1. Introduction

Compressed natural gas (CNG) is one of the most promising alternative fuels due to its rich resource and cheap price. Compared with a gasoline engine, a CNG engine can reduce carbon dioxide emissions by 25% [

1] and greenhouse gas emissions by 10–20% [

2]. The 2006 model year HONDA CIVIC GX, equipped with a CNG engine, was certified as a super ultra-low emission vehicle (SULEV) [

3]. Additionally, the 2016 model year IVECO Cursor 11 CNG engine (11.1 L) reached the Euro VI emission standard [

4]. However, natural gas has a lower energy density compared to diesel/gasoline. To provide a longer driving range for natural gas vehicles (NGV), liquefied natural gas (LNG) vehicles are proposed, with natural gas cooled to −162 °C at atmospheric pressure and stored in highly insulated cryogenic tanks [

5]. LNG is usually vaporized out a cylinder and injected into the intake port or into the cylinder directly through the gas injector. CNG/LNG heavy-duty vehicles are normally spark plug engines, which are less efficient than conventional diesel engines working on a diesel cycle; they are about 17% less efficient but the emission benefit is around 10% [

6]. On the other hand, dual-fuel vehicles (diesel and natural gas) have comparable efficiency as conventional diesel engines and combine the efficiency and torque characteristics of diesel engines while reducing the CO

2 emissions by as much as 20% compared to gas engines [

7]. It can be seen that the gas injection system will always be involved for CNG, LNG or natural gas/diesel dual-fuel engines.

According to the mode of gas injection system, these engines can be divided into two types: port fuel injection (PFI) and in-cylinder direct injection (DI) type. The DI mode can avoid the drop of volumetric efficiency, which is the disadvantage of a gas-fueled PFI engine. Thus, the former tends to have a higher engine power. However, the DI mode has some fatal disadvantages. The injector would be exposed directly to the combustion chamber under this mode. Thus, key parts of the injection system, such as the gas fuel injector, need the heat-resistant treatment to ensure work stability, which undoubtedly increases the manufacturing requirements. Moreover, the lubricating and cooling problems of direct CNG injector are remained unsolved currently [

8]. Thus, the PFI mode will still be an important developing direction of gas fuel engines.

The gas injector is the ultimate component of any kind of gas fuel injection system for CNG, LNG and dual-fuel engines. The injector’s controllability and injection characteristics have a great influence on the engine performance. Currently, the driver of injectors is mostly solenoid, and the executing component is mostly in the form of a spherical or needle valve [

8]. Such kinds of injectors are small in size and can be installed conveniently in the engine. However, its mass flow rate is quite low. In order to meet the gas fuel supply requirements of large-bore gas-fueled PFI engine, the injection pulse width was increased to 500 °C A, which was far beyond the intake stroke [

9]. Therefore, the gas fuel injected was gathered in the intake port before the intake valve was opened for the PFI injection system, which would cause backfire in the intake port. More importantly, the injector’s control accuracy, working reliability and life will be seriously decreased because of the solenoid, whose control characteristic is poor [

8].

