1. Introduction

As the global climate and PM

2.5 problems have become an issue around the world, major developed countries worldwide are implementing green energy policies. In 2001, the European Union introduced national targets for power and transportation in 2010, through the Green Electricity Directive, and the Biofuels Directive [

1]. In addition, the Directive for Renewable Energy was enacted to promote the development and distribution of renewable energy in 2009, and the country targets for renewable energy policies will become legally binding in 2020. As energy policies that increase the use of renewable energy in the world are established and implemented, renewable energy-related industries are growing rapidly.

The global supply of renewable energy is growing steadily, and as efforts are made to expand the amount of renewable energy in each country, and with the increase of the price competitiveness of renewable energy, continuous market growth is expected. In addition, like solar energy and wind energy account for about 85% of the new installed capacity, new facilities related to these energies are expected to be expanded in China, the United States, and India, which use them as the primary renewable energy sources. Accordingly, various studies are being actively conducted by the government, universities, and research institutes to improve the utilization and efficiency of renewable energy systems.

‘Renewable energy’ is a complex expression of new energy and renewable energy, and it refers to energy used by converting renewable energy, such as sunlight, water, wind, ocean, and biomass to replace fossil fuel. Among them, solar thermal energy means using the energy that is emitted from the sun that reaches the earth. The advantages of solar thermal energy are an infinite resource for as long as the sun is emitting light, a pollution-free source of energy without greenhouse gas emissions, less regional biases, and a high possibility for various applications and uses. However, it has the disadvantages consist of high initial installation costs. Additionally, the cost of heating obtained against the investment is generally low. Recently, interest in solar thermal energy is increasing, as the depletion of fossil fuels and environmental problems has become a big issue.

In the history of using solar energy, from the 7th century B.C., a fire was started by using magnifiers or convex lenses, which were used to focus the sun’s rays. In addition, in ancient Greece and Rome in the 3rd century B.C., solar energy was collected using reflectors to light torches used for religious purposes. In the early steps in the use of solar collectors, solar energy-based solar collectors began in the 1900s, with black painted tanks on the roof. The flat plate solar collector used to make low-pressure steam using solar heat was employed in Florida, and Southern California in the 1920s and interest in solar heating in North America rose in the aftermath of the 1960s. In particular, after the oil shock that hit the world in 1973, the interest in solar heat has increased.

To increase the cost-effectiveness of solar collectors by enhancing their efficiency, Jouybari et al. [

2] experimentally evaluated the performance of the flat plate solar collector when porous channels filled with SiO

2/water nanofluids were applied. The thermal efficiency increased by 6%–8% by increasing the volume concentration. Azad [

3] experimentally investigated the thermal performance of a flat plate solar collector with multiple heat pipes and reported that by increasing the number of heat pipes, the efficiency of the flat plate solar collector could be enhanced. In addition, Gunjo et al. [

4] conducted experiments and analysis on exergy and energy in a new tubular solar collector. The developed simulation models predicted the exit temperature, absorption plate temperature, energy efficiency, and heat loss parameter within the maximum error of 9%, and the thermal efficiency of the manufactured tubular solar collector was 71%. Gao et al. [

5] presented experimentally that the heat pipe type flat plate solar collector showed a large variation in thermal characteristics depending on the gradient angle, with a maximum efficiency of 74.3%, which was superior to those of other similar designed ones. Even though there were many attempts to increase the effectiveness of the solar collector by the change of structure, the method of structural change in the solar collector has technical limitations. It has the disadvantage of being more expensive than the conventional solar collector.

