The Use of a Heat Pump in a Ventilation Unit as an Economical and Ecological Source of Heat for the Ventilation System of an Indoor Swimming Pool Facility

Abstract

:1. Introduction

1.1. Energy-Saving Solutions for Swimming Pool Ventilation

1.2. Pool Air Handling Units

1.3. Heat Sources for Heating Ventilation Air

- Heating the swimming pool water;

- The heating system—convection or floor heating installation;

- Ventilation air heating;

- Heating domestic hot water, including showers.

- Substation supplied by the district heating network (with or without cogeneration);

- Gas boiler;

- Biomass boiler;

- Electrical energy (power supply for electric heaters or heat pumps);

- Solar energy.

1.4. Research Gap and Scope of the Research

1.5. Research Goal

2. Materials and Methods

2.1. The Algorithm for Assessing Each Variant

2.2. Variants

2.2.1. Analyzed Air Handling Units

- (1)

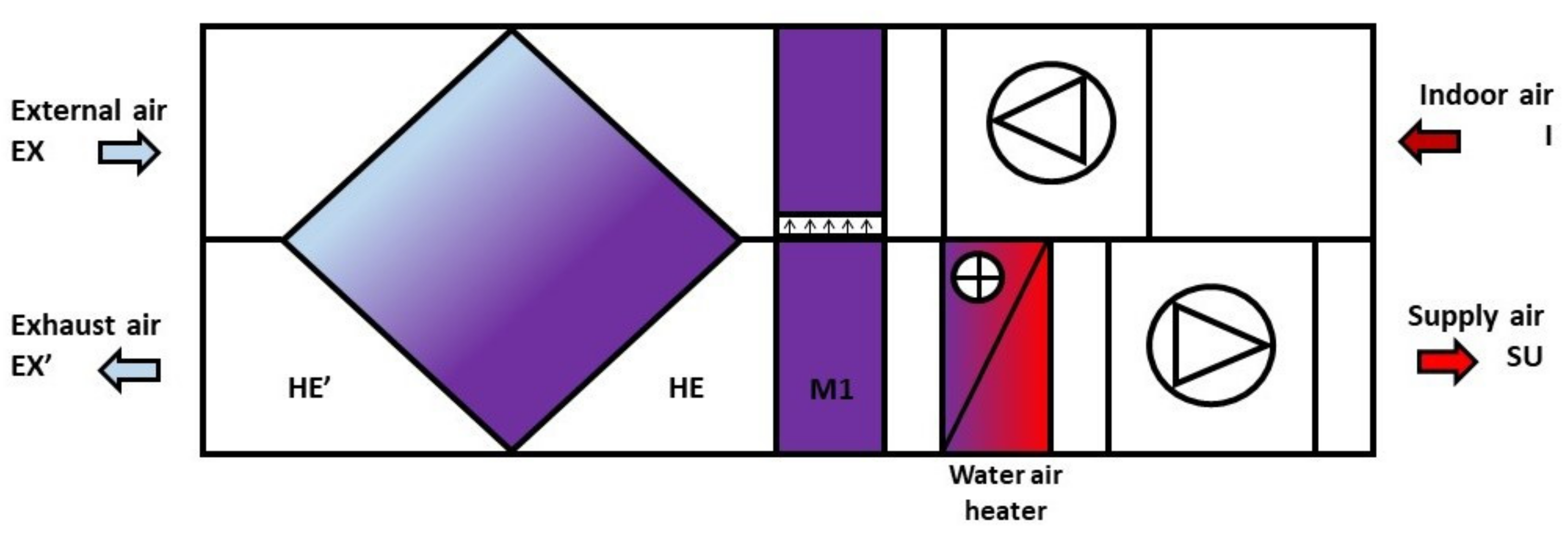

- Air handling unit AHU1, with a crossflow heat exchanger with 73–83% total heat recovery efficiency (assumed average of 78%) as well as recirculation and a water heater (Figure 1).

- (2)

- Air handling unit AHU2, with a heat exchanger with 73–75% total heat recovery efficiency (assumed average of 74%), a heat pump (with an air condenser), and a heat exchanger (Figure 2).

