Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana

Abstract

1. Introduction

2. Materials and Methods

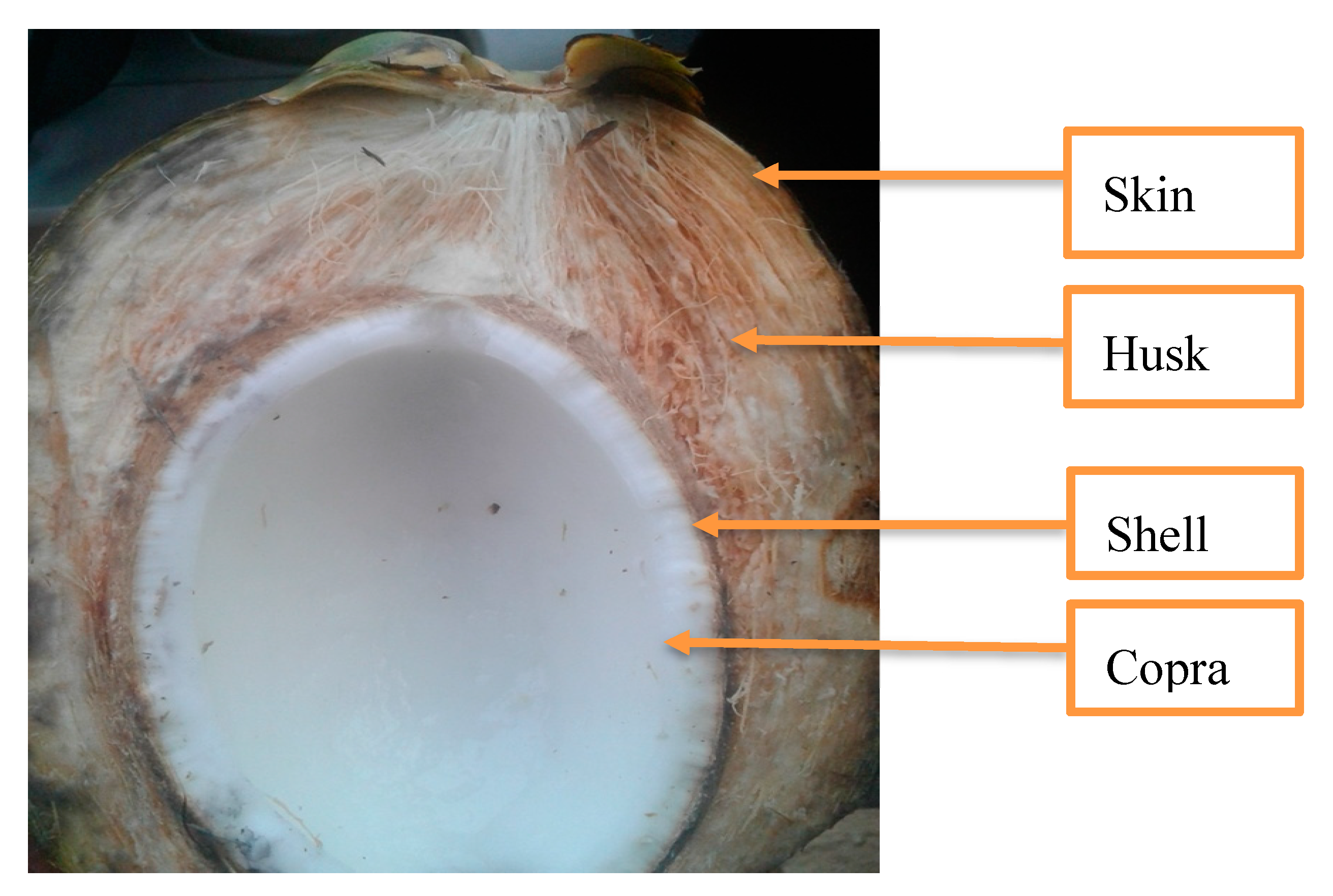

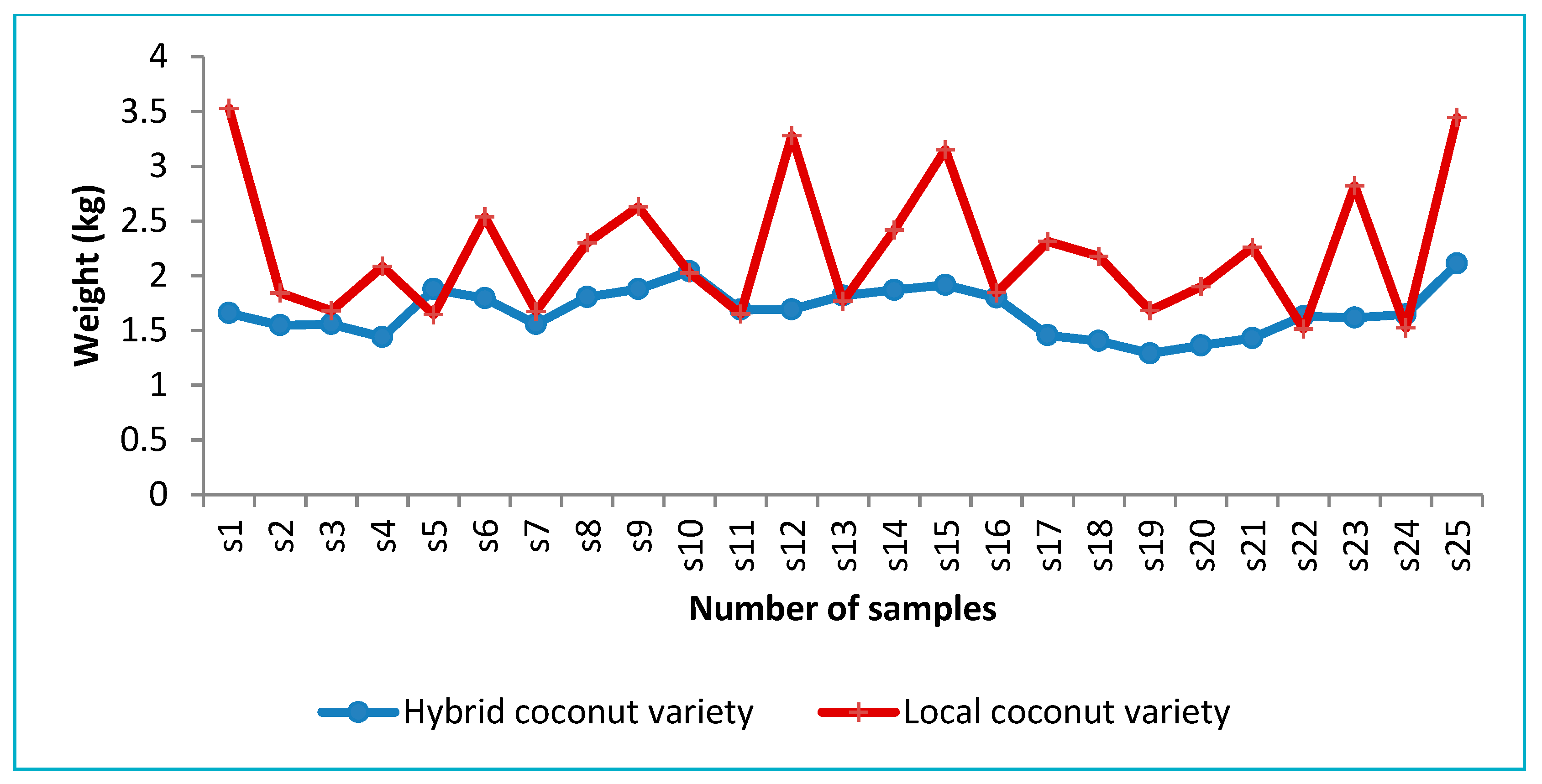

2.1. Quantifying the Proportion of Waste to be Generated from Whole Coconut

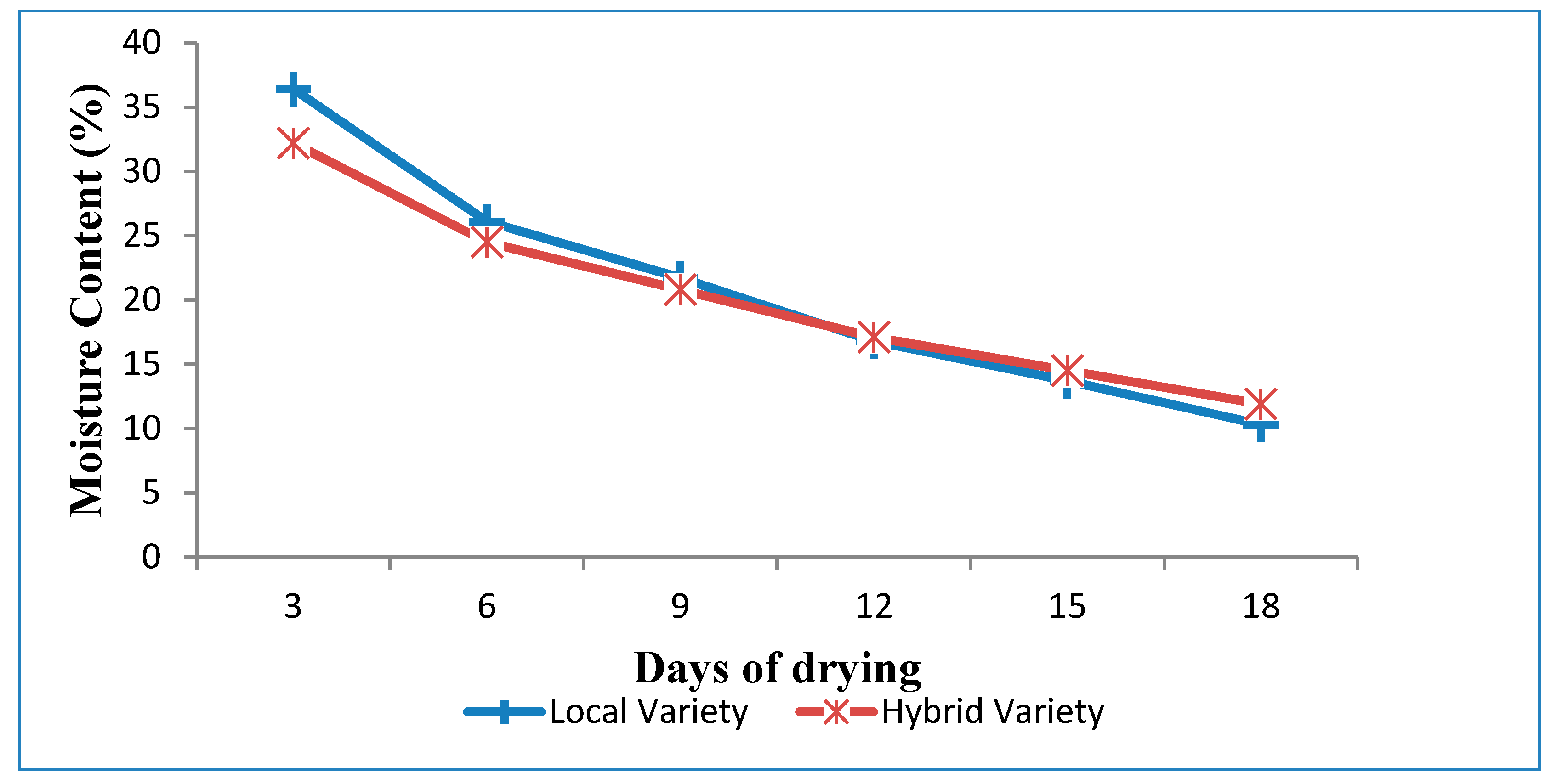

2.2. Drying and Determination of Moisture Content

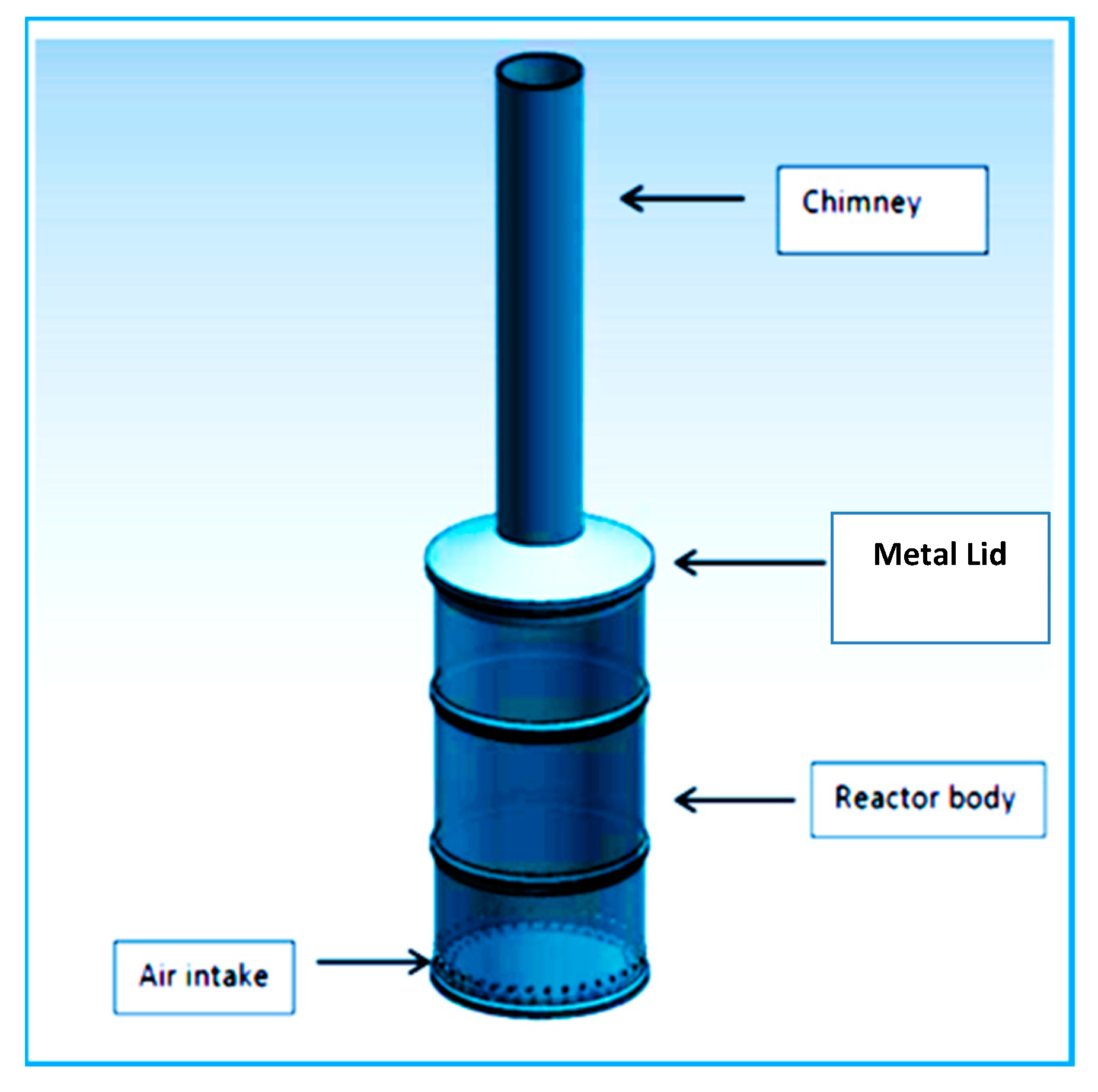

2.3. Charring

2.4. Determination of Calorific Value

2.5. Determination of Emissions

3. Results and Discussion

3.1. Proportion of Whole Coconut Waste

3.2. Variability in the Various Parts

3.3. Calorific Values of Charred and Uncharred Coconut Wastes

3.3.1. Uncharred Coconut Wastes (Husks and Shells)

3.3.2. Charred Coconut Wastes (Husks and Shells)

