configurations are presented in detail.

- An appropriate design scheme of a CCHP system hybridized with PV/T panels and TES can be given by the optimization method based on the particle swarm optimization algorithm.

- Evaluated by operation cost and primary energy saving, an effective operation strategy is presented. Compared with several traditional operation strategies, the effectiveness of this method is proved.

2. System Structure and its Effective Operation Strategy

2.1. Description of CCHP System

2.2. Effective Operation Strategy

- (a)

- When the total solar thermal energy converted by PV/T panels and stored in heat tanks is not enough to fulfill the heating loads, the auxiliary gas-fired boiler and electric chiller start to make up the deficiency of thermal power.

- (b)

- could not even meet the heating demand. Added with the thermal energy in tanks, the sum of the thermal energy can only fulfill the heating demand. In this case, the sum of low-grade heat energy collected by PV/T panels and discharged from the tanks meets the heating loads first. The electric chiller and absorption chiller both start to provide the cooling loads.

- (c)

- could not even meet the heating demand. Added with the thermal energy in tanks, the sum of the thermal energy can do both cooling and heating loads. The gas-fired boiler and electric chiller do not start.

- (d)

- Whether added to the thermal energy in tanks or not, can only fulfill the heating loads. In this case, the electric chiller starts to make up the deficiency of cooling demand.

- (e)

- Without adding the heat provided by the heat storage, the total heat source can only fulfill the heating load. However, added with the thermal energy in tanks, the total heat source can fulfill both the whole heating and cooling load.

- (f)

- When is enough to fulfill both heating and cooling loads, the surplus heat will be charged in thermal energy storage as much as possible.

- (a)

- When the total thermal energy provided by , and thermal energy storage cannot meet the heating demand, the auxiliary gas-fired boiler and electric chiller work. Meanwhile, the heat storage does not release heat.

- (b)

- When the total thermal energy provided by and cannot meet the heating demand, but is added with the thermal energy in tanks, the sum of the thermal energy can only fulfill the heating loads. The lectric chiller starts to make up the deficiency of the cooling loads.

- (c)

- When the total thermal energy provided by and cannot meet the heating demand, but is added with the thermal energy in tanks, the sum of the thermal energy can fulfill the total thermal energy demand. In this case, the heat storage tanks release an appropriate amount of heat energy to meet the whole thermal loads, and meanwhile, the gas-fired boiler and electric chiller do not start.

- (d)

- Whether added with the thermal energy in tanks or not, and can only fulfill the heating loads. In this case, the heat storage tanks release energy as much as possible to meet the cooling demand. The electric chiller will make up for the above shortage of the cooling demand.

- (e)

- When the total thermal energy provided by and can only meet the heating demand, but is added with the thermal energy in tanks, the sum of the thermal energy can fulfill the total thermal energy demand. In this case, the working states of heat storage tanks, electric chiller and gas-fired boiler are consistent with step c of Case 2.

- (f)

- When the total thermal energy provided by and is enough to fulfill both heating and cooling loads, the surplus heat will be charged in thermal energy storage as much as possible.

2.3. Evaluation Criterion

2.3.1. Annual Total Cost

2.3.2. Primary Energy Consumption and Primary Energy Saving Rate

2.4. Assumptions in CCHP System

- The proposed CCHP system is totally reliable and exporting electricity to external grid is not allowed.

- The thermal storage system is an ideal model; there is no energy in the process of heat charging or discharging.

- The models of electric chiller, absorption chiller and gas-fired boiler are based on a simplified hypothesis, and the efficiency of those components is considered to be a constant.

- There is enough space on the roof or ground of the residential zone to install the required numbers of PV/T panels.

