Multi-Objective Thermo-Economic Optimization of a Combined Organic Rankine Cycle (ORC) System Based on Waste Heat of Dual Fuel Marine Engine and LNG Cold Energy Recovery

Abstract

:1. Introduction

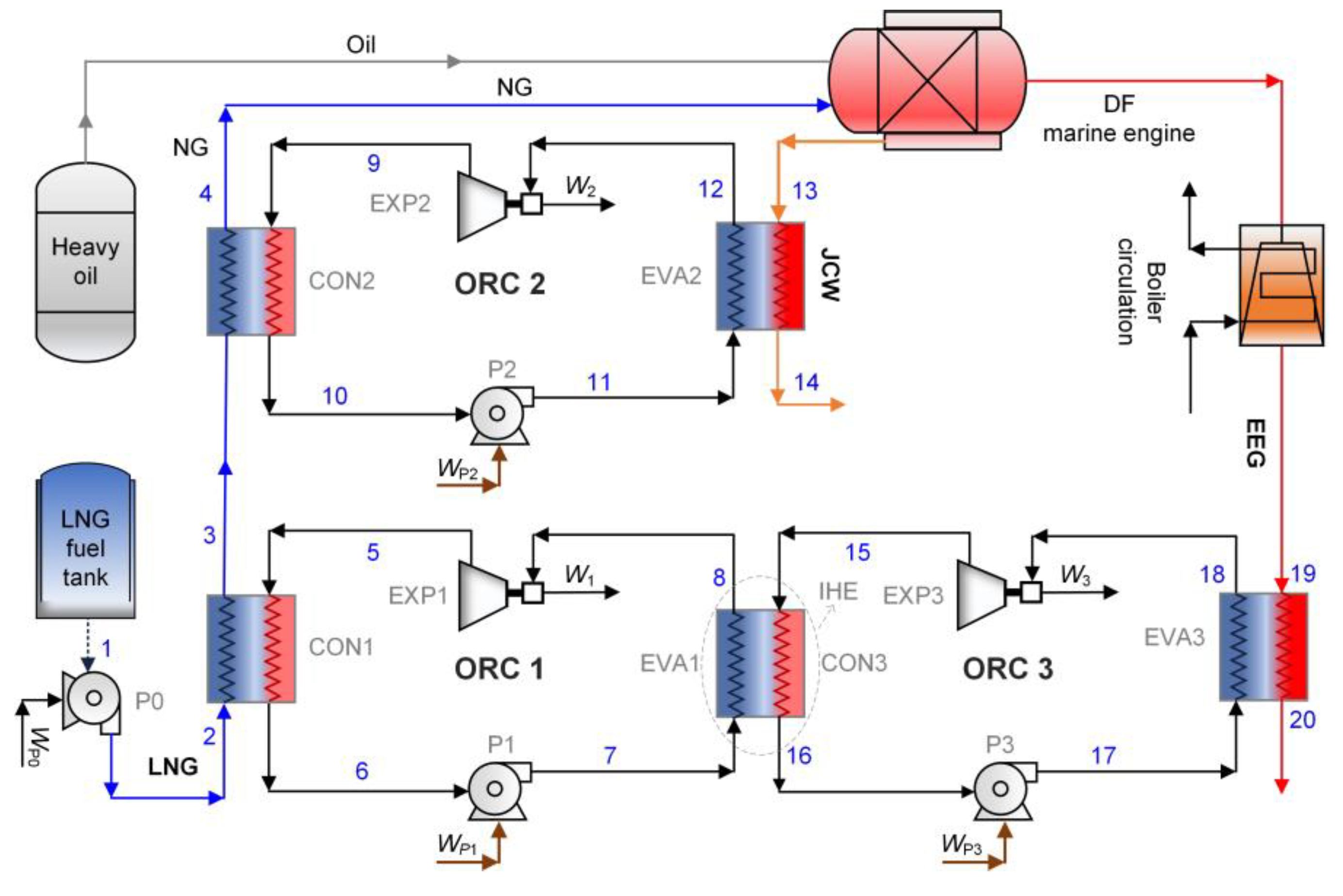

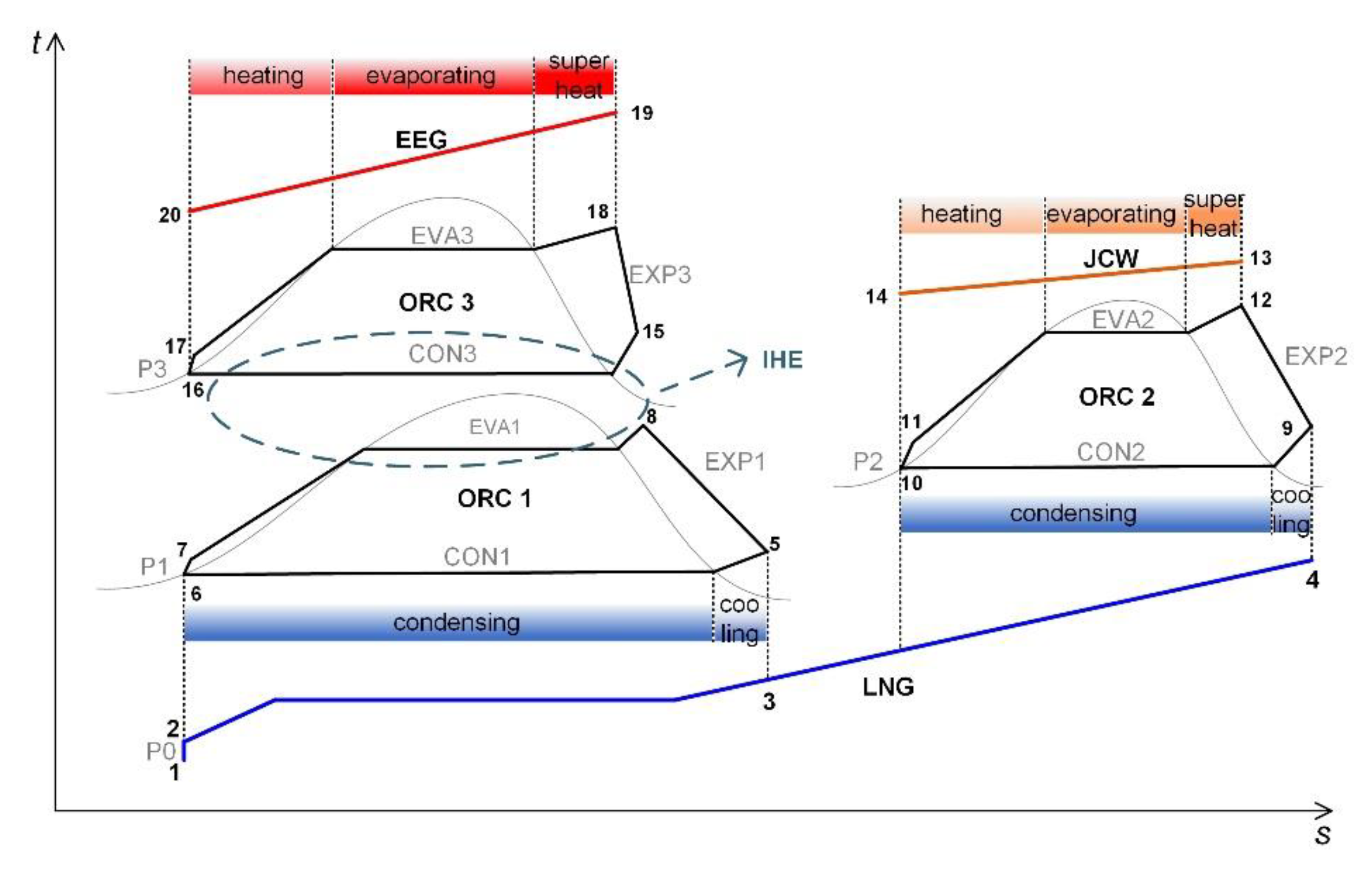

2. System Description

2.1. Marine Engine

2.2. ORC System Description

