The Key Factors That Determine the Economically Viable, Horizontal Hydrofractured Gas Wells in Mudrocks

Abstract

:1. Significance Statement

2. Introduction

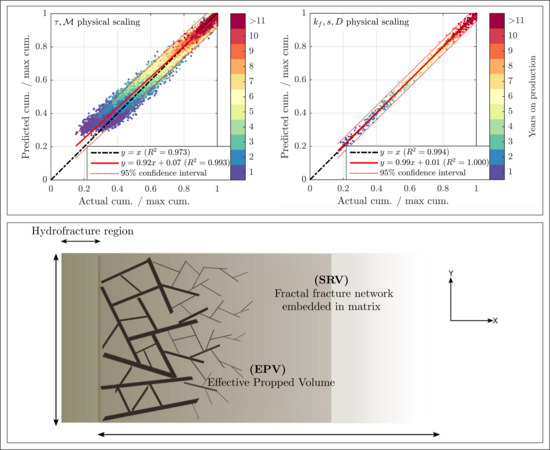

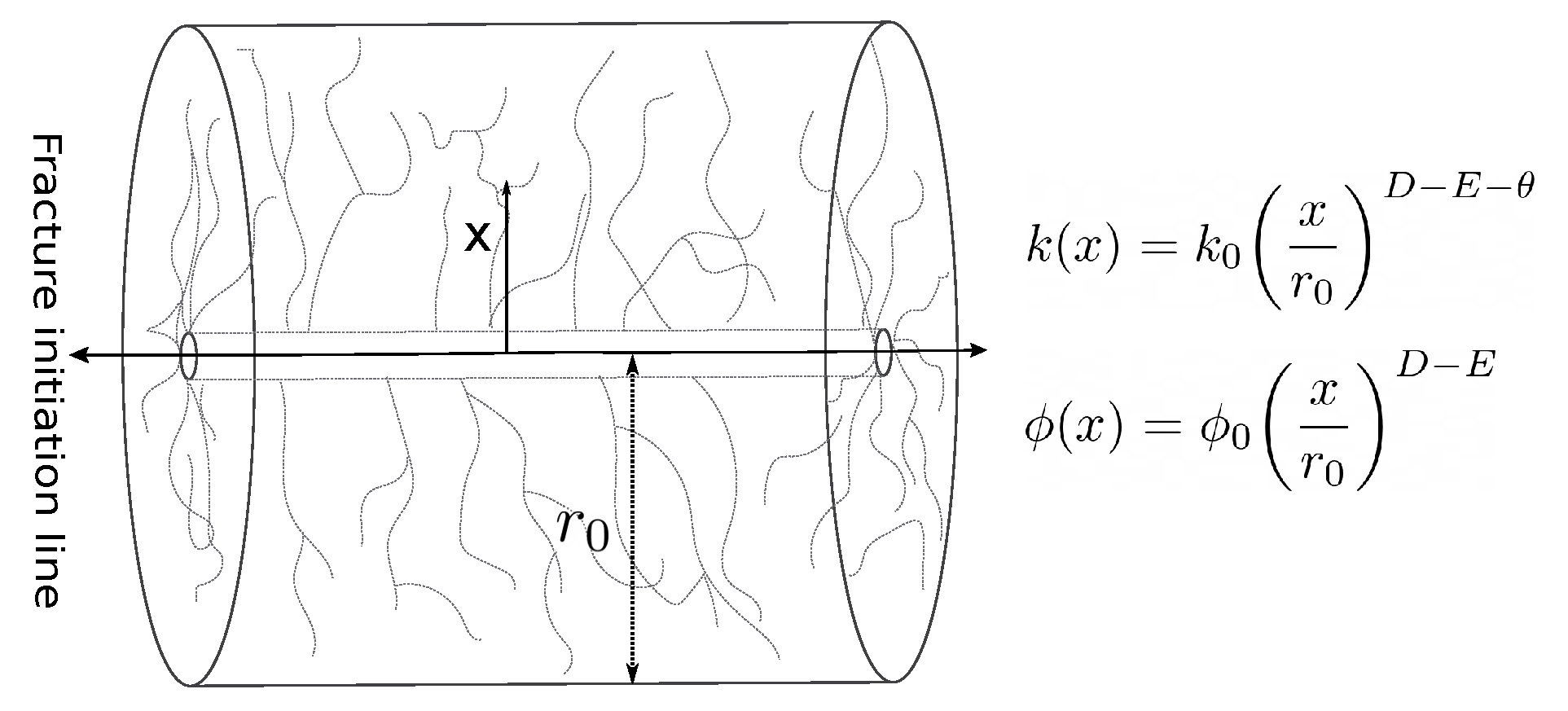

- SRV is composed of a fracture network and organic matrix.

- SRV is nonuniform because of the power law distribution of properties of the fracture network.

