Life-Cycle Assessment of the Wastewater Treatment Technologies in Indonesia’s Fish-Processing Industry

Abstract

:1. Introduction

1.1. Background and Literature Review

1.2. What Will Be Elucidated in This Research?

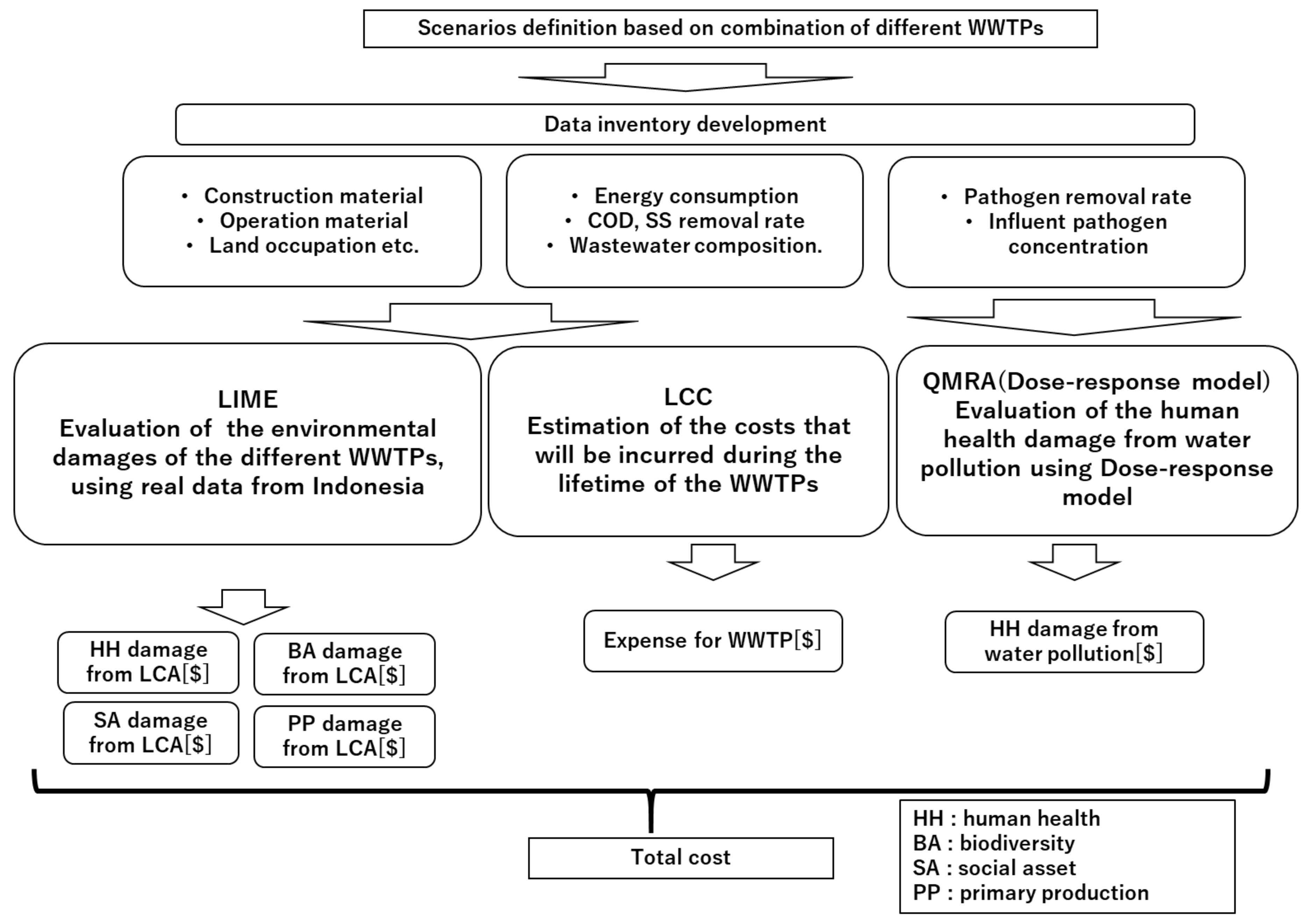

2. Model Development

2.1. Weighting Method and Damage Assessment

- HH: Total damage due to climate change [DALYs (Disability-Adjusted Life Years)]

- DFαHH: Damage from climate change per 1 kg CO2 emissions [DALYs/kgCO2]

- GWP: Global Warming Potential [kgCO2]

- ∆TEMP: Increase in temperature due to 1 [kg] of additional CO2 emissions [°C/kgCO2]

- RR: Rate of increase in relative risk per 1 [°C] increase in temperature [(%)/°C]

- INC: Base mortality rate [%]

- CAP: Population [people]

- HD: DALY for the death of one person [DALYs/people]

- SA: Social Assets damage [$]

- Rs: Income from the extraction of resource “s” per year [$/year]

- Ps: Production of resource “s” per year [kg]

- Vs: Unit price of fossil resource “s” [$/kg]

- RSs: Total amount of resource “s” that can be extracted [kg]

- Ms: Consumption of resource “s” [kg]

- r: Discount rate [%]

- BD: Biodiversity Damage due to climate change [EINES (Expected Increase in Number of Extinct Species)]

- DFBD: Expected number of extinct species form 1 [kg] CO2 emissions [EINES/kgCO2]

- ∆TEMP: Increase in temperature due to 1 [kg] of additional CO2 emissions [°C/kgCO2]

- Ac: Land area [m2]

- Lc: Growing area degradation per increase in temperature [%/°C]

- DFland,c: Increase in the number of extinct species per 1 [m2] growing area degradation [EINES/m2]

2.2. Quantitative Microbial Risk Assessment (QMRA)

- D: pathogen dose [MPN]

- CM: microbial concentration of the influent water [MPN/mL]

- Vex: Quantity of the influent water [mL]

- ηραr: removal rates of alternative technologies for various pathogens [%]

- MPN: most probable number of infectious units

- (a)

- Beta–Poisson dose-response model:

- P(D): Probability or risk of pathogen dose (D) [-]

- N50: the amount of pathogen dose (D) which can infect 50% of the exposed society [MPN]

- ρ: Pathogen infectivity [-]

- -

- Non-constant survival and infection probabilities.

- -

- Survival probabilities are given by the beta distribution.

- (b)

- Exponential dose-response model

- (c)