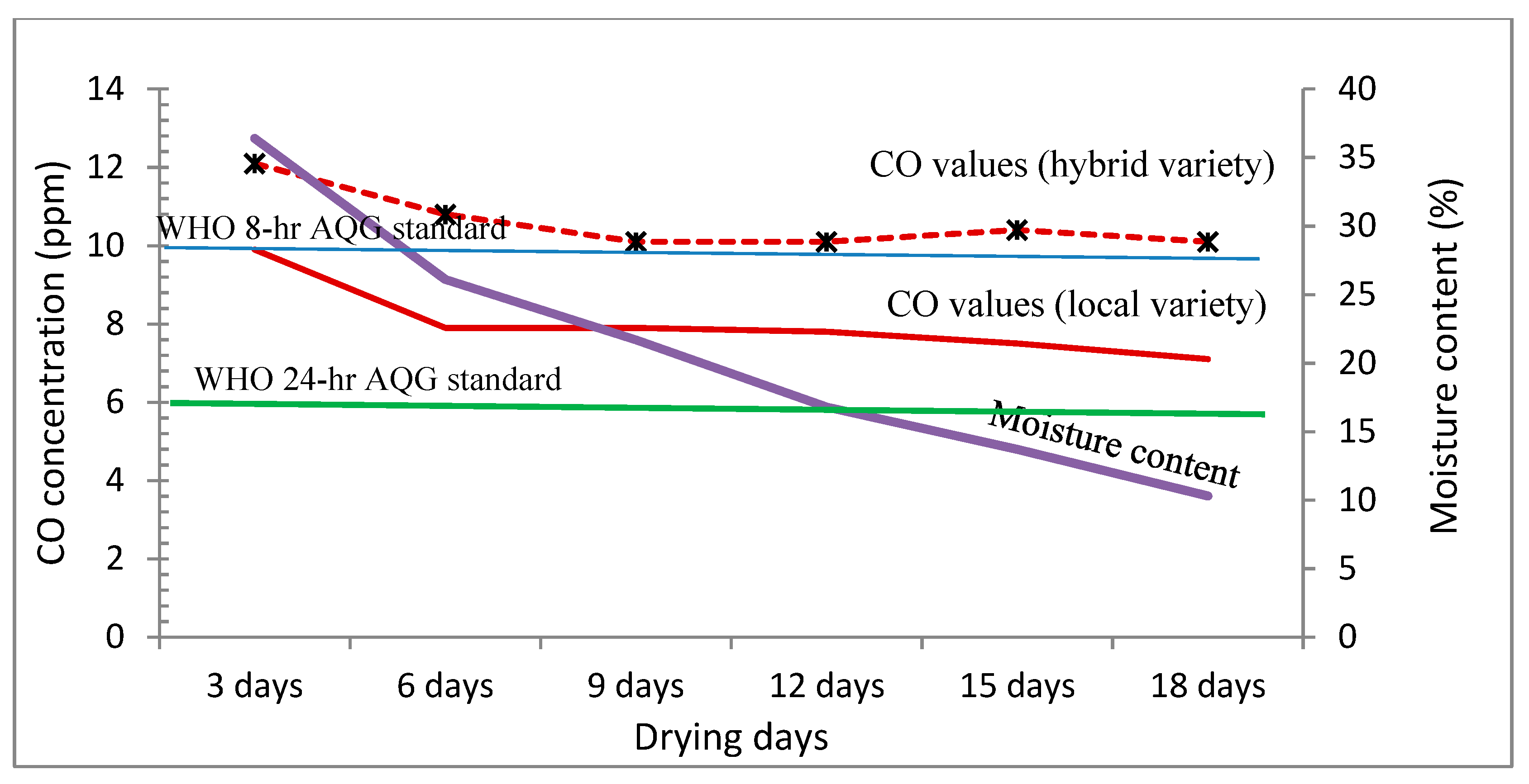

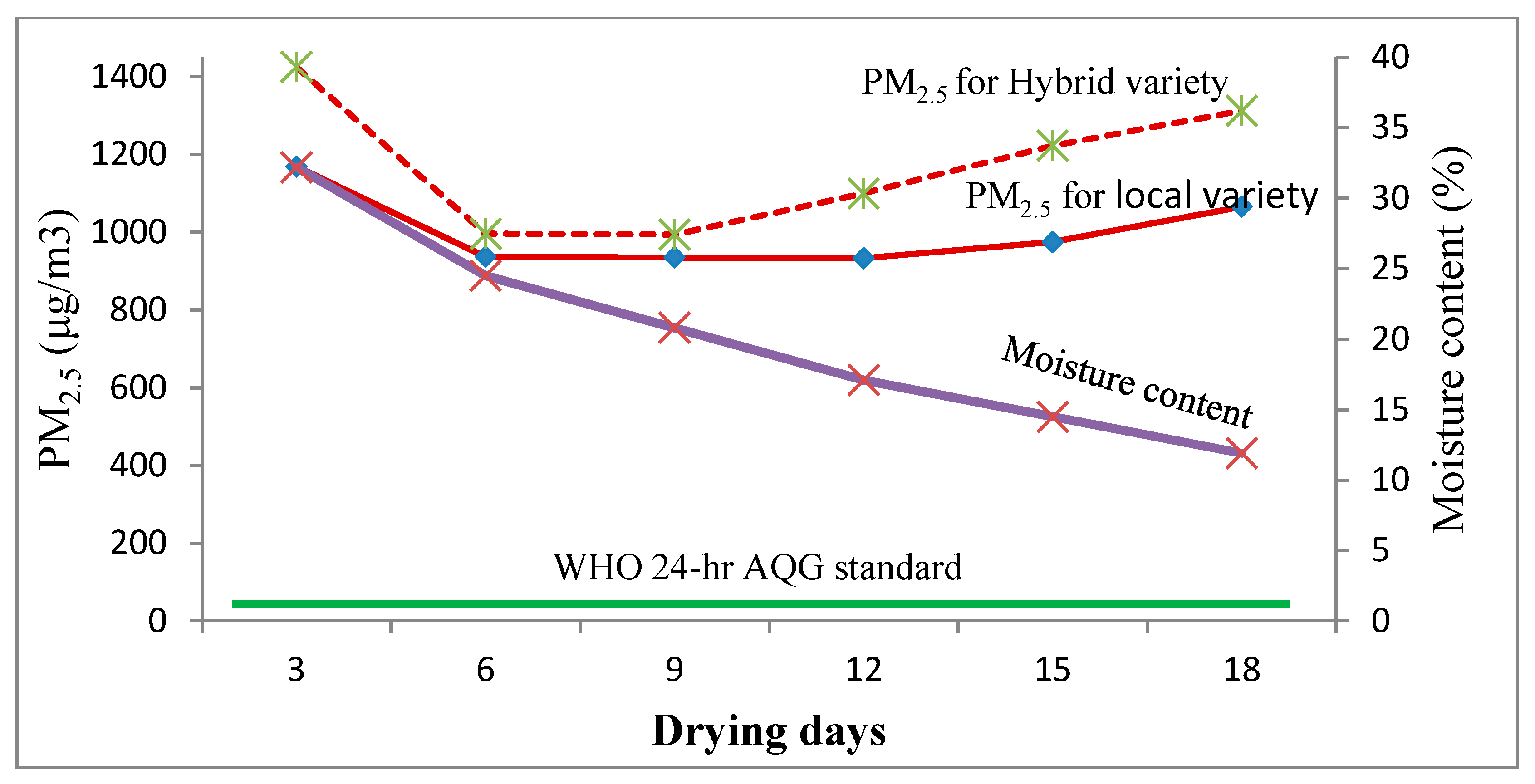

3.4. Moisture Content, Carbon Monoxide and Particulate Matter Emissions

4. Conclusions and Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- UNEP. Technologies for Converting Waste Agricultural Biomass to Energy; UNEP–United Nations Environment Programme: Nairobi, Kenya; Division of Technology, Industry and Economics International Environmental Technology Centre Osaka: Osaka, Japan, 2013; pp. 1–214. [Google Scholar]

- UNCTAD. National Green Export Review of Vanuatu: Copra-Coconut, Cocoa-Chocolate and Sandalwood, United Nations Conf. Trade Dev. (UNCTAD), 2016, United Nations Publ. Available online: https//unctad.org/en/PublicationsLibrary/ditcted2016d1_en.pdf (accessed on 5 May 2019).

