Review of Process Modeling of Solid-Fuel Thermal Power Plants for Flexible and Off-Design Operation

Abstract

:1. Introduction

2. Flexible Operation

2.1. Minimum Load—Part Load

2.2. Ramping Rate

2.3. Control and Fuel

3. Off-Design Operation

3.1. Minimum Load—Part Load

3.2. Ramping Rate

3.3. Control and Fuel

3.4. Undesired Operation and Accidents

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- IEA. Renewables 2019; IEA: Paris, France, 2019. [Google Scholar]

- IEA. Tracking Power; IEA: Paris, France, 2019. [Google Scholar]

- IRENA. Planning for the Renewable Future: Long-Term Modelling and Tools to Expand Variable Renewable Power in Emerging Economies; International Renewable Energy Agency: Abu Dhabi, UAE, 2017. [Google Scholar]

- IRENA. Renewable Energy Prospects for the European Union; International Renewable Energy Agency: Abu Dhabi, UAE, 2018. [Google Scholar]

- IEA; IRENA; UNSD; World Bank; WHO. Tracking SDG 7: The Energy Progress Report; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- IEA. Status of Power System Transformation 2019; IEA: Paris, France, 2019. [Google Scholar]

- Kroposki, B. Integrating High Levels of Variable Renewable Energy into Electric Power Systems. Available online: https://www.nrel.gov/docs/fy17osti/68349.pdf (accessed on 30 May 2020).

- Henderson, C. Increasing the Flexibility of Coal-Fired Power Plants; CCC/242; IEA Clean Coal Centre: London, UK, 2014. [Google Scholar]

- Garðarsdóttir, S.Ó.; Göransson, L.; Normann, F.; Johnsson, F. Improving the flexibility of coal-fired power generators: Impact on the composition of a cost-optimal electricity system. Appl. Energy 2018, 209, 277–289. [Google Scholar] [CrossRef]

- Sloss, L. Levelling the Intermittency of Renewables with Coal; CCC/268; IEA Clean Coal Centre: London, UK, 2016. [Google Scholar]

- Göransson, L.; Goop, J.; Odenberger, M.; Johnsson, F. Impact of thermal plant cycling on the cost-optimal composition of a regional electricity generation system. Appl. Energy 2017, 197, 230–240. [Google Scholar] [CrossRef]

- Wiatros-Motyka, M. Power Plant Design and Management for Unit Cycling; CCC/295; IEA Clean Coal Centre: London, UK, 2019. [Google Scholar]

- Neshumayev, D.; Rummel, L.; Konist, A.; Ots, A.; Parve, T. Power plant fuel consumption rate during load cycling. Appl. Energy 2018, 224, 124–135. [Google Scholar] [CrossRef]

- Hungerford, Z.; Bruce, A.; MacGill, I. The value of flexible load in power systems with high renewable energy penetration. Energy 2019, 188, 115960. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Niedźwiecki, Ł.; Ostrycharczyk, M.; Czerep, M.; Plutecki, Z. Potential and methods for increasing the flexibility and efficiency of the lignite fired power unit, using integrated lignite drying. Energy 2019, 181, 1142–1151. [Google Scholar] [CrossRef]

- Brouwer, A.S.; van den Broek, M.; Seebregts, A.; Faaij, A. Operational flexibility and economics of power plants in future low-carbon power systems. Appl. Energy 2015, 156, 107–128. [Google Scholar] [CrossRef] [Green Version]

- Zapata Riveros, J.; Bruninx, K.; Poncelet, K.; D’haeseleer, W. Bidding strategies for virtual power plants considering CHPs and intermittent renewables. Energy Convers. Manag. 2015, 103, 408–418. [Google Scholar] [CrossRef]

- Åström, K.J.; Bell, R.D. Drum-boiler dynamics. Automatica 2000, 36, 363–378. [Google Scholar] [CrossRef]

- Heimo, W.; Bernd, E. Numerical Simulation of Power Plants; Springer: Vienna, Austria, 2017. [Google Scholar]

- Ordys, A.; Pike, A.W.; Johnson, A.M.; Katebi, M.R.; Grimble, J.M. Modelling and Simulation of Power Generation Plants; Springer: London, UK, 1994. [Google Scholar]

- Dolezal, R. Simulation of Large State Variations in Steam Power Plants, Dynamics of Large Scale Systems; Springer: Berlin/Heidelberg, Germany, 1987. [Google Scholar]

- Annaratone, D. Steam Generators, Description and Design; Springer: Heidelberg, Germany, 2008. [Google Scholar]

- Bequette, B. Process Control: Modeling, Design, and Simulation/B.W. Bequette; IEEE Control Systems: New York, NY, USA, 2003. [Google Scholar]

- Alobaid, F. Numerical Simulation for Next Generation Thermal Power Plants; Springer International Publishing: Berlin, Germany, 2018. [Google Scholar]

- Atsonios, K.; Nesiadis, A.; Detsios, N.; Koutita, K.; Nikolopoulos, N.; Grammelis, P. Review on dynamic process modeling of gasification based biorefineries and bio-based heat & power plants. Fuel Process. Technol. 2020, 197, 106188. [Google Scholar] [CrossRef]

- Alobaid, F.; Mertens, N.; Starkloff, R.; Lanz, T.; Heinze, C.; Epple, B. Progress in dynamic simulation of thermal power plants. Progress Energy Combust. Sci. 2017, 59, 79–162. [Google Scholar] [CrossRef]

- Gonzalez-Salazar, M.A.; Kirsten, T.; Prchlik, L. Review of the operational flexibility and emissions of gas- and coal-fired power plants in a future with growing renewables. Renew. Sustain. Energy Rev. 2018, 82, 1497–1513. [Google Scholar] [CrossRef]

- Mac Dowell, N.; Shah, N. Dynamic modelling and analysis of a coal-fired power plant integrated with a novel split-flow configuration post-combustion CO2 capture process. Int. J. Greenh. Gas. Control 2014, 27, 103–119. [Google Scholar] [CrossRef]

- Mikulčić, H.; Ridjan Skov, I.; Dominković, D.F.; Wan Alwi, S.R.; Manan, Z.A.; Tan, R.; Duić, N.; Hidayah Mohamad, S.N.; Wang, X. Flexible Carbon Capture and Utilization technologies in future energy systems and the utilization pathways of captured CO2. Renew. Sustain. Energy Rev. 2019, 114, 109338. [Google Scholar] [CrossRef]

- Denholm, P.; Brinkman, G.; Mai, T. How low can you go? The importance of quantifying minimum generation levels for renewable integration. Energy Policy 2018, 115, 249–257. [Google Scholar] [CrossRef]

- Kumar, N.; Besuner, P.; Lefton, S.; Agan, D.; Hilleman, D. Power Plant Cycling Costs; National Renewable Energy Laboratory: Sunnyvale, CA, USA, 2012.

- Wang, J.; You, S.; Zong, Y.; Træholt, C.; Dong, Z.Y.; Zhou, Y. Flexibility of combined heat and power plants: A review of technologies and operation strategies. Appl. Energy 2019, 252, 113445. [Google Scholar] [CrossRef]

- Ali, U.; Akram, M.; Font-Palma, C.; Ingham, D.B.; Pourkashanian, M. Part-load performance of direct-firing and co-firing of coal and biomass in a power generation system integrated with a CO2 capture and compression system. Fuel 2017, 210, 873–884. [Google Scholar] [CrossRef]

- Dong, Y.; Jiang, X.; Liang, Z.; Yuan, J. Coal power flexibility, energy efficiency and pollutant emissions implications in China: A plant-level analysis based on case units. Resour. Conserv. Recycl. 2018, 134, 184–195. [Google Scholar] [CrossRef]

- Madejski, P.; Żymełka, P. Calculation methods of steam boiler operation factors under varying operating conditions with the use of computational thermodynamic modeling. Energy 2020, 197, 117221. [Google Scholar] [CrossRef]

- Huebel, M.; Berndt, A.; Meinke, S.; Richter, M.; Mutschler, P.; Hassel, E. Modelling a lignite power plant in modelica to evaluate the effects of dynamic operation and offering grid services. In Proceedings of the 10th International Modelica Conference, Lund, Sweden, 10–12 March 2014; pp. 1037–1046. [Google Scholar]

- Starkloff, R.; Alobaid, F.; Karner, K.; Epple, B.; Schmitz, M.; Boehm, F. Development and validation of a dynamic simulation model for a large coal-fired power plant. Appl. Therm. Eng. 2015, 91, 496–506. [Google Scholar] [CrossRef]

- Oko, E.; Wang, M. Dynamic modelling, validation and analysis of coal-fired subcritical power plant. Fuel 2014, 135, 292–300. [Google Scholar] [CrossRef]

- Alobaid, F.; Al-Maliki, W.A.K.; Lanz, T.; Haaf, M.; Brachthäuser, A.; Epple, B.; Zorbach, I. Dynamic simulation of a municipal solid waste incinerator. Energy 2018, 149, 230–249. [Google Scholar] [CrossRef]

- Kuczynski, K.J.; Fitzgerald, F.D.; Adams, D.; Glover, F.H.M.; White, V.; Chalmers, H.; Errey, O.; Stephenson, P. Dynamic modelling of oxyfuel power plant. Energy Procedia 2011, 4, 2541–2547. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Wang, Q.; Huang, X.; Liu, Z.; Zheng, C. Dynamic simulation and transient analysis of a 3MWth oxy-fuel combustion system. Int. J. Greenh. Gas Control 2015, 35, 138–149. [Google Scholar] [CrossRef]

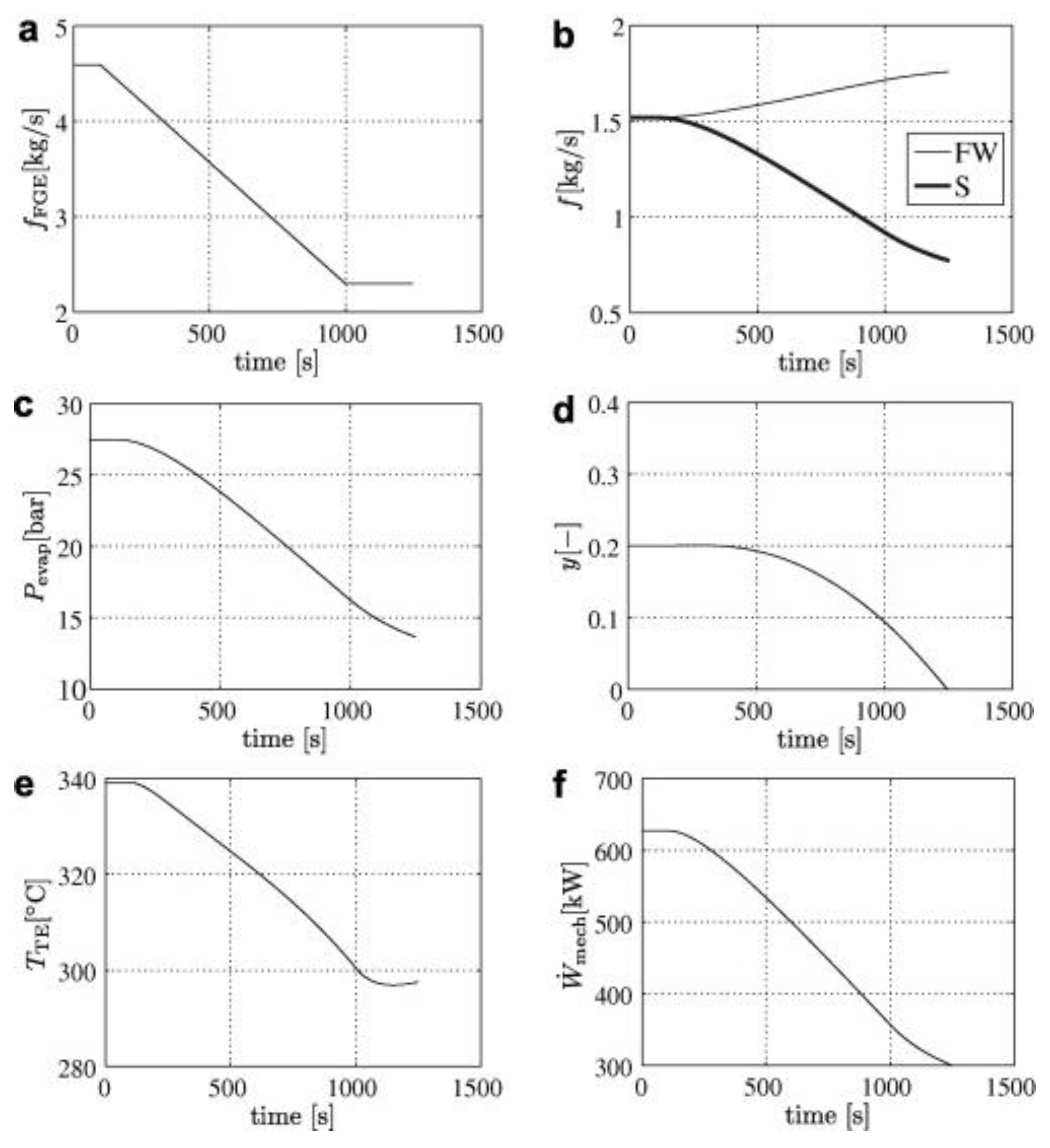

- Hentschel, J.; Zindler, H.; Spliethoff, H. Modelling and transient simulation of a supercritical coal-fired power plant: Dynamic response to extended secondary control power output. Energy 2017, 137, 927–940. [Google Scholar] [CrossRef]