Therefore, research on the improvement of the thermal and optical properties of the working fluid by using various nanofluids as a way to improve efficiency in conventional solar collectors has been actively conducted. To enhance the effectiveness of solar collectors, many studies have been undertaken by evaluating the heat loss parameter and flow analysis according to the arrangement of solar collectors [

6,

7]. Yousefi et al. [

8] and Said et al. [

9] experimentally presented the thermal performance of the flat plate solar collector by using Al

2O

3 nanofluid, and reported that the thermal efficiency was improved over 20% that of water. They also found that the addition of surfactants into an Al

2O

3 nanofluid significantly increased the effectiveness of the solar collector. In the study of MWCNT nanofluid [

10], the effect of concentration and mass flux on the efficiency of the flat plate solar collector was investigated experimentally. As a result, the heat gain parameter was improved by 27.4% and 45.8%, respectively, compared to the essential fluid, when the concentration of MWCNT nanofluid was 0.2 wt.%, and 0.4 wt.%, and the heat loss parameter decreased by 0.36% at 0.2 wt.%.

In comparison, it increased by 65.5% at 0.4 wt.%. Sharafeldin and Grof [

11] reported that the efficiency of the flat plate solar collector was proportionally increased with an increase of the mass flux of CeO

2 nanofluid, and the optimum concentration of CeO

2 nanofluid was 0.0333 vol.%. In the previous study of applying nanofluids to the vacuum tube solar collector, Sharafeldin and Grof [

12,

13] used WO

3/water and CeO

2/water nanofluids in the vacuum tube solar collector. They showed that the efficiency enhancement of the vacuum tube solar collector was 19.3% and 34.8% for WO

3/Water and CeO

2/water nanofluids, compared to water alone.

Further studies on the performance of the solar collector, and reviews on the performance of the solar collector with various nanofluids were also carried out. Li et al. [

14] experimentally analyzed the water-based on Al

2O

3, ZnO, and MgO nanofluid as a working fluid in a tubular solar collector. As a result, 0.2 vol.% ZnO nanofluid showed the best performance. Tong et al. [

15,

16] compared the performance of the heat pipe and U-tube collector, and they reported that the heat transfer coefficient in the U-tube solar collector at the 0.24 vol.% MWCNT nanofluid was about 8% higher than that of using water. Prasher et al. [

17] theoretically compared the performance of the direct absorption solar collector (DASC) and the flat plate solar collector using Al nanofluid, and reported that the absorption in Al nanofluid was nine times greater than that of pure water.

Moreover, the DASC using Al nanofluid presented 10% higher efficiency than that of the flat plate solar collector. Taylor et al. [

18,

19] investigated the effectiveness of the concentrating parabolic solar collector using Al

2O

3 nanofluid based on Therminol VP–1 and presented a 10% higher efficiency than water. Furthermore, Kang et al. [

20] reported that the effectiveness of flat plate and U-tube solar collectors of Al

2O

3 nanofluid was 14.8% and 10.7% higher than that of water, respectively. With the use of coal, CO

2 generation, and SO

2 production could reduce the solar collector efficiency, when 50 flat plate solar collectors using Al

2O

3 nanofluid were used for one year. Otanicar and Golden [

21] compared the environmental and economic impacts of using nanofluids to enhance solar collector efficiency as compared to conventional solar collectors in the domestic hot water system. Their results showed that for the current cost of nanoparticles, the nanofluid based solar collector has a slightly more extended payback period but at the end of its useful life has the same economic savings in a conventional solar collector. Previous studies show that the efficiency of the solar collector is greatly improved when various nanofluids are used as a working fluid. Presently, some nanofluids are more expensive than the existing working fluids. On the other hand, when the long-term use of nanofluid and dispersion stability are secured, the price of nanofluid can be dramatically reduced through the mass production system.

Recent studies have seriously focused on the use of working fluids in which the dispersion stability, thermal performance, and optical properties of a single nanofluid are ensured. Therefore, it is necessary to investigate the physical and chemical properties of hybrid nanofluid by studying binary nanofluids for improving the limit of single component nanofluids in the solar collector and improving the thermal properties of the working fluid. Menbari et al. [

22] studied the dispersion stability, viscosity, and extinction coefficient of Al

2O

3–CuO/water binary nanofluid experimentally. Experimental results showed that the optimal pH of the Al

2O

3–CuO/water binary nanofluid was pH = 7.5–8.5, and the increase of the volume fraction of nanoparticles improved the extinction coefficient and absorbance spectrum of nanofluid. Zeng and Xuan [