- Rahamat, S.F.; Manan, W.N.H.W.A.; Jalaludin, A.A.; Abllah, Z. Enamel subsurface remineralization potential of virgin coconut oil, coconut milk and coconut water. Mater. Today Proc. 2019, 16, 2238–2244. [Google Scholar] [CrossRef]

- Lu, X.; Su, H.; Guo, J.; Tu, J.; Lei, Y.; Zeng, S.; Chen, Y.; Miao, S.; Zheng, B. Rheological properties and structural features of coconut milk emulsions stabilized with maize kernels and starch. Food Hydrocoll. 2019, 96, 385–395. [Google Scholar] [CrossRef]

- de Oliveira, E.; Quitete, F.T.; Bernardino, D.N.; Guarda, D.S.; Caramez, F.A.H. Maternal coconut oil intake on lactation programmes for endocannabinoid system dysfunction in adult offspring. Food Chem. Toxicol. 2019, 130, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Akpro, L.A. Phytochemical compounds, antioxidant activity and non-enzymatic browning of sugars extracted from the water of immature coconut (Cocos nucifera L.). Sci. Afr. 2019, 6, e00123. [Google Scholar] [CrossRef]

- Ding, K. A rapid and efficient hydrothermal conversion of coconut husk into formic acid and acetic acid. Process Biochem. 2018, 68, 131–135. [Google Scholar] [CrossRef]

- Anuar, M.F.; Fen, Y.W.; Zaid, M.H.M.; Matori, K.A.; Khaidir, R.E.M. Synthesis and structural properties of coconut husk as potential silica source. Results Phys. 2018, 11, 1–4. [Google Scholar] [CrossRef]