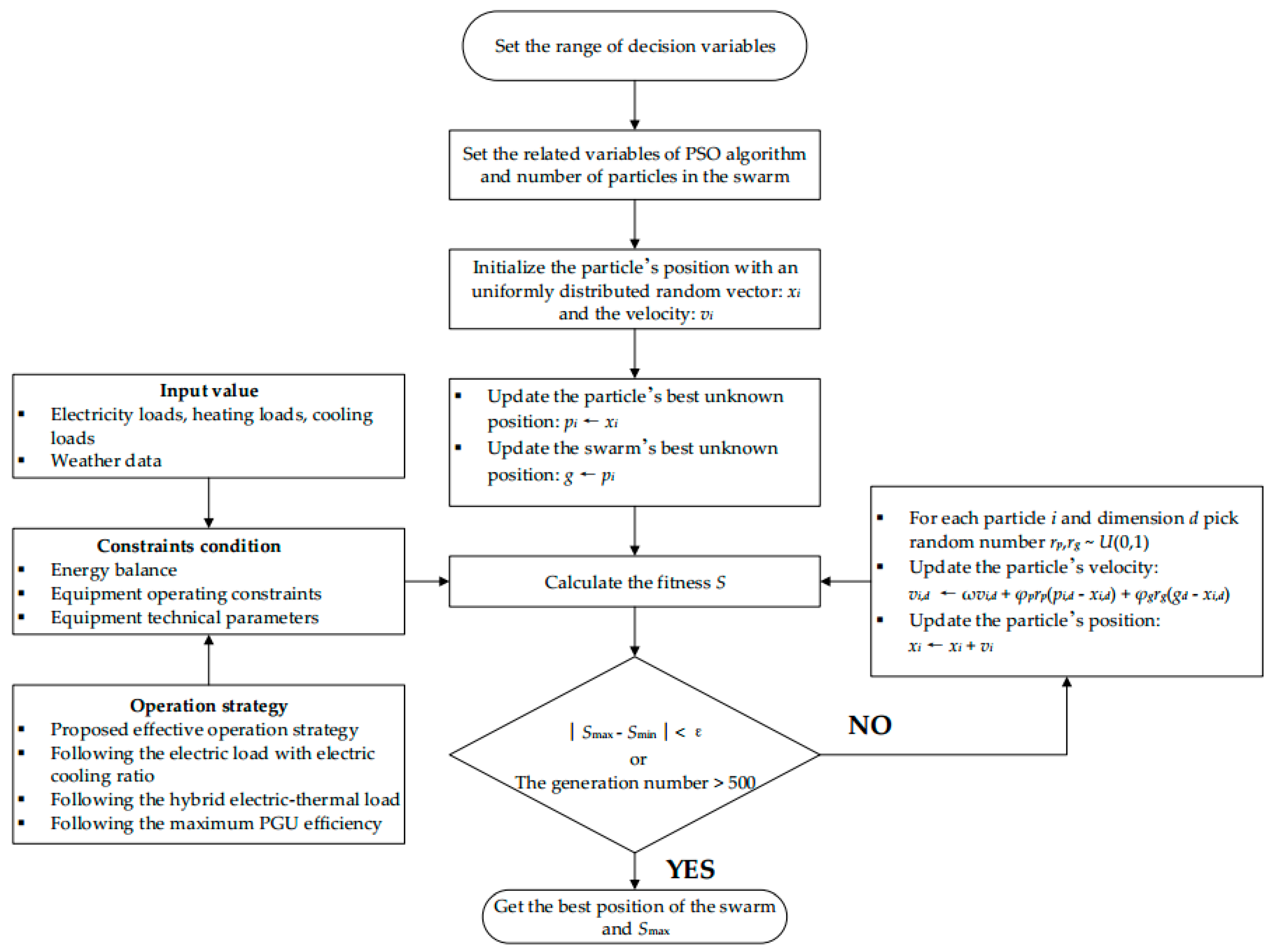

3. Optimization Method

3.1. Decision Variables

3.2. Objection Function

3.3. Constraints Condition

3.4. Solution Method

4. Case Study

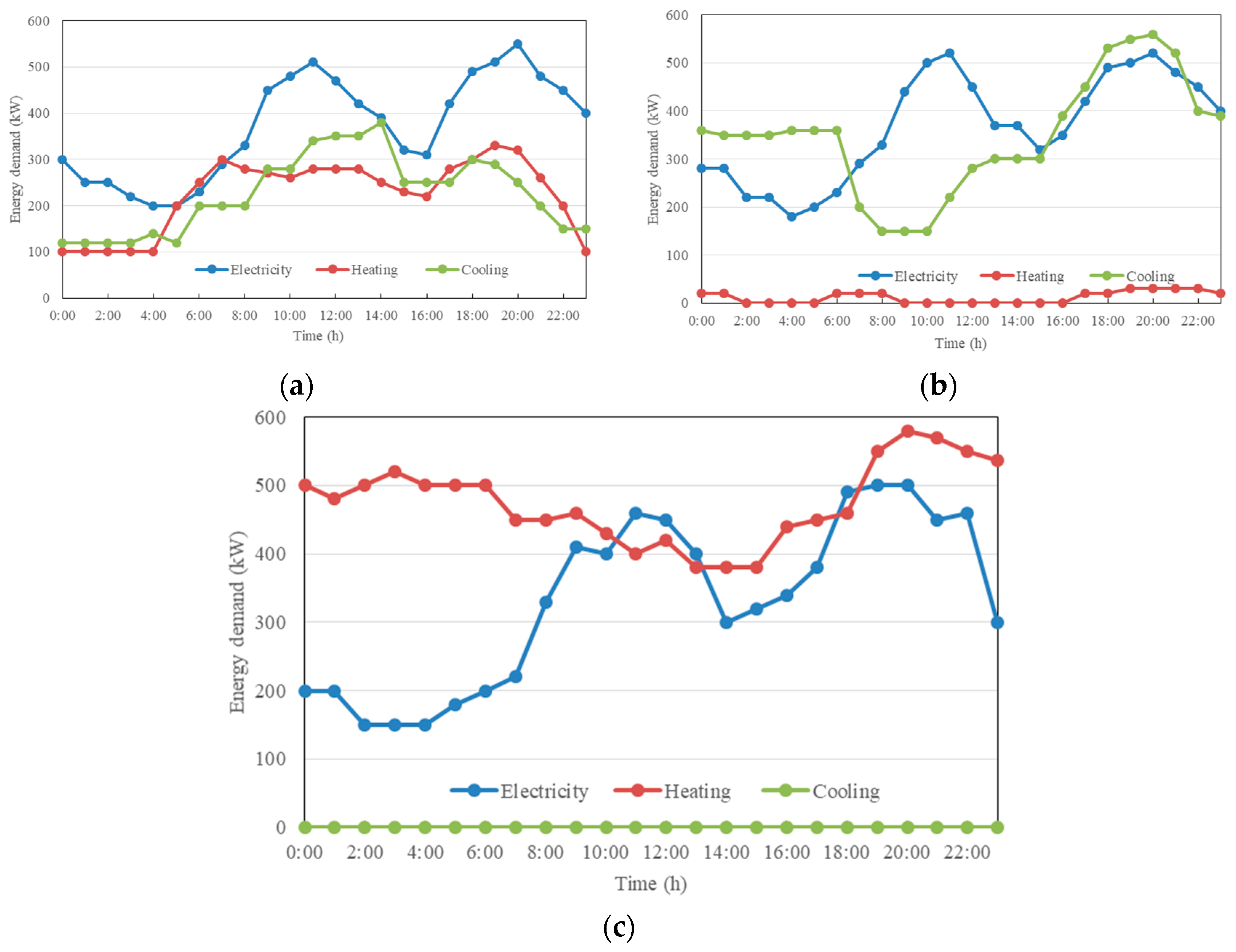

4.1. Case Introduction

4.2. Analysis and Discussion

4.2.1. Optimal Design Parameters of the CCHP System under Different Operation Strategies

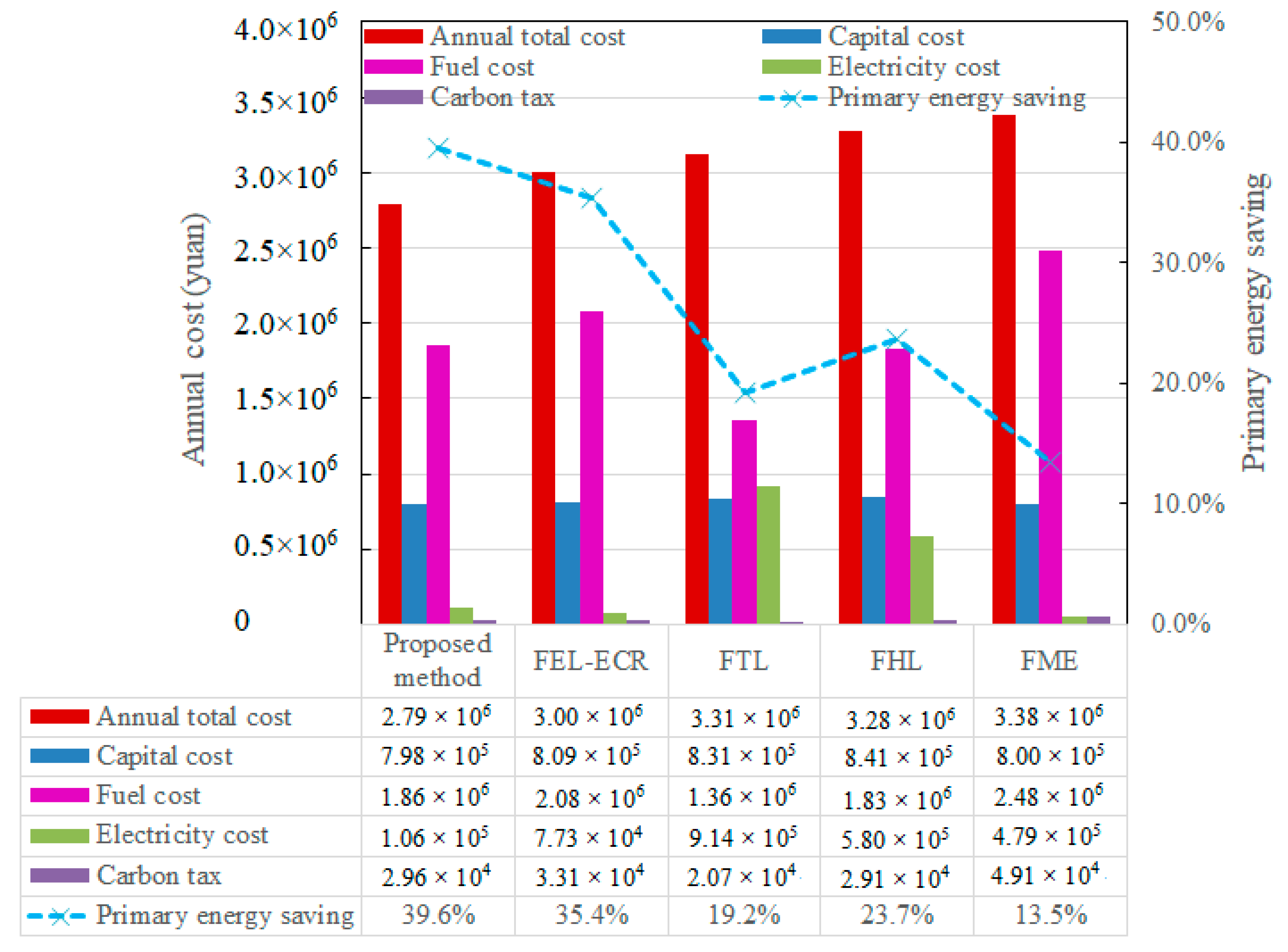

