Energy Savings Associated with the Use of Fly Ash and Nanoadditives in the Cement Composition

Abstract

:1. Introduction

- a clear improvement in the basic mechanical parameters of concrete composites, i.e., compressive and tensile strength and

- the reduction of natural resources and energy consumption required in the OPC production process.

2. Energy Consumption in Cement Production Process and Concepts of Its Reduction

- electricity consumption for production of clinker,

- electricity consumption for production of cement,

- specific consumption of electricity for clinker,

- specific consumption of electricity for cement,

- electricity consumption for other activities in the plant, and

- fuel consumption.

- 16 EJ of thermal energy and

- 484 TWh of electrical energy.

- increase of the energy efficiency in OPC production process due to the implementation of modern technologies for preparing raw materials for clinker burning while using the dry method and the resignation from the more energy-consuming and outdated wet method, e.g., [56],

- (1)

- Agricultural biomass residues.

- (2)

- Non-agricultural biomass residues.

- (3)

- Petroleum based wastes.

- (4)

- Miscellaneous wastes.

- (5)

- Chemical and hazardous wastes.

- (a)

- liquid waste fuels,

- (b)

- solid waste fuels, and

- (c)

- gaseous waste.

- (1)

- Industrial wastes.

- (2)

- Nano industrial wastes.

- (3)

- Agriculture farming waste.

- (4)

- Aquaculture farming wastes.

- (5)

- Natural minerals.

- (6)

- Dust and powders.

- reduction of FA landfills,

- reduction of extraction of natural resources,

- reduction of energy consumption needed to produce clinker, and

- reduction of CO2 emission produced during the production of clinker and cement.

- analysis of mechanical parameters of concrete composites made on quaternary binders with nanomaterials,

