Abstract

Temperature stability of dielectric, ferroelectric, and piezoelectric properties were investigated in situ by choosing (K,Na)NbO3-(Bi,K)ZrO3 (KNN-BKZ), (K,Na)NbO3-(Bi,Na,K,Li)ZrO3 (KNN-BNKLZ), and (K,Na)NbO3-(Bi,Li)ZrO3-(KNN-BLZ) as representative ceramics with rhombohedral-orthorhombic-tetragonal (R-O-T), R-T, and enriched T phase boundaries, respectively. The KNN-BNKLZ ceramics, which have an R-T phase boundary, showed the highest piezoelectricity but the worst temperature stability. On the other hand, the KNN-BLZ ceramics, which have an enriched T-phase, were slightly worse in terms of piezoelectricity compared to the R-O-T or R-T phase boundary, but their thermal stability was the best. From analyses of an extrinsic contribution by a difference between the small signal d33 and εrPr and an intensity variation of the (002) and (200) X-ray diffraction peaks for the KNN-based ceramics, it was suggested that increasing the extrinsic contribution in the morphotropic phase boundary region improves the piezoelectricity but decreases the thermal stability.

1. Introduction

Piezoelectric materials have long been used in sensor or actuator applications because of their ability to convert mechanical energy to electrical energy and vice versa. As an environmental issue, research on lead-free materials to replace the representative piezoelectric material, Pb(Zr,Ti)O3 (PZT), has been actively conducted, and (K,Na)NbO3 (KNN)-based ceramics are receiving the most attention as PZT alternatives due to their excellent piezoelectric coefficient and high Curie temperature. Recently, (Bi,M)ZrO3 (BMZ; M = Na, Li, K, Ag, or combinations thereof) systems have been studied as potential perovskite additives to enhance the piezoelectricity of KNN-based ceramics because they contribute to the formation of a morphotropic phase boundary (MPB), such as a rhombohedral (R)-orthorhombic (O)-tetragonal (T) or R-T phase boundary near room temperature by decreasing the O-T phase transition temperature (TO-T) and increasing the R-O phase transition temperature (TR-O) [1,2,3,4,5,6,7,8,9,10,11,12]. Unlike PZT, the MPB of the KNN-based systems is sensitively changed depending on temperature, which causes a problem as the temperature stability is lowered. In addition, since the increase in piezoelectricity reduces the Curie temperature in the trade-off relationship, temperature stability should be examined carefully for reliable operation over a wide temperature range.

From our recent study [13] investigating the piezoelectricity and thermal aging stability according to the M-composition of 0.955(K,Na)NbO3-0.045(Bi,M)ZrO3 systems (M: Na, K, (Na,K), (Na,K,Li), (Na,Li) (K,Li), L), it was revealed that 0.955(K0.48Na0.52)NbO3-0.045(Bi0.5(Na0.7K0.2Li0.1)0.5)ZrO3 (KNN-BNKLZ) ceramics with an R-T phase boundary show a higher piezoelectricity (static piezoelectric coefficient d33 ≈ 300 pC/N; dynamic piezoelectric coefficient d*33 ≈ 402 pm/V) compared to the ceramics with R-O-T phase boundary or enriched T-phase. It is also found that the increased fraction of T-phase in the R–T phase coexistence decreases the values of d33 and d*33; however, it is helpful in enhancing the thermal aging stability. In general, the temperature stability of the piezoceramics is evaluated by an ex situ method that measures d33 by maintaining the ceramic at an elevated temperature for a certain period of time, then cooling it to room temperature. However, evaluating the high temperature properties of the piezoceramics in situ is more desirable and advantageous for verifying their operation in an actual high-temperature environment.

In this work, 0.955(K0.48Na0.52)NbO3-0.045(Bi0.5K0.5)ZrO3 (KNN-BKZ), KNN-BNKLZ, and 0.955(K0.48Na0.52)NbO3-0.045(Bi0.5Li0.5)ZrO3 (KNN-BLZ) were chosen as representative ceramics with R-O-T, R-T, and enriched T-phase boundary, respectively. The temperature stability of the KNN-BMZ ceramics was examined using in situ measurement techniques of dielectric, ferroelectric, and piezoelectric properties. The piezoelectricity was analyzed for intrinsic contribution (lattice distortion and vibrations of reversible domain walls) and extrinsic contribution (domain wall motion). From analyses of the intensity changes of the (002) and (200) X-ray diffraction (XRD) peaks, the temperature dependence of the extrinsic contribution was estimated quantitatively and discussed with the results of the electrical measurements.

2. Materials and Methods

For the preparation of 0.955(K0.48Na0.52)NbO3-0.045(Bi0.5M0.5)ZrO3 (M: K, (Na0.7K0.2Li0.1), Li) ceramics, a conventional solid-state reaction method was used. The starting materials were Na2CO3 (≥99.5%, Sigma-Aldrich), K2CO3 (≥99.0%, Sigma-Aldrich), Nb2O5 (99.9%, Sigma-Aldrich), Bi2O3 (99.9%, Sigma-Aldrich), Li2CO3 (99.997%, Sigma-Aldrich), and ZrO2 (99.0%, Sigma-Aldrich). Before weighing, the Na2CO3 and K2CO3 powders with hygroscopicity were dried at a temperature higher than 100 °C for more than a day to remove the moisture. The weighed powders were ball-milled in ethanol for 24 h and then calcined at 850 °C for 6 h. The calcined powders were mixed with 0.5 wt% of poly-vinyl alcohol (PVA) used as a binder, grinded in an agate mortar, and sieved twice with 150 micro sieves. The sieved powders were axially compacted into discs with a diameter of 10 mm. The compacted discs were sintered at 1120 °C for 6 h in the presence of the atmosphere powder using a 4 °C/min heating rate, after the heat treatment at 650 °C for 30 min to burn-off the PVA. Finally, the sintered discs were thinned to a thickness of 1 mm.