4.2.2. Analysis of Economic and Environmental Results of Different Operation Strategies

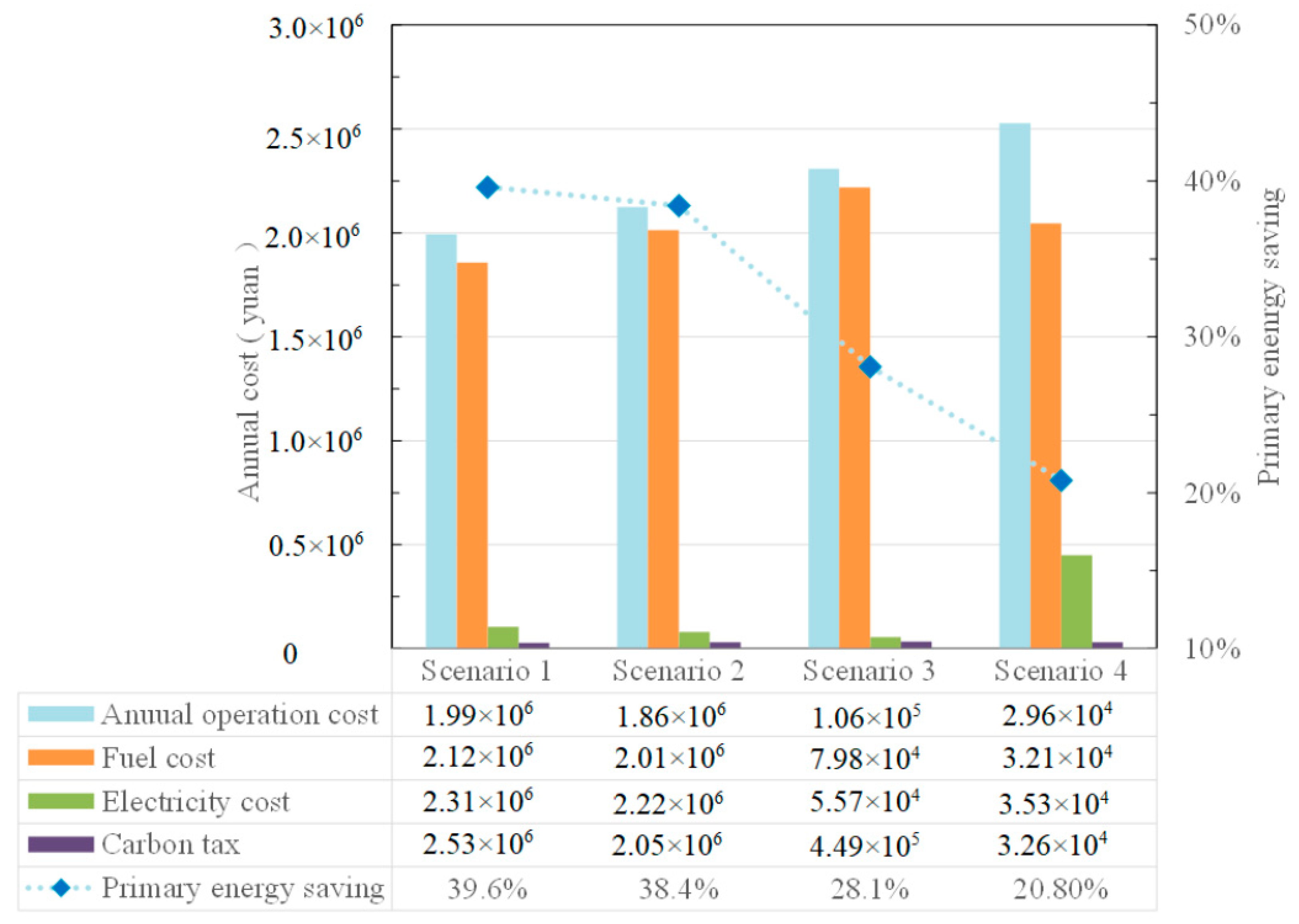

4.2.3. Analysis of Economic and Environmental Results in Different Scenarios

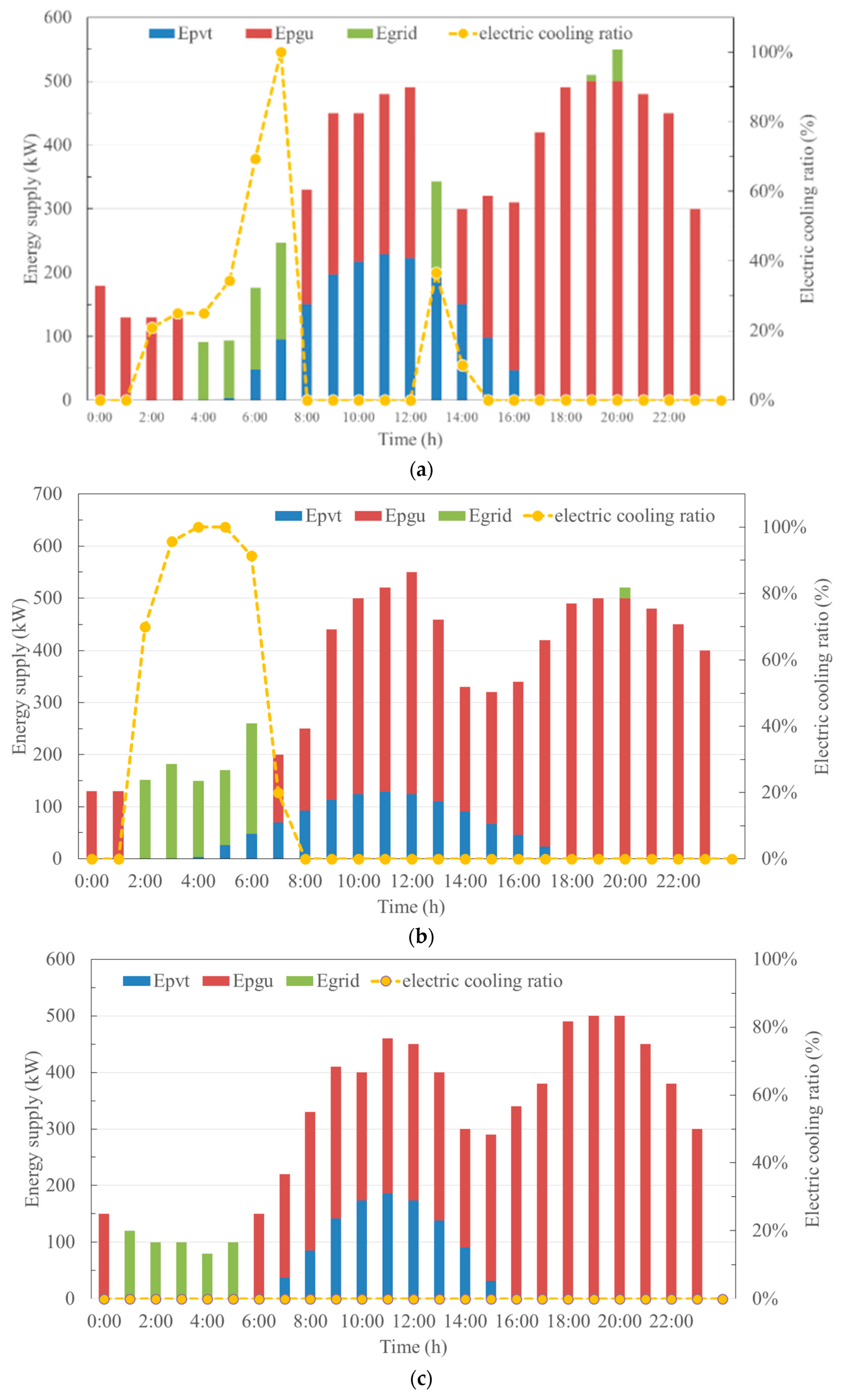

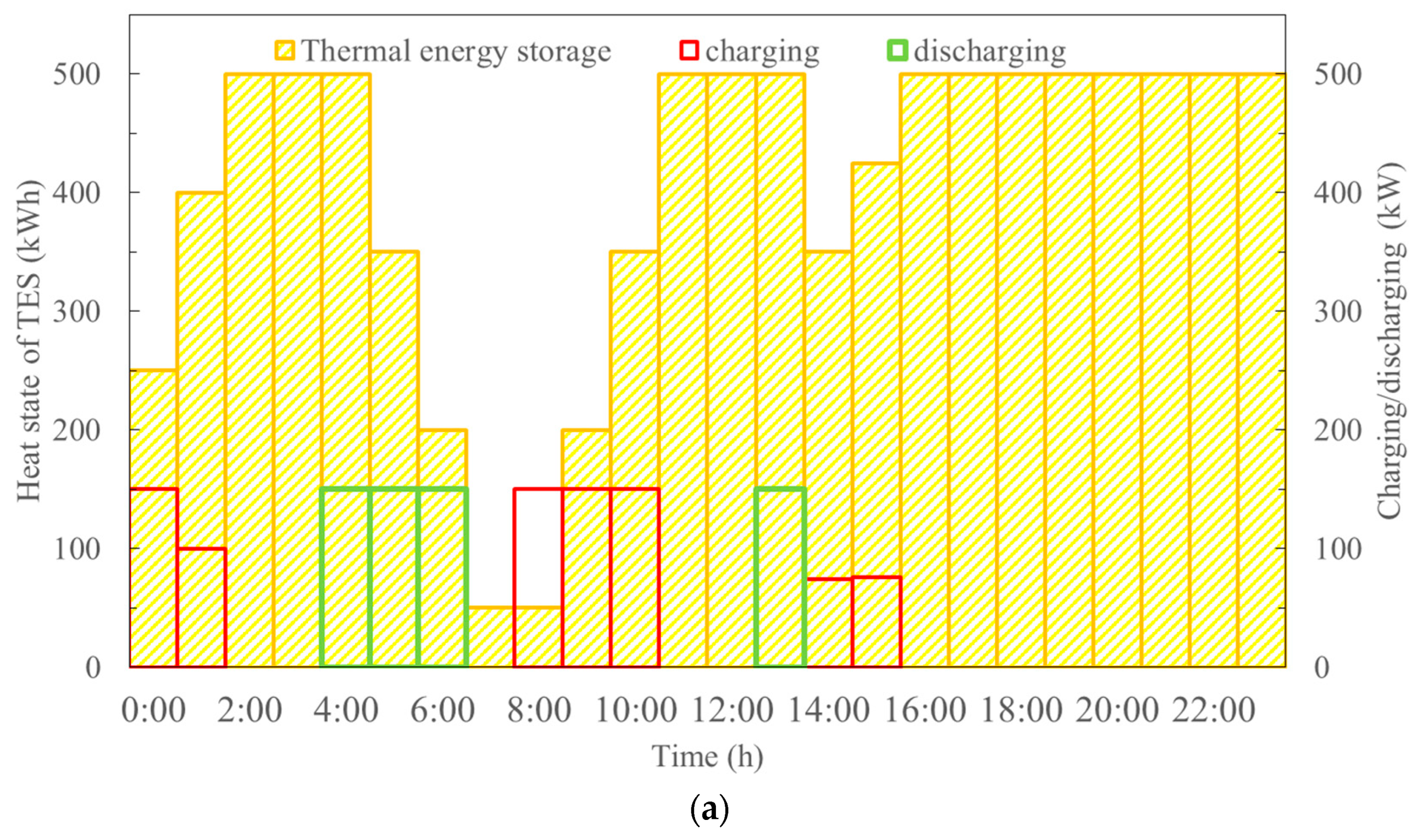

4.2.4. Analysis of Energy Flow in a Typical Day

5. Conclusions

- Adding the PV/T panels into the conventional CCHP, as scenario 2 has shown, the original value of primary energy saving is increased by 17.6%. The electricity purchased cost is greatly reduced by 3.264 × 105 yuan. The self-sufficiency rate of electric energy has been improved greatly. Adding the thermal energy storage into the conventional CCHP, as scenario 3 has shown, the original value of primary energy saving is increased by 7.3%.

- The application of CCHP with the integration of PV/T panels and thermal energy storage in a residential zone can achieve better effects for cost saving and energy saving. Compared with the conventional CCHP system, the value of primary saving increases greatly by 39.6% and the total cost decreases dramatically.

- The CCHP system under FTL and FME modes achieve much worse performance in primary energy saving. Compared with those two modes, applying the FHL may achieve better performance in primary energy saving, but does not perform well in cost saving. Compared with any other basic operation modes, the proposed operation strategy is much more suitable for the CCHP system with the integration of PV/T panels and thermal energy storage.