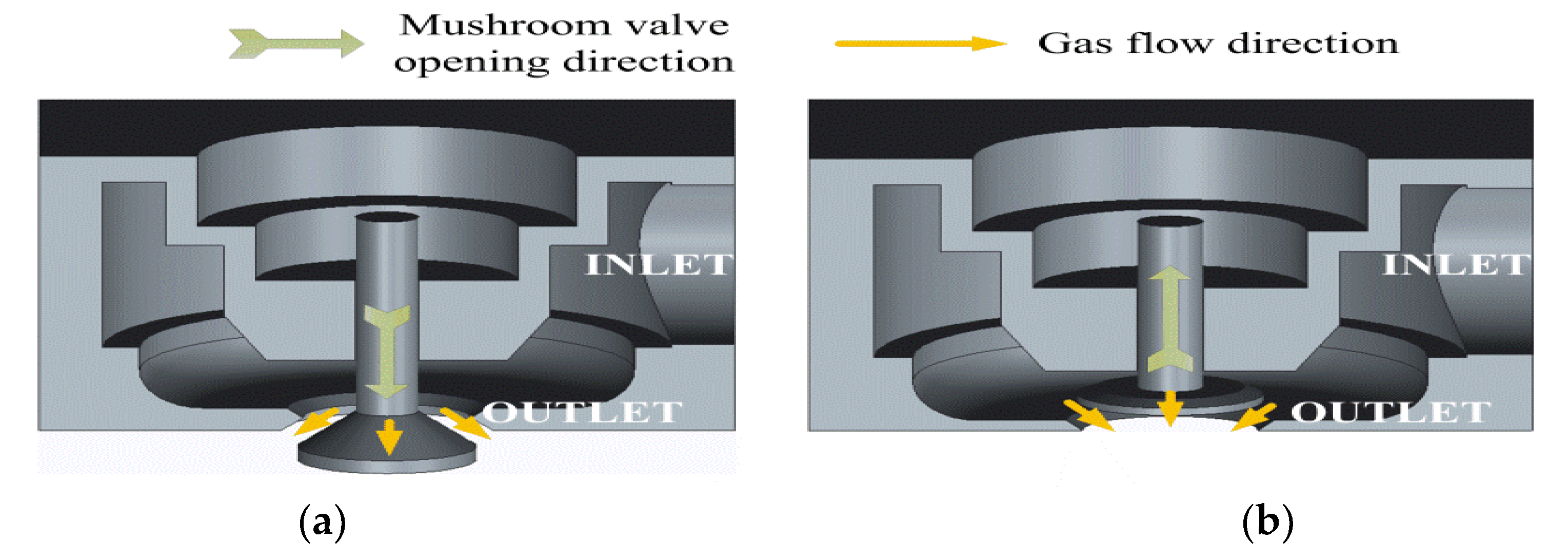

In order to solve the low injection-rate and the low controlling accuracy problems of the traditional injector, the authors had designed one new kind of gas fuel injector [

10]. The moving-coil electromagnetic linear actuator was used as the driver, because of its higher controlling accuracy and longer working life than solenoid. The mushroom type poppet valve was used as the executing component, because of its higher injection-rate and better sealing performance than spherical or needle valve.

For the traditional spherical or needle valve, considering that the valve is small and the outlet of the injector is usually round in shape, the virtual round-hole nozzle can be used to simplify the computational fluid dynamics (CFD) calculation process of the injection characteristic. The internal structure of the injector would not be taken into consideration. The influence of the injection strategy on the mixture formation and combustion process in a PFI natural gas rotary engine was studies using virtual round-hole nozzle [

11]. This simplified method was also used to simulate the mixing process in the dual-fuel (diesel-CNG or diesel-hydrogen) engine to optimize the gas injector orientation [

12]. The interaction between the gas fuel jet and the air movement in the intake port was focused, while the injection characteristics of the gas injector itself were ignored. This situation is the same for some DI studies. The in-cylinder high pressure ratio CNG jets issued at freestream and impinging conditions were studied [

13]. The effects of injection parameters, combustion chamber geometry and engine speed on mixing performance have been studied [

14]. All of the above studies needed to set the spray pattern and outlet mass flow before CFD calculation because they did not take the internal structure of the injector into consideration, which will affect the simulation accuracy.

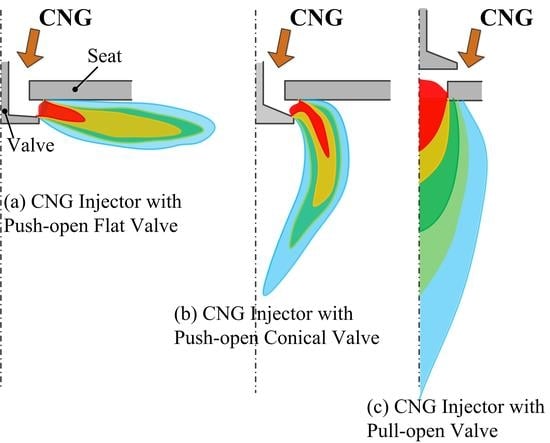

In recent years, a small number of researchers have begun to pay attention to the injection characteristics of the gas fuel injector. The sensitivity of the mixture formation process to nozzle type, injection pressure and injection timing was investigated [

15]. Three kinds of nozzles, namely a simple circular nozzle and a 45° and 55° hollow cone push-open nozzle, were compared. It was concluded that the impingement-induced mixing performance was more dominant with the circular nozzle and the 45° hollow cone nozzle. The umbrella jet formed by the push-open type injector was studied in a DI engine [

16]. It was found that to control the injection shape of the umbrella jet was difficult because it would be easily affected by the pressure and speed outside the outlet. These few research articles on the type of injector pay more attention to the influence on the mixing uniformity or stratification effect, and have not conducted in-depth research on the injection characteristics of the gas fuel injector itself.

