Calibration of the Interaction Parameters between the Proppant and Fracture Wall and the Effects of These Parameters on Proppant Distribution

Abstract

:1. Introduction

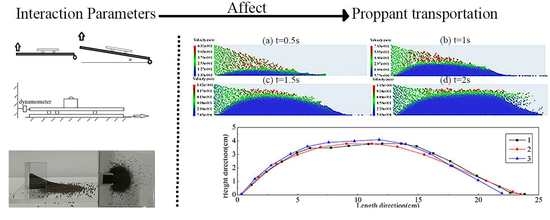

2. Calibration of the Interaction Parameters

2.1. Methods for Calibrating the Interaction Parameters between Proppant and Wall

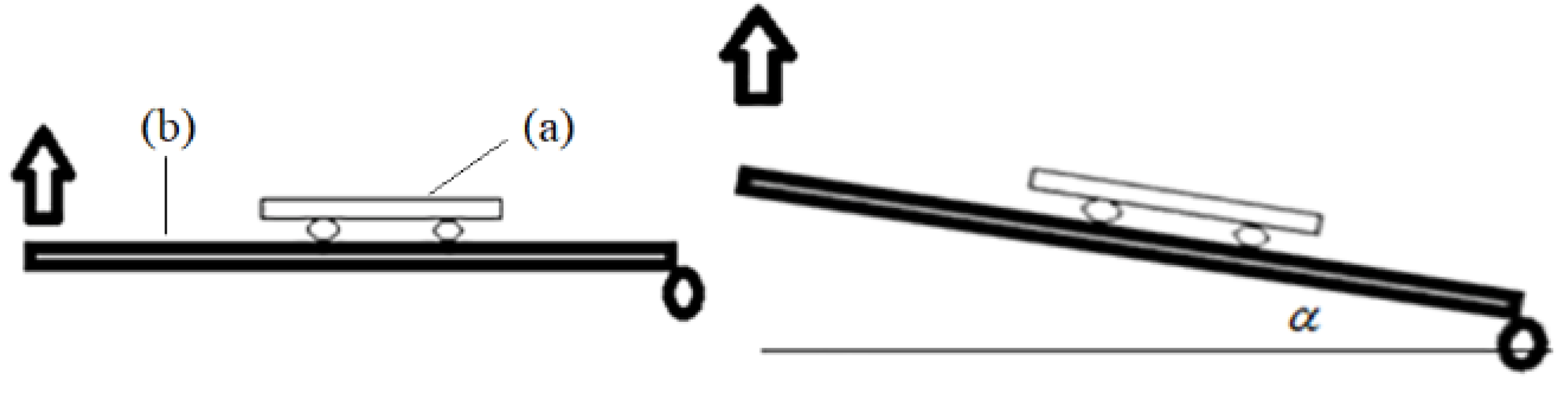

