1. Introduction

The subject of our investigations is the comparison of aramid-enhanced cellulose paper (DuPont Nomex® 910, Nomex® is a registered trademark of DuPont de Nemours, Inc. (Warszawa, Poland)) with standard cellulose paper. Both papers are intended for use in liquid-immersed transformers, both power and distribution. Nomex® 910 is used in power transformers mainly as conductor insulation, while in the distribution transformers as conductor insulation or as interlayer insulation.

The family of Nomex® insulations includes a range of papers and pressboards. These materials are based on synthetic aromatic polyamide (aramid) in fibrous form. Nomex® 910 has been developed only as a paper.

The Nomex® 910 is a layered composition of aramid and cellulose. The purpose of such a construction is the improvement of the paper’s mechanical strength when the cellulose degrades as a result of aging processes. Aramid materials show high thermal performance (thermal class up to 220 °C, test in air). They are resistant to aging processes and have very good electrical properties. However, aramid materials are more expensive than cellulosic materials. The Nomex® 910 has intermediate properties between aramid and cellulose, while maintaining a relatively low price.

Nomex

® 910 structure consists of three layers, as shown in

Figure 1 [

1]. It is offered in four thicknesses: 0.08, 0.13, 0.18, and 0.25 mm [

2]. Each of these thicknesses may have a different mass ratio of cellulose to aramid for optimized mechanical and thermal performance.

Nomex

® 910 papers have many advantages over pure cellulose products. The most important property of aramid-enhanced cellulose paper is increased thermal resistance. Pure aramid has a thermal class of 180 °C (test in oil). The material Nomex

® 910, when aged in mineral oil, has a thermal class of 130 °C, regardless of thickness. However, aged in representative natural ester, it has a thermal class of 140 °C. For comparison, non-upgraded cellulose products (Kraft papers) have the 105 °C class and Thermally Upgraded Kraft (TUK) has the 120 °C class. Transformers with Nomex

® 910 insulation can be designed for longer life or higher operating temperatures [

3,

4,

5].

The consequence of the increased thermal performance of Nomex

® 910 are its relatively good mechanical properties after aging. After aging for two weeks in mineral oil at 170 °C, the tensile strength of the Kraft cellulosic material decreased to 33% of new material, while Nomex

® 910 tensile strength only decreased to 79% of new material [

3].

Nomex

® 910 has good electrical properties. Its breakdown voltage in oil with a rapid rise AC test is about 30% higher than TUK [

4].

This work refers to partial discharges in materials used in the transformer insulation system. Partial discharges occur in weakened places of insulation, for example as a result of its moisture, and when developing they can lead to a short circuit in the transformer. That’s why they are a very serious threat to the insulation system. Surface partial discharges (creeping discharges) are treated as the most dangerous. A characteristic feature of surface discharges is the presence of the tangential and normal component of the partial discharge current, which is a consequence of the existence of a diagonal electric field. A diagonal electric field occurs in each transformer at the ends of the winding, as shown in

Figure 2. In this case, at the ends of the windings, the paper may be exposed to a diagonal electric field and, as a result, to surface discharges.

The tangential component of the partial discharge current is related to surface resistivity, while the normal component is mainly capacitive. Capacitive current depends on the geometrical dimensions of the insulation system and the electric permittivity. The capacitive component of the partial discharge current can sometimes have a very high value. Surface partial discharges, after ignition, intensify until electric breakdown. Therefore, when assessing the system, special attention should be paid to such discharges.

2. Purpose and Objects of Investigation

The purpose of the present investigation was to compare aramid-enhanced cellulose paper (Nomex® 910) and cellulose paper.

The research consisted of a comparison of the materials, Nomex

® 910 and pure cellulose papers of identical thicknesses, through stressing them electrically. The electrode arrangement is discussed in

Section 3. The research was of a material nature, that is, they consisted of comparing selected materials with identical geometrical dimensions.

Four sets of samples with different moisture levels were prepared using the method outlined below.

The sample preparation procedure consisted of the following stages: (a) drying the samples; (b) moistening the samples; (c) impregnation and conditioning of the samples; and (d) measuring water content in the samples. For samples from set I, stage (b) of the procedure was omitted.

All samples were initially dried in a vacuum chamber for 10 h at a temperature of 90 ± 5 °C and a pressure of about 0.3 mbar. Immediately after drying, the samples from set I (

Table 1) were impregnated with mineral oil in a vacuum chamber. Through this process the materials with the lowest moisture level were obtained. To obtain a higher level of moisture in the samples in sets II, III and IV, after drying, they were subjected to a controlled moistening process in a climatic chamber. The relative air humidity and temperature were maintained in the chamber in accordance with the water sorption isotherms given in [

7]. After the moistening process, the samples were impregnated with oil in a vacuum chamber, with parameters of this process chosen carefully for not causing drying, that is, the moisture of the sample and ambient air were in equilibrium.