- Kakaras, E.; Doukelis, A.; Giannakopoulos, D.; Koumanakos, A. Economic implications of oxyfuel application in a lignite-fired power plant. Fuel 2007, 86, 2151–2158. [Google Scholar] [CrossRef]

- Kakaras, E.; Koumanakos, A.; Doukelis, A.; Giannakopoulos, D.; Vorrias, I. Oxyfuel boiler design in a lignite-fired power plant. Fuel 2007, 86, 2144–2150. [Google Scholar] [CrossRef]

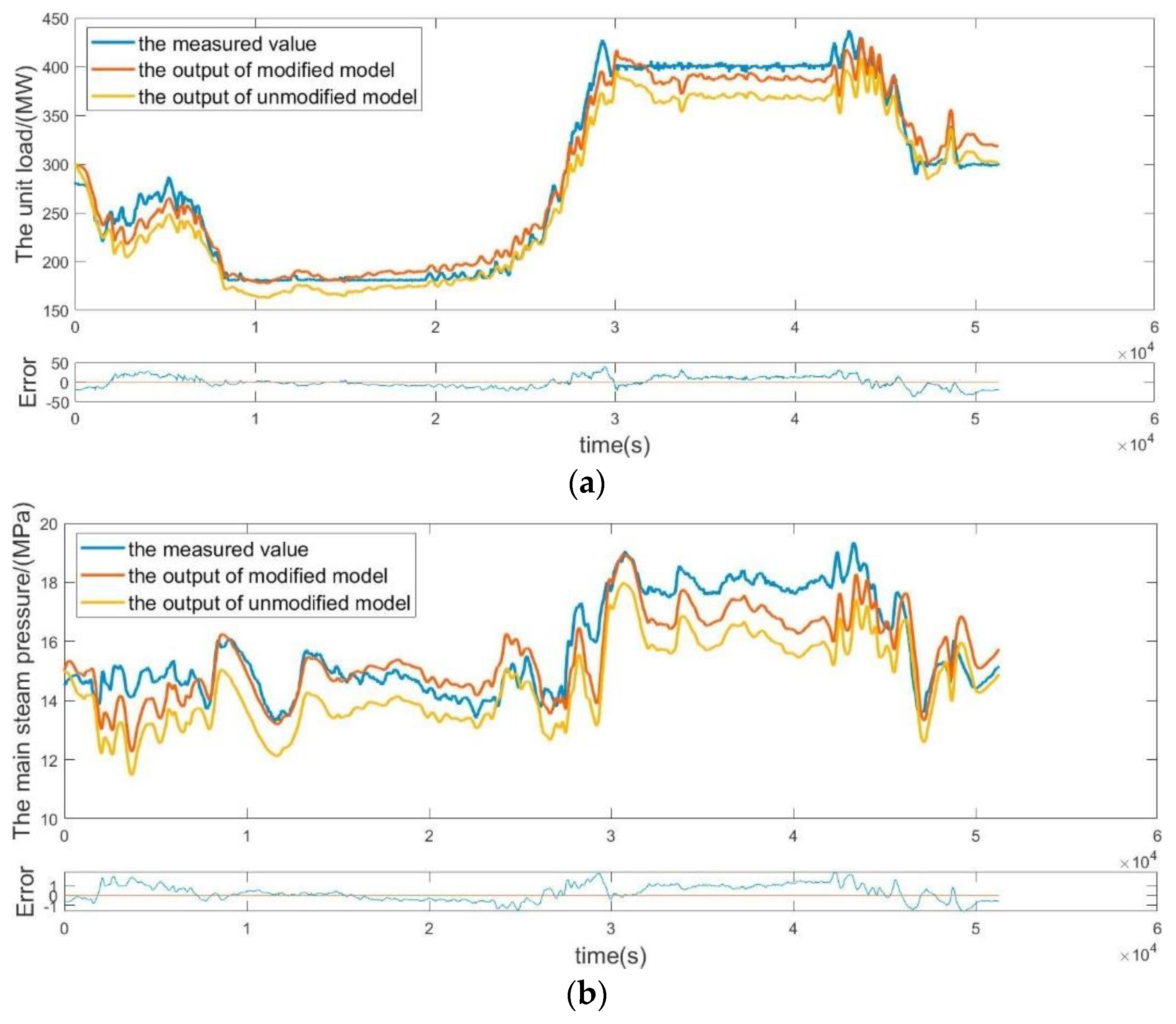

- Haryanto, A.; Hong, K.-S. Modeling and simulation of an oxy-fuel combustion boiler system with flue gas recirculation. Comput. Chem. Eng. 2011, 35, 25–40. [Google Scholar] [CrossRef]

- Sreepradha, C.; Panda, R.C.; Bhuvaneswari, N.S. Mathematical model for integrated coal fired thermal boiler using physical laws. Energy 2017, 118, 985–998. [Google Scholar] [CrossRef]

- Liu, J.-Z.; Yan, S.; Zeng, D.-L.; Hu, Y.; Lv, Y. A dynamic model used for controller design of a coal fired once-through boiler-turbine unit. Energy 2015, 93, 2069–2078. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, Y.-f.; Su, Z.-g.; Wang, B. A dynamic mathematical model of an ultra-supercritical coal fired once-through boiler-turbine unit. Appl. Energy 2017, 189, 654–666. [Google Scholar] [CrossRef] [Green Version]

- Rakopoulos, D.; Avagianos, I.; Almpanidis, D.; Nikolopoulos, N.; Grammelis, P. Dynamic Modeling of a Utility Once-Through Pulverized-Fuel Steam Generator. J. Energy Eng. 2017, 143, 04016070. [Google Scholar] [CrossRef]

- Wang, C.; Liu, M.; Li, B.; Liu, Y.; Yan, J. Thermodynamic analysis on the transient cycling of coal-fired power plants: Simulation study of a 660 MW supercritical unit. Energy 2017, 122, 505–527. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, D. An improved coordinated control technology for coal-fired boiler-turbine plant based on flexible steam extraction system. Appl. Therm. Eng. 2017, 125, 1047–1060. [Google Scholar] [CrossRef]

- Wu, X.; Wang, M.; Shen, J.; Li, Y.; Lawal, A.; Lee, K.Y. Flexible operation of coal fired power plant integrated with post combustion CO2 capture using model predictive control. Int. J. Greenh. Gas Control 2019, 82, 138–151. [Google Scholar] [CrossRef] [Green Version]

- Liao, P.; Li, Y.; Wu, X.; Wang, M.; Oko, E. Flexible operation of large-scale coal-fired power plant integrated with solvent-based post-combustion CO2 capture based on neural network inverse control. Int. J. Greenh. Gas Control 2020, 95, 102985. [Google Scholar] [CrossRef]

- Tiller, M.; Company, F.; Dearborn, U.; Tummescheit, H.; Hartford, U.; Franke, R.; Rode, M.; Krueger, K. On-line optimization of drum boiler startup. In Proceedings of the 3rd International Modelica Conference, Linköping, Sweden, 3–4 November 2003. [Google Scholar]

- Jin, B.; Zhao, H.; Zheng, C. Dynamic modeling and control for pulverized-coal-fired oxy-combustion boiler island. Int. J. Greenh. Gas Control 2014, 30, 97–117. [Google Scholar] [CrossRef]

- Mohamed, O.; Jihong, W.; Shen, G.; Duri, B.; Jianlin, W. Modelling Study Of Supercritical Power Plant And Parameter Identification Using Genetic Algorithms. In Proceedings of the World Congress on Engineering 2010, London, UK, 30 June–2 July 2010; pp. 973–978. [Google Scholar]

- Mohamed, O.; Al-Duri, B.; Wang, J. Predictive control strategy for a supercritical power plant and study of influences of coal mills control on its dynamic responses. In Proceedings of the 2012 UKACC International Conference on Control, Cardiff, UK, 3–5 September 2012; pp. 918–923. [Google Scholar]

- Wei, J.; Wang, J.; Guo, S. Mathematic modeling and condition monitoring of power station tube-ball mill systems. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 4699–4704. [Google Scholar]

- Niemczyk, P.; Dimon Bendtsen, J.; Peter Ravn, A.; Andersen, P.; Søndergaard Pedersen, T. Derivation and validation of a coal mill model for control. Control Eng. Pract. 2012, 20, 519–530. [Google Scholar] [CrossRef]

- Savola, T.; Keppo, I. Off-design simulation and mathematical modeling of small-scale CHP plants at part loads. Appl. Therm. Eng. 2005, 25, 1219–1232. [Google Scholar] [CrossRef]

- Han, X.; Chen, N.; Yan, J.; Liu, J.; Liu, M.; Karellas, S. Thermodynamic analysis and life cycle assessment of supercritical pulverized coal-fired power plant integrated with No.0 feedwater pre-heater under partial loads. J. Clean. Prod. 2019, 233, 1106–1122. [Google Scholar] [CrossRef]

- Niu, Y.; Du, M.; Ge, W.; Luo, H.; Zhou, G. A dynamic nonlinear model for a once-through boiler-turbine unit in low load. Appl. Therm. Eng. 2019, 161, 113880. [Google Scholar] [CrossRef]

- Żyrkowski, M.; Żymełka, P. Modelling of flexible boiler operation in coal fired power plant. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 12074. [Google Scholar] [CrossRef]

