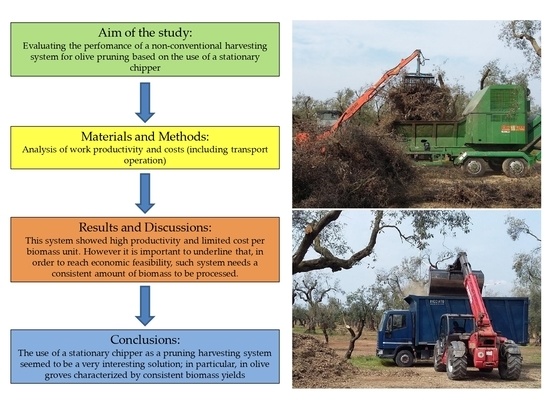

Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Field and Prunings’ Characteristics

2.2. Harvesting System Description

2.3. Harvesting System Performance and Quality of the Work Evaluations

2.4. Harvesting Cost Analysis

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GHG | greenhouse gases |

| SC | stationary chipper |

| TFC | theoretical field capacity (ha·h−1) |

| EFC | effective field capacity (ha·h−1) |

| FC | field efficiency % |

| MC | material capacity (t·h−1) |

| PSD | particle size distribution |

| WT | working time |

| B | biomass |

References

- Picchi, G.; Lombardini, C.; Pari, L.; Spinelli, R. Physical and chemical characteristics of renewable fuel obtained from pruning residues. J. Clean. Prod. 2018, 171, 457–463. [Google Scholar] [CrossRef]

- Magagnotti, N.; Pari, L.; Picchi, G.; Spinelli, R. Technology alternatives for tapping the pruning residue resource. Bioresour. Technol. 2013, 128, 697–702. [Google Scholar] [CrossRef] [PubMed]

- Pari, L.; Alfano, V.; Garcia-Galindo, D.; Suardi, A.; Santangelo, E. Pruning biomass potential in Italy related to crop characteristics, agricultural practices and agro-climatic conditions. Energies 2018, 11, 1365. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Tang, Y.; Xie, J.; Yuan, Y. The role of marginal agricultural land-based mulberry planting in biomass energy production. Renew. Energy 2009, 34, 1789–1794. [Google Scholar] [CrossRef]

- Gonçalves, C.; Evtyugina, M.; Alves, C.; Monteiro, C.; Pio, C.; Tomé, M. Organic particulate emissions from field burning of garden and agriculture residues. Atmos. Res. 2011, 101, 666–680. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Pastore, V.; Palese, A.M.; Arous, A.; Celano, G. A comprehensive Life Cycle Assessment (LCA) of three apricot orchard systems located in Metapontino area (Southern Italy). J. Clean. Prod. 2017, 142, 4059–4071. [Google Scholar] [CrossRef]

- García-Galindo, D.; López, E.; Gómez, M.; Sebastián, F.; Gebresenbet, G.; Jirjis, R.; Kern, J.; Germer, S.; Pari, L.; Suardi, A.; et al. Europruning project: Summary of final results. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 89–102. [Google Scholar]

- Spinelli, R.; Lombardini, C.; Pari, L.; Sadauskiene, L. An alternative to field burning of pruning residues in mountain vineyards. Ecol. Eng. 2014, 70, 212–216. [Google Scholar] [CrossRef]

- Avraamides, M.; Fatta, D. Resource consumption and emissions from olive oil production: A life cycle inventory case study in Cyprus. J. Clean. Prod. 2008, 16, 809–821. [Google Scholar] [CrossRef]

- Jacometti, M.A.; Wratten, S.D.; Walter, M. Management of understorey to reduce the primary inoculum of Botrytis cinerea: Enhancing ecosystem services in vineyards. Biol. Control. 2007, 40, 57–64. [Google Scholar] [CrossRef]

- Summaries ofAGROinLOG (Demonstration of Innovative Integrated Biomass Logistics Centres for the Agro-Industry Sector in Europe) project, Ref Number: 727961. Available online: https://cordis.europa.eu/project/rcn/205975_en.html. (accessed on 13 December 2019).