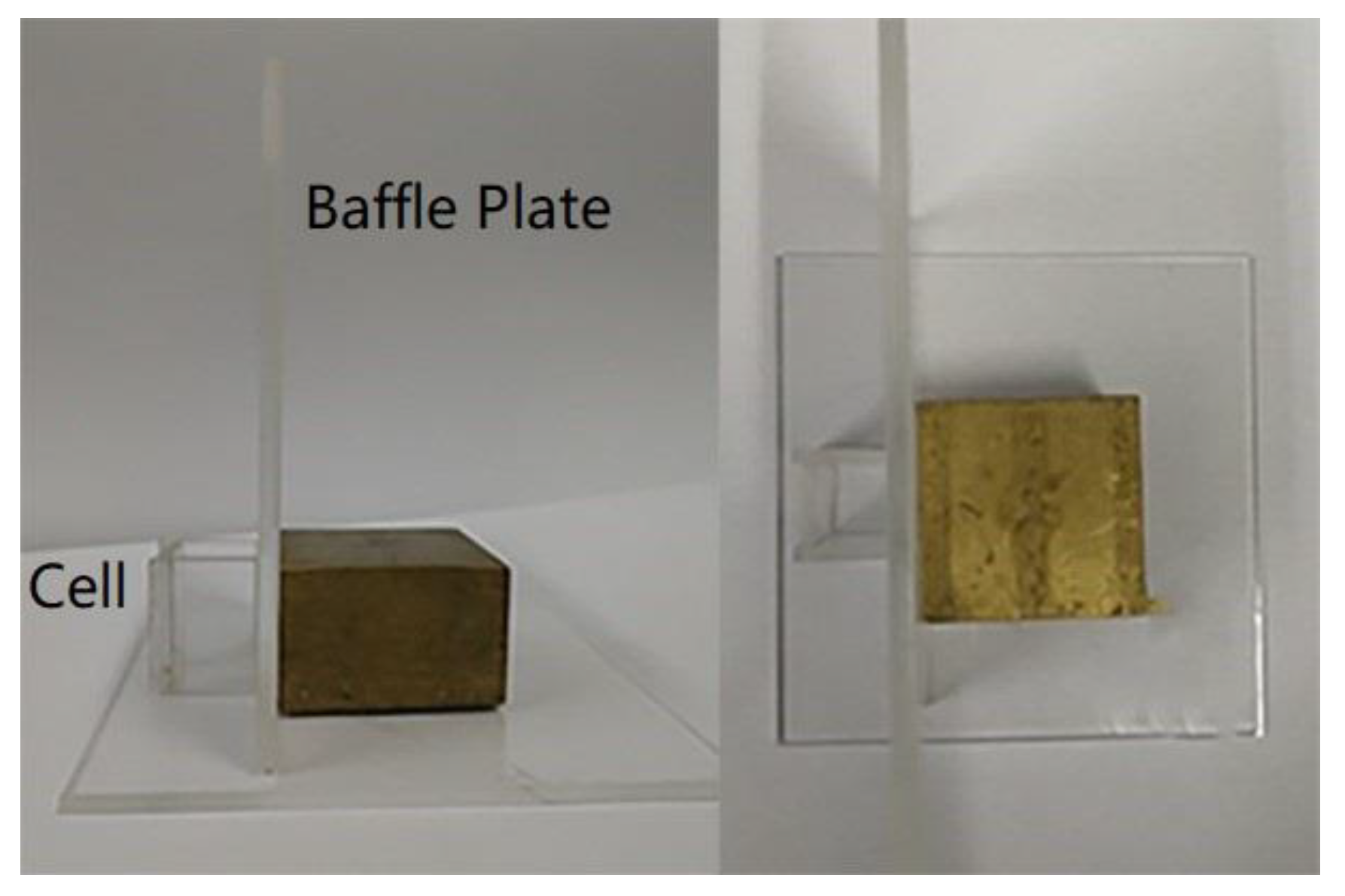

2.1.1. Static Friction Coefficient between the Proppant and Wall

2.1.2. Rolling Friction Coefficient between Proppant and Wall

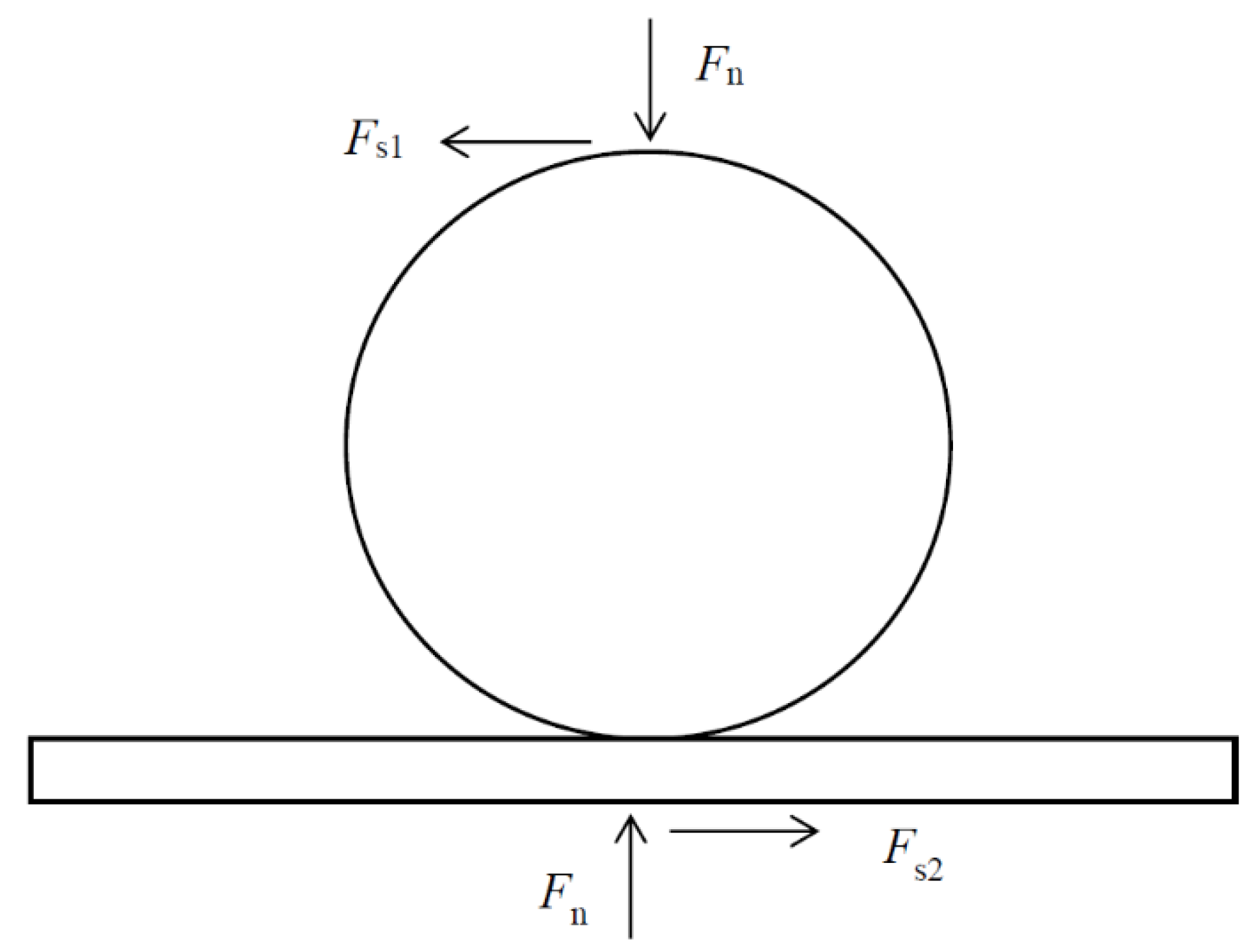

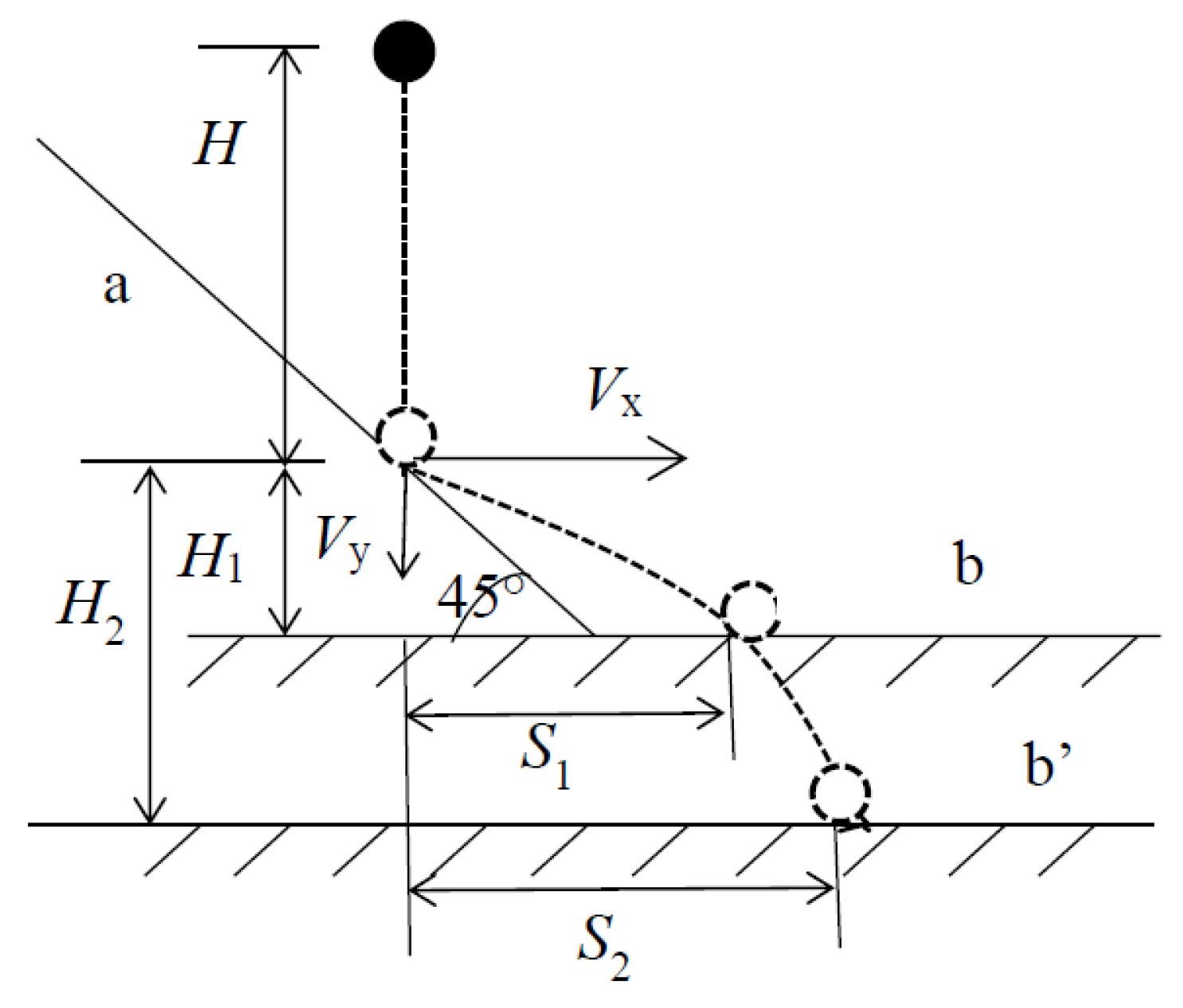

2.1.3. Coefficient of Restitution

2.1.4. The Results of the Interaction Parameters between the Proppant and Wall

2.2. Interaction Parameters between Proppants

- (1)