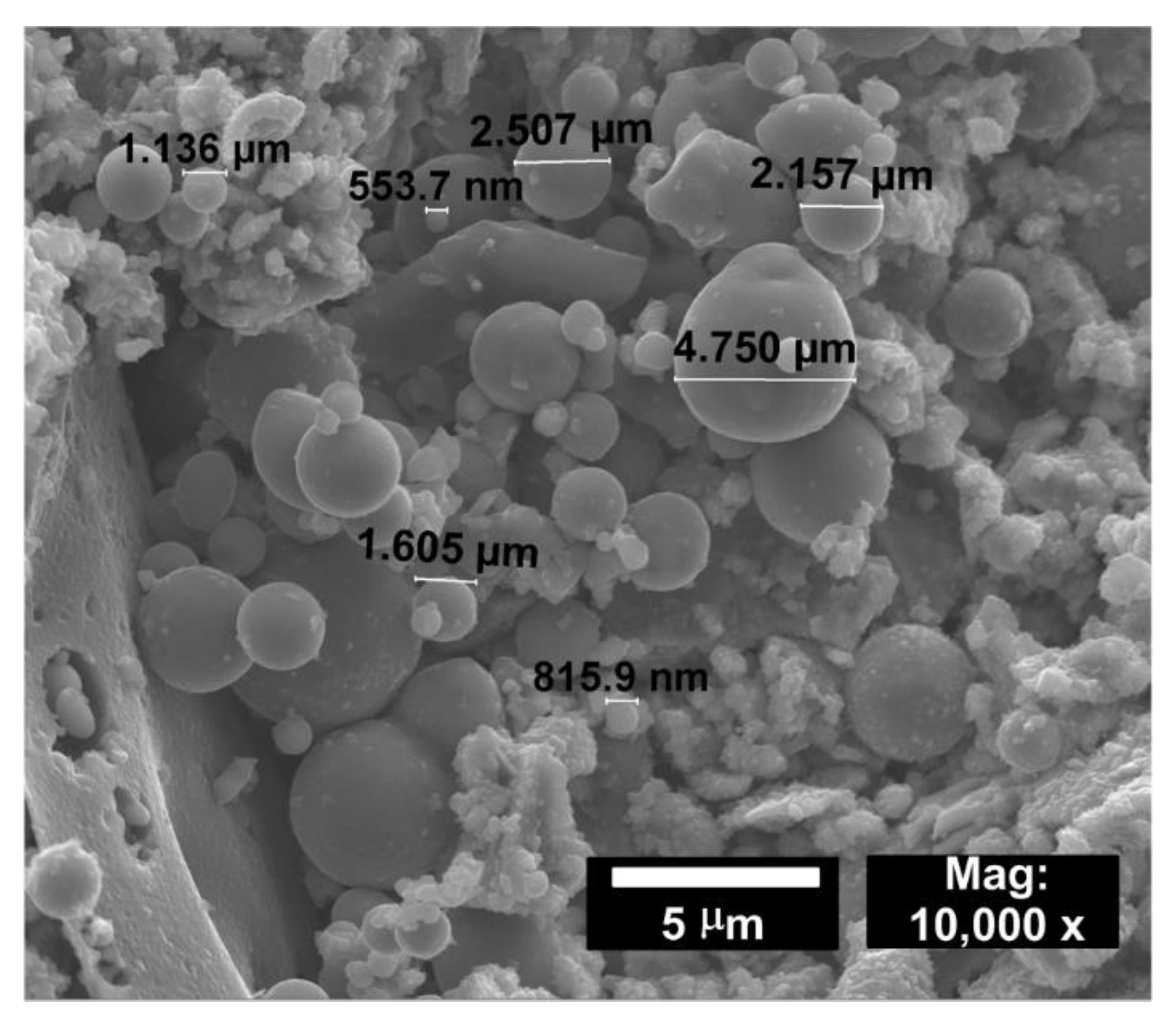

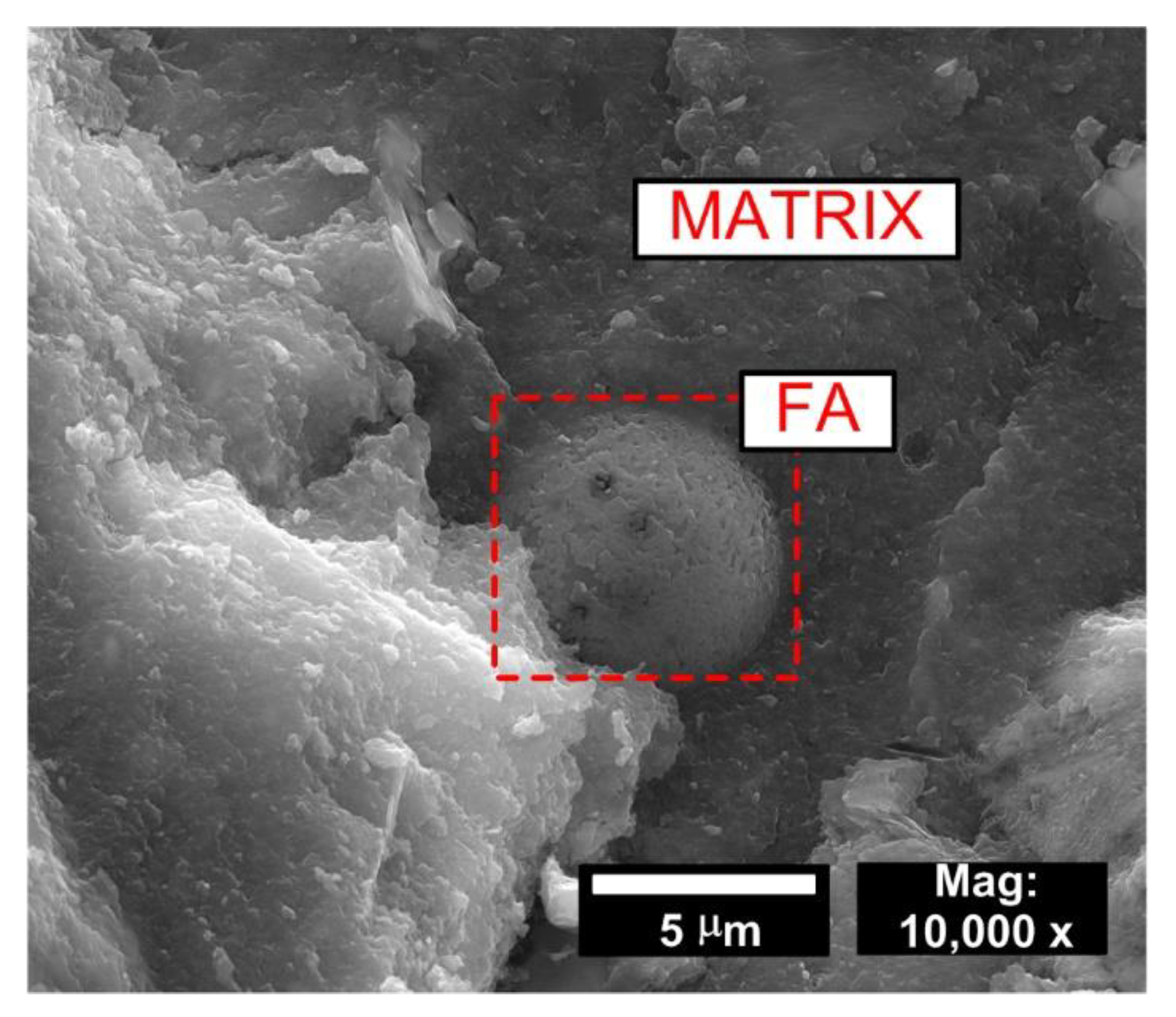

- microstructural examinations of the main concrete modifier, i.e., grains of fly ash, and

- assessment of the amount of thermal and electrical energy as well as raw materials that could be saved as a result of the proposed material modification.

3. Experimental Section

3.1. Materials

- ordinary Portland ceement CEM I 32.5 R from Chełm cement plant, with: the compressive strength equal to 23.3 MPa in the age of two days and 50 MPa after 28 days of curing, specific surface area 0.33 m2/g, specific gravity 3.11 g/cm3, mineralogical composition in accordance to the standard EN 197-1:2011- Cement - Part 1 [114],

- class F fly ash from local power plant is a result of energetic combustion of hard coal in the Puławy thermal-electric power station, with specific surface area 0.36 m2/g and specific gravity 2.14 g/cm3,

- non-condensed silica fume from Łaziska Ironworks, with specific surface area 1.40 m2/g and specific gravity 2.21 g/cm3,

- nanosilica Konasil K-200 from OCI Company Ltd., with specific surface area 200 m2/g and specific gravity 1.10 g/cm3,

- natural gravel aggregates of maximum grain size up to 8 mm, from Las Suwalski deposit, with specific density 2.65 g/cm3 and compressive strength 34 MPa,

- a pit sand from Markuszów deposit with: siliceous nature, a maximum diameter of 2 mm, specific density 2.60 g/cm3 and compressive strength 33 MPa,

- superplasticizer STACHEMENT 2750 based on polycarboxylates; 1.8% of binding material weight, with a very high liquefaction effect—which is retained for a longer period than with the common used superplasticizers,

- laboratory pipeline water free from contamination,

- In elaboration of recipes of concrete mixtures having the additives one took an assumptions that:

- the total amount of binding material in the concretes will be constant,

- the constant amount of the binder substitute at 10% and 5% was for SF and nS, respectively,

- a variable parameter was the addition of FA, which replaced the OPC in the amount of: 0%, 5% and 15%, and

- the same water-binder ratio at level 0.4 in all mixtures.

- REF—without any additives,

- FA-00+SF-10+nS-5;

- FA-5+SF-10+nS-5; and,

- FA-15+SF-10+nS-5.

3.2. Methods

- Lubrication the molds with an anti-adhesive agent.

- Preparation of a concrete mixture.

- Casting of cubes in plastic forms.

- Curing of the specimens after casting. This procedure lasted two days.

- Demoulding of cubes by using compressor.

- Curing of the specimens in a chamber with a moisture-saturated atmosphere. This procedure lasted two weeks.

- Removing specimens from the water.

- Final preparation of specimens for testing.

- raw materials for burning clinker,

- heat energy consumption, and

- electricity consumption.