23] showed experimentally that the photo-thermal efficiency of MWCNT–SiO

2/Ag binary nanofluid was more efficient than that of MWCNT and SiO

2/Ag nanofluids. Besides, the photoconversion efficiency increased with temperature in all nanofluids. Menbari et al. [

24] studied the absorption and thermal conductivities of various binary nanofluids. Since Al

2O

3 nanoparticle had high thermal capacities but low absorption spectra compared to those of CuO nanoparticle, the heat capacity, solar absorption, and heat and optical efficiencies of the solar collector could be improved when they were used as a binary nanofluid. Dalkılıç et al. [

25] experimentally found that the thermal conductivity of 0.8 vol.% CNT/0.2 vol.% SiO

2 binary nanofluid was 26.3% higher than that of water.

In this study, MWCNT/Fe

3O

4 binary nanofluid was applied as a working fluid for the flat plate and vacuum tube solar collectors because MWCNT has high thermal conductivity and Fe

3O

4 nanofluid has a high possibility of increase of optical properties because of its strong absorption in the near-infrared. Moreover, Fe

3O

4 nanofluid is a magnetic nanofluid and can be controlled by the change of strength and direction of the magnetic field. That can improve the thermophysical properties of Fe

3O

4 nanofluid compared to essential fluids such as ethylene glycol and water. Fu et al. [

26] investigated the turbulent heat transfer of Fe

3O

4/Ethylene glycol. By increasing the pH of suspended solids, nanoparticles with highly refined particles did not improve the heat transfer performance of nanofluids.

Moreover, the convective heat transfer coefficient of the nanofluid was 7% lower than that of the reference solution. Qu et al. [

27] presented results showing that the CuO-MWCNT binary nanofluid compounds significantly improved the absorption of solar energy spectra compared to single CuO or MWCNT nanofluid. Shi et al. [

28] found that the thermal conductivity of 0.25 vol.% Fe

3O

4/CNT binary nanofluid was more sensitive to temperature change than that of 0.25 vol.% Fe

3O

4 nanofluid, which is closely related to hydrogen bonding, because it accelerates heat transfer. Harandi et al. [

29] conducted an empirical study on the effect of temperature and concentration on the thermal conductivity off-MWCNTs–Fe

3O

4/EG binary nanofluid. They found that the thermal conductivity was improved with increasing intensity and temperature. In addition, the thermal conductivity off-MWCNTs–Fe

3O

4/EG binary nanofluid was increased by 30%. In addition, Jung et al. [

30] found that the thermal conductivity increased with the concentration of binary nanofluid, and dispersion stability was the key factor in increasing the thermal conductivity of nanofluid.

When a nanofluid is applied as a working fluid to a solar collector, it limits the dispersion stability and the concentration with maximum efficiency according to nanofluid. Since each type of nanofluid are different in characteristics. Therefore, it is necessary to analyze the efficiency characteristics according to various conditions and nanofluids to improve the utilization of the solar collector. Furthermore, a detailed study on the improvement of the efficiency of the solar collector is essential. Nanofluids have been found to improve thermal conductivity and can improve optical absorption, but stability is still an issue. Based on the subject, as mentioned earlier, it has led the researchers to focus on binary nanofluids in the heating system. However, an experimental study on the performance of the solar collector takes a long time and is hard to carry out continuously due to unexpected weather.