For the electrical measurements, a conductive silver paste was applied to the top and bottom surfaces of the ceramic disc and fired at 650 °C for 10 min. The prepared ceramic samples were poled at room temperature by applying a DC electric field of 40 kV/cm for 10 min in silicon oil. The piezoelectric coefficient (d33) was measured with a piezo-d33 meter (ZJ-6B, China). The dielectric properties were measured in a temperature range of 25–400 °C using an impedance analyzer (SI 1260, Solartron Group Ltd., Farnborough, England) with a high temperature furnace (HTF-1100, Biologic Company, Grenoble, France). Polarization versus electric field (P–E) hysteresis loops and piezoelectric coefficient (d33) versus electric field (D–E) loops were measured using a commercial piezoelectric evaluation system (aixPES, aixACCT Systems GmbH, Aachen, Germany)with a Piezo-Sample Holder HT (aixACCT Systems GmbH, Aachen, Germany) and a commercial single-beam laser interferometer (aixACCT Systems GmbH, Aachen, Germany). In situ high temperature XRD studies were carried out in a temperature range of 25–400 °C for the unpoled and poled ceramics by an X-ray diffractometer (XRD; D/MAX-2500; Rigaku, Tokyo, Japan) using Cu Kα radiation at a power of 40 kV and 15 mA with a scan speed of 1°/min. To quantify the types of phases and the fraction of each phase in the MPB, Rietveld refinement of the XRD patterns was performed using PDXL software (version 2.7, Rigaku, Tokyo, Japan) with the whole pattern powder fitting (WPPF) method, connected to an ICDD database (International Centre for Diffraction Data, Newtown Square, PA, USA). For the KNN-BKZ, -BNKLZ, and -BLZ samples, the reliability factors (Rp, Rwp) lower than 10% and goodness-of-fit indicator (S) smaller than 1.5 ensure the high reliability of the Rietveld refinement results.