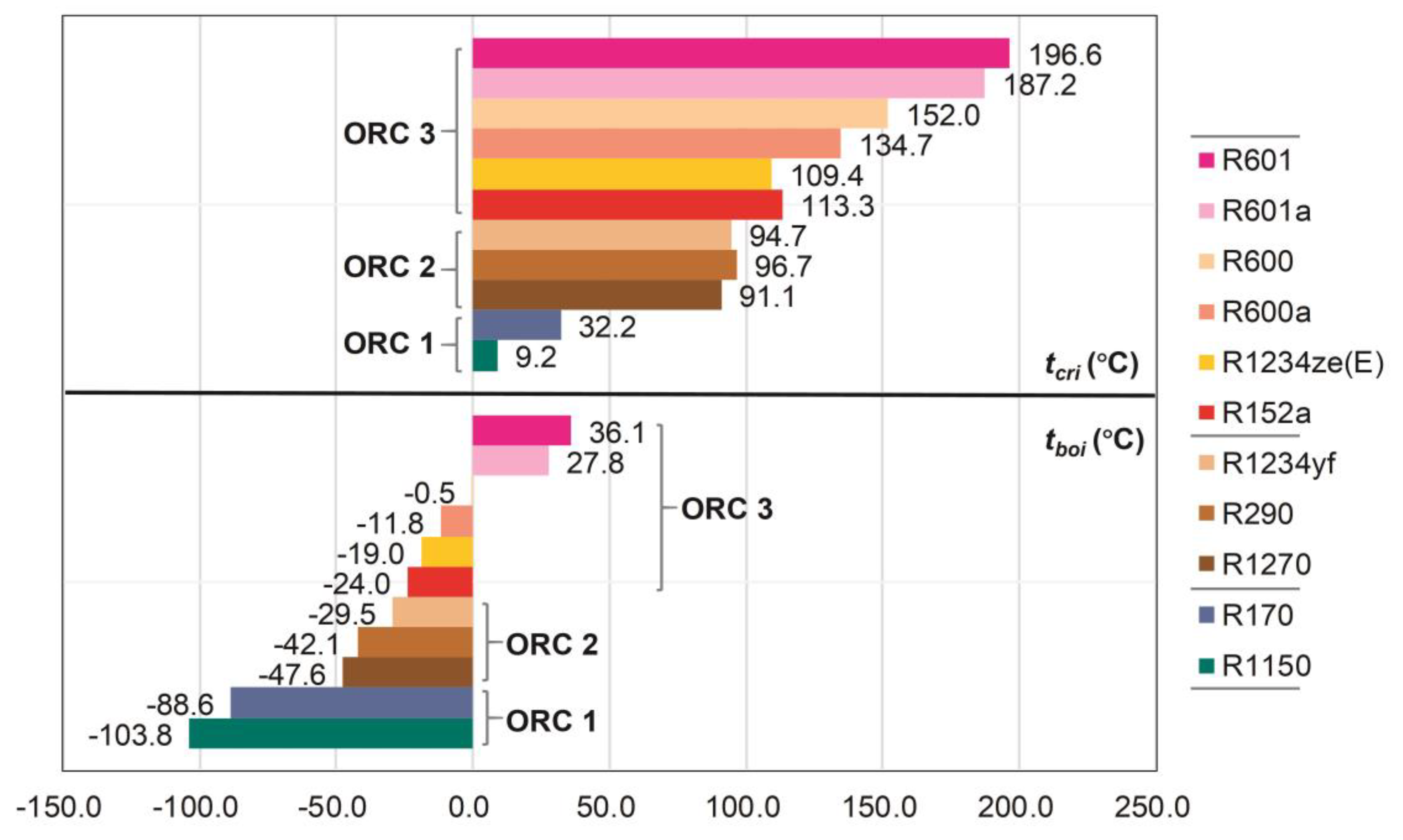

2.3. Candidate Working Fluids

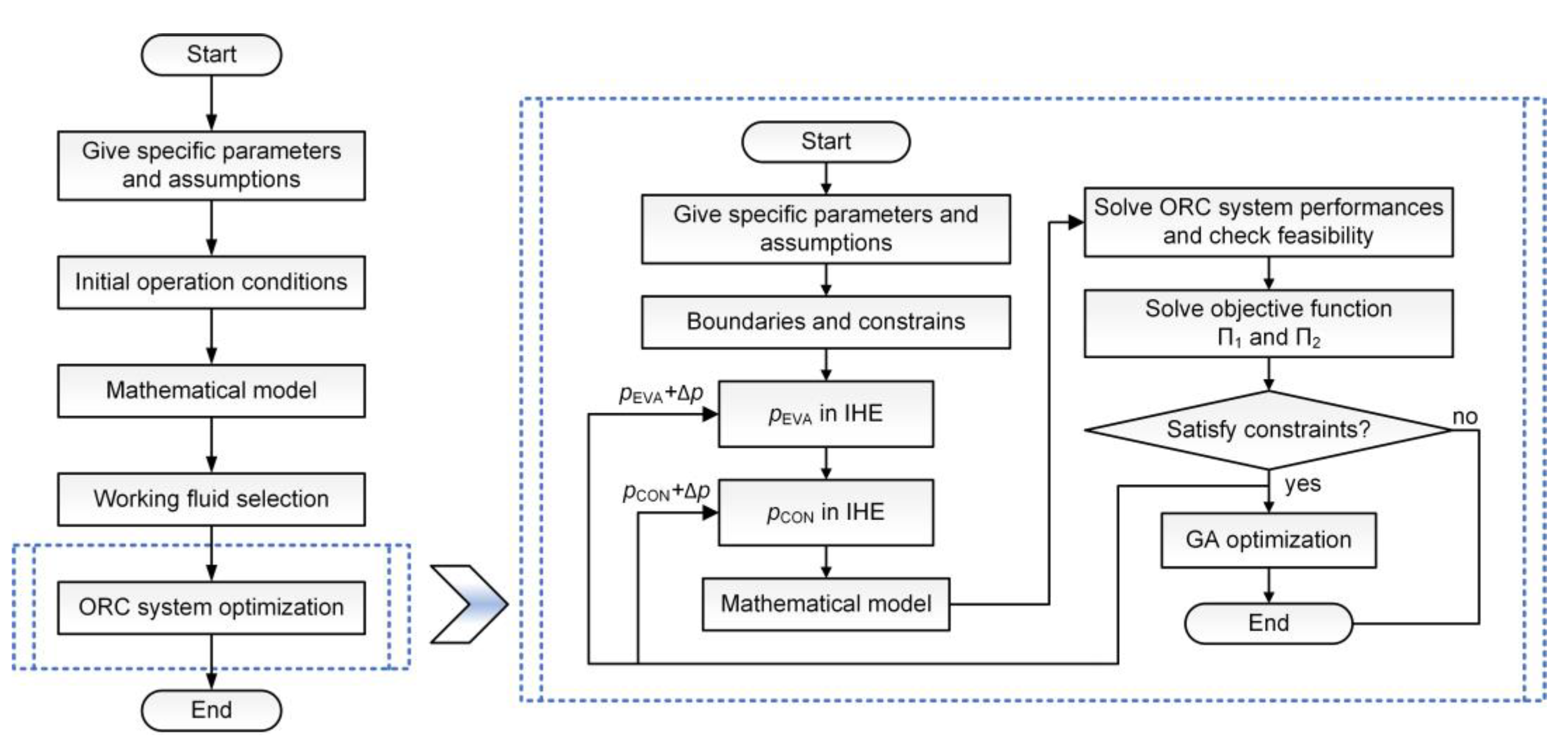

3. Methodology

3.1. Mathematic Model

3.2. Thermo-Economic Analysis

3.3. System Performance Criteria

3.4. ORC System Optimization

3.4.1. Optimization Method

3.4.2. Objective Functions and Decision Making