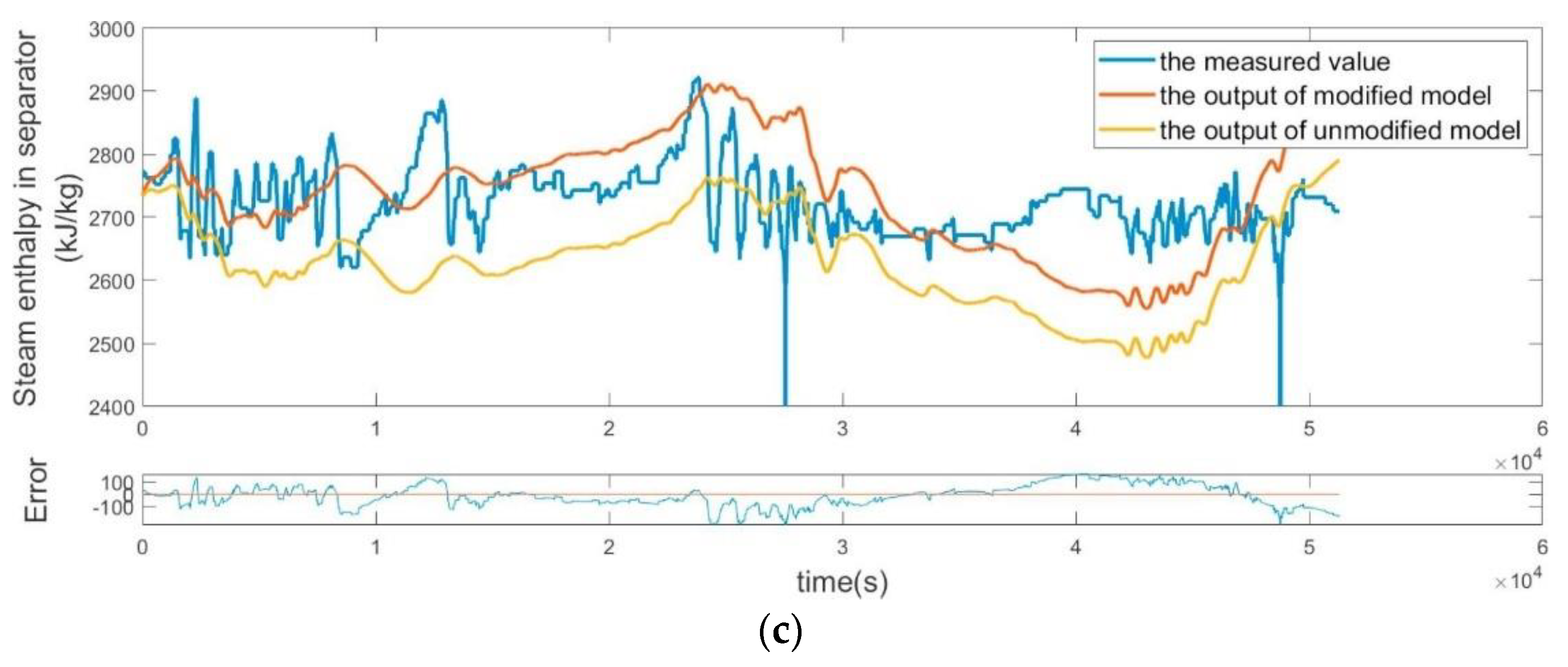

- Avagianos, I.; Atsonios, K.; Nikolopoulos, N.; Grammelis, P.; Polonidis, N.; Papapavlou, C.; Kakaras, E. Predictive method for low load off-design operation of a lignite fired power plant. Fuel 2017, 209, 685–693. [Google Scholar] [CrossRef]

- Colonna, P.; van Putten, H. Dynamic modeling of steam power cycles.: Part I—Modeling paradigm and validation. Appl. Therm. Eng. 2007, 27, 467–480. [Google Scholar] [CrossRef]

- van Putten, H.; Colonna, P. Dynamic modeling of steam power cycles: Part II – Simulation of a small simple Rankine cycle system. Appl. Therm. Eng. 2007, 27, 2566–2582. [Google Scholar] [CrossRef]

- Neuman, P. Power Plant and Boiler Models for Operator Training Simulators. IFAC Proc. Vol. 2011, 44, 8259–8264. [Google Scholar] [CrossRef] [Green Version]

- Zindler, H.; Walter, H.; Hauschke, A.; Leithner, R. Dynamic Simulation of a 800 MWel Hard Coal One-Through Supercritical Power Plant to Fulfill the Great Britain Grid Code. In Proceedings of the 6th IASME/WSEAS International Conference on Heat Transfer, Thermal Engineering and Environment, Rhodes, Greece, 20–22 August 2008. [Google Scholar]

- Richter, M.; Möllenbruck, F.; Starinski, A.; Oeljeklaus, G.; Görner, K. Flexibilization of Coal-fired Power Plants by Dynamic Simulation. In Proceedings of the 11th International Modelica Conference, Versailles, France, 21–23 September 2015. No. 118. [Google Scholar]

- Taler, J.; Zima, W.; Ocłoń, P.; Grądziel, S.; Taler, D.; Cebula, A.; Jaremkiewicz, M.; Korzeń, A.; Cisek, P.; Kaczmarski, K.; et al. Mathematical model of a supercritical power boiler for simulating rapid changes in boiler thermal loading. Energy 2019, 175, 580–592. [Google Scholar] [CrossRef]

- Chen, C.; Bollas, G. Dynamic Optimization of a Subcritical Steam Power Plant Under Time-Varying Power Load. Processes 2018, 6, 114. [Google Scholar] [CrossRef] [Green Version]

- Hübel, M.; Meinke, S.; Andrén, M.T.; Wedding, C.; Nocke, J.; Gierow, C.; Hassel, E.; Funkquist, J. Modelling and simulation of a coal-fired power plant for start-up optimisation. Appl. Energy 2017, 208, 319–331. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Liu, M.; Chong, D.; Yan, J. Improving operational flexibility by regulating extraction steam of high-pressure heaters on a 660 MW supercritical coal-fired power plant: A dynamic simulation. Appl. Energy 2018, 212, 1295–1309. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, M.; Wang, C.; Li, X.; Chong, D.; Yan, J. Increasing operational flexibility of supercritical coal-fired power plants by regulating thermal system configuration during transient processes. Appl. Energy 2018, 228, 2375–2386. [Google Scholar] [CrossRef]

- Zima, W. Simulation of rapid increase in the steam mass flow rate at a supercritical power boiler outlet. Energy 2019, 173, 995–1005. [Google Scholar] [CrossRef]

- Roth, K.; Scherer, V.; Behnke, K. Enhancing the dynamic performance of electricity production in steam power plants by the integration of transient waste heat sources into the feed-water pre-heating. Int. J. Energy Technol. Policy 2005, 3. [Google Scholar] [CrossRef]

- Beiron, J.; Montañés, R.M.; Normann, F.; Johnsson, F. Dynamic modeling for assessment of steam cycle operation in waste-fired combined heat and power plants. Energy Conver. Manag. 2019, 198, 111926. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, H.; Zheng, C. Dynamic simulation for mode switching strategy in a conceptual 600MWe oxy-combustion pulverized-coal-fired boiler. Fuel 2014, 137, 135–144. [Google Scholar] [CrossRef]

- Lappalainen, J.; Tourunen, A.; Mikkonen, H.; Hänninen, M.; Kovács, J. Modelling and dynamic simulation of a supercritical, oxy combustion circulating fluidized bed power plant concept—Firing mode switching case. Int. J. Greenh. Gas Control. 2014, 28, 11–24. [Google Scholar] [CrossRef]

- Wang, W.; Jing, S.; Sun, Y.; Liu, J.; Niu, Y.; Zeng, D.; Cui, C. Combined heat and power control considering thermal inertia of district heating network for flexible electric power regulation. Energy 2019, 169, 988–999. [Google Scholar] [CrossRef]

- Wang, C.; Qiao, Y.; Liu, M.; Zhao, Y.; Yan, J. Enhancing peak shaving capability by optimizing reheat-steam temperature control of a double-reheat boiler. Appl. Energy 2020, 260, 114341. [Google Scholar] [CrossRef]

- Sarda, P.; Hedrick, E.; Reynolds, K.; Bhattacharyya, D.; Zitney, E.S.; Omell, B. Development of a Dynamic Model and Control System for Load-Following Studies of Supercritical Pulverized Coal Power Plants. Processes 2018, 6, 226. [Google Scholar] [CrossRef] [Green Version]

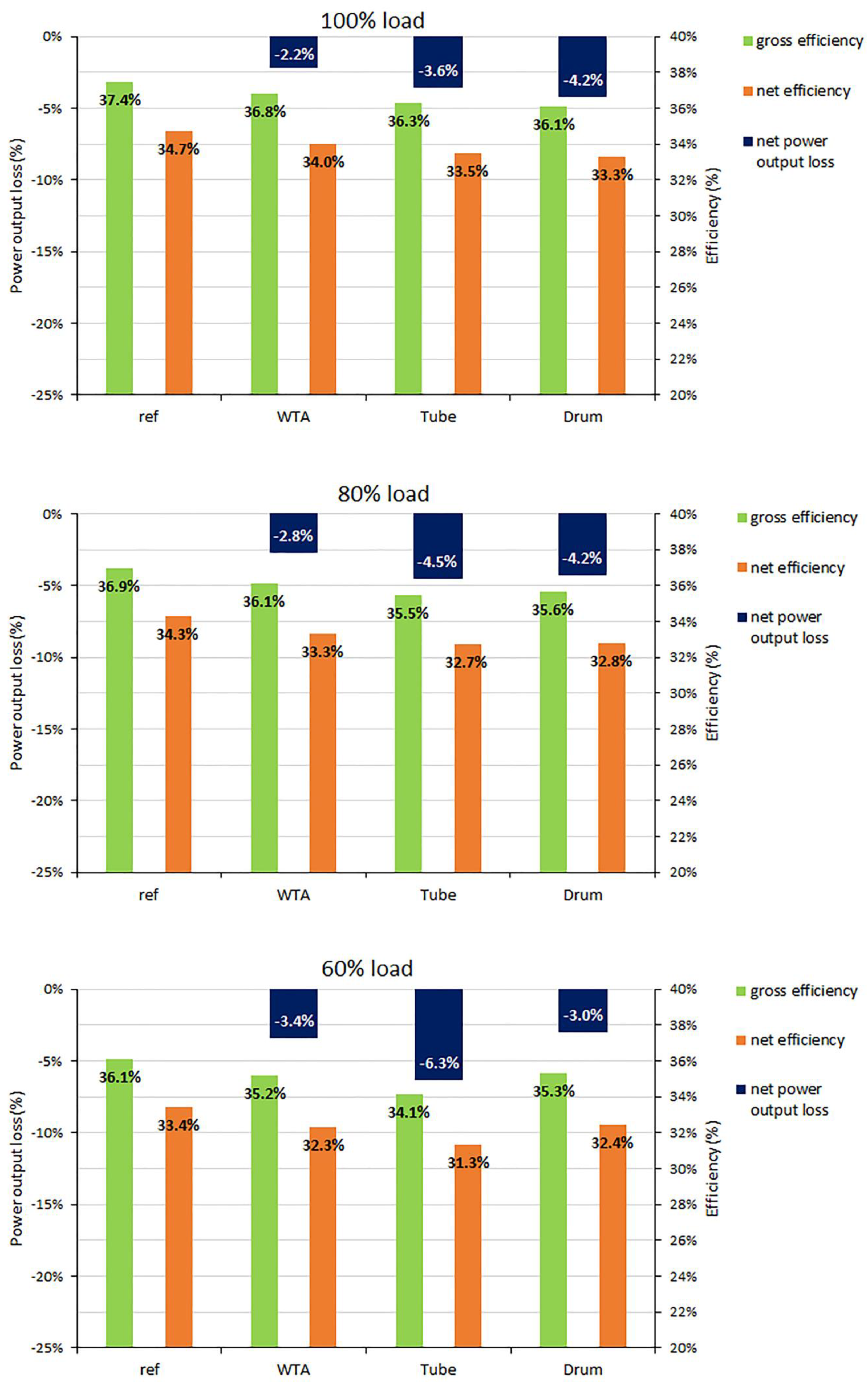

- Avagianos, I.; Violidakis, I.; Karampinis, E.; Rakopoulos, D.; Nanos, E.; Polonidis, N.; Papapavlou, C.; Grammelis, P.; Kakaras, E. Thermal Simulation and Economic Study of Predried Lignite Production Retrofit of a Greek Power Plant for Enhanced Flexibility. J. Energy Eng. 2019, 145, 04019001. [Google Scholar] [CrossRef]

- Liu, M.; Yan, J.; Bai, B.; Chong, D.; Guo, X.; Xiao, F. Theoretical Study and Case Analysis for a Predried Lignite-Fired Power System. Dry Technol. 2011, 29, 1219–1229. [Google Scholar] [CrossRef]