3. Results

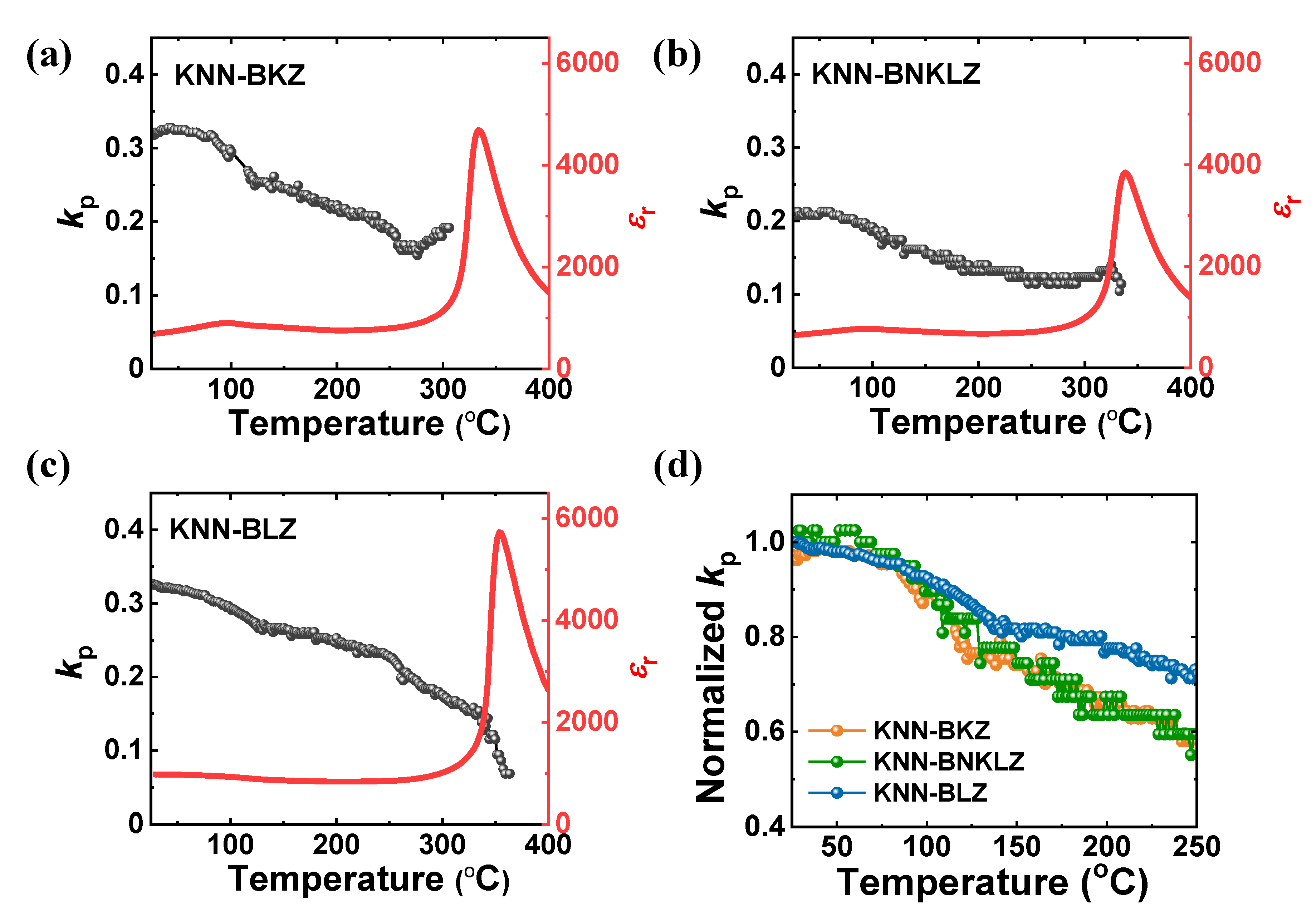

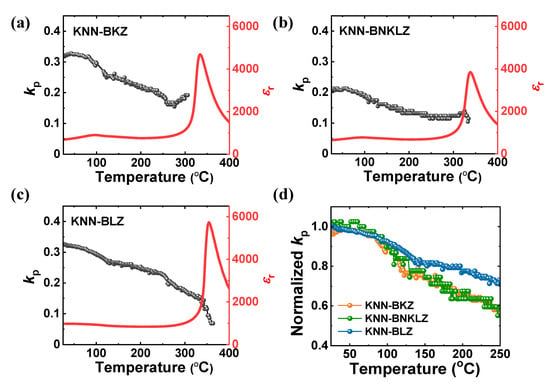

Figure 1a–c show the temperature dependent electromechanical coupling factor (kp) and dielectric constant (εr) curves, which were experimentally measured on the KNN-BKZ, KNN-BNKLZ, and KNN-BLZ ceramics, respectively. It was found in a previous study [13] that the KNN-BKZ ceramics have R-O-T phase boundaries, and the KNN-BNKLZ and KNN-BLZ ceramics show the coexistence of R-T phases. From the analysis of Rietveld refinement, the quantitative phase fractions are determined to be 19.5% R-phase, 11.4% O-phase, and 69.1% T-phase for the KNN-BKZ; 16% R-phase and 84% T-phase for the KNN-BNKLZ; and 6.4% R-phase and 93.6% T-phase for the KNN-BLZ ceramics. It was seen in Figure 1a–c that the kp value decreases with increasing temperatures for all three ceramics, and the normalized values are plotted in Figure 1d for easy comparison. The KNN-BKZ and KNN-BNKLZ ceramics show a kp reduction of more than 40% at 250 °C compared with the room temperature value. The KNN-BLZ ceramics show the most stable temperature dependent kp. The kp value decreased by ≈28% at 250 °C relative to room temperature. The Curie temperature (TC) was determined to be 334, 337, and 352 °C for KNN-BKZ, -BNKLZ, and -BLZ, respectively. The KNN-BKZ with R-O-T phase boundary shows TO−T at ≈60 °C, and the KNN-BNKLZ and KNN-BLZ with R-T phase boundary shows a R-T phase transition temperature (TR-T) at ≈60 °C and ≈−5 °C, respectively. For the KNN-BKZ, -BNKLZ, and -BLZ ceramics, the lowered phase transition temperature and the increased TC value with increasing Li+ content imply a wider tetragonal phase region.

Figure 1.

Temperature dependence of kp and εr for: (a) KNN-BKZ; (b) KNN-BNKLZ; and (c) KNN-BLZ ceramics and (d) Normalized value of kp with temperature variation.