- Talat, M.; Mohan, S.; Dixit, V.; Singh, D.K.; Hasan, S.H.; Srivastava, O.N. Effective removal of fluoride from water by coconut husk activated carbon in fixed bed column: Experimental and breakthrough curves analysis. Groundw. Sustain. Dev. 2018, 7, 48–55. [Google Scholar] [CrossRef]

- Muharja, M.; Junianti, F.; Ranggina, D.; Nurtono, T.; Widjaja, A. An integrated green process: Subcritical water, enzymatic hydrolysis, and fermentation, for biohydrogen production from coconut husk. Bioresour. Technol. 2018, 249, 268–275. [Google Scholar] [CrossRef]

- Buamard, N.; Benjakul, S. Effect of ethanolic coconut husk extract and pre-emulsification on properties and stability of surimi gel fortified with seabass oil during refrigerated storage. LWT Food Sci. Technol. 2019, 108, 160–167. [Google Scholar] [CrossRef]

- Ram, M.; Mondal, M.K. Comparative study of native and impregnated coconut husk with pulp and paper industry waste water for fuel gas production. Energy 2018, 156, 122–131. [Google Scholar] [CrossRef]

- Narayanankutty, A.; Illam, S.P.; Raghavamenon, A.C. Health impacts of different edible oils prepared from coconut (Cocos nucifera): A comprehensive review. Trends Food Sci. Technol. 2018, 80, 1–7. [Google Scholar] [CrossRef]

- Talha, N.S.; Sulaiman, S. In situ transesterification of solid coconut waste in a packed bed reactor with CaO/PVA catalyst. Waste Manag. 2018, 78, 929–937. [Google Scholar] [CrossRef]

- GSS. Main Report. Ghana Living Standard Survey Round 6 (GLSS 6); Ghana Statistical Service (GSS): Accra, Ghana, 2014.