- (1)

- Air handling unit AHU1:

- PSU = 0.0242 V2SU + 1.0748 VSU + 0.02, [kW], where VSU [m3/s], PSU [kW];

- PEX = 0.0279 V2SU + 0.9794 VSU + 0.04, [kW].

- (2)

- Air handling unit AHU2:

- PSU = 0.0493 V2SU + 1.0036 VSU + 0.12, [kW];

- PEX = 0.0621 V2SU + 0.8686 VSU + 0.14, [kW].

2.2.2. Devices for Heating the Ventilation Air

- (1)

- A water heater supplied with water heated by a gas boiler (AHU1);

- (2)

- A heater supplied with process water heated in the heat exchanger supplied (AHU1);

- Municipal District Heating MDH with cogeneration;

- Municipal District Heating MDH without cogeneration;

- From MDH Poznań 2016;

- From MDH Poznań 2018.

- (3)

- A heat pump condenser and a water heater (AHU2).

2.2.3. Heat Pump in the Air Handling Units (AHU2)

2.2.4. Fans and Pumps in the Air Handling Units

- (1)

- Supply air streams VSU of 50 m3/(h·m2P) and 70 m3/(h.m2P)—these are air streams that are able to receive moisture gains from evaporation in the swimming pool and the recreational pool, respectively;

- (2)

- Supply airflow during the day: B1 pool—15,000 m3/h; B2 pool—21,000 m3/h; at night between 10:00 p.m. and 6:00 a.m. the airflow was reduced by 20% for both pools;

- (3)

- Nominal powers of the fan motors and the devices for the B1 pool—15,000 m3/h:

- Air handling unit with recuperator and heater (without heat pump)—PSU = 4.0 kW; PEX = 3.7 kW; annual electricity consumption—188 kWh/(m2/year);

- Air handling unit with a recuperator, a heater, and a heat pump—PSU = 5.2 kW; PEX = 5.0 kW; annual electricity consumption—250 kWh/(m2/year);

- Heater circuit pump—75 W; annual electricity consumption 2.2 kWh/(m2/year).

- (4)

- Nominal powers of the fan motors and devices for the B2 pool—21,000 m3/h:

- Air handling unit with recuperator and a heater (without a heat pump)—PSU = 8.8 kW; PEX = 9.4 kW; annual electricity consumption—467 kWh/(m2/year);

- Air handling unit with a recuperator, heater, and a heat pump—PSU = 9.7 kW; PEX = 5.0 kW; annual electricity consumption—250 kWh/(m2/year);

- Heater circuit pump—125 W; annual electricity consumption 3.7 kWh/(m2/year).

2.2.5. Efficiency of the Air Heating Installations

2.2.6. Summary of All the Analyzed Variants

2.3. Determination of the Final Energy and Primary Energy Indicators

2.3.1. Final Energy Indicator

- —final energy of the heating process (EKH), ;

- —amount of heat required to heat the air (QH,nd), ;

- —efficiency of the air heating system (Table 2), .

- —final energy of the heating process (EKH), ;

- —amount of heat required to heat the air (QH,nd), ;

- —seasonal coefficient of heating efficiency for heating air using a heat pump (Table 2), .

- —final energy of the air circulation process,

2.3.2. Primary Energy Indicator

- —primary energy of the heating process (EPH) or from pumping the air or water (EPel), ;

- —final energy of the heating (EKH) or from pumping the air or water (EKel), ;

- —coefficient of the non-renewable primary energy input for the process related to air heating and air or water pumping (Table 2), .

- The amount of heat necessary to heat the ventilation air and the efficiency of heat transfer, multiplied by the coefficient of the non-renewable primary energy input for the fuel from which the heat is generated (gas, district heat, electricity);

- The electricity required to drive all the devices producing the airflow and that necessary for the system’s operation (fans, heater circulation pump, etc.).

- The electricity required to drive all devices producing the airflow and that necessary for the system’s operation (fans, compressor, and heater circulation pump).

2.4. Determining the CO2 Emissions

- —the final energy of the heating process (EKH) or from pumping air or water (EKel), ;

- —unit CO2 emissions for the fuel/Energy used to heat air (wCO2,H) or for pumping air or water (wCO2,el), (Table 1), .

