1. Introduction

The increasing awareness of the environmental impact of the shipping industry is pushing the development of novel solutions to reduce the emission of pollutants from ships. In this context, the International Maritime Organization (IMO) recently introduced a novel legislation framework constraining the emissions of nitrogen oxides (NO

x) [

1] and sulfur oxides (SO

x) [

2], and set the vision to reduce the greenhouse gas (GHG) emissions by 50% compared to the emissions levels of 2008 by 2050 [

3].

Several alternative solutions can, in theory, lead to a reduction of the emissions from shipping, one of them being the use of liquefied natural gas (LNG) [

4]. Compared to the use of traditional heavy fuel oils (HFO), the use of LNG leads to substantial reductions in the NO

x and SO

x emissions [

5]: the former can be reduced up to 85% thanks to the lean combustion process, while the latter are almost completely eliminated, because LNG does not contain sulfur. Additionally, a significant potential to reduce the environmental impact of ships lies in the possibility to recover the waste heat released by the ship’s engine system. According to the work from Bouman et al. [

6], the implementation of waste heat recovery (WHR) solutions on board a vessel can result in a reduction of the carbon dioxide (CO

2) emissions by up to 20%.

Waste-to-heat recovery solutions are particularly attractive for cruise ships [

7,

8], because such ships require a significant amount of heat for internal uses, while waste-to-power solutions are the most commonly investigated for containerships and tankers, among others [

9].

The organic Rankine cycle (ORC) power system has been identified as a promising solution for waste-to-power recovery applications on board vessels [

9], because it enables the attainment of higher design power outputs [

10] and improved off-design efficiencies [

11], in comparison with the traditional steam Rankine cycle technology.

Most of the previous works dealing with the optimal design of ORC power cycles for maritime applications have been following a model-driven approach, meaning that they rely on the use of numerical models based on the laws of thermodynamics, and validated by comparison with experimental data, when available. Such models are then used to investigate the performance of the unit under different design and off-design conditions.

The development of suitable numerical models to predict the performance and optimal design of ORC units for maritime applications is, however, a challenging task, because the designer needs to account for a multitude of aspects, including the availability of multiple waste heat sources, the ORC off-design performance, the ship sailing profile, the impact of the WHR unit on the engine’s performance, and the presence of dynamic instabilities, among others.

In this regard, Soffiato et al. [

12] described a procedure to integrate the use of multiple waste heat sources on board a LNG-carrier. Baldi et al. [

13] discussed multiple optimization approaches and concluded that the ship sailing profile needs to be accounted for during the ORC design procedure in order to maximize the annual energy production. Michos et al. [

14] highlighted the impact of the additional backpressure supplied to the exhaust line of a marine engine by the implementation of a WHR unit, while Baldasso et al. [

15] suggested that constraining the maximum backpressure on the exhaust side of the ORC WHR boiler leads to a significant reduction of the attainable power output from the recovery unit. Lastly, Rech et al. [

16] pointed out the importance of carrying out dynamic simulations to ensure that the system is correctly sized and is capable of reaching steady-state operation under a wide range of engine operating conditions.

The downsides of the approach followed by the aforementioned works lie in the model complexity, and in the computational time required to carry out the simulations, which increases as more aspects are taken into account. These approaches are therefore commonly used in a limited number of case studies, but are not suitable to carry out preliminary estimations of the potential for installing ORC-based WHR units on board a wide range of vessels.

To cover this need, another range of studies are available in the literature. Other authors, in fact, aimed at deriving simplified methodologies to estimate the performance of ORC units. Among these works, Liu et al. [

17] proposed an equation to estimate the thermal efficiency of an ORC unit based on the working fluid evaporation, condensation, and critical temperatures. Kuo et al. [

18] correlated the Jakob number with the attainable ORC thermal efficiency, while Wang et al. [

19] used the Jakob number in predictive models to estimate the ORC thermal and exergy efficiencies. Larsen et al. [

20] proposed the use of multiple regression models to predict the ORC thermal efficiency given the boundary conditions of the process. Lecompte et al. [

21] focused on the cycle second law efficiency and derived a simplified correlation to estimate its maximum value for a given waste heat source. Lastly, Palagi et al. [

22] developed surrogate models based on a neural network approach to carry out multi-objective optimization of a small-scale ORC unit, showing that the computational time could be reduced by two orders of magnitude in comparison with the traditional optimization approach.

