Starting Pulse Vibration Torque Analysis of Aviation Variable Frequency Asynchronous Motor Based on Low-Frequency Step-Down Starting Methods

Abstract

1. Introduction

2. Torque Characteristics of Aviation Variable Frequency Asynchronous Motor

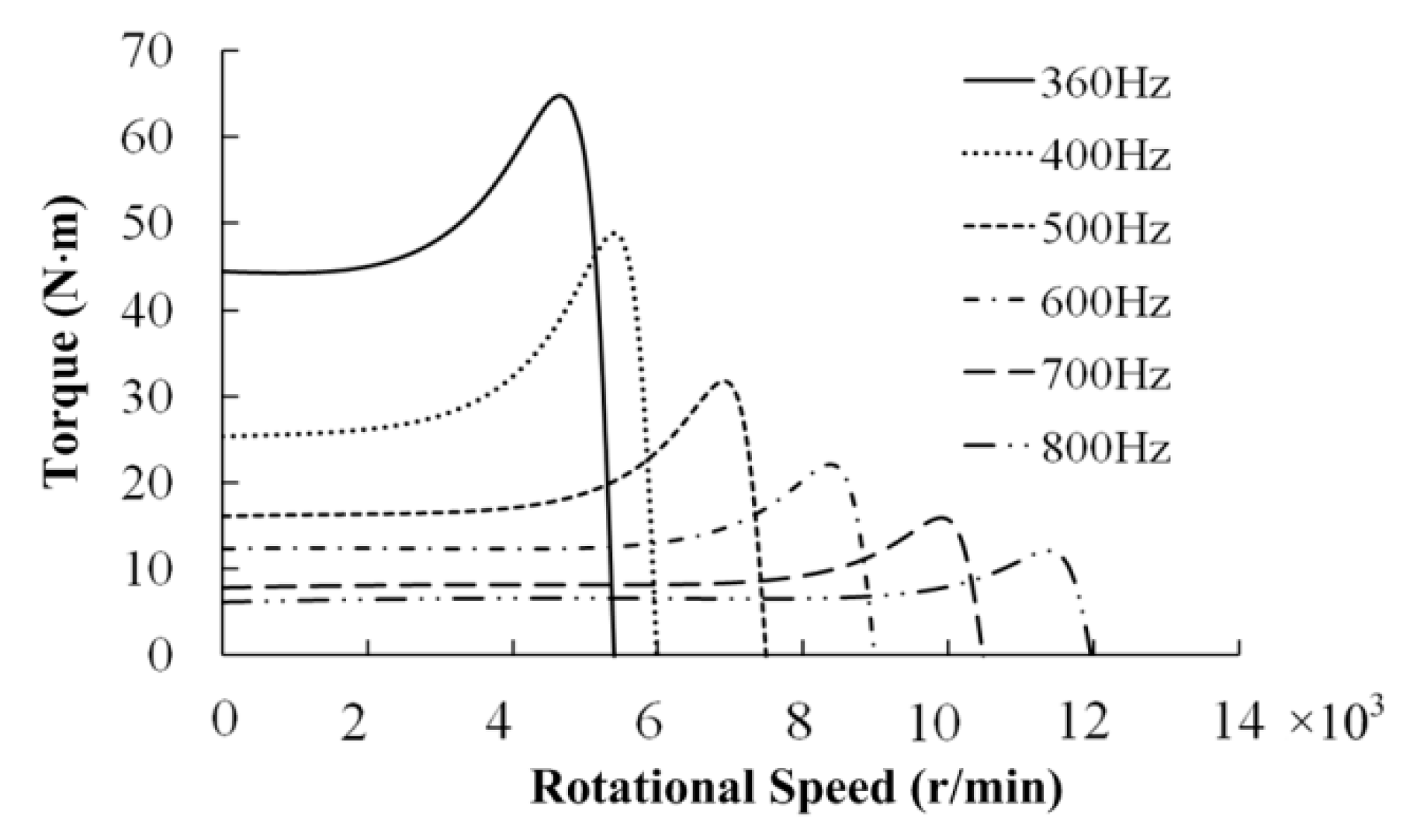

2.1. Mechanical Characteristics of Variable Frequency Asynchronous Motor

2.2. Starting Pulse Vibration Torque of Variable Frequency Asynchronous Motor

3. Starting Pulse Vibration Torque Model

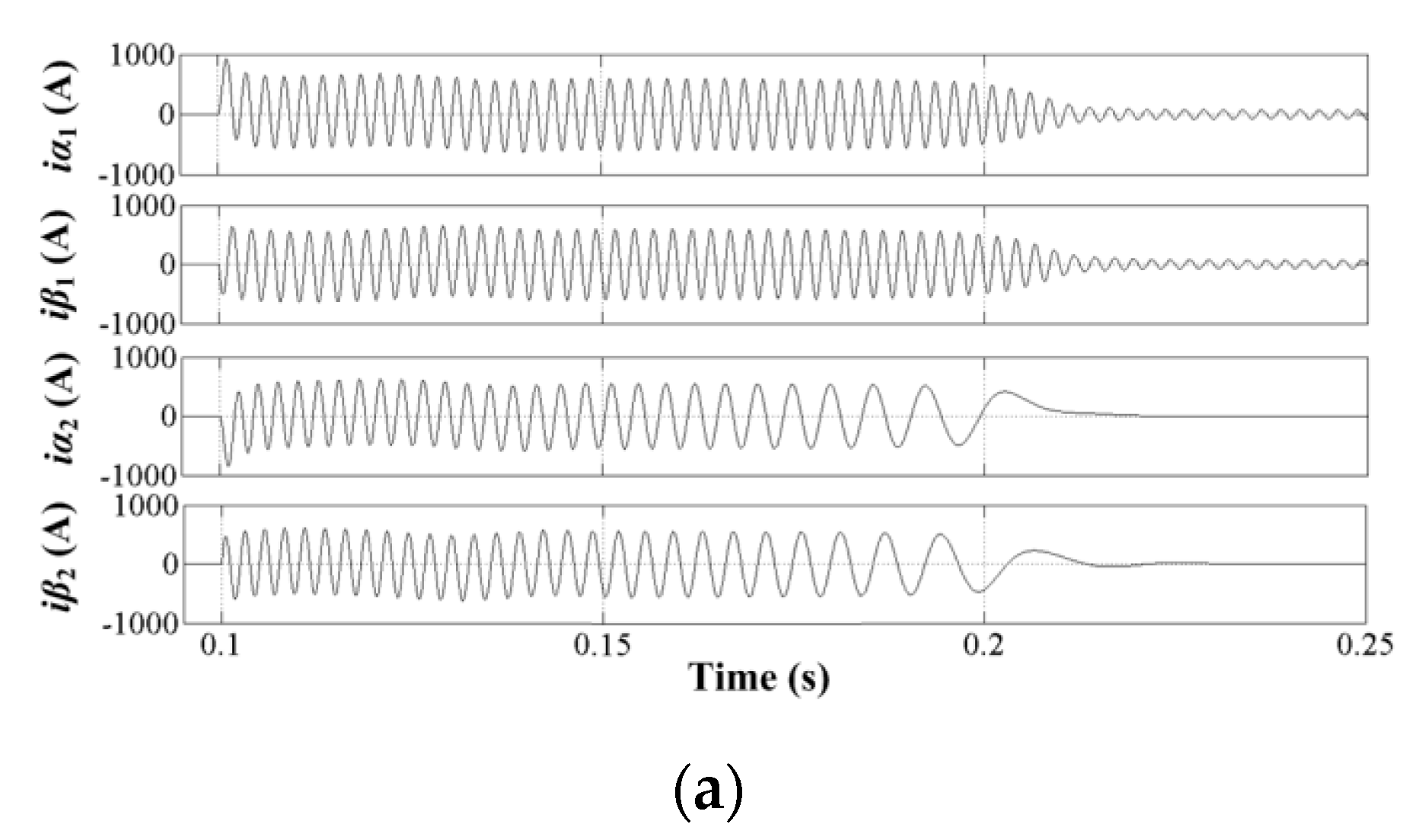

3.1. Transient Characteristics of Starting Current and Torque

3.2. Basic Principle of Starting Torque

- (1)

- Fss: the rotating magnetic potential on the stator with the synchronous speed (ω1) generated by the stator currents , of frequency f1.

- (2)

- F0s: the static magnetic potential on the stator with the speed of zero caused by the DC component of stator currents ,.

- (3)

- F0r: the rotating magnetic potential on the rotor with the synchronous speed (ωm) generated by the DC component of rotor currents ,.

- (4)

- Fsr: the rotating magnetic potential on the rotor with the synchronous speed (ω1 = ωs + ωm) generated by the rotor current , of frequency fs.

