Precise Determination of Liquid Layer Thickness with Downward Annular Two-Phase Gas-Very Viscous Liquid Flow

Abstract

:1. Introduction

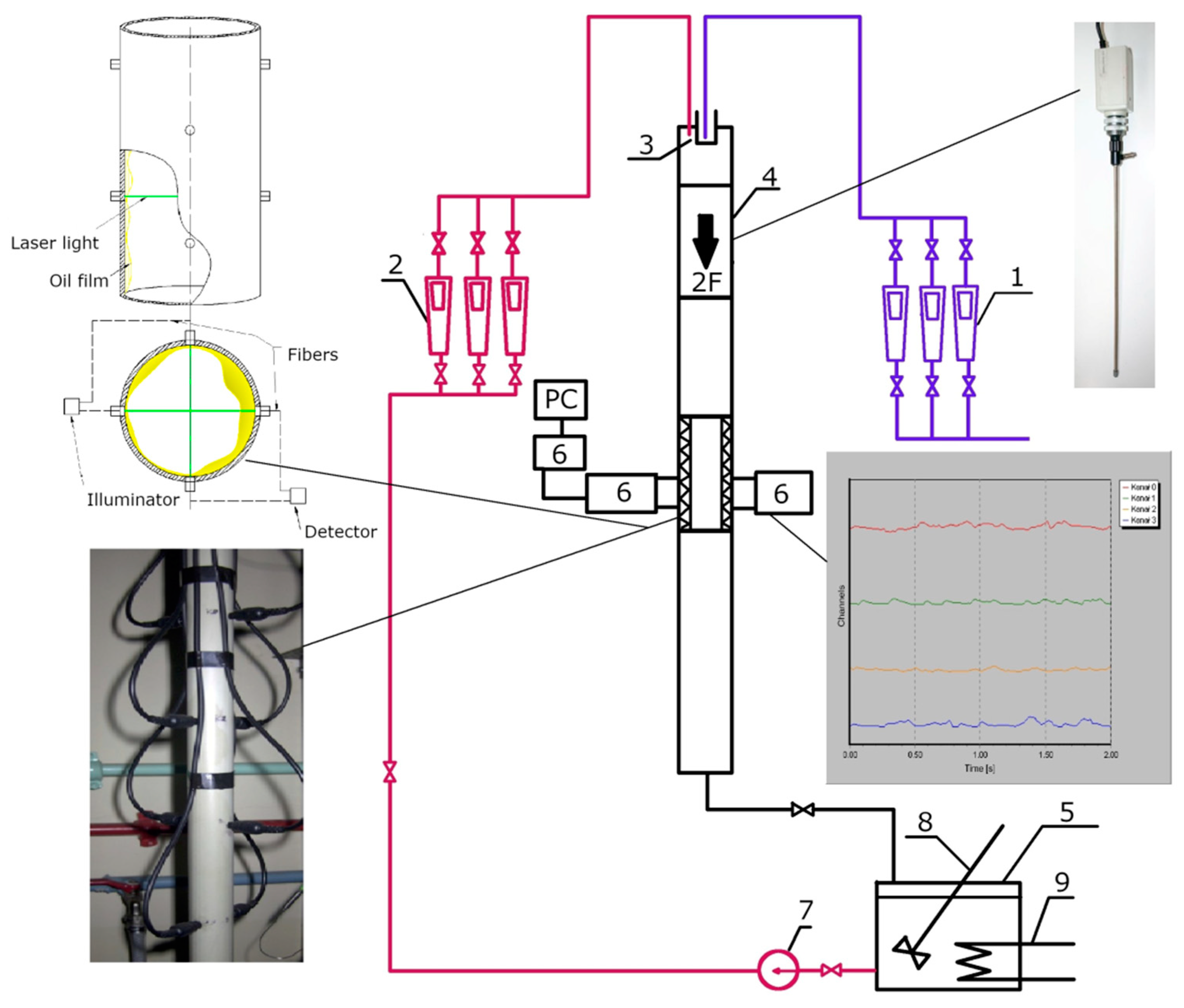