- Peet, W.J.; Leung, T.K.P. Development and Application of a Dynamic Simulation Model for a Drum Type Boiler with Turbine Bypass System. In Proceedings of the International Power Engineering Conference, Singapore, 27 Feburary–1 March 1995. [Google Scholar]

- Starkloff, R.; Postler, R.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Investigation into gas dynamics in an oxyfuel coal fired boiler during master fuel trip and blackout. J. Process. Control 2016, 41, 67–75. [Google Scholar] [CrossRef]

- Postler, R.; Epple, B.; Kluger, F.; Mönkert, P.; Heinz, G. Dynamic Process Simulation Model of an Oxyfuel 250 MWel Demonstration Power Plant. In Proceedings of the 2nd OxyFuel Combustion Conference, Queensland, Australia, 12–16 September 2011. [Google Scholar]

- Han, X.; Liu, M.; Zhai, M.; Chong, D.; Yan, J.; Xiao, F. Investigation on the off-design performances of flue gas pre-dried lignite-fired power system integrated with waste heat recovery at variable external working conditions. Energy 2015, 90, 1743–1758. [Google Scholar] [CrossRef]

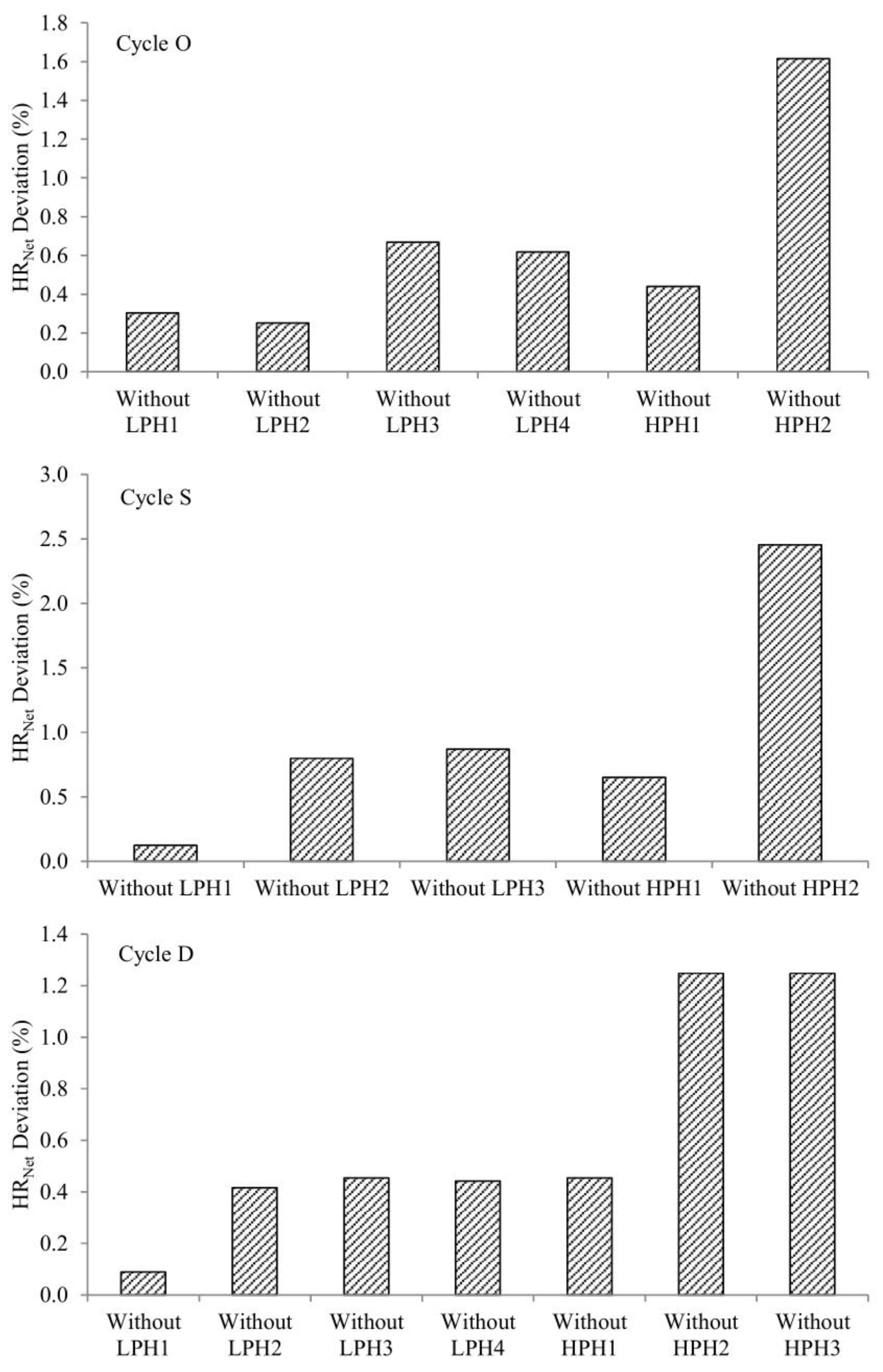

- Riesgo, A.; Folgueras, M.B. One feedwater heater taken out of service as a strategy to maintain full load and its effect on steam power cycle parameters and performance. Int. J. Energy Res. 2019, 43, 2296–2311. [Google Scholar] [CrossRef]

- Meinke, S.; Gottelt, F.; Müller, M.; Hassel, E. Modeling of Coal-Fired Power Units with ThermoPower Focussing on Start-Up Process. In Proceedings of the 8th Modelica conferenc, Dresden, Germany, 20–22 March 2011. [Google Scholar]

- Atsonios, K.; Violidakis, I.; Sfetsioris, K.; Rakopoulos, D.C.; Grammelis, P.; Kakaras, E. Pre-dried lignite technology implementation in partial load/low demand cases for flexibility enhancement. Energy 2016, 96, 427–436. [Google Scholar] [CrossRef]

- Beiron, J.; Montañés, R.M.; Normann, F.; Johnsson, F. Combined heat and power operational modes for increased product flexibility in a waste incineration plant. Energy 2020, 202, 117696. [Google Scholar] [CrossRef]

- Ciferno, J. Pulverized Coal Oxycombustion Power Plants; Final Report; NETL; DOE: Washington, DC, USA, 2007.

- Xiong, J.; Zhao, H.; Zheng, C. Exergy Analysis of a 600 MWe Oxy-combustion Pulverized-Coal-Fired Power Plant. Energy Fuels 2011, 25, 3854–3864. [Google Scholar] [CrossRef]

- Zoelle, A.; Keairns, D.; Pinkerton, L.L.; Turner, M.J.; Woods, M.; Kuehn, N.; Shah, V.; Chou, V. Cost and Performance Baseline for Fossil Energy Plants Volume 1a: Bituminous Coal (PC) and Natural Gas. to Electricity Revision 3; NETL: Pittsburgh, PA, USA, 6 July 2015.

| Fuel | Plant Capacity (MWe) | Simulation Tool | Flexibility Feature | Validation Data/Plant | Description | Main Conclusions | Ref. |

|---|---|---|---|---|---|---|---|

| Coal and biomass | 800 | Aspen Plus® | Part-load performance | Operational data | Part-load operation for 40%, 60%, and 80% load, with coal and biomass co-firing | The total substitution of coal with biomass implies a 30% derating of the output capacity of the plant when operating at full load. The co-firing scheme at part-load implied similar derating | [33] |

| Coal | 300 & 600 | In-house code relating data sets | Start-up, ramping, and deep cycling | Operational data | In-house linear-regression code for correlating fuel consumption, CO2, SO2, NOx and dust emissions, and load for two typical capacity plants under start-up, ramping, and deep-cycling operation | Frequent start-ups (cold, warm, hot), fast ramping rates, and deep cycling have a negative effect regarding the CO2 and pollutant emissions | [34] |

| Coal | 200 | Ebsilon® | Part-load performance | Operational data | Part-load operation for 60%, 80% and 100% load with three different fuels | Energy and exergy efficiency calculations of the boiler operation under varying external conditions depicted less than 4.5% relative error | [35] |

