Comparative Analysis of Small-Scale Integrated Solar ORC-Absorption Based Cogeneration Systems

Abstract

:1. Introduction

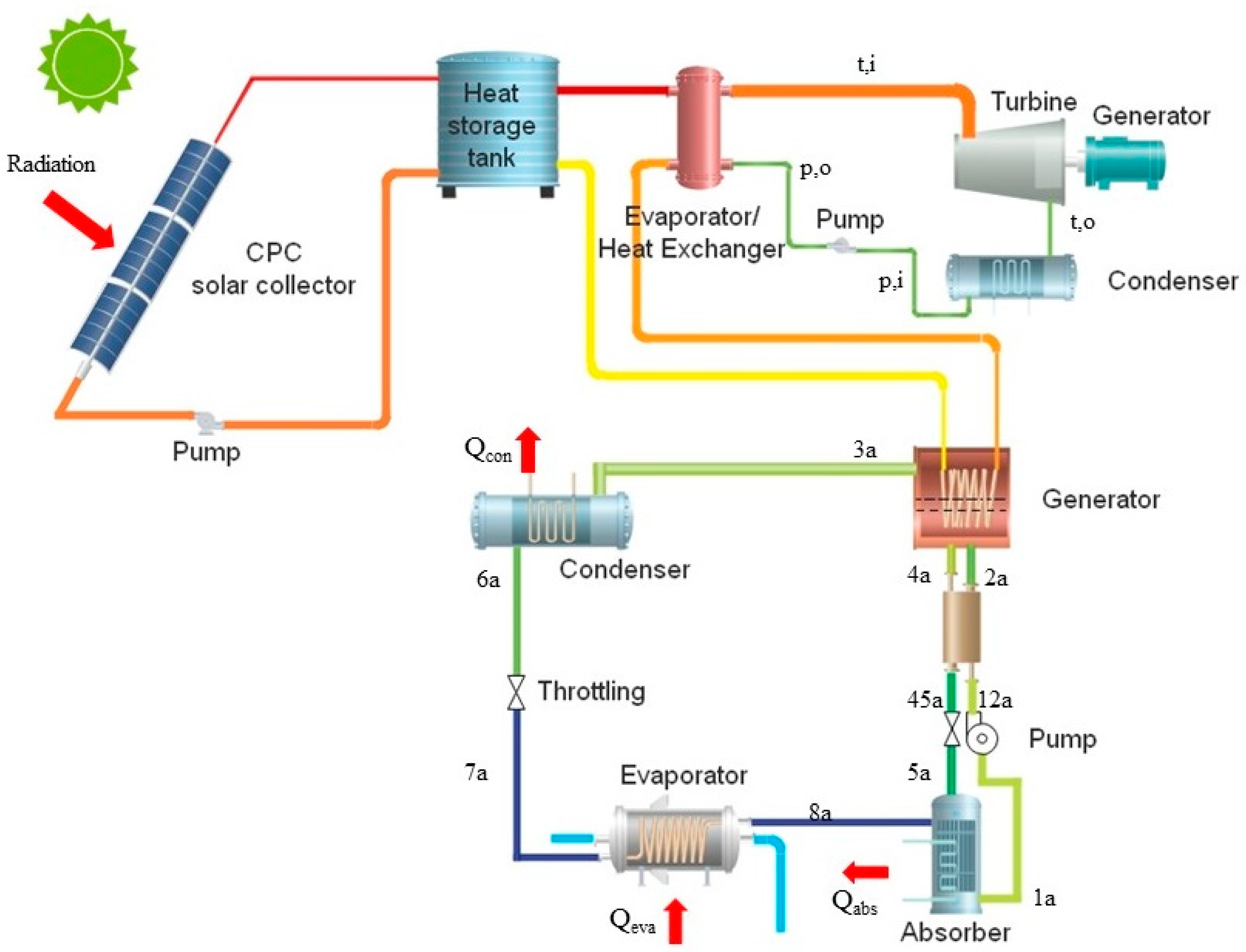

2. System Descriptions

3. Mathematical Analyses

- The system is considered to operate at steady state.