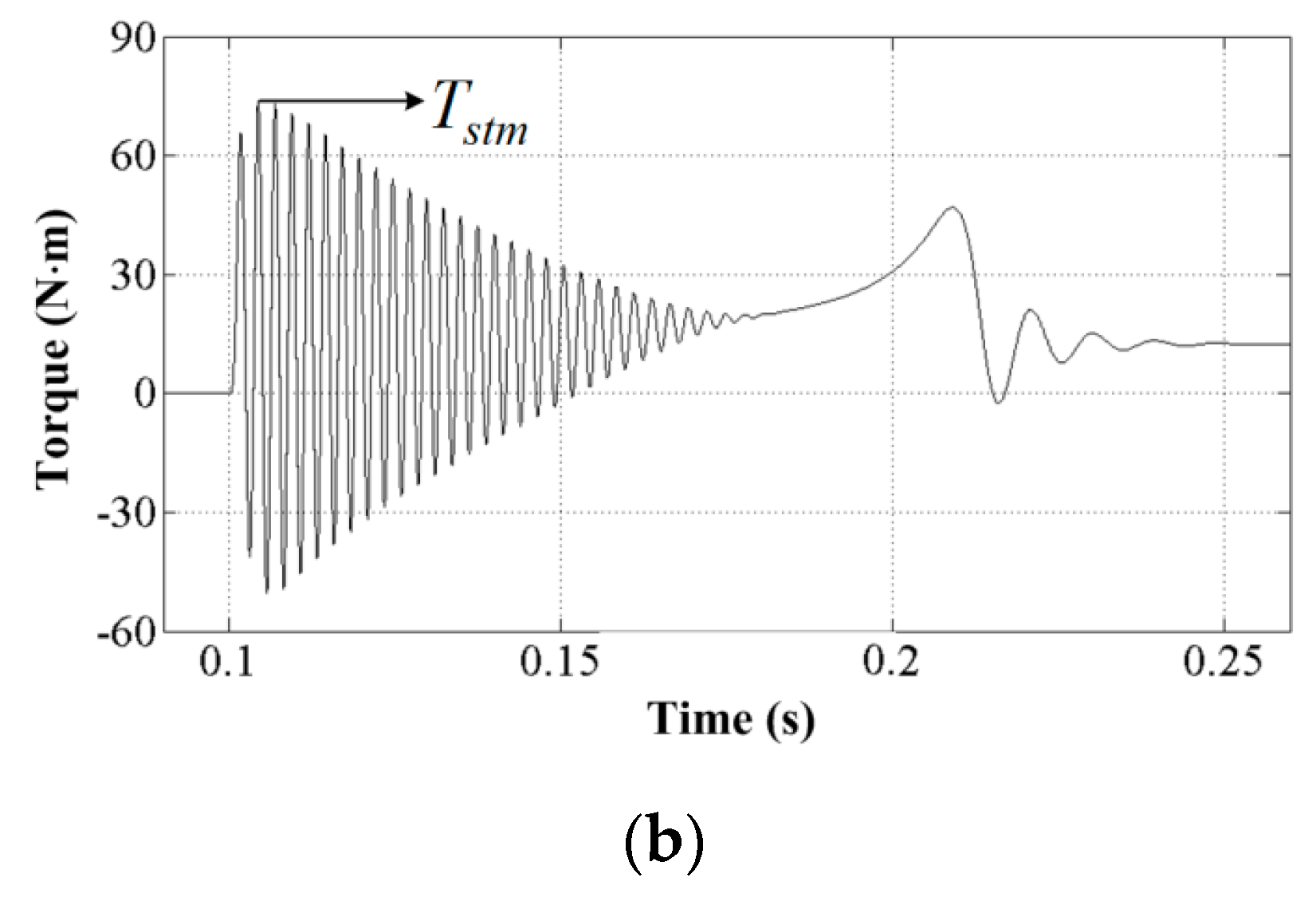

3.3. Approximate Model of Starting Peak Torque

4. Low-Frequency Step-Down Starting Method

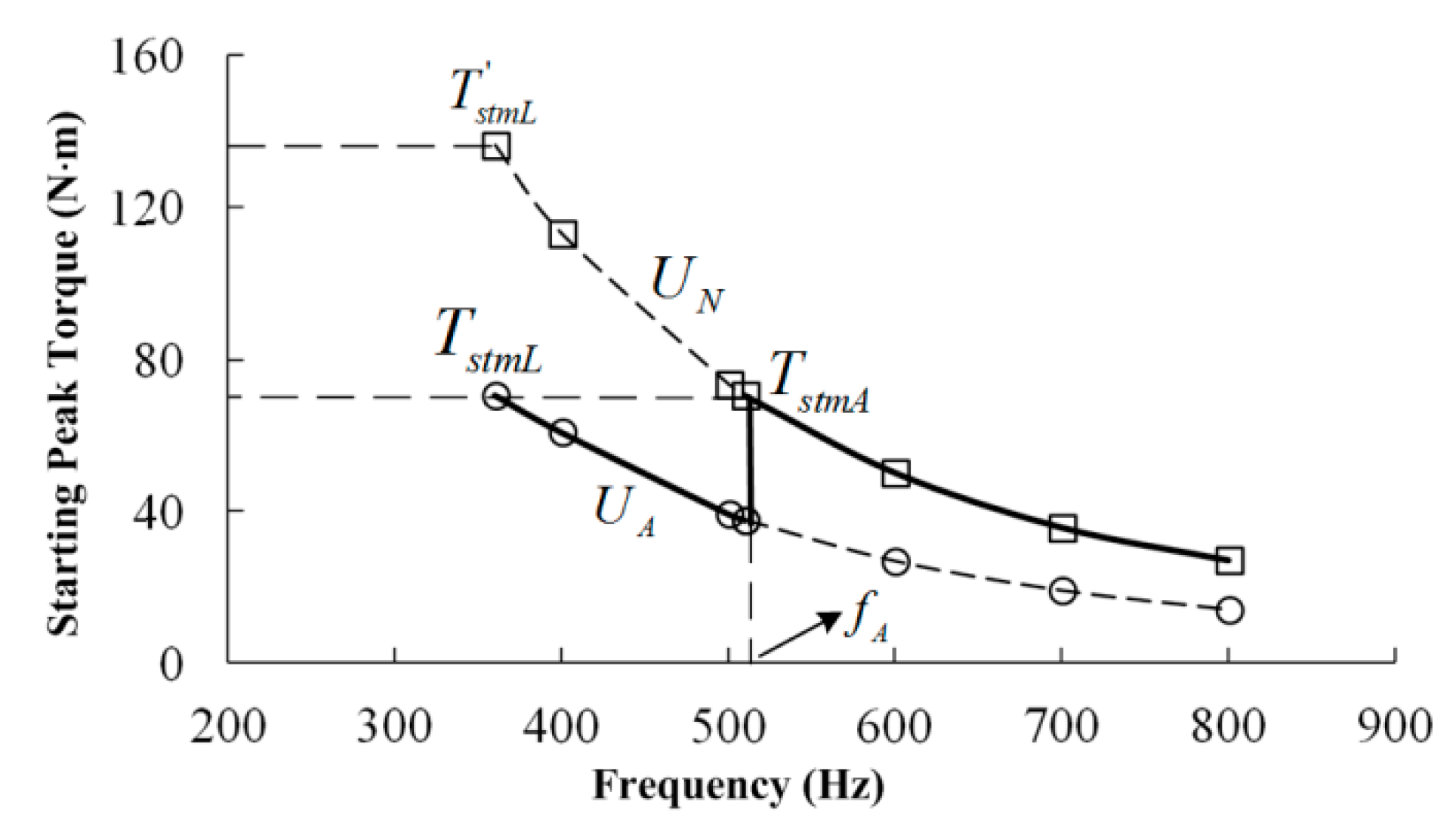

4.1. Principle of Low-Frequency Step-Down Starting

- (1)

- Principle I: The power supply voltage UA must ensure that kst and km meet the design requirements with the power frequency fA. If the working torque is TnA, the starting torque TstA ≥ kstTnA, and the critical torque TemA ≥ kmTnA;

- (2)

- Principle II: The TstmL with the power supply frequency f1L and the voltage UA is equal to the TstmA with the power supply frequency f1A and the voltage UN, that is, the maximum Tstm is the lowest in the entire frequency range.

