Model-Based Adaptive Joint Estimation of the State of Charge and Capacity for Lithium–Ion Batteries in Their Entire Lifespan

Abstract

1. Introduction

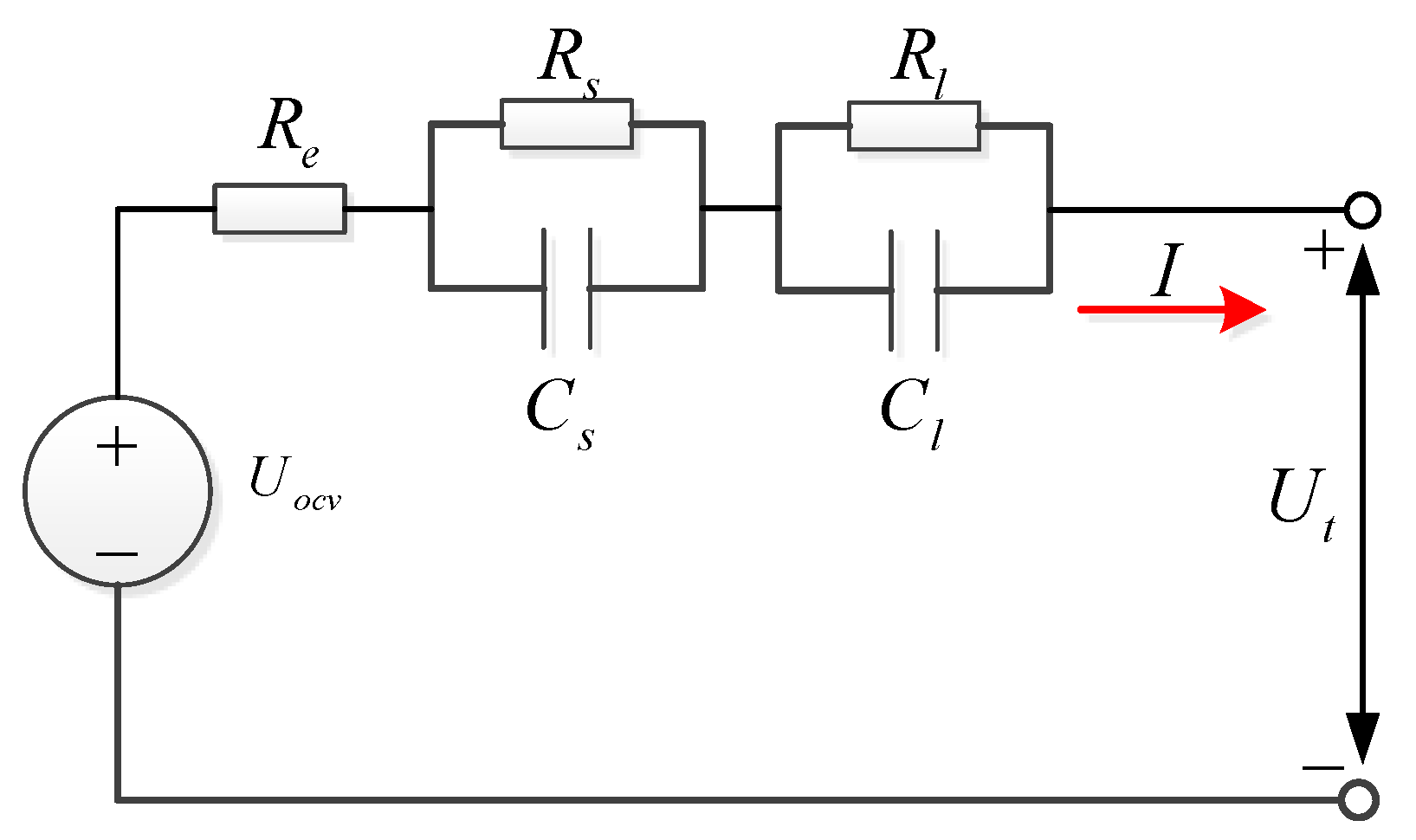

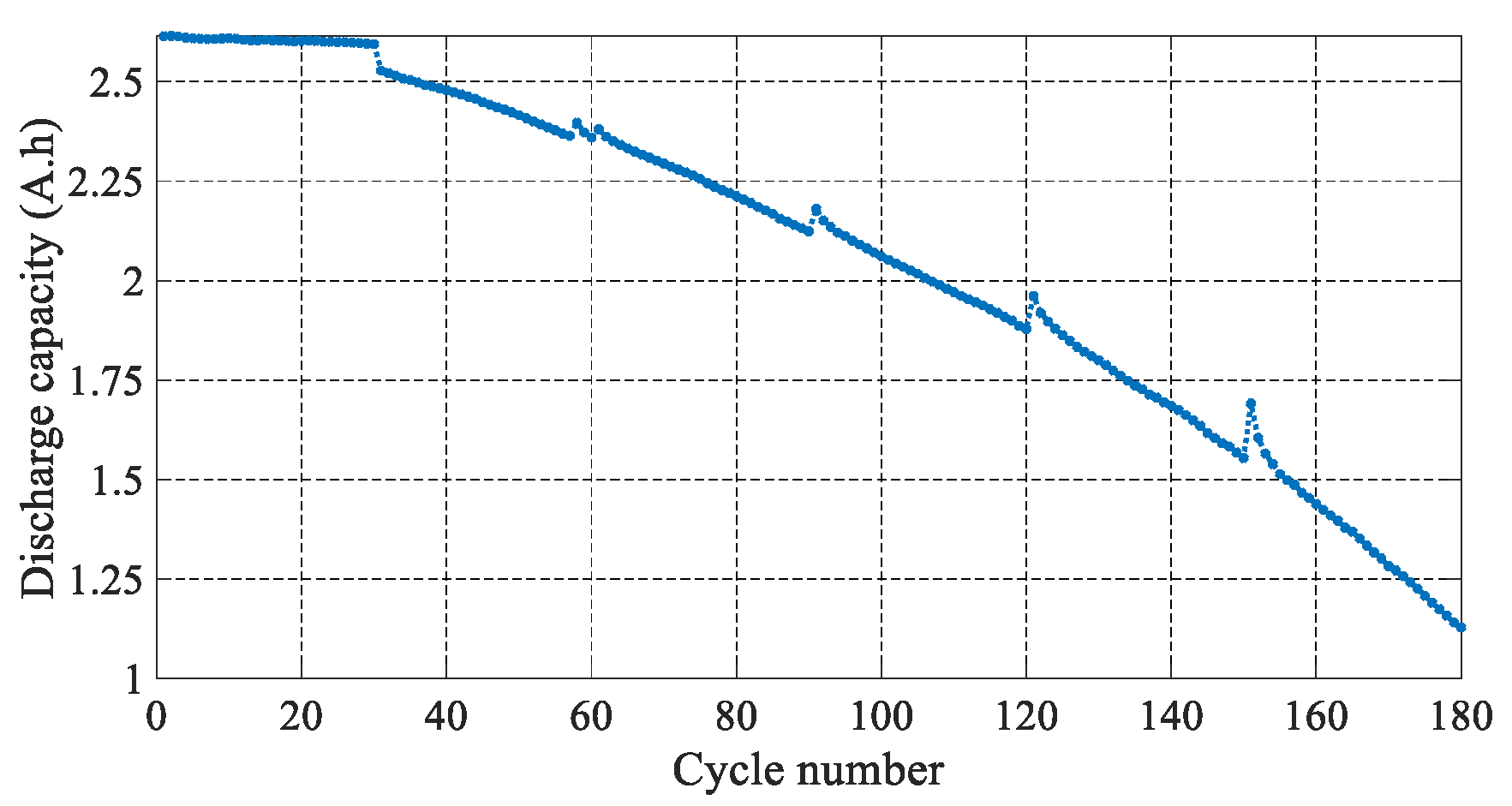

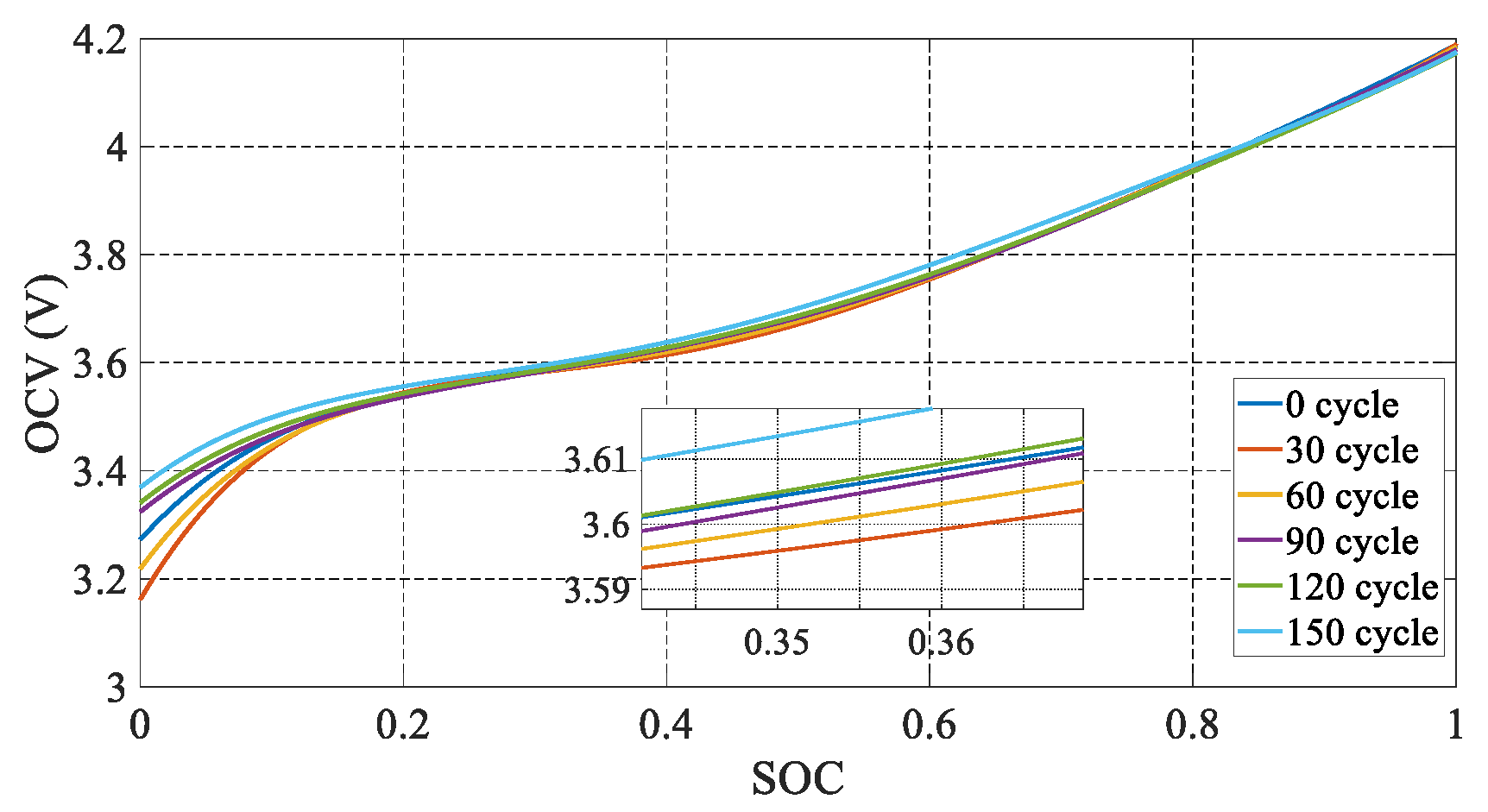

2. The Lithium–Ion Battery Model and the Experimental Details

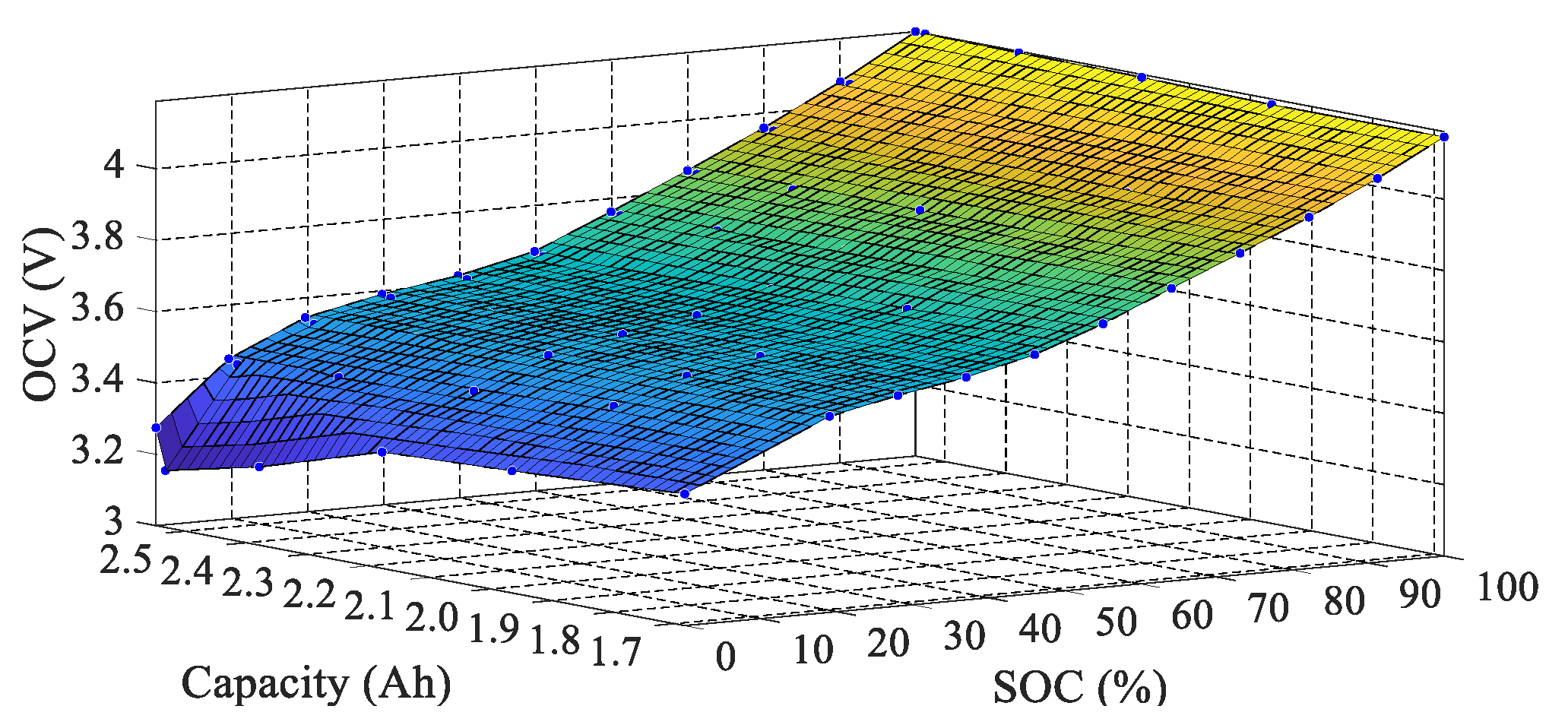

2.1. Battery Modeling and Analysis

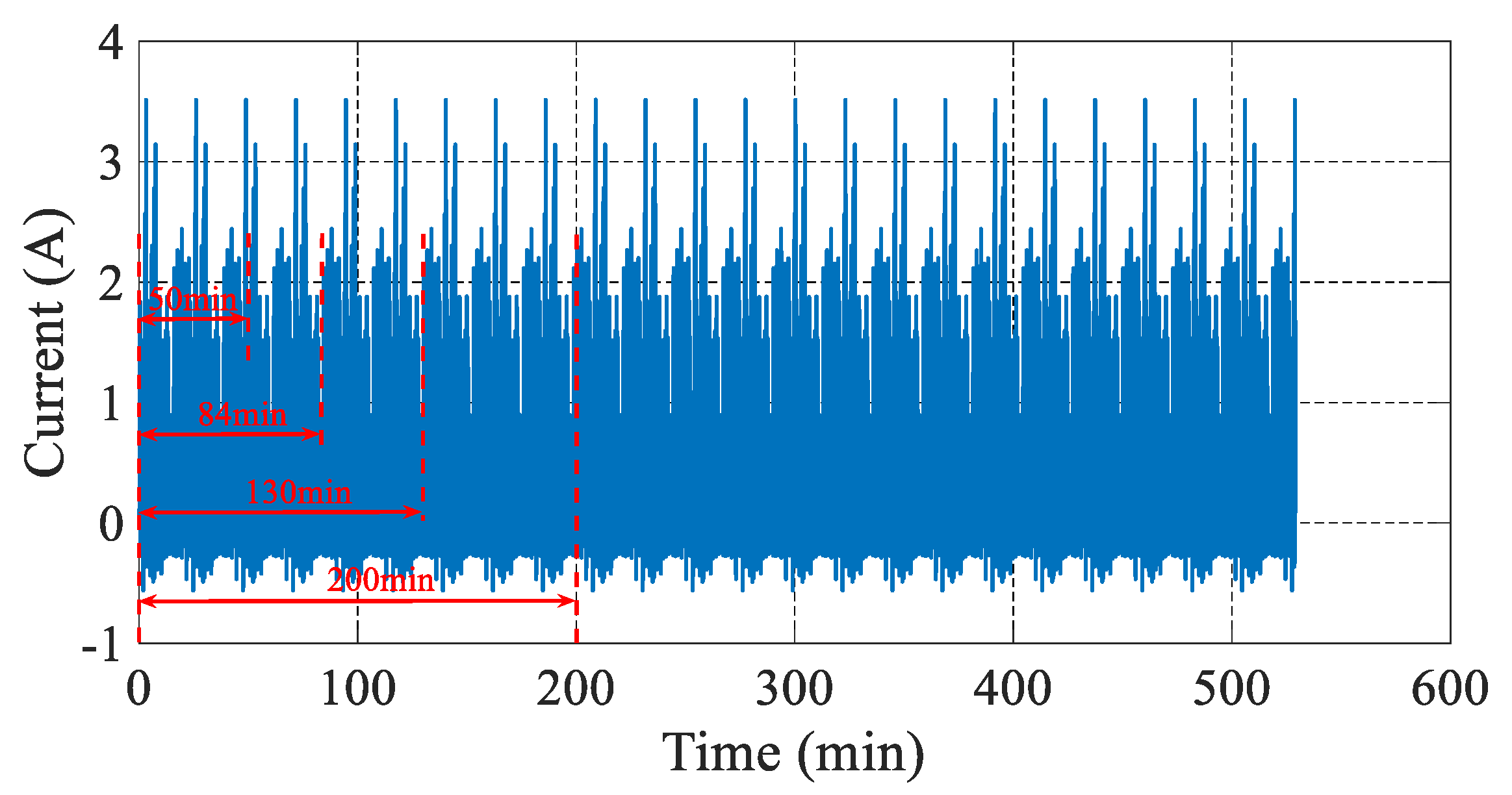

2.2. Experiments

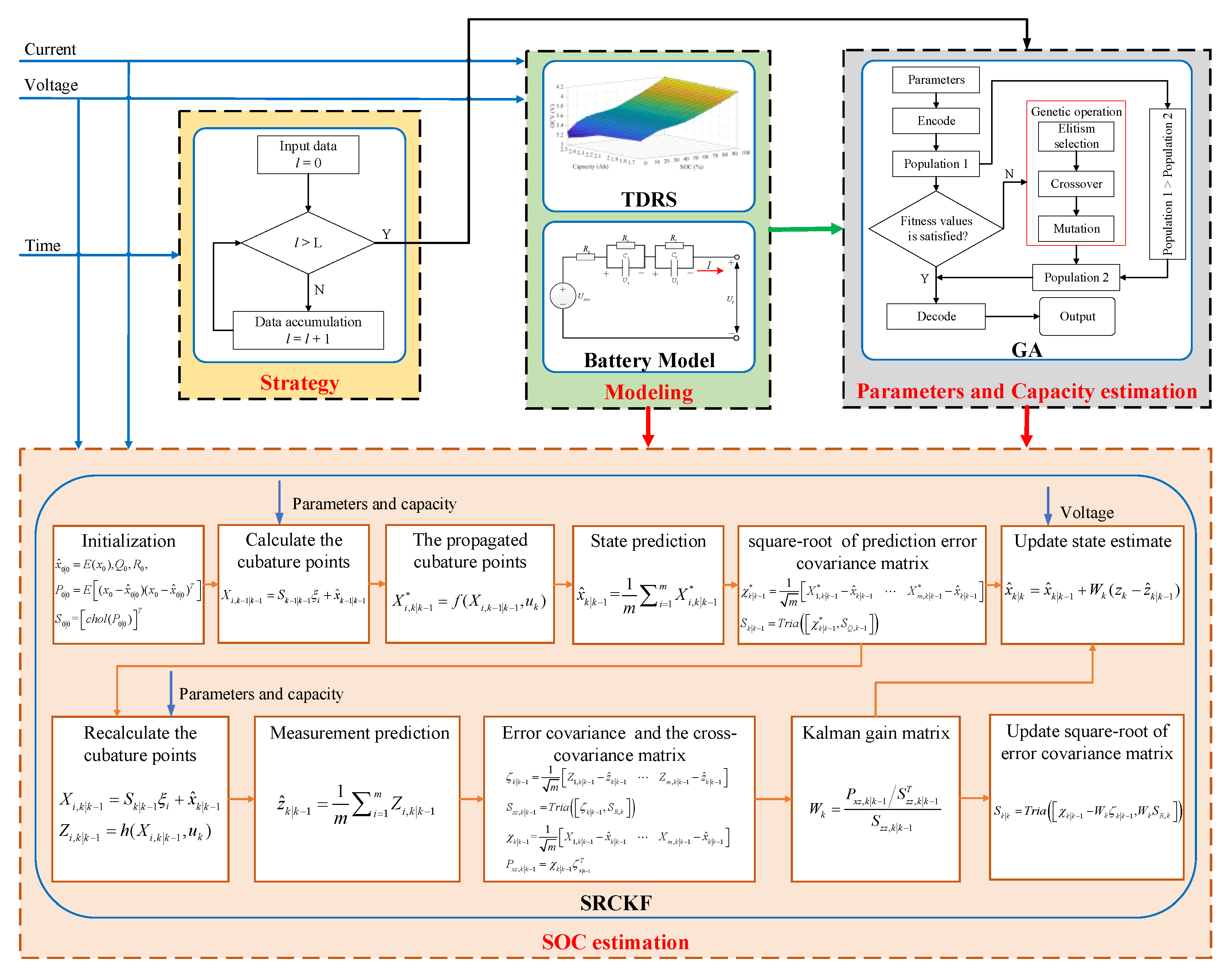

3. The Joint Estimation of SOC and Battery Capacity

3.1. The Capacity Estimation Algorithm

3.2. The SOC Estimation Algorithm

4. Verification and Discussion

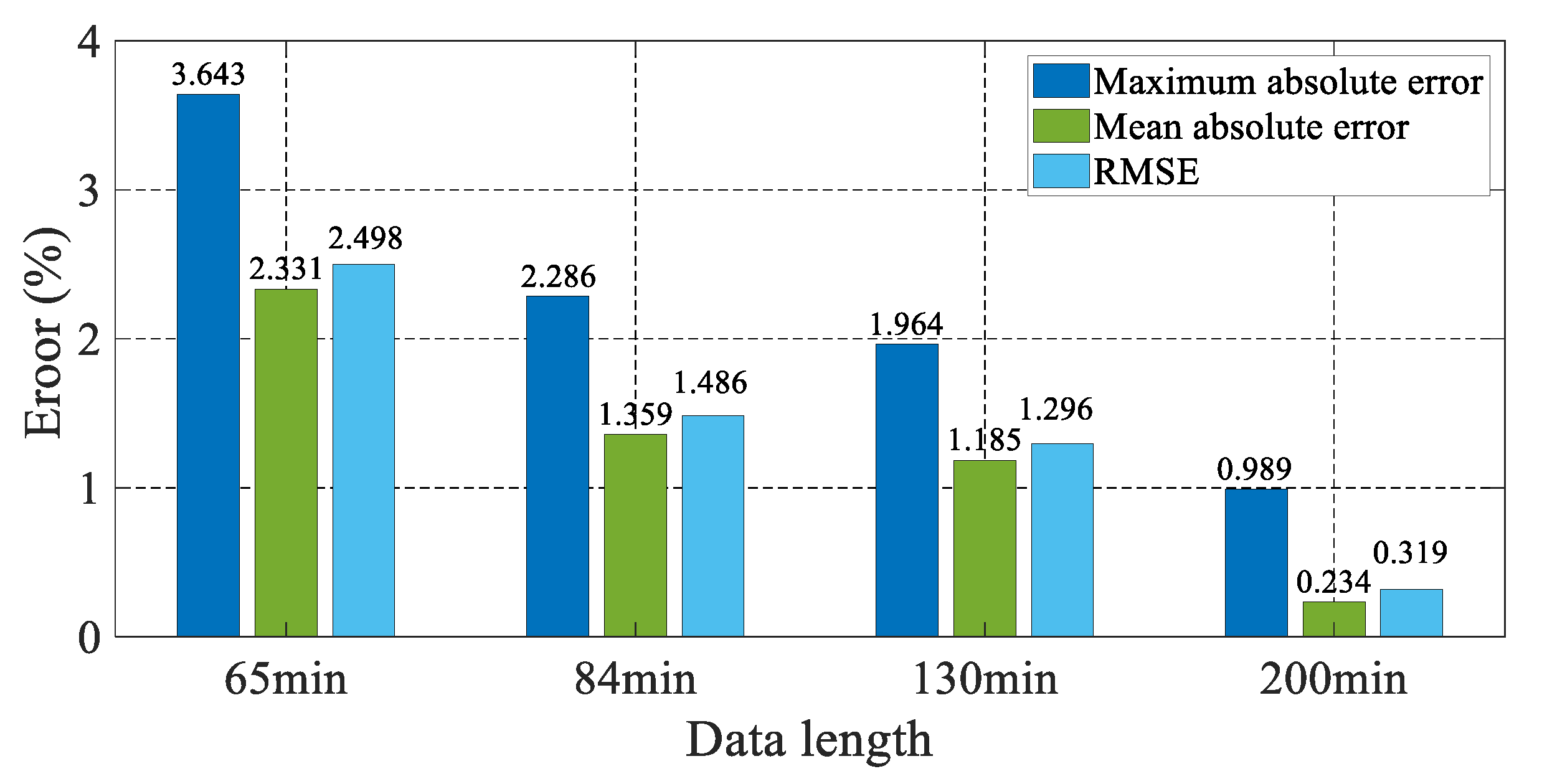