- Annual risk of infection

2.3. Life-Cycle Cost Analysis

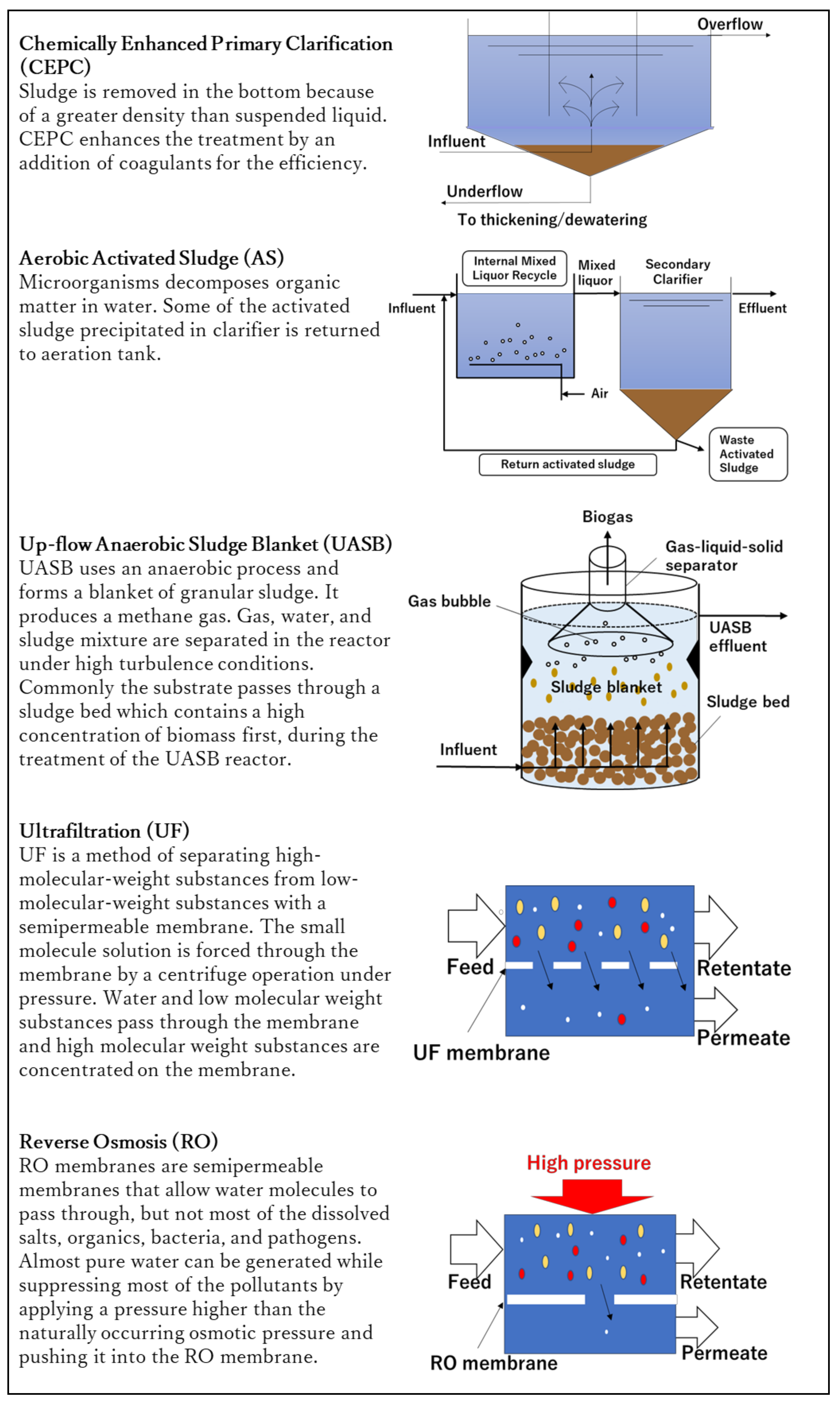

3. Case Study and Scenario Definition

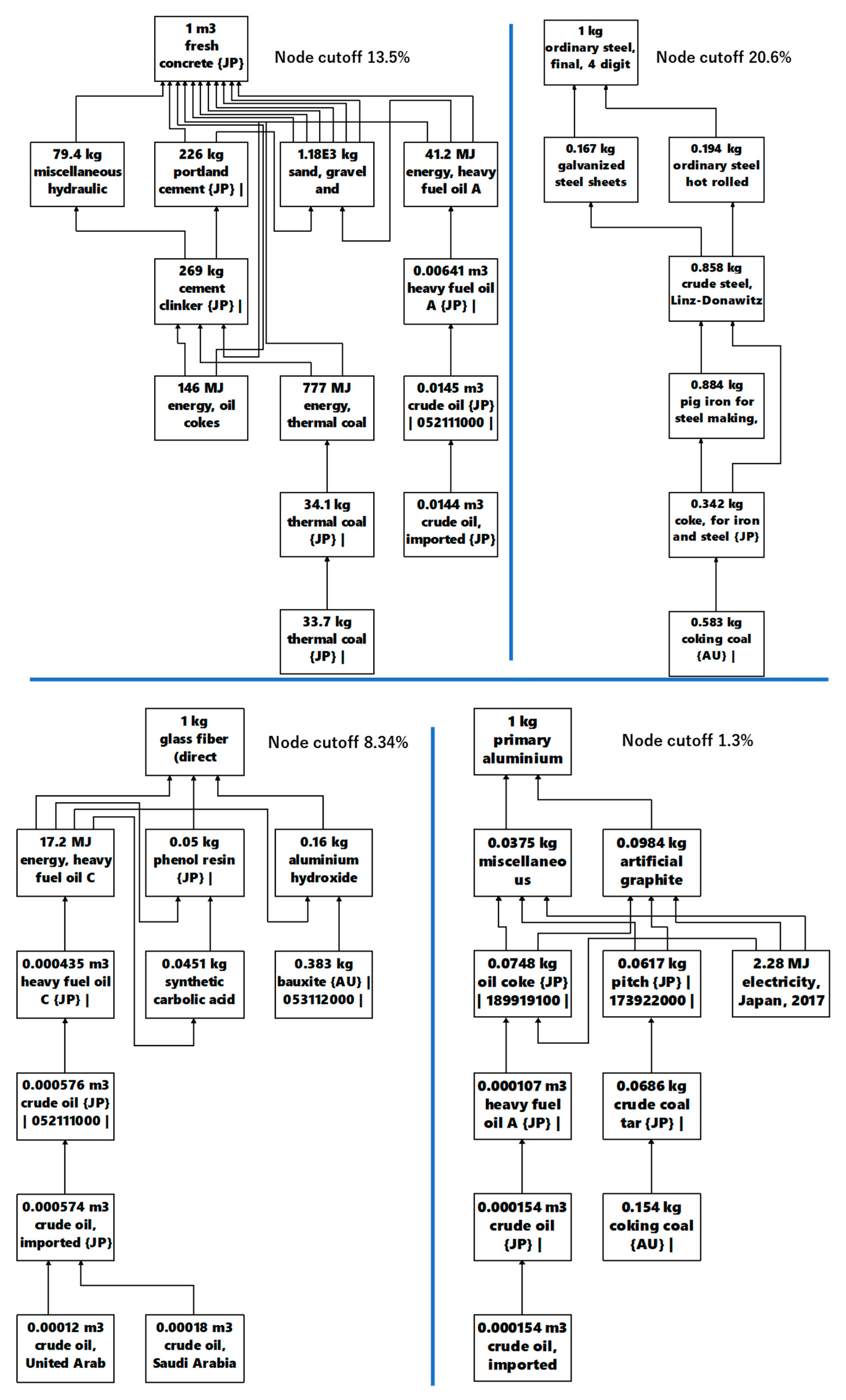

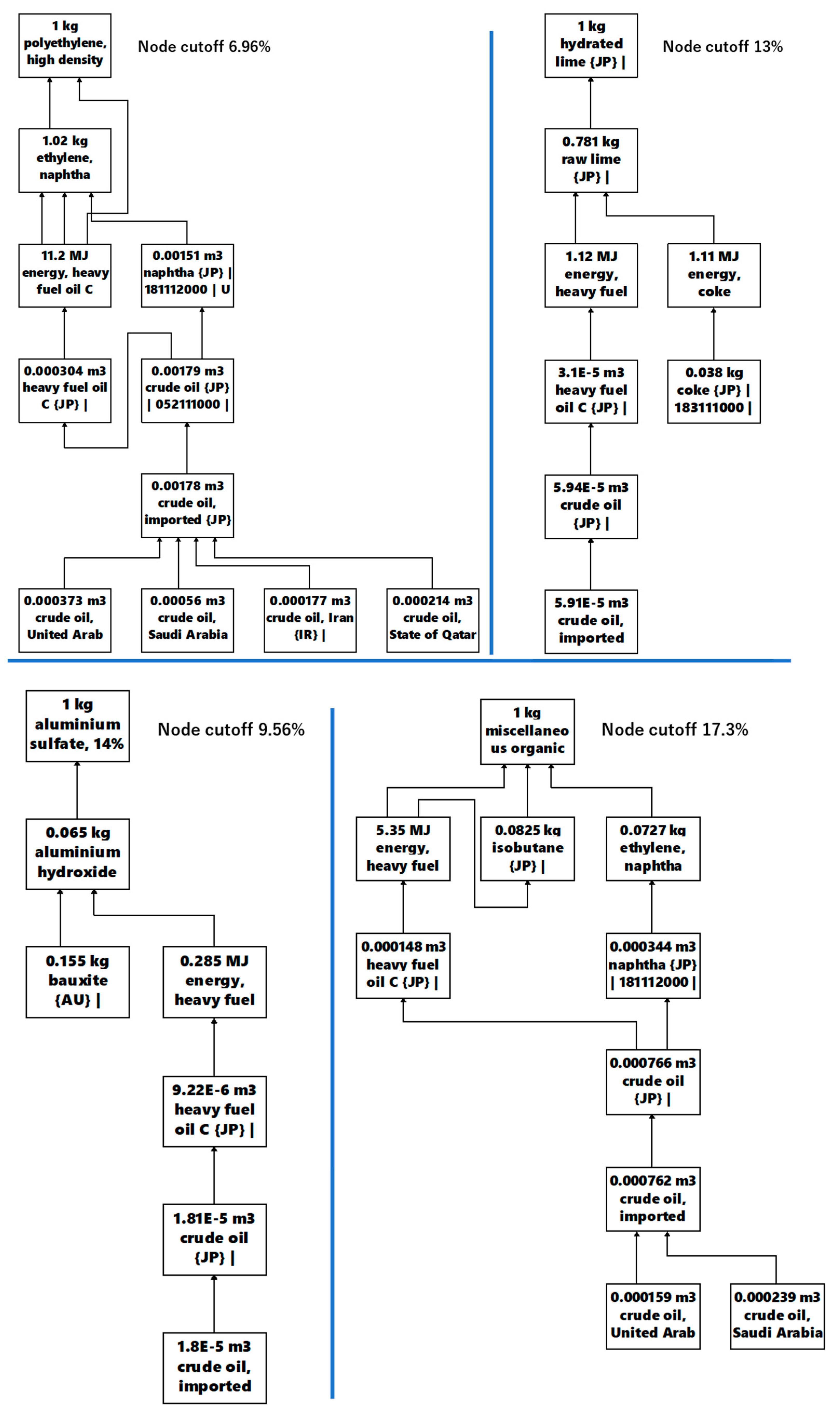

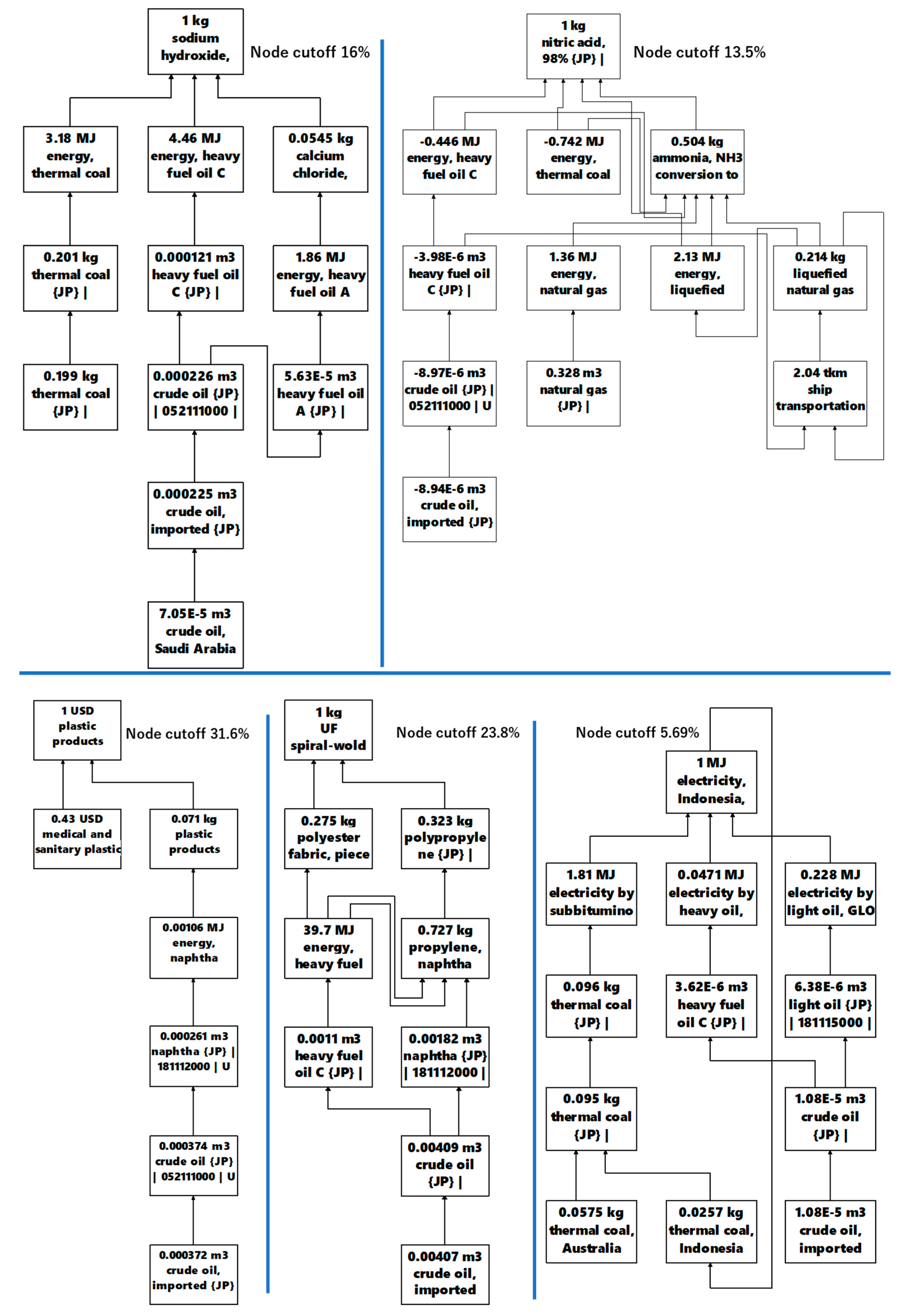

4. Data Inventory

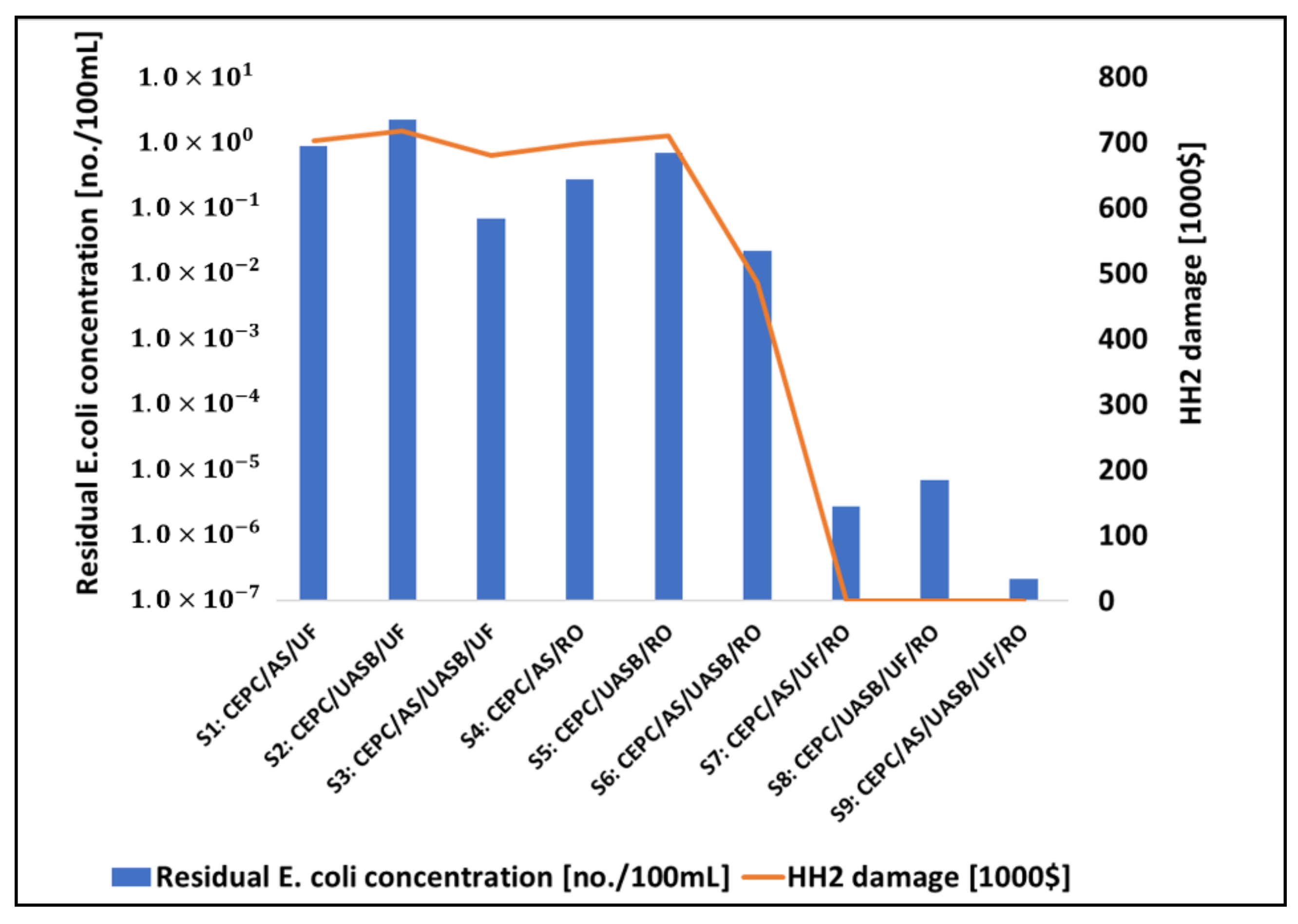

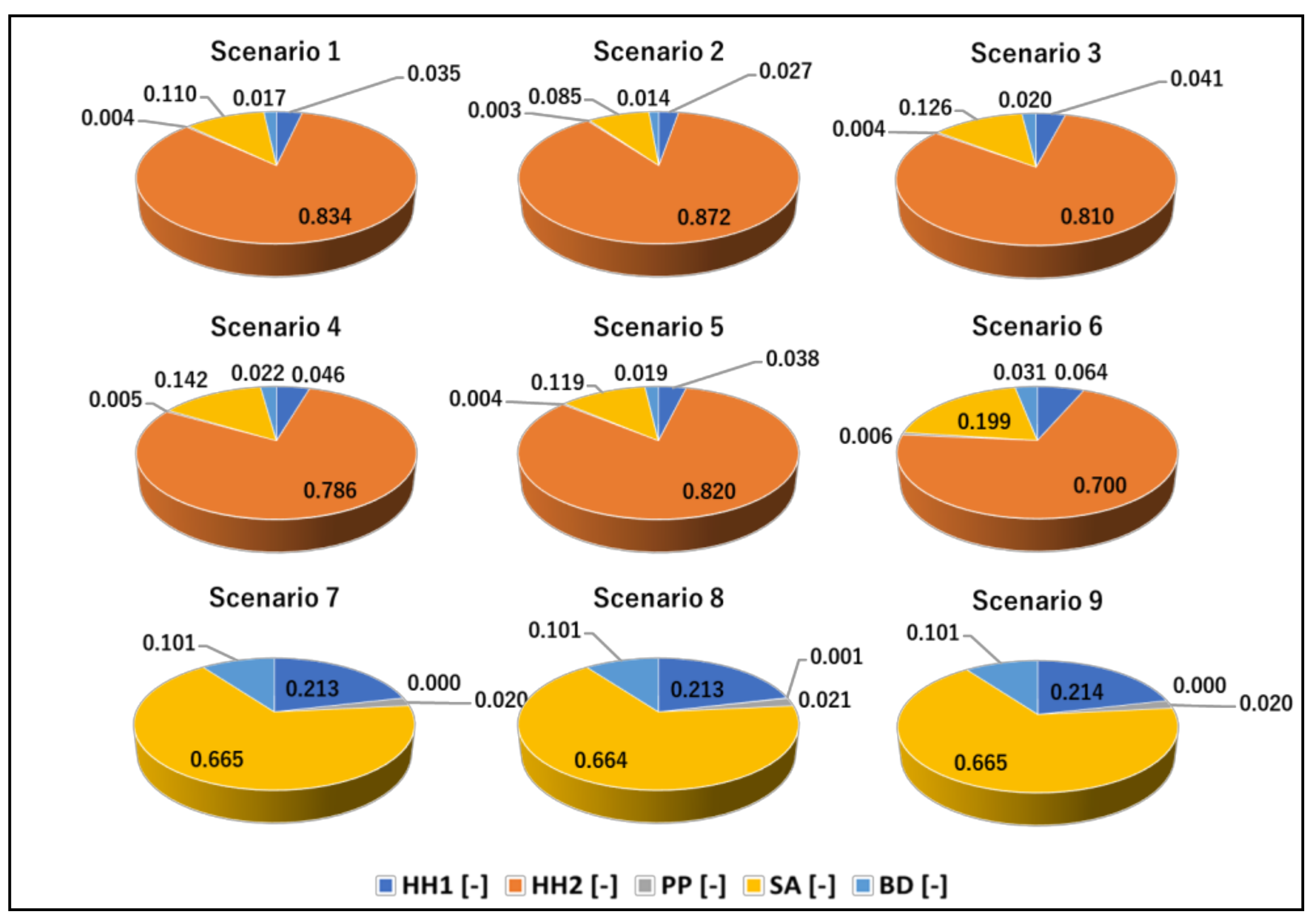

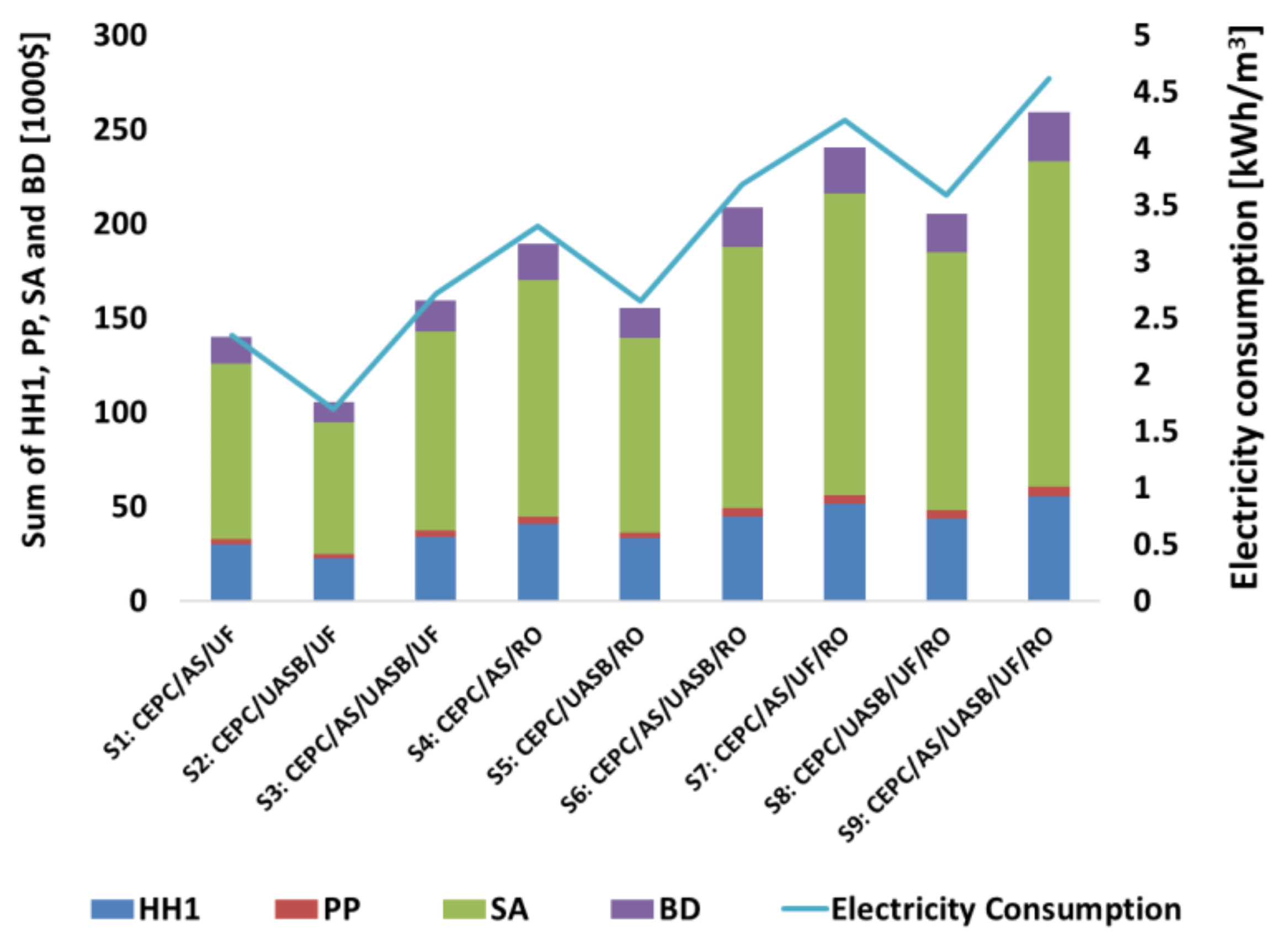

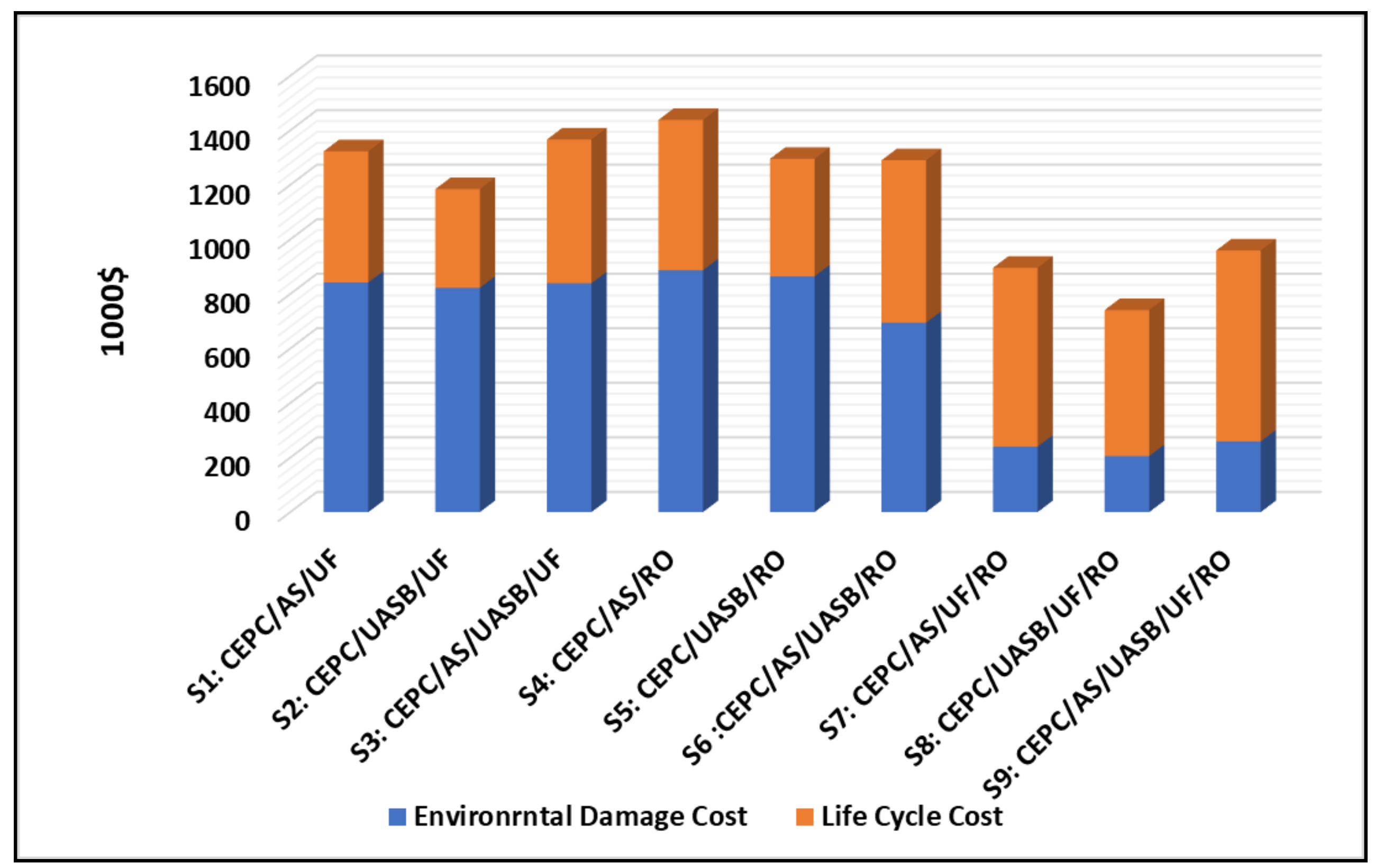

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gómez-Sanabria, A.; Zusman, E.; Höglund-Isaksson, L.; Klimont, Z.; Lee, S.; Akahoshi, K.; Farzaneh, H.; Chairunnisa. Sustainable wastewater management in Indonesia’s fish processing industry: Bringing governance into scenario analysis. J. Environ. Manag. 2020, 275, 111241. [Google Scholar]

- Farzaneh, H. Devising a Clean Energy Strategy for Asian Cities; Springer: New York, NY, USA, 2018. [Google Scholar]