4.2. Design of Low-Frequency Voltage Reduction

4.3. Design of Low-Frequency Series Resistance

4.4. Design of Low-Frequency Series Inductance

4.5. Design Example of Low-Frequency Step-Down Starting

5. Characteristic Analysis of Low-Frequency Step-Down Starting

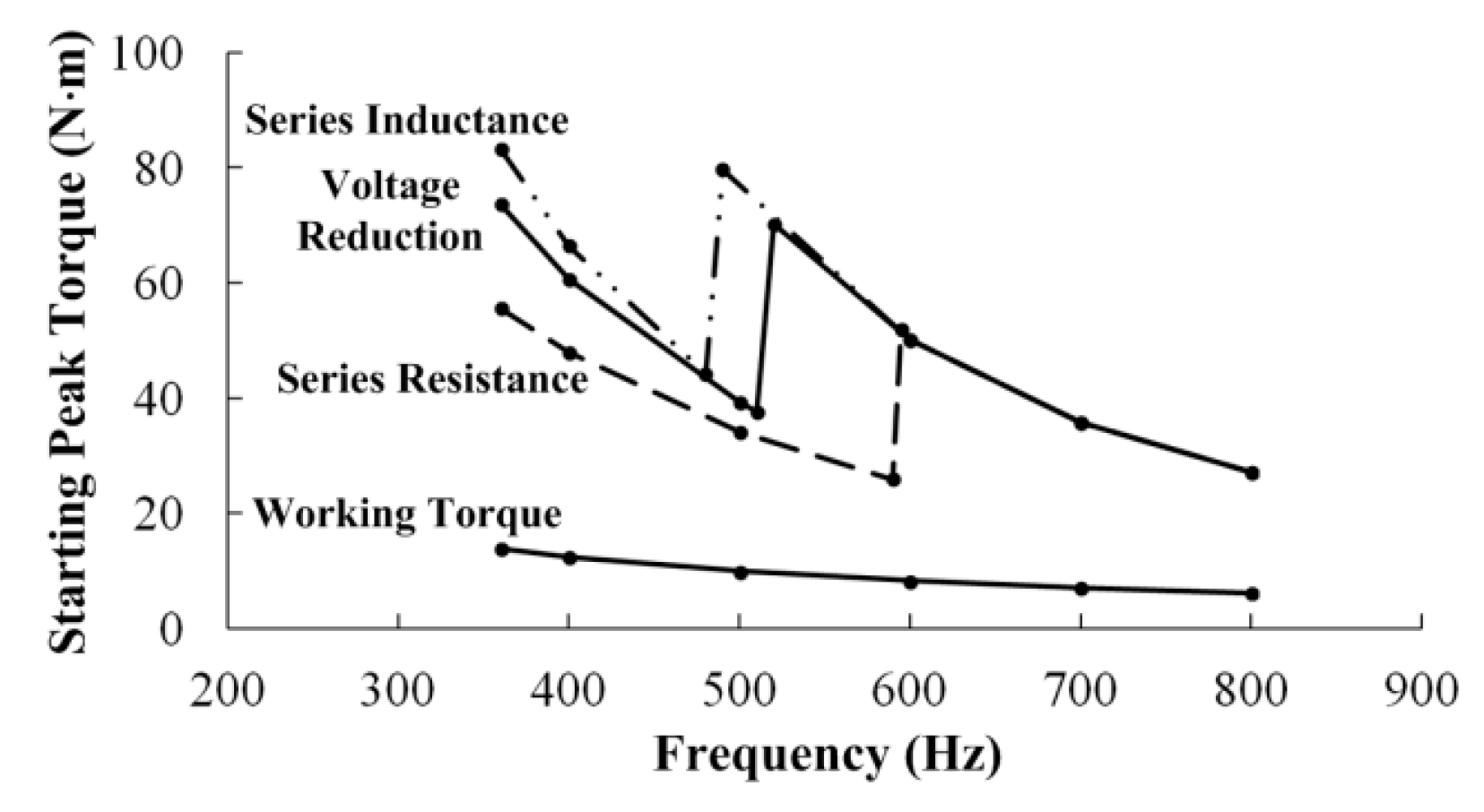

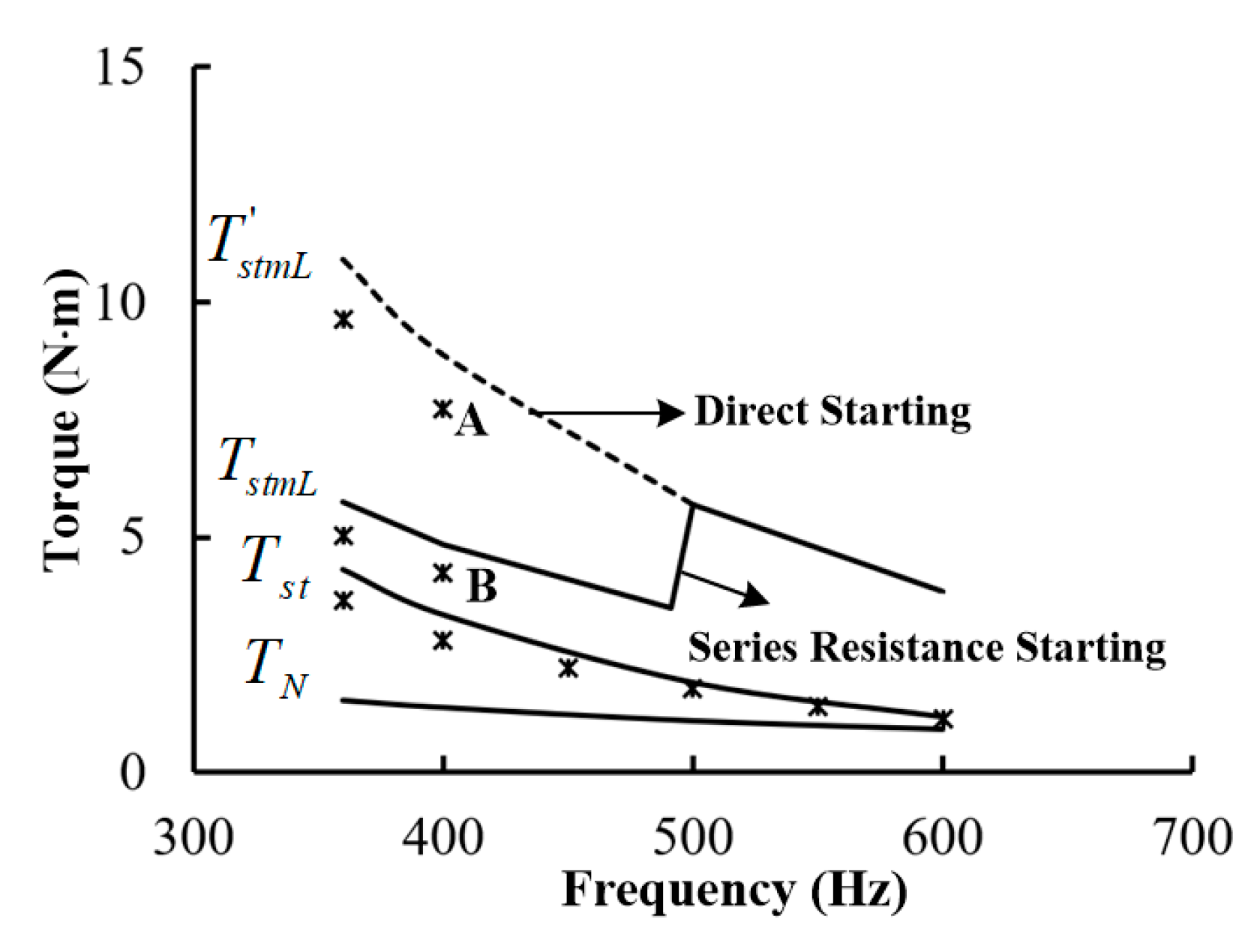

5.1. Characteristics of Starting Peak Torque

- (1)

- The series resistance method has the better suppression effect on the starting peak torque Tstm, as shown in Figure 8a. When the power supply frequency f1 decreases in the low-frequency stage, the voltage drop across the resistor RA increases due to the increase of starting current Ist. The voltage on the stator winding reduces to make Tstm decrease effectively.

- (2)

- The series inductance method has the poor suppression effect on the starting peak torque Tstm, as shown in Figure 8a. When the power supply frequency f1 decreases in the low-frequency stage, the impedance on the inductor LA decreases linearly. However, the starting current Ist does not increase linearly. The voltage drop on the inductor LA reduces and the voltage on the stator winding increases, causing the larger low-frequency Tstm.

- (3)

- The disadvantage of series resistance method is that it consumes the parts of power and causes the resistor heat. Therefore, it needs to be analyzed for the asynchronous motor that requires frequent starting. For the long-time work motor, the power consumed can be ignored since the starting time is short.