These works pose a solid foundation for the rapid estimation of the prospects for installing an ORC unit, but have two limitations: (1) they aim at estimating the unit efficiency, rather than its power output, which is the key performance indicator in case of WHR applications, and (2) they are suitable for design conditions estimations only, thus, they do not consider the off-design performance of the unit, which is of key importance when considering the maritime application, because the waste heat availability changes according to the engine load.

To the best of the authors’ knowledge, only one previously published work describes a simplified method to estimate the off-design performance of an ORC unit: Dickes et al. [

23] carried out experimental and numerical investigations on a 2 kW

el ORC system featuring a scroll expander and proposed a set of equations to characterize the optimal off-design operation of the ORC system. As the equations were derived based on a specific unit, their general applicability is, however, not guaranteed. In addition, the off-design characterization of ORC units featuring volumetric expanders is not comparable to the one of units featuring turbo-expanders (i.e., units tailored for maritime applications).

This work aims at deriving a set of models for the quick and accurate prediction of the annual energy production and economic attractiveness of ORC units optimized for marine applications, considering low-sulfur fuels. The models were derived by numerical regression of a synthetic database of optimized ORC units and their effectiveness was tested in several test cases, where the estimations of the simplified approaches are compared with the solutions of the thermodynamic simulations.

The main novel contributions of the work are: (1) the derivation of off-design performance curves applicable to ORC units of different sizes and operating at different design conditions, and (2) a method to combine design and off-design performance curves for the ORC optimal design point that maximizes either the annual energy production, or the economic effectiveness estimated by means of the levelized-cost-of-electricity (LCOE).

The proposed method is not computationally intensive, and is therefore suitable to be used in the context of large optimization problems, such as ship routing optimizations, and holistic optimization and evaluation of a ship machinery system [

24]. It is expected that the proposed method could support industry, decision makers, and researchers in the identification of the most feasible cases to integrate WHR units as part of the ship’s machinery system.

The article is structured as follows:

Section 2 describes the applied methods. The attained results are presented in

Section 3 and discussed in

Section 4. Finally, conclusions are outlined in

Section 5.

