Solar energy is a vital energy source in order to face critical energy problems such as fossil fuel depletion, global warming, the increasing energy demand and the increasing electricity price [

1,

2]. The building sector is one of the most energy-consuming sectors of our society and the exploitation of solar irradiation in the buildings is an interesting idea that can lead to future sustainability [

3]. Moreover, trigeneration systems are highly efficient units that can produce numerous useful outputs simultaneously [

4,

5] and usually they can produce the outputs that the building needs (heating, cooling and electricity). So, the use of solar energy for feeding trigeneration systems seems to be a viable and environmentally friendly idea. Especially in buildings with high energy needs, like hospitals and commercial buildings, trigeneration systems can be installed easily without scale restrictions which can be found in residential buildings.

In this direction, there are many literature studies with solar-driven trigeneration configurations for the building sector. The most usual design includes an organic Rankine cycle (ORC) and heat pumps, while the most usual solar technology is the parabolic trough collector (PTC). The heat pumps can be absorption chillers (ACH) or vapor compression cycles (VCC). Al-Sulaiman et al. [

6] examined a trigeneration system with ORC and ACH driven by PTC. The ACH is fed by the waste heat after the ORC turbine. They concluded that the exergy efficiency of the system is about 20% and the maximum turbine production is 115 kW. Bellos and Tzivanidis [

7] studied a similar configuration with a 1000 m

2 collecting area and they stated the optimized case has 152% energy efficiency, 29.4% exergy efficiency and 177.6 kW electricity production. At this point, it is important to state that in the system with heat pumps, the energy efficiency can be over 100% because the cooling load acts as an energy input in the system but it does not take into account the denominator of the energy efficiency definition. In another work, Eisavi et al. [

8] studied a configuration with ORC of around 0.5 MW

el nominal power and a double-effect absorption heat pump which presents 96% energy efficiency and 12.8% exergy efficiency. Zhao et al. [

9] performed a comparative study in order to determine the optimum technique for combining ACH, ORC and PTC. They concluded that feeding the ACH by the ORC’s waste heat is the optimum way for maximizing the exergy efficiency index which is found to be 41%, while the nominal power production of the system is 200 kW. Moreover, Khalid et al. [

10] studied a unit with ACH and ORC coupled to the solar field loop. The waste heat of the ORC assists a VCC for heating production. Geothermal energy and wind energy are also used in this system which presents 76.1% energy efficiency, 7.3% exergy efficiency, while the net present value is close to 350 k

$ for a nominal electrical power of 30 kW. Bellos et al. [

11] investigated a unit with VCC coupled to an ORC which is fed by 70 m

2 PTC and biomass fuel. This polygeneration system produced cooling, electricity and heating at two temperature levels. According to their results, the payback period is close to five years, the exergy efficiency 21.8%, the energy efficiency 51.3% and the electricity production is 8.2 kW. Mathkor et al. [

12] studied a system that produces fresh-water, cooling and electricity of around 1.2 MW. They found exergy efficiency close to 42% while the electricity capacity is 1 MW, the cooling capacity around 190 tons and the fresh-water production around 130 tons daily. Zhang et al. [

13] examined a simple system with ORC, ACH and PTC. They found that the optimum working fluid in the ORC is the MM, while the overall system efficiency is 40.95%. The heating/power ratio was found 4.2 and the cooling/power ratio 4.95, while the gross power production was 200 MW.

Moreover, there are other solar-driven trigeneration systems in the literature. Dabwan et al. [

14] investigated different ways to incorporate PTC in a gas turbine trigeneration system. They found that the use of PTC can reduce the levelized cost of electricity by about 22% and they found an optimum solar multiple at 0.4, while the maximum system power production is found at 360 MW. Wang et al. [

15] performed a detailed analysis of a trigeneration system with a fuel cell, absorption chiller and other devices for methanol-reforming, electricity and cooling production. The nominal power production of the system for winter and summer was selected at 120 kW. They found that in the summer, the system has 73.7% energy efficiency and exergy efficiency 18.8%, while in the winter, it has 51.7% energy efficiency and 26.1% exergy efficiency. Ozlu and Dincer [

16] studied a configuration for heating production, electricity fresh-water and hydrogen production. The studied system utilizes solar irradiation to feed a two-stage water/steam Rankine cycle. An electrolyzer and a distillation system are also included in the system. The system energy efficiency is found at 36% and the exergy efficiency is found to be 44%, while the maximum electricity production is 116 kW. In another work, Matta-Torres et al. [

17] studied a trigeneration system with Rankine water/steam cycle and distillation unit. The energy efficiency of this unit is found 19%, while the solar fraction is about 83% for the location of Venezuela, while for Chile the energy efficiency is 11% and the solar fraction 92%. The nominal capacity of the examined system was selected at 50 MW.