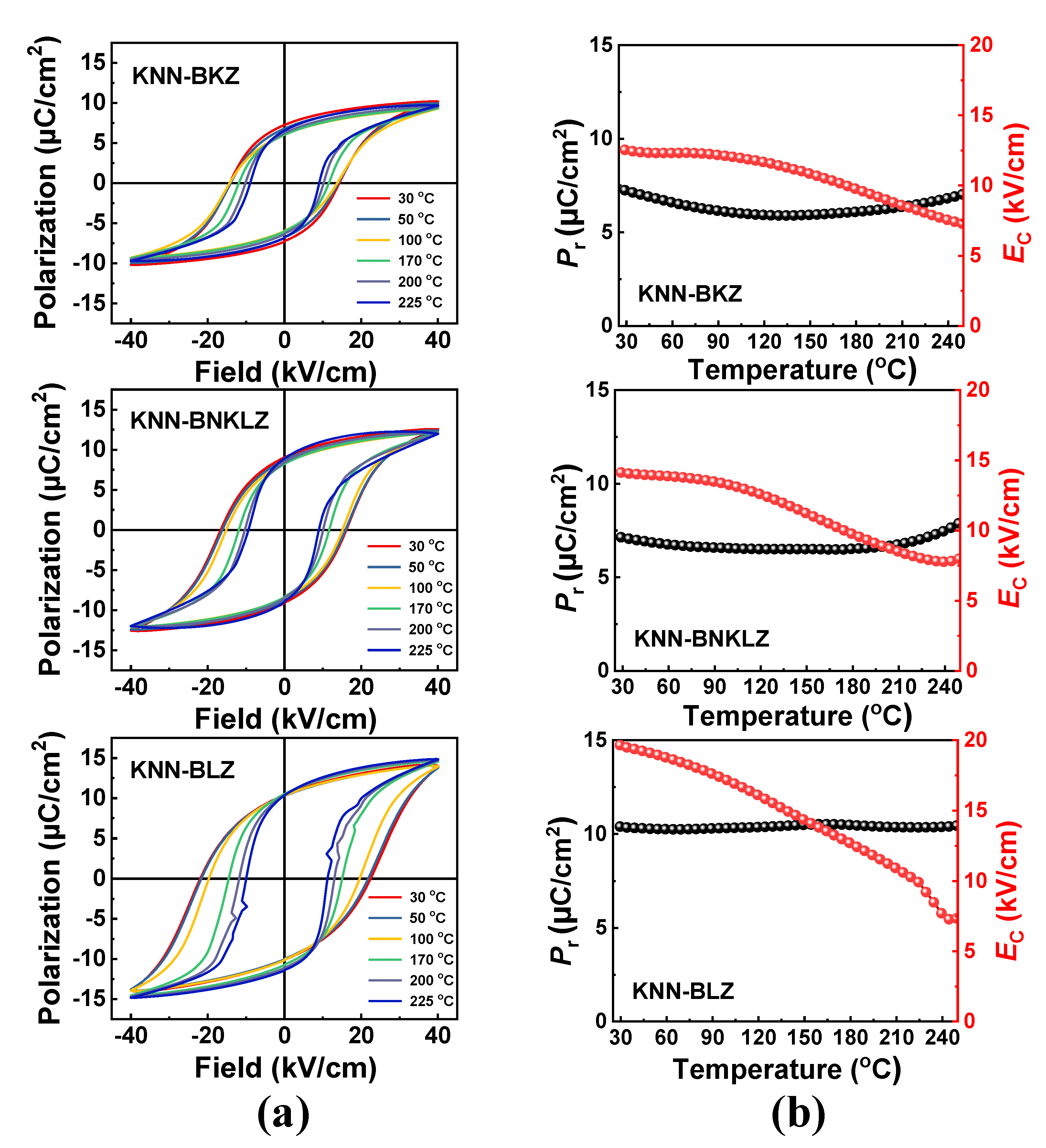

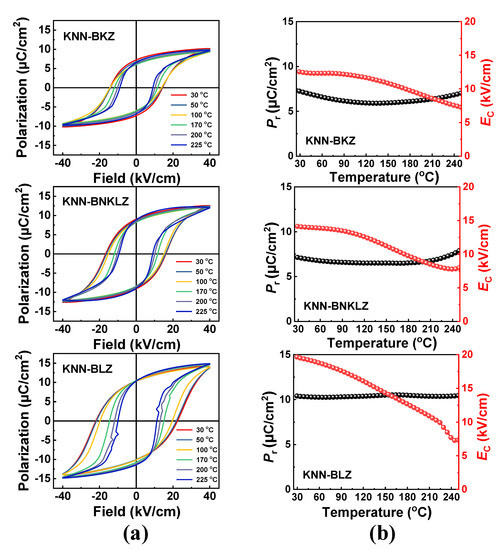

Figure 2a shows the temperature-dependent P–E hysteresis loops, and the values of the remnant polarization (Pr) and the coercive field (Ec) measured from the P–E hysteresis loops are displayed in Figure 2b for the KNN-BMZ ceramic samples. Well-saturated P–E hysteresis loops are confirmed, and Pr does not change substantially with the temperature for all the ceramics. The Ec value at room temperature increases in the order of KNN-BKZ, -BNKLZ, and -BLZ, because the higher fraction of T-phase makes domain switching more difficult with increasing Li+ content. The Ec value decreases with increasing temperature because the higher the temperature, the smaller the activation energy required to reverse the polarization direction [14,15]. The reduction width of Ec is the highest for the KNN-BLZ ceramics, and the Ec values at 250 °C are similar for all three ceramics.

Figure 2.

(a) Polarization versus electric field (P–E) hysteresis loops of the KNN-BKZ, KNN-BNKLZ, and KNN-BLZ ceramics and (b) Pr and Ec values versus temperature.