4.1. Verification Study on Different Data Lengths

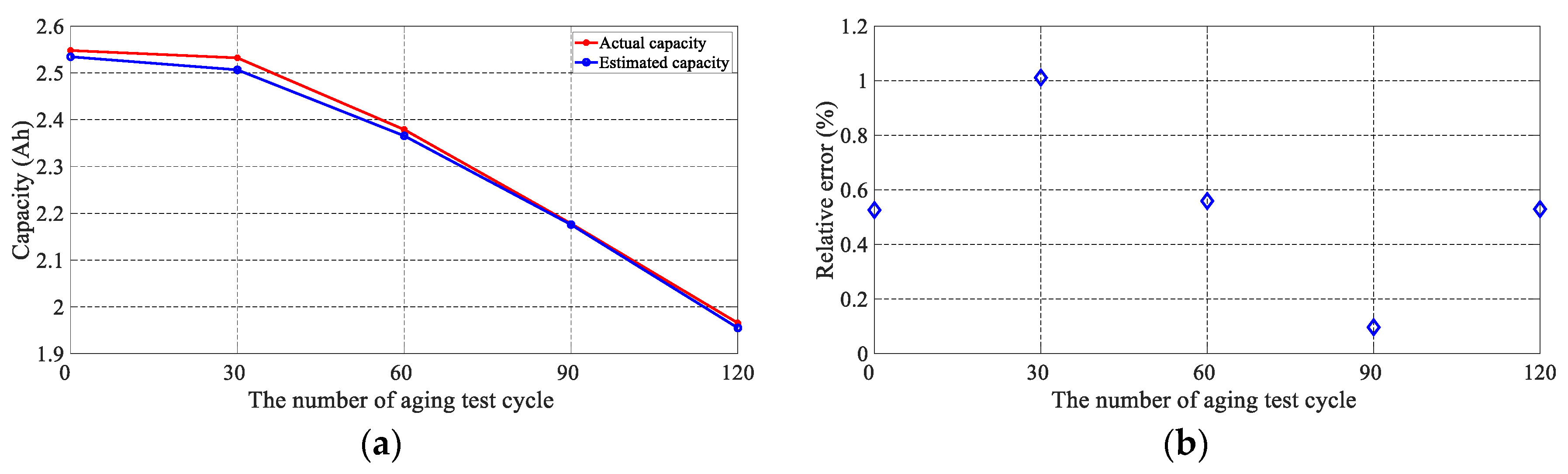

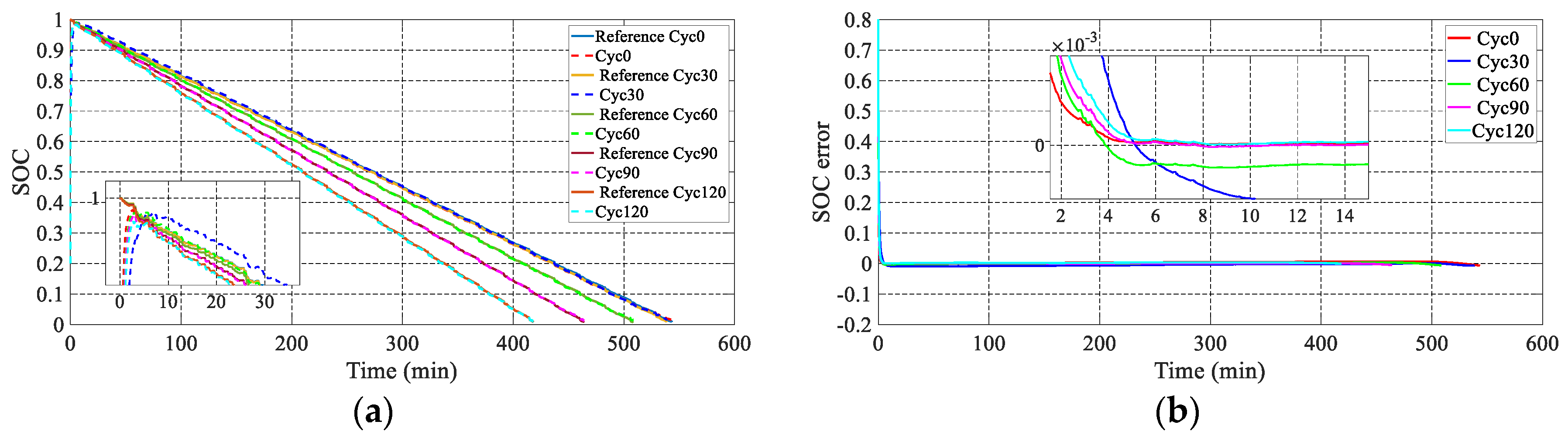

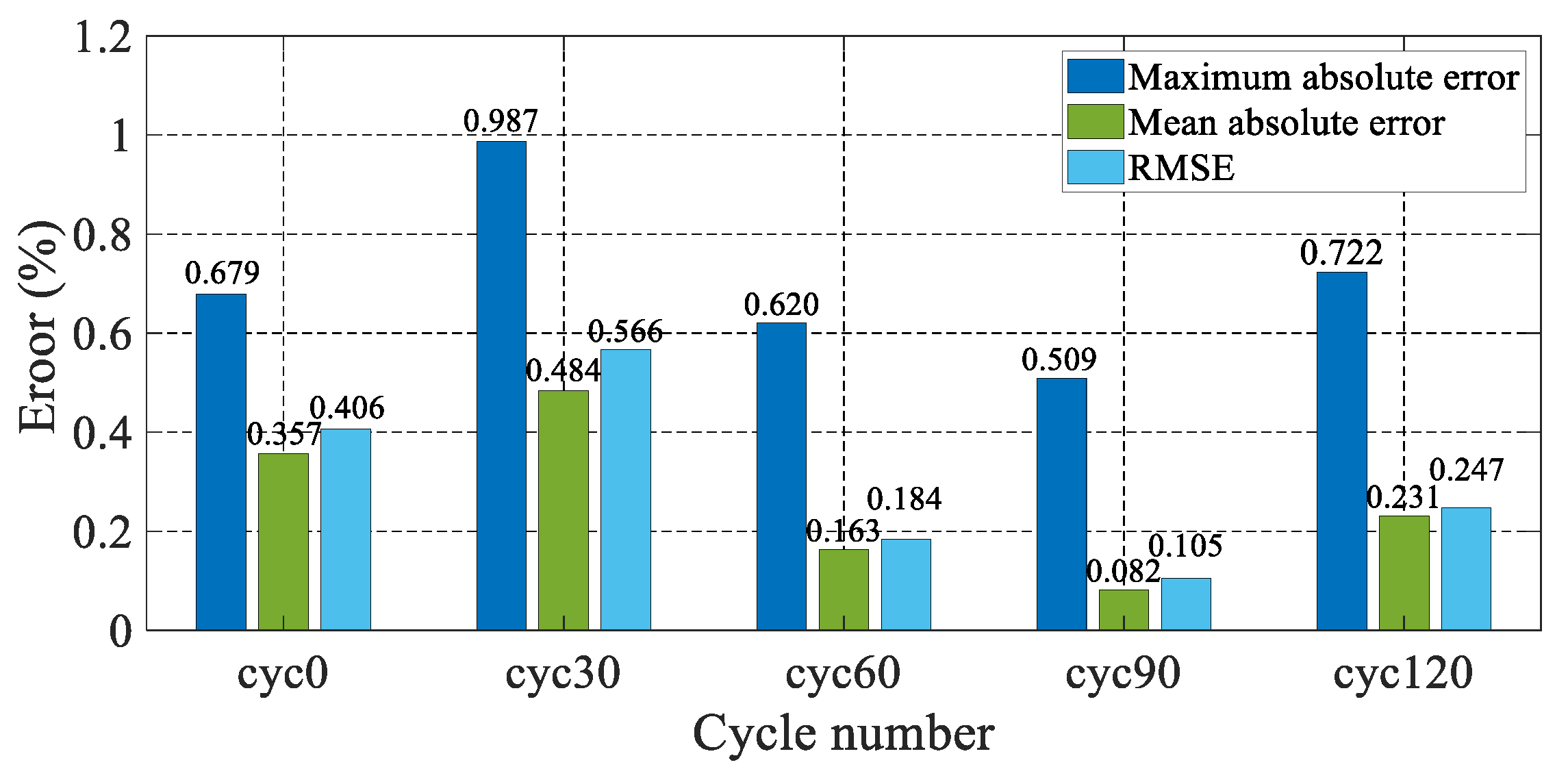

4.2. SOC Estimation under Various Degradation Stages

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Chen, Z.; Shu, X.; Li, X.; Xiao, R.; Shen, J. LiFePO4 battery charging strategy design considering temperature rise minimization. J. Renew. Sustain. Energy 2017, 9, 64103. [Google Scholar] [CrossRef]

- Chen, Z.; Shu, X.; Xiao, R.; Yan, W.; Liu, Y.; Shen, J. Optimal charging strategy design for lithium-ion batteries considering minimization of temperature rise and energy loss. Int. J. Energy Res. 2019, 43, 4344–4358. [Google Scholar] [CrossRef]