4. Results and Discussions

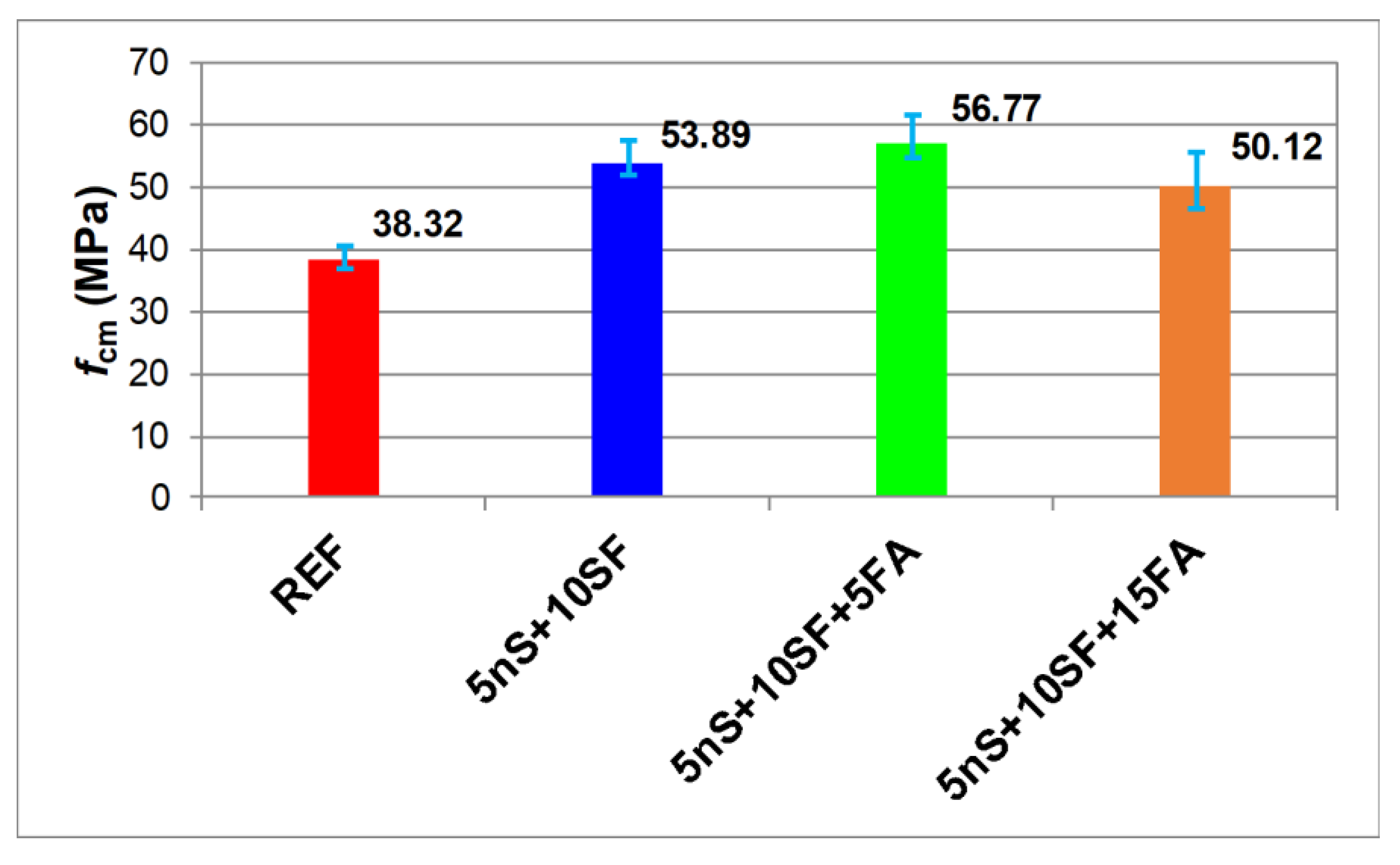

4.1. Mechanical Parameters

4.2. Microstructural Analysis

4.3. Energy Savings

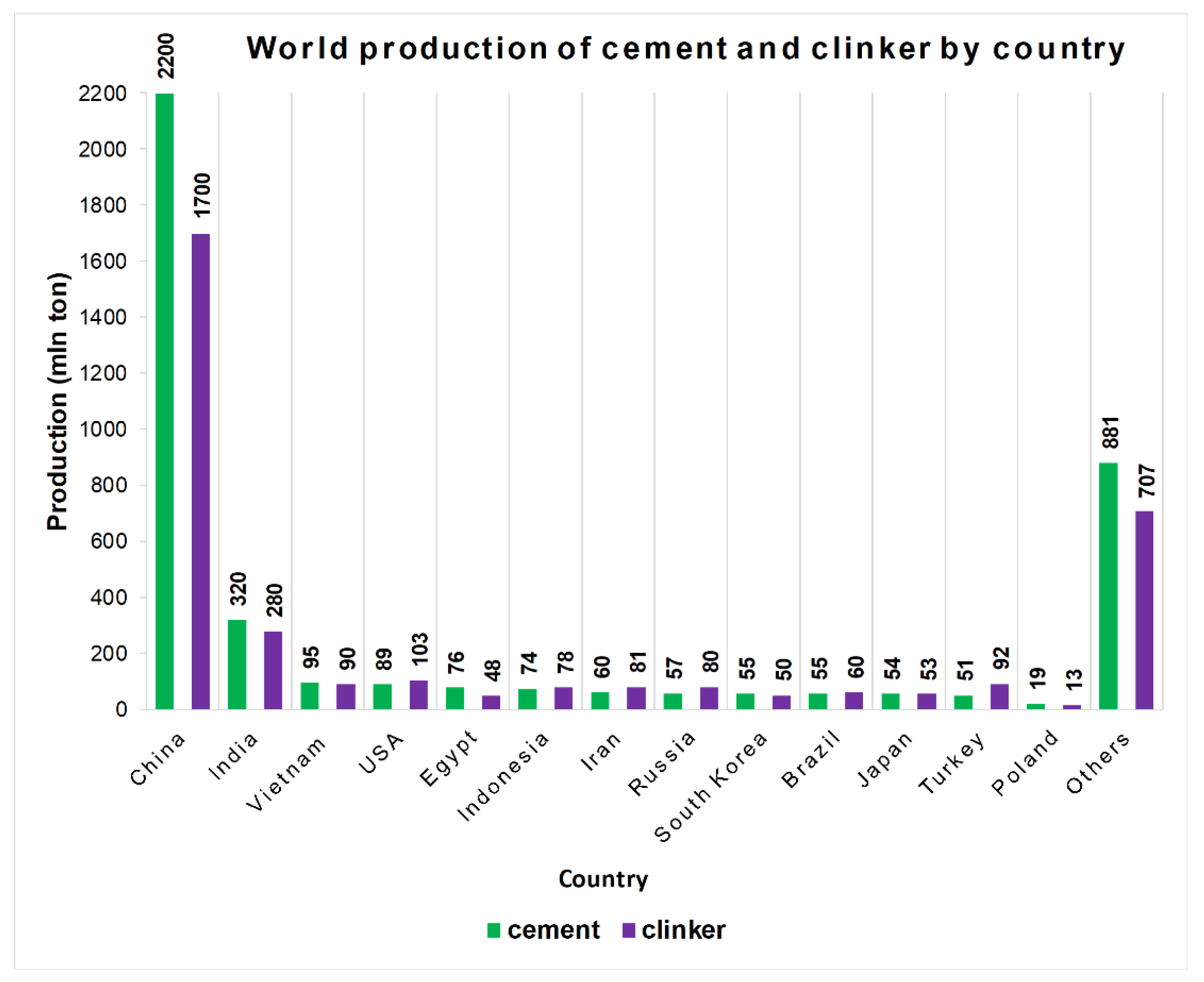

- cement production in the amount of 4.1 bn tons (Figure 1),

- consumption of natural resources in an amount of 6.97 bn tons [9],

- electricity consumption in the cement production process that occurs in China—484 TWh (Table 2), and

- heat energy consumption in the cement production process that occurs in China—16 EJ (Table 2).

- raw materials required for clinker burning by one- to two-billion tonnes,

- heat energy in the production of cement by 2.4 to 4.8 EJ, and,

- electricity in the production of cement by 73 to 145 TWh.

5. Conclusions

- (1)

- Concretes containing fly ash and nanoadditives in the cement composition have very favourable strength parameters—30% to over 40% in relation to the values obtained for concrete without additives.

- (2)

- The quaternary concrete containing: 80% OPC, 5% FA, 10% SF, and 5% nS have shown the best results of compressive strength and splitting tensile strength.

- (3)

- The worst mechanical parameters were characterized by concrete containing more content of FA additive in the concrete mix, i.e., 15% (70% OPC + 15% FA + 10% SF + 5% nS).

- (4)

- The results of compressive strength and splitting tensile strength are convergent qualitatively.

- (5)

- Replacing of cement in the composition of a concrete mix, with fly ash and nanoadditives, is advantageous from an ecological point of view. It primarily allows for reduction of electricity and heat energy in the processes of cement production.

- (6)

- Quaternary concrete containing fly ash and nanoadditives could be a good substitute of ordinary concretes. This material can promote the utilization of waste materials, such as fly ash and silica fume in construction.

Funding

Conflicts of Interest

References

- Malinowski, R.; Garfinkel, Y. Prehistory of concrete. Concr. Int. 1990, 13, 62–68. [Google Scholar]

- Bensted, J.; Coleman, N. Cement and concrete–7000 BC to 1900 AD. Cem. Wapno Beton 2003, 3, 134–142. [Google Scholar]