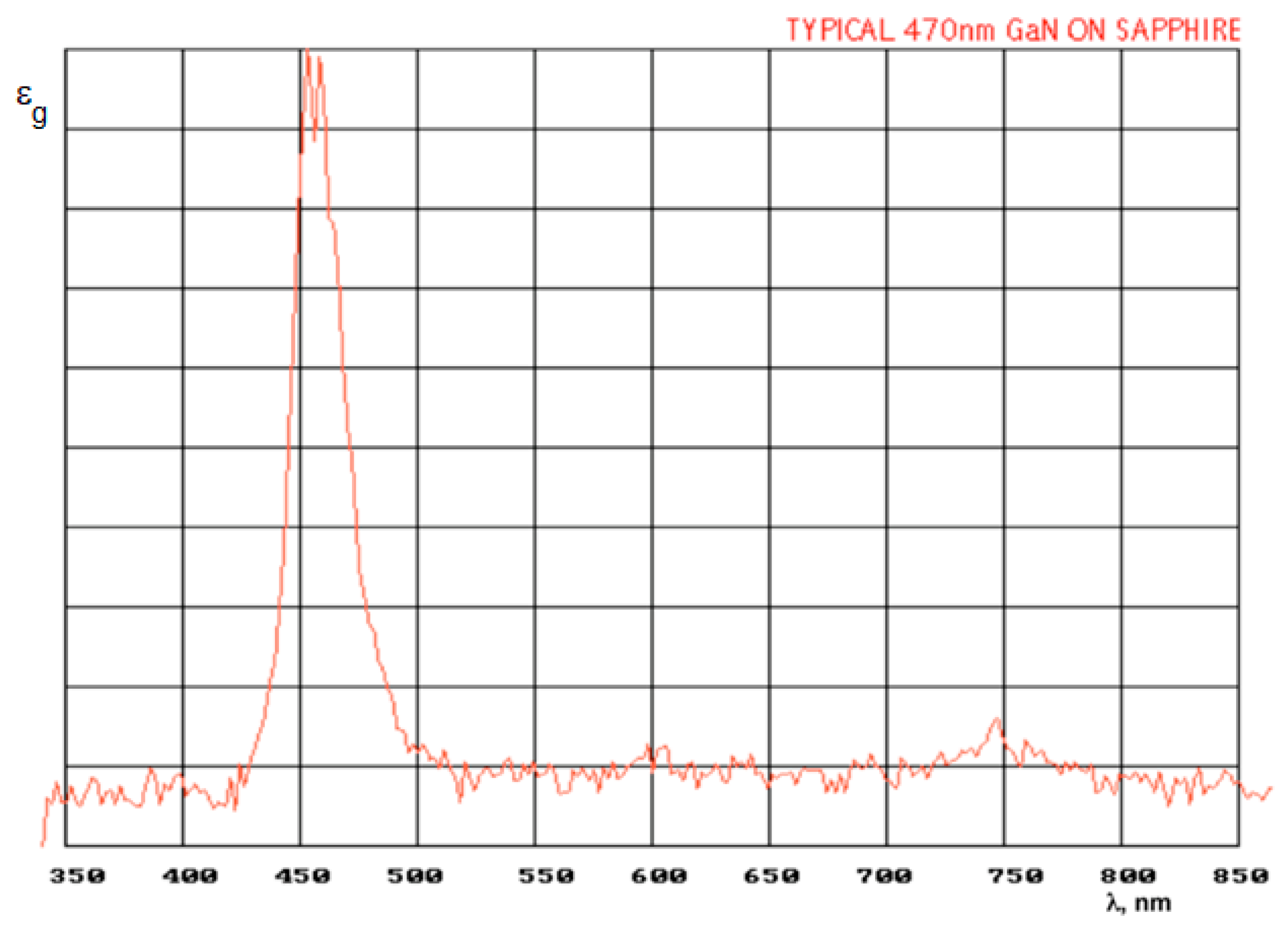

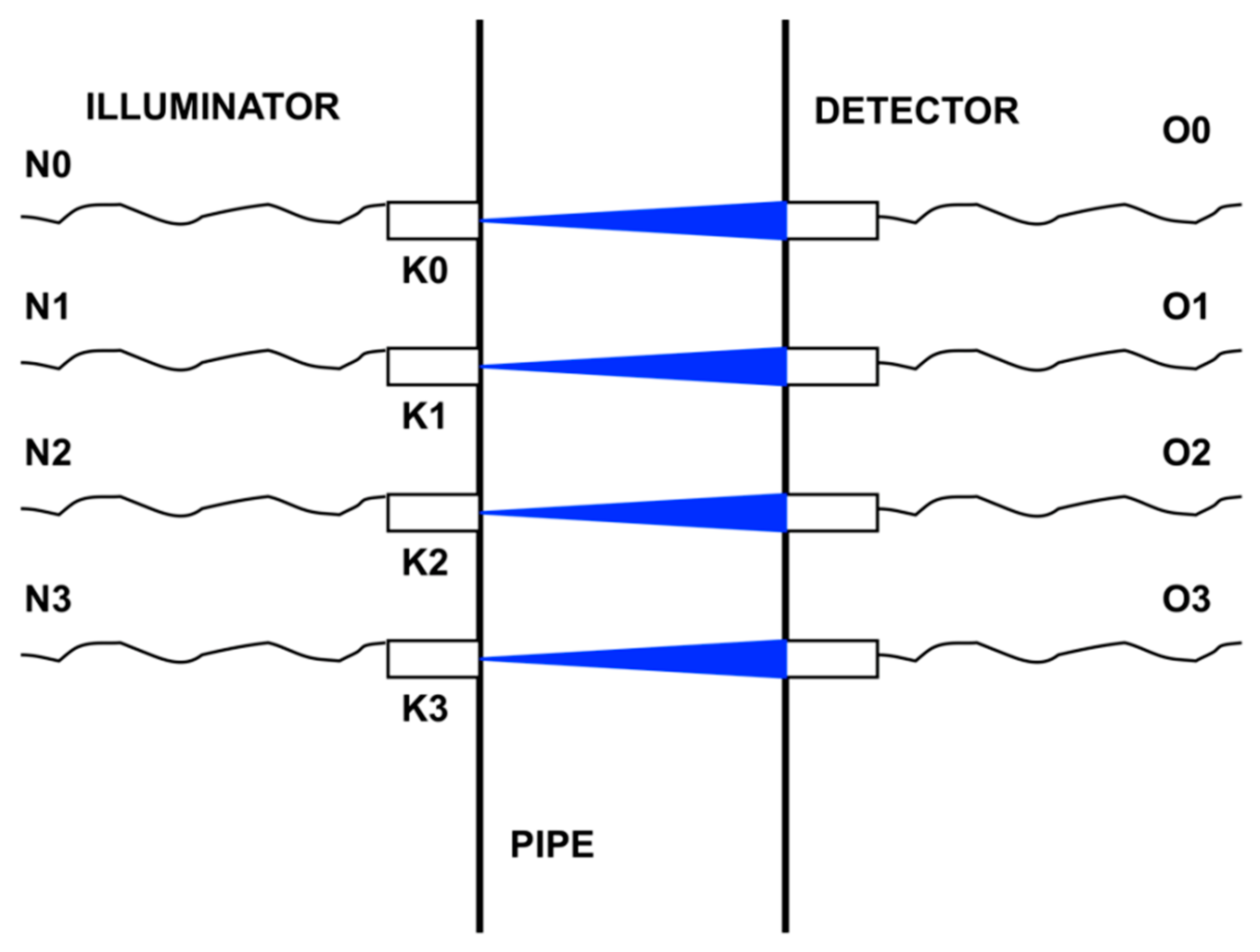

2. Materials and Methods

Experimental Setup

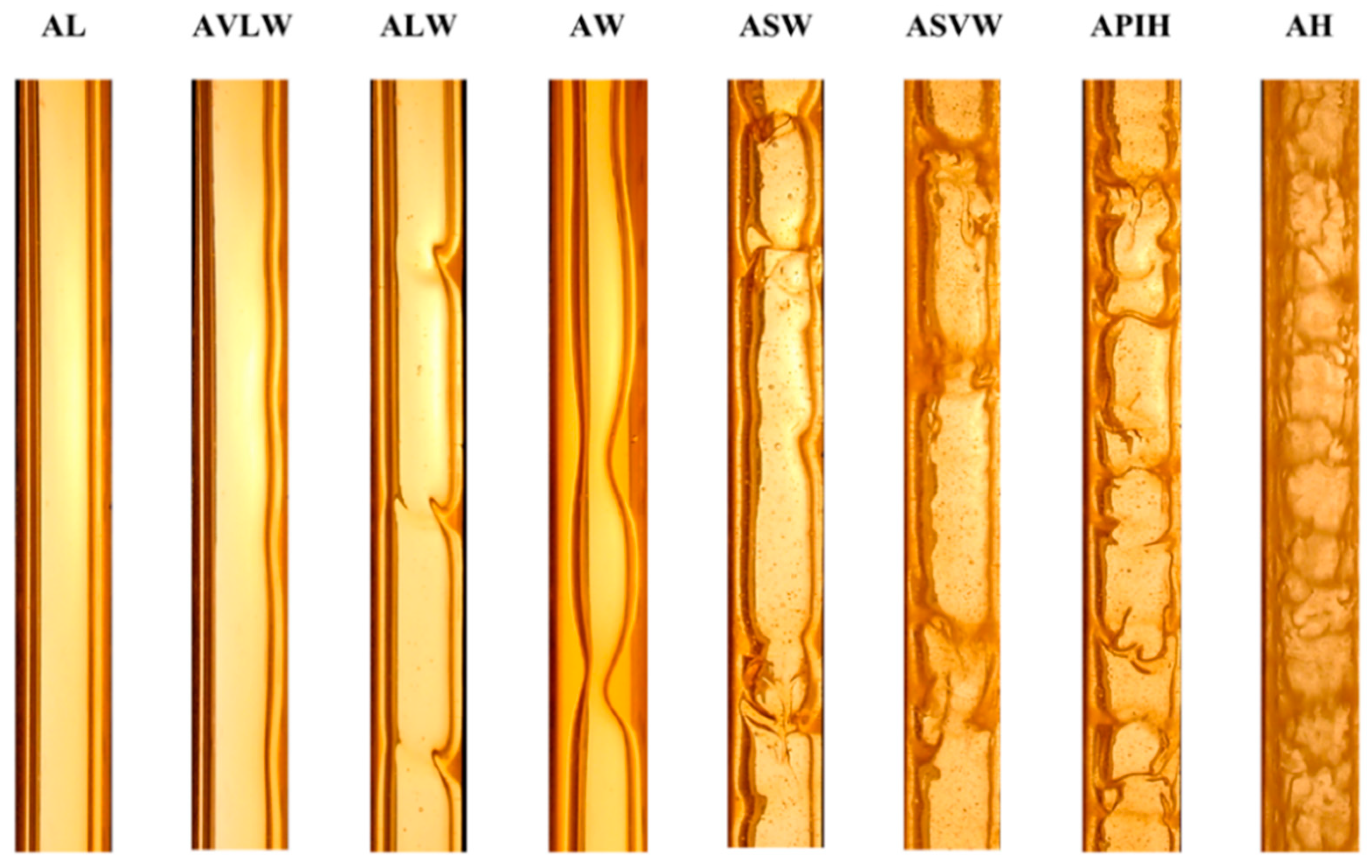