After the impregnation process, samples from all sets were conditioned in sealed vessels at a temperature of about 23 °C for about one week. Before measuring the partial discharges, the water content of the samples was determined by the Karl Fischer method, in accordance with International Electrotechnical Commission (IEC) 60814 [

8]. The measurement results obtained in this way are shown in the

Table 1. Moisture was determined for two samples in each set. The measurement uncertainty was about 0.1 %.

The method of sample preparation presented allowed the preparation of materials with similar relative humidity in each of the sets. However, both materials investigated show different water absorption properties, which is a consequence of their different polarity. The simplest assessment of material polarity is electric permittivity. The electric permittivity of paper Nomex

® 910 and cellulose paper is 1.6–3.2 and 3.3–4.1, respectively (25 °C, 50–60 Hz) [

2,

9]. Due to different electrical permittivity, samples of aramid-enhanced cellulose paper and cellulose paper from each set, conditioned under the same conditions, reached different levels of moisture.

3. Experimental Arrangement

The samples were tested in a chamber filled with mineral oil. The chamber is shown in

Figure 3a. In the case of two electrodes (

Figure 3b) with different diameters, partial discharges of the surface type (creeping discharges) are generated. Discharges of this type have tangential and normal components, resulting from the presence of an oblique electric field—such as that in the transformer, as shown in

Figure 2.

The PD-Smart partial discharge analyzer, produced by LDIC, was used in the investigation. PD-Smart measures partial discharges according to IEC 60270, VDE 0434, ANSI, with 14 bit resolution and input frequency range from DC to 2 MHz.

The measuring system is shown in

Figure 4.