- The refrigerant flows inside all components of the system is simplified as one-dimensional form.

- Heat losses from the working fluid transportation lines, ORC turbine and pumps to the ambient are neglected.

- The isentropic efficiencies of the ORC turbine and pumps are fixed at a constant value.

- The working fluids flow within all components of the system are considered as homogeneous mixtures. The thermal and physical properties are calculated as the averaged values of each substance.

- The working fluid exiting the condenser and evaporator of the absorption cycle is assumed at its saturated condition. Superheated vapour steam from generator of the absorption cycle is pure steam without LiBr substance.

3.1. CPC Solar Collector Model

3.2. ORC Model

3.3. Absorption Heat Pump Model

3.4. System Indexes

4. Model Validation

5. Results and Discussion

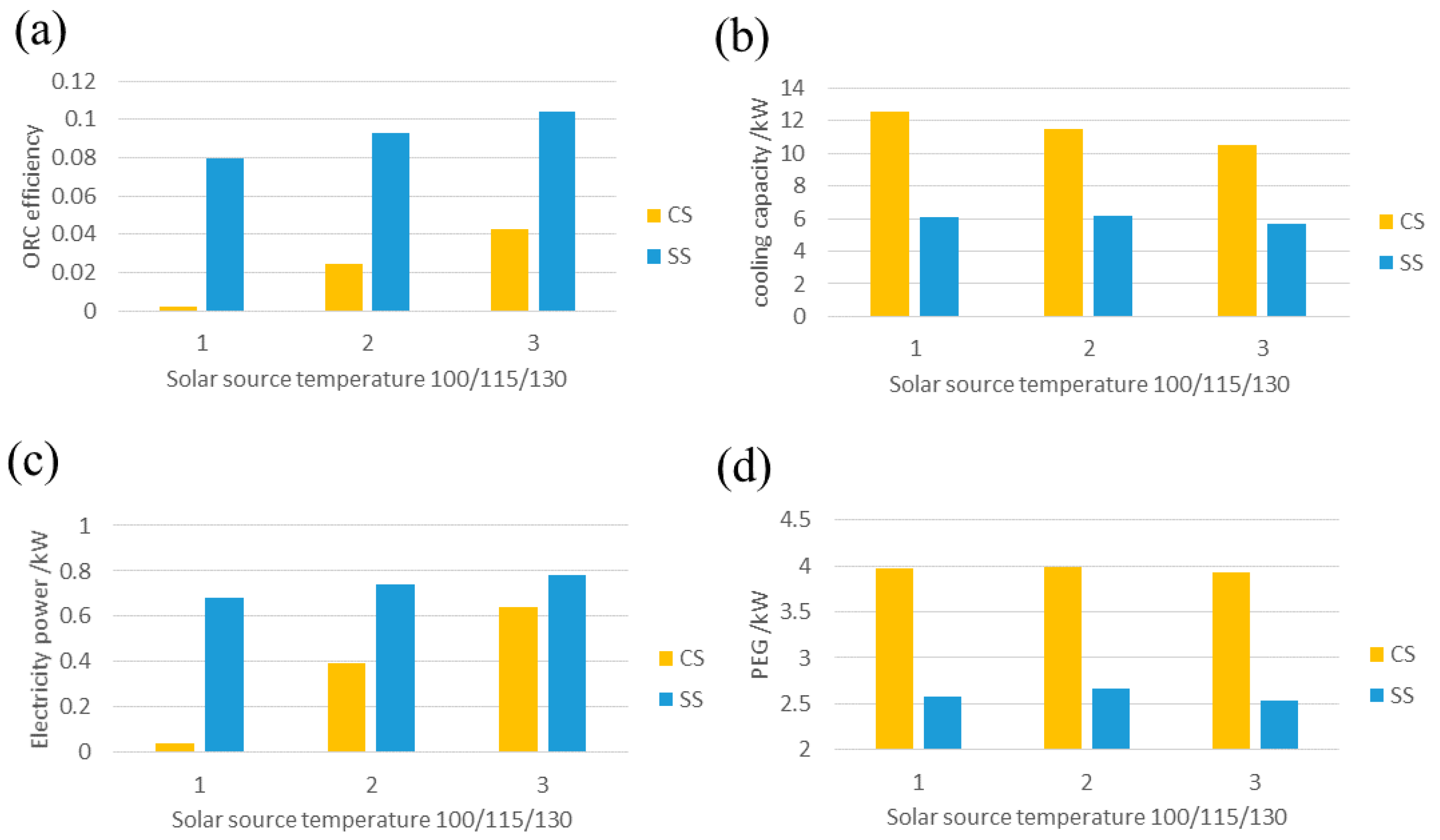

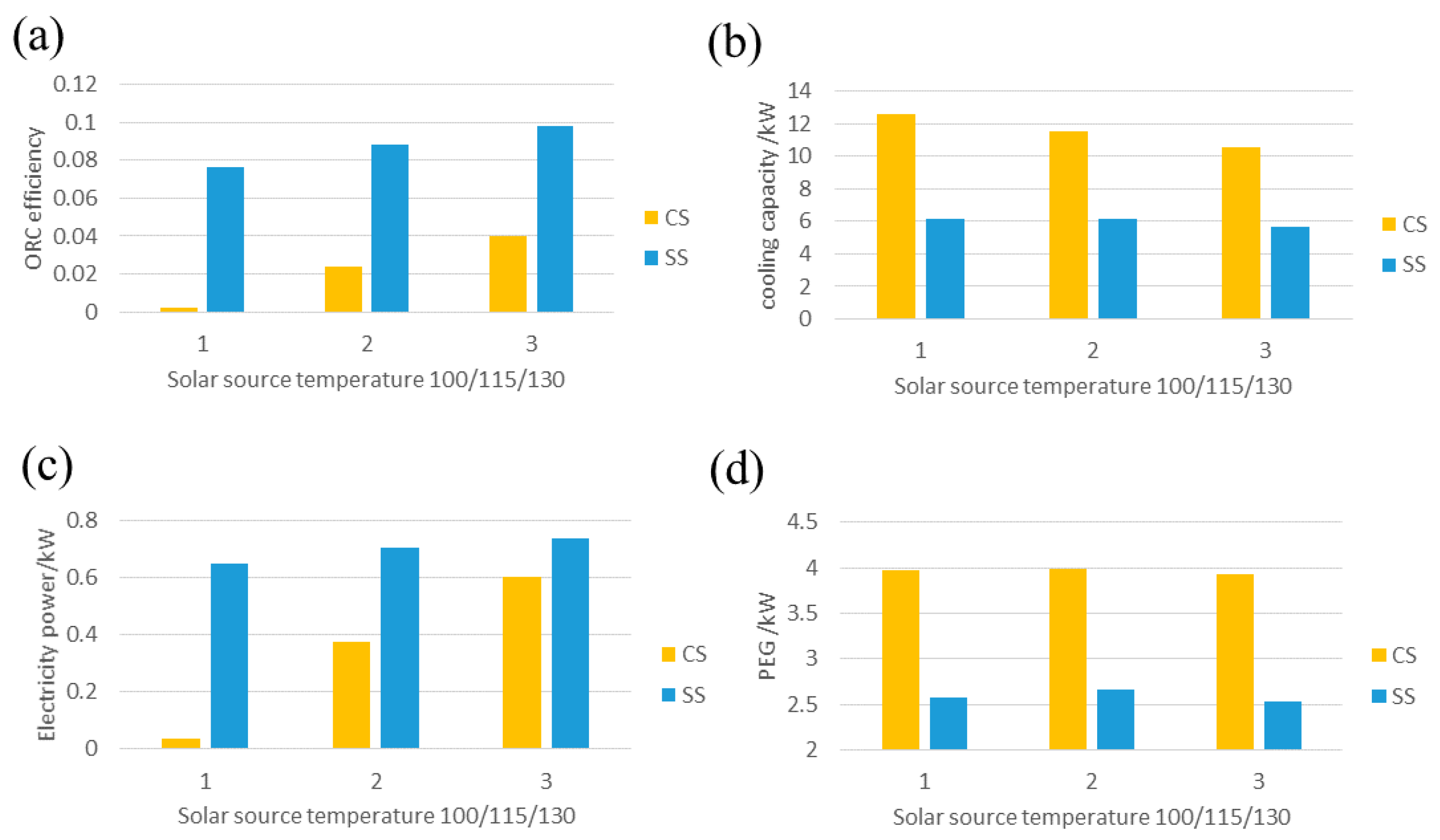

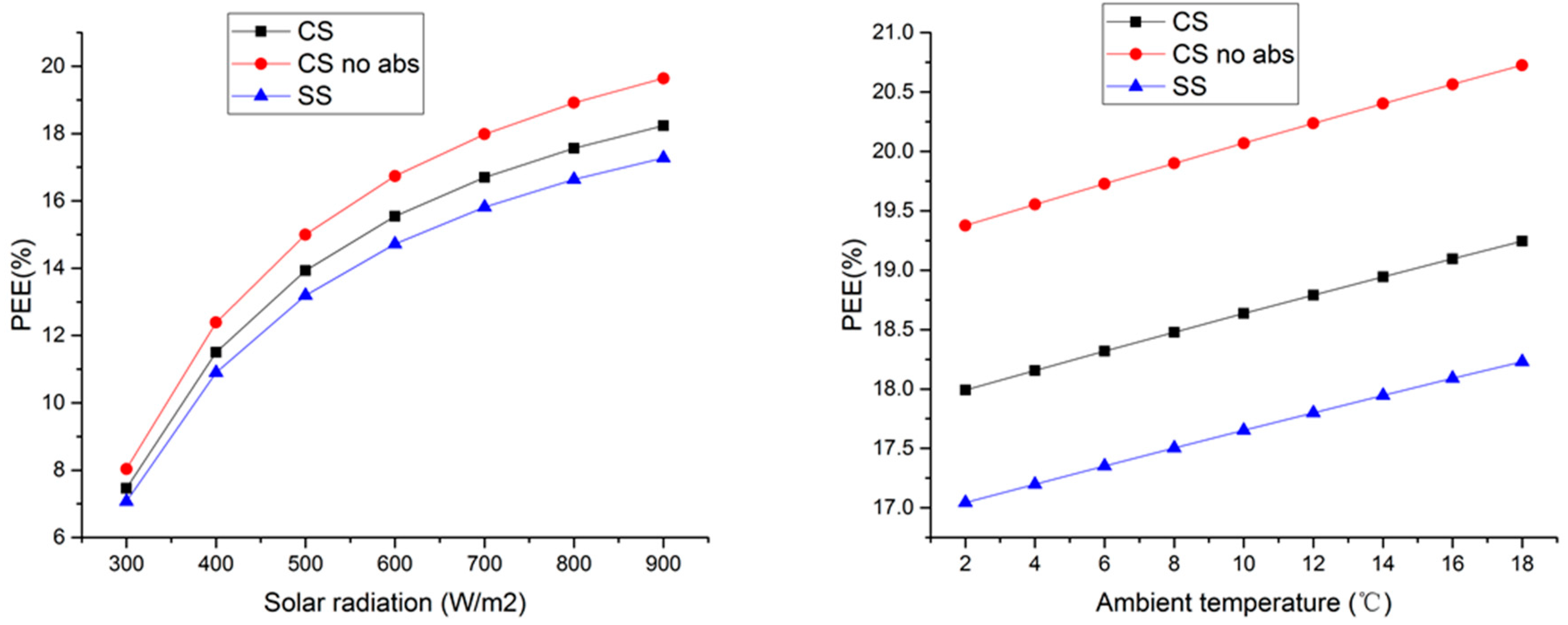

5.1. Cooling Mode

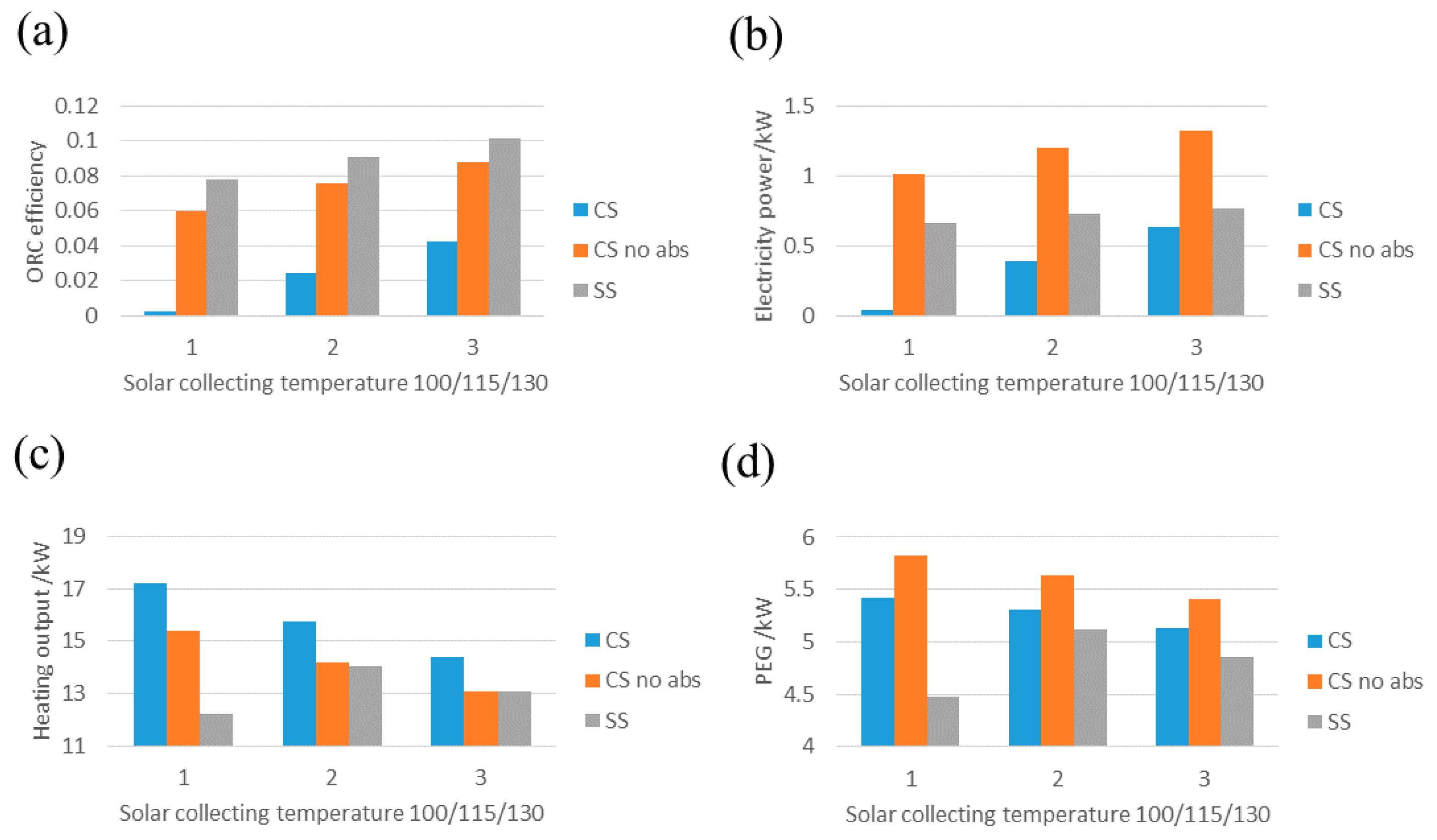

5.2. Heating Mode

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | first heat loss coefficient of CPC | X | value |

| Aa | aperture area of solar collector, (m2) | Greek | |

| B | second heat loss coefficient of CPC | η | efficiency |

| COPc | coefficient of performance of absorption heat pump for cooling | Subscripts | |

| COPc,st | coefficient of performance of standard cooling facility | a | absorption |

| COPh | coefficient of performance of absorption heat pump for heating | con | condenser |

| COPh,st | coefficient of performance of standard heating facility | con,orc | condenser of ORC |