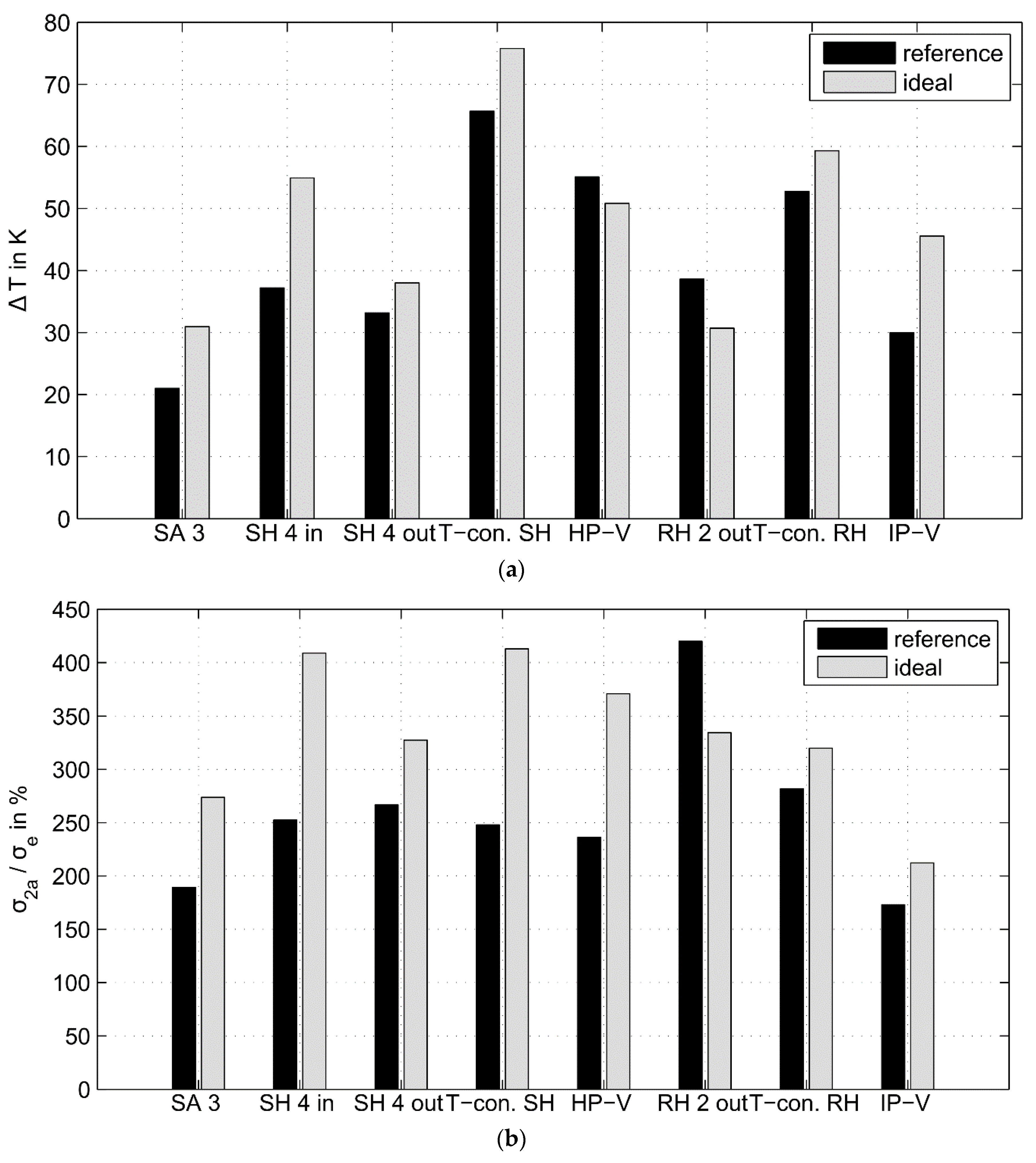

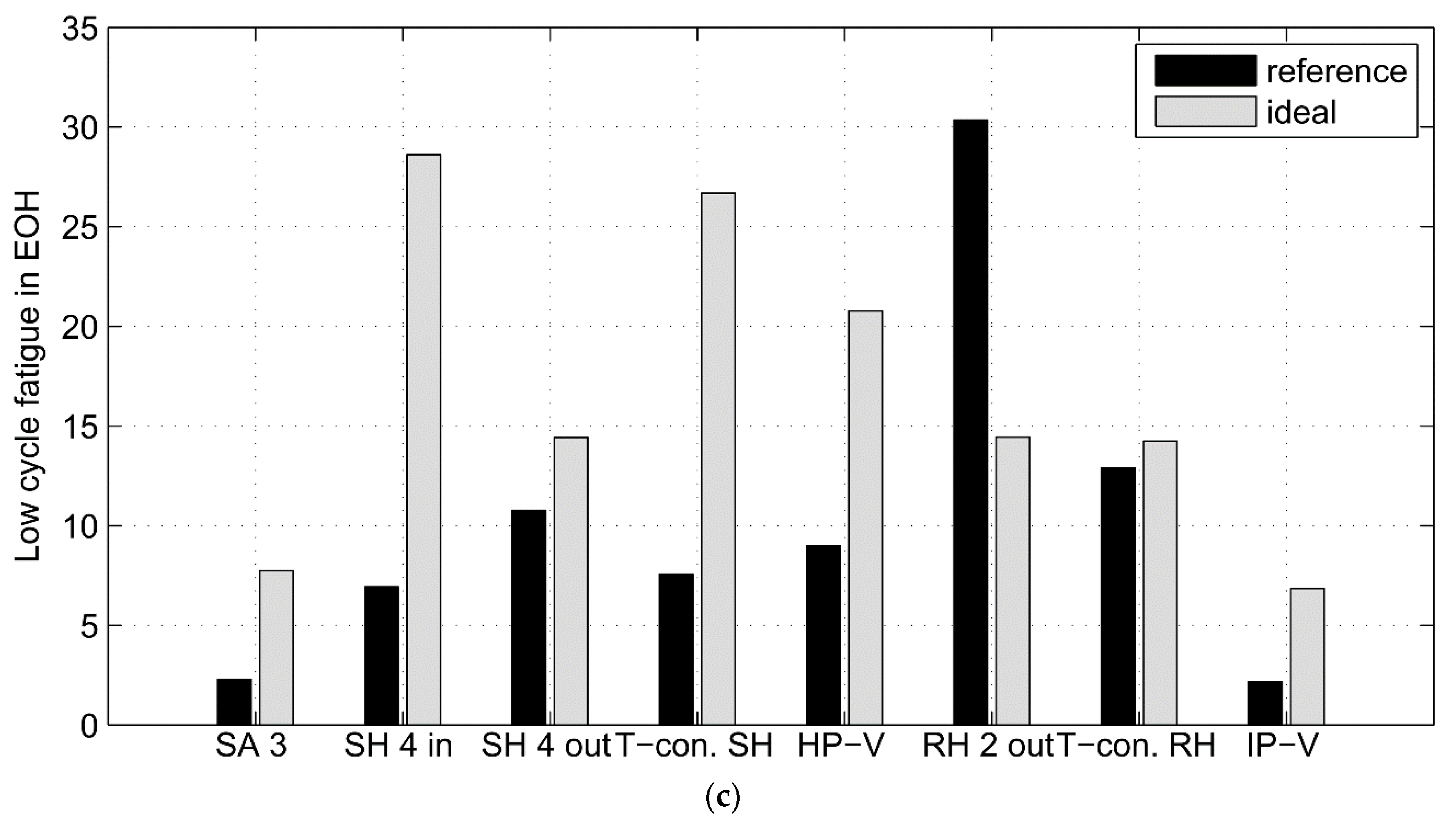

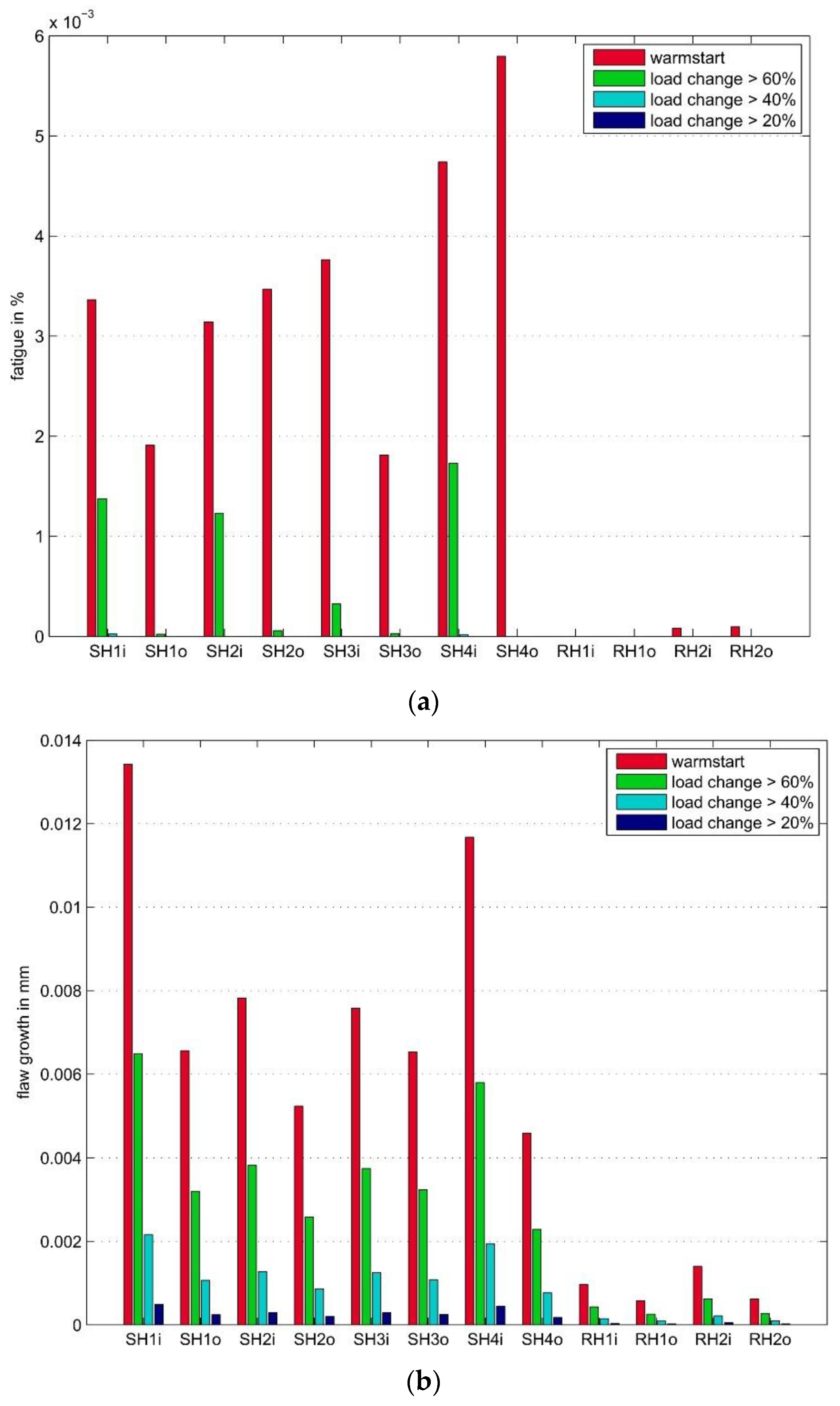

| Lignite | 265/530 | Modelica® | Step-load change and primary frequency control | Operational data | Dynamic simulations for a 25%-load step change with and without primary frequency control were performed, and the incurred fatigue of thick-wall components was monitored. The outlet headers before the turbine inlet of the superheated and reheated steam circuit were identified as the most affected ones | The impact of the primary frequency control is of the lifetime reduction of the thick-wall components and the main impact factors were identified to be the temperature, the pressure alterations and the shape/geometry of the component | [36] |

| Coal | 750 | APROS® | Ramping up and down | Operational data | Steady-state and dynamic simulation of a detailed model for the validation against operational data | Both the steady-state and the dynamic simulations presented a very small deviation from the plant operational data | [37] |

| Coal | 500 | gPROMS | Load step changes and ramping rates | Operational data | A detailed model of a subcritical coal-fired power plant was developed and validated with steady-state simulations against operational data. It was simulated under load step changes and 70–100% load-ramping range | Dynamic simulations were performed in the 70–100% load range showing ramping load changes being more suitable than load step changes. The steady-state load can be predicted from the model with less than 5% relative error in the 70–100% load range | [38] |

| Waste | 15.6 | APROS® | Hot start-up and shutdown | Design data at nominal load | Municipal grate incinerator model including the control system. Validation simulations against design data at the nominal load operation | Model validation shows less than 5% relative error at nominal load. Results for hot start-up and shutdown are provided as recommendation for future validation | [39] |

| Coal | 800 | Doosan SpaceGEN and Aspen Hysys® | Ramping up and down | - | An air-fired power-plant model was simulated under oxy-fired conditions and CO2 compression. The model comprised the control system, the air separation unit, and the compression and purification unit | Preliminary results were presented for a complete load cycle operation, from full load to minimum back to full load with an interval of a steady operation at minimum load | [40] |

| Coal | 3 (MWth) | Aspen Plus® Dynamic | Load step changes | Operational data | Oxy-fired boiler with flue-gas recirculation model simulated under fuel, oxidant, and water mass flow step changes | Model validation against operational data revealed that the slowest response was for heat transfer and could be even more in large scale systems. The load step changes were adequately reproduced from the model for air and oxy-fired modes | [41] |

| Coal | 550 | APROS® | Load step change | Operational data | Thermodynamic model and control system for of a coal-fired power plant. The model incorporated the coal mills. Simulation runs under secondary control reserve mode | Validation process exhibited less than 5% relative error. Results from the coal mills simulation under step change revealed the influence and the time delay needed for the power plant to reach steady-state load operation. The modeling approach of the coal mill was proven adaptable and transferable to other power plants mills | [42] |

| Pre-dried lignite | 360 | In-house code in MATLAB®/Simulink® | Step changes | Published operational data in Ref. [43,44] | Oxy-fuel combustion boiler model incorporating the combustion, the flue-gas recirculation and the water/steam side. Simulations under load step changes | A step-change reduction of 10% flow rate of the coal mass flow during a 10 min period was simulated. Four disturbances in the O2 purity, primary air mass flow and CO2 fluctuation for a disturbance of 15% decrease/increase in a 20 min period of time and a coal quality fluctuation of ±2.5% were simulated. Simulation results showed the fluctuation incurred to boiler operating parameters | [45] |

| Coal | 210 | In-house code in MATLAB® | Load step changes | Operational data | Detailed boiler model for transient simulations with the use of nonlinear least-square estimation method to fit the unknown parameters from the plant data | Two consecutive 5%-load step changes of feed water and heat flow rate were simulated, and results showed deviations from nominal values for drum and superheater pressure of 6% and 2% and 13% and 5%, respectively | [46] |

| Coal | 1000 | In-house code in MATLAB® | Load-ramping | Operational data | A coal-fired power-plant model was developed in Ref. [47]. An immune genetic algorithm was applied for parameters identification | The simulation results under monotonous load-ramping and the implementation of the immune genetic algorithm showed a decrease in relative errors between Refs [47,48] | [48] |

| Coal | - | APROS® | Cold start-up | Manufacturer data | Detailed model of a steam generator model incorporating all fuel and air supply nozzles and tilting mechanism of the burners | Simulation results for steady-state simulations compared against CFD model results with relative error below 5.1%. Cold start-up simulation results validated against manufacturer data for water/steam enthalpy showed a very good agreement | [49] |