2.5. Determining the Operating Costs for Each Variant

- —operating costs of the heating process (CH) or for pumping air or water (Cel), ;

- —final energy of the heating process (EKH) or for pumping air or water (EKel), ;

- —unit cost of the fuel or the energy consumed in the process of heating or pumping the air or water

- The costs of the heat carrier that heats the air in the heater (final energy determined for the calculated amount of heat necessary to heat the ventilation air multiplied by the unit price of fuel—gas, network heat, electricity);

- The electricity-related costs for pumping the air or water (electricity supplied to fans and pumps multiplied by the unit price of electricity).

- Pumping air through the fans (electricity supplied to the fans multiplied by the unit price of electricity);

- The power supply to the heat pump compressor for heating air in the air condenser in the unit;

- Potentially the costs of a heat carrier ensuring partial heating of the air in the heater;

- The cost of the electricity required to drive the heater pumps.

2.6. Simple Payback Time (SPBT)

- —the difference in the investment costs, i.e., purchasing the air handling unit in a given variant (AHU1) and purchasing an air handling unit with a heat pump (AHU2), [PLN];

- —the annual operating cost savings as a result of using the air handling unit in a given variant (variants 1–5) and the air handling unit with a heat pump (variant 6), [PLN/year].

2.7. Global Costs

3. Results and Discussion

3.1. Presentation of the Results

3.2. Recommended Solution—Discussion

3.3. Summary

4. Conclusions

- The way the swimming pool is used affects the investment and operating costs of the ventilation system. It has been shown that regardless of the way the swimming pool is used (sports or recreational), a heat pump is a good source of heat for the ventilation air;

- Air handling units with a heat pump are more expensive in terms of investment (by about 20%), but their advantage is lower operating costs by about 18–20% compared to the use of water heaters;

- Global costs calculated for a period of 20 years showed that heat pump unit has lower global costs, which means that that unit is more economically advantageous;

- There are more ecological heat sources for heating ventilation air than a heat pump, but the difference in the primary energy index for a heat pump compared to more environmentally friendly sources was higher by only 8–13%. It should be taking into account that the heat pump can be installed anywhere because the heat source is supplied with electricity, and in some places, there may not be access to district heating using biomass;

- The most ecological heat sources for heating the ventilation air for the swimming pool are even twice as expensive in operation. As the investment in a more expensive air handling unit with a heat pump can pay off after about two to three years, it is a solution worth investing in.

Author Contributions

Funding

Conflicts of Interest

References

- Ratajczak, K.; Szczechowiak, E. Energy consumption decreasing strategy for indoor swimming pools—Decentralized Ventilation system with a heat pump. Energy Build. 2020, 206, 109574. [Google Scholar] [CrossRef]

- Trianti-Stourna, E.; Spyropoulou, K.; Theofylaktos, C.; Droutsa, K.; Balaras, C.; Santamouris, M.; Asimakopoulos, D.; Lazaropoulou, G.; Papanikolaou, N. Energy conservation strategies for sports centers: Part B. Swimming pools. Energy Build. 1998, 27, 123–135. [Google Scholar] [CrossRef]

- Westerlund, L.; Dahl, J. Use of an open absorption heat-pump for energy conservation in a public swimming-pool. Appl. Energy 1994, 49, 275–300. [Google Scholar] [CrossRef]

- Lazzarin, R.M.; Longo, G.A. Comparison of heat recovery systems in public in-door swimming pools. Appl. Therm. Eng. 1996, 16, 561–570. [Google Scholar] [CrossRef]

- Johansson, L.; Westerlund, L. Energy savings in indoor swimming-pools: Comparison between different heat-recovery systems. Appl. Energy 2001, 70, 281–303. [Google Scholar] [CrossRef]

- Lee, W.-S.; Kung, C.-K. Optimization of heat pump system in indoor swimming pool using particle swarm algorithm. Appl. Therm. Eng. 2008, 28, 1647–1653. [Google Scholar] [CrossRef]

- Panaras, G.; Markogiannaki, M.; Tolis, E.; Sakellaris, Y.; Bartzis, J. Experimental and theoretical investigation of air exchange rate of an indoor aquatic center. Sustain. Cities Soc. 2018, 39, 126–134. [Google Scholar] [CrossRef]