3. Results and Discussion

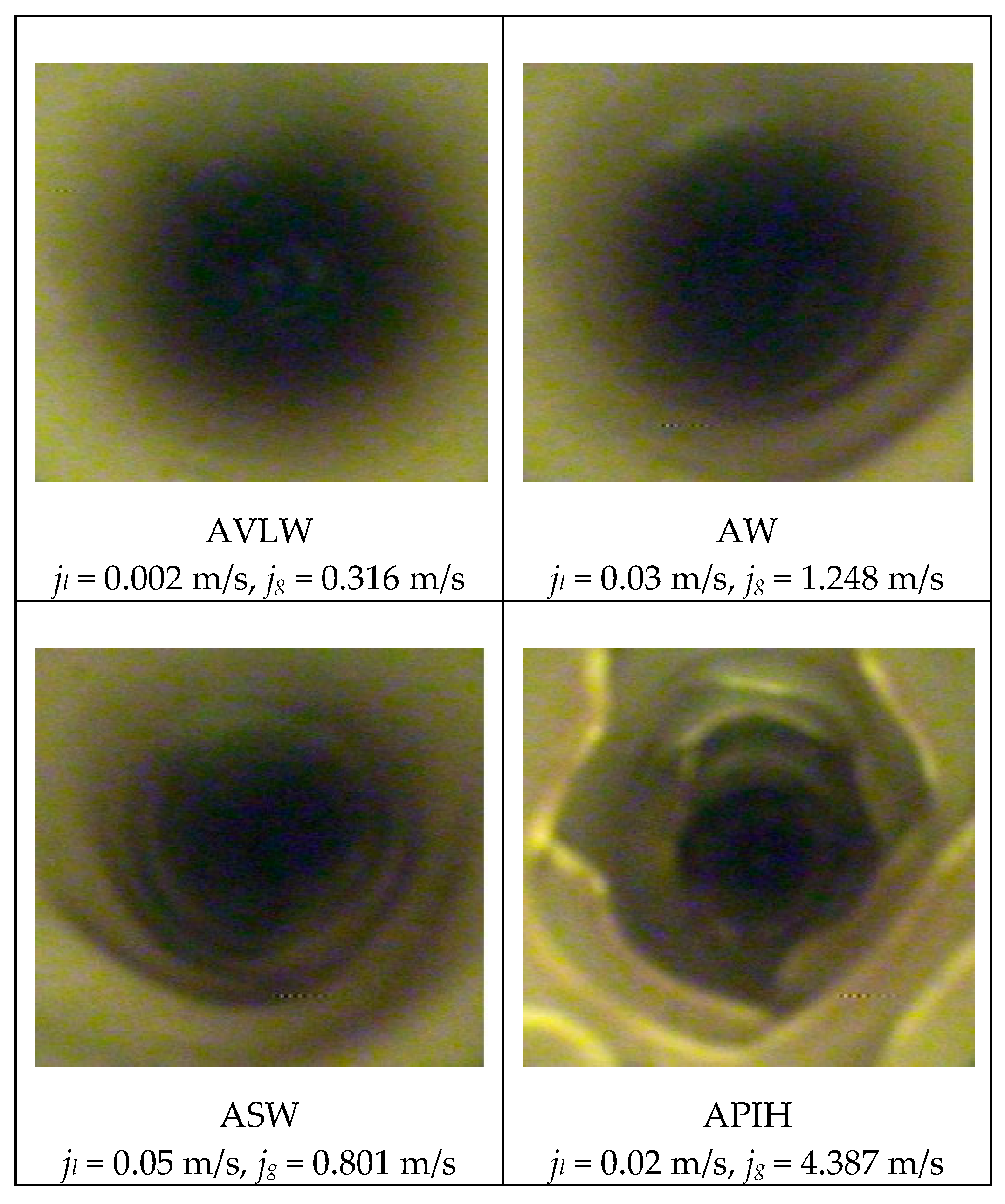

3.1. Flow Patterns

- (a)

- the limit AD-AL between full wettability of inner pipe wall and laminar flat film.