- Khawaja, C.; Janssen, R.; Kindler, A.; Solar, T.; Engelmann, K.; López, E.; García-galindo, D.; Poutrin, C. Triggering the Creation of Biomass Logistic Centres by the Agro-Industry Handbook for Agro-Industries Interested in Starting a New Activity as Biomass Logistic Centre: The Basic Demand of Information; FAO: Rome, Italy, 2015. [Google Scholar]

- Khawaja, C.; Janssen, C. D4.3a of the SUCELLOG Project—Summary of the Current Situation of Tschiggerl Agrar GmbH and Feasibility Study. SUCELLOG Project, Triggering the Creation of Biomass Logistic Centres by the Agro-Industry; Sucellog: Zaragoza, Spain, 2015. [Google Scholar]

- Up_running Take-Off for Sustainable Supply of Woody Biomass from Agrarian Pruning and Plantation Removal. H2020-LCE-2015, 2015-2016. Ref number: 691748. Available online: http://www.up-running.eu/. (accessed on 13 December 2019).

- Pari, L.; Suardi, A.; Santangelo, E.; García-Galindo, D.; Scarfone, A.; Alfano, V. Current and innovative technologies for pruning harvesting: A review. Biomass Bioenergy 2017, 107, 398–410. [Google Scholar] [CrossRef]

- Acampora, A.; Croce, S.; Assirelli, A.; Del Giudice, A.; Spinelli, R.; Suardi, A.; Pari, L. Product contamination and harvesting losses from mechanized recovery of olive tree pruning residues for energy use. Renew. Energy 2013, 53, 350–353. [Google Scholar] [CrossRef]

- Spinelli, R.; Cavallo, E.; Eliasson, L.; Facello, A. Comparing the efficiency of drum and disc chippers. Silva Fenn. 2013, 47, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Spinelli, R.; Hartsough, B.R.; Magagnotti, N. Testing mobile chippers for chip size distribution. Int. J. Eng. 2005, 16, 29–35. [Google Scholar] [CrossRef]

- Nati, C.; Spinelli, R.; Fabbri, P. Wood chips size distribution in relation to blade wear and screen use. Biomass Bioenergy 2010, 34, 583–587. [Google Scholar] [CrossRef]

- Civitarese, V.; Del Giudice, A.; Suardi, A.; Santangelo, E.; Pari, L. Study on the effect of a new rotor designed for chipping short rotation woody crops. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2015, 36, 101–108. [Google Scholar]

- Velázquez-Martí, B.; Fernández-González, E.; Callejón-Ferre, Á.J.; Estornell-Cremades, J. Mechanized methods for harvesting residual biomass from Mediterranean fruit tree cultivations. Sci. Agric. 2012, 69, 180–188. [Google Scholar] [CrossRef] [Green Version]

- ASAE. ASAE S495 Uniform Terminology for Agricultural Machinery Managemen; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; pp. 342–343. [Google Scholar]

- ISO 17828:2015. Solid biofuels — Determination of bulk density. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17828:en (accessed on 13 December 2019).

- ISO 18134-2:2017. Solid biofuels — Determination of moisture content — Oven dry method — Part 2: Total moisture — Simplified method. Available online: https://www.iso.org/obp/ui/#iso:std:iso:18134:-2:ed-2:v1:en (accessed on 13 December 2019).

- Eija, A.; Markus, H.; Jaana, L.-L.; Jaana, K. Properties of indigenous fuels in Finland. VTT Technol. 2016, 30–32. [Google Scholar]

- Pari, L.; Suardi, A.; Del Giudice, A.; Scarfone, A.; Santangelo, E. Influence of chipping system on chipper performance and wood chip particle size obtained from peach prunings. Biomass Bioenergy 2018, 112, 121–127. [Google Scholar] [CrossRef]

- UNI EN ISO 17225-4:2014. Solid Biofuels - Fuel Specifications and Classes - Part 4: Graded Wood Chips. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17225:-4:ed-1:v1:en (accessed on 13 December 2019).