- Muga, H.E.; Mihelcic, J.R. Sustainability of wastewater treatment technologies. J. Environ. Manag. 2008, 88, 437–447. [Google Scholar] [CrossRef] [PubMed]

- Hellweg, S.; Mila, I.; Canals, L. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- Awad, H.; Gar Alalm, M.; El-Etriby, H.K. Environmental and cost life cycle assessment of different alternatives for improvement of wastewater treatment plants in developing countries. Sci. Total Environ. 2019, 660, 57–68. [Google Scholar] [CrossRef]

- Lopes, T.A.; Queiroz, L.M.; Torres, E.A.; Kiperstok, A. Low complexity wastewater treatment process in developing countries: A LCA approach to evaluate environmental gains. Sci. Total Environ. 2020, 720, 137593. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Chenel, S.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Eco-efficiency analysis of Spanish WWTPs using the LCA + DEA method. Water Res. 2015, 68, 651–666. [Google Scholar] [CrossRef]

- Larrey-Lassalle, P.; Catel, L.; Roux, P.; Rosenbaum, R.K.; Lopez-Ferber, M.; Junqua, G.; Loiseau, E. An innovative implementation of LCA within the EIA procedure: Lessons learned from two wastewater treatment plant case studies. Environ. Impact Assess. Rev. 2017, 63, 95–106. [Google Scholar] [CrossRef]

- Hao, X.; Wang, X.; Liu, R.; Li, S.; van Loosdrecht, M.C.M.; Jiang, H. Environmental impacts of resource recovery from wastewater treatment plants. Water Res. 2019, 160, 268–277. [Google Scholar] [CrossRef]

- Itsubo, N.; Inaba, A. LIME3: Environmental Impact Assessment Method for Realizing Global Scale LCA; Maruzen Publishing: Tokyo, Japan, 2018. (In Japanese) [Google Scholar]

- Bai, S.; Wang, X.; Huppes, G.; Zhao, X.; Ren, N. Using site-specific life cycle assessment methodology to evaluate Chinese wastewater treatment scenarios: A comparative study of site-generic and site-specific methods. J. Clean. Prod. 2017, 144, 1–7. [Google Scholar] [CrossRef]

- Lu, B.; Du, X.; Huang, S. The economic and environmental implications of wastewater management policy in China: From the LCA perspective. J. Clean. Prod. 2017, 142, 3544–3557. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Nguyen, T.V.; Nghiem, D.L. Contribution of the construction phase to environmental impacts of the wastewater treatment plant. Sci. Total Environ. 2020, 743, 140658. [Google Scholar] [CrossRef]

- Yokoi, R.; Nakatani, J.; Motoshita, M.; Moriguchi, Y. Calculation and comparison of weighting factors based on different methods in life cycle impact assessment. J. Life Cycle Assess. Jpn. 2015, 11, 278–291. [Google Scholar] [CrossRef] [Green Version]

- 2013 Graduation Research Topic 3. Impact Assessment of LCA. Available online: http://www.urm.t.u-tokyo.ac.jp/research/graduation2013_2.pdf (accessed on 15 July 2020). (In Japanese).