- (b)

- the limit AL-AW between flat and wavy annular flow

- (c)

- the limit AW-AH separating wavy and hydraulically developed forms

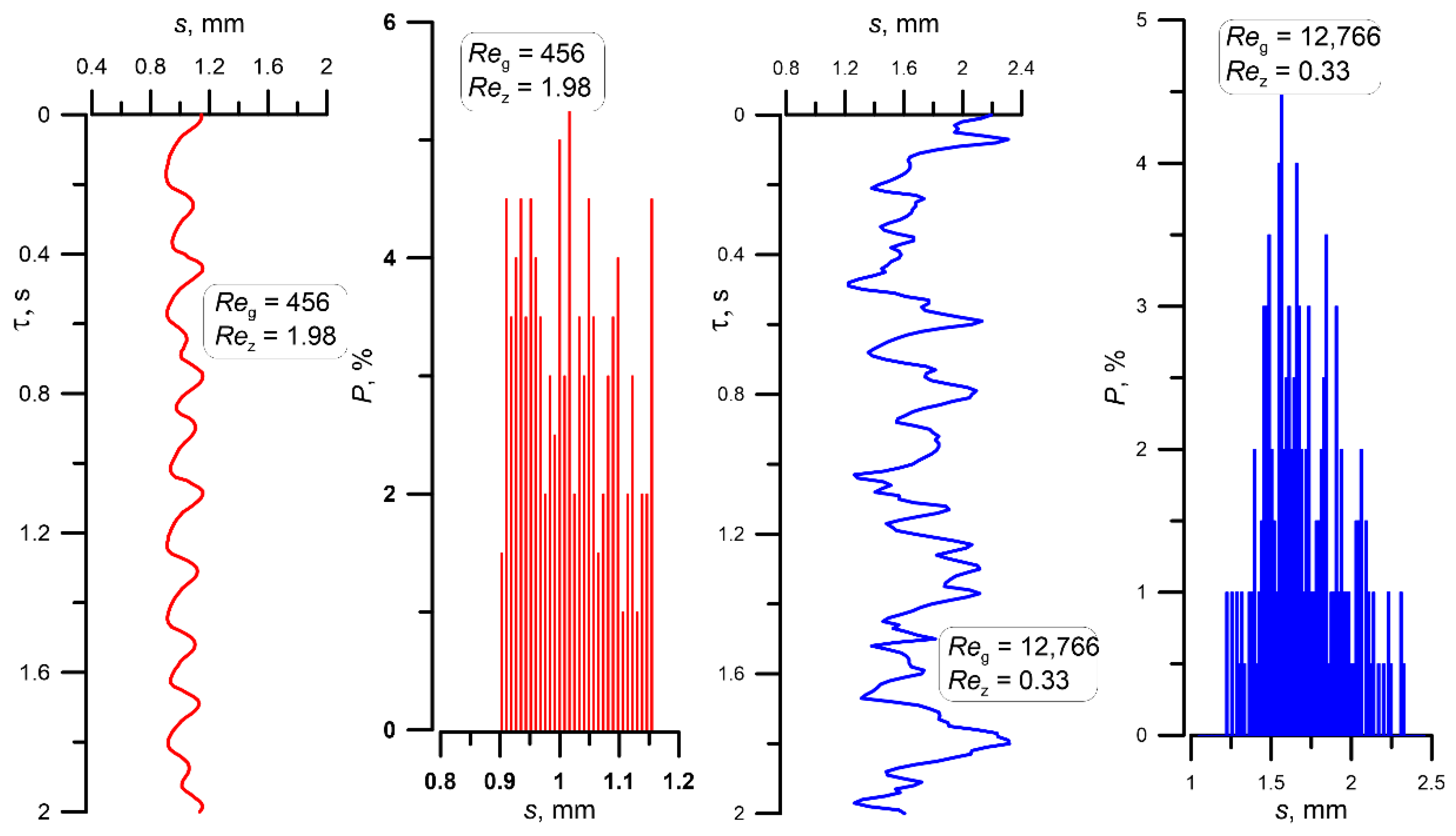

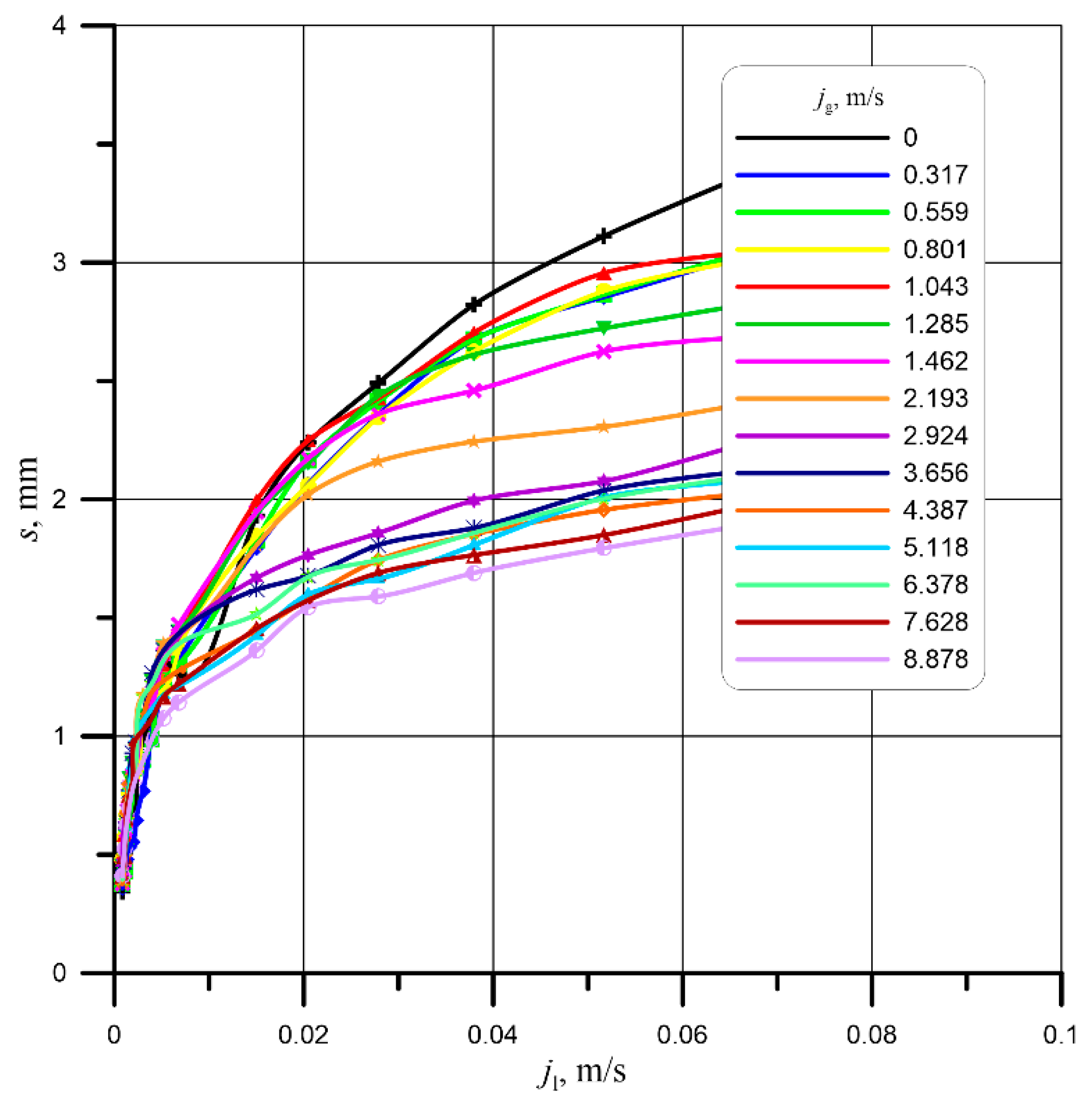

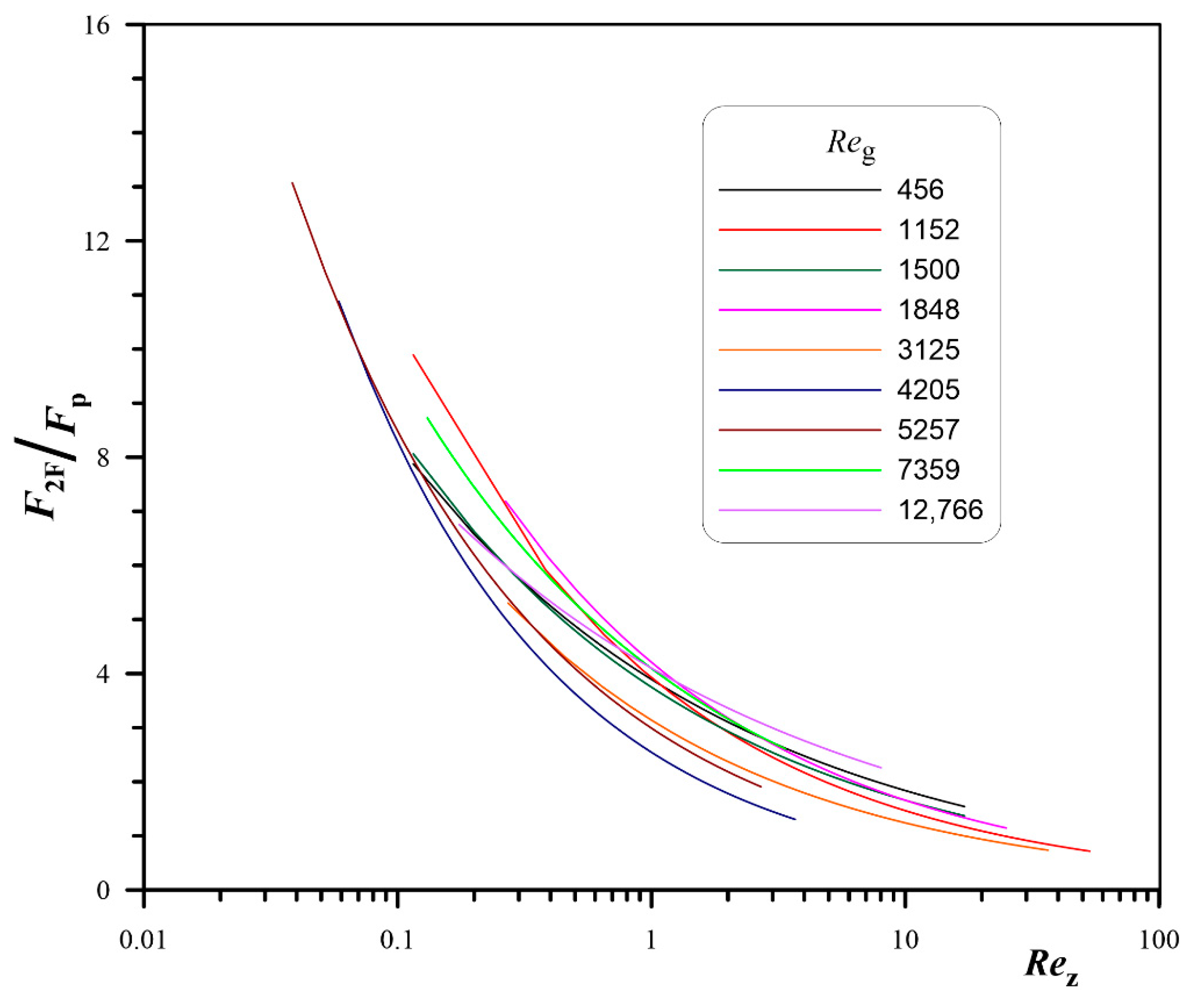

3.2. Liquid Film Characteristics

4. Conclusions

- The study result analysis demonstrated that the application of the optoelectronic measuring system enables a range of singularities in the flowing liquid films that resulted from the oil liquid viscosity changes, to be determined. This parameter considerably affects the local and mean thickness of the flowing liquid films and its capability for reducing liquid films undulation have been observed. The increase of liquid viscosity invariably implicates the increase the liquid layer thickness, whereas the increase of the gas phase velocity at the constant liquid velocity implicates the reduction of the film thickness. This tendency has been observed for all of the investigated pipe diameters and liquid viscosities.

- The designed and constructed original measuring system is also useful for the liquid undulation level study by determining the velocity, length, and amplitude of waves being formed.