- Toma, I.O.; Petrescu, T.C.; Toma, A.M.; Mihai, P.; Petcu, O.A. Evolution of concrete from a traditional material to a next generation sustainable solution. CPI Concr. Plant Int. 2020, 2, 46–53. [Google Scholar]

- Aitcin, P.-C. Cements of yesterday and today: Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- USGS. Mineral Commodity Summaries, 2001, 2011, 2020; U.S. Geological Survey: Reston, VA, USA. Available online: https://www.usgs.gov/centers/nmic/mineral-commodity-summaries (accessed on 18 February 2020).

- Farfan, J.; Fasihi, M.; Breyer, C. Trends in the global cement industry and opportunities for long-term sustainable CCU potential for Power-to-X. J. Clean. Prod. 2019, 217, 821–835. [Google Scholar] [CrossRef]

- Gregg, J.S.; Andres, R.J.; Marland, G. China: Emissions pattern of the world leader in CO2 emissions from fossil fuel consumption and cement production. Geoph. Res. Lett. 2008, 35, L08806. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Wu, B.; Zhang, Z. Axial compressive behaviour of geopolymer recycled lump concrete. Materials 2020, 13, 533. [Google Scholar] [CrossRef] [Green Version]

- Rahman, A.; Rasul, M.G.; Khan, M.M.K.; Sharma, S. Impact of alternative fuels on the cement manufacturing plant performance: An overview. Proc. Eng. 2013, 56, 393–400. [Google Scholar] [CrossRef] [Green Version]

- Zou, F.; Shen, K.; Hu, C.; Wang, F.; Yang, L.; Hu, S. Effect of sodium sulfate and C-S-H seeds on the reaction of fly ash with different amorphous alumina contents. ACS Sustain. Chem. Eng. 2020, 8, 1659–1670. [Google Scholar] [CrossRef]

- Benehelal, E.; Zahedi, G.; Hashim, H. A novel design for green and economical cement manufacturing. J. Clean. Prod. 2012, 22, 60–66. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Szymańska-Chargot, M.; Łagód, G. Effect of eco-friendly cellulose nanocrystals on physical properties of cement mortars. Polymers 2019, 11, 2088. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thenepalili, T.; Ngoc, N.T.M.; Tuấn, L.; Son, T.H.; Hieu, H.H.; Thuy, D.T.N.; Thao, N.T.T.; Tam, D.T.T.; Huyen, N.; Van, T.T.; et al. Technological solutions for recycling ash slag from the Cao Ngan Coal Power Plant in Vietnam. Energies 2018, 11, 2018. [Google Scholar] [CrossRef] [Green Version]