2. Methods

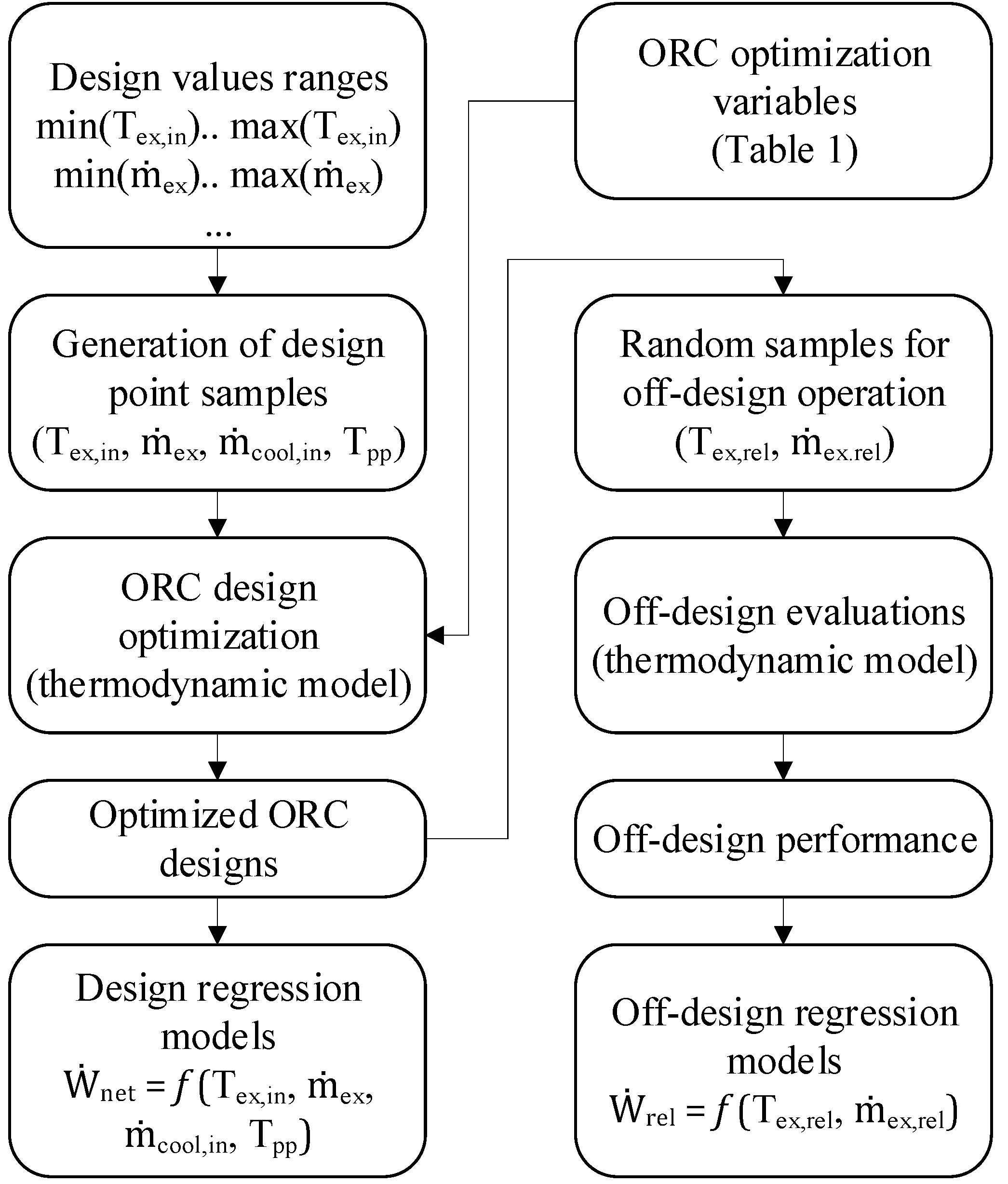

The overall method to carry out simplified evaluations for the prospects for installing ORC units on board vessels powered by low-sulfur fuels was built by implementing the following steps: (1) a dataset of ORC design power and part-load performance was generated; (2) regression models were developed based on the calculated data; and (3) the reliability of the proposed regression models was tested in two case studies comparing the outputs of the thermodynamic models with outputs of the simplified regression curves. The following subsections detail the approach used for each step.

2.1. ORC Models

The evaluations were carried out considering a simple non-recuperated ORC unit recovering heat from the exhaust gases of the ship’s main engine and using the seawater as heat sink. The power generated by the turbine is then converted into electricity in a generator.

Figure 1 shows the sketch of the considered unit layout and the corresponding T-s diagram.

The estimation of the ORC design power output was carried out using the numerical model described in Andreasen et al. [

25]. The model was previously validated by comparing its estimations with the results of other numerical studies published in the literature, indicating its suitability to estimate the ORC first and second law efficiencies with a maximum relative deviation of 3.3%.

The ORC net power output (

ẆNet) was calculated as follows:

where

ηgear and

ηgen are the efficiencies of the gearbox and the electric generator, while the subscripts

exp,

p, and

sw stand for expander, pump, and seawater.

represents the power consumption of the pump supplying seawater to the condenser.

The ORC design model was used to identify the ORC cycle parameters maximizing the cycle net power output for every given heat source/sink combination.

Table 1 lists the decision variables considered in the optimization procedure. A minimum superheating degree of 5 °C was imposed to ensure full evaporation of the working fluid, while the wide ranges were selected for the ORC mass flow rate, and condensation temperature were selected so that the optima always lies in between the boundaries. Because ships using low-sulfur fuels are considered, no design constraints were imposed to the ORC boiler in order to prevent issues related to possible sulfur condensation [

9].

Additionally, the maximum and minimum allowed cycle pressures were set to 3000 and 4.5 kPa, according to the recommendations by Rayegan et al. [

26], Drescher and Brüggeman [

27], and MAN Energy Solutions [

28]. Cyclopentane was selected as a working fluid in all cases, because it was previously shown to be a suitable working fluid candidate for maritime applications [

11,

15], and its properties were retrieved using Coolprop 4.2.5 [

29].