- The single phase, compressible, and isothermal flow of gas is from right to left (see Figure 5b).

- The fracture permeability is 2–3 orders of magnitude higher than the matrix permeability.

- The matrix is disconnected from the hydrofracture and the wellbore, and only transfers gas into the fracture network.

- Gas flow from the fracture network is parallel to the hydrofracture plane (x-y plane).

- Depletion occurs only through the SRV, and the boundary flow is neglected.

3. Results

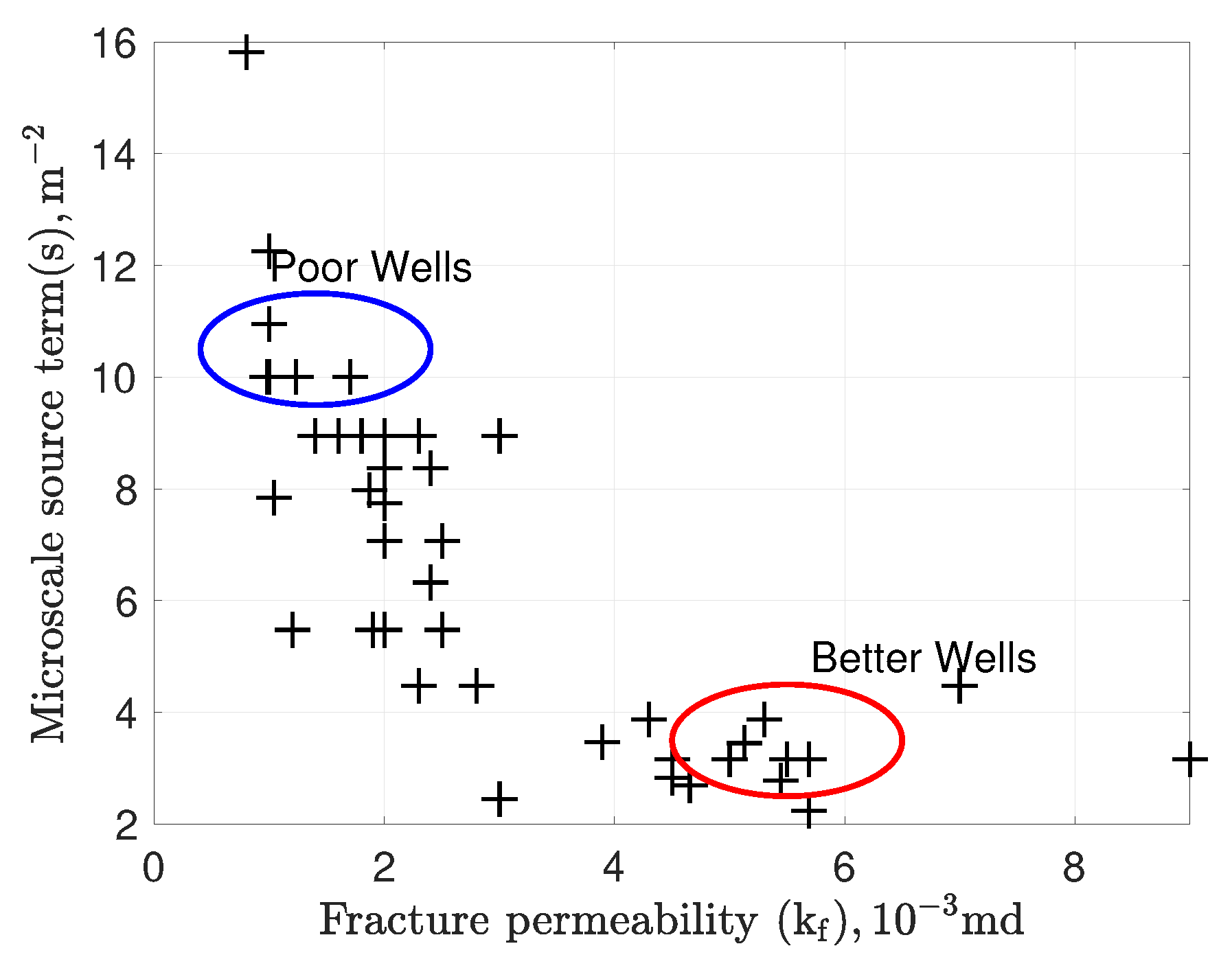

3.1. Relation between the Optimized Parameters: Fracture Permeability and Microscale Source Terms

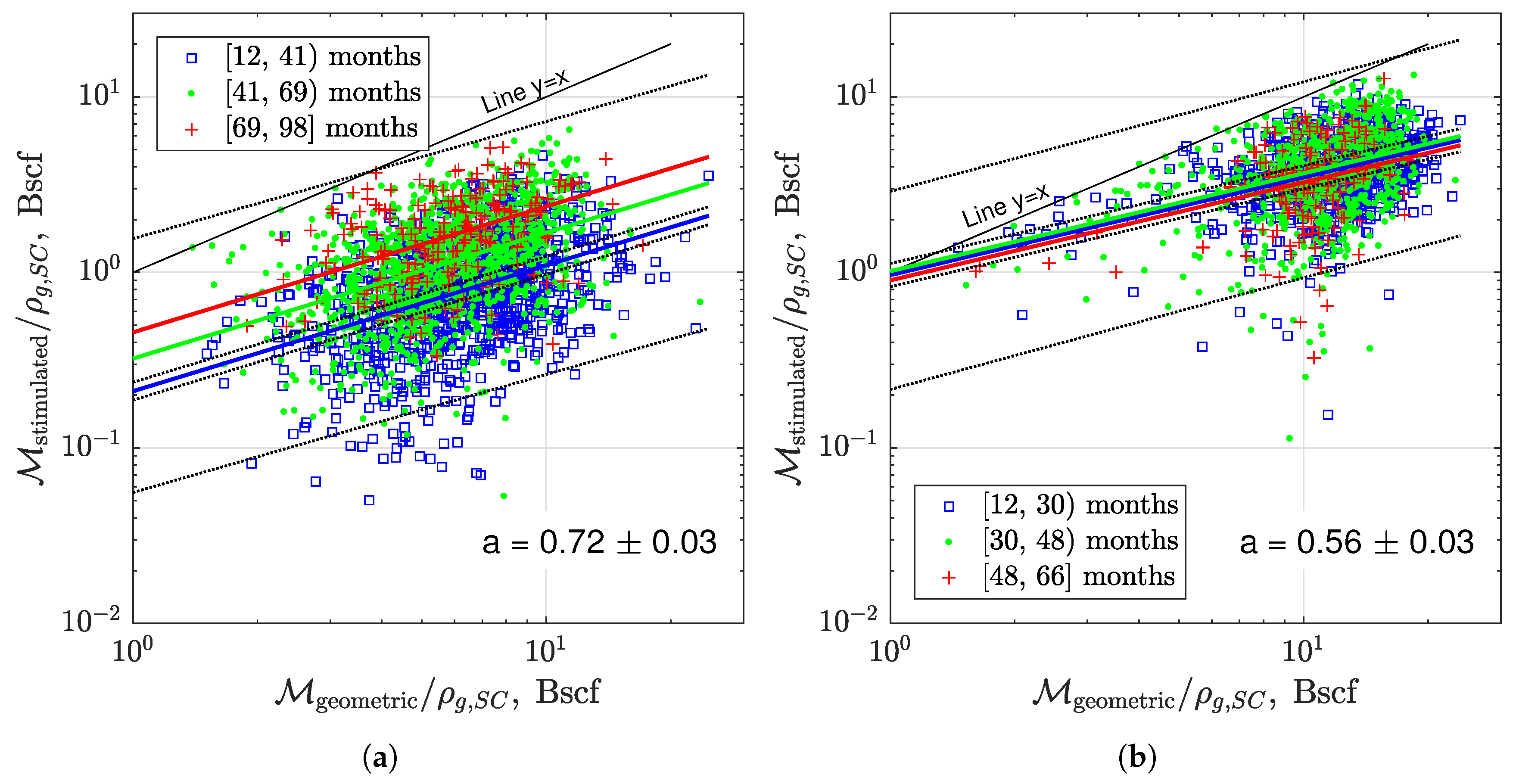

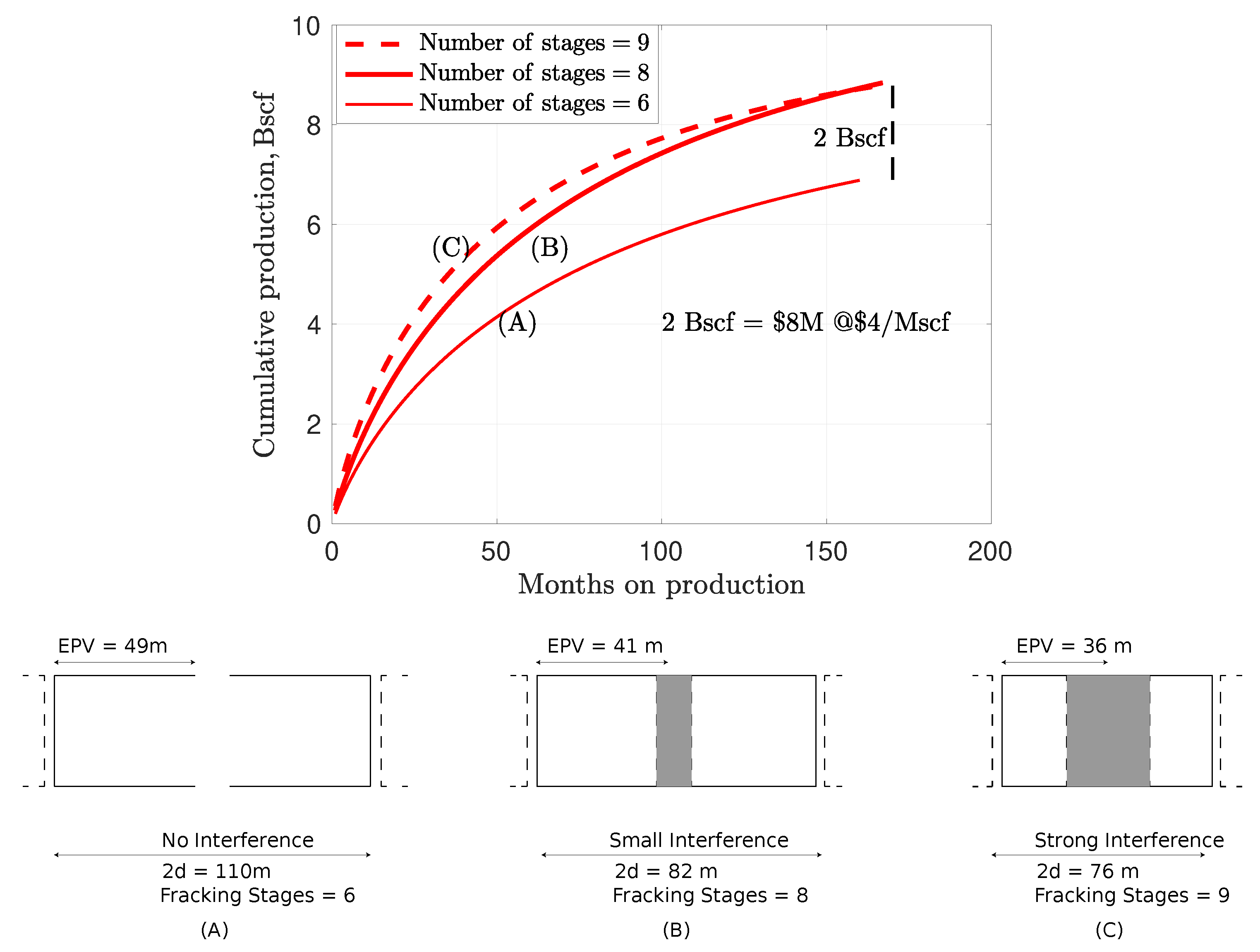

3.2. Effects of Interference and Distance between Frac Stages

4. Materials and Methods

4.1. Diffusivity Equation in the SRV Matrix

4.2. Diffusivity Equation in SRV Fracture Network

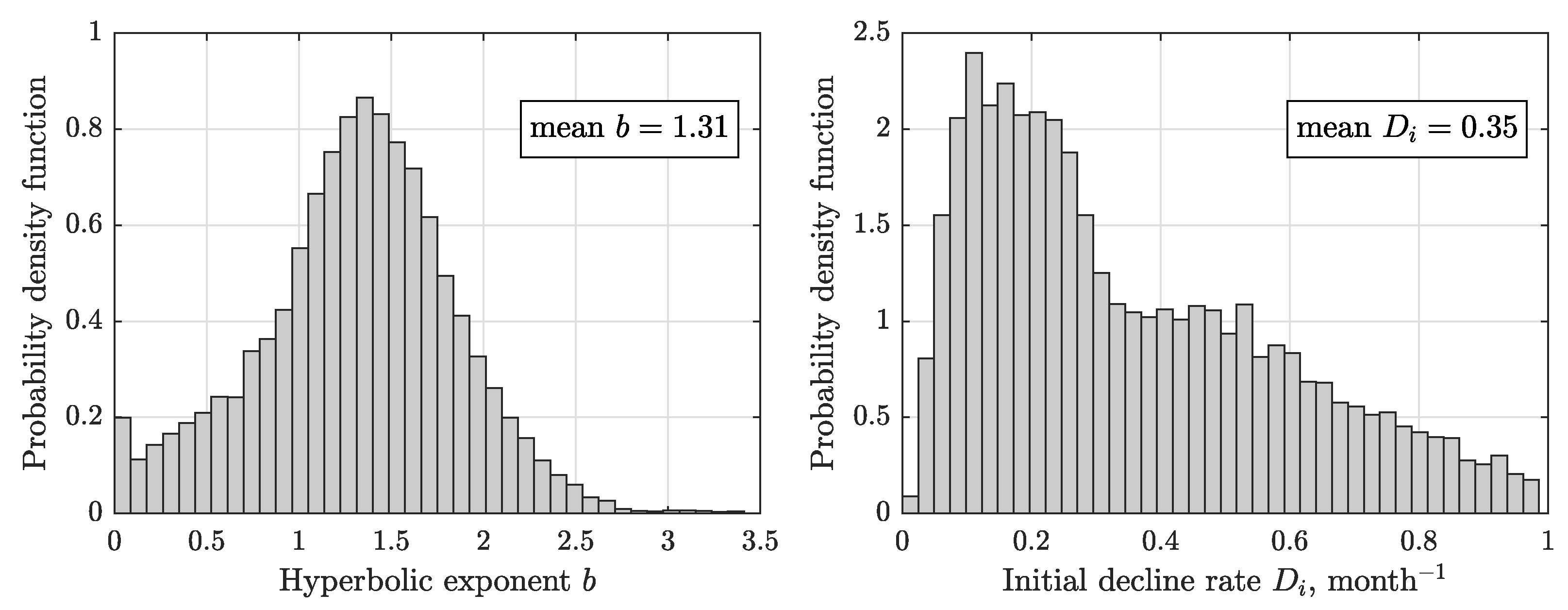

4.3. Match of Production Data

Constraints on SRV Parameters

5. Conclusions and Discussion

- The macroscale and microscale connectivities are represented by the fracture permeability, , and the microscale source term, s. The higher the values of these two parameters are, the better flow connectivity at the respective scale is. In general, at higher fracture permeability, the microscale source term is lower, because of the balance of hydrofracturing energy (see Figure 7).