- Haw, T.T.; Hart, F.; Rashidi, A.; Pasbakhsh, P. Sustainable cementitious composites reinforced with metakaolin and halloysite nanotubes for construction and building applications. Appl. Clay Sci. 2020, 188, 105533. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Ramachadran, D. Green concrete mix using solid waste and nanoparticles as alternatives–A review. Constr. Build. Mater. 2018, 162, 96–103. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. The fracture toughness the of concretes with fly ash (FA) additive. Constr. Build. Mater. 2017, 143, 444–454. [Google Scholar] [CrossRef]

- Ikponmwosa, E.E.; Ehikhuenmen, S.O.; Irene, K.K. Comparative study and empirical modelling of pulverized coconut shell, periwinkle shell and palm kernel shell as a pozzolans in concrete. Acta Polytech. 2019, 59, 560–572. [Google Scholar] [CrossRef]

- Cormos, A.-M.; Dragan, S.; Petrescu, L.; Sandu, V.; Cormos, C.-C. Techno-economic and environmental evaluations of decarbonized fossil-intensive industrial processes by reactive absorption & adsorption CO2 capture systems. Energies 2020, 13, 1268. [Google Scholar]

- Sanjuan, M.A.; Estevez, E.; Argiz, C. Carbon dioxide absorption by blast-furnace slag mortars in function of the curing intensity. Energies 2019, 12, 2346. [Google Scholar] [CrossRef] [Green Version]

- Voldsund, M.; Gardarsdottir, S.O.; Lena, E.D.; Pérez-Calvo, J.-F.; Jamali, A.; Berstad, D.; Fu, C.; Romano, M.; Roussanaly, S.; Anantharaman, R.; et al. Comparison of technologies for CO2 capture from cement production–Part 1: Technical evaluation. Energies 2019, 12, 559. [Google Scholar] [CrossRef] [Green Version]

- Gardarsdottir, S.O.; Lena, E.D.; Romano, M.; Roussanaly, S.; Voldsund, M.; Pérez-Calvo, J.-F.; Berstad, D.; Fu, C.; Anantharaman, R.; Sutter, D.; et al. Comparison of technologies for CO2 capture from cement production–Part 2: Cost analysis. Energies 2019, 12, 542. [Google Scholar] [CrossRef] [Green Version]

- Cao, C.; Liu, H.; Hou, Z.; Mehmood, F.; Liao, J.; Feng, W. A review of CO2 storage in view of safety and cost-effectiveness. Energies 2020, 13, 600. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.-H.; Kwon, Y.-H.; Moon, J. Quntitative analysis of CO2 uptake and mechanical properties of air lime-based materials. Energies 2019, 12, 2903. [Google Scholar] [CrossRef] [Green Version]

- Cascardi, A.; Micelli, F.; Aiello, M.A. FRCM-confined masonry columns: Experimental investigation on the effect of the inorganic matrix properties. Constr. Build. Mater. 2018, 186, 811–825. [Google Scholar] [CrossRef]

- Maddaloni, G.; Cascardi, A.; Balsamo, A.; Di Ludovico, M.; Micelli, F.; Aiello, M.A.; Prota, A. Confinement of full-scale masonry columns with FRCM systems. Key Eng. Mater. 2017, 747, 374–381. [Google Scholar] [CrossRef]

- Szeląg, M. Mechano-physical properties and microstructure of carbon nanotube reinforced cement paste after thermal load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef] [Green Version]

- Szeląg, M. Development of cracking patterns in modified cement matrix with microsilica. Materials 2018, 11, 1928. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Liang, K.; Gou, Y.; Wei, S.; Shen, W.; Cheng, F. Aluminum extraction technologies from high aluminum fly ash. Rev. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Dwivedi, A.; Jain, M.K. Fly ash—Waste management and overview: A review. Recent Res. Sci. Technol. 2014, 6, 30–35. [Google Scholar]

- Ye, J.; Zubair, M.; Wang, S.; Cai, Y.; Zhang, P. Power production waste. Water Environ. Res. 2019, 91, 1091–1096. [Google Scholar] [CrossRef] [Green Version]

- Kovacik, J.; Marsavina, L.; Linul, E. Poisson’s ratio of closed-cell aluminum foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. Estimation of the optimum content of fly ash in concrete composite based on the analysis of fracture toughness tests using various measuring systems. Constr. Build. Mater. 2019, 213, 142–155. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. A study of mode III fracture toughness in young and mature concrete with fly ash additive. Solid State Phenom. 2016, 254, 120–125. [Google Scholar] [CrossRef]

- Shen, Y.; Huang, J.; Ma, X.; Hao, F.; Lv, J. Experimental study on the free shrinkage of lightweight polymer concrete incorporating waste rubber powder and ceramsite. Compos. Struct. 2020, 242, 112152. [Google Scholar] [CrossRef]

- Song, H.; Fan, H.; Gao, H.-T.; Liu, J.-A.; Mou, H. Improving fly ash brightness with carbon and iron oxide removal. Recycling 2020, 5, 5. [Google Scholar] [CrossRef] [Green Version]

- Afkhami, B.; Akbarian, B.; Beheshti, N.; Kakaee, A.H.; Shabani, B. Energy consumption assessment in a cement production plant. Sustain. Energy Technol. Assess. 2015, 10, 84–89. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Mikulcic, H.; Vujanovic, M.; Markovska, N.; Filkoski, R.V.; Ban, M.; Duic, N. CO2 emission reduction in the cement industry. Chem. Eng. Trans. 2013, 35, 703–708. [Google Scholar]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Deja, J.; Uliasz-Bochenczyk, A.; Mokrzycki, E. CO2 emissions from Polish cement industry. Int. J. Greenh. Gas Control 2010, 4, 583–588. [Google Scholar] [CrossRef]