Table 2 shows the parameters that were kept fixed during the optimization procedure. The properties of the exhaust gases were assumed to be equal to those of air at 100 kPa.

All the optimizations were carried out using a combination of particle swarm (swarm size = 1000, number of generations = 50) and pattern search (500 iterations) available in the Matlab optimization toolbox [

30].

The off-design performance of the ORC units was estimated by using the numerical model described in Baldasso et al. [

15], whose estimations were validated in comparison with the experimental campaign carried out during the PilotORC project [

31]. The comparison between the numerical estimations and the experimental values indicated that the model is suitable to predict the ORC power output, pressure levels, and mass flow rate with an accuracy within 5%.

The ORC units were assumed to be operated with a sliding pressure strategy during part-load operation, and the both superheating at the turbine inlet and the cooling water mass flow rate were kept constant.

2.2. Economic Evaluations

The economic performance of the ORC unit was evaluated by means of the levelized cost of electricity of the generated electricity, computed as [

32]:

where the calculation considers that the system is operated for a number of years equal to

n = 25. The symbols

and

represent the maintenance costs and the electricity generation at the year

y. The symbol

represents the initial investment cost. The electricity generation represents the annual energy production from the ORC unit. The annual

O&M costs were set to 1.5% the ORC capital cost, while the discount rate (

r) was set to 6%. The

O&M costs were assumed to be the only operating costs of the system, as waste heat is used as heat input to the ORC unit.

Different estimation techniques are possible for the quantification of the investment cost related to the purchase of the ORC unit. The most common techniques are based on the estimation of the cost of the various components, which is dependent on their size, materials, and operating pressure [

33]. These approaches require, however, a preliminary sizing of the components. Cost estimation can therefore represent a complex task. Here, we included a simplified costing approach based on the size of the ORC unit. The work from Lemmen [

34] includes a list of real and estimated specific costs for the installation of ORC units whose size ranges from 200 kW to 8000 kW.

Figure 2 reports the ORC-specific costs connected with the installation of ORC units for WHR applications, which were reported by Lemmens [

34], and the regression curve which was used in this work.

The costs presented in the previous work were available in €

2014 and were here converted into US dollar (

$2015) using the Chemical Engineering Plant Cost Index (CEPCI) and a Euro-to-US dollar conversion factor of 1.1. The attained regression curve describing the variation of the ORC-specific cost as a function of its capacity is the following:

2.3. Data Generation and Regression Models

The regression surfaces for the estimation of the ORC design point power output were obtained by fitting the results of a dataset attained by running 200 independent ORC design optimizations, based on random design parameters. Two regression surfaces were attained:

Design regression model #1, where the sampled parameters were the heat source inlet temperature and mass flow rate, as well as the cooling water inlet temperature.

Design regression model #2, where also the boiler and condenser pinch point temperatures (ΔTpp,boil and ΔTpp,cond) were included as sampled parameters in the optimization routines.

In both cases, the samples of the ORC design parameters were generated using the Sobol method [

35] to ensure a good coverage of the sampling space, and the sampled parameters were constrained to be within the boundaries described in

Table 2. Only the samples leading to ORC units with a power output in the range 250 kW to 2500 kW were considered in the regression procedure, and this ensured that the accuracy of the attained regression curves was not affected by the presence of outliers.

With respect to the boundaries defined for the heat source temperature, mass flow rate, and the cooling water temperature, a comparison with data retrieved from the MAN Energy Solutions CEAS calculation tool [

36], suggests that the engine waste heat characteristics are within the considered ranges, when considering engines in the range from 5 MW to 50 MW operating with different tuning techniques and sailing both in cold and warm waters.

The off-design performance of every optimized ORC configuration was evaluated in 20 different and randomly generated off-design conditions. Each half of the randomly generated off-design points were imposed a temperature of the exhaust gases higher and lower than the design point, respectively. The exhaust gas mass flow rate was varied within 25% to 100% of the ORC design mass flow rate. The heat source temperature was allowed a deviation of +/- 80 °C compared to the design value. The sea water temperature was kept constant in all the off-design simulations.

A single regression model was attained for the characterization of the ORC off-design performance, considering an ORC load ranging for 10% to 100%, and based on the ORC designs used for both design models (fixed and variable pinch point temperatures).

