Thermal Diffusion in Fibrous Aerogel Blankets

Abstract

1. Introduction

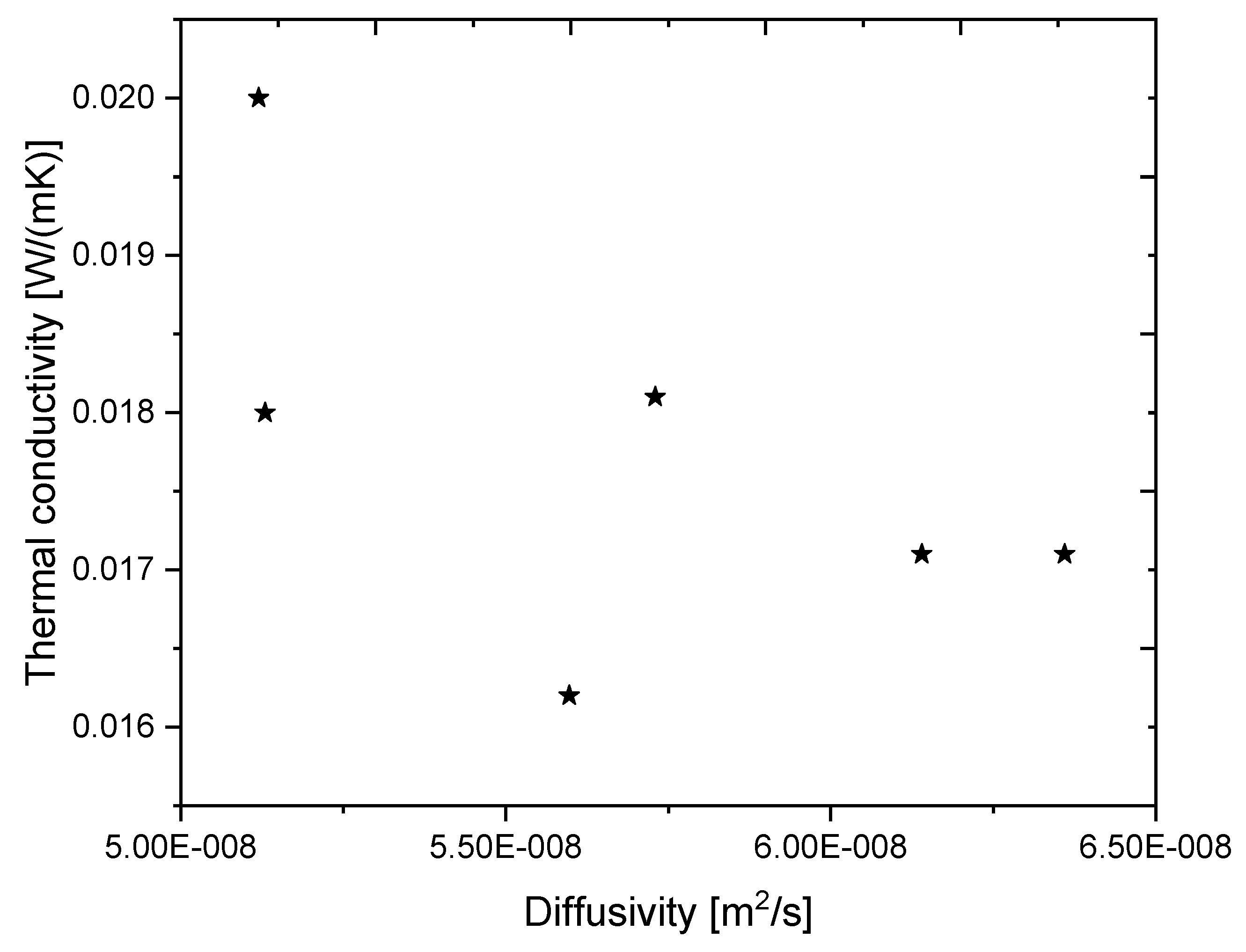

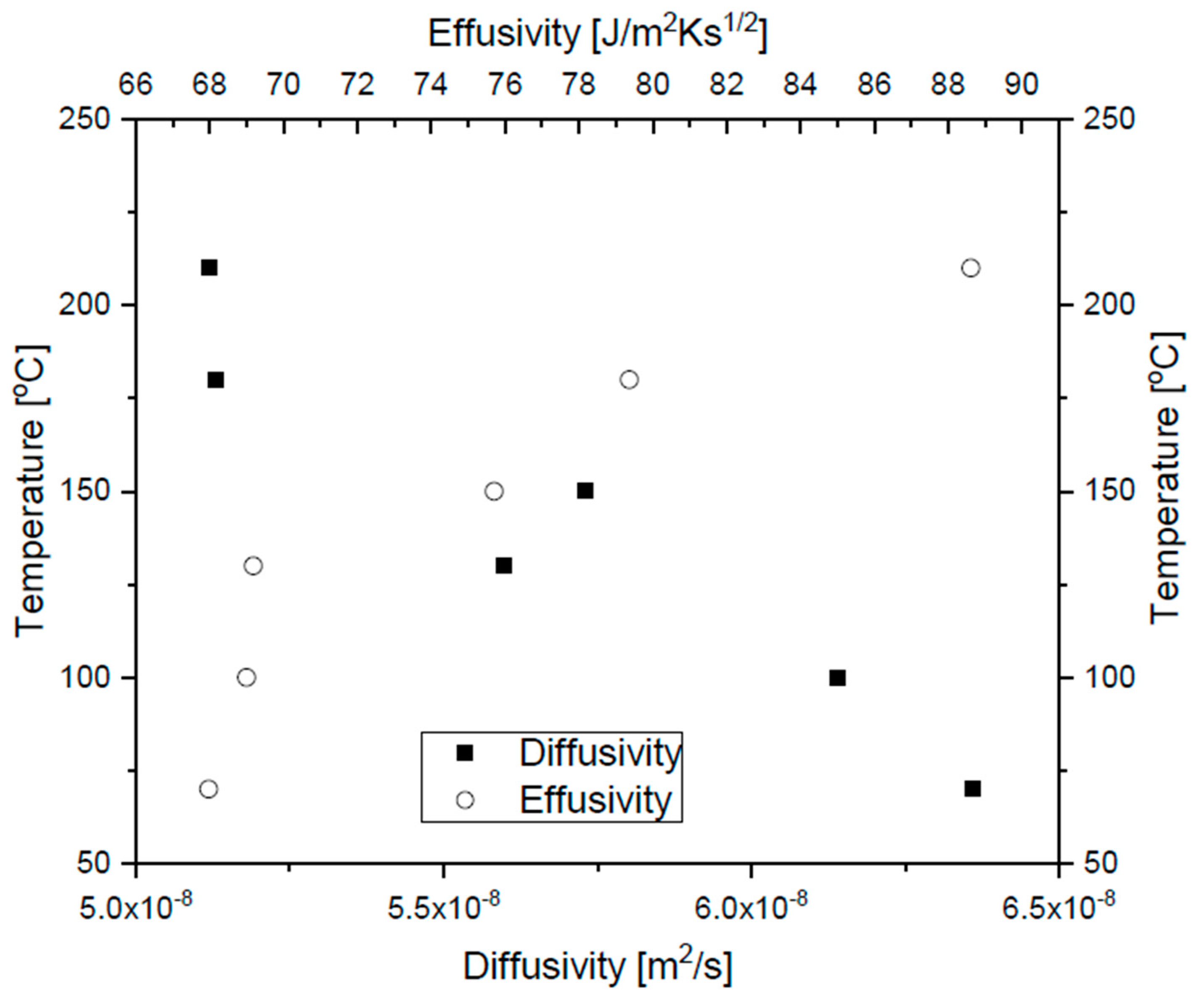

- Thermal conductivity measurement tests executed on glass-fiber-reinforced aerogel insulation after isochronal (t = 24 h) heat treatments at 70, 100, 130, 150, 180, and 210 °C.

- Measurement of the change in the mass density of the samples after heat treatments.

- Differential scanning calorimetry measurements on the sample.

- From the measured values we calculated the most important transient building physical parameters of the samples, such as (a) diffusivity, (b) effusivity, and (c) inertia. As a result, we concluded the changes due to the heat treatments, and we defined the effective heat capacity.