Thus, it is difficult to experimentally summarize and define the characteristics of the solar collector, depending on the working fluid. Additionally, many types of research on the efficiency improvement in the solar collector, according to the working fluid, are currently being conducted. The experiment information in the open literature using multi-components nanofluid with more than two components is still in the early stage. In particular, MWCNT/Fe3O4 binary nanofluid, which is a mixture of MWCNT and Fe3O4 nanofluid, has a high possibility of improving the thermal efficiency of the solar collector because MWCNT nanofluid has the highest capacity when it is applied to the conventional solar collector. Moreover, the Fe3O4 nanofluid, when it is used as a working fluid in the flat plate and vacuum tube solar collectors, has high potential to increase efficiency due to its substantial photon absorption cross-section. While the magnetic properties of Fe3O4 have been exploited to improve convective heat transfer in previous studies, the main advantage for the solar collector is presumably in its absorption in the near-infrared. In this study, the performance characteristics of flat plate and vacuum tube solar collectors were analyzed according to the concentration and mass flux of MWNCT/Fe3O4 binary nanofluid for variable operating conditions under without magnetic field, and the results compared with those when water was used. Four cases of MWNCT/Fe3O4 binary nanofluids with different mixing ratios were used to compare the efficiency of solar collectors depending on the mixing ration of MWNCT/Fe3O4 binary nanofluid.

3. Results and Discussion

In this study, water and MWCNT/Fe

3O

4 binary nanofluid were applied to the flat plate and vacuum tube solar collector for various operating conditions. In the case of MWCNT/Fe

3O

4 binary nanofluid, four cases of MWCNT/Fe

3O

4 binary nanofluids were used.

Figure 5a shows the efficiency of the solar collector when water and MWCNT/Fe

3O

4 binary nanofluid were used. It was confirmed that the efficiency of the solar collector was noticeably improved when the MWCNT/Fe

3O

4 binary nanofluid was used, compared to that when water was used. When water was applied to the flat plate solar collector, the maximum efficiency was 62.7%. In the case of MWCNT/Fe

3O

4 binary nanofluid, when Case3 was used as a working fluid in the flat plate solar collector, the efficiency was the highest, and it was 80.3%, which was 28.1% higher than that when water was used. The maximum efficiencies of the flat plate solar collector for using Case1, Case2, and Case4 were 76.9%, 73.5%, and 75.9%, respectively. These were 22.6%, 17.2%, and 21.1% enhanced efficiency, respectively, compared to that using water. In the previous study [

31], when MWCNT and Fe

3O

4 nanofluid were individually applied to the flat plate solar collector, the optimum concentrations of MWCNT and Fe

3O

4 nanofluid were 0.005 vol.% and 0.015 vol.%, respectively. In this study, the mixture of optimal concentration for individual MWCNT and Fe

3O

4 nanofluid was Case4. Thus, it was confirmed that the efficiency of Case3 was higher than that of Case4, even though Case3 had lower total concentration than Case4. This is because the dispersion stability of the MWCNT/Fe

3O

4 binary nanofluid decreases while the binding of two nanofluids increases as the concentration of the MWCNT/Fe

3O

4 binary nanofluid increases, thereby increasing the aggregation phenomenon in the nanofluid. That means the size increase of nanoparticles per unit volume and a decrease in the number of single particles in the nanofluid. Therefore, the efficiency of the solar collector decreases due to the decrease in heat transfer and heat absorption capacity of the nanofluid.

Figure 5b shows the efficiency of the vacuum tube solar collector at various concentration conditions when water and MWCNT/Fe

3O

4 binary nanofluid were used. The performance of the vacuum tube solar collector showed a similar trend to that of the flat plate solar collector. The maximum efficiency was 54.9% when water was used for the vacuum tube solar collector. When Case3 was applied to the vacuum tube solar collector, the maximum efficiency was 79.3%, which was 45.4% higher than that when water was used. The maximum capabilities were 76.1%, 73.6%, and 76.2%, respectively, for Case1, Case2, and Case4 as the working fluid in the vacuum tube solar collector. These showed 38.6%, 34.1%, and 38.7% enhanced efficiency over the efficiency using water. In addition, it was also found that when Case3 was used, the maximum efficiency of the vacuum tube solar collector was improved by 4.7%, compared with that when Case4 was used. The maximum capabilities of the flat plate and the vacuum tube solar collector when water was used were 62.7% and 54.9%, respectively. The maximum efficiency of a flat plate solar collector was about 12.4% higher than that of the vacuum tube solar collector. Moreover, the maximum capabilities of each solar collector using MWCNT/Fe