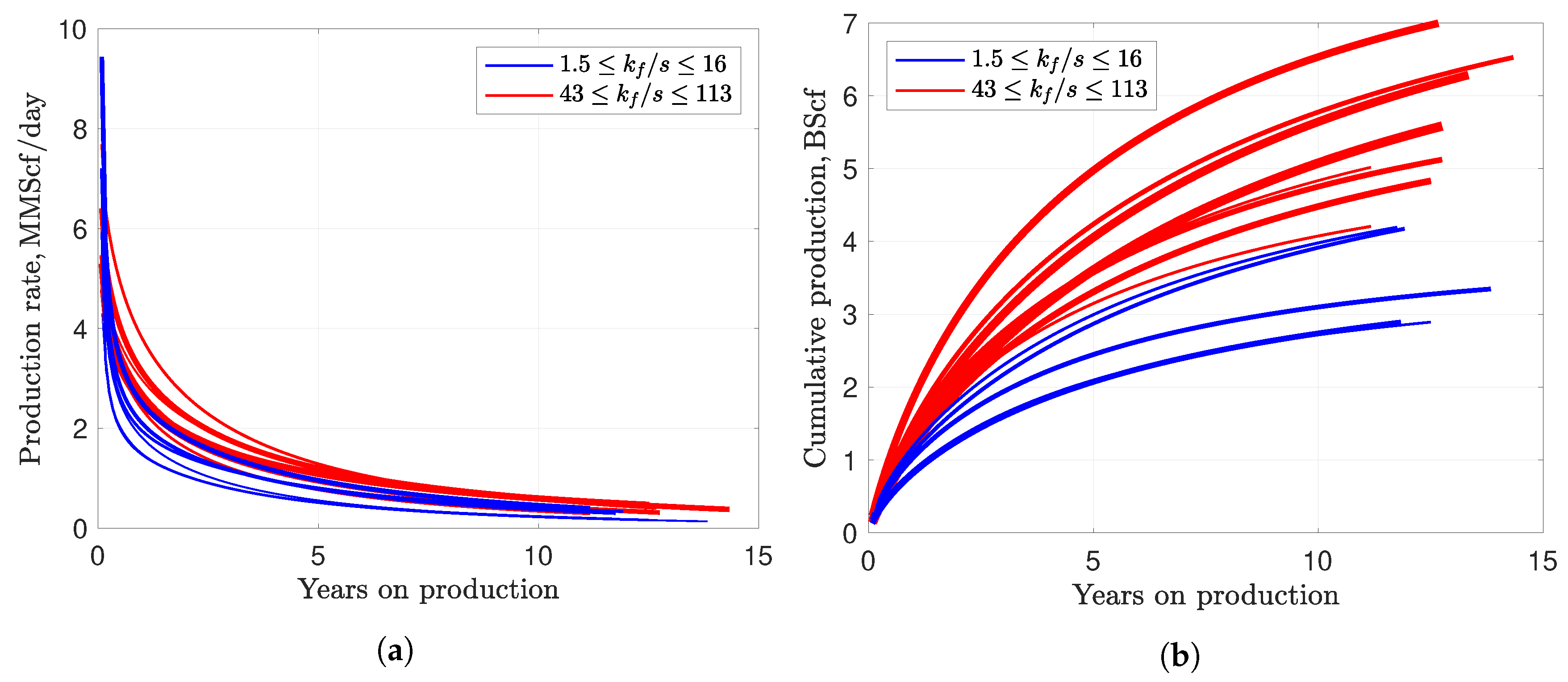

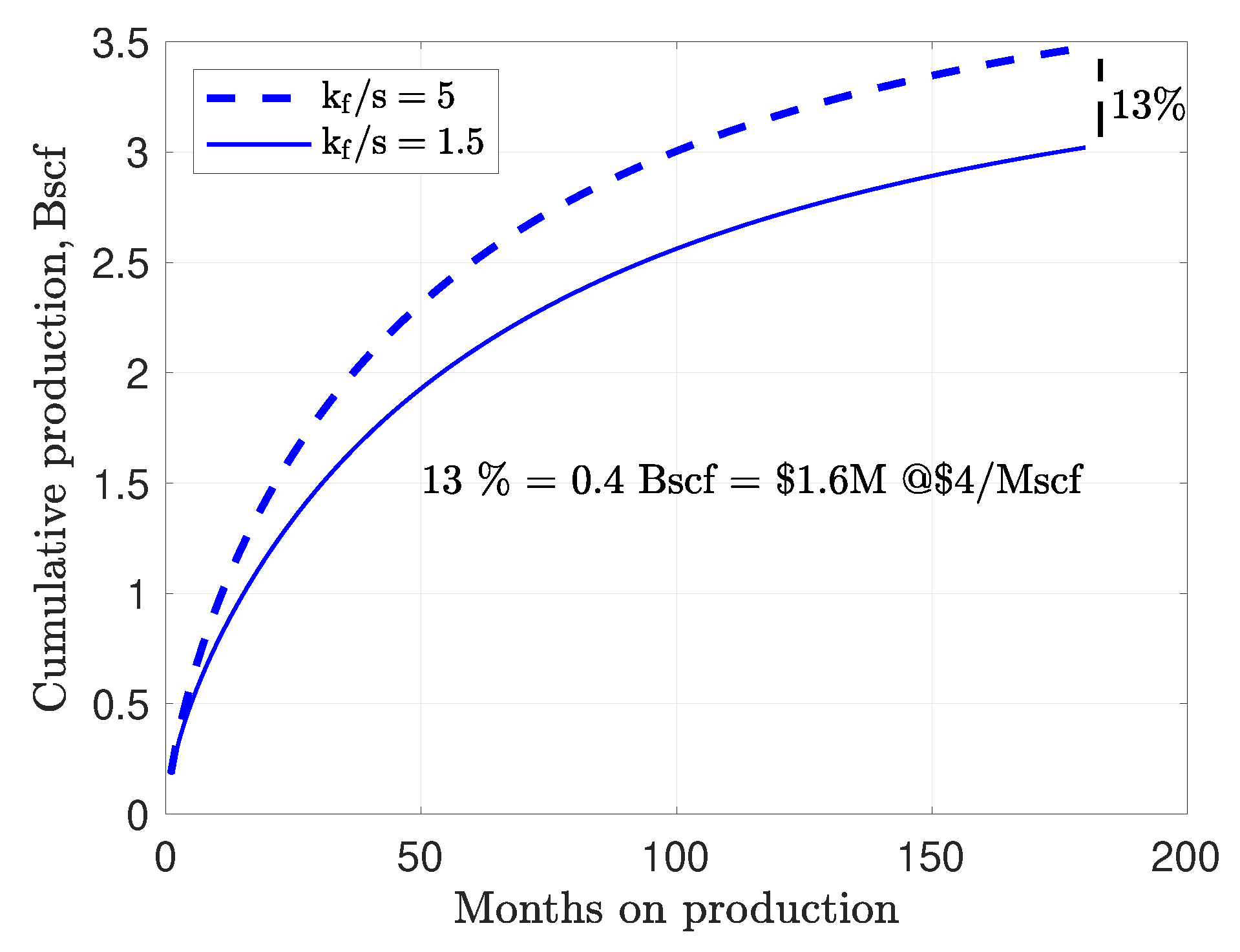

- The overall well quality depends on the ratio of macroscale and microscale connectivities, physically represented by the ratio . A higher value of causes slow pressure decline in the matrix and results in high cumulative production. Poor microscale scale connectivity is compensated by better macroscale connectivity. A low value of causes high initial production rate resulting from fast gas discharge at the microscale. The matrix pressure depletes faster and limits overall cumulative production.

- There can be indirect ways of accessing the ratio of using the magnitude of microseismic events during hydrofracturing. The distribution of event magnitudes can be used to estimate the size distribution of microfractures/macrofractures created in the source rock. Eventually, hydrofracturing can be optimized by interpreting microseismicity.