| Coal | 660 | GSE | Cycling with two ramping rates | Operational data | Detailed model for transient cycling simulations with two different ramping rates of 8 MW/min and 20 MW/min in the range of 50–100% steam turbine thermal acceptance | Cycling simulation resulted into a maximum deviation in standard coal consumption variation rate of 1.21 g/kg h during the loading up and 0.81 g/kg h during the loading down | [50] |

| Coal | 300 | In-house code | Load step change and load-ramping | Operational data | Detailed model for transient simulations incorporating a coordinated control system enabling plants flexibility | Load step changes and ramping simulations were performed under the proposed control system showing relative error less than 8% | [51] |

| Coal | 0.176 | gPROMS/gCCS | Load and steam step changes | Operational data | Coal-fired power-plant model and post-combustion CO2 capture plant models were jointly simulated under load and steam step changes, and a new control system was proposed | The proposed control system of the whole plant was tested under three operating scenarios, normal operation, load step change, and strict CO2 capture rate, showing a small deviation from reference | [52] |

| Coal | 660 | gPROMS/gCCS | Load and CO2 capture rate step changes | Operational data | Coal-fired power plant with post-combustion CO2 capture plant model development and incorporated with a neural network inverse control system | Simulation scenarios of power set point variations were simulated showing that flue-gas and steam extraction for the reboiler is the most crucial interaction between the two plants. The proposed neural network control achieved a feed-forward control of different variables | [53] |

| Coal | 700 | Modelica®/Dymola Media Fluid | Start-up | - | A drum-boiler plant with the control system is modeled based on publicly available data from previous publication [18], and three parameters were controlled and start-up procedure was optimized | The optimized control system yielded a shorter start-up time. The proposed control was applied to a 700 MW coal-fired power plant | [54] |

| Coal | 600 | Aspen Plus® Dynamics | Load, oxygen purity, and air leakage step changes | - | Conceptual coal oxy-combustion power plant and control system model simulated under three different scenarios | Simulations performed for load change, planned disturbances, switching operational mode, and different control strategies, showing good dynamic results compared with the literature available data. Alternative control strategy revealed more beneficial the O2 control in flue gas than in the oxidant | [55] |

| Coal | 600 | In-house code in MATLAB®/Simulink® | Load step changes | Operational data | A coal-fired model was developed in Ref. [56] and a predictive control method with genetic algorithms was applied for ±20 MW load step changes | The application of the predictive control showed a more rapid response to the set point | [57] |

| Fuel | Plant Capacity (MW) | Simulation Tool | Off-Design Feature | Validation Data/Plant | Description | Main Conclusions | Ref. |

|---|---|---|---|---|---|---|---|

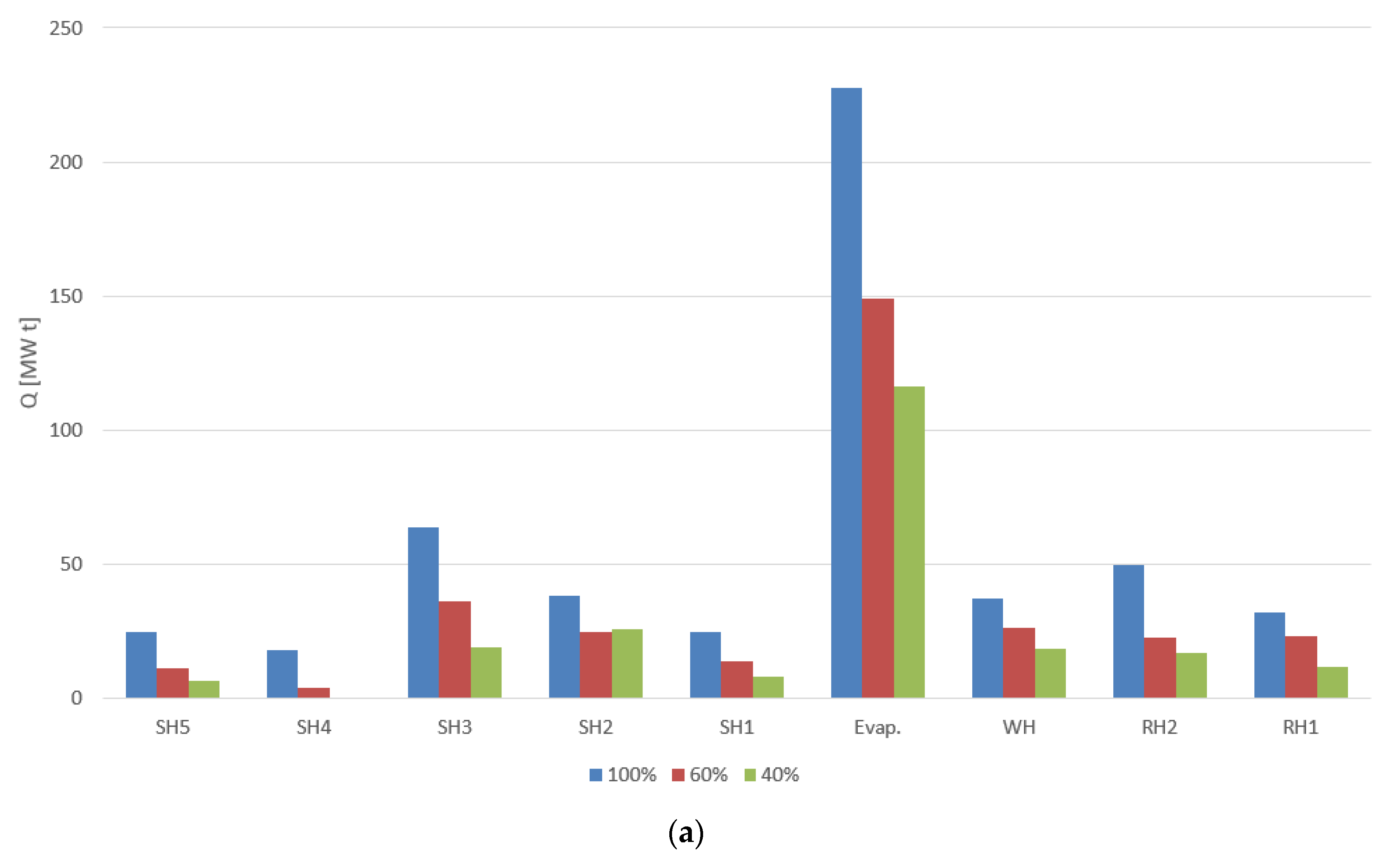

| Wood | 1.8, 6.1, 11.0, 14.0 | ProSim | Low load 35% and 40% | Steady-state simulations and operational data | Four CHP plants, one grate and three BFB | Nonlinear reduction of net power production during partial-load operation | [60] |

| Coal | 1000 | GSE | Low load 30% | Steady-state simulations and design data | Supercritical plant pollutants formation and LCA analysis for environmental impact | Rapid increase of environmental impact at partial-load operation, promising proposed mitigation measures | [61] |

| Coal | 600 | In-house code | Low load 30% | Transient simulations and design data | Supercritical plant modeled and validated under transient simulations in the load range 30–100% | Operation prediction with standard and improved codes with relative error 2.5% and 3.8%, respectively | [62] |

| Coal | 225 | Ebsilon® Professional | Low load 40% | Operational data | New technical minimum load reached | Significant drop in live-steam parameters and flue-gas temperature | [63] |

| Raw and Pre-dried Lignite | 340 | Aspen Plus® | Low load 35% | Operational data and CFD simulation results | New technical minimum load simulated with pre-dried lignite as supporting fuel | Predictive method results show good accordance against CFD results for new technical minimum-load operation | [64] |

| Biomass | 0.6 | SimECS | Low load 50% | Experimental data and Cycle-tempo software simulation results | A biomass-fired power plant was modeled and simulated in Ref. [65] followed by on-design and low off-design load validation steady-state simulations. Transient simulations were also performed for 3%-load step changes and ramping-down rate of 3.3% load/min | The off-design point of operation was steady-state simulated and results showed a maximum difference of 6.0%. Transient simulations revealed that the off-design operation causes an almost two times slower response of the plant’s parameters | [66] |

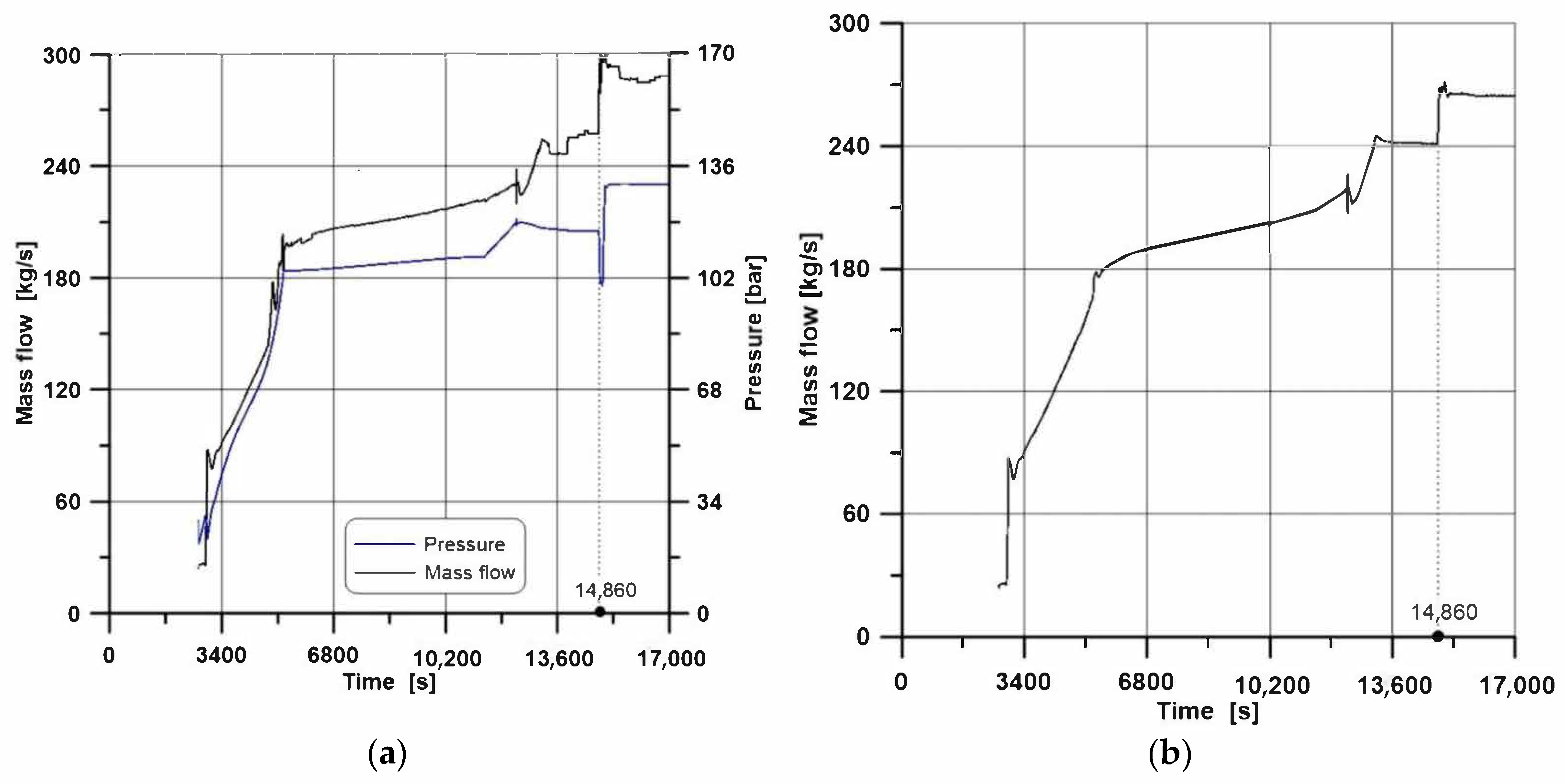

| Coal | 6 × 60 | In-house code and MATLAB®- SIMULINK® | Ramping 0–100% load | Operational data | Six boilers with common steam collector and six steam turbines model as training simulator for plant operators | Normal and abnormal operation modes were successfully simulated | [67] |

| Coal | 800 | ENBIPRO | 6%/min ramping rate | Dynamic simulations | Primary measures for increased ramping rate simulated for start-up and ramping-up schemes | A 6%/min load change is feasible with high-pressure steam throttling and increased mass flow injection | [68] |

| Coal | - | Modelica®/Dymola ClaRa | 6%/min ramping rate | Operational data | A thermal energy storage system was incorporated to the model for enhanced flexibility | The permissible rate of 2%/min load change is feasible with the addition of the heat storage system | [69] |

| Coal | 910 | In-house code | 7.9%/min ramping rate | Design data | Supercritical boiler model simulated for fast ramping rate and cold start-up | Rapid boiler load change is feasible within the 40–80% load range | [70] |

| Coal | 605 | Modelica®/Dymola Modelon ThermalPower | Dynamic optimization of variables | Operational data | High-pressure steam temperature and air temperature, steam loss flow rates for high and intermediate pressure steam are the two optimization cases | A supervisory control system was implemented yielding operational benefits of 1.95% points to efficiency, 184.7 tons/day coal savings and a reduction of 0.035 kg/kWh CO2 emissions | [71] |

| Lignite | 500 | Modelica®/Dymola Modelon ThermalPower | Start-up optimization | Operational data | The model incorporates the plant and the control system. Thick-wall components were modeled in detail. Cold, warm, and hot start-ups were simulated | Identification of critical thick-wall components during start-up. Feasible reduction of start-up duration of 30% and oil consumption of 70% | [72] |