3O

4 binary nanofluid (Case3) were 80.3% and 79.8%, respectively. The flat plate solar collector showed 0.62% higher efficiency than the vacuum tube solar collector. It was confirmed that when the MWCNT/Fe

3O

4 binary nanofluid was used, the efficiency difference between the flat plate and vacuum tube solar collector was significantly decreased. When MWCNT/Fe

3O

4 nanofluid was applied to the flat plate solar collector, the performance decreased rapidly with the increase of the temperature parameter, which is the low outdoor temperature condition. Meanwhile, the application of MWCNT/Fe

3O

4 binary nanofluid to the vacuum tube solar collector could maintain high performance not only in high temperatures but also in low temperatures. Therefore, when the MWCNT/Fe

3O

4 binary nanofluid was applied to the vacuum tube solar collector, the efficiency improvement was much higher compared with the flat plate solar collector.

Figure 6a,b shows the increase in the heat gain and heat loss parameters, which are directly associated with efficiency, when applying MWCNT/Fe

3O

4 binary nanofluid to the flat plate and the vacuum tube solar collectors, compared with the efficiency when water was used in the flat plate solar collector. Generally, the flat plate solar collector is the most widely used solar collector in the world, and water is a primary working fluid. Thus, in this study, the base condition is defined as the efficiency of the flat plate solar collector when water with a mass flux of 420 kg/s·m

2 was used. In the effectiveness of the solar collector, the

FR(τα) is the heat gain parameter, and represents the intersection of the y-axis with the heat gain parameter, and is determined by the thermal absorption rate of the solar collector. The

FRUL is the heat loss parameter, which indicates the slope of the curve inefficiency. Therefore, the solar collector with the larger

FR(τα) and the smaller

FRUL is, the better one.

Figure 6a shows the increase of

FR(τα) of the flat plate and vacuum tube solar collector when water and MWCNT/Fe

3O

4 binary nanofluid were used, compared to the base condition. The application of water to the vacuum tube solar collector reduced the

FR(τα) of the solar collector by 12.4%, compared to the flat plate solar collector. When Case3 (0.005 vol.% MWCNT/0.01 vol.% Fe

3O

4 binary nanofluid) was applied to the solar collector,

FR(τα) was improved by 28.1% and 27.3%, respectively, in the flat plate and vacuum tube solar collector, compared to the base condition. In addition, the application of Case1 improved the efficiency by about 22.6% and 21.4%, respectively, for the flat plate and vacuum tube solar collector, compared with that when water was used. Case1 and Case3 achieved a 5.97% and 2.92% improvement, respectively, in the flat plate solar collector efficiency over the use of the vacuum tube solar collector. However, for Case2 and Case4, the effectiveness of the flat plate solar collector showed a 0.93% and 2.22% decrease, respectively, compared to that of the vacuum tube solar collector. Both Case3 and Case1 have a Fe

3O

4 concentration of 0.01vol.% and have relatively more stable dispersion stability than Case2 and Case4 with 0.015% Fe

3O

4 concentration. Therefore, it was confirmed that the performance of the solar collector could be further improved at the optimum concentration with stable dispersion stability compared with the application of the high-concentration nanofluid with improved properties and low dispersion stability in the solar collector. In this study, high-concentration binary nanofluid with low dispersion stability decreased heat energy transfer and absorption capacity. Thus, the

FR(τα) of the vacuum tube solar collector for Case2 and Case4 increased, compared to that of the flat plate solar collector. Accordingly, the use of high-concentration binary nanofluid with stable dispersion stability can significantly improve the performance of the vacuum tube solar collector. Generally, it is essential to use the solar collector for a long time more than ten years after installation. The decrease in the thermal properties of the working fluid leads to a reduction in the efficiency of the solar collector, which can drastically reduce the economic efficiency of solar collector system. Therefore, when the nanofluid is used commercially as the working fluid in the solar collector, the dispersion stability of the nanofluid can be an important influence on economic efficiency.