4. Investigations Results and Discussion

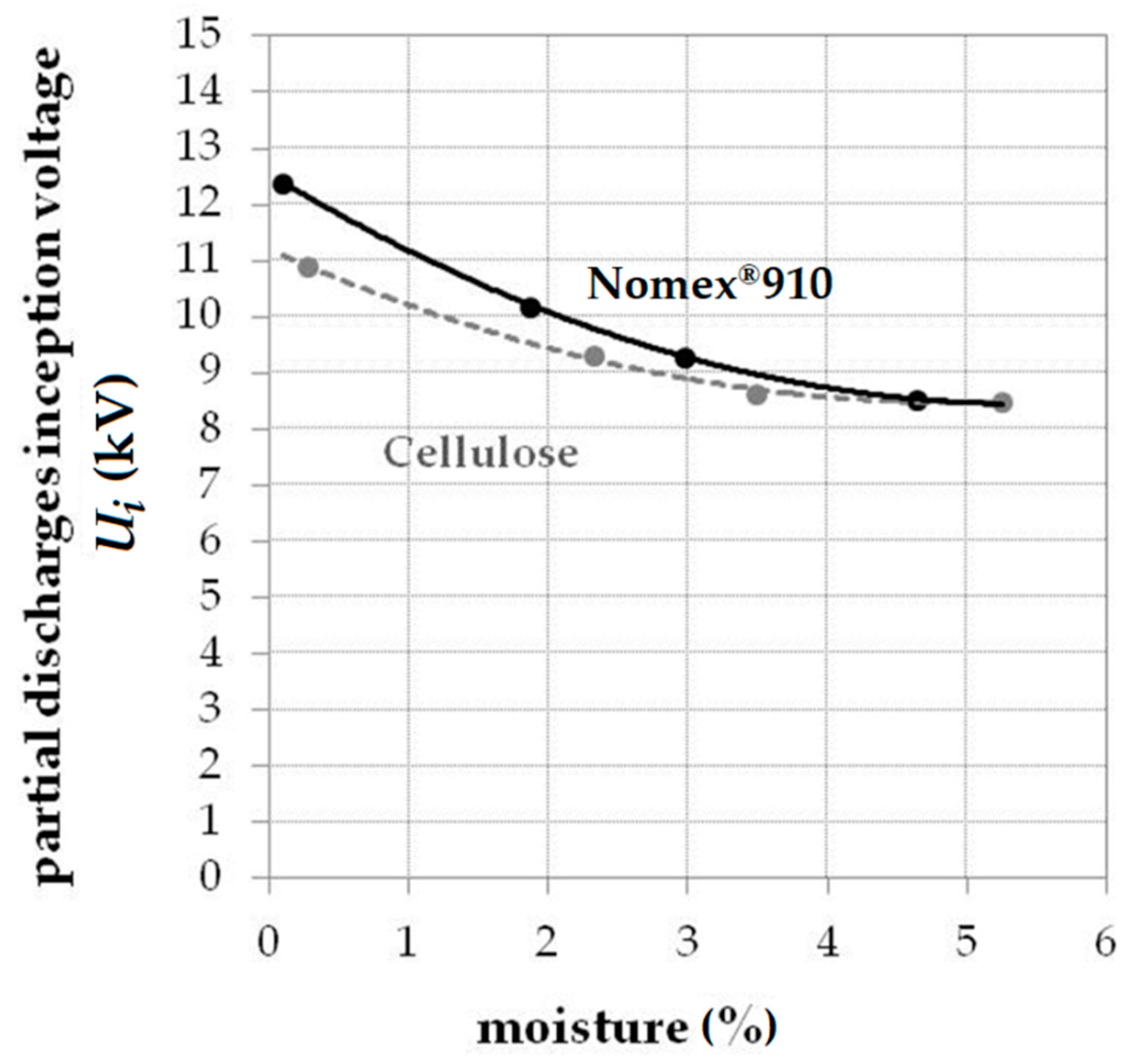

In the first step, the inception voltage of partial discharge

Ui of all tested samples immersed in mineral oil was measured, as the

Figure 5 shows. The PD inception voltage was measured on 2 or 3 samples, in several places on each sample (the sample was moved between the electrodes). This means that 8–10 measurements were done. The inception voltage difference for each sample never exceeded 0.2 kV. We can see that the samples of aramid-enhanced cellulose paper had a slightly higher inception voltage than the pure cellulose paper samples. This difference decreased with increase in moisture content.

Determination of a uniform test voltage during partial discharge measurements for all tested samples was impossible, because each sample had different inception and extinction of partial discharge voltages. However, it was possible to determine the same value of the test voltage for each pair of samples of materials conditioned in the same conditions. The test voltage was between the inception and the extinguishing voltage. Only for the samples of cellulose paper and Nomex® 910, with moisture contents of 2.32% and 1.87%, respectively, the same value of the test voltage could not be determined. For this reason, partial discharge analysis for this pair of samples was not performed.

Figure 6,

Figure 7 and

Figure 8 present frequency-amplitude distributions of partial discharges. Each distribution was obtained within 1 s of measurement. Figures show the investigation results for a pair of samples: with Nomex

® 910 paper and with cellulose paper conditioned in the same conditions. It is difficult to clearly assess the impact of moisture on the intensity of partial discharges in the samples investigated, because samples at each moisture level were tested at a different voltage level.

Figure 6 shows that for very dry insulation (0.1% for Nomex

® 910 and 0.27% for cellulose), the frequency of the discharge pulses and the range of their charge in both materials have a very similar value. However, with increasing moisture content of the samples (

Figure 7), it can be seen in the case of cellulose paper that the maximum charge in this material was much higher than in Nomex

® 910. Also, the frequency of impulses appearing was much higher in cellulose.

At the highest moisture content of the samples (

Figure 8), for a given test voltage, no partial discharges were found in the Nomex

® 910 material, with a relatively high frequency of partial discharges appearance and their maximum charge in cellulose. This situation should be treated with great caution. Although partial discharges in the highest moisture content Nomex

® 910 material did not appear, it should be kept in mind that with increasing moisture its thermal breakdown is more and more probable [

10]. Of course, there may also be a thermal breakdown in cellulose, but partial discharges are an additional threat to it.

Comparisons of partial discharges in both materials can be made based on the analysis of selected quantities, for example, pulse frequency, maximum charge carried by a single current pulse, or total charge carried by pulses over a selected time period [

10,

11]. In this work the total charge carried by current pulses within one second was selected. This value is best correlated with the progressive degradation of the material.

Analyzing the results of the investigation of the three pairs of samples conditioned under the selected conditions, it can be concluded that in all three cases, the total charge carried by partial discharges pulses within 1 s in aramid-enhanced cellulose paper was much smaller than in cellulose paper (

Figure 9). When the samples of cellulose and Nomex

® 910 were relatively dry, 0.27% and 0.1% moisture respectively, the total charge in aramid-enhanced cellulose paper was 5.1 times smaller. With higher moisture, 3.49% and 2.98% respectively, the total charge in aramid-enhanced cellulose paper material was 15 times smaller, while with significant moisture, equal to 5.25% and 4.64% respectively, partial discharges for the selected test voltage were not present in the Nomex

® 910 samples at all. The lower intensity of partial discharges in aramid-enhanced cellulose paper than in cellulose should be considered an important advantage of this material.

The assessment of the impact of sample moisture on the total charge carried by current pulses counted during 1 s is difficult, because the measurements of partial discharges for three sets of samples with different levels of moisture were made at different voltage values. But with some caution it can be stated that with increasing moisture, cellulose samples initially showed an increase in total charge, which is in accordance with literature reports [

9], and then we observed a decrease in the total charge, which is equated with the effect of partial discharges extinguishing with deterioration of the system insulation state. This phenomenon is well known in high voltage insulation systems [

10]. However, all samples from the Nomex

® 910 material, within the tested moisture range, showed the effect of partial discharge being extinguished. However, this situation should be treated with great caution. Although partial discharges are extinguished, thermal breakdown becomes more likely.