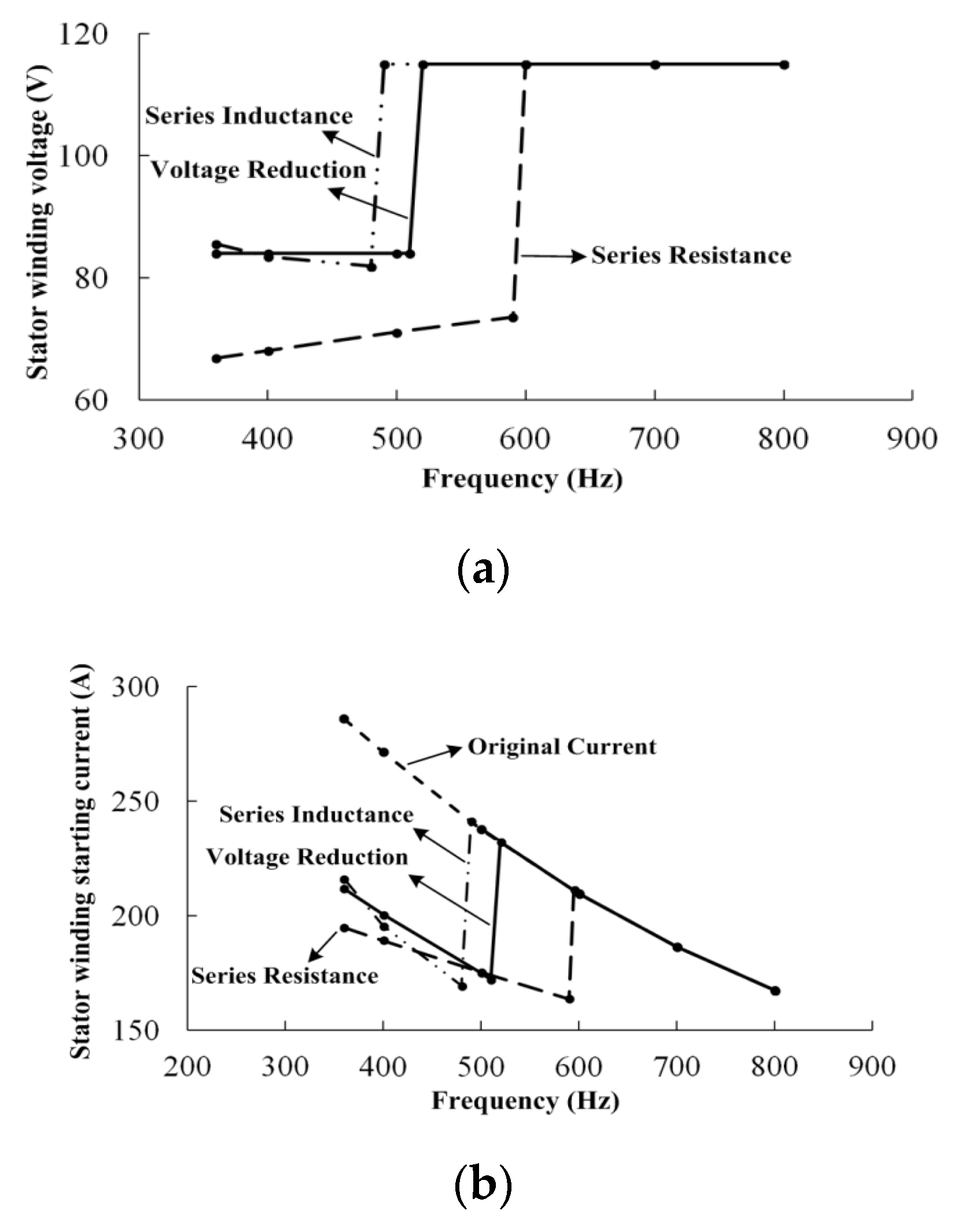

5.2. Characteristic Analysis of Starting Current

- (1)

- The frequency boundary point of series resistance method is the highest, and the starting current is the smallest with the rated voltage, which is 214A. The frequency boundary point of series inductance method is the lowest, and the starting current is the largest, which is 243A. The voltage reduction method is center, and the current is 236A.

- (2)

- For the starting current at the frequency f1L, the series resistance method has the lowest voltage, and the starting current is also the lowest, which is 195A. The starting currents of voltage reduction and the series inductance are 212A and 216A, respectively. The effect of series resistance is the best.