- Lee, K.; Park, E. Residential air quality in wood burning houses in Costa Rica. Proc. Indoor Air 2002, 4, 612–617. [Google Scholar]

- Peters, A.; Wichmann, H.E.; Tuch, T.; Heinrich, J.; Heyder, J. Respiratory effects are associated with the number of ultrafine particles. Am. J. Respir. Crit. Care Med. 1997, 155, 1376–1383. [Google Scholar] [CrossRef] [PubMed]

- Kelly, M.; Donnelly, R. The Humongous Book of Statistics Problems; Penguin Group: New York, NY, USA, 2009; ISBN 978-1-59257-865-8. [Google Scholar]

- Zafar, S. Energy Potential of Coconut Biomass, BioEnergy Consult. Available online: https//www.bioenergyconsult.com/coconut-biomass/ (accessed on 17 October 2019).

- ÖzyuǧUran, A.; Yaman, S. Prediction of calorific value of biomass from proximate analysis. Energy Procedia 2017, 107, 130–136. [Google Scholar] [CrossRef]

- Lu, Z. Feasibility study of gross calorific value, carbon content, volatile matter content and ash content of solid biomass fuel using laser-induced breakdown spectroscopy. Fuel 2019, 258, 116150. [Google Scholar] [CrossRef]

- Tang, J.P.; Lam, H.L.; Aziz, M.K.A.; Morad, N.A. Enhanced biomass characteristics index in palm biomass calorific value estimation. Appl. Therm. Eng. 2016, 105, 941–949. [Google Scholar] [CrossRef]

- Ozyuguran, A.; Akturk, A.; Yaman, S. Optimal use of condensed parameters of ultimate analysis to predict the calorific value of biomass. Fuel 2018, 214, 640–646. [Google Scholar] [CrossRef]

- Kaltschmitt, M.; Hartmann, H.; Hofbauer, H. Energie Aus Biomasse. Grundlagen, Techniken und Verfahren, 2nd ed.; Springer: Berlin, Germany, 2009. [Google Scholar]

- Wang, Q.; Sarkar, J. Pyrolysis behaviors of waste coconut shell and husk biomasses. Int. J. Energy Prod. Mgmt. 2018, 3, 34–43. [Google Scholar] [CrossRef]

- Zafar, S. Coconut Husk—Energy Potential of Coconut Biomass. BioEnergy Consult March 15. 2019. Available online: https://www.bioenergyconsult.com/tag/coconut-husk/ (accessed on 20 January 2020).

- Amoako, G.; Mensah-Amoah, P. Determination of calorific values of coconut shells and coconut husks. J. Mater. Sci. Res. Rev. 2018, 2, 1–7. [Google Scholar]

- Raghavan, K. Biofuels from Coconut. FACT, August 2010, pp. 1–107. Available online: https://energypedia.info/images/f/f9/EN-Biofuels_from_Coconuts-Krishna_Raghavan.pdf (accessed on 25 September 2019).

- Tooy, D.; Nelwan, L.; Pangkerego, F. Evaluation of biomass gasification using coconut husks in producing energy to generate small-scale electricity. In Proceedings of the International Conference on Artificial Intelligence, Energy and Manufacturing Engineering (ICAEME’2014), Kuala Lumpur, Malaysia, 9–10 June 2014; pp. 84–88. [Google Scholar] [CrossRef]

- Huda, N.; Rashid, M.; Hasfalina, C. Particulate emission from agricultural waste fired boiler. Int. J. Innov. Appl. Stud. 2014, 8, 1265–1295. [Google Scholar]

- Krajnc, N. Woodfuels Handbook; Food Agricultural Organization (FAO) of the United Nations: Pristina, Kosovo, 2015; ISBN 978-92-5-108728-2. Available online: https://roycestreeservice.com/wp-content/uploads/Wood-Fuels-Handbook.pdf (accessed on 20 January 2020).