5. Conclusions

In the transformer insulation system, at the ends of the windings, there is an oblique electric field that can cause surface partial discharges. These discharges are treated as the most dangerous, which prompted the undertaking of this research.

Conditioning under the same conditions of aramid-enhanced cellulose paper and cellulose paper causes a different level of moisture, which is the result of their different polarity.

The inception voltage of partial discharges (PDIV) of all tested samples decreased with increasing moisture content. Nomex® 910 has a significantly higher inception voltage than the cellulose paper, although this difference decreased with the moisture of the samples.

The total charge carried by partial discharge impulses within 1 s in samples of aramid-enhanced cellulose paper is much smaller than in cellulose paper, which is a significant advantage of this material. This difference occurs regardless of material moisture.

The Nomex® 910 paper investigated consists predominantly of cellulose with only a small addition of the aramid component. It is significant that even a small addition of aramid has a positive impact on the properties of this material.

Author Contributions

Conceptualization, H.M. and H.M.-G.; data curation, H.M., H.M.-G. and P.P.; formal analysis, H.M., H.M.-G., K.W. and R.S.; funding acquisition, H.M., H.M.-G. and R.S.; investigation, H.M., H.M.-G. and P.P.; methodology, H.M., H.M.-G., P.P. and R.S.; project administration, H.M.-G.; resources, R.S.; supervision, H.M. and H.M.-G.; validation, H.M. and R.S.; visualization, H.M.; writing—original draft, H.M.-G.; writing—review & editing, H.M., P.P., K.W. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education for statutory activities No 04/41/SBAD/4413. Material test samples provided by DuPont and Krempel.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Szewczyk, R. Papier izolacyjny wzmocniony aramidem—Wlasciwosci i zastosowania. In Proceedings of the Transformatory w Eksploatacji 2019, Ustka, Poland, 8–10 May 2019. (In Polish). [Google Scholar]

- DUPONT™ NOMEX® 910 ENGINEERED CELLULOSE INSULATION PAPERS FOR THE 21ST CENTURY. Preliminary Technical Data Sheet. Available online: http://www.comercialph.cl/wp-content/uploads/2016/11/DPP_Nomex_910_.pdf (accessed on 7 November 2019).

- Marek, R.P.; Wicks, R.C.; Galhardo, L.; Szewczyk, R. New cellulose paper enhanced with aramid—practical example of material thermal evaluation acc. to IEEE Std C57.100-2011. In Proceedings of the CIGRE SC D1 Colloquium, Rio de Janeiro, Brazil, 13–18 September 2015. [Google Scholar]

- Lee, K.; Szewczyk, R.; Zhou, Y. A New insulation system for liquid-immersed distribution transformers. In Proceedings of the 5th European Conference on HV & MV Substation Equipments Power Utilities (MATPOST 2015), Lyon, France, 24–25 November 2015. [Google Scholar]

- IEEE Std. C57.154-2012. IEEE Standard for the Design, Testing, and Application of Liquid-Immersed Distribution, Power, and Regulating Transformers Using High-Temperature Insulation Systems and Operating at Elevated Temperatures; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Jezierski, E.; Gogolewski, Z.; Kopczynski, Z.; Szmit, J. Transformatory—Budowa i Projektowanie; Panstwowe Wydawnictwa Techniczne: Warszawa, Poland, 1956; pp. 1–422. (In Polish) [Google Scholar]

- Przybylek, P. Water saturation limit of insulating liquids and hygroscopicity of cellulose in aspect of moisture determination in oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1886–1893. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. IEC 60814. Insulating Liquids—Oil-Impregnated Paper and Pressboard—Determination of Water by Automatic Coulometric Karl Fischer Titration; International Electrotechnical Commission (IEC): New York, NY, USA, 1997; pp. 1–43. [Google Scholar]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture migration in an oil-paper insulation system in relation to online partial discharge monitoring of power transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef] [Green Version]

- Florkowska, B. Application of partial discharge patterns for assessment of multi-stress synergy in thermosettings stator bar insulation. In Proceedings of the 9th International Symposium on High Voltage Engineering, Graz, Austria, 28 August–1 September 1995. [Google Scholar]

- Florkowska, B.; Florkowski, M.; Wlodek, R.; Zydron, P. Mechanizmy, Pomiary i Analiza Wyladowan niezupelnych w diagnostyce ukladow izolacyjnych wysokiego napiecia; Wydawnictwo IPPT PAN: Warszawa, Poland, 2001; pp. 1–311. (In Polish) [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).