3.5. Solution Algorithm and Model Validation

4. Results and Discussions

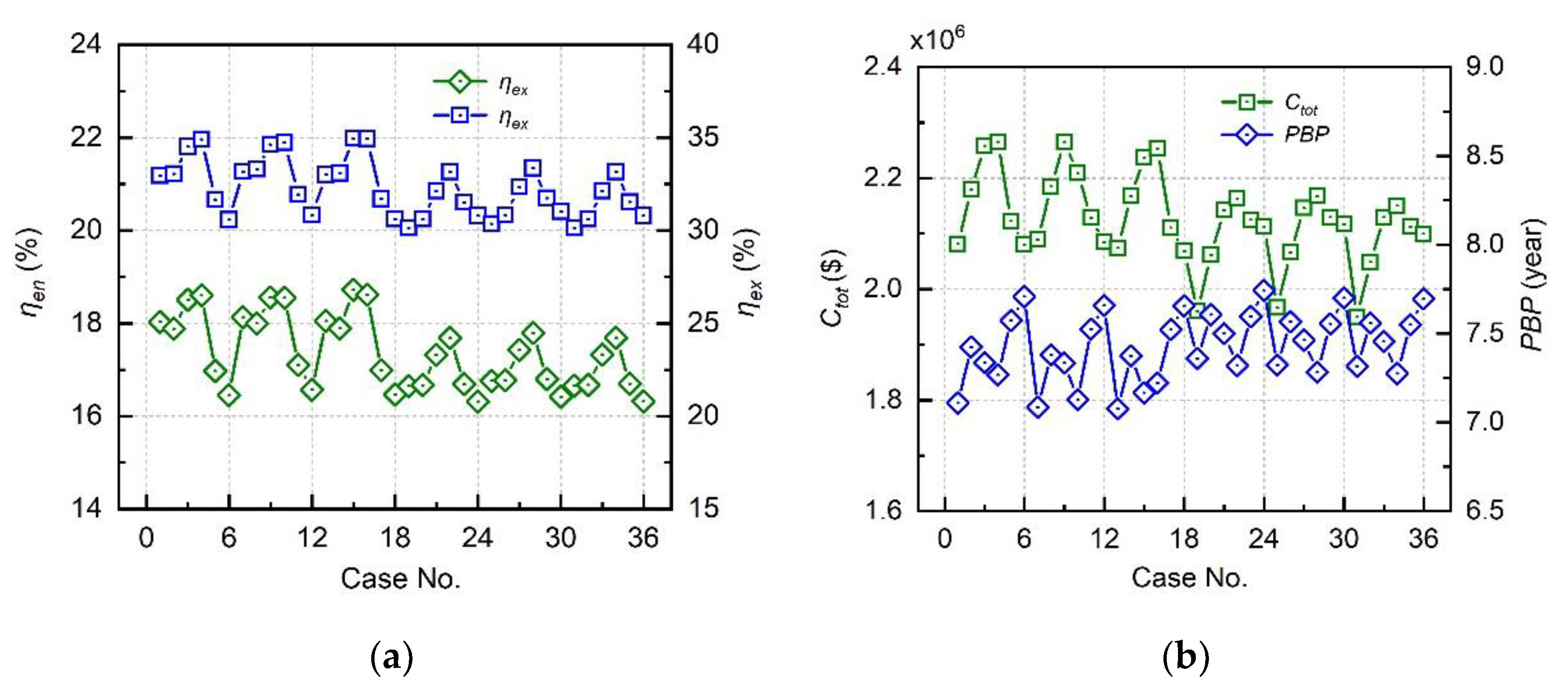

4.1. WF Combination Selection

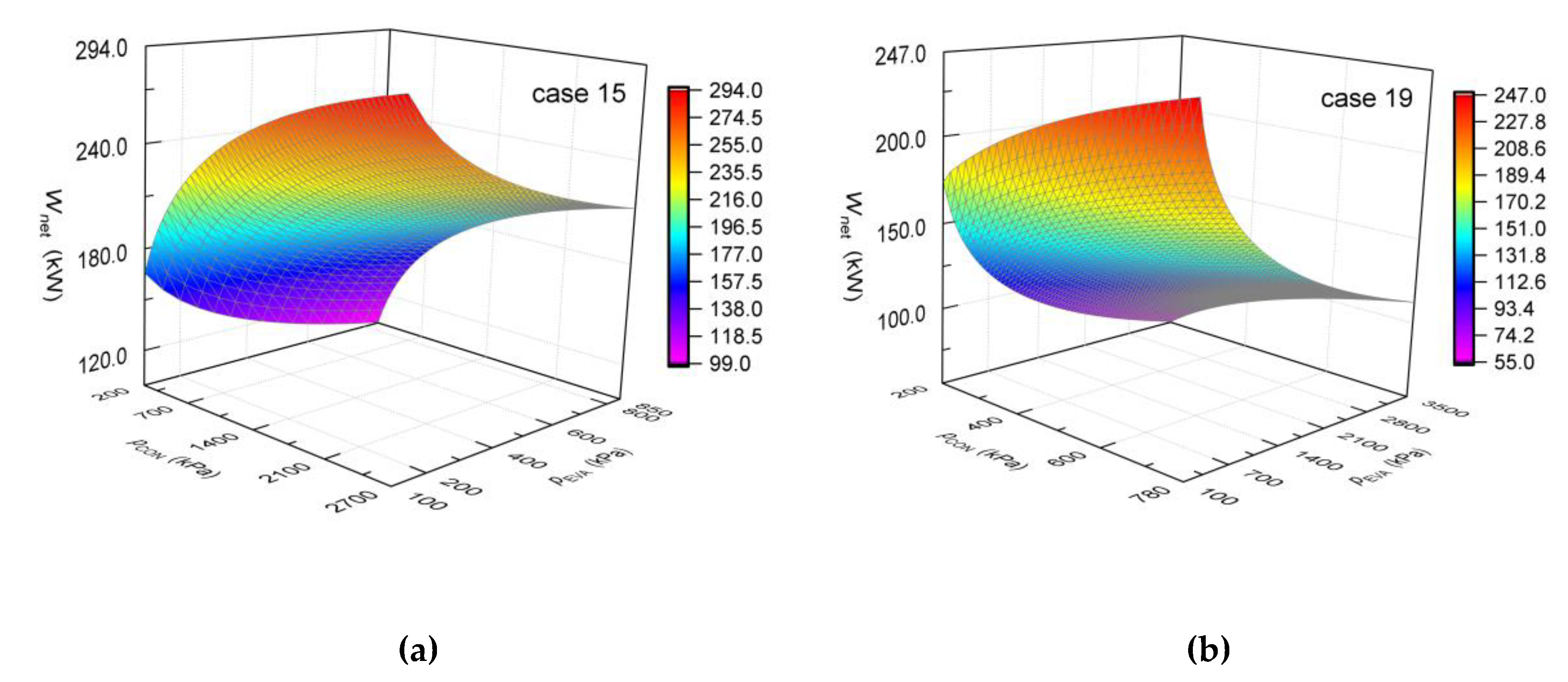

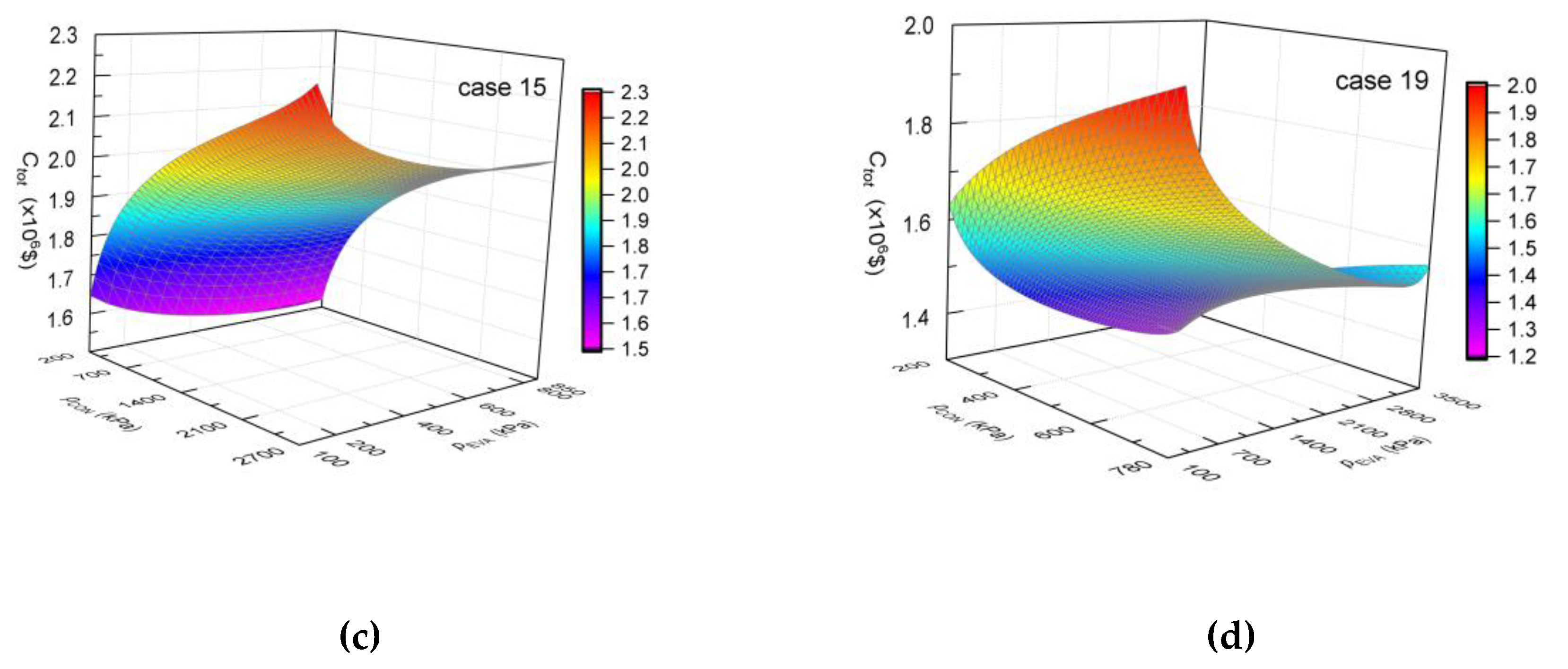

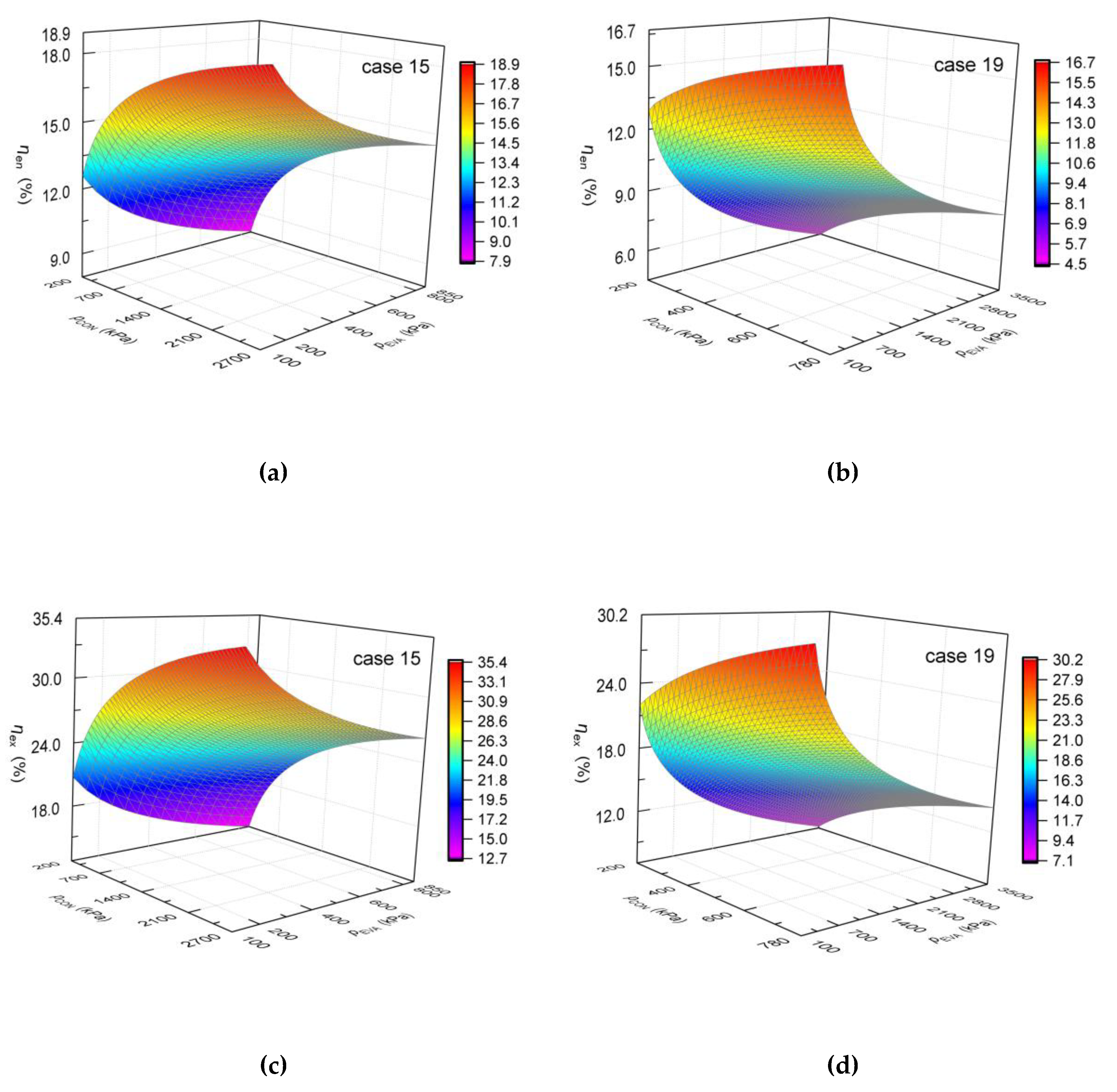

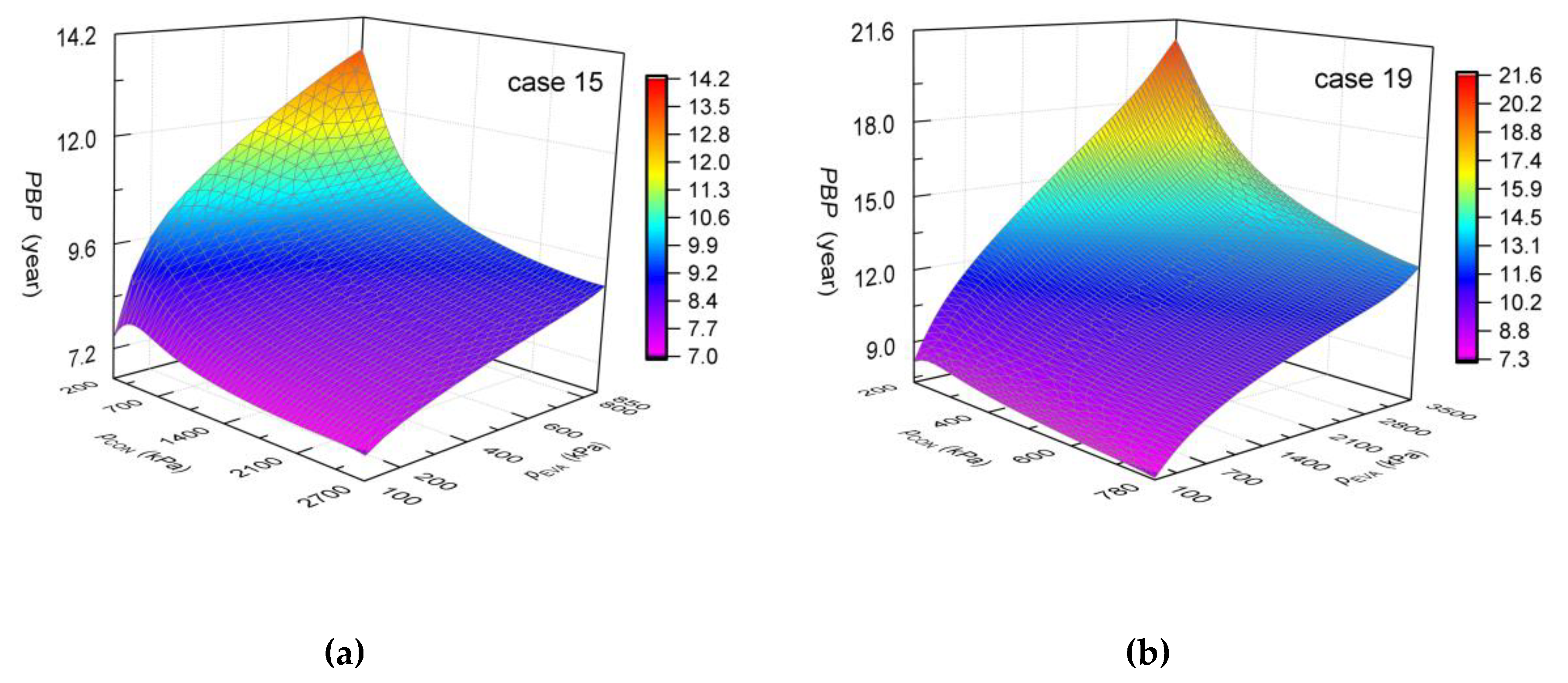

4.2. Effect of Condensation and Evaporation Pressures