Figure 3 provides a graphical overview of the procedure used to derive the regression models. The symbols included in the sketch are explained in

Section 3.1 (T

pp refers both to the condenser and boiler pinch point temperature).

The statistical robustness of a regression curve is ensured if the residuals follow a normal distribution and their mean is equal to zero. In addition, there should be no correlation between the residuals themselves and the parameters used to build the regression curve, nor the data points that are being estimated (the ORC net power output and its off-design performance). The validity of the mentioned aspects for the proposed regression surface models was checked with the scatter plots shown in the following sections.

2.4. Case Studies and Optimization Approach

The accuracy of the proposed regression surface models was checked in two test cases. The first case study considers the installation of an ORC unit on board an LNG-fueled feeder ship powered by a 10.5 MW MAN 7S60E-C10.5-GI engine with low pressure selective catalytic reactor tuning. In the second case study, an ORC unit on board a medium size LNG-fueled container vessel powered by a 23 MW MAN 6S80ME-C9.5-GI engine with part-load tuning was considered. The two vessels were assumed to operate according to the load profiles shown in

Figure 4, for 4380 and 6500 hours annually, respectively.

These are typical data for the two considered types of vessels. Sea water temperatures of 10 °C, 15 °C, and 20 °C were considered for the case studies.

Table 3 reports the exhaust mass flow rate and temperature for the two engines as a function of the load. The data was retrieved from the MAN CEAS engine calculation tool [

36].

The ORC maximum annual energy production and minimum LCOE required to produce the electricity by means of the ORC unit, were computed both using thermodynamic model and regression model. Both the thermodynamic calculations and the estimations using the regression models were carried out following the procedure shown in

Figure 5.

When using the thermodynamic model, the ORC design parameters and design point were selected as optimization parameters, while only the latter was optimized when using the simplified approach based on the regression curves. For the estimation of the accuracy of the regression model #2, three alternative pinch point temperature combinations were considered: (i) ΔTpp,boil = 25 °C and ΔTpp,cond = 10 °C, (ii) ΔTpp,boil = 20 °C and ΔTpp,cond = 8 °C, and (iii) ΔTpp,boil = 15 °C and ΔTpp,cond = 5 °C.

4. Discussion

The procedure followed to derive the proposed regression curves is typical of the data-driven modelling approach, which is now gaining interest due to the increasing data availability and the development of more and more sophisticated machine-learning algorithms. The proposed algorithms are attained by implementing a supervised machine learning approach, where both the model outputs (i.e., the ORC power output) and the model input (i.e., the characteristics of the main engine exhaust gases) are known.

A more rigorous implementation of the data-driven modelling approach to derive the regression curves would have required to split the available dataset into training and test sets. This is because regression algorithms are generally developed based on a portion of the overall data (train set), and then their accuracy is tested on the remaining portion of the data (test set). This allows to prove the reliability of the proposed algorithm to predict the model output also for data outside the space covered by the data used for its development.

This was considered not to be required for our case, because the accuracy of the proposed approach, which combines design and off-design regression models, was verified through several case studies, whose inputs parameters were not used when generating the regression curves.

In any case, the authors do not recommend the use of the proposed regression models when using such curves outside their validation space (i.e., increased temperatures of the exhaust gases, or reduced flow rates).

In addition, as a way to reduce the model complexity, several assumptions were made which could influence the attained results. In particular, the evaluations were limited to one fluid, the backpressure effect on the engine was neglected, and the pressure drops in the heat exchangers were not accounted for. The decision not to consider the impact on the backpressure effect was mainly connected to two reasons: (1) the findings from Michos et al. [

14] indicated that such parameter has a weak impact on the overall estimated savings, and (2) the acceptable backpressure level to the engine varies both with the selected engine and the considered engine load, making it a complex feature to include in simplified regression models.

With respect to the approach used to estimate the cost of the unit, it should be mentioned that large uncertainties are expected, because the cost of the unit is not uniquely identified by its overall size, but is influenced also by other parameters, such as the operating pressures, the selected materials, and the configuration of the installation in the engine system. The attained economic results are therefore to be considered as preliminary and are meant to give a first estimate.