- Gielen, D.; Taylor, P. Indicators for industrial energy efficiency in India. Energy 2009, 34, 962–969. [Google Scholar] [CrossRef]

- Mikulcic, H.; Vujanovic, M.; Duic, N. Reducing the CO2 emissions in Croatian cement industry. Appl. Energy Prod. 2013, 101, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Atmaca, A.; Yumrutas, R. Analysis of the parameters effecting energy consumption of a rotary kiln in cement industry. Appl. Therm. Eng. 2014, 66, 435–444. [Google Scholar] [CrossRef]

- Radwan, A.M. Different possible ways for saving energy in the cement production. Adv. Appl. Sci. Res. 2012, 3, 1162–1174. [Google Scholar]

- Mikulcic, H.; Vujanovic, M.; Duic, N. Improving the sustainability of cement production by using numerical simulation of limestone thermal degradation and pulverized coal combustion in a cement calciner. J. Clean. Prod. 2015, 88, 262–271. [Google Scholar] [CrossRef] [Green Version]

- Grillo Reno, M.L.; Ferrari Alves, L.F.; Escobar Palacio, J.C.; Souza, L.; Centeno González, F.O.; Pacheco Torres, P.J. Environmental analyze of cement production with application of wastes. Engevista 2017, 19, 916–930. [Google Scholar] [CrossRef]

- Ali, N.; Jaffar, A.; Anwer, M.; Khurram, S.; Alwi, K.; Muhammad; Anjum, M.N.; Ali, N.; Muhammad, R.; Raja; et al. The greenhouse gas emissions produced by cement production and its impact on environment: A review of global cement processing. Int. J. Res. 2015, 2, 488–500. [Google Scholar]

- Benehelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Golewski, G.; Sadowski, T. Fracture toughness at shear (mode II) of concretes made of natural and broken aggregates. Brittle Matrix Compos. 2006, 8, 537–546. [Google Scholar]

- Golewski, G.L.; Sadowski, T. Macroscopic evaluation of fracture processes in fly ash concrete. Solid State Phenom. 2016, 254, 188–193. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Experimental investigation and numerical modeling fracture processes in fly ash concrete at early age. Solid State Phenom. 2012, 188, 158–163. [Google Scholar] [CrossRef]

- Jin, R.; Chen, Q.; Soboyejo, A. Survey of the current status of sustainable concrete production in the U.S. Resour. Conser. Recycl. 2015, 105, 148–159. [Google Scholar] [CrossRef]

- Imounga, H.M.; Bastidas-Arteaga, E.; Pitti, R.M.; Ango, S.E.; Wang, X.-H. Bayesian assessment of the effects of cyclic lods on the chloride ingress process into reinforced concrete. Appl. Sci. 2020, 10, 2040. [Google Scholar] [CrossRef] [Green Version]

- Atsonios, K.; Grammelis, P.; Antiohos, S.K.; Nikolopoulos, N.; Kakaras, E.M. Interation of calcium looping technology in existing cement plant for CO2 capture: Process modeling and technical considerations. Fuel 2015, 153, 210–223. [Google Scholar] [CrossRef]

- Mikulcic, H.; Vujanovic, M.; Fidaros, D.K.; Priesching, P.; Minic, I.; Tatschl, R.; Duic, N.; Stefanović, G. The application of CFD modelling to support the reduction of CO2 emissions in cement industry. Energy 2012, 45, 264–473. [Google Scholar] [CrossRef] [Green Version]

- Mokrzycki, E.; Uliasz-Bocheńczyk, A. Alternative fuels for the cement industry. Appl. Energy 2003, 74, 95–100. [Google Scholar] [CrossRef]

- Mokrzycki, E.; Uliasz-Bocheńczyk, A.; Sarna, M. Use of alternative fuels in the Polish cement industry. Appl. Energy 2003, 74, 101–111. [Google Scholar] [CrossRef]

- Kääntee, U.; Zevenhoven, R.; Backman, R.; Hupa, M. Cement manufacturing using alternative fuels and the advantages of process modelling. Fuel Process. Technol. 2004, 85, 293–301. [Google Scholar] [CrossRef]

- Chatziaras, N.; Psomopoulos, C.S.; Themelis, N.J. Use of alternative fuels in cement industry. In Proceedings of the 12th International Conference on Protection and Restoration of the Environment, Skiathos Island, Greece, 29 June–3 July 2014; pp. 521–529. [Google Scholar]

- Mikulcic, H.; Klemes, J.J.; Vujanovic, M.; Urbaniec, K.; Duic, N. Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of fracture toughness in concretes containing siliceous fly ash during mode III loading. Struct. Eng. Mech. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of fly ash addition on the fracture toughness of plain concrete at third model of fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. Measurement of fracture mechanics parameters of concrete containing fly ash thanks to use of Digital Image Correlation (DIC) method. Measurement 2019, 135, 96–105. [Google Scholar] [CrossRef]

- Malhotra, V.M. Reducing CO2 emissions. Concr. Int. 2006, 28, 42–45. [Google Scholar]

- Li, H.; Sun, H.; Tian, J.; Yang, Q.; Wan, Q. Mechanical and ultraconic testing of self-compacting concrete. Energies 2019, 12, 2187. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Sun, H.; Zhang, W.; Gou, H.; Yang, Q. Study on mechanical properties of self-compacting concrete and its filled in-line multi-cavity steel tube bundle shear wall. Energies 2019, 12, 3466. [Google Scholar] [CrossRef] [Green Version]

- Parzenny, H.R.; Róg, L. Distribution of some ecotoxic elements in fuel and solid combustion residues in Poland. Energies 2020, 13, 1131. [Google Scholar] [CrossRef] [Green Version]

- Aprianti, S.E. A huge number of artificial waste material can be supplementary cementitious material (SCM) for concrete production—A review part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Golewski, G.L. Studies of natural radioactivity of concrete with siliceous fly ash addition. Cem. Wapno Beton 2015, 2, 106–114. [Google Scholar]

- Xie, T.; Visitin, P. A unified approach for mix design of concrete containing supplementary cementitious materials based on reactivity moduli. J. Clean. Prod. 2018, 203, 68–82. [Google Scholar] [CrossRef]