| CP | specific heat capacity(J/kg/K) | eva | evaporator |

| CS | cascade system | eva,orc | evaporator of ORC |

| G | solar irradiation(W/m2) | HEX | heat exchanger |

| hfi | heat transfer coefficient(W/m2/K) | g | gearbox and generator |

| h | enthalpy(kJ/mol) | gen | absorption generator |

| k | conductivity(W/m/K) | o | outlet |

| m | mass flow rate (kg/s) | i | inlet |

| n | number | p | pump |

| PEE | primary energy efficiency | t | turbine |

| Q | energy(W) | r | receiver, refrigerant |

| SS | series system | s | isentropic |

| T | temperature (°C) | str | strong solution |

| UL | heat loss coefficient (W/m2/K) | u | useful |

| W | power work(W) | w | weak solution |

References

- Li, J.; Pei, G.; Li, Y.Z.; Wang, D.Y.; Ji, J. Energetic and exergetic investigation of an organic Rankine cycle at different heat source temperatures. Energy 2012, 38, 85–95. [Google Scholar] [CrossRef]

- Riffat, S.B.; Zhao, X. A novel hybrid heat-pipe solar collector/CHP system—Part II: Theoretical and experimental investigations. Renew. Energy 2004, 29, 1965–1990. [Google Scholar] [CrossRef]

- Goswami, D. Solar thermal power: Status of technologies and opportunities for research. Heat Mass Transf. 1995, 95, 57–60. [Google Scholar]

- Martin, C.; Goswami, D.Y. Effectiveness of cooling production with a combined power and cooling thermodynamic cycle. Appl. Therm. Eng. 2006, 26, 576–582. [Google Scholar] [CrossRef]

- Zare, V.; Mahmoudi, S.M.S.; Yari, M.; Amidpour, M. Thermoeconomic analysis and optimization of an ammonia–water power/cooling cogeneration cycle. Energy 2012, 47, 271–283. [Google Scholar] [CrossRef]

- Mahlia, M.I.T.; Syaheed, H.; Abas, E.P.A.; Kusumo, F.; Shamsuddin, H.A.; Ong, C.H.; Bilad, M.R. Organic Rankine Cycle (ORC) System Applications for Solar Energy: Recent Technological Advances. Energies 2019, 12, 2930. [Google Scholar] [CrossRef] [Green Version]

- Cho, H.; Smith, A.D.; Mago, P. Combined cooling, heating and power: A review of performance improvement and optimization. Appl. Energy 2014, 136, 168–185. [Google Scholar] [CrossRef]

- Salek, F.; Moghaddam, A.N.; Naserian, M.M. Thermodynamic analysis of diesel engine coupled with ORC and absorption refrigeration cycle. Energy Convers. Manag. 2017, 140, 240–246. [Google Scholar] [CrossRef]

- Kanoglu, M.; Dincer, I. Performance assessment of cogeneration plants. Energy Convers. Manag. 2009, 50, 76–81. [Google Scholar] [CrossRef]

- Dong, L.; Liu, H.; Riffat, S. Development of small-scale and micro-scale biomass-fuelled CHP systems—A literature review. Appl. Therm. Eng. 2009, 29, 2119–2126. [Google Scholar] [CrossRef] [Green Version]

- Alcaide, F.; Cabot, P.-L.; Brillas, E. Fuel cells for chemicals and energy cogeneration. J. Power Sources 2006, 153, 47–60. [Google Scholar] [CrossRef]

- Lee, K.H.; Strand, R.K. SOFC cogeneration system for building applications, part 1: Development of SOFC system-level model and the parametric study. Renew. Energy 2009, 34, 2831–2838. [Google Scholar] [CrossRef]

- Descombes, G.; Boudigues, S. Modelling of waste heat recovery for combined heat and power applications. Appl. Therm. Eng. 2009, 29, 2610–2616. [Google Scholar] [CrossRef] [Green Version]

- Maidment, G.G.; Eames, I.W.; Psaltas, M.; Lalzad, A.; Yiakoumetti, K. Flash-type barometric desalination plant powered by waste heat from electricity power stations in Cyprus. Appl. Energy 2007, 84, 66–77. [Google Scholar] [CrossRef]