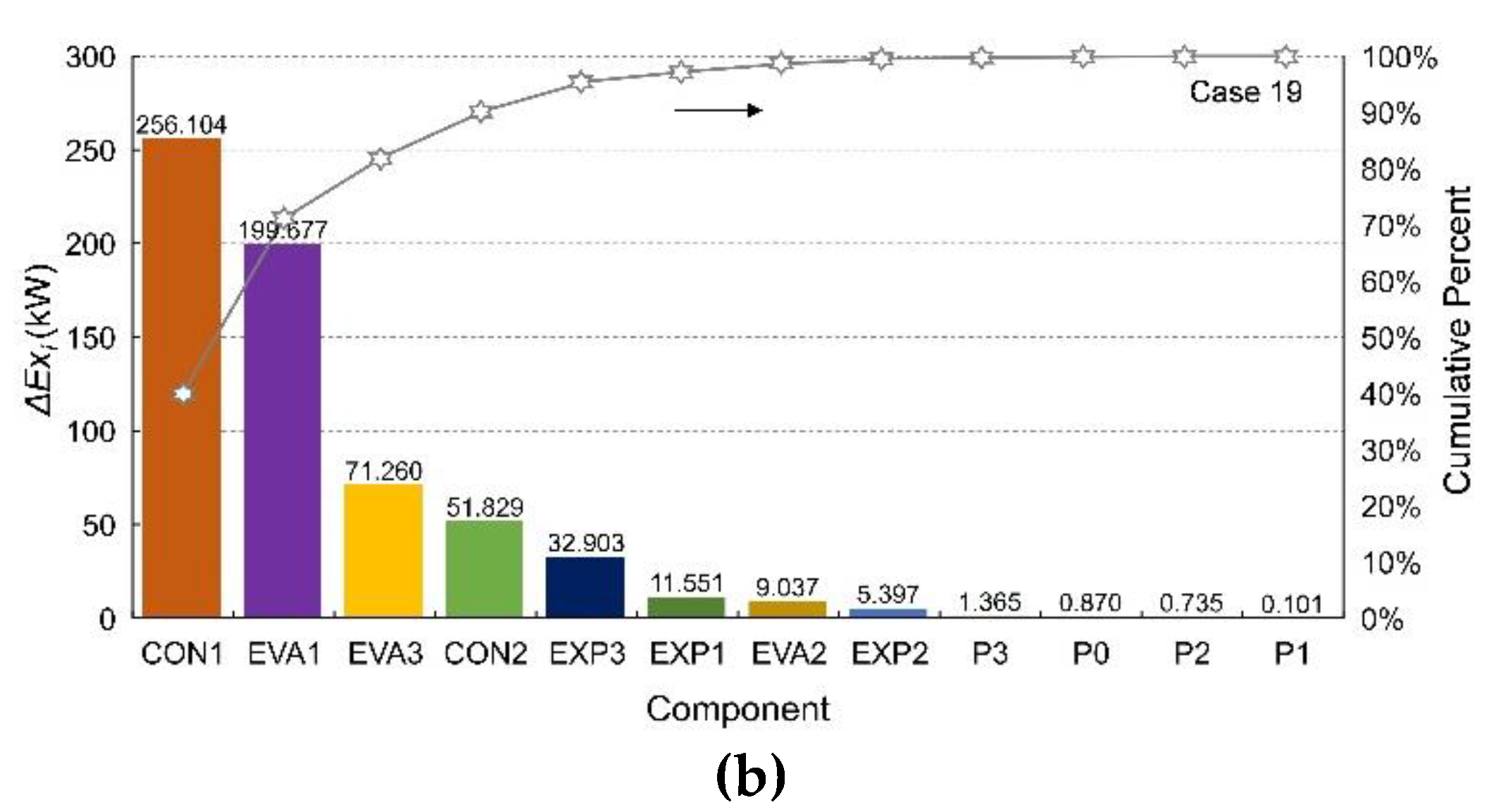

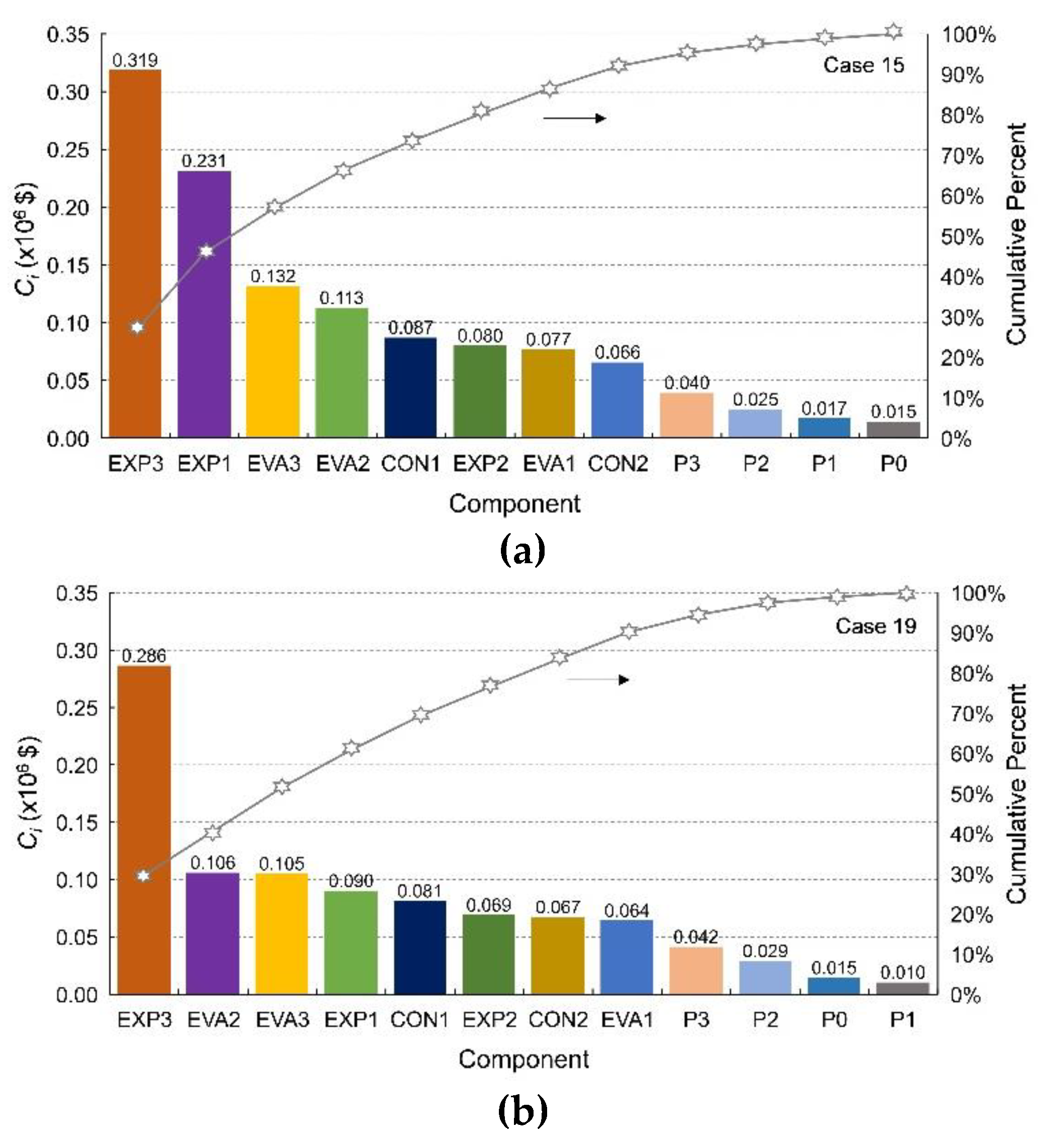

4.3. Overall Thermo-Economic Performances

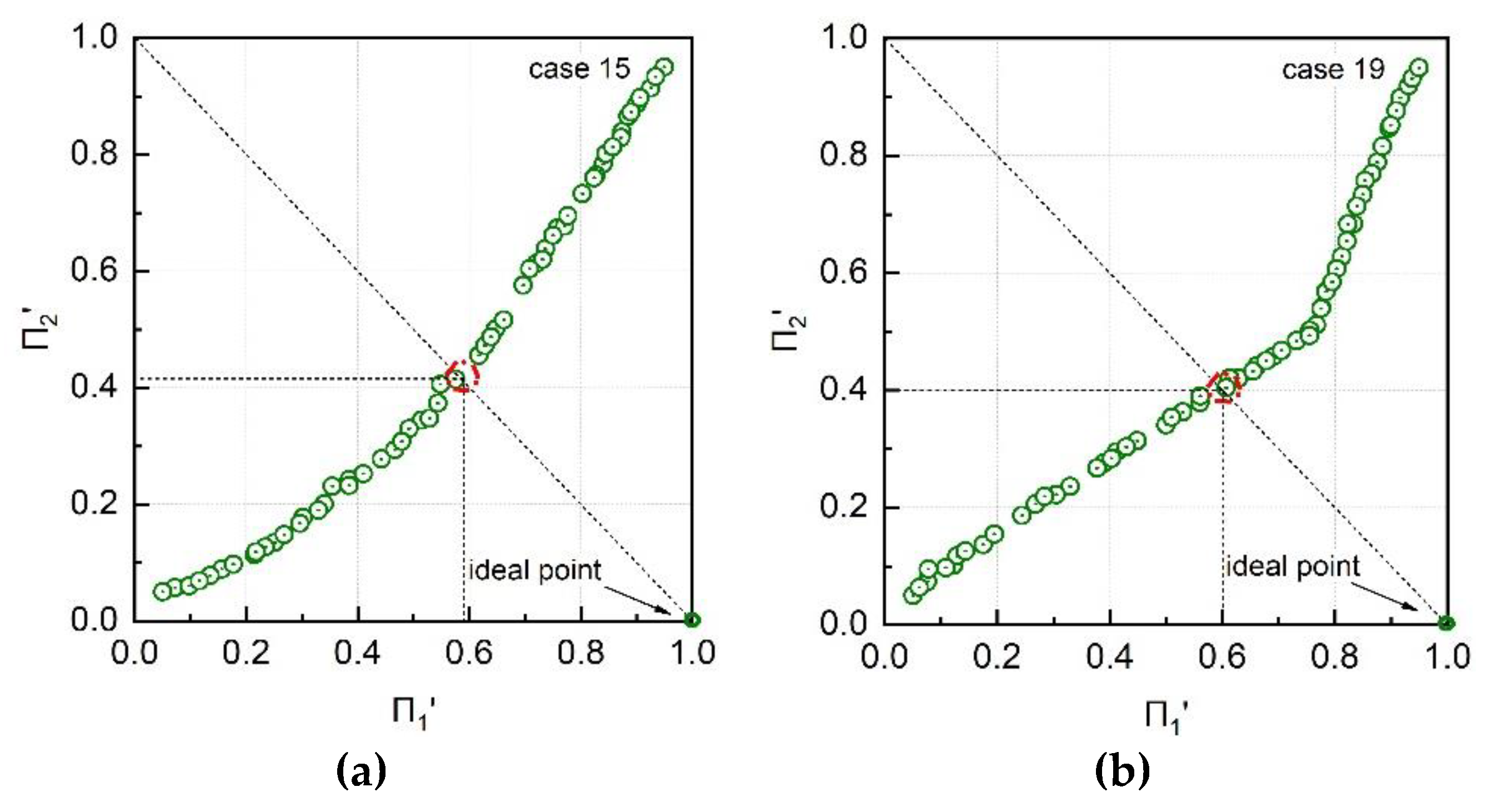

4.4. Multi-Objective Optimization Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ait Allal, A.; Mansouri, K.; Youssfi, M.; Qbadou, M. Toward an evaluation of marine fuels for a clean and efficient autonomous ship propulsion energy. Mater. Today Proc. 2019, 13, 486–495. [Google Scholar] [CrossRef]

- IMO Prevention of Air Pollution from Ships-Revised MARPOL Annex VI. Available online: http://www.imo.org/en/OurWork/Environment/PollutionPrevention/AirPollution/Pages/Air-Pollution.aspx (accessed on 5 February 2020).