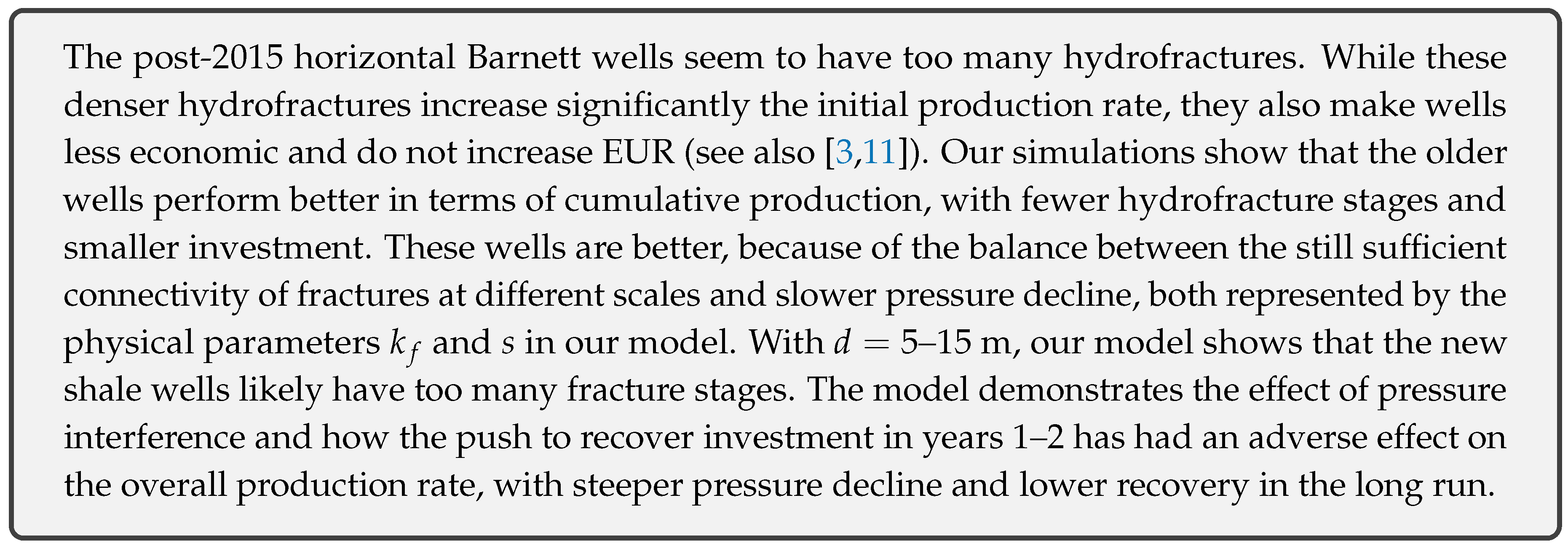

- Stimulated mass is an important factor in controlling the overall production. The non-monotonic increase in the cumulative production histories for the 13 Barnett wells in Figure 9 highlights the importance of initial mass in place, which is the product of gas density, porosity, gas saturation, and volume stimulated after hydrofracturing.