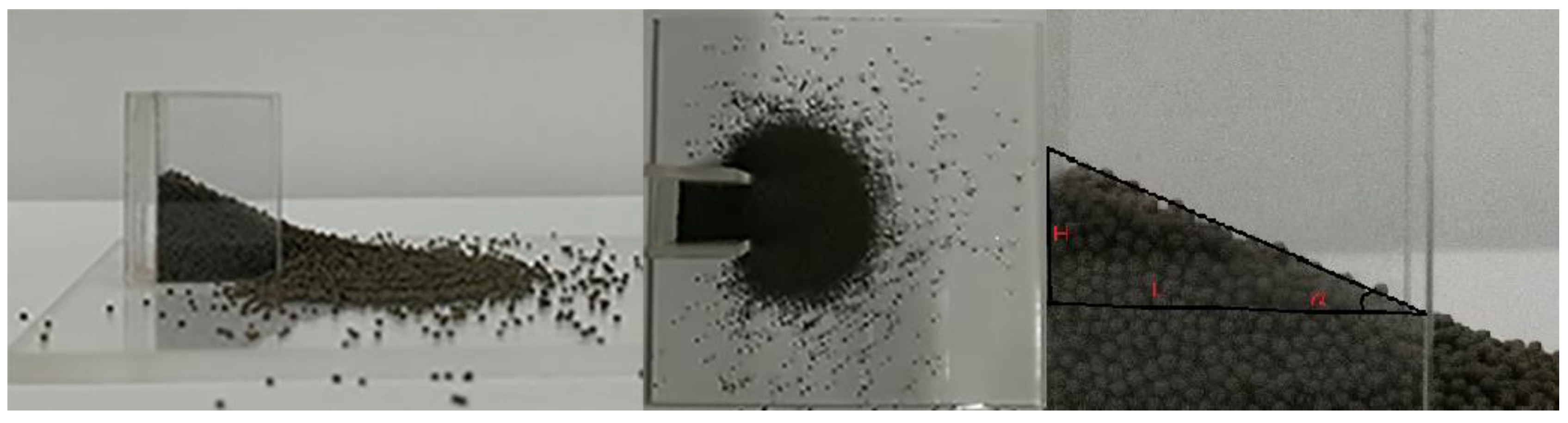

- Experimental measurement of the angle of repose

- (2)