- George, D.G.; Eleftherios, K.D.; Chariklia, G.A. LNG carrier two-stroke propulsion systems: A comparative study of state of the art reliquefaction technologies. Energy 2020, 195, 116997. [Google Scholar] [CrossRef]

- Lee, H.-J.; Yoo, S.-H.; Huh, S.-Y. Economic benefits of introducing LNG-fuelled ships for imported flour in South Korea. Transp. Res. D Transp. Environ. 2020, 78, 102220. [Google Scholar] [CrossRef]

- Chu Van, T.; Ramirez, J.; Rainey, T.; Ristovski, Z.; Brown, R.J. Global impacts of recent IMO regulations on marine fuel oil refining processes and ship emissions. Transp. Res. D Transp. Environ. 2019, 70, 123–134. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Yang, Y.; Ren, C.; Zhu, G. A new approach for exhaust energy recovery of internal combustion engine: Steam turbocharging. Appl. Therm. Eng. 2013, 52, 150–159. [Google Scholar] [CrossRef]

- Kyriakidis, F.; Sørensen, K.; Singh, S.; Condra, T. Modeling and optimization of integrated exhaust gas recirculation and multi-stage waste heat recovery in marine engines. Energy Convers. Manag. 2017, 151, 286–295. [Google Scholar] [CrossRef]

- Mito, M.T.; Teamah, M.A.; El-Maghlany, W.M.; Shehata, A.I. Utilizing the scavenge air cooling in improving the performance of marine diesel engine waste heat recovery systems. Energy 2018, 142, 264–276. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, J.; Huang, X.; Mei, N. Experimental investigation on binary ammonia–water and ternary ammonia–water–lithium bromide mixture-based absorption refrigeration systems for fishing ships. Energy Convers. Manag. 2018, 166, 13–22. [Google Scholar] [CrossRef]

- Feng, Y.; Du, Z.; Shreka, M.; Zhu, Y.; Zhou, S.; Zhang, W. Thermodynamic analysis and performance optimization of the supercritical carbon dioxide Brayton cycle combined with the Kalina cycle for waste heat recovery from a marine low-speed diesel engine. Energy Convers. Manag. 2020, 206, 112483. [Google Scholar] [CrossRef]

- Mondejar, M.; Andreasen, J.; Pierobon, L.; Larsen, U.; Thern, M.; Haglind, F. A review of the use of organic Rankine cycle power systems for maritime applications. Renew. Sustain. Energy Rev. 2018, 91, 126–151. [Google Scholar] [CrossRef]

- Ouyang, T.; Su, Z.; Gao, B.; Pan, M.; Chen, N.; Huang, H. Design and modeling of marine diesel engine multistage waste heat recovery system integrated with flue-gas desulfurization. Energy Convers. Manag. 2019, 196, 1353–1368. [Google Scholar] [CrossRef]

- Lion, S.; Vlaskos, I.; Taccani, R. A review of emissions reduction technologies for low and medium speed marine Diesel engines and their potential for waste heat recovery. Energy Convers. Manag. 2020, 207, 112553. [Google Scholar] [CrossRef]

- Saloux, E.; Sorin, M.; Nesreddine, H.; Teyssedou, A. Reconstruction procedure of the thermodynamic cycle of organic Rankine cycles (ORC) and selection of the most appropriate working fluid. Appl. Therm. Eng. 2018, 129, 628–635. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Kirmse, C.J.W.; Pantaleo, A.M.; Markides, C.N. Performance of working-fluid mixtures in ORC-CHP systems for different heat-demand segments and heat-recovery temperature levels. Energy Convers. Manag. 2017, 148, 1508–1524. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, S.; Zhao, L.; Lin, S.; Ni, J.; Ma, M.; Xu, W. Optimization and multi-time scale modeling of pilot solar driven polygeneration system based on organic Rankine cycle. Appl. Energy 2018, 222, 396–409. [Google Scholar] [CrossRef]

- Walraven, D.; Laenen, B.; D’Haeseleer, W. Economic system optimization of air-cooled organic Rankine cycles powered by low-temperature geothermal heat sources. Energy 2015, 80, 104–113. [Google Scholar] [CrossRef] [Green Version]

- Roumpedakis, T.C.; Christou, T.; Monokrousou, E.; Braimakis, K.; Karellas, S. Integrated ORC-Adsorption cycle: A first and second law analysis of potential configurations. Energy 2019, 179, 46–58. [Google Scholar] [CrossRef]

- Liu, P.; Shu, G.; Tian, H. How to approach optimal practical Organic Rankine cycle (OP-ORC) by configuration modification for diesel engine waste heat recovery. Energy 2019, 174, 543–552. [Google Scholar] [CrossRef]

- Heberle, F.; Brüggemann, D. Thermo-Economic Analysis of Zeotropic Mixtures and Pure Working Fluids in Organic Rankine Cycles for Waste Heat Recovery. Energies 2016, 9, 226. [Google Scholar] [CrossRef]

- Han, Z.; Li, P.; Han, X.; Mei, Z.; Wang, Z. Thermo-Economic Performance Analysis of a Regenerative Superheating Organic Rankine Cycle for Waste Heat Recovery. Energies 2017, 10, 1593. [Google Scholar] [CrossRef] [Green Version]

- Uusitalo, A.; Honkatukia, J.; Turunen-Saaresti, T.; Grönman, A. Thermodynamic evaluation on the effect of working fluid type and fluids critical properties on design and performance of Organic Rankine Cycles. J. Clean. Prod. 2018, 188, 253–263. [Google Scholar] [CrossRef]

- Valencia, G.; Fontalvo, A.; Cárdenas, Y.; Duarte, J.; Isaza, C. Energy and Exergy Analysis of Different Exhaust Waste Heat Recovery Systems for Natural Gas Engine Based on ORC. Energies 2019, 12, 2378. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Zhang, Y.; Cao, M.; Wang, J.; Wu, Y.; Ma, C. Working Fluid Selection for Organic Rankine Cycle Using Single-Screw Expander. Energies 2019, 12, 3197. [Google Scholar] [CrossRef] [Green Version]

- Ge, Z.; Li, J.; Liu, Q.; Duan, Y.; Yang, Z. Thermodynamic analysis of dual-loop organic Rankine cycle using zeotropic mixtures for internal combustion engine waste heat recovery. Energy Convers. Manag. 2018, 166, 201–214. [Google Scholar] [CrossRef]

- Chys, M.; van den Broek, M.; Vanslambrouck, B.; De Paepe, M. Potential of zeotropic mixtures as working fluids in organic Rankine cycles. Energy 2012, 44, 623–632. [Google Scholar] [CrossRef]

- Lecompte, S.; Ameel, B.; Ziviani, D.; van den Broek, M.; De Paepe, M. Exergy analysis of zeotropic mixtures as working fluids in Organic Rankine Cycles. Energy Convers. Manag. 2014, 85, 727–739. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Markides, C.N. Thermo-Economic and Heat Transfer Optimization of Working-Fluid Mixtures in a Low-Temperature Organic Rankine Cycle System. Energies 2016, 9, 448. [Google Scholar] [CrossRef] [Green Version]

- Su, W.; Hwang, Y.; Deng, S.; Zhao, L.; Zhao, D. Thermodynamic performance comparison of Organic Rankine Cycle between zeotropic mixtures and pure fluids under open heat source. Energy Convers. Manag. 2018, 165, 720–737. [Google Scholar] [CrossRef]

- Rao, W.-J.; Zhao, L.-J.; Liu, C.; Zhang, M.-G. A combined cycle utilizing LNG and low-temperature solar energy. Appl. Therm. Eng. 2013, 60, 51–60. [Google Scholar] [CrossRef]

- He, S.; Chang, H.; Zhang, X.; Shu, S.; Duan, C. Working fluid selection for an Organic Rankine Cycle utilizing high and low temperature energy of an LNG engine. Appl. Therm. Eng. 2015, 90, 579–589. [Google Scholar] [CrossRef]

- Yu, H.; Kim, D.; Gundersen, T. A study of working fluids for Organic Rankine Cycles (ORCs) operating across and below ambient temperature to utilize Liquefied Natural Gas (LNG) cold energy. Energy 2019, 167, 730–739. [Google Scholar] [CrossRef]

- Han, F.; Wang, Z.; Ji, Y.; Li, W.; Sundén, B. Energy analysis and multi-objective optimization of waste heat and cold energy recovery process in LNG-fueled vessels based on a triple organic Rankine cycle. Energy Convers. Manag. 2019, 195, 561–572. [Google Scholar] [CrossRef]

- Öhman, H.; Lundqvist, P. Comparison and analysis of performance using Low Temperature Power Cycles. Appl. Therm. Eng. 2013, 52, 160–169. [Google Scholar] [CrossRef]

- Choi, B.C.; Kim, Y.M. Thermodynamic analysis of a dual-loop heat recovery system with trilateral cycle applied to exhaust gases of internal combustion engine for propulsion of the 6800 TEU container ship. Energy 2013, 58, 404–416. [Google Scholar] [CrossRef]