- Xie, T.; Yang, G.; Zhao, X.; Xu, J.; Fang, C. A unified model for predicting the compressive strength of recycled aggregate concrete containing supplementary cementitious materials. J. Clean. Prod. 2020, 251, 119752. [Google Scholar] [CrossRef]

- Carevi, I.; Serdar, M.; Stirmer, N.; Ukrainczyk, N. Preliminary screening of wood biomass ashes for partial resources replacements in cementitious materials. J. Clean. Prod. 2019, 229, 1054–1064. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Golewski, G.L. An assessment of microcracks in the Interfacial Transition Zone of durable concrete composites with fly ash additives. Compos. Struct. 2018, 200, 515–520. [Google Scholar] [CrossRef]

- Sobolev, K.; Ferrada-Gutierrez, M. How nanotechnology can change the concrete world, Part 1. Am. Ceram. Soc. Bull. 2005, 84, 14–17. [Google Scholar]

- Horszczaruk, E. Role of nanosiloca in the formation of the properties of cement composites, state of the art. Cem. Wapno Beton. 2018, 6, 487–495. [Google Scholar]

- Raki, L.; Beaudoin, J.; Aizadeh, R.; Makar, J.; Sato, T. Cement and concrete nanoscience and nanotechnology. Materials 2010, 3, 918–942. [Google Scholar] [CrossRef] [Green Version]

- Szostak, B.; Golewski, G.L. Effect of nano admixture of CSH on selected strength parameters of concrete including fly ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, L. The development of nanoalumina-based cement mortars for overlay applications in concrete floors. Materials 2019, 12, 3465. [Google Scholar] [CrossRef] [Green Version]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Li, Y.; Fu, T.; Wang, R.; Li, Y. An assessment of microcracks in the interfacial transition zone of recycled concrete aggregates cured by CO2. Constr. Build. Mater. 2020, 236, 117543. [Google Scholar] [CrossRef]

- Zhang, R.; Guo, F.; Xia, Y.; Tan, J.; Xing, Y.; Gui, X. Recovering unburned carbon from gasification fly ash using saline water. Waste Manag. 2019, 98, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Li, Q.; Chen, Y.; Shi, Y.; Ling, Y.-F. Durability of steel fiber-reinforced concrete containing SiO2 nano-particles. Materials 2019, 12, 2184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics–Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Effect of silica fume and siliceous fly ash addition on the fracture toughness of plain concrete in mode I. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012065. [Google Scholar] [CrossRef]

- Blissett, R.S.; Rowson, N.A. A review of the multi-component utilization of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Potential of siliceous fly ash and silica fume as a substitute of binder in cementitious concrete. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef] [Green Version]

- Zeng, S.; Wang, J. Characterization of mechanical and electric properties of geopolymers synthesized using four locally available fly ashes. Constr. Build. Mater. 2016, 121, 386–399. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. The influence of microcrack width on the mechanical parameters in concrete with the addition of fly ash: Consideration of technological and economical benefit. Constr. Build. Mater. 2019, 197, 849–861. [Google Scholar] [CrossRef]

- Golewski, G.L. Generalized fracture toughness and compressive strength of sustainable concrete including low calcium fly ash. Materials 2017, 10, 1393. [Google Scholar] [CrossRef] [Green Version]

- Golewski, G.L. An analysis of fracture toughness in concrete with fly ash addition, considering all models of cracking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012029. [Google Scholar] [CrossRef] [Green Version]

- Fuzail Hashmi, A.; Shariq, M.; Baqi, A.; Haq, M. Optimization of fly ash concrete mix–A solution for sustainable development. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of curing time on the fracture toughness of fly ash concrete composites. Compos. Struct. 2018, 185, 105–112. [Google Scholar] [CrossRef]

- Zhang, P.; Wan, J.; Wang, K.; Li, Q. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state-of-the-art review. Constr. Build. Mater. 2017, 148, 648–658. [Google Scholar] [CrossRef]

- Ling, Y.; Zhang, P.; Wang, J.; Chen, Y. Effect of PVA fiber on mechanical properties of cementitious composite with and without nano-SiO2. Constr. Build. Mater. 2019, 229, 117068. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, J.-X.; Dai, X.-B.; Zhang, T.-H. Fracture behavior of fly ash concrete containing silica fume. Struct. Eng. Mech. 2016, 59, 261–275. [Google Scholar] [CrossRef]

- Biricik, H.; Sarier, N. Comparative study of the characteristics of nanosilica-, silica fume- and fly ash-incorporated cement mortars. Mater. Res. 2014, 17, 570–582. [Google Scholar] [CrossRef]

- More, S.; Londhe, R.S. Experimental analysis of quaternary cement binder. Recent Trends Civ. Eng. Technol. 2020, 10, 12–17. [Google Scholar]

- Pipilikaki, P.; Katsioti, M. Study of the hydration process of quaternary blended cements and durability of the produced mortars and concretes. Constr. Build. Mater. 2009, 23, 2246–2250. [Google Scholar] [CrossRef]

- El-Chabib, H.; Ibrahim, A. The performance of high-strength flowable concrete made with binary, ternary, or quaternary binder in hot climate. Constr. Build. Mater. 2013, 47, 245–253. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Sharma, A.K.; Kaushik, S.K. Study on quaternary micro-structure, strength, durability considering the influence of multi-factors. Constr. Build. Mater. 2017, 139, 447–457. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Kaushik, S.K. Setting time and standard consistency of quaternary binders: The influence of cementitious material addition and mixing. Int. J. Sustain. Built Environ. 2017, 6, 30–36. [Google Scholar] [CrossRef] [Green Version]

- Dave, N.; Misra, A.K.; Srivastava, A.; Kaushik, S.K. Experimental analysis of strength and durability properties of quaternary cement binder and mortar. Constr. Build. Mater. 2016, 107, 117–124. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Sharma, A.K.; Kaushik, S.K. Green quaternary concrete composites: Characterization and evaluation of the mechanical properties. Struct. Concr. 2018, 19, 1280–1289. [Google Scholar] [CrossRef]