- Sun, P.; Wu, J.Y.; Wang, R.Z.; Xu, Y.X. Analysis of indoor environmental conditions and heat pump energy supply systems in indoor swimming pools. Energy Build. 2011, 43, 1071–1080. [Google Scholar] [CrossRef]

- Kampel, W.; Carlucci, S.; Aas, B.; Bruland, A. A proposal of energy performance indicators for a reliable benchmark of swimming facilities. Energy Build. 2016, 129, 186–198. [Google Scholar] [CrossRef]

- Kampel, W.; Aas, B.; Bruland, A. Energy-use in Norwegian swimming halls. Energy Build. 2013, 59, 181–186. [Google Scholar] [CrossRef]

- Rajagopalan, P.; Jamei, P. Thermal comfort of multiple user group in indoor aquatic centers. Energy Build. 2015, 105, 129–138. [Google Scholar] [CrossRef]

- Revel, G.M.; Arnesano, M. Perception of the thermal environment in sports facilities through subjective approach. Build. Environ. 2014, 77, 12–19. [Google Scholar] [CrossRef]

- Kampel, W.; Aas, B.; Bruland, A. Characteristics of energy-efficient swimming facilities—A case study. Energy 2014, 75, 508–512. [Google Scholar] [CrossRef] [Green Version]

- Mousia, A.; Dimoudi, A. Energy performance of open air swimming pools in Greece. Energy Build. 2015, 90, 166–172. [Google Scholar] [CrossRef]

- Zuccari, F.; Santiangeli, A.; Orecchini, F. Energy analysis of swimming pools for sports activities: Cost effective solutions for efficiency improvement. Energy Procedia 2017, 126, 123–130. [Google Scholar] [CrossRef]

- Saari, A.; Sekki, T. Energy Consumption of a Public Swimming Bath. Open Constr. Build. Technol. J. 2008, 2, 202–206. [Google Scholar] [CrossRef] [Green Version]

- Delgado, J.P.M.; Garcia, F.V.; Garcia Gascales, J.R. Use of a predictive control to improve the Energy efficiency in indor swimming pools using solar thermal Energy. Solar Energy 2019, 179, 380–390. [Google Scholar] [CrossRef]

- Tagliafico, L.A.; Scarpa, F.; Tagliafico, G.; Valsuani, F. An approach to energy saving assessment of solar assisted heat pumps for swimming pool water heating. Energy Build. 2012, 55, 833–840. [Google Scholar] [CrossRef]

- Marinopoulos, I.; Katsifarakis, K. Optimization of Energy and Water Management of Swimming Pools. A Case Study in Thessaloniki, Greece. Procedia Environ. Sci. 2017, 38, 773–780. [Google Scholar] [CrossRef]

- Katsaprakakis, D.A. Comparison of swimming pools alternative passive and active heating systems based on renewable energy sources in Southern Europe. Energy 2015, 81, 738–753. [Google Scholar] [CrossRef]

- Chow, T.; Bai, Y.; Fong, K.; Lin, Z. Analysis of a solar assisted heat pump system for indoor swimming pool water and space heating. Appl. Energy 2012, 100, 309–317. [Google Scholar] [CrossRef]

- Lam, J.C.; Chan, W.W. Life cycle energy cost analysis of a heat pump application for a hotel swimming pools. Energy Conserv. Manag. 2001, 42, 1299–1306. [Google Scholar] [CrossRef]

- Ratajczak, K.; Szczechowiak, E. Efektywność pomp ciepła w centralach klimatyzacyjnych basenowych. Chłod. Klimatyzacja 2017, 4, 58–61. (In Polish) [Google Scholar]

- Internet System of Legal Acts. Journal Of Laws of 1994 No. 89, item 414 Act of 7 July 1994. Construction Law. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU19940890414 (accessed on 17 December 2020).