- Zhao, L.; Lin, M.; Chen, Y. Least-squares based coulomb counting method and its application for state-of-charge (SOC) estimation in electric vehicles. Int. J. Energy Res. 2016, 40, 1389–1399. [Google Scholar] [CrossRef]

- Xiong, R.; Yu, Q.; Wang, L.Y.; Lin, C. A novel method to obtain the open circuit voltage for the state of charge of lithium ion batteries in electric vehicles by using H infinity filter. Appl. Energy 2017, 207, 346–353. [Google Scholar] [CrossRef]

- Houlian, W.; Gongbo, Z. State of charge prediction of supercapacitors via combination of Kalman filtering and backpropagation neural network. IET Electr. Power Appl. 2018, 12, 588–594. [Google Scholar] [CrossRef]

- Meng, J.; Luo, G.; Fei, G. Lithium Polymer Battery State-of-Charge Estimation Based on Adaptive Unscented Kalman Filter and Support Vector Machine. IEEE Trans. Power Electron. 2016, 31, 2226–2238. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Gong, J. A multi-model probability SOC fusion estimation approach using an improved adaptive unscented Kalman filter technique. Energy 2017, 141, 1402–1415. [Google Scholar] [CrossRef]

- Campestrini, C.; Heil, T.; Kosch, S.; Jossen, A. A comparative study and review of different Kalman filters by applying an enhanced validation method. J. Energy Storage 2016, 8, 142–159. [Google Scholar] [CrossRef]

- Charkhgard, M.; Zarif, M.H. Design of adaptive H-infinity filter for implementing on state-of-charge estimation based on battery state-of-charge-varying modelling. IET Power Electron. 2015, 8, 1825–1833. [Google Scholar] [CrossRef]