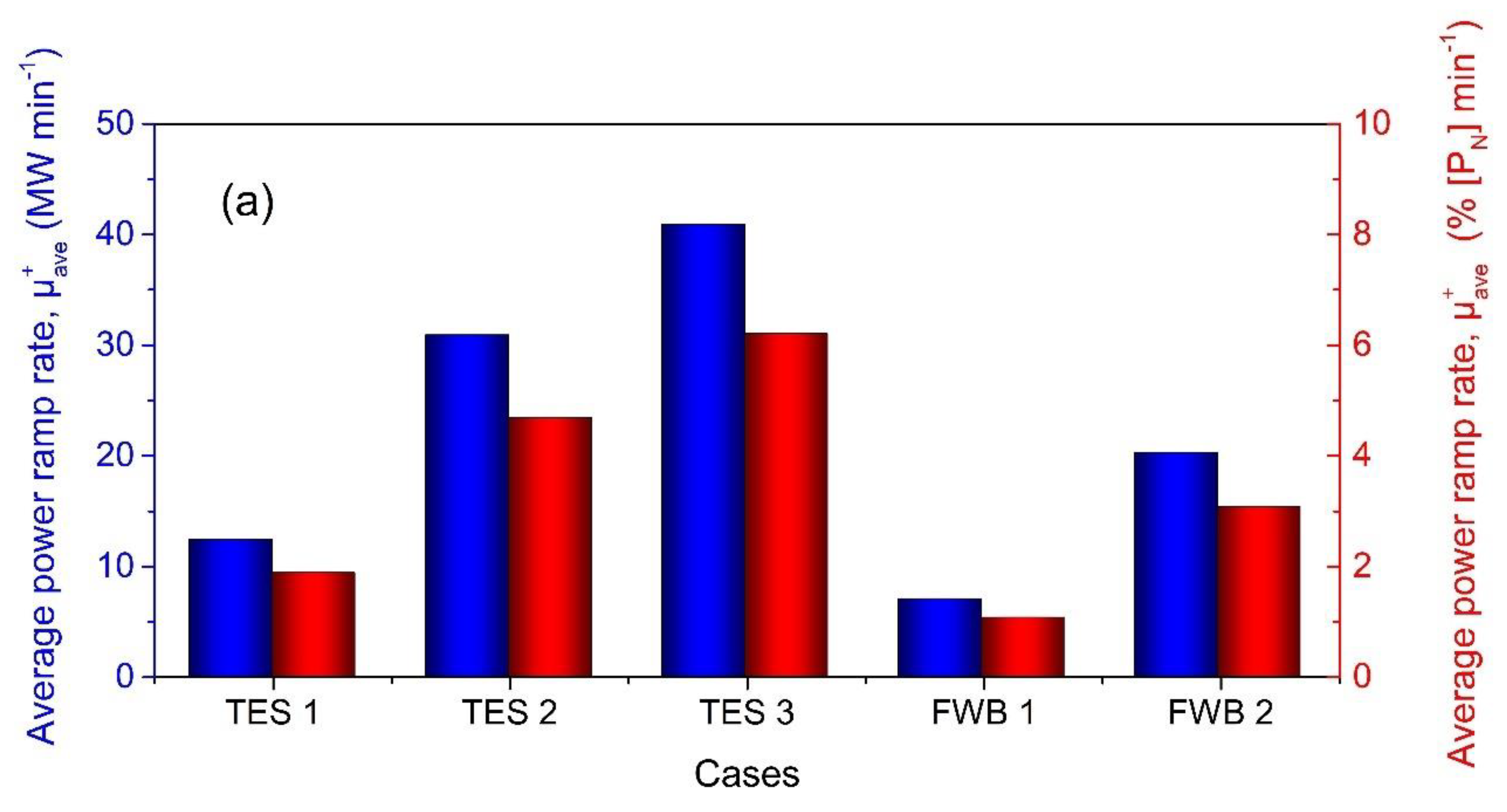

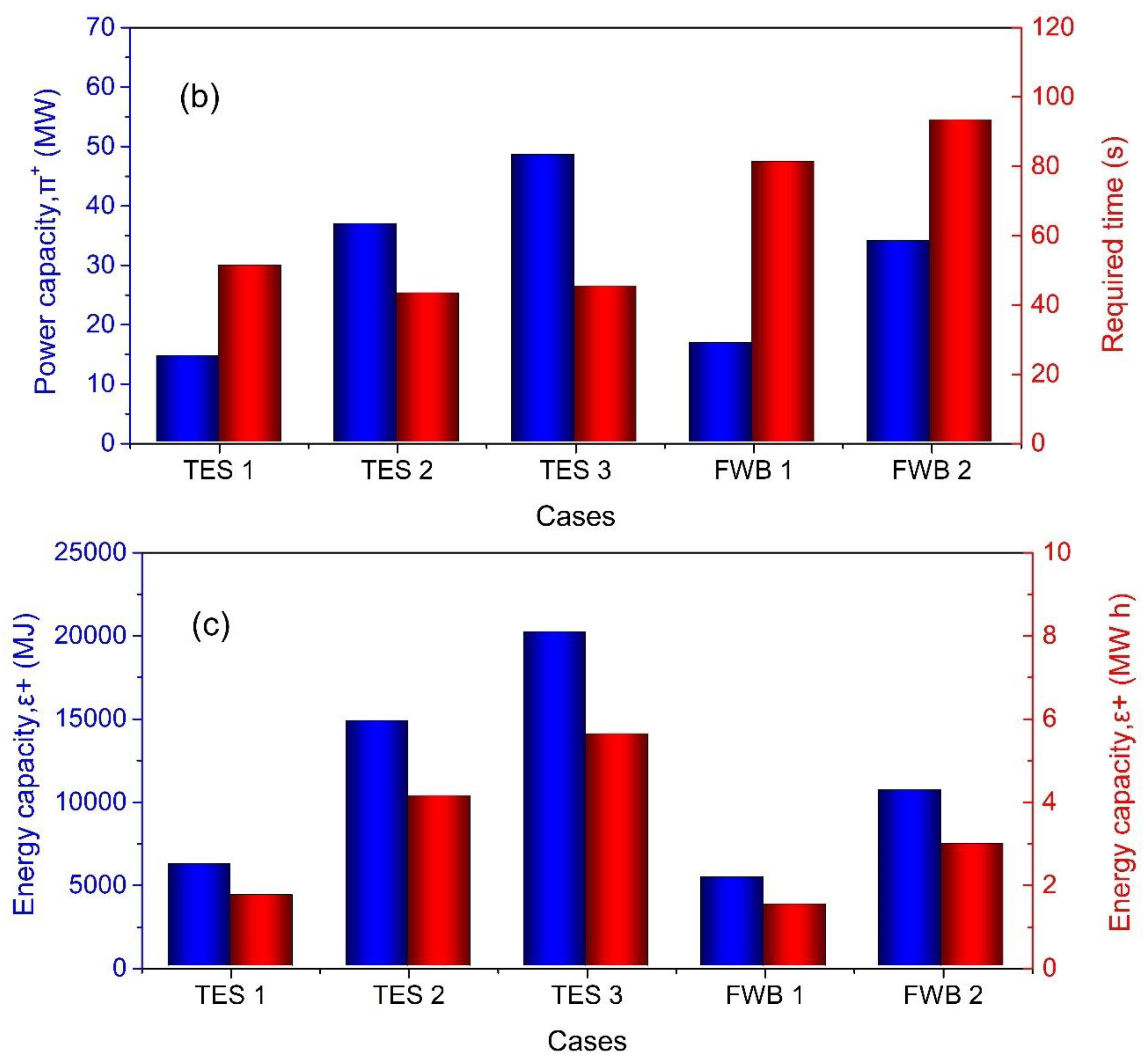

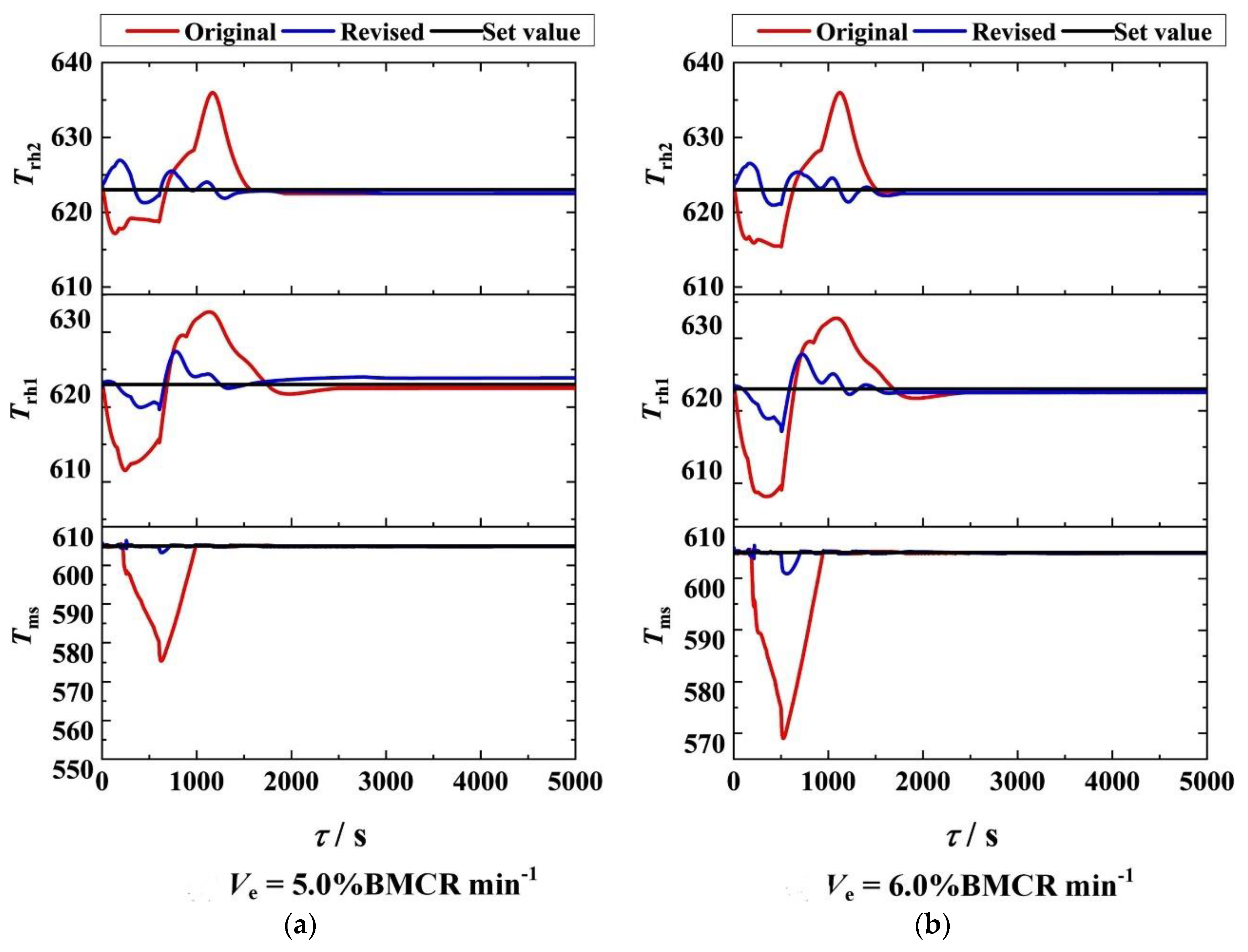

| Coal | 660 | GSE | 6.19%/min and 6.31%min ramping rate | Operational data | The model was simulated under a thermal storage use and configuration as options for improved flexibility | Both options proved feasible and meet primary and secondary frequency control regulations. The configuration option was more suited for power-up regulation | [73,74] |