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Rice Prod. Anim. 2005, 5, 1–10. [Google Scholar]

- ASAE. EP496.2 Agricultural Machinery Management; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2000; pp. 344–349. [Google Scholar]

- Ministero delle Infrastrutture e dei Trasporti (Ministry of Infrastructure and Transport). Linee Guida Per La Valutazione Degli Investimenti in Opere Pubbliche, Nei Settori Di Competenza Del Ministero Delle Infrastrutture e Dei Trasporti (Guidelines for the Evaluation of Investments in Public Works, in the Areas of Competence of the Ministry; Ministero Delle Infrastrutture e Dei Trasporti: Rome, Italy, 2014.

- Spinelli, R.; Magagnotti, N.; Nati, C.; Cantini, C.; Sani, G.; Picchi, G.; Biocca, M. Integrating olive grove maintenance and energy biomass recovery with a single-pass pruning and harvesting machine. Biomass Bioenergy 2011, 35, 808–813. [Google Scholar] [CrossRef]

- Cuchet, E.; Roux, P.; Spinelli, R. Performance of a logging residue bundler in the temperate forests of France. Biomass Bioenergy 2004, 27, 31–39. [Google Scholar] [CrossRef]

- Yoshioka, T.; Hirata, S.; Matsumura, Y.; Sakanishi, K. Woody biomass resources and conversion in Japan: The current situation and projections to 2010 and 2050. Biomass Bioenergy 2005, 29, 336–346. [Google Scholar] [CrossRef]

- Johansson, J.; Liss, J.-E.; Gullberg, T.; Björheden, R. Transport and handling of forest energy bundles—Advantages and problems. Biomass Bioenergy 2006, 30, 334–341. [Google Scholar] [CrossRef]

- Spinelli, R.; Picchi, G. Industrial harvesting of olive tree pruning residue for energy biomass. Bioresour. Technol. 2010, 101, 730–735. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E. Analysis of the process of biomass harvesting with collecting-chippers fed by pick up headers in plantations of olive trees. Biosyst. Eng. 2009, 104, 184–190. [Google Scholar] [CrossRef]

- Krajnc, N.; Jemec, T.; Rogelja, T.; Mattioli, D.; Schmatzberger, S.; Luttmann, A.; Oršanič, T.H.; Kunst, M.; Kezdy, P.; Michele, L.; et al. Steps in Setting Up Wood Biomass Production Chains in Protected Areas; Bioeuparks project: 2015. Available online: https://slideplayer.com/slide/8879362/ (accessed on 13 December 2019).

- Pari, L.; Suardi, A.; Frąckowak, P.; Adamczyk, F.; Szaroleta, M.; Santangelo, E.; Bergonzoli, S.; Del Giudice, A.; Dyjakon, A. Two innovative prototypes for collecting pruning biomass: Early performance tests and assessment of the work quality. Biomass Bioenergy 2018, 117, 96–101. [Google Scholar] [CrossRef]

- Latterini, F.; Consiglio per la Ricerca in Agricoltura e l’Analisi dell’Economia Agraria (CREA), Rome, Italy. Personal Comunication, 2019.

| Parameters | Unit | Landini Rex 90 S DT Cab | Caravaggi BIO900 | Agrisav CAS 1000 | Same Virtus 140 dt Cab | Manitou 940–120 LSU | IVECO Trakker 190T36 |

|---|---|---|---|---|---|---|---|

| Investment | € | 54,554.00 | 92,800.00 | 15,060.00 | 96,340.00 | 110,000.00 | 130,850.00 |