- Pola, D.A.; Navarrete, H.F.; Orchard, M.E.; Rabie, R.S.; Cerda, M.A.; Olivares, B.E.; Silva, J.F.; Espinoza, P.A.; Perez, A. Particle-Filtering-Based Discharge Time Prognosis for Lithium-Ion Batteries with a Statistical Characterization of Use Profiles. IEEE Trans. Reliab. 2015, 64, 710–720. [Google Scholar] [CrossRef]

- Chen, Z.; Fu, Y.; Mi, C.C. State of Charge Estimation of Lithium-Ion Batteries in Electric Drive Vehicles Using Extended Kalman Filtering. IEEE Trans. Veh. Technol. 2013, 62, 1020–1030. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Pan, R.; Chen, Z. Modeling and state-of-charge prediction of lithium-ion battery and ultracapacitor hybrids with a co-estimator. Energy 2017, 121, 739–750. [Google Scholar] [CrossRef]

- Alkaya, A. Unscented Kalman filter performance for closed-loop nonlinear state estimation: A simulation case study. Electr. Eng. 2014, 96, 299–308. [Google Scholar] [CrossRef]

- Liu, Z.; Dang, X.; Jing, B.; Ji, J. A novel model-based state of charge estimation for lithium-ion battery using adaptive robust iterative cubature Kalman filter. Electron. Pow. Syst. Res. 2019, 177, 105951. [Google Scholar] [CrossRef]

- Yu, Q.; Xiong, R.; Lin, C. Online Estimation of State-of-charge Based on the H infinity and Unscented Kalman Filters for Lithium Ion Batteries. Energy Procedia 2017, 105, 2791–2796. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, J.; Wang, G.; Lu, D.D.-C.; He, T. Differential voltage analysis based state of charge estimation methods for lithium-ion batteries using extended Kalman filter and particle filter. Energy 2018, 158, 1028–1037. [Google Scholar] [CrossRef]

- Li, S.; Hu, M.; Li, Y.; Gong, C. Fractional-order modeling and SOC estimation of lithium-ion battery considering capacity loss. Int. J. Energy Res. 2019, 43, 417–429. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Sources 2011, 196, 6007–6014. [Google Scholar] [CrossRef]

- Waag, W.; Kaebitz, S.; Sauer, D.U. Experimental investigation of the lithium-ion battery impedance characteristic at various conditions and aging states and its influence on the application. Appl. Energy 2013, 102, 885–897. [Google Scholar] [CrossRef]