- Yang, M.-H.; Yeh, R.-H. Analyzing the optimization of an organic Rankine cycle system for recovering waste heat from a large marine engine containing a cooling water system. Energy Convers. Manag. 2014, 88, 999–1010. [Google Scholar] [CrossRef]

- Baldi, F.; Larsen, U.; Gabrielii, C. Comparison of different procedures for the optimisation of a combined Diesel engine and organic Rankine cycle system based on ship operational profile. Ocean Eng. 2015, 110, 85–93. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Song, Y.; Gu, C.-W. Thermodynamic analysis and performance optimization of an Organic Rankine Cycle (ORC) waste heat recovery system for marine diesel engines. Energy 2015, 82, 976–985. [Google Scholar] [CrossRef]

- Yun, E.; Park, H.; Yoon, S.Y.; Kim, K.C. Dual parallel organic Rankine cycle (ORC) system for high efficiency waste heat recovery in marine application. J. Mech. Sci. Technol. 2015, 29, 2509–2515. [Google Scholar] [CrossRef]

- Valencia Ochoa, G.; Acevedo Peñaloza, C.; Duarte Forero, J. Thermoeconomic Optimization with PSO Algorithm of Waste Heat Recovery Systems Based on Organic Rankine Cycle System for a Natural Gas Engine. Energies 2019, 12, 4165. [Google Scholar] [CrossRef] [Green Version]

- Valencia Ochoa, G.; Piero Rojas, J.; Duarte Forero, J. Advance Exergo-Economic Analysis of a Waste Heat Recovery System Using ORC for a Bottoming Natural Gas Engine. Energies 2020, 13, 267. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.-H. Optimizations of the waste heat recovery system for a large marine diesel engine based on transcritical Rankine cycle. Energy 2016, 113, 1109–1124. [Google Scholar] [CrossRef]

- Lecompte, S.; Lemmens, S.; Huisseune, H.; Van den Broek, M.; De Paepe, M. Multi-Objective Thermo-Economic Optimization Strategy for ORCs Applied to Subcritical and Transcritical Cycles for Waste Heat Recovery. Energies 2015, 8, 2714–2741. [Google Scholar] [CrossRef] [Green Version]

- Grljušić, M.; Medica, V.; Račić, N. Thermodynamic Analysis of a Ship Power Plant Operating with Waste Heat Recovery through Combined Heat and Power Production. Energies 2014, 7, 7368–7394. [Google Scholar] [CrossRef] [Green Version]

- Sung, T.; Kim, K.C. Thermodynamic analysis of a novel dual-loop organic Rankine cycle for engine waste heat and LNG cold. Appl. Therm. Eng. 2016, 100, 1031–1041. [Google Scholar] [CrossRef]

- Habibi, H.; Zoghi, M.; Chitsaz, A.; Javaherdeh, K.; Ayazpour, M. Thermo-economic analysis and optimization of combined PERC—ORC—LNG power system for diesel engine waste heat recovery. Energy Convers. Manag. 2018, 173, 613–625. [Google Scholar] [CrossRef]

- Le, S.; Lee, J.-Y.; Chen, C.-L. Waste cold energy recovery from liquefied natural gas (LNG) regasification including pressure and thermal energy. Energy 2018, 152, 770–787. [Google Scholar] [CrossRef]

- Koo, J.; Oh, S.-R.; Choi, Y.-U.; Jung, J.-H.; Park, K. Optimization of an Organic Rankine Cycle System for an LNG-Powered Ship. Energies 2019, 12, 1933. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.; Zhang, H.; Song, S.; Yang, F.; Liu, H.; Zhao, G.; Zhang, J.; Yao, B. Effects of Degree of Superheat on the Running Performance of an Organic Rankine Cycle (ORC) Waste Heat Recovery System for Diesel Engines under Various Operating Conditions. Energies 2014, 7, 2123–2145. [Google Scholar] [CrossRef] [Green Version]

- Wärtsilä 50DF. Available online: https://www.wartsila.com/marine/build/engines-and-generating-sets (accessed on 1 February 2020).

- Lemmon, E.W.; Huber, M.L.; Mclinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1. Gaithersburg Natl. Inst. Stand. Technol. 2010, 20, 2010. [Google Scholar]

- Györke, G.; Deiters, U.K.; Groniewsky, A.; Lassu, I.; Imre, A.R. Novel classification of pure working fluids for Organic Rankine Cycle. Energy 2018, 145, 288–300. [Google Scholar] [CrossRef]

- Javanshir, A.; Sarunac, N.; Razzaghpanah, Z. Thermodynamic analysis of a regenerative organic Rankine cycle using dry fluids. Appl. Therm. Eng. 2017, 123, 852–864. [Google Scholar] [CrossRef]

- Li, T.; Meng, N.; Liu, J.; Zhu, J.; Kong, X. Thermodynamic and economic evaluation of the organic Rankine cycle (ORC) and two-stage series organic Rankine cycle (TSORC) for flue gas heat recovery. Energy Convers. Manag. 2019, 183, 816–829. [Google Scholar] [CrossRef]

- Zitzler, E.; Deb, K.; Thiele, L.J.E.C. Comparison of Multiobjective Evolutionary Algorithms: Empirical Results. Evol. Comput. 2000, 8, 173–195. [Google Scholar] [CrossRef] [Green Version]

- Sadatsakkak, S.A.; Ahmadi, M.H.; Ahmadi, M.A. Thermodynamic and thermo-economic analysis and optimization of an irreversible regenerative closed Brayton cycle. Energy Convers. Manag. 2015, 94, 124–129. [Google Scholar] [CrossRef]

- Li, Y.; Liao, S.; Liu, G. Thermo-economic multi-objective optimization for a solar-dish Brayton system using NSGA-II and decision making. Int. J. Electr. Power Energy Syst. 2015, 64, 167–175. [Google Scholar] [CrossRef]

- Sun, Z.; Lai, J.; Wang, S.; Wang, T. Thermodynamic optimization and comparative study of different ORC configurations utilizing the exergies of LNG and low grade heat of different temperatures. Energy 2018, 147, 688–700. [Google Scholar] [CrossRef]

- Yang, M.-H. Payback period investigation of the organic Rankine cycle with mixed working fluids to recover waste heat from the exhaust gas of a large marine diesel engine. Energy Convers. Manag. 2018, 162, 189–202. [Google Scholar] [CrossRef]

| Research | Heat Source (Inlet Temperature) | ORC Configuration | Working Fluid | Optimization Algorithm |

|---|---|---|---|---|

| He et al. [31] | LNG-fired vehicle engine exhaust gas (336.9 °C) | Combined ORC with dual heat source | 5 pure fluids | - |

| Yu et al. [32] | Seawater (20 °C)/Waste heat (-) | Combined ORC with precooler and preheater | 22 pure fluids | Particle Swarm Optimization (PSO) algorithm |

| Han et al. [33] | Seawater (20 °C) /Main engine exhaust gas (270°C)/Jacket cooling water (90 °C) | Triple ORC | 15 pure fluids | Self-adaptive firefly algorithm (SAFA) |

| Sung and Kim [45] | Main engine exhaust gas (230 °C)/Jacket cooling water (91 °C) | Dual-loop ORC | 13 pure fluids | - |

| Habibi et al. [46] | Main engine exhaust gas (300 °C)/Jacket cooling water (90 °C) | Combined ORC | 6 pure fluids | Non-dominated Sorting Genetic Algorithm - II (NSGA-II) |

| Koo et al. [48] | Jacket cooling water (80 °C) | Six different ORCs | 6 pure fluids | Particle Swarm Optimization (PSO) algorithm |

| Parameter | Value |

|---|---|

| Power (kW) | 11700 |

| Cylinder Bore × Stroke (mm) | 500 × 580 |

| Cylinder Configuration | 12 in V-form |

| Normal Speed (rpm) | 514 |

| Side | Parameter | Value |

|---|---|---|

| Environment | Ambient temperature (°C) | 25 |

| Ambient pressure (kPa) | 100 | |

| LNG storage temperature (°C) | −163 | |

| Cold Source | LNG storage pressure (kPa) | 101 |

| LNG pressure at DF marine engine inlet (kPa) | 600 | |

| LNG temperature at DF marine engine inlet (°C) | 20 | |

| LNG mass flow rate (kg/s) | 0.61 (100% load) | |

| Heat Source | Engine exhaust gas inlet temperature (°C) | 150 |

| Engine exhaust gas outlet temperature (°C) | 100 | |

| Jacket cooling water inlet temperature (°C) | 95 | |

| Jacket cooling water outlet temperature (°C) | 78 |

| Working Fluid | Chemical Formula | ttri (°C) | pcri (kPa) | Type | ODP | GWP | Safety Group |