2. Materials and Methods

2.1. Theory

Thermal Conductivity

2.2. Heat Treatments of the Samples

2.3. Differential Scanning Calorimetry Measurements

2.4. Calculated Material Properties

2.4.1. Thermal Diffusivity

2.4.2. Thermal Effusivity or Heat Absorption

2.4.3. Thermal Inertia

3. Results

Changes in the Thermal Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lakatos, Á.; Trnik, A. Thermal Characterization of Fibrous Aerogel Blanket, MATEC Web Conf 282, 01001. In Proceedings of the 2019 Central European Symposium on Building Physics 2019 CESBP, Prague, Czech Republic, 2–5 September 2019. [Google Scholar] [CrossRef]

- Lakatos, Á.; Csík, A.; Trník, A.; Budai, I. Effects of the Heat Treatment in the Properties of Fibrous Aerogel Thermal Insulation. Energies 2019, 12, 2001. [Google Scholar] [CrossRef]

- Iswara, S.; Griffa, M.; Kaufmann, R.; Beltrand, M.; Hubera, L.; Brunner, S.; Lattuad, M.; Koebel, M.M.; Malfait, W.J. Effect of aging on thermal conductivity of fiber-reinforced aerogel composites: An X-ray tomography study. Micr. Mes. Mat. 2019, 278, 289–296. [Google Scholar] [CrossRef]

- Ebert, H.P. Thermal Properties of Aerogels. In Aerogels Handbook; Aegerter, A., Leventis, N., Koebel, M., Eds.; Springer: New York, NY, USA, 2011; pp. 537–564. [Google Scholar] [CrossRef]

- Lakatos, Á. Stability investigations of the thermal insulating performance of aerogel blanket. Energy Build. 2019, 139, 506–516. [Google Scholar] [CrossRef]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogels for Superinsulation: A Synoptic View. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Schultz, J.M.; Jensen, K.I.; Kristiansen, F.H. Super insulating aerogel glazing. Sol. Eneregy Mat. Sol. Cells 2005, 89, 275–285. [Google Scholar] [CrossRef]

- Galliano, R.; Ghazi Wakili, K.; Stahl, T.; Binder, B.; Daniotti, B. Performance evaluation of aerogel-based and perlite-based prototyped insulations for internal thermal retrofitting: HMT model validation by monitoring at demo scale. Eneregy Build. 2016, 12, 275–286. [Google Scholar] [CrossRef]

- Ghazi Wakili, K.; Stahl, T.; Heiduk, E.; Schuss, M.; Vonbank, R.; Pont, U.; Sustr, C.; Wolosiuk, D.; Mahdavi, D. High Performance Aerogel Containing Plaster for Historic Buildings with Structured Façades. Energy Proc. 2015, 78, 949–954. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Lucchi, E.; Roberti, F.; Alexandra, T. Definition of an experimental procedure with the hot box method for the thermal performance evaluation of inhomogeneous walls. Energy Build. 2018, 179, 99–111. [Google Scholar] [CrossRef]

- Berardi, U.; Lakatos, Á. Thermal bridges of metal fasteners for aerogel-enhanced blankets. Energy Build. 2019, 185, 307–315. [Google Scholar] [CrossRef]

- Stahl, T.; Brunner, S.; Zimmermann, M.; Ghazi Wakili, K. Thermo-hygric properties of a newly developed aerogel based insulation rendering for both exterior and interior applications. Energy Build. 2012, 44, 114–117. [Google Scholar] [CrossRef]

- Lucchi, E.; Becherini, F.; Di Tuccio, M.C.; Troi, A.; Frick, J.; Roberti, F.; Hermann, C.; Fairnington, I.; Mezzasalma, G.; Pockelé, L.; et al. Thermal performance evaluation and comfort assessment of advanced aerogel as blown-in insulation for historic buildings. Build. Environ. 2017, 122, 258–268. [Google Scholar] [CrossRef]

- Lakatos, Á. Moisture induced changes in the building physics parameters of insulation materials. J. Sci. Technol. Built Environ. 2016, 22, 3. [Google Scholar] [CrossRef]

- Hoseini, A.; Bahrami, M. Effects of humidity on thermal performance of aerogel insulation blankets. J. Build. Eng. 2017, 13, 107–115. [Google Scholar]

- Lakatos, Á. Investigation of the moisture induced degradation of the thermal properties of aerogel blankets: Measurements, calculations, simulations. Energy Build. 2017, 139, 506–516. [Google Scholar] [CrossRef]