- Lund, H.; Möller, B.; Mathiesen, B.V.; Dyrelund, A. The role of district heating in future renewable energy systems. Energy 2010, 35, 1381–1390. [Google Scholar] [CrossRef]

- Nielsen, S.; Hansen, K.; Lund, R.; Moreno, D. Unconventional Excess Heat Sources for District Heating in a National Energy System Context. Energies 2020, 13, 5068. [Google Scholar] [CrossRef]

- Internet System of Legal Acts. Regulation of the Minister of Infrastructure of 6th November [2008] Concerning Energy Characteristic Methodology for Building or its Part. [Rozporządzenie Ministra Infrastruktury z Dnia 6 Listopada 2008 r. w Sprawie Metodologii Obliczania Charakterystyki Energetycznej Budynku i Lokalu Mieszkalnego lub Części Budynku Stanowiącej Samodzielną Całość Techniczno-użytkową Oraz Sposobu Sporządzania i Wzorów świadectw ich Charakterystyki Energetycznej. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20082011240 (accessed on 17 December 2020).

- Data on Non-Renewable Primary Energy Inputs: Energy for Poznań. Available online: http://www.energiadlapoznania.pl/cieplo-systemowe/zielone-cieplo (accessed on 18 February 2018).

- Eur-Lex Access to European Union Law. Commission Regulation (EU) No 601/2012 of 21 June 2012 on monitoring and reporting of greenhouse gas emissions in accordance with Directive 2003/87/EC of the European Parliament and of the Council (Official Journal EU L 181 of 12.07.2012, p. 30, as amended). Available online: http://data.europa.eu/eli/reg/2012/601/oj (accessed on 17 December 2020).

- Port, P.C. Emisja CO2 z energii elektrycznej w Polsce. Rynek Instalacyjny 2019, 7-8. (in polish). Available online: http://www.rynekinstalacyjny.pl/artykul/id3856,emisja-co2-z-energii-elektrycznej-w-polsce (accessed on 17 December 2020).

- Sewastianik, S.; Gajewski, A. Energetic and Ecologic Heat Pumps Evaluation in Poland. Energies 2020, 13, 4980. [Google Scholar] [CrossRef]

- Grygierek, K.; Ferdyn-Grygierek, J.; Gumińska, A.; Baran, L.; Barwa, M.; Czerw, K.; Gowik, P.; Makselan, K.; Potyka, K.; Psikuta, A. Energy and environmental analysis of single-family houses located in Poland. Energies 2020, 13, 2740. [Google Scholar] [CrossRef]

- Data for Energy Calculations of Buildings. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 8 May 2020).

- VDI-Fachbereich Technische Gebäudeausrüstung. VDI 2089 Blatt 1. Technische Gebaeudeausruestung von Schwimmbaedern. Hallenbaeder; VDI-Fachbereich Technische Gebäudeausrüstung: München, Germany, 2008. [Google Scholar]

- VDI-Fachbereich Technische Gebäudeausrüstung. VDI 2089 Blatt 2. Technische Gebaeudeausruestung von Schwimmbaedern. Energie- und Wassereffizienz in Schwimmbaedern; VDI-Fachbereich Technische Gebäudeausrüstung: München, Germany, 2008. [Google Scholar]

- Data of Air Handling Units DanX. Available online: https://www.dantherm.com/pl/wentylacja/wentylacja-basenow/centrale-basenowe-danx/ (accessed on 7 December 2020).

- Basińska, M.; Koczyk, H.; Szczechowiak, E. Sensivity analysis in determining the optimum energy for residential buildings in Poland conditions. Energy Build. 2015, 107, 307–318. [Google Scholar] [CrossRef]

- Basińska, M.; Koczyk, H. Analysis of the possibilities to achieve the low energy residential buildings standards. Technol. Econ. Dev. Econ. 2016, 22, 830–849. [Google Scholar] [CrossRef]

- Basińska, M.; Kaczorek, D.; Koczyk, H. Building Thermo-Modernisation Solution Based on the Multi-Objective Optimisation Method. Energies 2020, 13, 1433. [Google Scholar] [CrossRef] [Green Version]