| Service life | yr | 10 | 10 | 10 | 10 | 10 | - |

| Usage | h·yr−1 | 460 | 460 | 460 | 460 | 460 | - |

| Labor costs | €·h−1 | 11.50 | 11.50 | 11.50 | 11.50 | 11.50 | 16.66 |

| Crew | n | 1 | 1 | 1 | 1 | 1 | 1 |

| Load | t | - | - | - | - | - | 16.8 |

| Distance to power plant | km | - | - | - | - | - | 9.3 |

| Variable | Unit | Value |

|---|---|---|

| Theoretical Field Capacity (TFC) | ha·h−1 | 0.61 ± 0.13 |

| Effective Field Capacity (EFC) | ha·h−1 | 0.60 ± 0.13 |

| Field efficiency (FE) | % | 99.0 |

| Yield | tfm·ha−1 | 12.8 |

| Material Capacity (MC) | tfm·h−1 | 7.26 ± 1.13 |

| Material Capacity (MC) | tdm·h−1 | 5.23 ± 0.81 |

| Fuel Consumption | l·tfm | 3.5 ± 0.40 |

| Fuel Consumption | l·h−1 | 25.1 ± 0.80 |

| Bulk Density | kgfm·m−3 | 246 ± 11 |

| Moisture content | % | 28 ± 0.40 |

| d50 value for particle size distribution | mm | 9.17 |

| Particle size distribution class | - | P16 |

| Cost Item | Measure Unit | Caravaggi BIO900 | Landini Rex 90 S DT Cab | Agrisav CAS 1000 | Same Virtus 140 dt Cab | Manitou 940–120 LSU | |

|---|---|---|---|---|---|---|---|

| Fixed costs | Reintegration quote | €·yr−1 | 7638.91 | 3644.64 | 1206.74 | 6436.28 | 7360.67 |

| Interests | €·yr−1 | 1638.16 | 1089.92 | 270.79 | 1924.76 | 2195.90 | |

| Shelter | €·yr−1 | 45.61 | 14.63 | 27.50 | 21.44 | 28.36 | |

| Insurance | €·yr−1 | 232.00 | 136.39 | 37.65 | 240.85 | 275.00 | |

| Miscellaneous expenses | €·yr−1 | 277.61 | 151.02 | 65.15 | 262.29 | 303.36 | |

| Total fixed costs per year | €·yr−1 | 9554.69 | 4885.58 | 1542.68 | 8623.33 | 9859.93 | |

| Total fixed costs per hour | €·h−1 | 20.77 | 10.62 | 3.35 | 18.75 | 21.43 | |

| Variable costs | Maintenance | €·h−1 | 7.41 | 1.02 | 1.20 | 1.81 | 2.07 |

| Fuel | €·h−1 | 7.20 | 5.04 | 2.16 | 3.10 | ||

| Lubricant | €·h−1 | 0.30 | 0.19 | 0.24 | 0.23 | ||

| Manpower | €·h−1 | 11.50 | 11.50 | 11.50 | 11.50 | 11.15 | |

| Total variable costs per hour | €·h−1 | 18.91 | 17.76 | 12.70 | 15.71 | 16.54 | |

| Total costs per year | €·yr−1 | 18253.80 | 13053.99 | 7385.92 | 15847.68 | 17469.68 | |

| Total costs per hour | €·h−1 | 39.68 | 28.38 | 16.06 | 34.45 | 37.98 | |

| Total costs per hectare | €·ha−1 | 66.14 | 47.30 | 26.76 | 57.42 | 32.77 | |

| Total costs per ton | €·tfm−1 | 5.47 | 3.92 | 2.22 | 4.75 | 2.71 |

| Harvesting System | Reference | Initial Investment (€) | Harvesting Cost | ||

|---|---|---|---|---|---|

| (€·h−1) | (€·ha−1) | (€·tfm−1) | |||

| SAT-4 | [32] | 190,000.00 | 158.00 | 67.05 | 29.99 |

| Jordan | [32] | 250,000.00 | 149.00 | 263.20 | 22.53 |

| Favaretto | [31] | 180,000.00 | 77.20 | 97.87 | 58.70 |

| Caravaggi | this study | 368,754.00 | 156.55 | 230.38 | 19.07 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Pari, L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies 2020, 13, 1359. https://doi.org/10.3390/en13061359

Suardi A, Latterini F, Alfano V, Palmieri N, Bergonzoli S, Pari L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies. 2020; 13(6):1359. https://doi.org/10.3390/en13061359

Chicago/Turabian StyleSuardi, Alessandro, Francesco Latterini, Vincenzo Alfano, Nadia Palmieri, Simone Bergonzoli, and Luigi Pari. 2020. "Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production" Energies 13, no. 6: 1359. https://doi.org/10.3390/en13061359

APA StyleSuardi, A., Latterini, F., Alfano, V., Palmieri, N., Bergonzoli, S., & Pari, L. (2020). Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies, 13(6), 1359. https://doi.org/10.3390/en13061359