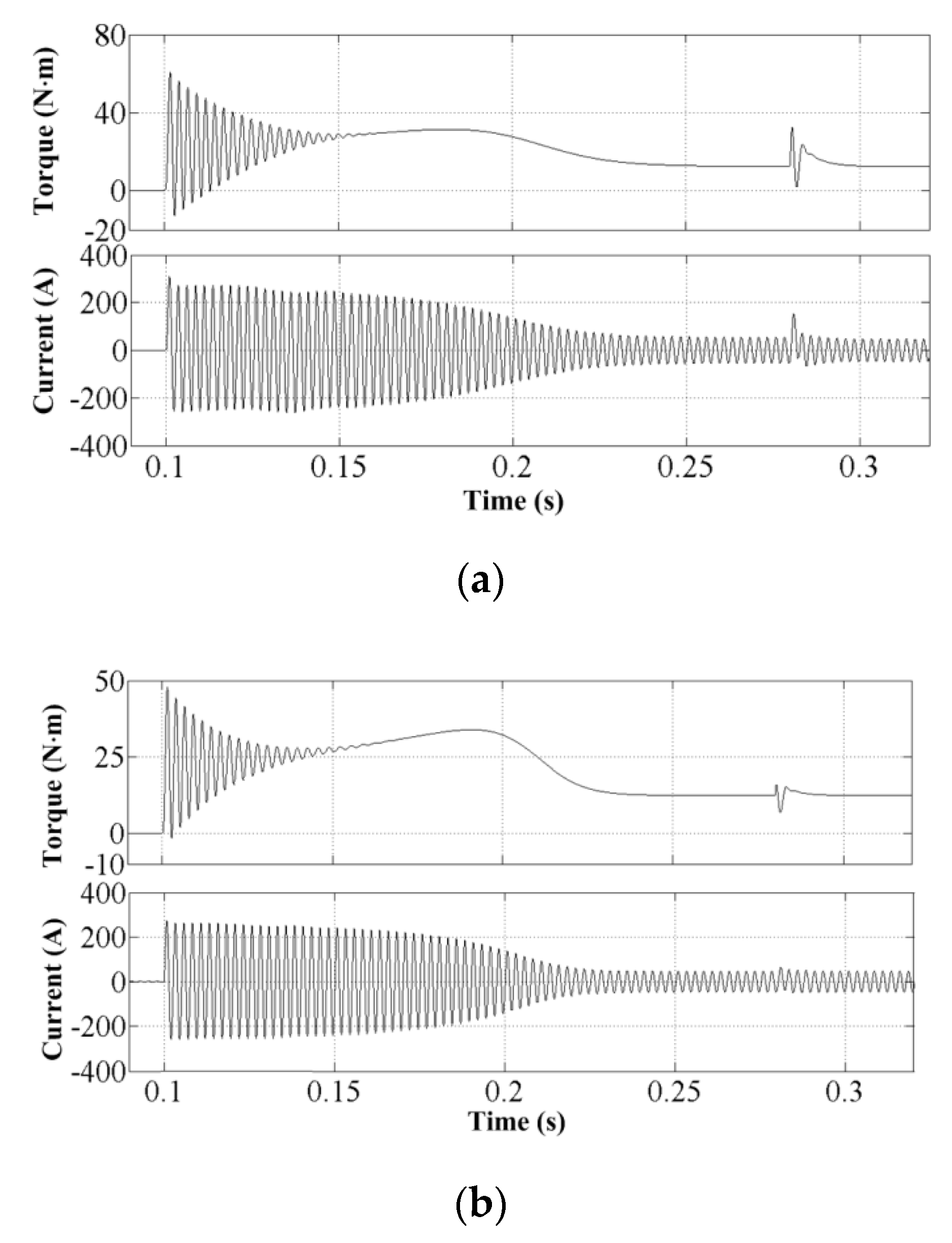

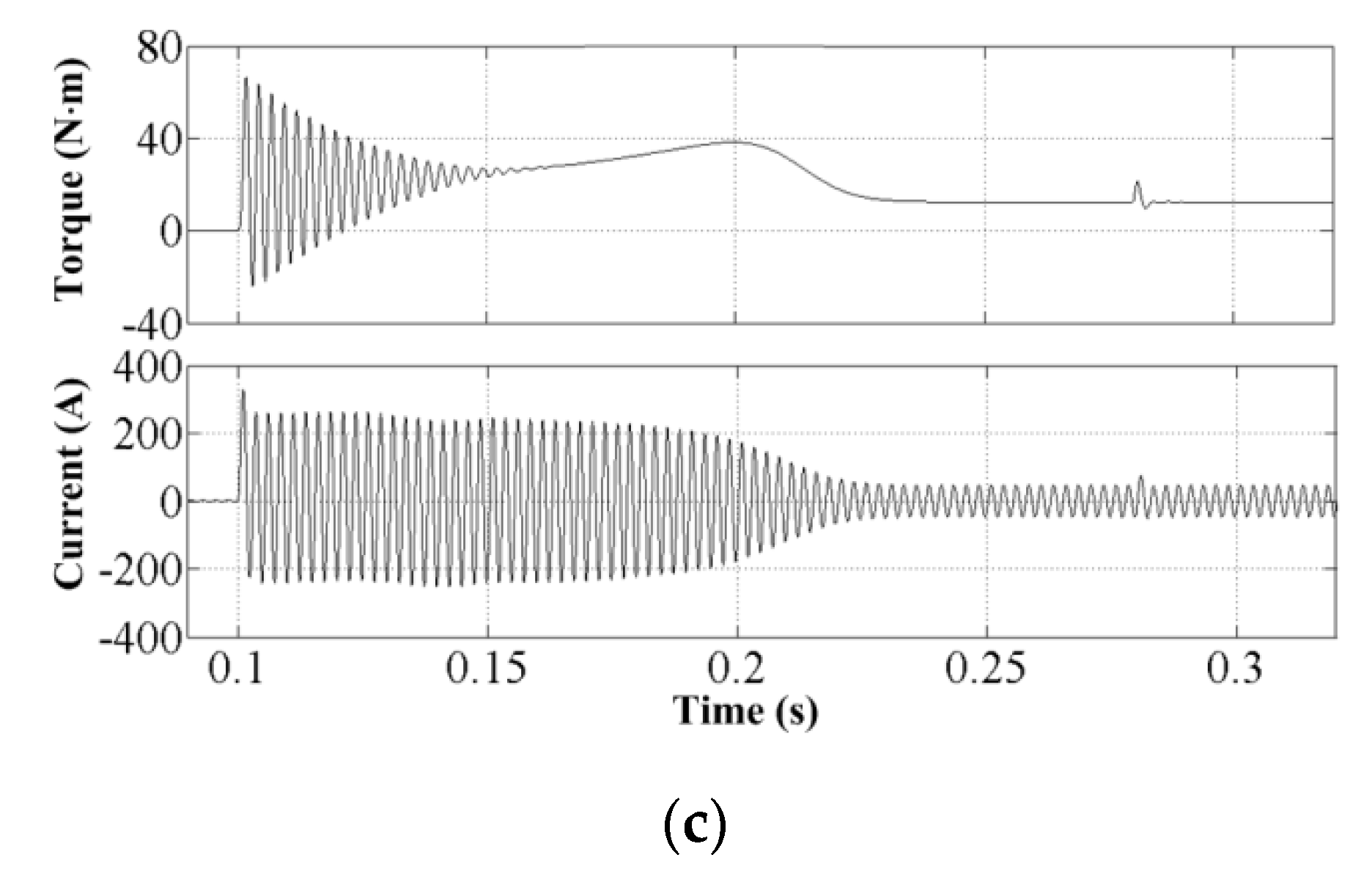

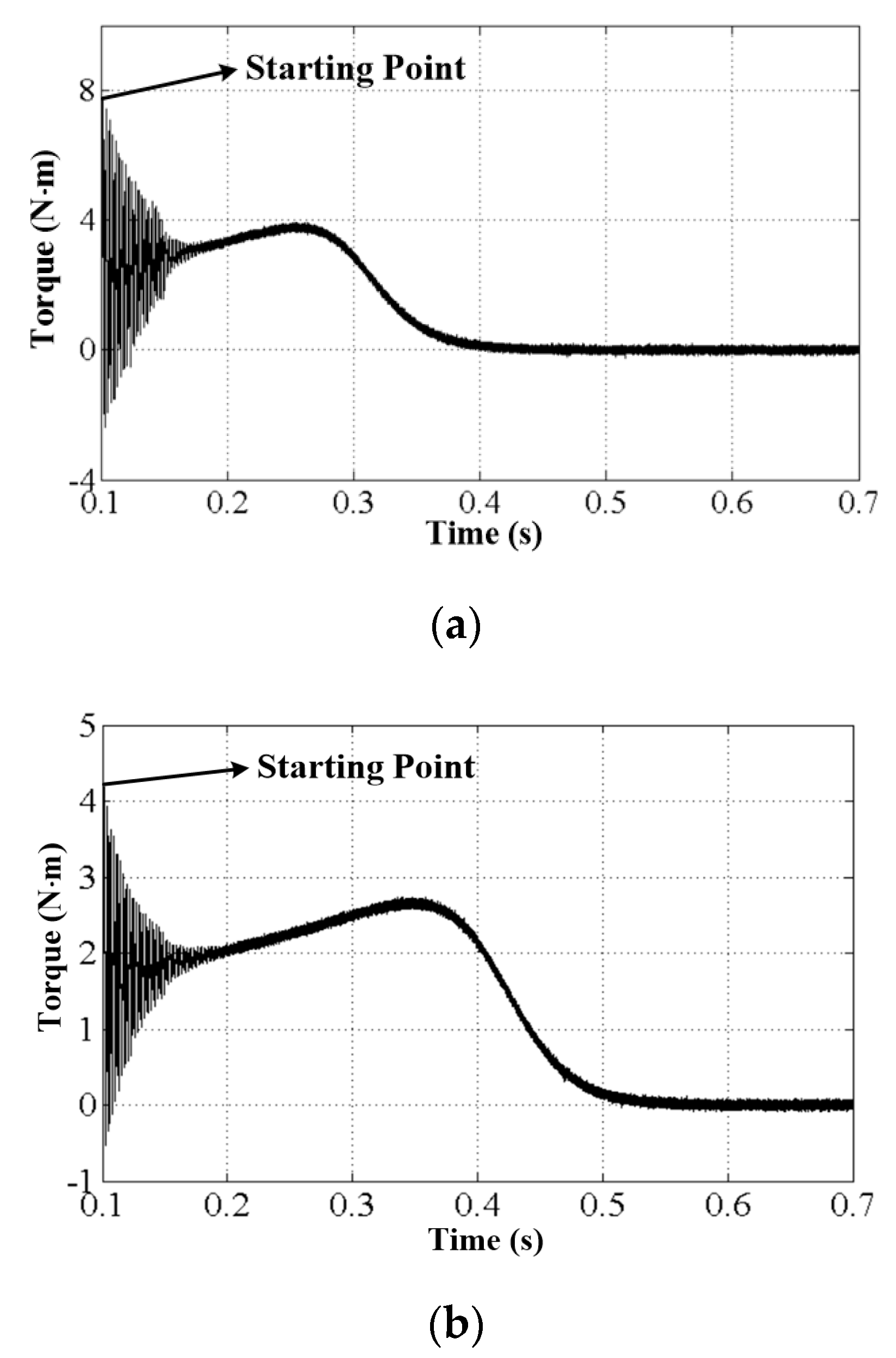

5.3. Simulation Test and Analysis of Starting Process

- (1)

- The starting torque Tstm of three methods is consistent with the characteristics of Figure 7. The series resistance method is the smallest, and the starting torque Tst is not a huge different.