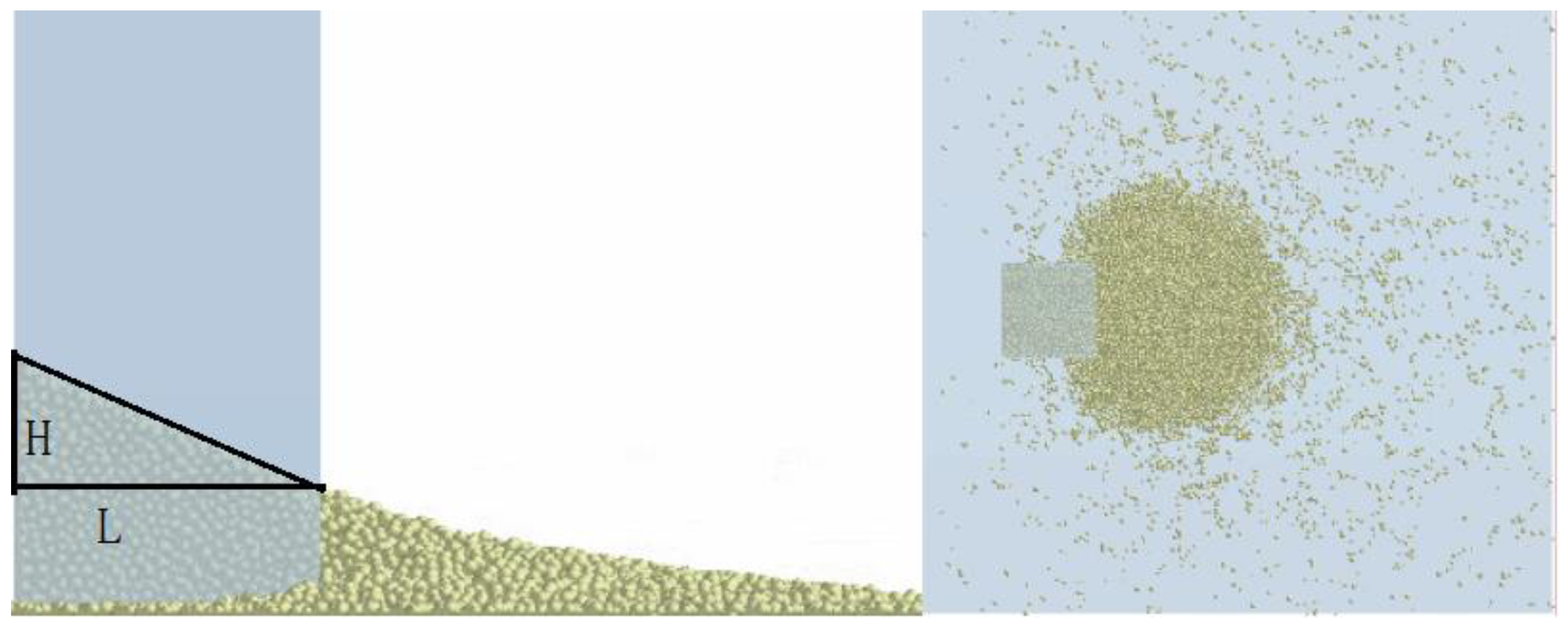

- Numerical simulation of the angle of repose

3. Effects of the Interaction Parameters on Proppant Migration

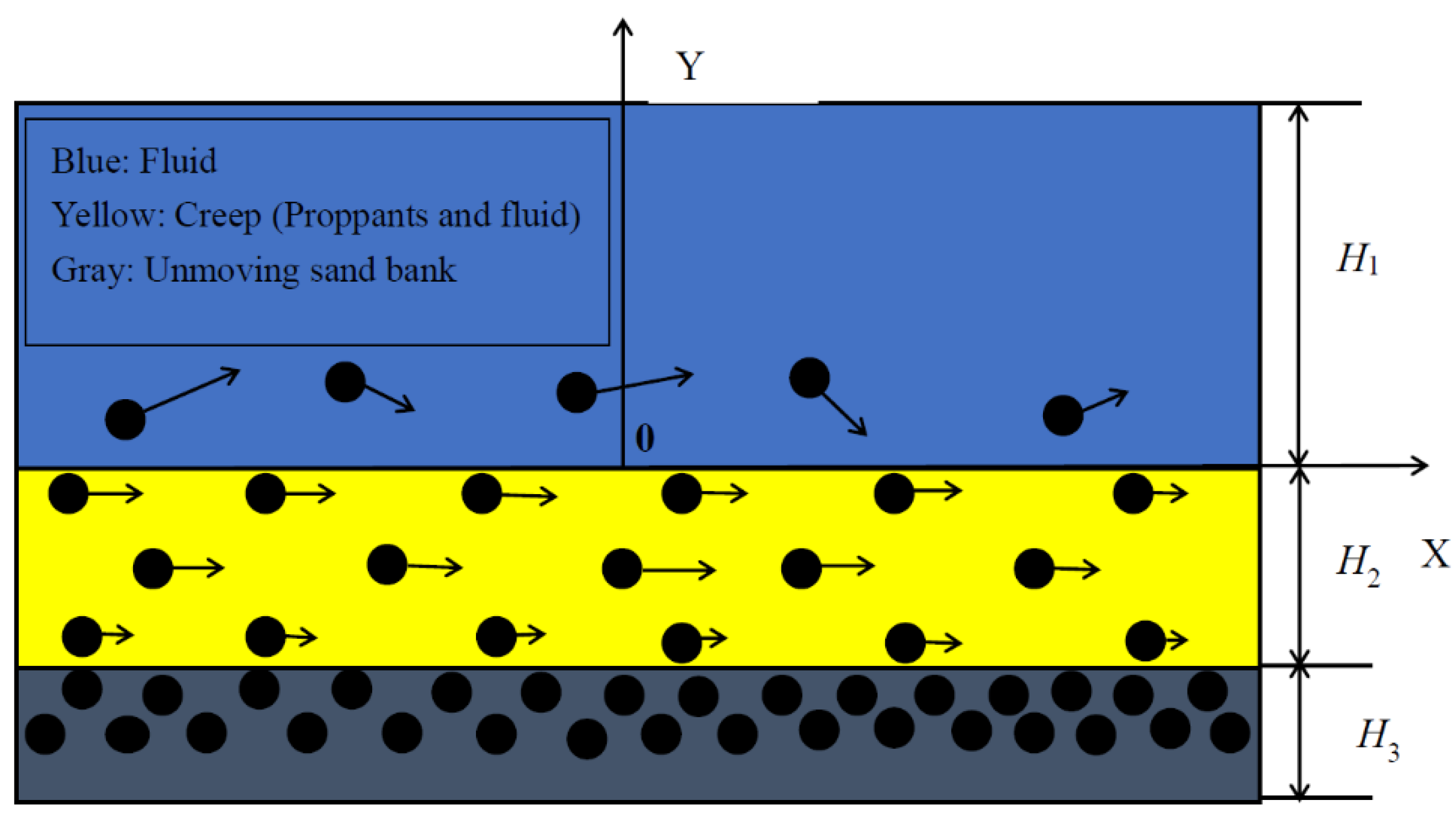

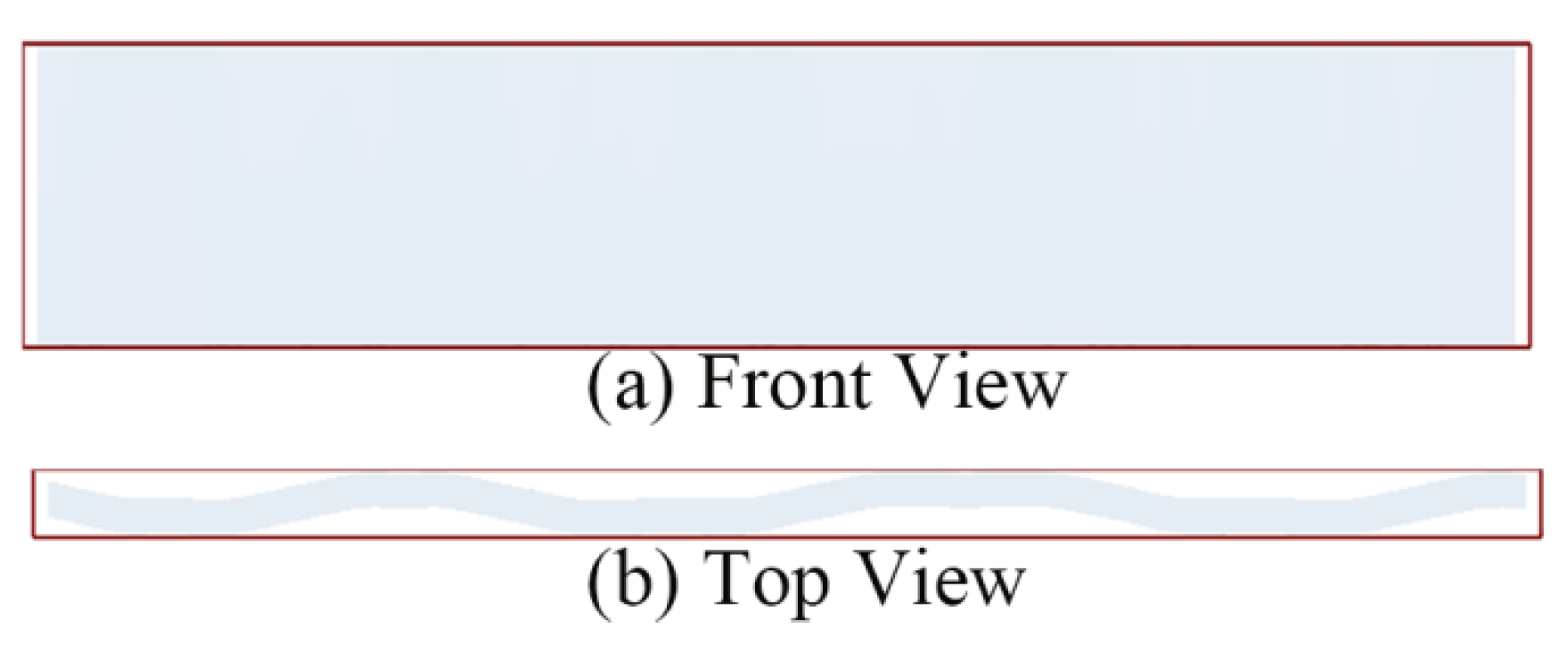

3.1. Coupled CFD–DEM Model

3.1.1. Fluid Control Equations

- (1)

- Mass conservation equation

- (2)

- Momentum conservation equation

3.1.2. Particle Control Equations

3.1.3. Initial and Boundary Conditions

- (1)

- CFD initial and boundary conditions

- (2)

- DEM initial and boundary conditions

- (3)

- Coupling of CFD and DEM

- Solving the pressure and velocity fields of the liquid phase with the CFD part without considering the particles.