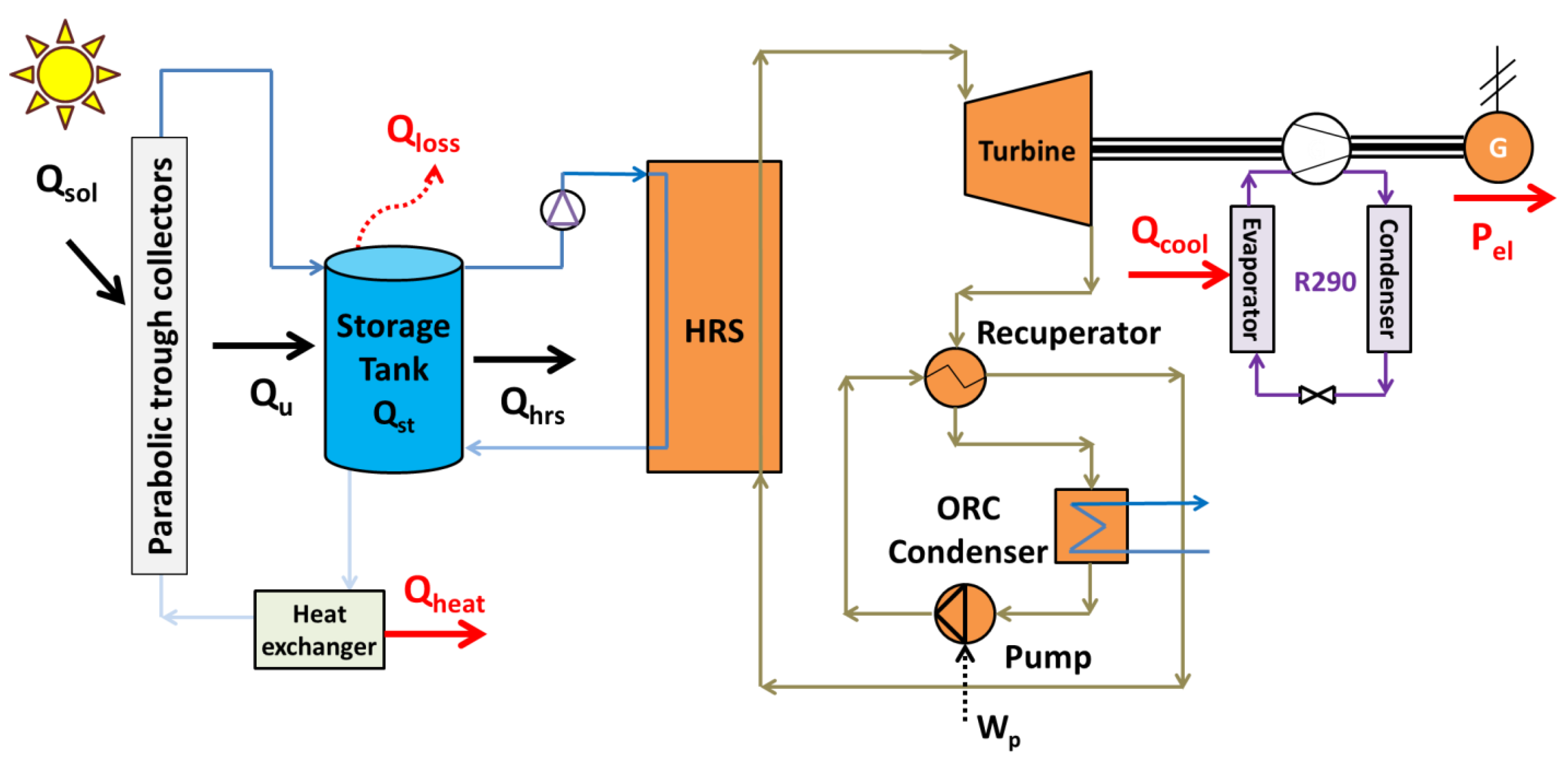

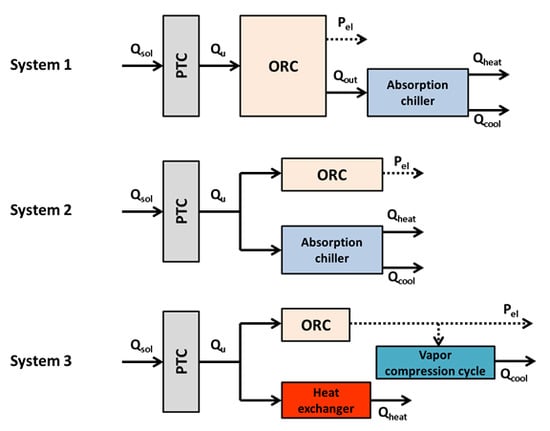

The previous literature review indicates that there is a lot of interest for solar-driven trigeneration systems and especially of systems with ORC and absorption heat pumps. So, the objective of the present work is the detailed comparison of three different versions of the trigeneration systems which combine with different ways an ORC with a heat pump. These systems can be applied in buildings with increased energy needs in order to utilize all the quantities of the produced energy rates. The comparison is energetic, exergetic and financial for presenting a multilateral analysis. The examined systems are initially optimized in steady-state conditions and their optimum designs are evaluated and compared to each other. The first system includes PTC, ORC and an ACH which is fed by the ORC’s waste heat. The second system includes PTC which feeds both ORC and ACH separately. The last system includes PTC which feeds both ORC and heating production heat exchanger separately, while the cooling is produced by a VCC which is fed by the ORC electricity production. In systems with the ACH, the heating and the cooling are both produced by this device. The yearly analysis is conducted using data for the location of Athens, Greece. The analysis is performed with developed thermodynamic models in Engineering Equation Solver (EES) [

18], while the yearly analysis with a developed dynamic model in FORTRAN.