- (2)

- The starting current Ist of three methods is consistent with the characteristics of Figure 8b, and series resistance method is the smallest.

- (3)

- After the step-down starting is completed, the normal power supply switching is restored, and the ΔTem, ΔIAm of series resistor method are the smallest.

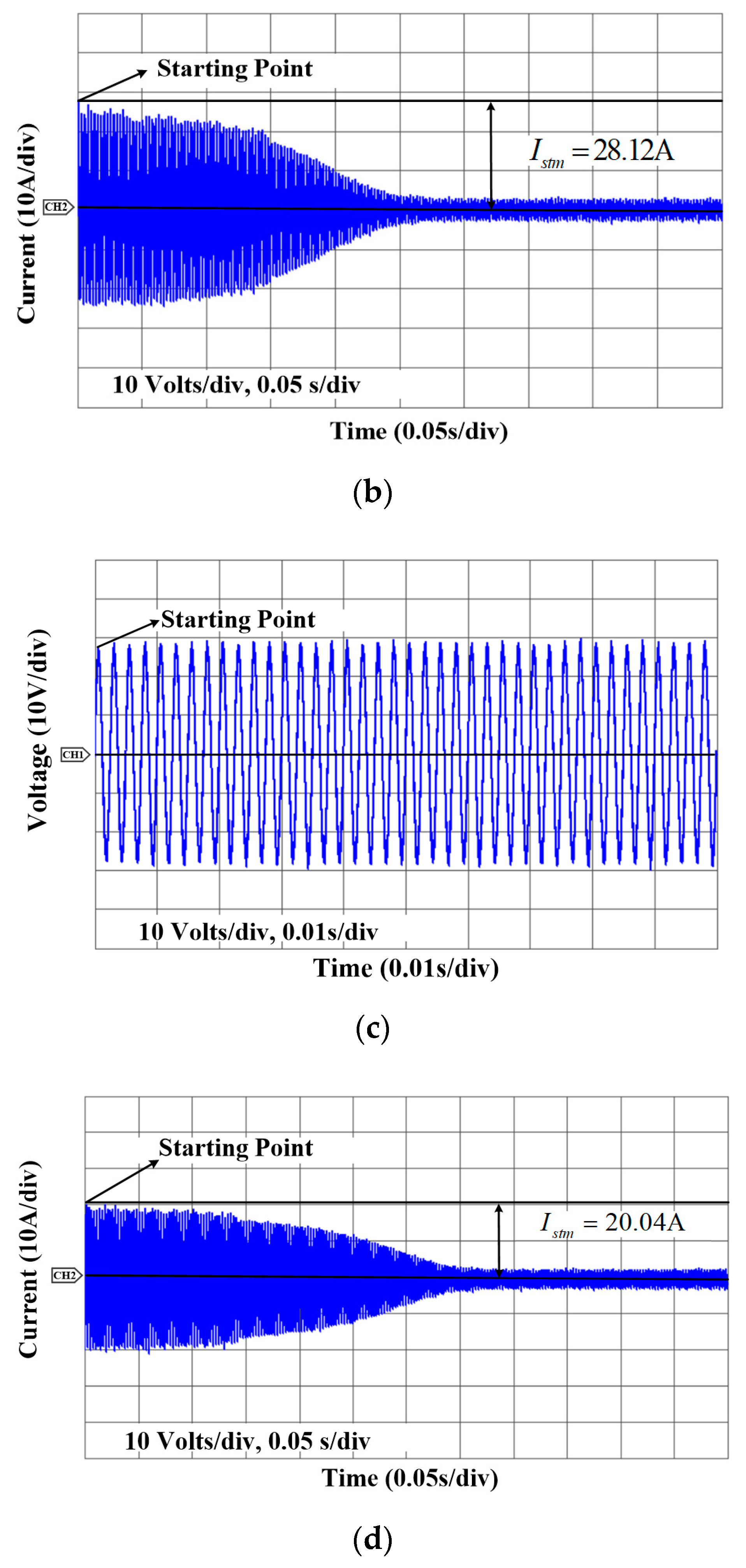

5.4. Experiment of Pump-Type Variable Frequency Asynchronous Motor

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xie, L.R.; Wang, Z.Y.; Chou, Q. Research on mechanical characteristics of squirrel cage asynchronous motor. J. Chin. Electr. Eng. Sci. 2008, 28, 68–72. [Google Scholar]

- Yetgin, A.G. Investigation of Effects of Stator Slot Permeance on Induction Motor and Obtaining the Best Starting Torque Using Permeance Calculation. Electr. Comput. Eng. 2020, 43, 25–29. [Google Scholar]

- Kia, S.H.; Henao, H. Torsional Vibration Assessment Using Induction Machine Electromagnetic Torque Estimation. IEEE Trans. Ind. Electron. 2009, 57, 209–219. [Google Scholar] [CrossRef]

- Xie, Y.; Pi, C.; Li, Z.W. Study on Design and Vibration Reduction Optimization of High Starting Torque Induction Motor. Energies 2019, 12, 1263. [Google Scholar]

- Kia, S.H.; Henao, H.; Capolino, G.A. Torsional Vibration Effects on Induction Machine Current and Torque Signatures in Gearbox-based Electromechanical System. IEEE Trans. Ind. Electron. 2009, 56, 4689–4699. [Google Scholar]

- Huang, X.Z.; Li, Q.F.; Zhao, X.Y. Research on Pulse Torque of Three-phase Asynchronous Motor Based on Skew Slot. J. Electrotech. Soc. 2015, 7, 194. [Google Scholar]

- Widdle, R.D.; Krousgrill, C.M.; Sudhoff, S.D. An Induction Motor Model for High-frequency Torsional Vibration Analysis. J. Sound Vib. 2008, 290, 865–881. [Google Scholar] [CrossRef]

- Abdel-Rahim, N.M.B.; Shaltout, A. Cost-Effective Control Scheme for Reduction of Torsional Torque Oscillations in Starting Large Induction Motors. Electr. Power Compon. Syst. 2006, 34, 1163–1175. [Google Scholar] [CrossRef]