- The velocities of particles are exerted on the CFD grid blocks where they are “covered” by the particles. As a result of this process, the flow field violates the conservation of mass requirements and is corrected to ensure this condition is once more satisfied.

- The force exerted on each particle by the fluid is calculated and sent to the DEM code.

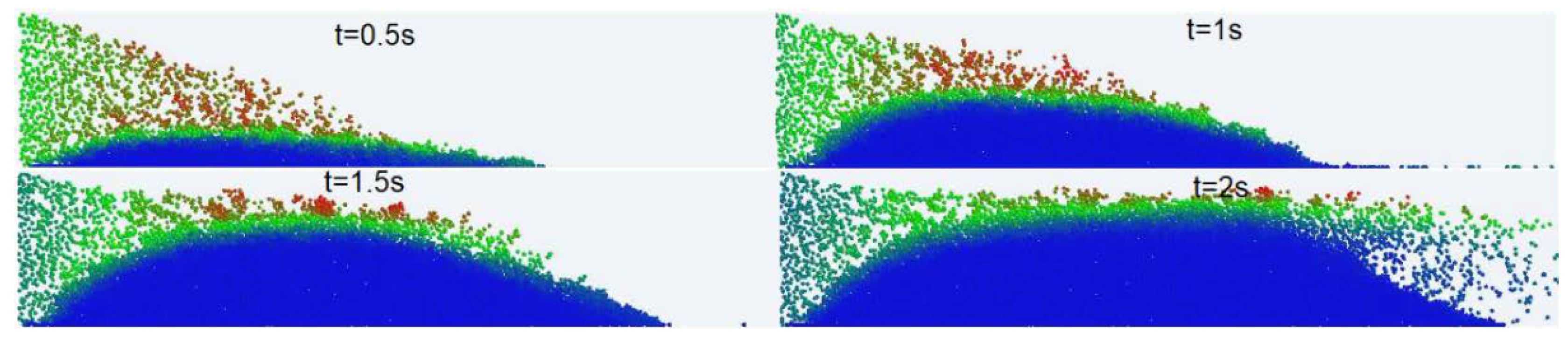

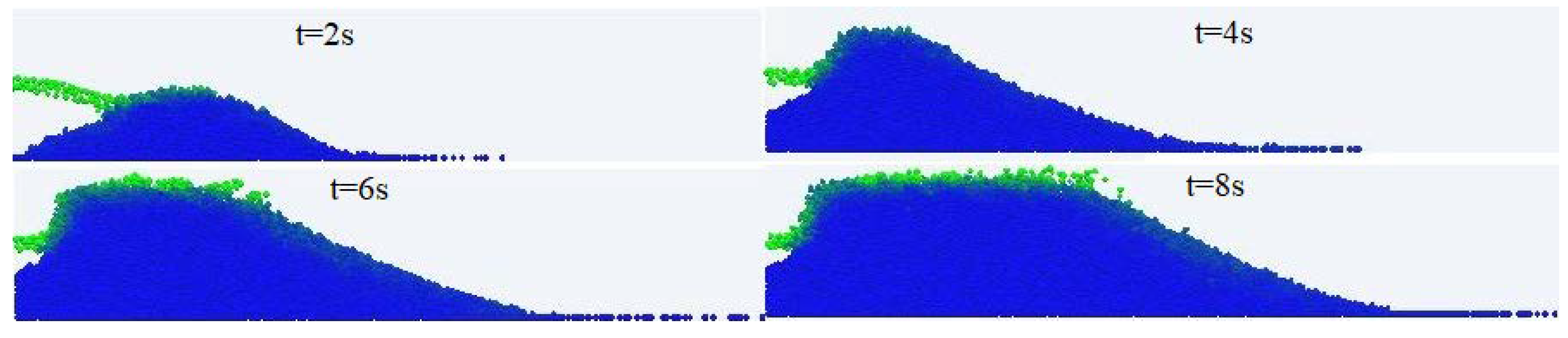

3.2. Mechanisms of Proppant Transport in the Fracture

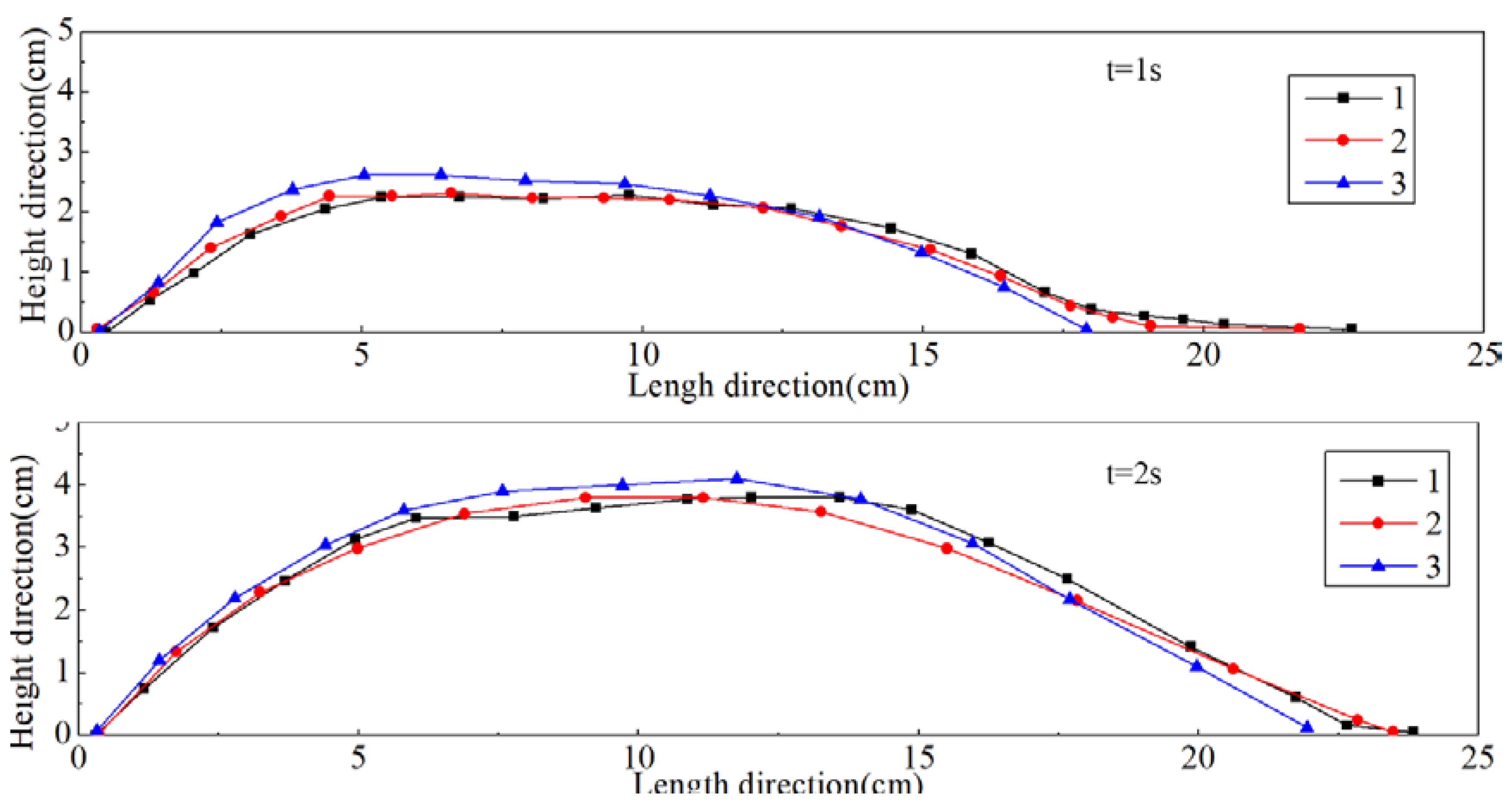

3.3. Effects of Interaction Parameters on Proppant Distribution in the Fracture

- (1)

- The sand bed morphology with single-diameter proppants

- (2)

- The effects of a rough fracture on proppant distribution

- (3)

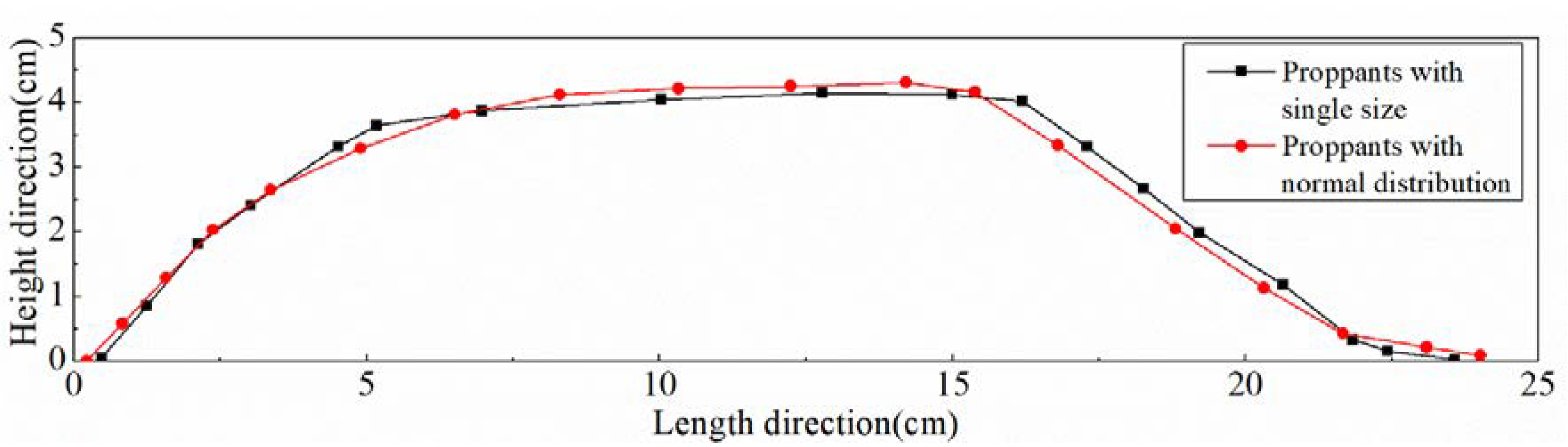

- The effects of an unevenly distributed proppant diameter on proppant distribution

4. Discussion

5. Conclusions

- (1)

- A lower static friction coefficient and rolling friction coefficient between the proppant and proppant or the wall can result in a smaller equilibrium height of sandbank and a smaller build angle and drawdown angle, which is beneficial for transporting the proppant to the distal end of fractures.

- (2)

- The wall roughness increases the collision between the proppant and proppant or the wall, whereas the interactions have little impacts on the sandbank morphology. Wall roughness slightly increases the equilibrium height of the sandbank, while it does not have any influence on the build angle or drawdown angle.

- (3)

- In the early stage of fracturing, an uneven particle size increases the complexity of the movement of the suspended proppant. However, when the sand bed reaches the equilibrium height, it has little impact on the sandbank morphology, only slightly increasing the equilibrium height.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gu, M.; Dao, E.; Mohanty, K.K. Investigation of ultra-light weight proppant application in shale fracturing. Fuel 2015, 150, 191–201. [Google Scholar] [CrossRef]