- In the apparatus system introduced in the paper, is believed to be the most effective in terms of investigating the characteristics of oil liquid films and other dielectric liquids with a significant level of absorbing monochromatic radiation.

- Dependencies allowing for calculations of values that are typical of two-phase flow dynamics, devised in the range of viscosity (55–1517) mPas unprecedented until now. Because of the above, they are highly recommended for the purposes of design and structure calculations of thin-layer reactors.

Author Contributions

Funding

Conflicts of Interest

References

- Padilla, M.; Revellin, R.; Wallet, J.; Bonjour, J. Flow regime visualization and pressure drops of HFO-1234yf, R-134a and R-410A during downward two-phase flow in vertical return bends. Int. J. Heat Fluid Flow 2013, 40, 116–134. [Google Scholar] [CrossRef]

- Gabriel, S.; Schulenberg, T.; Albrecht, G.; Heiler, W.; Miassoedov, A.; Kaiser, F.; Wetzel, T. Optical void measurement method for stratified wavy two phase flows. Exp. Therm. Fluid Sci. 2018, 97, 341–350. [Google Scholar] [CrossRef]

- Pietrzak, M.; Witczak, S. Flow patterns and void fractions of phases during gas-liquid two-phase and gas-liquid-liquid three-phase flow in U-bends. Int. J. Heat Fluid Flow 2013, 44, 700–710. [Google Scholar] [CrossRef]

- Singh, G.K.; Pradhan, S.; Tanna, V. Experimental studies of two phase flow characteristics and void fraction predictions in steady state horizontal two-phase nitrogen flow. Cryogenics 2019, 100, 77–84. [Google Scholar] [CrossRef]

- Colombo, L.P.M.; Guilizzoni, M.; Sotgia, G.M.; Marzorati, D. Influence of sudden contractions on in situ volume fractions for oil-water flows in horizontal pipes. Int. J. Heat Fluid Flow 2015, 53, 91–97. [Google Scholar] [CrossRef]

- Charnay, R.; Bonjour, J.; Revellin, R. Experimental investigation of R-245fa flow boiling in minichannels at high saturation temperatures: Flow patterns and flow pattern maps. Int. J. Heat Fluid Flow 2014, 46, 1–16. [Google Scholar] [CrossRef]

- Yang, P.; Zhang, Y.; Wang, X.; Liu, Y. wen Heat transfer measurement and flow regime visualization of two-phase pulsating flow in an evaporator. Int. J. Heat Mass Transf. 2018, 127, 1014–1024. [Google Scholar] [CrossRef]

- Rassame, S.; Hibiki, T. Drift-flux correlation for gas-liquid two-phase flow in a horizontal pipe. Int. J. Heat Fluid Flow 2018, 69, 33–42. [Google Scholar] [CrossRef]

- Whan Na, Y.; Chung, J.N. Two-phase annular flow and evaporative heat transfer in a microchannel. Int. J. Heat Fluid Flow 2011, 32, 440–450. [Google Scholar] [CrossRef]

- Jige, D.; Inoue, N. Boiling heat transfer, pressure drop, and flow pattern in a horizontal square minichannel. Int. J. Heat Fluid Flow 2019, 78, 108433. [Google Scholar] [CrossRef]

- Cioncolini, A.; Thome, J.R. Algebraic turbulence modeling in adiabatic and evaporating annular two-phase flow. Int. J. Heat Fluid Flow 2011, 32, 805–817. [Google Scholar] [CrossRef]

- Ebrahimi-Mamaghani, A.; Sotudeh-Gharebagh, R.; Zarghami, R.; Mostoufi, N. Dynamics of two-phase flow in vertical pipes. J. Fluids Struct. 2019, 87, 150–173. [Google Scholar] [CrossRef]

- Hamidi, M.J.; Karimi, H.; Boostani, M. Flow patterns and heat transfer of oil-water two-phase upward flow in vertical pipe. Int. J. Therm. Sci. 2018, 127, 173–180. [Google Scholar] [CrossRef]

- Liu, H.; Pan, L.-M.; Hibiki, T.; Zhou, W.; Ren, Q.-Y.; Li, S.-S. One-dimensional interfacial area transport for bubbly two-phase flow in vertical 5 × 5 rod bundle. Int. J. Heat Fluid Flow 2018, 72, 257–273. [Google Scholar] [CrossRef]

- Smith, T.R.; Schlegel, J.P.; Hibiki, T.; Ishii, M. Two-phase flow structure in large diameter pipes. Int. J. Heat Fluid Flow 2012, 33, 156–167. [Google Scholar] [CrossRef]

- Shen, X.; Schlegel, J.P.; Hibiki, T.; Nakamura, H. Some characteristics of gas–liquid two-phase flow in vertical large-diameter channels. Nucl. Eng. Des. 2018, 333, 87–98. [Google Scholar] [CrossRef]

- Shen, X.; Sun, H.; Deng, B.; Hibiki, T.; Nakamura, H. Experimental study on interfacial area transport of two-phase bubbly flow in a vertical large-diameter square duct. Int. J. Heat Fluid Flow 2017, 67, 168–184. [Google Scholar] [CrossRef]

- Shen, X.; Hibiki, T.; Ono, T.; Sato, K.; Mishima, K. One-dimensional interfacial area transport of vertical upward bubbly flow in narrow rectangular channel. Int. J. Heat Fluid Flow 2012, 36, 72–82. [Google Scholar] [CrossRef]

- Ju, P.; Yang, X.; Schlegel, J.P.; Liu, Y.; Hibiki, T.; Ishii, M. Average liquid film thickness of annular air-water two-phase flow in 8 × 8 rod bundle. Int. J. Heat Fluid Flow 2018, 73, 63–73. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, J.; Li, W.Z. A two-phase, two-component model for vertical upward gas-liquid annular flow. Int. J. Heat Fluid Flow 2011, 32, 796–804. [Google Scholar] [CrossRef]

- Dang, Z.; Wang, G.; Ju, P.; Yang, X.; Bean, R.; Ishii, M.; Bajorek, S.; Bernard, M. Experimental study of interfacial characteristics of vertical upward air-water two-phase flow in 25.4 mm ID round pipe. Int. J. Heat Mass Transf. 2017, 108, 1825–1838. [Google Scholar] [CrossRef]

- Gao, Y.; Cui, Y.; Xu, B.; Sun, B.; Zhao, X.; Li, H.; Chen, L. Two phase flow heat transfer analysis at different flow patterns in the wellbore. Appl. Therm. Eng. 2017, 117, 544–552. [Google Scholar] [CrossRef]