Author Contributions

Funding

Conflicts of Interest

References

- Cho, H.; Smith, A.D.; Mago, P. Combined cooling, heating and power: A review of performance improvement and optimization. Appl. Energy 2014, 136, 168–185. [Google Scholar] [CrossRef]

- Gu, W.; Wu, Z.; Bo, R.; Liu, W.; Zhou, G.; Chen, W. Modeling, planning and optimal energy management of combined cooling, heating and power microgrid: A review. Int. J. Electr. Power Energy Syst. 2014, 54, 26–37. [Google Scholar] [CrossRef]

- Liu, M.; Shi, Y.; Fang, F. Combined cooling, heating and power systems: A survey. Renew. Sustain. Energy Rev. 2014, 35, 1–22. [Google Scholar] [CrossRef]

- Maryam, F.; Amirhassan, S. Solar assisted CCHP system, energetic, economic and environmental analysis, case study: Educational office buildings. Energy Build. 2017, 136, 100–109. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Mao, X. Intelligent scheduling optimization of seasonal CCHP system using rolling horizon hybrid optimization algorithm and matrix model framework. IEEE Access 2018, 6, 75132–75142. [Google Scholar] [CrossRef]

- Wegener, M.; Malmquist, A.; Isalgué, A.; Martin, A. Biomass-fired combined cooling, heating and power for small scale applications—A review. Renew. Sustain. Energy Rev. 2018, 96, 392–410. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Hu, P.; Zhu, N.; Lei, F.; Xing, L. Performance analysis and optimization of a CCHP-GSHP coupling system based on quantum genetic algorithm. Sustain. Cities Soc. 2019, 46, 101408. [Google Scholar] [CrossRef]

- Rostamzadeh, H.; Ebadollahi, M.; Ghaebi, H.; Shokri, A. Comparative study of two novel micro-CCHP systems based on organic Rankine cycle and Kalina cycle. Energy Convers. Manag. 2019, 183, 210–229. [Google Scholar] [CrossRef]

- Mahmood, C.; Mohammad, S. Energy, environmental and economic evaluations of a CCHP system driven by Stirling engine with helium and hydrogen as working gases. Energy 2019, 174, 1251–1266. [Google Scholar] [CrossRef]

- Houssein, A.M.; Farouk, F.; Hasna, L. Selection based on differences between cogeneration and trigeneration in various prime mover technologies. Renew. Sustain. Energy Rev. 2017, 74, 491–511. [Google Scholar] [CrossRef]

- Su, B.; Han, W.; Qu, W.; Liu, C.; Jin, H. A new hybrid photovoltaic/thermal and liquid desiccant system for trigeneration application. Appl. Energy 2018, 226, 808–818. [Google Scholar] [CrossRef]

- Yousefi, H.; Ghodusinejad, M.; Kasaeian, A. Multi-objective optimal component sizing of a hybrid ICE + PV/T driven CCHP microgrid. Appl. Therm. Eng. 2017, 122, 126–138. [Google Scholar] [CrossRef]

- Yang, G.; Zhai, X. Optimization and performance analysis of solar hybrid CCHP systems under different operation strategies. Appl. Therm. Eng. 2018, 133, 327–340. [Google Scholar] [CrossRef]

- Yang, G.; Zhai, X. Optimal design and performance analysis of solar hybrid CCHP system considering influence of building type and climate condition. Energy 2019, 174, 647–663. [Google Scholar] [CrossRef]

- Herrando, M.; Pantaleo, A.; Wang, K.; Markides, C. Solar combined cooling, heating and power systems based on hybrid PVT, PV or solar-thermal collectors for building applications. Renew. Energy 2019, 143, 637–647. [Google Scholar] [CrossRef]

- Mohammadkhani, N.; Sedighizadeh, M.; Esmaili, M. Energy and emission management of CCHPs with electric and thermal energy storage and electric vehicle. Therm. Sci. Eng. Progress 2018, 8, 494–508. [Google Scholar] [CrossRef]

- Liu, W.; Chen, G.; Yan, B.; Zhou, Z.; Du, H.; Zuo, J. Hourly operation strategy of a CCHP system with GSHP and thermal energy storage (TES) under variable loads: A case study. Energy Build. 2015, 93, 143–153. [Google Scholar] [CrossRef]

- Zheng, C.; Wu, J.; Zhai, X.; Wang, R. A novel thermal storage strategy for CCHP system based on energy demands and state of storage tank. Electr. Power Energy Syst. 2017, 85, 117–129. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Yu, S.; Mu, H.; Li, H. Optimization and evaluation of CCHP systems considering incentive policies under different operation strategies. Energy 2018, 162, 825–840. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, D.; Wang, S.; Wu, T. Standardized modelling and economic optimization of multi-carrier energy systems considering energy storage and demand response. Energy Convers. Manag. 2019, 182, 126–142. [Google Scholar] [CrossRef]