- Barjoveanu, G.; Comandaru, I.M.; Rodriguez-Garcia, G.; Hospido, A.; Teodosiu, C. Evaluation of water services system through LCA. A case study for Iasi city, Romania. Int. J. Life Cycle Assess. 2013, 19, 449–462. [Google Scholar] [CrossRef]

- Risch, E.; Loubet, P.; Núñez, M.; Roux, P. How environmentally significant is water consumption during wastewater treatment? Application of recent developments in LCA to WWT technologies used at 3 contrasted geographical locations. Water Res. 2014, 57, 20–30. [Google Scholar] [CrossRef]

- Thibodeau, C.; Monette, F.; Bulle, C.; Glaus, M. Comparison of Black water source-separation and conventional sanitation systems using life cycle assessment. J. Clean. Prod. 2014, 67, 45–57. [Google Scholar] [CrossRef]

- Lam, L.; Kurisu, K.; Hanaki, K. Comparative environmental impacts of source-separation systems for domestic wastewater management in rural China. J. Clean. Prod. 2015, 104, 185–198. [Google Scholar] [CrossRef]

- Fuchs, V.J.; Mihelcic, J.R.; Gierke, J.S. Life cycle assessment of vertical and horizontal flow constructed wetlands for wastewater treatment considering nitrogen and carbon greenhouse gas emissions. Water Res. 2011, 45, 2073–2081. [Google Scholar] [CrossRef]

- Buonocore, E.; Mellino, S.; De Angelis, G.; Liu, G.; Ulgiati, S. Life cycle assessment indicators of urban wastewater and sewage sludge treatment. Ecol. Indic. 2018, 94, 13–23. [Google Scholar] [CrossRef]

- O’Connor, M.; Garnier, G.; Batchelor, W. Life cycle assessment comparison of industrial effluent management strategies. J. Clean. Prod. 2014, 79, 168–181. [Google Scholar] [CrossRef]

- Amini, A.; Kim, Y.; Zhang, J.; Boyer, T.; Zhang, Q. Environmental and economic sustainability of ion exchange drinking water treatment for organics removal. J. Clean. Prod. 2015, 104, 413–421. [Google Scholar] [CrossRef]

- Hong, J.; Hong, J.; Otaki, M.; Jolliet, O. Environmental and economic life cycle assessment for sewage sludge treatment processes in Japan. Waste Manag. 2009, 29, 696–703. [Google Scholar] [CrossRef] [PubMed]

- Harder, R.; Peters, G.M.; Molander, S.; Ashbolt, N.J.; Svanström, M. Including pathogen risk in life cycle assessment: The effect of modelling choices in the context of sewage sludge management. Int. J. Life Cycle Assess. 2015, 21, 60–69. [Google Scholar] [CrossRef] [Green Version]

- AVILEN AI Trend. Available online: https://ai-trend.jp/basic-study/estimator/likehood-score-fisher/ (accessed on 1 December 2020). (In Japanese).

- Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. Fit-for-purpose wastewater treatment: Conceptualization to development of decision support tool (I). Sci. Total Environ. 2017, 607–608, 600–612. [Google Scholar] [CrossRef] [PubMed]

- Nihon Suido Consultants Co., Ltd. 2017 Indonesian Fisheries Processing Industry Co-Benefit Wastewater Countermeasure Survey Commissioned Business Report; Nihon Suido Consultants Co., Ltd.: Tokyo, Japan, 2018; pp. 43, 54, 404, 417. (In Japanese) [Google Scholar]

- Freire, C.S.; Silvestre, A.J.; Neto, C.P. Carbohydrate-derived chlorinated compounds in ECF bleaching of hardwood pulps: Formation, degradation, and contribution to AOX in a bleached Kraft pulp mill. Environ. Sci. Technol. 2003, 37, 811–814. [Google Scholar] [CrossRef] [PubMed]

- Žarković, D.B.; Todorović, Ž.N.; Rajaković, L.V. Simple and cost-effective measures for the improvement of paper mill effluent treatment—A case study. J. Clean. Prod. 2011, 19, 764–774. [Google Scholar] [CrossRef]

- EPA. The United States Environmental Protection Agency. Emerging Technologies for Wastewater Treatment and In-Plant Wet Weather Management. 2013. Available online: https://www.epa.gov/sites/production/files/2019-02/documents/emerging-tech-wastewater-treatment-management.pdf (accessed on 17 September 2020).

- Doka, G. Life cycle inventory of wastewater treatment. Part IV Chapter 4. In Life Cycle Inventories of Waste Treatment Services; Ecoinvent Report No. 13; Swiss Centre for Life Cycle Inventories: Dubendorf, Switzerland, 2003. [Google Scholar]

- Foley, J.; De Haas, D.; Hartley, K.; Lant, P. Comprehensive life cycle inventories of alternative wastewater treatment systems. Water Res. 2010, 44, 1654–1666. [Google Scholar] [CrossRef] [PubMed]

- Bonton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. Desalination 2012, 284, 42–54. [Google Scholar] [CrossRef]

- Buyukkamaci, N.; Koken, E. Economic evaluation of alternative wastewater treatment plant options for pulp and paper industry. Sci. Total Environ. 2010, 408, 6070–6078. [Google Scholar] [CrossRef]

- Pizzichini, M.; Russo, C.; Meo, C.D. Purification of pulp and paper wastewater, with membrane technology, for water reuse in a closed loop. Desalination 2005, 178, 351–359. [Google Scholar] [CrossRef]

- Von Sperling, M. Wastewater characteristics, treatment and disposal. Water Intell. Online 2015, 6, 224–225. [Google Scholar] [CrossRef]

- Plakas, K.V.; Georgiadis, A.A.; Karabelas, A.J. Sustainability assessment of tertiary wastewater treatment technologies: A multi-criteria analysis. Water Sci. Technol. 2015, 73, 1532–1540. [Google Scholar] [CrossRef]

- European Environment Agency. Glossary of Terms Related to Urban Waste Water. 2020. Available online: https://www.eea.europa.eu/help/glossary/eea-glossary/population-equivalent (accessed on 17 September 2020).

- Nsavyimana, G.; Kaboneka, S.; Bigumandondera, P.; Ngahane, E.L.; Ndikumana, T.; Vasel, J.L. Exploring a new approach of the population equivalent concept through a detailed characterization of grey and Black waters. Int. J. Adv. Sci. Res. Eng. 2020, 6, 32–49. [Google Scholar] [CrossRef]

- International Energy Situation Survey. 2017. Available online: https://www.meti.go.jp/meti_lib/report/H29FY/000219.pdf (accessed on 17 September 2020). (In Japanese).

- Average Land Price in Greater Jakarta Q1 2019, by Region. Available online: https://www.statista.com/statistics/1042205/indonesia-average-land-price-in-greater-jakarta/ (accessed on 17 September 2020).

- Indonesia Monthly Earnings. Available online: https://www.ceicdata.com/en/indicator/indonesia/monthly-earnings (accessed on 17 September 2020).

- World Steel Prices. Available online: https://worldsteelprices.com/ (accessed on 17 September 2020).

- Made in China TM. Available online: https://tianmagroup.en.made-in-china.com/product/rjAxvRBPHmkZ/China-E-Glass-Fiberglass-Direct-Roving-for-Winding-EDR2400-T908.html (accessed on 17 September 2020).

- Trading Economics. Available online: https://tradingeconomics.com/commodity/aluminum (accessed on 17 September 2020).

- Lime Price Per kg. Available online: https://motormatcher.com.au/forum/lime-price-per-kg-f644a7 (accessed on 17 September 2020).

- City of Bloomington Illinois. Available online: https://www.cityblm.org/Home/ShowDocument?id=10595 (accessed on 17 September 2020).

- Cost of Concreting Per m3 (Cubic Metre). Available online: https://www.serviceseeking.com.au/blog/concrete-cost-per-cubic-metre/#:~:text=The%20supply%20cost%20of%20concreting,concreters%20run%20from%20%2480%2Fhr (accessed on 17 September 2020).

- Plastics Recycling Update. Available online: https://resource-recycling.com/plastics/2020/02/12/hdpe-prices-fall-from-record-highs/#:~:text=The%20national%20average%20price%20of%20color%20HDPE%20dropped%20again%20this,at%2012.47%20cents%20per%20pound (accessed on 17 September 2020).

- Baniyababu.com. Available online: http://baniyababu.com/product/grocery-and-staples/turti-alum-1-kg/ (accessed on 17 September 2020).

- Nikkei Asin Review. Available online: https://asia.nikkei.com/Business/Markets/Commodities/Caustic-soda-prices-on-upward-trend-in-Asian-markets (accessed on 17 September 2020).