- Lee, J.; O’Neill, L.E.; Lee, S.; Mudawar, I. Experimental and computational investigation on two-phase flow and heat transfer of highly subcooled flow boiling in vertical upflow. Int. J. Heat Mass Transf. 2019, 136, 1199–1216. [Google Scholar] [CrossRef]

- Jiang, C.; Bai, B. Flow patterns and pressure drop of downward two-phase flow in a capsule-type plate heat exchanger. Exp. Therm. Fluid Sci. 2019, 103, 347–354. [Google Scholar] [CrossRef]

- Julia, J.E.; Ozar, B.; Jeong, J.J.; Hibiki, T.; Ishii, M. Flow regime development analysis in adiabatic upward two-phase flow in a vertical annulus. Int. J. Heat Fluid Flow 2011, 32, 164–175. [Google Scholar] [CrossRef]

- Julia, J.E.; Hibiki, T. Flow regime transition criteria for two-phase flow in a vertical annulus. Int. J. Heat Fluid Flow 2011, 32, 993–1004. [Google Scholar] [CrossRef]

- Qiao, S.; Mena, D.; Kim, S. Inlet effects on vertical-downward air–water two-phase flow. Nucl. Eng. Des. 2017, 312, 375–388. [Google Scholar] [CrossRef]

- Xue, Y.; Li, H.; Hao, C.; Yao, C. Investigation on the void fraction of gas–liquid two-phase flows in vertically-downward pipes. Int. Commun. Heat Mass Transf. 2016, 77, 1–8. [Google Scholar] [CrossRef]

- Dall’Acqua, D.; Terenzi, A.; Leporini, M.; D’Alessandro, V.; Giacchetta, G.; Marchetti, B. A new tool for modelling the decompression behaviour of CO2 with impurities using the Peng-Robinson equation of state. Appl. Energy 2017, 206, 1432–1445. [Google Scholar] [CrossRef]

- Afshari, F.; Zavaragh, H.G.; Sahin, B.; Grifoni, R.C.; Corvaro, F.; Marchetti, B.; Polonara, F. On numerical methods; optimization of CFD solution to evaluate fluid flow around a sample object at low Re numbers. Math. Comput. Simul. 2018, 152, 51–68. [Google Scholar] [CrossRef]

- Leporini, M.; Arianna, B.; Marco, F.; Pietro, P. The extension of the 1D two-fluid slug capturing method to simulate slug flow in vertical pipes. Int. J. Numer. Methods Fluids 2020, 1–18. [Google Scholar] [CrossRef]

- Al-Kizwini, M.; Wylie, S.; Al-Khafaji, D.; Al-Shamma, A. The monitoring of the two phase flow-annular flow type regime using microwave sensor technique. Meas. J. Int. Meas. Confed. 2013, 46, 45–51. [Google Scholar] [CrossRef]

- An, Z.; Ningde, J.; Lusheng, Z.; Zhongke, G. Liquid holdup measurement in horizontal oil–water two-phase flow by using concave capacitance sensor. Meas. J. Int. Meas. Confed. 2014, 49, 153–163. [Google Scholar] [CrossRef]

- Da Silva, M.; Thiele, S.; Abdulkareem, L.; Azzopardi, B.; Hampel, U. High-resolution gas–oil two-phase flow visualization with a capacitance wire-mesh sensor. Flow Meas. Instrum. 2010, 21, 191–197. [Google Scholar] [CrossRef]

- Damsohn, M.; Prasser, H.-M. High-speed liquid film sensor for two-phase flows with high spatial resolution based on electrical conductance. Flow Meas. Instrum. 2009, 20, 1–14. [Google Scholar] [CrossRef]

- Hanafizadeh, P.; Ghanbarzadeh, S.; Saidi, M.H. Visual technique for detection of gas–liquid two-phase flow regime in the airlift pump. J. Pet. Sci. Eng. 2011, 75, 327–335. [Google Scholar] [CrossRef]

- Marchetti, J.; Svendsen, H. Improvements on a laser scattering technique for droplet size measurements applied to a gas–liquid separation equipment. Meas. J. Int. Meas. Confed. 2011, 44, 493–499. [Google Scholar] [CrossRef]

- Tibiriçá, C.B.; Nascimento, F.J.D.; Ribatski, G. Film thickness measurement techniques applied to micro-scale two-phase flow systems. Exp. Therm. Fluid Sci. 2010, 34, 463–473. [Google Scholar] [CrossRef]

- Boden, S.; Bieberle, M.; Hampel, U. Quantitative measurement of gas hold-up distribution in a stirred chemical reactor using X-ray cone-beam computed tomography. Chem. Eng. J. 2008, 139, 351–362. [Google Scholar] [CrossRef]

- Heindel, T.J.; Gray, J.N.; Jensen, T.C. An X-ray system for visualizing fluid flows. Flow Meas. Instrum. 2008, 19, 67–78. [Google Scholar] [CrossRef]

- Osta, A.R.; Lee, J.; Sallam, K.A.; Fezzaa, K. Study of the effects of the injector length/diameter ratio on the surface properties of turbulent liquid jets in still air using X-ray imaging. Int. J. Multiph. Flow 2012, 38, 87–98. [Google Scholar] [CrossRef]

- Roshani, G.H.; Feghhi, S.; Mahmoudi-Aznaveh, A.; Nazemi, E.; Adineh-Vand, A. Precise volume fraction prediction in oil–water–gas multiphase flows by means of gamma-ray attenuation and artificial neural networks using one detector. Meas. J. Int. Meas. Confed. 2014, 51, 34–41. [Google Scholar] [CrossRef]

- Roshani, G.H.; Nazemi, E.; Feghhi, S.; Setayeshi, S. Flow regime identification and void fraction prediction in two-phase flows based on gamma ray attenuation. Meas. J. Int. Meas. Confed. 2015, 62, 25–32. [Google Scholar] [CrossRef]

- Roshani, G.H.; Roshani, S.; Nazemi, E.; Roshani, S. Online measuring density of oil products in annular regime of gas-liquid two phase flows. Meas. J. Int. Meas. Confed. 2018, 129, 296–301. [Google Scholar] [CrossRef]

- Charalampous, G.; Hadjiyiannis, C.; Hardalupas, Y. Comparative measurement of the breakup length of liquid jets in airblast atomisers using optical connectivity, electrical connectivity and shadowgraphy. Meas. J. Int. Meas. Confed. 2016, 89, 288–299. [Google Scholar] [CrossRef] [Green Version]