- Basińska, M. The use of multi-criteria optimization to choose solutions for energy-efficient buildings. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 815–826. [Google Scholar] [CrossRef] [Green Version]

| Heat Source for Heating Ventilation Air or For Circulating It | Fuel/Energy Type | Input Coefficients of Non-Renewable Primary Energy (wi) (−) | Conversion Efficiency 1 (%) | CO2 Emissions 2 (kgCO2/kWh) | |

|---|---|---|---|---|---|

| Air heater | District heating | With cogeneration | 0.8 [27] | 99 | 0.246 |

| No cogeneration | 1.3 [27] | 99 | 0.392 | ||

| MDH Poznań 2016 | 0.624 [28] | 99 | 0.192 | ||

| MDH Poznań 2018 | 1.05 [28] | 99 | 0.323 | ||

| Natural gas | 1.1 [27] | 96 | 0.207 | ||

| Heat pump condenser | Electricity | 3.0 [27] | 5.0–5.5 3 | 225.6 | |

| Heat pump compressor | Electricity | 3.0 [27] | 5.0–5.5 3 | 225.6 | |

| Fans | Electricity | 3.0 [27] | 100 | 225.6 | |

| Parameters of the Swimming Pool | B1—Sport | B2—Recreational | |

|---|---|---|---|

| Pool Basin Area | AP | 300 m2P | 300 m2P |

| Size of the Pool Basin | - | 25 × 12 m | irregular |

| Water Temperature | tw | 28 °C | 30 °C |

| Indoor Air Temperature | tI | 30 °C | 32 °C |

| Area of the Windows | AW | 220 m2 | 220 m2 |

| Area of the External Walls | AEW | 1200 m2 | 1200 m2 |

| Internal Volume | Vi | 3800 m3 | 3800 m3 |

| Heat Transfer Coefficients | UWINDOWS | 1.30 W/(m2.K) | 1.30 W/(m2.K) |

| UEXTERNAL WALLS | 0.25 W/(m2.K) | 0.25 W/(m2.K) | |

| UAVERAGE | 0.48 W/(m2.K) | 0.48 W/(m2.K) | |

| Total Heat Losses | HTR+INF | 670 W/K | 670 W/K |

| Number of Users | N | 48 | 48 |

| Opening Hours | - | 6:00–22:00 | 6:00–22:00 |

| Variant | Air Handling Unit | Heat Source for Heating the Ventilation Air or For Pumping Air | Total Efficiency (%) | Coefficient of the Non-Renewable Primary Energy Input wi (−) | Fuel/Energy Unit Costs 1 ci (PLN3/Unit) |

|---|---|---|---|---|---|

| 1 | AHU 1 | Water air heater—with cogeneration | 92 | 0.8 | 0.20 PLN/kWh |

| 2 | AHU 1 | Water air heater—without cogeneration | 92 | 1.3 | 0.21 PLN/kWh |

| 3 | AHU 1 | Water air heater—MDHPoznań 2016 | 92 | 0.624 | 0.19 PLN/kWh |

| 4 | AHU 1 | Water air heater—MDHPoznań 2018 | 92 | 1.05 | 0.19 PLN/kWh |

| 5 | AHU 1 | Water air heater natural gas | 92 | 1.1 | 0.20 PLN/kWh |

| 6 | AHU 2 | Heat pump condenser 2 | SCOP | 3.0 | 0.50 PLN/kWh |

| 1–6 | AHU 1,2 | Fans | 100 | 3.0 | 0.50 PLN/kWh |

| 6 | AHU 2 | Heat pump compressor | 100 | 3.0 | 0.50 PLN/kWh |

| Air Handling Unit | Pool B1 15,000 m3/h | Pool B2 21,000 m3/h | ||

|---|---|---|---|---|

| AHU 1 | 52,000 € | 221,000 PLN | 69,000 € | 293,250 PLN |

| AHU 2 | 65,000 € | 276,250 PLN | 86,000 € | 365,500 PLN |

| Variant | Heating of Ventilation Air | Electricity EKel [kWh/(m2/Year)] | The Energy Reserve Transferred to the Water Condenser | |||

|---|---|---|---|---|---|---|

| Amount of Heat (kWh/(m2/Year)) | Final Energy EKH (kWh/(m2/Year)) | Pumping Air | Compressor | Heater Pump/Water Condenser Pump | ΔEKH (kWh/(m2/Year)) | |