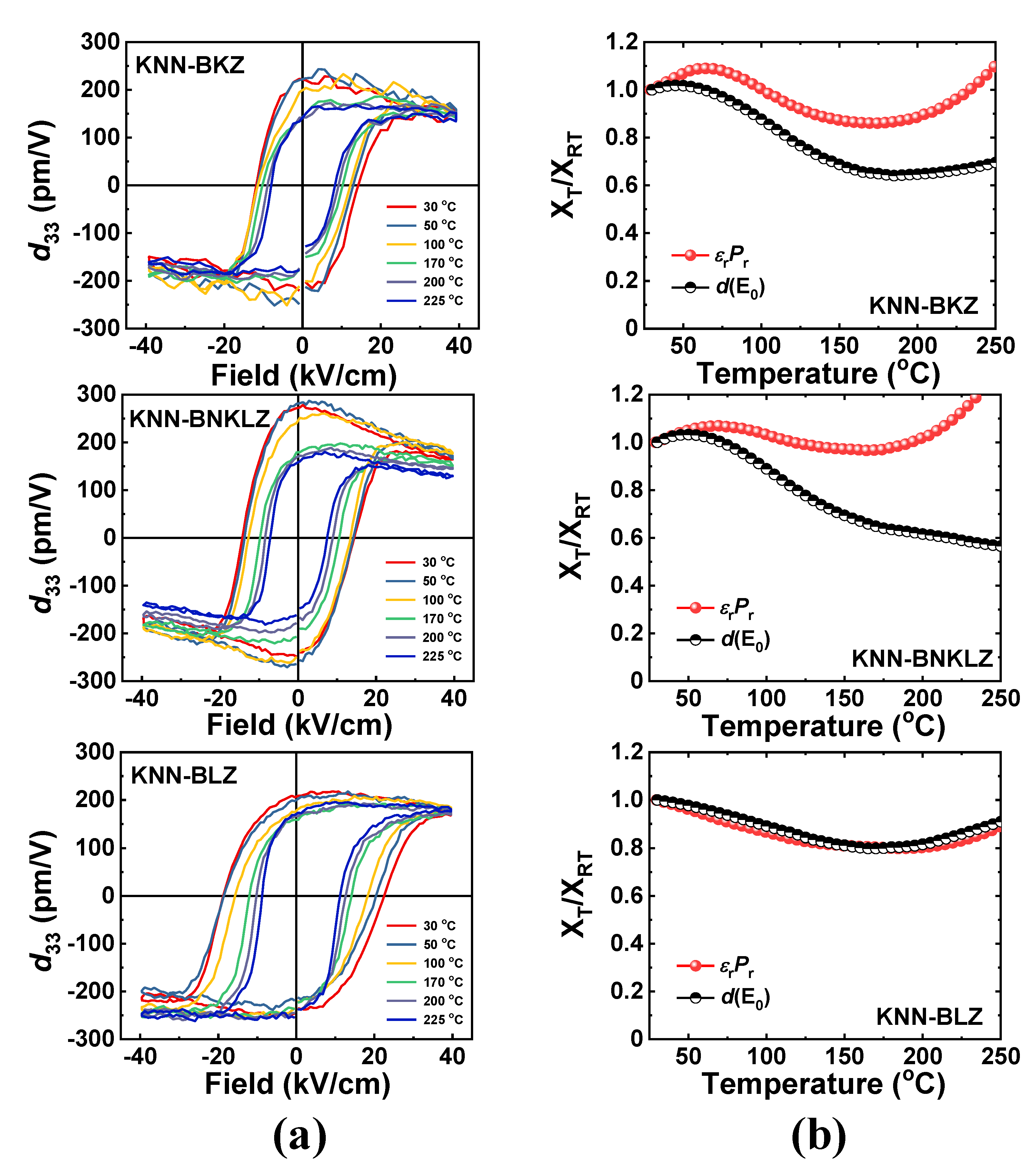

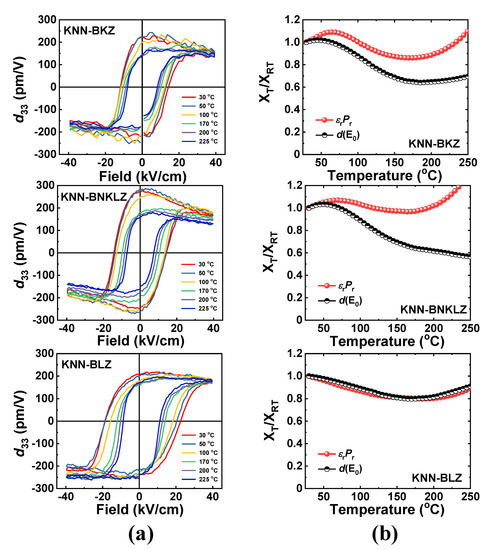

Figure 3a shows the temperature-dependent D–E loops of the KNN-BMZ ceramic samples. The small-signal d33 (i.e., d(E0)) is determined by the positive y-intercept value in the D–E loops. The results are plotted in Figure 3b as a normalized value with change of the temperature. The d(E0) values at room temperature are estimated to be ≈220, ≈271, and ≈205 pm/V for the KNN-BKZ, -BNKLZ, and -BLZ ceramics, respectively. These values are similar to those measured with the quasi-static d33 meter (≈241, ≈300, and ≈223 pC/N for the KNN-BKZ, -BNKLZ, and -BLZ ceramics, respectively). Because the in situ temperature-dependent d(E0) can be considered equivalent to the value measured by the quasi-static d33 meter, the temperature sensitivity of piezoelectric coefficient can be conveniently and effectively studied using temperature-dependent d(E0). It was noted from Figure 3b that the small-signal d33 gradually decreases with increasing temperature for all the ceramics, and the value at 250 °C decreases by about 30%, 40%, and 10% for the KNN-BKZ, -BNKLZ, and -BLZ ceramics, respectively, compared with those values at room temperature.

Figure 3.

(a) Piezoelectric coefficient d33 versus electric field (D–E) loops of the KNN-BKZ, KNN-BNKLZ, and KNN-BLZ ceramics measured at a frequency of 1 Hz and (b) normalized values of εrPr and d(E0) values versus temperature.