- Han, X.; Ouyang, M.; Lu, L.; Li, J. A comparative study of commercial lithium ion battery cycle life in electric vehicle: Capacity loss estimation. J. Power Sources 2014, 268, 658–669. [Google Scholar] [CrossRef]

- Feng, X.; Li, J.; Ouyang, M.; Lu, L.; Li, J.; He, X. Using probability density function to evaluate the state of health of lithium-ion batteries. J. Power Sources 2013, 232, 209–218. [Google Scholar] [CrossRef]

- Zou, Y.; Hu, X.; Ma, H.; Li, S.E. Combined State of Charge and State of Health estimation over lithium-ion battery cell cycle lifespan for electric vehicles. J. Power Sources 2015, 273, 793–803. [Google Scholar] [CrossRef]

- He, T.; Xu, W.; Lu, Z.; Yong, H.; Tian, G. Adaptive Fuzzy Logic Energy Management Strategy Based on Reasonable SOC Reference Curve for Online Control of Plug-in Hybrid Electric City Bus. IEEE Trans. Intell. Transp. 2018, 19, 1607–1617. [Google Scholar]

- Hussein, A.A. Capacity Fade Estimation in Electric Vehicle Li-Ion Batteries Using Artificial Neural Networks. IEEE Trans. Ind. Appl. 2015, 51, 2321–2330. [Google Scholar] [CrossRef]

- Jin, N.; Danilov, D.L.; van den Hof, P.M.J.; Donkers, M.C.F. Parameter estimation of an electrochemistry-based lithium-ion battery model using a two-step procedure and a parameter sensitivity analysis. Int. J. Energy Res. 2018, 42, 2417–2430. [Google Scholar] [CrossRef]

- Wang, C.; He, H.; Zhang, Y.; Mu, H. A comparative study on the applicability of ultracapacitor models for electric vehicles under different temperatures. Appl. Energy 2017, 196, 268–278. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, M.; Buyya, R.; Fan, Q. Deadline-constrained coevolutionary genetic algorithm for scientific workflow scheduling in cloud computing. Concurr. Comput. Pract. Exp. 2017, 29, e3942. [Google Scholar] [CrossRef]

- Jin, L.W.; Lee, P.S.; Kong, X.X.; Fan, Y.; Chou, S.K. Ultra-thin minichannel LCP for EV battery thermal management. Appl. Energy 2014, 113, 1786–1794. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; He, H.; Mu, H.; Wang, C. A novel method on estimating the degradation and state of charge of lithium-ion batteries used for electrical vehicles. Appl. Energy 2017, 207, 336–345. [Google Scholar] [CrossRef]

- Sun, X.; Ji, J.; Ren, B.; Xie, C.; Yan, D. Adaptive Forgetting Factor Recursive Least Square Algorithm for Online Identification of Equivalent Circuit Model Parameters of a Lithium-Ion Battery. Energies 2019, 12, 2242. [Google Scholar] [CrossRef]

- Cheng, S.; Li, L.; Chen, J. Fusion algorithm design based on adaptive SCKF and integral correction for side-slip angle observation. IEEE Trans. Ind. Electron. 2017, 65, 5754–5763. [Google Scholar] [CrossRef]

| Material | Ternary Lithium–Ion Battery |

|---|---|

| Nominal capacity | 2.55 Ah |

| Nominal voltage | 3.6 V |

| End-of-charge voltage | 4.2 V |

| End-of-charge current | 51 mA |

| End-of-discharge voltage | 2.5 V |

| (a) Initialization:

for Time update: Step 1: calculate the cubature points: Step 1: recalculate the cubature points: Step 1: estimate the Kalman gain matrix: |

| Data Length | Estimated Capacity/Ah | Absolute Error/Ah | Relative Error/% |

|---|---|---|---|

| 65 min | 2.4366 | 0.0955 | 3.7716 |

| 84 min | 2.4710 | 0.0611 | 2.4130 |

| 130 min | 2.4854 | 0.0467 | 1.8443 |

| 200 min | 2.5065 | 0.0256 | 1.0110 |

| Cycle Number | Actual Capacity/Ah | Estimated Capacity/Ah | Absolute Error/Ah | Relative Error/% |

|---|---|---|---|---|

| cyc0 | 2.5478 | 2.5344 | 0.0134 | 0.5259 |

| cyc30 | 2.5321 | 2.5065 | 0.0256 | 1.0110 |

| cyc60 | 2.3788 | 2.3655 | 0.0133 | 0.5591 |

| cyc90 | 2.1779 | 2.1758 | 0.0021 | 0.0964 |

| cyc120 | 1.9655 | 1.9551 | 0.0104 | 0.5291 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Xiao, J.; Shu, X.; Shen, S.; Shen, J.; Liu, Y. Model-Based Adaptive Joint Estimation of the State of Charge and Capacity for Lithium–Ion Batteries in Their Entire Lifespan. Energies 2020, 13, 1410. https://doi.org/10.3390/en13061410

Chen Z, Xiao J, Shu X, Shen S, Shen J, Liu Y. Model-Based Adaptive Joint Estimation of the State of Charge and Capacity for Lithium–Ion Batteries in Their Entire Lifespan. Energies. 2020; 13(6):1410. https://doi.org/10.3390/en13061410

Chicago/Turabian StyleChen, Zheng, Jiapeng Xiao, Xing Shu, Shiquan Shen, Jiangwei Shen, and Yonggang Liu. 2020. "Model-Based Adaptive Joint Estimation of the State of Charge and Capacity for Lithium–Ion Batteries in Their Entire Lifespan" Energies 13, no. 6: 1410. https://doi.org/10.3390/en13061410

APA StyleChen, Z., Xiao, J., Shu, X., Shen, S., Shen, J., & Liu, Y. (2020). Model-Based Adaptive Joint Estimation of the State of Charge and Capacity for Lithium–Ion Batteries in Their Entire Lifespan. Energies, 13(6), 1410. https://doi.org/10.3390/en13061410