Figure 6b shows the increase of

FRUL of the solar collector when MWCNT/Fe

3O

4 binary nanofluid was used, compared to that when water was used for the flat plate solar collector (base condition). The application of water to the vacuum tube solar collector brought a 4.76% reduction in

FRUL of solar collector, compared to the base condition. In the case of using MWCNT/Fe

3O

4 binary nanofluid, the

FRUL of the flat plate solar collector decreased, compared to the application of water. Still, the

FRUL increased slightly for the vacuum tube solar collector. When Case3 was used, the

FRUL of the flat plate and vacuum tube solar collector compared to the base condition showed a 27.3% reduction and a 23.7% enhancement, respectively. In the case of Case1, a 47.6% reduction and 7.02% enhancement of

FRUL in the flat plate and vacuum tube solar collector, respectively, compared to the base condition were found. Applying MWCNT/Fe

3O

4 binary nanofluid to the flat plate solar collector would reduce heat losses by up to 47.6% compared to water. Still, it increased heat losses by 23.7% in the vacuum tube solar collector, compared to the base condition. Therefore, when the MWCNT/Fe

3O

4 binary nanofluid was applied, the heat gain parameter (

FR(τα)) was increased by 17.1%–28.1% in the flat plate solar collector, and 17.2–27.3% in the vacuum tube solar collector, respectively. The heat The loss parameter

(FRUL) was reduced by 25.7%–47.6% in the flat plate solar collector, while it was increased by 6.93–17.1% in the vacuum tube solar collector. When the MWCNT/Fe

3O

4 binary nanofluid was used in the solar collector, the maximum efficiency of the flat plate and vacuum tube solar collector increased simultaneously. In addition, the heat loss parameter was reduced for the flat plate solar collector, while the heat loss parameter was increased for the vacuum tube solar collector. Thus, it can be seen that the application of MWCNT/Fe

3O

4 binary nanofluid to the solar collector should consider their characteristics, depending on the operating conditions and type of solar collector.

Figure 7a shows the temperature increase of working fluid in the flat plate solar collector when MWCNT/Fe

3O

4 binary nanofluid was applied. When MWCNT/Fe

3O

4 binary nanofluid was applied as a working fluid to the flat plate solar collector, Case3 shows the largest temperature increase in the solar collector. The temperature increased in the order Case3 < Case2 < Case4 < Case1 for relatively low solar radiation, such as 300–500 W/m

2, and then it changed to the order Case3 < Case4 < Case2 < Case1 for high solar radiation.

Figure 7b shows the temperature increase of working fluid in the vacuum tube solar collector when MWCNT/Fe

3O

4 binary nanofluid was applied. When the MWCNT/Fe

3O

4 binary nanofluid was applied as a working fluid to a vacuum tube solar collector, the temperature of the working fluid increased in the order Case4 < Case2 < Case1 < Case3 for 300–450 W/m

2. Then it changed to the order Case3 < Case2 < Case4 < Case1 for high solar radiation. The temperature increase of working fluid in the vacuum tube solar collector varied more than that in the flat plate solar collector for relatively low solar radiation of 300–500 W/m

2. However, since the slope of the temperature change of the flat plate solar collector was steeper, it is confirmed that the A temperature increase of working fluid in the flat plate solar collector varied more significantly for 500–650 W/m

2.