- WHO. WHO Guidelines for Indoor Air Quality: Selected Pollutants; WHO Reg. Off. Eur.: Copenhagen, Denmark, 2010; ISBN 978928902134. [Google Scholar]

- WHO. Carbon Monoxide: Air Quality Guidelines. Chapter 5.5, 2nd ed.; Regional Office for Europe: Copenhagen, Denmark, 2000; Available online: http://www.euro.who.int/__data/assets/pdf_file/0020/123059/AQG2ndEd_5_5carbonmonoxide.PDF (accessed on 20 January 2020).

- Adam, T. W179 Wood Products Information—Moisture Content of ‘Seasoned’ Firewood; UT Extension Publications, The University of Tennessee Agricultural Extension Service: Knoxville, TN, USA, 2010. [Google Scholar]

- WHO. WHO Indoor Air Quality Guidelines: Household Fuel Combustion; Publ. World Heal. Organ. (WHO): Geneva, Switzerland, 2014; ISBN 9789241548878 (print), ISBN 9789241548885 (CD-ROM). [Google Scholar]

- Chen, J.; Li, C.; Ristovski, Z.; Milic, A.; Gu, Y.; Wang, S.; Hao, J.; Zhang, H.; He, C.; Guo, H.; et al. A review of biomass burning: Emissions and impacts on air quality, health and climate in China. Sci. Total Environ. 2017, 579, 1000–1034. [Google Scholar] [CrossRef] [PubMed]

| Whole Coconut Fruit | Husk | Shell | Copra and Juice | |

|---|---|---|---|---|

| Hybrid Coconut Variety | ||||

| Range (min–max) (kg) | 1.29–2.11 | 0.57–1.09 | 0.13–0.44 | 0.32–0.97 |

| Mean weight + Std. dev (kg) | 1.68 ± 0.21 | 0.80 ± 0.14 | 0.25 ± 0.08 | 0.53 ± 0.18 |

| Weight proportion (%) | 100 | 47.75 | 14.87 | 37.38 |

| Husk + shell weight (%) | 62.62 | |||

| Coefficient of variation (%) | 12.5 | 17.5 | 32 | 33.96 |

| Local Coconut Variety | ||||

| Range (min–max) (kg) | 1.51–3.53 | 0.69–2.08 | 0.20–0.56 | 0.34–1.55 |

| Mean weight + Std. dev (kg) | 2.23 ± 0.61 | 1.12 ± 0.33 | 0.34 ± 0.09 | 0.77 ± 0.29 |

| Weight proportion (%) | 100 | 50.16 | 15.44 | 34.41 |

| Husk + shell weight (%) | 65.60 | |||

| Coefficient of variation (%) | 26.35 | 29.46 | 26.47 | 37.66 |

| Sample size (N1 = hybrid variety; N2 = local variety) | N1 = 25; N2 = 25 | |||

| Readings | Mass of Sample (kg) | Calorific Value (MJ/kg) |

|---|---|---|

| Uncharred coconut waste of the local variety | ||

| 1 | 1.00 | 12.82 |

| 2 | 1.00 | 12.82 |

| 3 | 1.00 | 10.17 |

| 11.63 | ||

| Mean calorific value +/- Std. dev | 11.54 ± 1.32 MJ/kg | |

| Uncharred Coconut Waste of The Hybrid Variety | ||

| 1 | 1.00 | 9.394 |

| 2 | 1.00 | 9.762 |

| 3 | 1.00 | 10.044 |

| Mean calorific value +/- Std. dev | 9.73 ± 0.33 MJ/kg | |

| Samples | Average Calorific Value (MJ/kg) |

|---|---|

| Charred coconut waste (P < 2 mm) | 21.307 ± 1.75 |

| Charred coconut waste (P > 2 mm) | 17.471 ± 5.53 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obeng, G.Y.; Amoah, D.Y.; Opoku, R.; Sekyere, C.K.K.; Adjei, E.A.; Mensah, E. Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana. Energies 2020, 13, 2178. https://doi.org/10.3390/en13092178

Obeng GY, Amoah DY, Opoku R, Sekyere CKK, Adjei EA, Mensah E. Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana. Energies. 2020; 13(9):2178. https://doi.org/10.3390/en13092178

Chicago/Turabian StyleObeng, George Yaw, Derrick Yeboah Amoah, Richard Opoku, Charles K. K. Sekyere, Eunice Akyereko Adjei, and Ebenezer Mensah. 2020. "Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana" Energies 13, no. 9: 2178. https://doi.org/10.3390/en13092178

APA StyleObeng, G. Y., Amoah, D. Y., Opoku, R., Sekyere, C. K. K., Adjei, E. A., & Mensah, E. (2020). Coconut Wastes as Bioresource for Sustainable Energy: Quantifying Wastes, Calorific Values and Emissions in Ghana. Energies, 13(9), 2178. https://doi.org/10.3390/en13092178