- Wheller, P. Technology for the More and All Electric Aircraft of Future. In Proceedings of the International Conference on Automatic, Curico, Chile, 19–21 October 2016. [Google Scholar]

- Piancastelli, L.; Gatti, A.; Frizziero, L.; Ragazzi, L.; Cremonini, M. CFD Analysis of Zimmerman’s V173 Stol Aircraft. J. Eng. Appl. Sci. 2015, 10, 8063–8070. [Google Scholar]

- Rosero, J.A.; Ortega, J.A.; Aldabase, E. Moving Towards a More Electric Aircraft. IEEE Aerosp. Electron. Syst. 2007, 22, 3–9. [Google Scholar]

- Li, W.L.; Yang, Y.; Zhang, X.B. Digital Generator Control Unit Design for a Variable Frequency Synchronous Generator in MEA. Energies 2018, 11, 96. [Google Scholar] [CrossRef]

- Du, X.F.; Hou, Y.Z.; Sun, C. Optimization Analysis of Rectangular Rotor Slot Structure of Squirrel Cage Asynchronous Motor under Aviation Variable Frequency Power. J. Aeronaut. 2015, 36, 614–624. [Google Scholar]

- Charles, O.; Moataz, E.; Augustin, M.M. Multi-Phase Modular Drive System: A Case Study in Electrical Aircraft Applications. Energies 2018, 11, 5. [Google Scholar]

- Zheng, X.C.; Gao, F.; Husan, A. A Droop Control Based Three Phase Bidirectional AC-DC Converter for More Electric Aircraft Applications. Energies 2017, 10, 400. [Google Scholar] [CrossRef]

- Benarous, M. Design of a Director On-Line Induction Motor for Variable Frequency Aerospace Application. In Proceedings of the IET International Conference on Power Electronics, Machines and Drives, Dublin, Ireland, 4–6 April 2006; pp. 202–206. [Google Scholar]

- Du, X.F.; Wang, D.Q. Transient Simulation Studies of Squirrel-cage Induction Motor Directly Supplied with Aircraft Variable Frequency Power. In Proceedings of the IEEE Electrical machines and System, Busan, Korea, 26–29 October 2013; pp. 2000–2005. [Google Scholar]

- Du, X.F. Study on Performance Characteristics of Induction Motor operated with Aero Variable Frequency Power Supply. Ph.D. Thesis, Beihang University, Beijing, China, 2014. [Google Scholar]

- Cao, Z.; Zhou, Y.J.; Han, Z.L.; Guo, B.T. Design Stress Analysis of Mechanical Equipment for Aviation Variable Frequency Asynchronous Motors. J. Micromotor 2018, 51, 1–5. [Google Scholar]

- Li, S.M. Mechanical Fatigue and Reliability Analysis, 1st ed.; Science Press: Beijing, China, 2006. [Google Scholar]

- Mroz, J.; Wojciech, P. Improvement of Thermal and Mechanical Strength of Starting Cage of Double-Cage Induction Motors. Energies 2019, 12, 4551. [Google Scholar] [CrossRef]

- Abdel-Rahim, N.M.B.; Shaltout, A. Torsional Vibration Control of Large Induction Motors Using Constant Air Gap Flux Cheme. IET Electr. Power Appl. 2012, 8, 515–522. [Google Scholar]

- Feehally, T.; Damián, I.E.; Apsley, J.M. Analysis of Electromechanical Interaction in Aircraft Generator Systems. IEEE Trans. Ind. Appl. 2016, 50, 4327–4335. [Google Scholar] [CrossRef]

- Liu, L.H. The Comparison and Test Check for Goodness of Fit. J. Yangtze Univ. 2013, 10, 14–16. [Google Scholar]

| Parameters | Value |

|---|---|

| PN (kW) | 7.5 |

| p | 4 |

| R1 (Ω) | 0.12 |

| Ll1 (mH) | 0.06035 |

| R’2 (Ω) | 0.147 |

| L’l2 (mH) | 0.08715 |

| Lm (mH) | 1.986 |

| Frequency | Cstm | kstm |

|---|---|---|

| 360 | 0.00166 | 1 |

| 400 | 0.00153 | 0.92 |

| 500 | 0.00129 | 0.78 |

| 600 | 0.00114 | 0.69 |

| 700 | 0.00103 | 0.62 |

| 800 | 0.00094 | 0.57 |

| Control Parameters | Voltage Reduction | Series Resistance | Series Inductance |

|---|---|---|---|

| fA (Hz) | 510 | 590 | 480 |

| Step-down Data | UA = 84 V | RA = 0.242 Ω | LA = 0.091 mH |

| TnA (N·m) | 9.75 | 8.45 | 10.38 |

| TstA (N·m) | 13.23 | 11.15 | 12.68 |

| kstA | 1.36 | 1.32 | 1.22 |

| TstmA (N·m) | 70.2 | 52 | 77.71 |

| TstmL (N·m) | 73.63 | 55.5 | 83.13 |

| Control Methods | Starting Characteristics | Switching Characteristics | ||||

|---|---|---|---|---|---|---|

| Parameters | Tstm (N·m) | Tst (N·m) | Ist (A) | ∆Tem (N·m) | ∆IAm (A) | |

| Voltage reduction | 60.73 | 24.07 | 219.85 | 20.25 | 71.06 | |

| Series resistance | 47.87 | 23.23 | 193.58 | 5.61 | 7.37 | |

| Series inductance | 66.43 | 21.19 | 231.58 | 8.82 | 14.08 | |

| Parameters | Value |

|---|---|

| R1 (Ω) | 1.381 |

| Ll1 (mH) | 0.612 |

| R’2 (Ω) | 1.762 |

| L’l2 (mH) | 1.328 |

| Lm (mH) | 10.226 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Z.; Zhou, Y.; Wang, N. Starting Pulse Vibration Torque Analysis of Aviation Variable Frequency Asynchronous Motor Based on Low-Frequency Step-Down Starting Methods. Energies 2020, 13, 1337. https://doi.org/10.3390/en13061337

Cao Z, Zhou Y, Wang N. Starting Pulse Vibration Torque Analysis of Aviation Variable Frequency Asynchronous Motor Based on Low-Frequency Step-Down Starting Methods. Energies. 2020; 13(6):1337. https://doi.org/10.3390/en13061337

Chicago/Turabian StyleCao, Zheng, Yuanjun Zhou, and Na Wang. 2020. "Starting Pulse Vibration Torque Analysis of Aviation Variable Frequency Asynchronous Motor Based on Low-Frequency Step-Down Starting Methods" Energies 13, no. 6: 1337. https://doi.org/10.3390/en13061337

APA StyleCao, Z., Zhou, Y., & Wang, N. (2020). Starting Pulse Vibration Torque Analysis of Aviation Variable Frequency Asynchronous Motor Based on Low-Frequency Step-Down Starting Methods. Energies, 13(6), 1337. https://doi.org/10.3390/en13061337