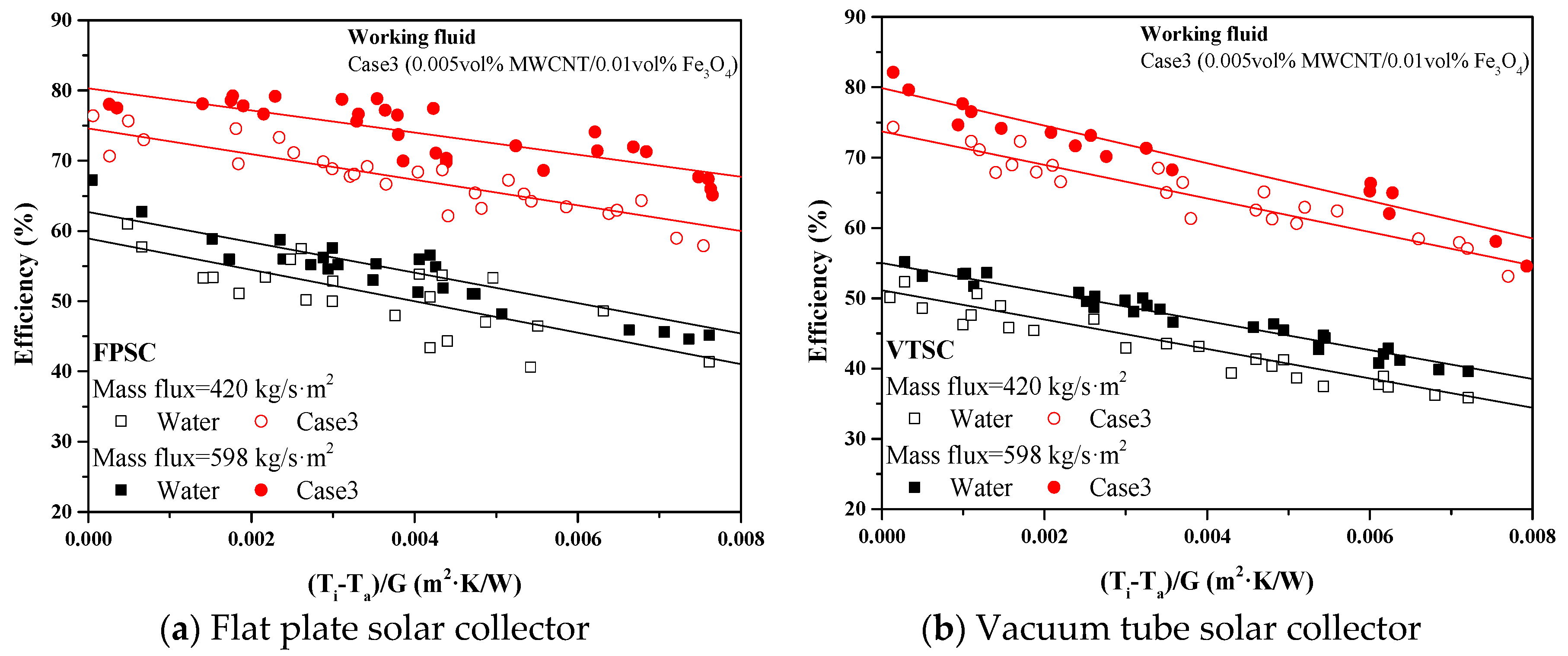

Figure 8 shows the variation of efficiency for two solar collectors according to the mass flux of working fluid. In this study, the water and Case3 as the working fluid, and 420 and 598 kg/s·m

2 as mass flux, were used, respectively.

Figure 8a shows that when the mass flux of MWCNT/Fe

3O

4 binary nanofluid was changed from 420 to 598 kg/s·m

2, the efficiency of the flat plate solar collector was increased by 7.8%. In the case of water, for the same mass flux change, it was increased by 6.5%. The efficiency of the flat plate solar collector was more sensitive to the change of mass flux in the MWCNT/Fe

3O

4 binary nanofluid, than that of water. In this study, the maximum efficiency of the flat plate solar collector using Case3 was 74.5% and 80.3% at the mass fluxes of 420 and 598 kg/s·m

2, respectively.