- Japper-Jaafar, A.; Escudier, M.P.; Poole, R.J. Laminar, transitional and turbulent annular flow of drag-reducing polymer solutions. J. Non-Newtonian Fluid Mech. 2010, 165, 1357–1372. [Google Scholar] [CrossRef]

- Ismail, I.; Gamio, J.C.; Bukhari, S.; Yang, W.Q. Tomography for multi-phase flow measurement in the oil industry. Flow Meas. Instrum. 2005, 16, 145–155. [Google Scholar] [CrossRef]

- Li, Y.; Soleimani, M. Imaging conductive materials with high frequency electrical capacitance tomography. Meas. J. Int. Meas. Confed. 2013, 46, 3355–3361. [Google Scholar] [CrossRef]

- Tschentscher, R.R.; Schubert, M.; Bieberle, A.; Nijhuis, T.X.A.; Van Der Schaaf, J.J.; Hampel, U.; Schouten, J.J. Tomography measurements of gas holdup in rotating foam reactors with Newtonian, non-Newtonian and foaming liquids. Chem. Eng. Sci. 2011, 66, 3317–3327. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.; Wang, X.; Tian, P. Reconstruction method of electrical capacitance tomography based on wavelet fusion. Meas. J. Int. Meas. Confed. 2018, 126, 223–230. [Google Scholar] [CrossRef] [Green Version]

- Akafuah, N.K.; Salazar, A.J.; Saito, K. Infrared thermography-based visualization of droplet transport in liquid sprays. Infrared Phys. Technol. 2010, 53, 218–226. [Google Scholar] [CrossRef]

- Albion, K.; Briens, L.; Briens, C.; Berruti, F. Flow regime determination in horizontal pneumatic transport of fine powders using non-intrusive acoustic probes. Powder Technol. 2007, 172, 157–166. [Google Scholar] [CrossRef]

- Chiou, Y.-C.; Li, W.-C. Flaw detection of cylindrical surfaces in PU-packing by using machine vision technique. Meas. J. Int. Meas. Confed. 2009, 42, 989–1000. [Google Scholar] [CrossRef]

- Fang, L.; Liang, Y.; Lu, Q.; Li, X.; Liu, R.; Wang, X. Flow noise characterization of gas–liquid two-phase flow based on acoustic emission. Meas. J. Int. Meas. Confed. 2013, 46, 3887–3897. [Google Scholar] [CrossRef]

- Furlan, J.; Mundla, V.; Kadambi, J.; Hoyt, N.; Visintainer, R.J.; Addie, G. Development of A-scan ultrasound technique for measuring local particle concentration in slurry flows. Powder Technol. 2012, 215, 174–184. [Google Scholar] [CrossRef]

- Wang, M.; Zheng, D.; Xu, Y. A new method for liquid film thickness measurement based on ultrasonic echo resonance technique in gas-liquid flow. Meas. J. Int. Meas. Confed. 2019, 146, 447–457. [Google Scholar] [CrossRef]

- Xu, Y.; Yu, P.; Zhu, Z.; Yuan, C.; Zhang, T. Over-reading modeling of the ultrasonic flow meter in wet gas measurement. Meas. J. Int. Meas. Confed. 2017, 98, 17–24. [Google Scholar] [CrossRef]

- Hazuku, T.; Takamasa, T.; Matsumoto, Y. Experimental study on axial development of liquid film in vertical upward annular two-phase flow. Int. J. Multiph. Flow 2008, 34, 111–127. [Google Scholar] [CrossRef]

- Hu, H.L.; Dong, J.; Zhang, J.; Cheng, Y.J.; Xu, T.M. Identification of gas/solid two-phase flow regimes using electrostatic sensors and neural-network techniques. Flow Meas. Instrum. 2011, 22, 482–487. [Google Scholar] [CrossRef]

- Liu, W.X.; Jin, N.D.; Han, Y.F.; Zhai, L.S.; Chen, X.; Zhang, H.X. Effects of flow patterns and salinity on water holdup measurement of oil-water two-phase flow using a conductance method. Meas. J. Int. Meas. Confed. 2016. [Google Scholar] [CrossRef]

- De Jong, J.; Salazar, J.P.L.C.; Woodward, S.H.; Collins, L.R.; Meng, H. Measurement of inertial particle clustering and relative velocity statistics in isotropic turbulence using holographic imaging. Int. J. Multiph. Flow 2010. [Google Scholar] [CrossRef]

- Oshinowo, T.; Charles, M.E. Vertical two-phase flow part I. Flow pattern correlations. Can. J. Chem. Eng. 1974. [Google Scholar] [CrossRef]

- Troniewski, L.; Ulbrich, R. The analysis of flow regime maps of two -phase gas-liquid flow in pipes. Chem. Eng. Sci. 1984, 39, 1213–1224. [Google Scholar] [CrossRef]

- Yamazaki, Y.; Yamaguchi, K. Characteristics of Cocurrent Two-Phase Downflow in Tubes. J. Nucl. Sci. Technol. 1979, 16, 245–255. [Google Scholar] [CrossRef]

- Crawford, T.; Weinberger, C.; Weisman, J. Two-phase flow patterns and void fractions in downward flow Part I: Steady-state flow patterns. Int. J. Multiph. Flow 1985, 11, 761–782. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czernek, K.; Witczak, S. Precise Determination of Liquid Layer Thickness with Downward Annular Two-Phase Gas-Very Viscous Liquid Flow. Energies 2020, 13, 6529. https://doi.org/10.3390/en13246529

Czernek K, Witczak S. Precise Determination of Liquid Layer Thickness with Downward Annular Two-Phase Gas-Very Viscous Liquid Flow. Energies. 2020; 13(24):6529. https://doi.org/10.3390/en13246529

Chicago/Turabian StyleCzernek, Krystian, and Stanisław Witczak. 2020. "Precise Determination of Liquid Layer Thickness with Downward Annular Two-Phase Gas-Very Viscous Liquid Flow" Energies 13, no. 24: 6529. https://doi.org/10.3390/en13246529

APA StyleCzernek, K., & Witczak, S. (2020). Precise Determination of Liquid Layer Thickness with Downward Annular Two-Phase Gas-Very Viscous Liquid Flow. Energies, 13(24), 6529. https://doi.org/10.3390/en13246529