- Dhrangadharia, S.; Vishwakarma, S.; Kumar, A.; Saran, B. Effect of quaternary binders systems on mechanical properties of concrete. Int. J. Eng. Sci. Res. 2018, 6, 1–10. [Google Scholar]

- Manju, R.; Premalatha, J. Binary, ternary and quaternary effect of pozzolanic binders and filler materials on the properties of self compacting concrete (SCC). Int. J. Adv. Eng. Technol. 2016, 7, 674–683. [Google Scholar]

- Manju, R.; Premalatha, J. Binary, ternary and quaternary effect of fillers on fresh and hardened properties of self compacting concrete (SCC). Int. J. Adv. Inf. Sci. Technol. 2014, 21, 12–19. [Google Scholar]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C. Development of a zero-cement binder using slag, fly ash, and rice husk ash with chemical activator. Adv. Mater. Sci. Eng. 2015, 247065. [Google Scholar] [CrossRef] [Green Version]

- Patel, N.; Dave, R.; Modi, S.; Joshi, C.; Vora, S.; Solanki, M. Effect of binary and quaternary blends on compressive strength. Int. J. Civ. Eng. Technol. 2016, 7, 242–246. [Google Scholar]

- Bassuoni, M.T.; Nehdi, M.L. Resistance of self-consolidating concrete of sulfuric acid attack with consecutive pH reduction. Cem. Concr. Res. 2007, 37, 1070–1084. [Google Scholar] [CrossRef]

- Chinnaraju, K.; Subramanian, K.; Senthil Kumar, S.R.R. Strength properties of HPC using binary, ternary and quaternary cementitious blends. Struct. Concr. 2010, 11, 191–198. [Google Scholar] [CrossRef]

- EN 197-1:2011. Cement–Part 1: Composition, Specifications and Conformity Criteria For Common Cements; NSAI Standard: Dublin, Ireland, 2011. [Google Scholar]

- EN 12390-3:2011+AC:2012. Testing Hardened Concrete–Part 3: Compressive Strength of Test Specimens; British Standards Institution (BSI): London, UK, 2012. [Google Scholar]

- EN 12390-6:2009. Testing Hardened Concrete–Part 6: Tensile Splitting Strenght of Test Specimens; British Standards Institution (BSI): London, UK, 2009. [Google Scholar]

- Vassilev, S.V.; Vassileva, C.G. Methods for characterization of composition of fly ashes from coal-fired power stations: A critical overview. Energy Fuels 2005, 19, 1084–1098. [Google Scholar] [CrossRef]

- Bicer, A. Effect of production temperature on thermal and mechanical properties of polystyrene-fly ash composites. Adv. Compos. Lett. 2020, 29, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Sadowski, T.; Golewski, G.L. A failure analysis of concrete composites incorporating fly ash during torsional loading. Compos. Struct. 2018, 183, 527–535. [Google Scholar] [CrossRef]

- Golewski, G.L. A novel specific requirements for materials used in reinforced concrete composites subjected to dynamic loads. Compos. Struct. 2019, 223, 110939. [Google Scholar] [CrossRef]

- Golewski, G.L. A new principles for implementation and operation of foundations for machines: A review of recent advances. Struct. Eng. Mech. 2019, 71, 317–327. [Google Scholar]

- Niewiadomski, P.; Hoła, J.; Ćwirzeń, A. Study on properties of self-compacting concrete modified with nanoparticles. Arch. Civ. Mech. Eng. 2018, 18, 877–886. [Google Scholar] [CrossRef]

| Type of Energy | Type of Method | |

|---|---|---|

| Dry Process | Wet Process | |

| Thermal energy consumption (GJ/ton clinker) | 4.60 | 5.86–6.28 |

| Total electricity required (kWh/ton clinker) | 130 | 149 |

| Country | Type of SEC | |

|---|---|---|

| Electrical SEC (kWh/ton) | Thermal SEC (GJ/ton) | |

| India | 88 | 3.00 |

| China | 118 | 4.00 |

| United States | 141 | 4.60 |

| World best | 65 | 2.72 |

| Mix | The Values of Analysed Parameters Compared to Concrete REF (%) | |

|---|---|---|

| fcm | fctm | |

| REF | 100 | 100 |

| FA-00+SF-10+Ns-5 | 140.6 | 138.6 |

| FA-5+SF-10+Ns-5 | 148.2 | 146.9 |

| FA-15+SF-10+Ns-5 | 130.8 | 129.7 |

| Analysed Product | Reduction for Consumption of Product for Different Series of Concrete | Unit | |||

|---|---|---|---|---|---|

| REF | FA-00+SF-10+Ns-5 | FA-5+SF-10+Ns-5 | FA-15+SF-10+Ns-5 | ||

| Cement | 0 | 615,000,000 | 820,000,000 | 1,230,000,000 | (ton) |

| Raw materials for burning clinker | 0 | 104,550,000 | 1,394,000,000 | 2,091,000,000 | (ton) |

| Electricity | 0 | 72.6 | 96.8 | 145.2 | (TWh) |

| Heat energy | 0 | 2.4 | 3.2 | 4.8 | (EJ) |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golewski, G.L. Energy Savings Associated with the Use of Fly Ash and Nanoadditives in the Cement Composition. Energies 2020, 13, 2184. https://doi.org/10.3390/en13092184

Golewski GL. Energy Savings Associated with the Use of Fly Ash and Nanoadditives in the Cement Composition. Energies. 2020; 13(9):2184. https://doi.org/10.3390/en13092184

Chicago/Turabian StyleGolewski, Grzegorz Ludwik. 2020. "Energy Savings Associated with the Use of Fly Ash and Nanoadditives in the Cement Composition" Energies 13, no. 9: 2184. https://doi.org/10.3390/en13092184

APA StyleGolewski, G. L. (2020). Energy Savings Associated with the Use of Fly Ash and Nanoadditives in the Cement Composition. Energies, 13(9), 2184. https://doi.org/10.3390/en13092184