|---|---|---|---|---|---|---|---|

| R1150 | CH2CH2 | −169.16 | 5042 | Wet | 0 | 20 | A3 |

| R170 | CH3CH3 | −182.78 | 4872 | Wet | 0 | 20 | A3 |

| R1270 | CH2CHCH3 | −185.2 | 4555 | Wet | 0 | 1.8 | A3 |

| R290 | CH3CH2CH3 | −187.63 | 4251 | Wet | 0 | 5 | A3 |

| R1234yf | CF3CFCH2 | −53.15 | 3382 | Isotropic | 0 | <1 | A2L |

| R152a | CHF2CH3 | −118.59 | 4517 | Wet | 0 | 138 | A2 |

| R1234ze(E) | CHFCHCF3 | −104.53 | 3636 | Isotropic | 0 | <1 | A1 |

| R600a | CH(CH3)3 | −159.42 | 3629 | Dry | 0 | 20 | A3 |

| R600 | CH3(CH2)2CH3 | −138.25 | 3796 | Dry | 0 | 4 | A3 |

| R601a | (CH3)2CHCH2CH3 | −160.5 | 3378 | Dry | 0 | 20 | A3 |

| R601 | CH3(CH2)3CH3 | −129.68 | 3370 | Dry | 0 | 20 | A3 |

| No. | Specifications and Constraints |

|---|---|

| 1 | Condensation pressures in CON1, CON2 and CON3 are set at the ambient pressure |

| 2 | Evaporation pressures in EVA1, EVA2 and EVA3 are set at the highest point, which is constrained by the pinch point temperature difference or critical pressure |

| 3 | The subcooling of WFs at the inlet of pump is stipulated at 5 °C to prevent cavitation |

| 4 | The wet WFs are superheated with 10 °C while the isotropic and dry WFs are saturated vapor at the inlet of expander |

| 5 | The pinch point in the heat exchangers is varied in the range of 5–40 °C |

| 6 | The isentropic efficiencies of expander and pump are 80% |

| 7 | All operating pressure should be 200 kPa lower than the critical pressure to ensure stability |

| Component | Energy Analysis Model | Exergy Analysis Model |

|---|---|---|

| P0 | ||

| CON1 | ||

| EXP1 | ||

| EVA1/CON3 | ||

| P1 | ||

| CON2 | ||

| EXP2 | ||

| EVA2 | ||

| P2 | ||

| EXP3 | ||

| EVA3 | ||

| P3 |

| Components | Economic Analysis Model |

|---|---|

| Condenser | |

| Evaporator | |

| Pump | |

| Expander |

| Components | K1 | K2 | K3 | C1 | C2 | C3 | B1 | B2 | Fm | Fbm |

|---|---|---|---|---|---|---|---|---|---|---|

| Condenser | 4.325 | −0.303 | 0.163 | 0.039 | −0.113 | 0.082 | 1.63 | 1.66 | 1.4 | - |

| Evaporator | 4.325 | −0.303 | 0.163 | 0.039 | −0.113 | 0.082 | 1.63 | 1.66 | 1.4 | 4.325 |

| Pump | 3.389 | 0.053 | 0.153 | −0.394 | 0.396 | −0.002 | 1.89 | 1.35 | 1.6 | 0 |

| Expander | 2.705 | 1.440 | −0.178 | 0 | 0 | 0 | 0 | 1 | 3.4 | 3.5 |

| Parameter | Value |

|---|---|

| Population Size | 200 |

| Crossover Probability | 0.8 |

| Mutation Function | constraint dependent |

| Selection Process | tournament |

| Generations | inf |

| Stall Generations | 100 |

| Items | Ref. [58] | This Study | Ref. [58] | This Study | Ref. [59] | This Study |

|---|---|---|---|---|---|---|

| Heat Source | Waste Heat (100 to 60.8 °C) | JCW (98 to 75 °C) | Waste Heat (200 to 58.2 °C) | EEG (150 to 100 °C) | EEG (160 to -) | EEG (160 to 107.9 °C) |

| Cold Source | LNG | LNG | LNG | LNG | Water | Water |

| Working Fluids | R170/NH3 | R170/NH3 | R170/NH3 | R170/NH3 | R600 | R600 |

| pLNG (kPa) | 3000 | 3000 | 3000 | 3000 | 101.3 | 101.3 |

| tEVA (°C) | 62.38/−38.33 | 73.78/−38.33 | 130.93/−38.33 | 130.93/−38.33 | 98 | 98.93 |

| tCON (°C) | −33.33/−88.58 | −33.33/−88.58 | −33.33/−88.58 | −33.33/−88.58 | 30 | 34.29 |

| mLNG (kg/s) | 1 | 1 | 1 | 1 | - | - |

| Wnet (kW) | 244.24 | 218.63 | 320.83 | 249.29 | 925 | 989.2 |

| Exhs,in (kW) | 167.85 | 165.57 | 231.62 | 322.75 | - | - |

| ExLNG,in (kW) | 1085.08 | 1085.08 | 1085.08 | 1085.08 | - | - |

| ηex (%) | 19.49% | 17.48% | 24.37% | 17.71% | - | - |

| Ctot (×106$) | - | - | - | - | 2.95 | 3.21 |

| PBP (year) | - | - | - | - | 6.2 | 6.03 |

| Case No. | WF Combination | Π1 (%) | Π2 (105 $/Year) |

|---|---|---|---|

| 1 | R1150-R1270-R152a | 5.94 | 2.93 |

| 2 | R1150-R1270-R1234ze(E) | 5.91 | 2.94 |

| 3 | R1150-R1270-R600a | 6.39 | 3.08 |

| 4 | R1150-R1270-R600 | 6.49 | 3.12 |

| 5 | R1150-R1270-R601a | 5.38 | 2.80 |

| 6 | R1150-R1270-R601 | 5.03 | 2.70 |

| 7 | R1150-R290-R152a | 6.02 | 2.95 |

| 8 | R1150-R290-R1234ze(E) | 6.00 | 2.96 |

| 9 | R1150-R290-R600a | 6.43 | 3.09 |

| 10 | R1150-R290-R600 | 6.44 | 3.10 |

| 11 | R1150-R290-R601a | 5.46 | 2.83 |

| 12 | R1150-R290-R601 | 5.11 | 2.72 |

| 13 | R1150-R1234yf-R152a | 5.96 | 2.93 |

| 14 | R1150-R1234yf-R1234ze(E) | 5.92 | 2.94 |

| 15 | R1150-R1234yf-R600a | 6.68 | 3.12 |

| 16 | R1150-R1234yf-R600 | 6.51 | 3.12 |

| 17 | R1150-R1234yf-R601a | 5.39 | 2.81 |

| 18 | R1150-R1234yf-R601 | 5.04 | 2.70 |

| 19 | R170-R1270-R152a | 5.02 | 2.66 |

| 20 | R170-R1270-R1234ze(E) | 5.10 | 2.71 |

| 21 | R170-R1270-R600a | 5.56 | 2.86 |

| 22 | R170-R1270-R600 | 5.86 | 2.96 |

| 23 | R170-R1270-R601a | 5.26 | 2.80 |

| 24 | R170-R1270-R601 | 5.02 | 2.73 |

| 25 | R170-R290-R152a | 5.09 | 2.69 |

| 26 | R170-R290-R1234ze(E) | 5.17 | 2.73 |

| 27 | R170-R290-R600a | 5.63 | 2.88 |

| 28 | R170-R290-R600 | 5.93 | 2.98 |

| 29 | R170-R290-R601a | 5.33 | 2.82 |

| 30 | R170-R290-R601 | 5.09 | 2.75 |

| 31 | R170-R1234yf-R152a | 5.0 | 2.67 |

| 32 | R170-R1234yf-R1234ze(E) | 5.10 | 2.71 |

| 33 | R170-R1234yf-R600a | 5.57 | 2.86 |

| 34 | R170-R1234yf-R600 | 5.86 | 2.96 |

| 35 | R170-R1234yf-R601a | 5.26 | 2.80 |

| 36 | R170-R1234yf-R601 | 5.03 | 2.73 |

| Parameters | Case 15 | Case 19 |

|---|---|---|

| pCON (kPa) | 796.87 | 204.79 |

| pEVA (kPa) | 112.21 | 214 |

| LMTD in EVA1 (°C) | 44.3 | 69.1 |

| Wnet (kW) | 236.4 | 154.99 |

| ηen (%) | 16.32 | 11.59 |

| ηex (%) | 29.06 | 19.47 |

| Ctot (×106$) | 1.96 | 1.58 |

| PBP (year) | 7.68 | 9.43 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Yue, Y.; Zhang, Y.; Gu, B.; Gao, W. Multi-Objective Thermo-Economic Optimization of a Combined Organic Rankine Cycle (ORC) System Based on Waste Heat of Dual Fuel Marine Engine and LNG Cold Energy Recovery. Energies 2020, 13, 1397. https://doi.org/10.3390/en13061397

Tian Z, Yue Y, Zhang Y, Gu B, Gao W. Multi-Objective Thermo-Economic Optimization of a Combined Organic Rankine Cycle (ORC) System Based on Waste Heat of Dual Fuel Marine Engine and LNG Cold Energy Recovery. Energies. 2020; 13(6):1397. https://doi.org/10.3390/en13061397

Chicago/Turabian StyleTian, Zhen, Yingying Yue, Yuan Zhang, Bo Gu, and Wenzhong Gao. 2020. "Multi-Objective Thermo-Economic Optimization of a Combined Organic Rankine Cycle (ORC) System Based on Waste Heat of Dual Fuel Marine Engine and LNG Cold Energy Recovery" Energies 13, no. 6: 1397. https://doi.org/10.3390/en13061397