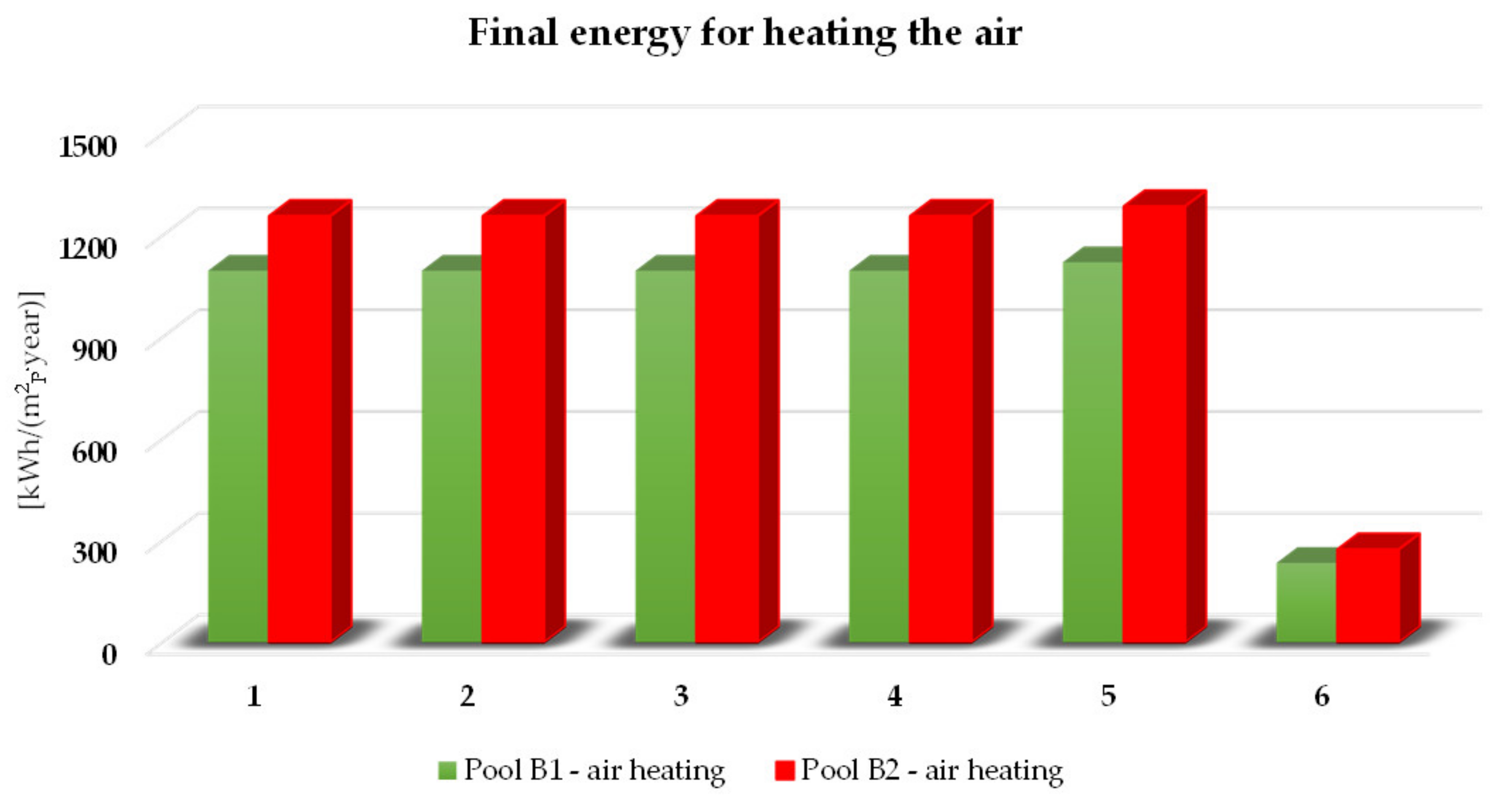

| 1 | 987 | 1097 | 188 | - | 2.2 | - |

| 2 | 987 | 1097 | 188 | - | 2.2 | - |

| 3 | 987 | 1097 | 188 | - | 2.2 | - |

| 4 | 987 | 1097 | 188 | - | 2.2 | - |

| 5 | 987 | 1122 | 188 | - | 2.2 | - |

| 6 | 1172 | 234 | 250 | 234 | - | - |

| Variant | Heating of Ventilation Air | Electricity EKel [kWh/(m2/Year)] | The Energy Reserve Transferred to the Water Condenser | |||