- Naval, G.; Shah, S. A Rheological Criterion for Fracturing Fluids to Transport Proppant during a Stimulation Treatment. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001; Society of Petroleum Engineers: Richardson, TX, USA, 2001. [Google Scholar]

- Gu, M.; Kulkarni, P.M.; Rafiee, M.; Ivarrud, E.; Mohanty, K.K. Understanding the Optimum Fracture Conductivity for Naturally Fractured Shale and Tight Reservoirs. In Proceedings of the SPE/CSUR Unconventional Resources Conference, Calgary, AB, Canada, 30 September–2 October 2014; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Wu, K.; Olson, J.E. Numerical Investigation of Complex Hydraulic Fracture Development in Naturally Fractured Reservoirs. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 3–5 February 2015; Society of Petroleum Engineers: Richardson, TX, USA, 2016. [Google Scholar]

- Taherdangkoo, R.; Tatomir, A.; Taylor, R.; Sauter, M. Numerical investigations of upward migration of fracking fluid along a fault zone during and after stimulation. Energy Procedia 2017, 125, 126–135. [Google Scholar] [CrossRef]

- Taherdangkoo, R.; Tatomir, A.; Anighoro, T.; Sauter, M. Modeling fate and transport of hydraulic fracturing fluid in the presence of abandoned wells. J. Contam. Hydrol. 2019, 221, 58–68. [Google Scholar] [CrossRef]

- Mack, M.; Sun, J.; Khadilkar, C. Quantifying Proppant Transport in Thin Fluids: Theory and Experiments. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Kern, L.R.; Perkins, T.K.; Wyant, R.E. The Mechanics of Sand Movement in Fracturing. J. Petrol. Technol. 1959, 11, 55–57. [Google Scholar] [CrossRef]

- Barree, R.D. Experimental and numerical modeling of convective proppant transport. J. Petrol. Technol. 1995, 47, 216–222. [Google Scholar] [CrossRef]

- Sahai, R.; Miskimins, J.L.; Olson, K.E. Laboratory Results of Proppant Transport in Complex Fracture Systems. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Woodworth, T.R.; Miskimins, J.L. Extrapolation of Laboratory Proppant Placement Behavior to the Field in Slickwater Fracturing Applications. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, College Station, TX, USA, 29–31 January 2007; Society of Petroleum Engineers: Richardson, TX, USA, 2007. [Google Scholar]