- Wang, J.; Sui, J.; Jin, H. An improved operation strategy of combined cooling heating and power system following electrical load. Energy 2015, 85, 654–666. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.; Wang, P.; Liang, J. Optimal Design of a Combined Cooling, Heating, and Power System and Its Ability to Adapt to Uncertainty. Energies 2020, 13, 3588. [Google Scholar] [CrossRef]

- Lingmin, C.; Jiekang, W.; Fan, W.; Huiling, T.; Changjie, L.; Yan, X. Energy flow optimization method for multi-energy system oriented to combined cooling, heating and power. Energy 2020, 211, 118536. [Google Scholar] [CrossRef]

- Yang, H.; Xiong, T.; Qiu, J.; Qiu, D.; Dong, Z.Y. Optimal operation of DES/CCHP based regional multi-energy prosumer with demand response. Appl. Energy 2016, 167, 353–365. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, J.; Hu, Y.; Zhang, X. Optimal operation strategy of multi-energy complementary distributed CCHP system and its application on commercial building. IEEE Access 2019, 7, 127839–127849. [Google Scholar] [CrossRef]

| Variables | Symbol | Unit | Range |

|---|---|---|---|

| Capacity of the power generation unit (PGU) | kW | [0, 10 × max(E)] | |

| Capacity of the hybrid photovoltaic/thermal (PV/T) panels | kW | [0, 10 × max(E)] | |

| Capacity of the thermal energy storage (TES) | kW | [0, 30 × max(Qh)] | |

| Capacity of the AC | kW | [0, 10 × max(Qc)] |

| Parameter | Unit | Value | Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|---|---|---|

| kW | 50 | - | 4 | h | 1 | |||

| kW | 150 | % | 80 | n | - | 20 | ||

| kW | 150 | % | 90 | i | - | 0.08 | ||

| % | 80 | % | 32 | |||||

| - | 0.7 | 9.78 | ||||||

| - | 0.9 | 0.202 |

| Parameter | Representative | Value |

|---|---|---|

| Unit price | PGU | 8000 yuan/kW |

| PV/T panels | 12,500 yuan/kW | |

| Thermal energy storage | 230 yuan/kW | |

| Absorption chiller | 1500 yuan/kW | |

| Electric chiller | 1000 yuan/kW | |

| Heating exchanger | 150 yuan/kW | |

| Boiler | 180 yuan/kW | |

| Utility electricity price | Peak: 14:00–16:59,19:00–21:59 | 0.87 yuan/kWh |

| Flat: 8:00–13:59, 17:00–18:59, 22:00–23:59 | 0.61 yuan/kWh | |

| Valley: 0:00–7:59 | 0.31 yuan/kWh | |

| Price of natural gas | Whole day | 2.70 yuan/m3 |

| Carbon tax | Whole day | 0.02 yuan/kg |

| Scenarios | Equipment in a CCHP System | |||||||

|---|---|---|---|---|---|---|---|---|

| PGU | HRS | PV/T | TES | HE | Boiler | AC | EC | |

| scenario 1 | √ | √ | √ | √ | √ | √ | √ | √ |

| scenario 2 | √ | √ | √ | × | √ | √ | √ | √ |

| scenario 3 | √ | √ | × | √ | √ | √ | √ | √ |

| scenario 4 | √ | √ | × | × | √ | √ | √ | √ |

| Operation Strategy | PGU/kW | TES/kW | PV/T/kW | EC/kW | AC/kW | Boiler/kW | CATC/yuan |

|---|---|---|---|---|---|---|---|

| Following electric load with electric cooling ratio (FEL-ECR) | 530 | 550 | 260 | 280 | 380 | 650 | 8.41 × 105 |

| Following thermal load (FTL) | 510 | 330 | 180 | 510 | 120 | 650 | 8.68 × 105 |

| Following hybrid load (FHL) | 525 | 542 | 220 | 350 | 210 | 650 | 8.72 × 105 |

| Following the maximum PGU efficiency (FME) | 550 | 650 | 170 | 460 | 150 | 650 | 8.33 × 105 |

| Proposed method | 500 | 630 | 350 | 360 | 560 | 650 | 8.27 × 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Y.; Wu, J.; Zhang, W. An Effective Operation Strategy for CCHP System Integrated with Photovoltaic/Thermal Panels and Thermal Energy Storage. Energies 2020, 13, 6418. https://doi.org/10.3390/en13236418

Mao Y, Wu J, Zhang W. An Effective Operation Strategy for CCHP System Integrated with Photovoltaic/Thermal Panels and Thermal Energy Storage. Energies. 2020; 13(23):6418. https://doi.org/10.3390/en13236418

Chicago/Turabian StyleMao, Yunshou, Jiekang Wu, and Wenjie Zhang. 2020. "An Effective Operation Strategy for CCHP System Integrated with Photovoltaic/Thermal Panels and Thermal Energy Storage" Energies 13, no. 23: 6418. https://doi.org/10.3390/en13236418