- Kalinowski, P.; Hwang, Y.; Radermacher, R.; Al Hashimi, S.; Rodgers, P. Application of waste heat powered absorption refrigeration system to the LNG recovery process. Int. J. Refrig. 2009, 32, 687–694. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Exergy modeling of a new solar driven trigeneration system. Sol. Energy 2011, 85, 2228–2243. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Y.; Gao, L.; Ma, S. A new combined cooling, heating and power system driven by solar energy. Renew. Energy 2009, 34, 2780–2788. [Google Scholar] [CrossRef]

- Eisavi, B.; Khalilarya, S.; Chitsaz, A.; Rosen, M.A. Thermodynamic analysis of a novel combined cooling, heating and power system driven by solar energy. Appl. Therm. Eng. 2018, 129, 1219–1229. [Google Scholar] [CrossRef]

- Settino, J.; Sant, T.; Micallef, C.; Farrugia, M.; Spiteri Staines, C.; Licari, J.; Micallef, A. Overview of solar technologies for electricity, heating and cooling production. Renew. Sustain. Energy Rev. 2018, 90, 892–909. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Y.; Deng, S.; Ni, J.; Xu, W.; Ma, M.; Lin, S.; Yu, Z. Solar driven ORC-based CCHP: Comparative performance analysis between sequential and parallel system configurations. Appl. Therm. Eng. 2018, 131, 696–706. [Google Scholar] [CrossRef]

- Cioccolanti, L.; Hamedani, S.R.; Villarini, M. Environmental and energy assessment of a small-scale solar Organic Rankine Cycle trigeneration system based on Compound Parabolic Collectors. Energy Convers. Manag. 2019, 198, 13. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Investigation of a hybrid ORC driven by waste heat and solar energy. Energy Convers. Manag. 2018, 156, 427–439. [Google Scholar] [CrossRef]

- Collings, P.; McKeown, A.; Wang, E.; Yu, Z. Experimental Investigation of a Small-Scale ORC Power Plant Using a Positive Displacement Expander with and without a Regenerator. Energies 2019, 12, 1452. [Google Scholar] [CrossRef] [Green Version]

- Boyaghchi, F.A.; Chavoshi, M. Monthly assessments of exergetic, economic and environmental criteria optimization of a solar micro-CCHP based on DORC. Sol. Energy 2018, 166, 351–370. [Google Scholar] [CrossRef]

- Tascioni, R.; Cioccolanti, L.; Del Zotto, L.; Habib, E. Numerical Investigation of Pipelines Modeling in Small-Scale Concentrated Solar Combined Heat and Power Plants. Energies 2020, 13, 429. [Google Scholar] [CrossRef] [Green Version]

- Kutlu, C.; Erdinc, M.T.; Li, J.; Wang, Y.B.; Su, Y.H. A study on heat storage sizing and flow control for a domestic scale solar-powered organic Rankine cycle-vapour compression refrigeration system. Renew. Energy 2019, 143, 301–312. [Google Scholar] [CrossRef]

- Arteconi, A.; Del Zotto, L.; Tascioni, R.; Cioccolanti, L. Modelling system integration of a micro solar Organic Rankine Cycle plant into a residential building. Appl. Energy 2019, 251, 14. [Google Scholar] [CrossRef]

- Tian, M.; Su, Y.; Zheng, H.; Pei, G.; Li, G.; Riffat, S. A review on the recent research progress in the compound parabolic concentrator (CPC) for solar energy applications. Renew. Sustain. Energy Rev. 2018, 82, 1272–1296. [Google Scholar] [CrossRef] [Green Version]

- Gang, P.; Jing, L.; Jie, J. Design and analysis of a novel low-temperature solar thermal electric system with two-stage collectors and heat storage units. Renew. Energy 2011, 36, 2324–2333. [Google Scholar] [CrossRef]

- Zheng, Z.; Johnston, A.M.; Fletcher, D.F.; Haynes, B.S. Heat exchanger specification: Coupling design and surface performance evaluation. Chem. Eng. Res. Des. 2015, 93, 392–401. [Google Scholar] [CrossRef]

- Turns, S.R. Thermodynamics: Concepts and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Herold, K.E.; Radermacher, R.; Klein, S.A. Absorption Chillers and Heat Pumps; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- JGJ 75-2012. Design Standard for Energy Efficiency of Residential Buildings in Hot Summer and Warm Winter Zone; China Architecture & Building Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Lemmon, E.W.; Huber, M.L.; Mclinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1; NIST NSRDS; NIST: Gaithersburg, MD, USA, 2013.