Figure 8b shows the efficiency variation of the vacuum tube solar collector according to mass flux when MWCNT/Fe

3O

4 binary nanofluid (Case3) and water were used. When the mass flux of the vacuum tube solar collector was 420, and 598 kg/s·m

2, the maximum efficiency of the vacuum tube solar collector using Case3 was 73.7% and 79.8%, respectively. The effectiveness of the vacuum tube solar collector using Case3 was increased by 8.3% for the change of mass flux, and in the case of water, it was 7.4%. It was confirmed that by increasing the mass flux of the working fluid in the flat plate and the vacuum tube solar collector, simultaneously, the efficiency of the solar collector was increased. At the mass flux of 420 kg/s·m

2, the maximum efficiency of the flat plate and the vacuum tube solar collector was 74.5% and 73.7%, respectively, and the effectiveness of the flat plate solar collector was 1.0% higher than that of the vacuum tube solar collector. At the mass flux of 598 kg/s·m

2, the maximum efficiency was 80.3% and 79.8% for the flat plate and the vacuum tube solar collector, respectively. The effectiveness of the flat plate solar collector showed 0.62% higher efficiency than that of the vacuum tube solar collector. In the case of water, the maximum efficiency of the flat plate and vacuum tube solar collector was 58.9% and 51.1% for the mass flux of 420 kg/s·m

2, and 62.7% and 54.9% for the mass flux of 598 kg/s·m

2, respectively. In addition, when the mass flux was varied from 420 to 598 kg/s·m

2, the maximum efficiencies of the flat plate solar collector and vacuum tube solar collector were increased by 6.4% and 7.4%, respectively. As the mass flux of the working fluid increases, the strength of mixing and the turbulence between nanoparticles are increased, and these increases, in turn, increase the heat transfer coefficient and the Nu number. Therefore, more active heat transfer phenomenon occurs, and this noticeably increases the efficiency of the solar collector.

Figure 9a,b shows the increase of

FR(τα) and

FRUL when the MWCNT/Fe

3O

4 binary nanofluid (Case3) was applied to the flat plate and vacuum tube solar collector, compared with those in the base condition. To compare

FR(τα) and

FRUL according to the change of the mass flux of the working fluid between nanofluid and water, Case3 MWCNT/Fe

3O

4 binary nanofluid was used, which showed the maximum efficiency among the MWCNT/Fe

3O

4 binary nanofluids. In the base condition,

FR(τα) and

FRUL in the flat plate solar collector using water at a mass flux of 420 kg/s·m

2 were 0.589 and 22.36, respectively.

Figure 9a shows the increase of

FR(τα) when water and Case3 are applied to the flat plate and vacuum tube solar collector with a mass flux of 420 and 598 kg/s·m

2, compared to the base condition.

FR(τα) was reduced by 13.3% when water with a mass flux of 420 kg/s·m

2 was applied to the vacuum tube solar collector. On the other hand, when Case3 with a mass flux of 420 kg/s·m

2 was used,

FR(τα) improved by 26.5% and 25.1%, respectively, for the flat plate and vacuum tube solar collector. The

FR(τα) showed a tendency to increase with increasing mass flux of the working fluid. When water with a mass flux of 598 kg/s·m

2 was used,

FR(τα) of the flat plate solar collector increased by 6.45%, while that of the vacuum tube solar collector decreased by 6.79%, compared to the base condition. The application of water as a working fluid to the vacuum tube solar collector improved

FR(τα) by 7.43% when the mass flux increased from 420 to 598 kg/s·m

2. For the same change of mass flux in the working fluid, when Case 3 was applied,

FR(τα) of the flat plate and vacuum tube solar collector increased by 36.3% and 35.5%, respectively.

Figure 9b shows the increase of

FRUL when water and Case3 were applied to the flat plate and vacuum tube solar collector at a mass flux of 420 and 598 kg/s·m

2, compared to the base condition. In the vacuum tube solar collector,

FRUL was reduced by 6.39% by applying water at a mass flux of 420 kg/s·m

2, compared to the base condition. In Case3, MWCNT/Fe

3O

4 binary nanofluid with a mass flux of 420 kg/s·m

2,

FRUL showed 18.6% reduction for the flat plate solar collector and 6.71% enhancement for the vacuum tube solar collector. As the mass flux increased,

FRUL decreased by 3.22% and 4.61% for the flat plate and vacuum tube solar collector, compared to the base condition. In the case that water was used in the vacuum tube solar collector when the mass flux was increased from 420 to 598 kg/s·m

2,

FRUL was reduced by 1.53%.