In the present study, the steady-state injection characteristics of two kinds of injectors with different opening manners (push-open and pull-open poppet valve) were emphasized using the FLUENT code. Furthermore, the effects of the valve profile and valve sealing method on the jet pattern are revealed.

Section 2 presents the calculation model, the grid independency study and the steady-state experiment to verify the mesh independence. Moreover, the effects of the valve profile, valve opening manner and sealing method are analyzed in

Section 3. This paper is concluded in

Section 4.

3. Numerical Results and Discussion

3.1. Effects of the Valve Profile

The steady jet patterns of flat (type A) and conical (type B) push-open poppet valve are shown in

Figure 8 and

Figure 9, respectively. It is obvious that the jets of these two kinds of push-open poppet valves are utterly different from each other, coinciding with the results obtained from the literature [

11]. As shown in

Figure 8, the expansion wave is formed at the corner near the valve body, with a drop of pressure. The supersonic jet is blocked by the flat valve, and then the jet direction is changed. This phenomenon is similar to the jet Coanda effect. A low-pressure area is created near the upper wall, which leads to the jet being drawn to the wall and ejected along the radial direction. Thus, the supersonic jet turns along the body bend, and diverges in the radial direction.

However, for the conical valve, the gas fuel supersonic jet flows along the valve profile rather than along the body bend. Moreover, a low-pressure area is formed near the side and bottom face of poppet valve. As a result, the supersonic gas jet is attracted to the direction of the outlet axis.

According to the results of literature [

19], with the increase of the inlet/outlet pressure ratio, it is easier to form the divergence phenomenon as shown in

Figure 8. On the contrary, with the decrease of the pressure ratio, the jet tends to the outlet axis direction. To verify this law, the injection pressure of type A push-open valve was reduced to 0.1 MPa, and the steady jet patterns is shown in

Figure 10. It can be seen that the supersonic gas jet will be attracted to the direction of outlet axis, according to what was expected. Thus, it can be guaranteed that the gas jet of type B push-open valve will be attracted to the outlet axis direction while the pressure ratio is less than 5:1.

3.2. Effects of the Valve Opening Manner

The steady jet patterns of the push-open and pull-open gas fuel injectors are presented in

Figure 11 and

Figure 12, respectively. Obviously, they have distinct jet patterns. For the push-open injector, the fastest velocity appears in the gap between the popper valve and valve body. At the bottom side of the valve, an elliptical low-pressure area has been formed. As a result, vortexes appear. For the pull-open injector, as shown in

Figure 12, the fastest area is located near the axis of cylinder-shape outflow zone. Different from the axisymmetric jet in

Figure 8 and

Figure 9, for these two cases, the jets slightly deviate from the axis due to the non-axisymmetric inlet position upstream.

In order to analyze the injection characteristics in more detail, the stagnation pressure, velocity and Mach number distribution along the injector’s outlet axis are plotted in

Figure 13. It can be seen that the axial velocity reaches the stable value within the range of 40–100 mm downstream the outlet for both two cases. The jet velocity of pull-open injector is higher than that of push-open injector. Additionally, the velocity decreases gradually due to the momentum diffusion after 100 mm downstream. Then, the axial velocity and Mach number radial distribution on the cross section 50 mm and 90 mm downstream outlet, within the stable range, are plotted in

Figure 14. The maximum velocity of push-open injector deviates from the outlet axis. On contrary, the maximum velocity of the pull-open injector appears near the outlet axis. The mean velocity of the pull-open injector is much faster than that of the push-open injector. Thus, in the aspect of injection velocity, the pull-open injector shows a better performance.

There will be a considerable stagnation pressure loss when the gas fuel passes through injector. According to the results of literature [

19], the actual jet velocity of one injector was completely subsonic under the inlet/outlet pressure ratio 4.06:1, while the theoretical velocity calculated according to the one-dimensional isentropic flow relationship was supersonic, as high as 1.6 Ma. This indicates that the stagnation pressure loss during injection process is high enough to affect the fundamental jet characteristic.