- Bellos, E.; Tzivanidis, C. Parametric analysis and optimization of a solar driven trigeneration system based on ORC and absorption heat pump. J. Clean. Prod. 2017, 161, 493–509. [Google Scholar] [CrossRef]

| Operating Case | Pressure of Condenser /kPa | Pressure of Evaporator /kPa | Evaporating Temperature/°C | Superheating Temperature /°C | Efficiency of Ref [1] | Efficiency of Present Work | Deviation |

|---|---|---|---|---|---|---|---|

| Case 1 | 90.2 | 610.2 | 88.97 | 10.52 | 8.2% | 8.21% | 0.12% |

| Case 2 | 83 | 497.8 | 80.65 | 9.05 | 7.7% | 7.7% | 0% |

| Case 3 | 73.1 | 414.8 | 73.53 | 5.86 | 7.4% | 7.39% | 0.14% |

| TE (°C) | TG (°C) | TC (°C) | TA (°C) | COP of Ref [25] | COP of Present Work | Deviation |

|---|---|---|---|---|---|---|

| 4 | 70 | 31 | 31 | 0.799 | 0.796 | 0.4% |

| 4 | 69 | 31 | 35 | 0.675 | 0.683 | 1.1% |

| 5 | 66 | 28 | 35 | 0.763 | 0.760 | 0.4% |

| 6 | 72 | 33 | 37 | 0.715 | 0.719 | 0.5% |

| 8 | 63 | 25 | 37 | 0.832 | 0.817 | 1.8% |

| 8 | 85 | 46 | 39 | 0.574 | 0.577 | 0.6% |

| 9 | 66 | 28 | 34 | 0.853 | 0.844 | 1.1% |

| Parameters | Value | Unit |

|---|---|---|

| Collector With | 2.5 | m |

| Collector Length | 14 | m |

| Solar system working fluid | Therminol 66 | |

| Volume of the thermo oil storage tank | 2 | m3 |

| ORC system | 2.5 | kW |

| ORC working fluid | R123/R141b/R1233zd | |

| ORC superheating temperature | 10 | °C |

| Pressure drop through ORC pipe | 40 | kPa |

| Turbine isentropic efficiency | 80 | % |

| Generator efficiency | 70 | % |

| Pump efficiency | 70 | % |

| Cooling capacity of absorption heat pump | 11 | kW |

| Evaporator temperature of absorption chiller | 4 | °C |

| Condenser temperature of absorption chiller | 34 | °C |

| Absorber temperature of absorption chiller | 34 | °C |

| Condenser temperature of absorption heat pump | 37 | °C |

| Absorber temperature of absorption heat pump | 37 | °C |

| Solar radiation | 900 | W/m2 |

| Ambient temperature for cooling mode | 32 | °C |

| Ambient temperature for heating mode | 5 | °C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, X.; Shi, F. Comparative Analysis of Small-Scale Integrated Solar ORC-Absorption Based Cogeneration Systems. Energies 2020, 13, 946. https://doi.org/10.3390/en13040946

Hong X, Shi F. Comparative Analysis of Small-Scale Integrated Solar ORC-Absorption Based Cogeneration Systems. Energies. 2020; 13(4):946. https://doi.org/10.3390/en13040946

Chicago/Turabian StyleHong, Xiaoqiang, and Feng Shi. 2020. "Comparative Analysis of Small-Scale Integrated Solar ORC-Absorption Based Cogeneration Systems" Energies 13, no. 4: 946. https://doi.org/10.3390/en13040946

APA StyleHong, X., & Shi, F. (2020). Comparative Analysis of Small-Scale Integrated Solar ORC-Absorption Based Cogeneration Systems. Energies, 13(4), 946. https://doi.org/10.3390/en13040946