The intrinsic part of the piezoelectricity can be determined using the equation as follows [16]:

where Q is the electrostrictive constant, ε0 is the vacuum permittivity, ε33 is the permittivity, and P3 is the polarization in the direction of the polar axis, which can be considered almost similar to remnant polarization, Pr. The extrinsic contribution is attributed to the irreversible motion of internal interfaces, such as domain wall and phase boundaries. Because the small signal d33 contains both intrinsic and extrinsic effects, the difference between the small signal d33 and εrPr in Figure 3b can be considered an extrinsic contribution [15]. The KNN-BKZ and KNN-BNKLZ ceramics show a remarkable difference between small signal d33 and εrPr, and the difference further increases with increasing temperature. However, KNN-BLZ ceramics show little difference between small signal d33 and εrPr. The results of in situ dielectric, ferroelectric, and piezoelectric measurements indicate that the KNN-BNKLZ ceramics with R-T phase boundaries have the highest piezoelectricity at room temperature but the lowest temperature stability. This can be explained by the role of the extrinsic contribution in the composition with an MPB. To support the above result, the intensity variation of the XRD pattern profiles was examined to identify the percentage of 90° domain reorientation.

d33 = 2Qε0ε33P3,

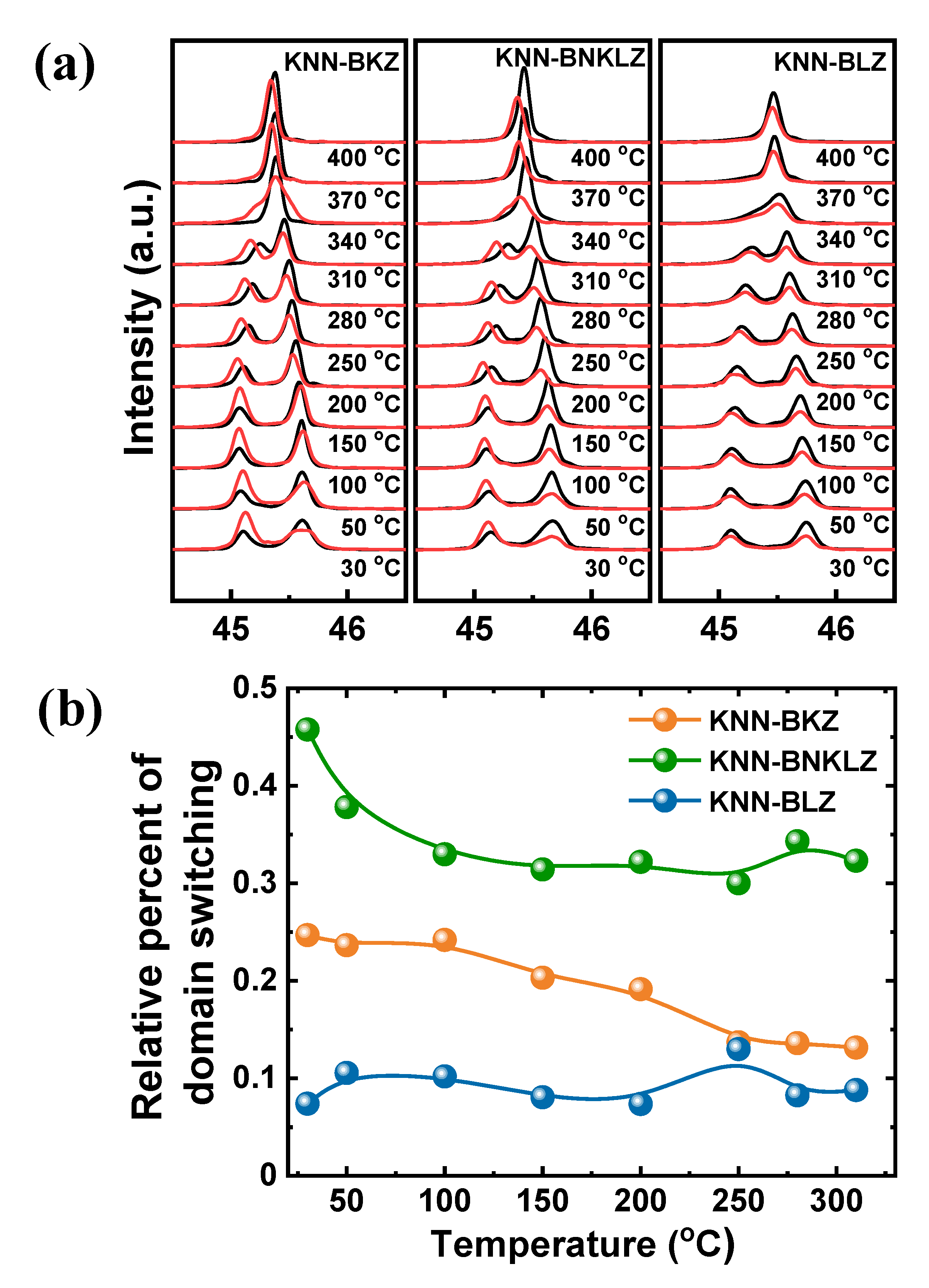

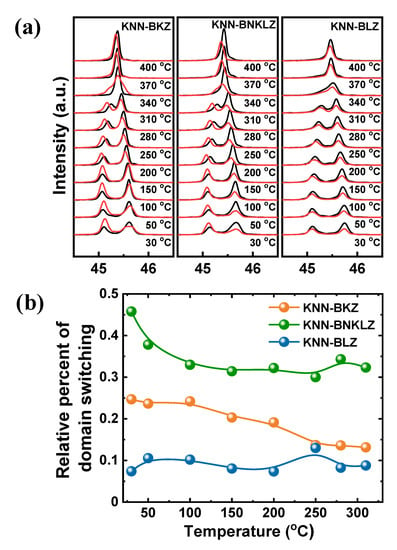

Figure 4a shows the high-temperature XRD patterns that were measured in situ at each elevated temperature for the unpoled (black line) and the poled (red line) KNN-BMZ ceramic samples. At 30 °C, the XRD patterns of the poled ceramics show increased intensity of the (002) peak and decreased intensity of the (200) peak compared to the unpoled ceramics, which is related to domain reorientation during the poling process. It was reported [17,18,19] that the reorientation of the non-180° domains perpendicular to the sample face causes the intensity of the (002) and (200) peaks to change, while 180° domains do not affect the XRD peak intensities. As the temperature increases, the poled samples exhibit decreased intensity of the (002) peak and increased intensity of the (200) peak. Moreover, the distance between the (002) and (200) peaks gradually decrease with temperature, and they finally merge into an apparently single peak near the Curie temperature. The relative percent of domain switching η002 (extrinsic contribution) can be calculated by the integrated areas of the (002) and (200) peaks for the unpoled and poled samples at each temperature, as follows [20]:

where N is the area of the corresponding fitted peak. The value of η002 was calculated from the XRD patterns at each temperature in Figure 4a and the results are plotted in Figure 4b.

Figure 4.

(a) High-temperature XRD patterns, which were measured in situ at each elevated temperature for unpoled (black line) and poled (red line) KNN-BMZ ceramic samples and (b) relative percentage of domain switching η002 (extrinsic contribution), which was obtained from variation of the integrated areas of the (002) and (200) peaks.

As seen in Figure 4b, the KNN-BNKLZ ceramics show a higher value of η002 (0.46) than the KNN-BKZ (0.25) and KNN-BLZ (0.07) ceramics do at room temperature. Considering that the piezoelectric coefficient increases with an increase in the poling electric field, mainly as a result of non-180° domain reorientation [21], it is reasonable to say that the KNN-BNKLZ ceramics show the highest d33 value due to having the highest η002 value. On the other hand, as the temperature increases, the value of η002 for the KNN-BNKLZ ceramics decreases to the greatest extent. The KNN-BKZ ceramics show a decrease in η002 with temperature (as with KNN-BNKLZ). The KNN-BLZ ceramics exhibit the smallest η002 value at room temperature but show little change in η002 with temperature. The greatest decrease in η002 according to temperature, which was shown by the KNN-BNKLZ ceramics, agrees well with the result of the largest difference between the small signal d33 and εrPr with temperature in Figure 3b. The relative percentage of extrinsic contribution (η002) and the extent of decrease in η002 with temperature increased in the order of KNN-BLZ, KNN-BKZ, and KNN-BNKLZ ceramics. This is consistent with the temperature dependency of the difference between the small signal d33 and εrPr. The above results suggest that the extrinsic contribution significantly affects the piezoelectricity as well as the temperature stability. High extrinsic contribution in the MPB region (R-O-T or R-T phase boundary) results in an improvement in piezoelectricity, but adversely affects in situ temperature stability.

4. Conclusions

The piezoelectricity increased in the order KNN-BLZ with enriched T phase, KNN-BKZ with R-O-T phase, and KNN-BNKLZ with R-T phase boundary, while the temperature stability of the piezoelectricity decreased in the same order. The KNN-BKZ and KNN-BNKLZ ceramics showed a remarkable difference between small signal d33 and εrPr (which can be considered an extrinsic contribution), and the difference increased further with increasing temperature. However, KNN-BLZ showed little difference between small signal d33 and εrPr with temperature. The intensity analyses of the (002) and (200) XRD peaks strongly support the result that the poled KNN-BNKLZ ceramics show the highest d33 value due to having the highest value of η002 (0.46) (i.e., the main role of 90° domain reorientation), compared to the KNN-BKZ (0.25 of η002) and KNN-BLZ (0.07 of η002) ceramics at room temperature. However, the decrease in η002 with temperature was greatest for the KNN-BNKLZ ceramics, resulting in the worst temperature stability of piezoelectricity. For the excellent performance and reliable high-temperature application of the piezoceramics, it is necessary to control the value of the extrinsic contribution closely related to the phase type of the MPB and the fraction of each phase, and the temperature stability of the extrinsic contribution. These results provide an idea that simultaneously satisfies the operation characteristics and the temperature stability of a sensor based on piezoelectric ceramics.

Author Contributions

Conceptualization, M.-K.L. and G.-J.L.; investigation, G.-J.L.; validation, M.-K.L.; formal analysis, M.-K.L. and G.-J.L.; writing—original draft preparation, G.-J.L.; writing—review and editing, M.-K.L. and G.-J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Korean Nuclear R&D program organized by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (NRF-2017M2A8A4017220), and by the Korea Atomic Energy Research Institute (KAERI) R&D program.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Cheng, X.; Wu, J.; Wang, X.; Zhang, B.; Zhu, J.; Xiao, D.; Wang, X.; Lou, X. Giant d33 in (K,Na)(Nb,Sb)O3-(Bi,Na,K, Li)ZrO3 based Lead-Free Piezoelectrics with High Tc. Appl. Phys. Lett. 2013, 103, 052906. [Google Scholar] [CrossRef]