| Coal | 910 | In-house code | 5%/30 s | Design data | Simulation runs for reaching grid mandatory ramping rate of 5%/30 sec | Two pressure drop steps and respective fuel mass flow rises as feasible options for fast load change | [75] |

| Coal | 393 | APROS® | 2.7 MW/min | Design and guarantee values | External heat sources addition such as gas-turbine flue gas and steam line in the pre-heating | Power output increase from 393 to 425 MW in 12 min. Steam cycle dynamics are not a limiting factor to fast ramping rates | [76] |

| Waste | 48 | Modelica®/Dymola Modelon ThermalPower | 2, 4, 8 and 16%/min | Operational data | Combined heat and power waste incinerator modeled and simulated under fast-load-change scenarios | Ramping-down rate reduplication from 2 to 4%/min implies a 42% decrease in time. Settling times higher when load increases | [77] |

| Waste | 48 | Modelica® | Step changes, ramps, and sinusoidal disturbances | Operational data | Dynamic simulations for different load changes for a CHP plant with CFB boiler within the range of 72–100% load | The double of the typical ramping rate of 2%/min to 4%/min leads to a 42% reduction of incensement time of power generation | [77] |

| Coal | 600 | Aspen Plus® Dynamics | Mode switch in 17 min | Benchmark data | Coal power-plant model with control system simulated for oxy-fuel combustion switch during operation | Switching from air mode to oxy-mode operation and vice versa in 17 min | [78] |

| Coal and Petcoke | 300 | APROS® | Mode switch in 25–37 min | Performance data | A circulating fluidized-bed power plant with control system and carbon-capture system model developed and simulated for mode switch between oxy-mode and air-mode operation | Linear control of mass flow rates has successfully applied for the switch operation within 20 min towards oxy-mode and steady state was reached in 37 min. The relevant time for inverse mode switch was 24–25 min | [79] |

| Undefined | 330 | In-house and MATLAB® | 4%/min | Operational data | In-house modeled combined heat and power plant with control system for load following operation mode | A combined strategy of coordinated control strategy and heat-source regulation yielded a maximum ramping rate of 4%/min and decreasing the response time to load-follow mode operation | [80] |

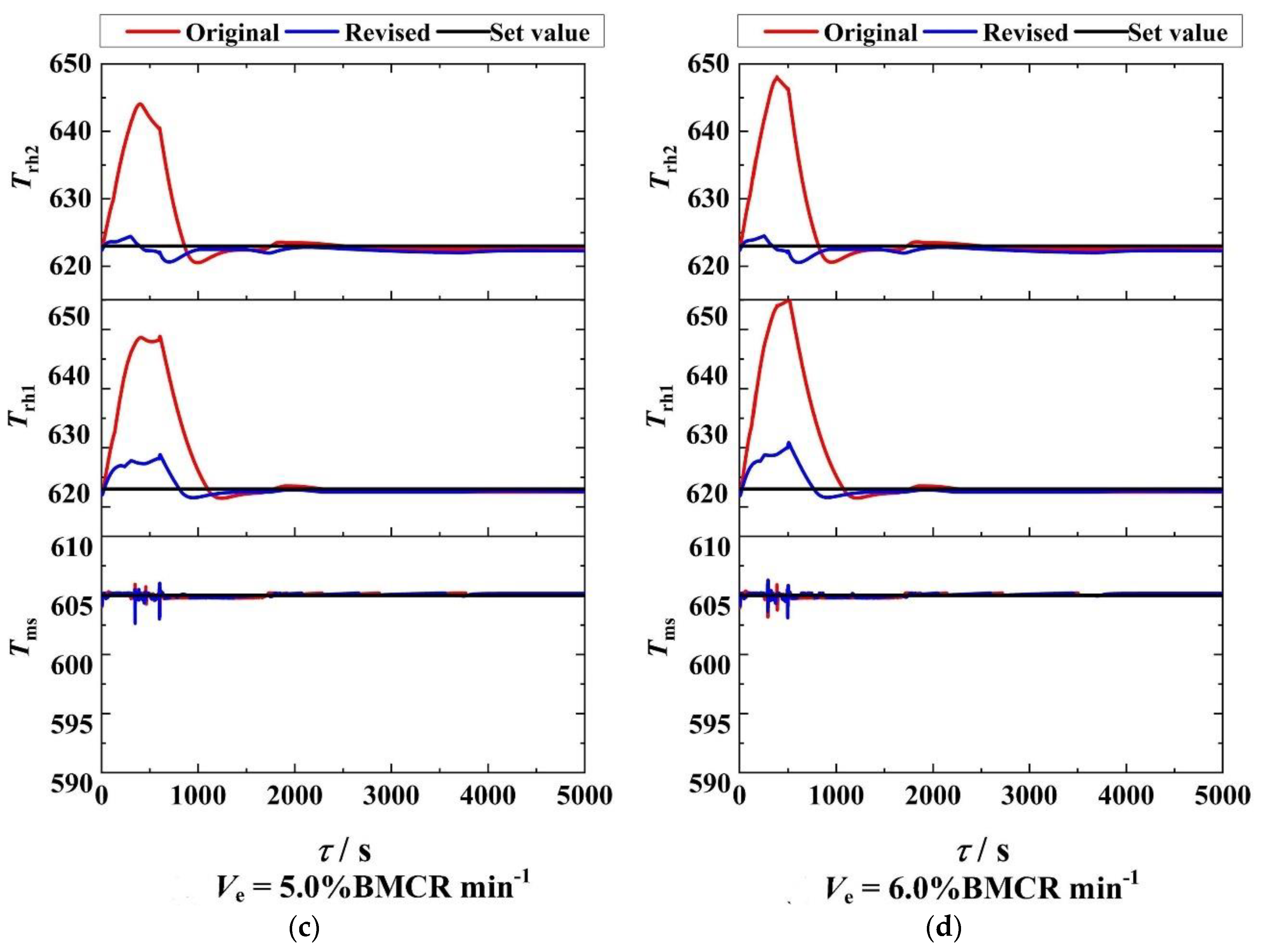

| Coal | 660 | GSE | 4%/min | Operational data | A coal-fired power plant and the control system were modeled with the focus being towards the boiler operation during transient operation | The ramping-up and -down rate of 4%/min is achieved with the modified reheated steam control under cycling operation | [81] |

| Coal | 640 | Aspen Plus® Dynamics | 3%/min | Benchmark data | A coal-fired plant and the control system were modeled and simulated for load-follow operation | Three different control systems were simulated for a load decrease from 100% to 40% load with 3%/min rate and minimum 7 °C deviation for superheated steam was achieved | [82] |

| Lignite | 360 | Aspen Plus® | Pre-dried lignite as supporting fuel | Operational data | Power plant and integrated dryer model development for economically viable flexible operation of power plant with pre-dried lignite as supporting fuel | Three drying technologies were integrated to plants operation and economic parameters were calculated resulting in increased plant efficiency at part-load operation | [83] |

| Lignite | 600 | In-house | Pre-dried lignite as supporting fuel | Not defined | Integrated model of a supercritical power plant with a rotary dryer | Pre-dried lignite integrated production and use yielded an efficiency improvement of the plant | [84] |

| Coal | 650 | PC-TRAX | New control philosophy for load rejection | Design and operational data | Power plant with control system model developed and simulated for full-load rejection at maximum-load operation | Simulation results showed an increase in condenser low vacuum pressure and a doubling of heat load in the condenser compared to the full load | [85] |

| Lignite | 250 | APROS® | Fuel trip and blackout | Operational data | Oxy-fuel coal-fired power plant and control system was modeled and simulated for master fuel trip and blackout conditions | Control strategies were investigated to avoid boiler implosions during master fuel trip. Existing safety measures proved sufficient for the blackout scenario | [86] |

| Lignite | 250 | APROS® | Recycle fan trip | Design data | Oxy-fuel dry lignite power plant and control system model was developed and simulated for load change and a recycle fan trip followed by a master fuel trip | Furnace negative pressure maximum 12% reduction of design value | [87] |

| Lignite | 600 | GSE | High ambient air temperature and varying fuel moisture | Design data | Power plant with lignite dryer and waste-heat recovery system model development and simulated under off-design conditions for ambient air temperature and fuel moisture content | Higher ambient air temperatures have a negative impact on plant efficiency and reduce the efficiency bonus from the waste-heat recovery system. The elevated moisture content of pre-dried lignite has a beneficial impact on plant efficiency | [88] |

| - | 160, 210, and 434.7 | THERMOFLEX® | One feedwater heater was out of service | - | Three different regenerative thermodynamic cycles were modeled and simulated with one water preheater out of service as an option to maintain full load | Regardless of the preheater out of service, the heat rate is increased. The redistribution of steam mostly affects the water preheater downstream. The highest-pressure water preheater could be set out of service when superheated and/or reheated steam temperature decreases, in order to maintain full load | [89] |

| Coal | 550 | Modelica® Modelon ThermalPower | Extended load change | Operational data | A coal power plant detailed model was developed and simulated for start-up and three load changes from which one was extended out of plant nominal load range | Simulations have shown very good agreement with operational data and less than 5.2% relative error. Only for a period or 20 min a relative error of 28% was noted for the inlet pressure of the economizer. Inlet-outlet temperatures for thick-wall components were also calculated followed by stress calculations and fatigue evaluations were presented for load cycle estimations | [90] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avagianos, I.; Rakopoulos, D.; Karellas, S.; Kakaras, E. Review of Process Modeling of Solid-Fuel Thermal Power Plants for Flexible and Off-Design Operation. Energies 2020, 13, 6587. https://doi.org/10.3390/en13246587

Avagianos I, Rakopoulos D, Karellas S, Kakaras E. Review of Process Modeling of Solid-Fuel Thermal Power Plants for Flexible and Off-Design Operation. Energies. 2020; 13(24):6587. https://doi.org/10.3390/en13246587

Chicago/Turabian StyleAvagianos, Ioannis, Dimitrios Rakopoulos, Sotirios Karellas, and Emmanouil Kakaras. 2020. "Review of Process Modeling of Solid-Fuel Thermal Power Plants for Flexible and Off-Design Operation" Energies 13, no. 24: 6587. https://doi.org/10.3390/en13246587

APA StyleAvagianos, I., Rakopoulos, D., Karellas, S., & Kakaras, E. (2020). Review of Process Modeling of Solid-Fuel Thermal Power Plants for Flexible and Off-Design Operation. Energies, 13(24), 6587. https://doi.org/10.3390/en13246587