- Alotaibi, M.A.; Miskimins, J.L. Slickwater Proppant Transport in Complex Fractures: New Experimental Findings & Scalable Correlation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015; Society of Petroleum Engineers: Richardson, TX, USA, 2015. [Google Scholar]

- Li, N.; Li, J.; Zhao, L.; Luo, Z.; Liu, P.; Guo, Y. Laboratory Testing on Proppant Transport in Complex-Fracture Systems. SPE Prod. Oper. 2017, 32, 382–391. [Google Scholar] [CrossRef]

- Mobbs, A.T.; Hammond, P.S. Computer Simulations of Proppant Transport in a Hydraulic Fracture. SPE Prod. Oper. 2001, 16, 112–121. [Google Scholar] [CrossRef]

- Adachi, J.; Siebrits, E.; Peirce, A.; Desroches, J. Computer simulation of hydraulic fractures. Int. J. Rock Mech. Min. Sci. 2007, 44, 739–757. [Google Scholar] [CrossRef]

- Weng, X.; Kresse, O.; Cohen, C.E.; Wu, R.; Gu, H. Modeling of Hydraulic-Fracture-Network Propagation in a Naturally Fractured Formation. SPE 140253 PA 2011, 26, 368–380. [Google Scholar] [CrossRef]

- Dontsov, E.V.; Peirce, A. Proppant Transport in Hydraulic Fracturing: Crack Tip Screen-Out in KGD and P3D Models; The University of British Columbia: Vancouver, BC, Canada, 2014. [Google Scholar] [CrossRef]

- Kong, X.; McAndrew, J. A Computational Fluid Dynamics Study of Proppant Placement in Hydraulic Fracture Networks. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AL, Canada, 15–16 February 2017; Society of Petroleum Engineers: Richardson, TX, USA, 2017. [Google Scholar]

- Yang, R.; Guo, J.; Zhang, T.; Zhang, X.; Ma, J.; Li, Y. Numerical Study on Proppant Transport and Placement in Complex Fractures System of Shale Formation Using Eulerian Multiphase Model Approach. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019; IPTC: Richardson, TX, USA, 2019. [Google Scholar]

- Han, J.; Yuan, P.; Huang, X.; Zhang, H.; Sookprasong, A.; Li, C.; Dai, Y. Numerical Study of Proppant Transport in Complex Fracture Geometry. In Proceedings of the SPE Low Perm Symposium, Denver, CO, USA, 5–6 May 2016; Society of Petroleum Engineers: Richardson, TX, USA, 2016. [Google Scholar]

- Tsai, K.; Degaleesan, S.S.; Fonseca, E.R.; Lake, E. Advanced Computational Modeling of Proppant Settling in Water Fractures for Shale Gas Production. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 6–8 February 2012; Society of Petroleum Engineers: Richardson, TX, USA, 2012. [Google Scholar]

- Snider, D.M. An Incompressible Three-Dimensional Multiphase Particle-in-Cell Model for Dense Particle Flows. J. Comput. Phys. 2001, 170, 523–549. [Google Scholar] [CrossRef]

- Snider, D.; Banerjee, S. Heterogeneous gas chemistry in the CPFD Eulerian–Lagrangian numerical scheme (ozone decomposition). Powder Technol. 2010, 199, 100–106. [Google Scholar] [CrossRef]

- Rahmati, H.; Jafarpour, M.; Azadbakht, S.; Nouri, A.; Vaziri, H.; Chan, D.; Xiao, Y. Review of Sand Production Prediction Models. J. Petrol. Eng. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Zeng, J.; Li, H.; Zhang, D. Numerical simulation of proppant transport in hydraulic fracture with the upscaling CFD-DEM method. J. Nat. Gas Sci. Eng. 2016, 33, 264–277. [Google Scholar] [CrossRef]

- Blyton, C.A.J.; Gala, D.P.; Sharma, M.M. A Comprehensive Study of Proppant Transport in a Hydraulic Fracture. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015; Society of Petroleum Engineers: Richardson, TX, USA, 2015. [Google Scholar]

- Tomac, I.; Gutierrez, M. Micromechanics of proppant agglomeration during settling in hydraulic fractures. J. Petrol. Explor. Prod. Technol. 2015, 5, 417–434. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Gutierrez, M.; Li, M. Numerical simulation of transport and placement of multi-sized proppants in a hydraulic fracture in vertical wells. Granul. Matter 2017, 19, 1–15. [Google Scholar] [CrossRef]

- Kou, R.; Moridis, G.J.; Blasingame, T.A. Analysis and Modeling of Proppant Transport in Inclined Hydraulic Fractures. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018; Society of Petroleum Engineers: Richardson, TX, USA, 2018. [Google Scholar]

- Baldini, M.; Carlevaro, C.M.; Pugnaloni, L.A.; SáNchez, M. Numerical simulation of proppant transport in a planar fracture. A study of perforation placement and injection strategy. Int. J. Multiph. Flow 2018, 109, 207–218. [Google Scholar] [CrossRef]

- Kou, R.; Moridis, G.; Blasingame, T. Bridging Criteria and Distribution Correlation for Proppant Transport in Primary and Secondary Fracture. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019; Society of Petroleum Engineers: Richardson, TX, USA, 2019. [Google Scholar]

- Zhang, G.; Gutierrez, M.; Li, M. A coupled CFD-DEM approach to model particle-fluid mixture transport between two parallel plates to improve understanding of proppant micromechanics in hydraulic fractures. Powder Technol. 2017, 308, 235–248. [Google Scholar] [CrossRef]

- Goniva, C.; Kloss, C.; Deen, N.G.; Kuipers, J.A.; Pirker, S. Influence of rolling friction on single spout fluidized bed simulation. Particuology 2012, 10, 582–591. [Google Scholar] [CrossRef]

- Mack, M.G.; Coker, C.E. Proppant Selection for Shale Reservoirs: Optimizing Conductivity, Proppant Transport and Cost. In Proceedings of the SPE Unconventional Resources Conference Canada, Calgary, AL, Canada, 5–7 November 2013; Society of Petroleum Engineers: Richardson, TX, USA, 2013. [Google Scholar]

- Joseph, G.G.; Zenit, R.; Hunt, M.L.; Rosenwinkel, A.M. Particle–wall collisions in a viscous fluid. J. Fluid Mech. 2001, 433, 329–346. [Google Scholar] [CrossRef] [Green Version]

- Joseph, G.; Hunt, M. Oblique particle–wall collisions in a liquid. J. Fluid Mech. 2004, 510, 71–93. [Google Scholar] [CrossRef] [Green Version]

- Coetzee, C.J.; Els, D.N.J. Calibration of granular material parameters for DEM modelling and numerical verification by blade–granular material interaction. J. Terramech. 2009, 46, 15–26. [Google Scholar] [CrossRef]

- Jin, F.; Xin, H.; Zhang, C.; Sun, Q. Probability-based contact algorithm for non-spherical particles in DEM. Powder Technol. 2011, 212, 134–144. [Google Scholar] [CrossRef]

- Geer, S.; Bernhardt-Barry, M.; Garboczi, E.; Whiting, J.; Donmez, A. A more efficient method for calibrating discrete element method parameters for simulations of metallic powder used in additive manufacturing. Granul. Matter 2018, 20, 1–17. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Defining the effect of sweep tillage tool cutting edge geometry on tillage forces using 3D discrete element modelling. Inf. Process. Agric. 2015, 2, 130–141. [Google Scholar] [CrossRef] [Green Version]

- Salawu, A.T.; Suleiman, M.L.; Isiaka, M. Physical Properties of Jatropha curcas Seed. Electronic Journal of Polish Agricultural Universities. Available online: http://www.ejpau.media.pl/volume16/issue4/art-07.html (accessed on 13 December 2013).