In order to analyze the difference of stagnation pressure loss between the pull-open and push-open valves, and to make the comparison more quantitative, based on the one-dimensional isentropic flow relationship, the effective injection pressure (EIP) is defined. EIP is the equivalent stagnation pressure required to produce the same centerline Mach number according to the one-dimensional isentropic flow relationship. Obviously, the value of stagnation pressure loss is equal to the actual supply pressure minus the EIP.

Considering that the centerline Mach numbers of both two injectors reached a stable value within the range of 40–100 mm downstream, as shown in

Figure 13, the cross section 50 mm downstream was taken as the effective face to analyze the stagnation pressure loss of poppet valves. The EIP is defined in Equation (1):

where

p0,eff is the effective injection pressure and

Me,eff is the mass-weighted average of Mach number on the effective face under back pressure

pe.

The pressure-based injection efficiency (IE),

ep, is defined in Equation (2) as a parameter to compare the injection performance of different injectors quantitatively:

where

p0,nom is the actual inlet supply pressure. It is obviously that the parameter IE is the ratio of EIP and the actual inlet supply pressure, and the value must be less than 100%. The higher the IE is, the higher the EIP is and the lower the stagnation pressure loss is.

Based on the definition of IE, the IEs of the push-open and pull-open injectors are 50.3% and 56.0%, respectively. Thus, in the aspect of stagnation pressure loss, the pull-open injector is also better than the push-open injector.

Lastly, the calculated steady mass flow rates and aerodynamic forces suffered by the valves of these two injectors were analyzed as shown in

Table 1. The mass flow rate of the push-open injector is less than that of the pull-open injector in the case of the same other conditions. The lateral forces suffered by the valve stems of two injectors have the same direction, opposite to the incoming flow. They have little influence on the valve moving process because they are significantly smaller than the force of the electromagnetic linear actuator (about 200 N) and valve movement friction force. In the aspect of axial force, these two injectors are almost the same. Thus, it can be concluded that the pull-open injector is better than the push-open one for its larger mass flow rate and higher injection efficiency.

3.3. Effects of the Valve Sealing Method

The axial velocity along the outlet axis of two types of pull-open injectors, with the conical sealing method and flat sealing method, respectively, is plotted in

Figure 15. It can be seen that the injector with flat sealing method is slightly faster than that with conical way. The axial velocity reaches the stable stage in a 40–60 mm range downstream of the outlet and decreases gradually due to the momentum diffusion after the core area. Thus, the cross section 50 mm downstream is still taken as the effective face to analyze the stagnation pressure loss of the pull-open injector with a flat seal.

The IE of the pull-open injector with a flat seal was about 55.2%, slightly lower than that with a conical seal (56.0%). The mass flow rate of the flat sealing method was smaller (about 43.5 g/s), although its core velocity was faster. This led to a decline in IE. Moreover, its axial back force suffered by the valve disc was about 8.47 N, slightly larger than that of conical seal, because the flat sealing method had a larger valve disc than the conical sealing method. Thus, it can be concluded that the sealing method has little influence on the steady injection pattern of the pull-open injector.

4. Conclusions

The effects of the valve profile, valve opening manner and sealing method on the gas fuel injector’s steady flow characteristics was discussed in the present study. Additionally, a pressure-based injection efficiency was proposed to discuss the injection performance. Based on the analyses in the previous sections, we can conclude the following:

The push-open injector has a lower mass injection rate, slower core area speed and lower injection efficiency when compared with the pull-open injector, although the former is currently more commonly used in the case of high-pressure gas-fuel direct-injection engine because of its better sealing performance under back pressure.

In addition, the jet pattern of a push-open injector would be affected easily by the valve profile, not only affected by the pressure and flow speed of external environment. The flat profile would lead to a divergent shape jet, while for the conical profile the gas fuel would be attracted to the direction of the outlet axis because of the low-pressure area beneath the valve.

Lastly, different sealing methods seemed to have little influence on the jet pattern of the pull-open injector. The flat sealing method had a faster core speed than the conical sealing method, while this difference was assimilated by the declination of the mass flow rate.