- Koci, V.; Madera, J.; Jerman, M.; Trnik, A.; Cerny, R. Determination of the equivalent thermal conductivity of complex material systems with large-scale heterogeneities. Int. J. Therm. Sci. 2014, 86, 365–373. [Google Scholar] [CrossRef]

- Lakatos, Á.; Deák, I.; Berardi, U. Thermal characterization of different graphite polystyrene. Int. Rev. App. Sci. Eng. 2018, 9, 163–168. [Google Scholar] [CrossRef]

- Jelle, B.P. Accelerated climate ageing of building materials, components and structures in the laboratory. J. Mat. Sci. 2012, 47, 6475–6496. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Miros, A. Thermal Aging Effect on Thermal Conductivity Properties of Mineral Wool Pipe Samples at High Temperature. In Proceedings of the 3rd World Congress on Mechanical, Chemical, and Material Engineering (MCM’17), Rome, Italy, 8–10 June 2017, Paper No. HTFF 172. ISSN 2369-8136. [Google Scholar] [CrossRef]

- Siligardi, C.; Miselli, P.; Francia, E.; Gualtieri, M.L. Temperature-induced microstructural changes of fiber-reinforced silica aerogel (FRAB) and rock wool thermal insulation materials: A comparative study. Energy Build. 2017, 138, 80–87. [Google Scholar] [CrossRef]

- Salazar, A. On thermal diffusivity. Eur. J. Phys. 2003, 24, 351–358. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, X.; Yu, F.; Chen, K. Thermal diffusivity measurements on insulation materials with the laser flash method. Int. J. Thermophys. 2006, 27, 235–243. [Google Scholar] [CrossRef]

- Boulaoued, I.; Amara, I.; Mhimid, A. Experimental determination of thermal conductivity and diffusivity of new building insulating materials. Int. J. Heat Techn. 2016, 34, 325–331. [Google Scholar] [CrossRef]

- Lamrani, M.; Laaroussi, N.; Khabbazi, A.; Khalfaoui, M.; Garoum, M.; Feiz, A. Experimental study of thermal properties of a new ecological building material based on peanut shells and plaster. Case Stud. Const. Mat. 2017, 7, 294–304. [Google Scholar] [CrossRef]

- Lakatos, Á.; Csarnovics, I. Influence of thermal annealing on structural properties of silica aerogel super insulation material. J. Thermal. Anal. Calorim. 2019, 1–9. [Google Scholar] [CrossRef]

| λ Via Holometrix Apparatus [W/(m K)] | 0.017 at 17 °C |

| cp [J/(kg K)] | 1000 at 40 °C |

| ρ [kg/m3] | 150 |

| 70 °C | 100 °C | 130 °C | 150 °C | 180 °C | 210 °C | |

|---|---|---|---|---|---|---|

| λ[W/(m K)] | 0.0171 | 0.0171 | 0.0162 | 0.0181 | 0.0180 | 0.0200 |

| ρ[kg/m3] | 150.17 | 150.24 | 150.24 | 148.68 | 147.96 | 147.48 |

| cp[J/(kg K)] | 1795 | 1853 | 1962 | 2128 | 2369 | 2656 |

| Microscope (M = 20×) | growth of SiO2 grains |

| Scanning Electron microscopy (M = 100×) | growth of SiO2 grains |

| X-ray diffraction—2Θ | Twin peaks 22.5–27°, maybe crystallization |

| Raman spectroscopy |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakatos, Á.; Trník, A. Thermal Diffusion in Fibrous Aerogel Blankets. Energies 2020, 13, 823. https://doi.org/10.3390/en13040823

Lakatos Á, Trník A. Thermal Diffusion in Fibrous Aerogel Blankets. Energies. 2020; 13(4):823. https://doi.org/10.3390/en13040823

Chicago/Turabian StyleLakatos, Ákos, and Anton Trník. 2020. "Thermal Diffusion in Fibrous Aerogel Blankets" Energies 13, no. 4: 823. https://doi.org/10.3390/en13040823

APA StyleLakatos, Á., & Trník, A. (2020). Thermal Diffusion in Fibrous Aerogel Blankets. Energies, 13(4), 823. https://doi.org/10.3390/en13040823