- Lajeunesse, E.; Mangeney-Castelnau, A.; Vilotte, J. Spreading of a granular mass on a horizontal plane. Phys. Fluids 2004, 16, 2371–2381. [Google Scholar] [CrossRef]

- Al-Hashemi, H.; Baghabra Al-Amoudi, O. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education: London, UK, 2007. [Google Scholar]

- Hobbs, A. Simulation of an aggregate dryer using coupled CFD and DEM methods. Int. J. Comput. Fluid Dyn. 2009, 23, 199–207. [Google Scholar] [CrossRef]

- Wang, Y.; Ai, J. Coupled CFD-DEM Simulation of Upward Seepage Flow in Granular Media. In Proceedings of the The Twenty-fifth International Ocean and Polar Engineering Conference, Kona, HI, USA, 21–26 June 2015; Society of Petroleum Engineers: Richardson, TX, USA, 2015. [Google Scholar]

- Herzt, H. Ueber die Beruhrrung fester elastischer Korper. J. Reine Angew. Math. 1881, 92, 156–171. [Google Scholar]

- Mindlin, R.D.; Deresiewicz, H. Elastic Spheres in Contact Under Varying Oblique Forces. J. Appl. Mech. Asme 1953, 20, 327–344. [Google Scholar]

- Tsuo, Y.P.; Gidaspow, D. Computation of flow patterns in circulating fluidized beds. AIChE J. 1990, 36, 885–896. [Google Scholar] [CrossRef]

- Wang, Z.T.; Zheng, X.J. Theoretical prediction of creep flux in aeolian sand transport. Powder Technol. 2004, 139, 123–128. [Google Scholar] [CrossRef]

- Chang, O.; Kinzel, M.; Dilmore, R.; Wang, J.Y. Physics of Proppant Transport Through Hydraulic Fracture Network. J. Energy Res. Technol. 2018, 140, 032912. [Google Scholar] [CrossRef]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practice. Rock Mech. 1977, 10, 1–54. [Google Scholar] [CrossRef]

| Case | (air) | (Slickwater) | ||

|---|---|---|---|---|

| Proppant–plexiglass wall | 0.6 | 0.24 | 0.1944 | 6.5 × 10−4 |

| Proppant–shale wall | 0.36 | 0.144 | 0.84 | 0.24 |

| Group | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| The sieving diameter (10−6 m) | 425–500 | 500–600 | 600–710 | >710 |

| Group | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Mass fraction (%) | 10 | 32 | 38 | 20 |

| Parameters | Value |

|---|---|

| Proppant density (kg/m3) | 3223 |

| The density of plexiglass (kg/m3) | 1130 |

| The static friction coefficient between proppant and wall | 0.1944 |

| The rolling friction coefficient between proppant and wall | 0.00065 |

| The coefficient of restitution between proppants | 0.53 |

| Case # | Static Friction Coefficient (Proppant–Proppant) | Rolling Friction Coefficient (Proppant–Proppant) | Angle of Repose (°) | The Difference in the Angle of Repose with Experimental Results (%) |

|---|---|---|---|---|

| 1 | 0.6 | 0.005 | 17.05 | 29.626878 |

| 2 | 0.5 | 0.005 | 16.69 | 31.1127621 |

| 3 | 0.4 | 0.005 | 15.99 | 34.0019812 |

| 4 | 0.3 | 0.005 | 15.64 | 35.4465907 |

| 5 | 0.6 | 0.01 | 18.43 | 23.9309889 |

| 6 | 0.5 | 0.01 | 18.09 | 25.3343239 |

| 7 | 0.4 | 0.01 | 17.74 | 26.7789335 |

| 8 | 0.3 | 0.01 | 17.05 | 29.626878 |

| 9 | 0.6 | 0.05 | 24.39 | −0.6686478 |

| 10 | 0.5 | 0.05 | 23.75 | 1.9729239 |

| 11 | 0.4 | 0.05 | 23.43 | 3.2937098 |

| 12 | 0.3 | 0.05 | 23.11 | 4.6144956 |

| Parameters | Coefficient of Restitution | Static Friction Coefficient | Rolling Friction Coefficient |

|---|---|---|---|

| Proppant–proppant | 0.21 | 0.6 | 0.05 |

| Proppant–wall | 0.24 | 0.1944 | 0.005 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Injection rate | 0.3 m/s | Fracturing fluid viscosity | 1 mPa·s |

| Particle diameters | 1.4 mm | Sand ratio | 20% |

| Case | The Contact Parameters (Proppant–Proppant) | The Contact Parameters (Proppant–Wall) | ||||

|---|---|---|---|---|---|---|

| Coefficient of Restitution | Static Friction Coefficient | Rolling Friction Coefficient | Coefficient of Restitution | Static Friction Coefficient | Rolling Friction Coefficient | |

| 1 | 0.21 | 0.6 | 0.05 | 0.24 | 0.19 | 0.005 |

| 2 | 0.27 | 0.6 | 0.05 | 0.31 | 0.3 | 0.005 |

| 3 | 0.21 | 0.8 | 0.1 | 0.24 | 0.26 | 0.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Liu, C.; Zhang, G. Calibration of the Interaction Parameters between the Proppant and Fracture Wall and the Effects of These Parameters on Proppant Distribution. Energies 2020, 13, 2099. https://doi.org/10.3390/en13082099

Li M, Liu C, Zhang G. Calibration of the Interaction Parameters between the Proppant and Fracture Wall and the Effects of These Parameters on Proppant Distribution. Energies. 2020; 13(8):2099. https://doi.org/10.3390/en13082099

Chicago/Turabian StyleLi, Mingzhong, Chunting Liu, and Guodong Zhang. 2020. "Calibration of the Interaction Parameters between the Proppant and Fracture Wall and the Effects of These Parameters on Proppant Distribution" Energies 13, no. 8: 2099. https://doi.org/10.3390/en13082099

APA StyleLi, M., Liu, C., & Zhang, G. (2020). Calibration of the Interaction Parameters between the Proppant and Fracture Wall and the Effects of These Parameters on Proppant Distribution. Energies, 13(8), 2099. https://doi.org/10.3390/en13082099