- Cheng, X.; Gou, Q.; Wu, J.; Wang, X.; Zhang, B.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. Dielectric, Ferroelectric, and Piezoelectric Properties in Potassium Sodium Niobate Ceramics with Rhombohedral–Orthorhombic and Orthorhombic–Tetragonal Phase Boundaries. Ceram. Int. 2014, 40, 5771–5779. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Cheng, X.; Zheng, T.; Lou, X.; Zhang, B.; Zhu, J. New Potassium–Sodium Niobate Ceramics with a Giant d33. ACS Appl. Mater. Interfaces 2014, 6, 6177–6180. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Zhu, J.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Wang, X. Giant Piezoelectricity in Potassium–Sodium Niobate Lead-Free Ceramics. J. Am. Chem. Soc. 2014, 136, 2905–2910. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Cheng, X.; Zheng, T.; Zhang, B.; Xiao, D.; Zhu, J.; Lou, X. New Potassium-Sodium Niobate Lead-Free Piezoceramic: Giant-d33 vs. Sintering Temperature. J. Phys. Lett. 2014, 115, 114104. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Cheng, X.; Wang, X.; Zhang, B.; Xiao, D.; Zhu, J.; Lou, X.; Wang, X. New Potassium–Sodium Niobate Material System: A Giant-d33 and High-TC Lead-Free Piezoelectric. Dalton Trans. 2014, 43, 11759–11766. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Cheng, X.; Wang, X.; Zhang, B.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. High Strain in (K0.40Na0.60)(Nb0.955Sb0.045)O3–Bi0.50Na0.50ZrO3 Lead-Free Ceramics with Large Piezoelectricity. J. Mater. Chem. C 2014, 2, 8796–8803. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, J.; Tao, H.; Lv, X.; Wang, X.; Lou, X. Composition Design and Electrical Properties in (1-y)(K0.40Na0.60)0.985Li0.015(Nb1−xSbx)O3-yBi0.5Na0.5ZrO3 Lead-Free Ceramics. J. Appl. Phys. 2015, 117, 084103. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J. Giant d33 in Nonstoichiometric (K,Na)NbO3-based Lead-Free Ceramics. Scripta Mater. 2015, 94, 25–27. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. Potassium–Sodium Niobate Lead-Free Ceramics: Modified Strain as well as Piezoelectricity. J. Mater. Chem. A 2015, 3, 1868–1874. [Google Scholar] [CrossRef]

- Zheng, T.; Zu, Y.; Wu, J. Composition Dependence of Phase Structure and Electrical Properties in Lead-Free (1-x)(K0.42Na0.585)(Nb1−ySby)O3-xBi0.5K0.5ZrO3 Piezoceramics. J. Alloys Compd. 2015, 647, 927–934. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Li, L.; Li, J.; Zhai, J.; Li, Y. Phase Structures and Piezoelectric Properties of (K,Na,Li)(Nb,Sb)O3-(Bi,Ag)ZrO3 Lead-Free Ceramics. J. Electron. Mater. 2016, 45, 3167–3173. [Google Scholar] [CrossRef]

- Kim, B.H.; Yang, S.A.; Lee, M.K.; Lee, G.J. Properties of (Bi,M)ZrO3 (M: Alkali metals)-Modified (K,Na)NbO3 Lead-Free Piezoceramics. Ceram. Int. 2017, 43, 15880–15885. [Google Scholar] [CrossRef]

- Zhou, J.S.; Wang, K.; Yao, F.Z.; Zheng, T.; Wu, J.; Xiao, D.; Zhu, J.; Li, J.F. Multi-Scale Thermal Stability of Niobate-based Lead-Free Piezoceramics with Large Piezoelectricity. J. Mater. Chem. C 2015, 3, 8780–8787. [Google Scholar] [CrossRef]

- Zhang, M.H.; Wang, K.; Zhou, J.S.; Zhou, J.J.; Chu, X.; Lv, X.; Wu, J.; Li, J.F. Thermally Stable Piezoelectric Properties of (K,Na)NbO3-based Lead-Free Perovskite with Rhombohedral-Tetragonal Coexisting Phase. Acta Mater. 2017, 122, 344–351. [Google Scholar] [CrossRef]

- Damjanovic, D. Contributions to the Piezoelectric Effect in Ferroelectric Single Crystals and Ceramics. J. Am. Ceram. Soc. 2005, 88, 2663–2676. [Google Scholar] [CrossRef]

- Yao, Z.; Liu, H.; Hao, H.; Cao, M. Structure, Electrical Properties, and Depoling Mechanism of BiScO3-PbTiO3-Pb(Zn1/3Nb2/3)O3 High-Temperature Piezoelectric Ceramics. J. Appl. Phys. 2011, 109, 014105. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Y.; Huang, R.; Liu, R.; Zhou, H. Poling Field Dependence of Ferroelectric Domains in Tetragonal KNNLN Ceramics. Ceram. Int. 2012, 38, 6067–6070. [Google Scholar] [CrossRef]

- Val-Gómez, P.; del Campo, A.; Rubio-Marcos, F.; Fernández, J.F.; Moure, A. Poling and Depoling Influence on the Micro-stress States and Phase Coexistence in KNN-based Piezoelectric Ceramics. J. Eur. Ceram. Soc. 2019, 39, 1011–1019. [Google Scholar] [CrossRef]

- Rubio-Marcos, F.; Fernandez, J.F.; Ochoa, D.A.; García, J.E.; Rojas-Hernandez, R.E.; Castro, M.; Ramajo, L. Understanding the Piezoelectric Properties in Potassium-Sodium Niobate-based Lead-Free Piezoceramics: Interrelationship between Intrinsic and Extrinsic Factors. J. Eur. Ceram. Soc. 2017, 37, 3501–3509. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, C.; Chen, K. Ferroelectric 90° Domain Evaluation in Tetragonal Pb(Mg1/3Nb2/3)O3-PbTiO3 Ceramics. J. Am. Ceram. Soc. 2005, 88, 335–338. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).