- Chemical Profile: Nitric Acid. Available online: https://www.icis.com/explore/resources/news/2008/05/19/9124327/chemical-profile-nitric-acid/ (accessed on 17 September 2020).

- Monotaro. Available online: https://www.monotaro.com/g/01240073/?t.q=%83%7C%83%8A%83v%83%8D%83s%83%8C%83%93%83t%83B%83%8B%83%5E%81%5B%20%8E%BF%97%CAspm=a2700.7724857.normalList.26.5770df268OjVeQ&s=p (accessed on 17 September 2020). (In Japanese).

- Alibaba.com. Available online: https://www.alibaba.com/product-detail/UFf160-Polyvinylidine-fluoride-PVDF-spiral-wound_60838240576.html?spm=a2700.7724857.normalList.81.67c1c0a5Uzi1Es (accessed on 17 September 2020).

- David, W.; Widianingsih, N.N.; Ploeger, A. Water usage pattern on different group residing in vicinity Harapan rainforest. Agric. Agric. Sci. Procedia 2016, 9, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Preliminary Treatment and Primary Sedimentation. Available online: http://www.waterpathogens.org/book/preliminary-treatment (accessed on 8 July 2020).

- Health Canada. Canadian Guidelines for Domestic Reclaimed Water for Use in Toilet and Urinal Flushing; Ministry of Health: Ottawa, ON, Canada, 2010. [Google Scholar]

- EPHC/NHMRC/NRMMC. Australian Guidelines for Water Recycling: Augmentation of Drinking Water Supplies (Phase 2); Environment Protection and Heritage Council, National Health and Medical Research Council, Natural Resource Management Ministerial Council: Canberra, Australia, 2008. [Google Scholar]

- Anaerobic Sludge Blanket Reactors. Available online: http://www.waterpathogens.org/book/anaerobic-sludge-blanket-reactors (accessed on 8 July 2020).

- Health Canada. Guidelines for Canadian Drinking Water Quality: Guideline Technical Document—Escherichia coli; Health Canada: Ottawa, ON, Canada, 2013. [Google Scholar]

- Health Canada. Guidelines for Canadian Drinking Water Quality: Guideline Technical Document—Enteric Viruses; Health Canada: Ottawa, ON, Canada, 2011. [Google Scholar]

- Lim, K.; Hamilton, A.J.; Jiang, S.C. Assessment of public health risk associated with viral contamination in harvested urban stormwater for domestic applications. Sci. Total Environ. 2015, 523, 95–108. [Google Scholar] [CrossRef]

- Vergara, G.; Rose, J.; Gin, K. Risk assessment of noroviruses and human adenoviruses in recreational surface waters. Water Res. 2016, 103, 276–282. [Google Scholar] [CrossRef]

- Messner, M.J.; Berger, P.; Nappier, S.P. Fractional Poisson-A simple dose-response model for human norovirus. Risk Anal. 2014, 34, 1820–1829. [Google Scholar] [CrossRef]

- Schmidt, P.J. Norovirus dose-response: Are currently available data informative enough to determine how susceptible humans are to infection from a single virus? Risk Anal. 2014, 35, 1364–1383. [Google Scholar] [CrossRef]

- Robertson, L.; Greig, J.; Gjerde, B.; Fazil, A. The potential for acquiring cryptosporidiosis or giardiosis from consumption of mung bean sprouts in Norway: A preliminary step-wise risk assessment. Int. J. Food Microbiol. 2005, 98, 291–300. [Google Scholar] [CrossRef]

- US EPA. Quantitative Microbial Risk Assessment to Estimate Illness in Freshwater Impacted by Agricultural Animal Sources of Fecal Contamination; EPA 822-R-10-005; Office of Water, US EPA: Washington, DC, USA, 2010. [Google Scholar]

- Mok, H.; Barker, S.F.; Hamilton, A.J. A probabilistic quantitative microbial risk assessment model of norovirus disease burden from wastewater irrigation of vegetables in Shepparton, Australia. Water Res. 2014, 54, 347–362. [Google Scholar] [CrossRef]

- Gibney, K.B.; O’Toole, J.; Sinclair, M.; Leder, K. Disease burden of selected gastrointestinal pathogens in Australia, 2010. Int. J. Infect. Dis. 2014, 28, 176–185. [Google Scholar] [CrossRef] [Green Version]

- Crabtree, K.; Gerba, C.; Rose, J.; Haas, C. Waterborne adenovirus: A risk assessment. Water Sci. Technol. 1997, 35, 1–6. [Google Scholar] [CrossRef]

| Area | Goal | Assessment Model | LCA Method | Impact Category | Reference |

|---|---|---|---|---|---|

| Romania | To assess the environmental profile of the entire water services system for Iasi city, Romania | LCA | CML2000, Ecological scarcity (endpoint) | Environmental damages | [16] |

| France | To assess the impacts of water consumption linked to different wastewater treatment technologies | LCA | ReCiPe | Human health, Ecosystems, Resources | [17] |

| Canada | To compare the environmental performances of black water source-separation (BWS) and conventional WWTP | LCA | Impact-2002+ | Human health, Ecosystem quality, Climate change, Resources | [18] |

| China | To evaluate the life cycle and local environmental impacts of source separation systems | LCA | LIME | Freshwater use, Global warming, Acidification, Eutrophication | [19] |

| USA | To determine which constructed wetlands for wastewater have the lowest environmental impacts | LCA | Eco-indicator99, (CML 2 Baseline 2000 is used in part) | Environmental damages | [20] |

| Italy | To compare the environmental performance of different scenarios for wastewater and sludge disposal in a wastewater treatment plant in Italy | LCA | ReCiPe midpoint | Climate change, Fossil depletion, Freshwater eutrophication, Human toxicity, Particulate matter formation, Photochemical oxidant formation, Terrestrial acidification | [21] |

| Australia | To evaluate and compare the environmental performance of fourteen pulp and paper effluent treatment technology configurations | LCA | CML–IA baseline 4.1 | Eutrophication, human toxicity, freshwater aquatic ecotoxicity, GHG emissions | [22] |

| USA | To evaluate the environmental and economic impacts of ion exchange technology | LCA + Cost analysis | TRACI 2.1 | Environmental damages, Operation cost | [23] |

| Japan | To assess the environmental and economic impacts of sewage sludge | LCA+ Life Cycle Cost (LCC) | USES-LCA model | Global warming potential, Acidification potential, Human toxicity potential, Land use, Cost | [24] |

| Sweden | To investigate the use of quantitative microbial risk assessment (QMRA) can be an adequate way of integrating pathogen impact potential in LCA | LCA+ QMRA | ReCiPe | Human health | [25] |

| HH 1 | BD 2 | SA 3 | PP 4 |

|---|---|---|---|

|

|

|

|

| −0.63 | −0.016 | −0.0069 | −0.0072 | −0.0023 |

| Sumatera | 13,947 |

| Java | 26,840 |

| Bali | 5231 |

| Kalimantan | 8880 |

| Sulawesi | 5137 |

| Maluku-Papua | 1767 |

| BOD 1 [mg/L] | COD 2 [mg/L] | TSS 3 [mg/L] | SS 4 [mg/L] | |

|---|---|---|---|---|

| Influent | 1400 [28] | 2900 [28] | 1900 [29] | 4000 [30] |

| Removal Efficiency (%) | ||||

|---|---|---|---|---|

| COD | BOD | TSS | SS | |

| CEPC 1 | 54 | 58 | 86 | 88 |

| AS 2 | 62 | 52 | 37 | 37 |

| UASB 3 | 68 | 68 | 0 | 0 |

| UF 4 | 77 | 75 | 96 | 96 |

| RO 5 | 89 | 91 | 100 | 100 |

| Scenario No. | Primary Treatment | Secondary Treatment | Tertiary Treatment |

|---|---|---|---|

| 1 | CEPC | AS | UF |

| 2 | CEPC | UASB | UF |

| 3 | CEPC | AS + UASB | UF |

| 4 | CEPC | AS | RO |

| 5 | CEPC | UASB | RO |

| 6 | CEPC | AS + UASB | RO |

| 7 | CEPC | AS | UF + RO |

| 8 | CEPC | UASB | UF + RO |

| 9 | CEPC | AS + UASB | UF + RO |

| Scenario No. | BOD Concentration [mg/L] | COD Concentration [mg/L] | SS Concentration [mg/L] |