|---|---|---|---|---|---|---|

| Amount of Heat (kWh/(m2/Year)) | Final Energy EKH (kWh/(m2/Year)) | Pumping Air | Compressor | Heater Pump/Water Condenser Pump (kWh/(m2/Year)) | EKH (kWh/(m2/Year)) | |

| 1 | 1132 | 1258 | 418 | - | 3.7 | - |

| 2 | 1132 | 1258 | 418 | - | 3.7 | - |

| 3 | 1132 | 1258 | 418 | - | 3.7 | - |

| 4 | 1132 | 1258 | 418 | - | 3.7 | - |

| 5 | 1132 | 1287 | 418 | - | 3.7 | - |

| 6 | 1371 | 274 | 467 | 274 | - | - |

| Variant | Heat Source | Fuel/Energy | Non-Renewable Primary Energy Ratio | CO2 Emissions | Operating Costs | ||||

|---|---|---|---|---|---|---|---|---|---|

| EPH | EPel | EPH+el | ECO2 | CH | Cel | CH+el | |||

| (kWh/(m2/Year)) | (kgCO2/(m2/Year)) | (PLN/(m2/Year)) | |||||||

| 1 | Water air heater | District heating CHP | 877 | 571 | 1448 | 427 | 219 | 95 | 314 |

| 2 | Water air heater | District heating(DH) | 1426 | 571 | 1996 | 587 | 230 | 95 | 325 |

| 3 | Water air heater | DH Poznań 2016 | 684 | 571 | 1255 | 367 | 208 | 95 | 303 |

| 4 | Water air heater | DH Poznań 2018 | 1152 | 571 | 1722 | 511 | 208 | 95 | 303 |

| 5 | Water air heater | Natural gas | 1234 | 571 | 1805 | 389 | 224 | 95 | 319 |

| 6 | Heat pump | Electricity | 703 | 750 | 1453 | 399 | 0 | 242 | 242 |

| Variant | Heat Source | Fuel/Energy | Non-Renewable Primary Energy Ratio | CO2 Emissions | Operating Costs | ||||

|---|---|---|---|---|---|---|---|---|---|

| EPH | EPel | EPH+el | ECO2 | CH | Cel | CH+el | |||

| (kWh/(m2/Year)) | (kgCO2/(m2/Year)) | (PLN/(m2/Year)) | |||||||

| 1 | Water air heater | District heating CHP | 1006 | 1265 | 2271 | 657 | 252 | 211 | 462 |

| 2 | Water air heater | District heating(DH) | 1635 | 1265 | 2900 | 841 | 264 | 211 | 475 |

| 3 | Water air heater | DH Poznań 2016 | 785 | 1265 | 2050 | 589 | 239 | 211 | 450 |

| 4 | Water air heater | DH Poznań 2018 | 1321 | 1265 | 2586 | 754 | 239 | 211 | 450 |

| 5 | Water air heater | Natural gas | 1415 | 1265 | 2680 | 614 | 257 | 211 | 468 |

| 6 | Heat pump | Electricity | 823 | 1401 | 2224 | 611 | 0 | 371 | 371 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ratajczak, K.; Szczechowiak, E. The Use of a Heat Pump in a Ventilation Unit as an Economical and Ecological Source of Heat for the Ventilation System of an Indoor Swimming Pool Facility. Energies 2020, 13, 6695. https://doi.org/10.3390/en13246695

Ratajczak K, Szczechowiak E. The Use of a Heat Pump in a Ventilation Unit as an Economical and Ecological Source of Heat for the Ventilation System of an Indoor Swimming Pool Facility. Energies. 2020; 13(24):6695. https://doi.org/10.3390/en13246695

Chicago/Turabian StyleRatajczak, Katarzyna, and Edward Szczechowiak. 2020. "The Use of a Heat Pump in a Ventilation Unit as an Economical and Ecological Source of Heat for the Ventilation System of an Indoor Swimming Pool Facility" Energies 13, no. 24: 6695. https://doi.org/10.3390/en13246695

APA StyleRatajczak, K., & Szczechowiak, E. (2020). The Use of a Heat Pump in a Ventilation Unit as an Economical and Ecological Source of Heat for the Ventilation System of an Indoor Swimming Pool Facility. Energies, 13(24), 6695. https://doi.org/10.3390/en13246695