|---|---|---|---|

| 1 | 56.3 | 146 | 18.8 |

| 2 | 47.4 | 97.4 | 29.8 |

| 3 | 18.0 | 46.8 | 18.8 |

| 4 | 26.9 | 52.6 | 0.00 |

| 5 | 22.7 | 35.1 | 0.00 |

| 6 | 8.61 | 16.8 | 0.00 |

| 7 | 6.19 | 13.2 | 0.00 |

| 8 | 5.21 | 8.77 | 0.00 |

| 9 | 1.98 | 4.21 | 0.00 |

| Component | CEPC | AS | UASB | UF | RO |

|---|---|---|---|---|---|

| Construction [] 1 | |||||

| Frech concrete | 0.0360 [32,33] | 0.0780 [33] | 0.0120 [33] | 0.00300 [34] | 0.00328 [32] |

| Ordinary steel | 0.00128 [30,31] | 0.00276 [33] | 0.000425 [33] | 0.000760 [34] | 0.000760 [34] |

| Glass fiber (direct roving) | 0.0000294 [33] | 0.0000637 [33] | 0.00000998 [33] | 0.000150 [34] | 0.000150 [34] |

| Aluminum | 0.0000131 [33] | 0.0000283 [33] | 0.00000435 [33] | 0 | 0 |

| Polyethylene, high density (HDPE) | 0 | 0.0000793 [33] | 0.0000122 [33] | 0 | 0 |

| Operation (Chemicals) [mg/L] 2 | |||||

| Hydrated lime | 400 [35] | 0 | 0 | 0 | 0 |

| Aluminium sulfate, 14% solution | 10 [35] | 0 | 0 | 0 | 0 |

| Anionic surface-activate agents (Anionic polymer) | 6 [35] | 0 | 0 | 0 | 0 |

| Sodium hydroxide, 97% | 0 | 0 | 0 | 4.20 [34] | 4.20 [34] |

| Nitric acid, 98% | 0 | 0 | 0 | 1.85 [36] | 0 |

| Plastic products which are not elsewhere classified (Filters for the prefilters) | 0 | 0 | 0 | 0.260 [34] | 0.260 [34] |

| Ultrafiltration Spiral wound modules | 0 | 0 | 0 | 0.510 [34] | 0.510 [34] |

| Land occupation [] 3 | Land occupation [] | ||||

| Resources, building site, land use, land occupation | 0.05 [37] | 0.185 [37] | 0.065 [37] | 0.083 [38] | 0.25 [38] |

| Electricity consumption [] 1 | |||||

| Electricity, Indonesia | 0.38 [22] | 1.03 [22] | 0.37 [22] | 0.94 [22] | 1.90 [22] |

| Items | Value | Unit | Reference |

|---|---|---|---|

| Electricity | 1051 | [41] | |

| Land | 17.93 | [42] | |

| Labor | 183 | [43] | |

| Steel | 504 | [44] | |

| Fiberglass | 625 | [45] | |

| Aluminum | 1777 | [46] | |

| Lime | 17 | [47] | |

| Anionic polymer | 1.25 | [48] | |

| Concrete | 300 | [49] | |

| HDPE | 54.81 | [50] | |

| Alum | 120 | [51] | |

| Membrane cleaning agent (NaOH) | 375 | [52] | |

| Nitric Acid | 262.5 | [53] | |

| Filters | 889 | [54] | |

| UF spiral-wound modules | 800 | [55] |

| WWTP | Labor/Year |

|---|---|

| CEPC, AS and USAB | 13 |

| UF | 17 [38] |

| RO | 12 [38] |

| Exposure Source | Frequency per Year n [th/year] | |

|---|---|---|

| Drinking | 2800 [56] | 365 |

| E. coli [-] | Campylobacter [-] | Salmonella spp. [-] | Adenoviruses [-] | Noroviruses [-] | Rotavirus [-] | Cryptosporidium [-] | Giardia spp. [-] | Reference | |

|---|---|---|---|---|---|---|---|---|---|

| CEPC | 1.06 | 0.955 | 0.955 | 2.6 | 2.6 | 2.6 | 0.14 | 0.62 | [57] |

| AS | 1.5 | 1.5 | 1.5 | 1.25 | 1.25 | 1.25 | 0.75 | 0.75 | [58] |

| UASB | 1.1 | 1.2 | 1 | 0.7 | 0.2 | 0 | 0.3 | 0.3 | [59] |

| UF | 5 | 5 | 4.5 | 4.5 | 4.5 | 6.2 | 6.35 | [60] | |

| RO | 5.5 | 5.5 | 5.5 | 4.85 | 4.85 | 4.85 | 8 | 8 | [61] |

| Microorganisms | Reference | |

|---|---|---|

| E. coli | 31,622,777 | [58] |

| Campylobacter | 3162 | [59] |

| Salmonella spp. | 10,000 | [58] |

| Adenoviruses | 316 | [58] |

| Noroviruses | 316 | [58] |

| Rotavirus | 3162 | [58] |

| Cryptosporidium | 100 | [59] |

| Giardia spp. | 3162 | [59] |

| Pathogens | Beta-Poisson | Exponential | Reference | |

|---|---|---|---|---|

| [-] | N50 [-] | r [-] | ||

| E. coli | 0.2019 | 1120 | – | [58] |

| Salmonella spp. | 0.3126 | 23,600 | – | [62] |

| Adenovirus | – | – | 0.4172 | [63] |

| Norovirus | – | – | 0.722 | [64] |

| Campylobacter | 0.145 | 896 | – | [65] |

| Rotavirus | 0.27 | 5.6 | – | [66] |

| Cryptosporidium parvum | – | – | 0.004 | [67] |

| Giardia spp. | – | – | 0.0199 | [68] |

| Pathogens | Maximum Disease Burden [DALY 1/year] | Susceptibility Fraction | Reference | |

|---|---|---|---|---|

| E. coli | 0.4 | 0.055 | 0.9 | [69] |

| Campylobacter | 0.35 | 0.00335 | 0.9 | [70] |

| Salmonella spp. | 0.2 | 0.0446 | 0.9 | [71] |

| Adenovirus | 0.5 | 0.0534 | 0.9 | [71] |

| Norovirus | 0.55 | 0.0006 | 0.9 | [70] |

| Rotavirus | 0.67 | 0.0084 | 0.06 | [70] |

| Cryptosporidium | 0.45 | 0.00195 | 0.9 | [69] |

| Giardia spp. | 0.45 | 0.00225 | 0.9 | [69] |

| Scenario | HH1 1 | HH2 2 | PP | SA | BD | Total Damage | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| DALYs | 1000$ | DALYs | 1000$ | Ton | 1000$ | 1000$ | 1000$ | 1000$ | ||

| 1 | ||||||||||

| 2 | ||||||||||

| 3 | ||||||||||

| 4 | ||||||||||

| 5 | ||||||||||

| 6 | ||||||||||

| 7 | ||||||||||

| 8 | ||||||||||

| 9 | ||||||||||

| Scenario No. | |||

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 | |||

| 5 | |||

| 6 | |||

| 7 | |||

| 8 | |||

| 9 |

| Scenario No. | Construction Cost 10,000 [$] | Land Cost 10,000 [$] | Annual Operation 10,000 [$/Y] | LCC * 10,000 [$] |

|---|---|---|---|---|

| 1 | ||||

| 2 | ||||

| 3 | ||||

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 7 | ||||

| 8 | ||||

| 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takeshita, S.; Farzaneh, H.; Dashti, M. Life-Cycle Assessment of the Wastewater Treatment Technologies in Indonesia’s Fish-Processing Industry. Energies 2020, 13, 6591. https://doi.org/10.3390/en13246591

Takeshita S, Farzaneh H, Dashti M. Life-Cycle Assessment of the Wastewater Treatment Technologies in Indonesia’s Fish-Processing Industry. Energies. 2020; 13(24):6591. https://doi.org/10.3390/en13246591

Chicago/Turabian StyleTakeshita, Shinji, Hooman Farzaneh, and Mehrnoosh Dashti. 2020. "Life-Cycle Assessment of the Wastewater Treatment Technologies in Indonesia’s Fish-Processing Industry" Energies 13, no. 24: 6591. https://doi.org/10.3390/en13246591