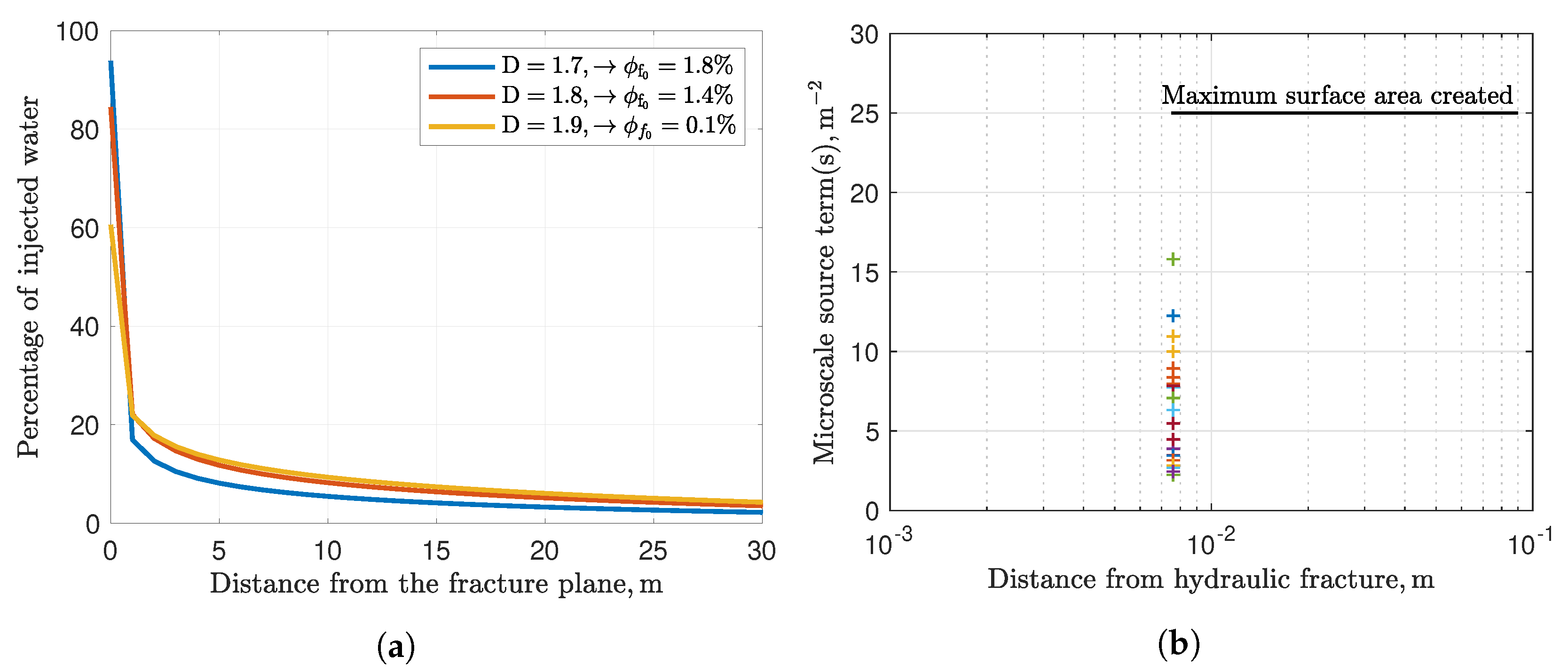

- Efficient hydrofracturing is crucial to maximizing production. An important factor is the average distance between hydrofractures, . Small values of can cause strong interference between two consecutive hydrofractures and can accelerate pressure loss in the matrix, thus limiting cumulative production (see Figure 10). Another key factor is the correct estimation of the Effective Propped Volume (EPV) width using microseismic data. The EPV width can give an estimate for the number of hydrofractures one should generate without causing a strong pressure interference and decreasing production.

- In addition to the correct estimation of EPV width from a cloud of microseismic events, it is important to understand configuration of the new/reactivated fracture network after stimulation. The same EPV width can give different EURs, depending on the ratio of that controls the efficiency of the backbone fracture network that drains gas at different scales (see Figure 9).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| EPV | Effective Propped Volume |

| EUR | Estimated Ultimate Recovery |

| RF | Recovery Factor |

| SRV | Stimulated Reservoir Volume |

Nomenclature

| Parameters | |

| Tip-to-tip length [m] | |

| mass of gas in a reservoir rock volume [kg] | |

| Viscosity [kg/m.s] | |

| Porosity | |

| recovery factor [-] | |

| Density [kg/m] | |

| Tortuosity | |

| c | Compressibility [1/N/m] |

| D | Fractal dimension |

| E | Euclidean dimension |

| H | Hydrofracture height [m] |

| K | Adsorption coefficient [m(gas)/m(rock)] |

| k | Permeability [m] |

| M | Molar mass [kg] |

| Pressure [N/m] | |

| S | Saturation |

| s | Source term [m] |

| T | Temperature [K] |

| t | Time [s] |

| u | Velocity [m/s] |

| V | Volume [m] |

| w | Width [m] |

| x | Distance [m] |

| CI | confidence interval |

| Subscripts | |

| 0 | Fracture face |

| a | Adsorbed gas |

| a | power law exponent |

| f | Fracture |

| g | Gas |

| Hydrofracture | |

| L | Langmuir |

| m | Matrix |

| Standard conditions | |

| Total | |

| eff | Effective |

References

- Patzek, T.W.; Male, F.; Marder, M. Gas production in the Barnett shale obeys a simple scaling theory. Proc. Natl. Acad. Sci. USA 2013, 110, 19731–19736. [Google Scholar] [CrossRef] [Green Version]

- Patzek, T.W.; Male, F.; Marder, M. A simple model of gas production from hydrofractured horizontal wells in shales. AAPG Bull. 2014, 98, 2507–2529. [Google Scholar] [CrossRef]

- Patzek, T.W.; Saputra, W.; Kirati, W.; Marder, M. Generalized Extreme Value Statistics, Physical Scaling, and Forecasts of Gas Production in the Barnett Shale. Energy Fuels 2019, 33, 12154–12169. [Google Scholar] [CrossRef]

- Anonymous. Report Forecasts “Major Slowdown” in US Oil Output Growth. J. Pet. Technol. 2019. Available online: https://pubs.spe.org/en/jpt/jpt-article-detail/?art=6197 (accessed on 5 April 2020).

- Suk Min, K.; Sen, V.; Ji, L.; Sullivan, R.B. URTeC: 2897656: Optimization of Completion and Well Spacing for Development of Multi-Stacked Reservoirs using Integration of Data Analytics, Geomechanics and Reservoir Flow Modeling. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; Society of Petroleum Engineers: Richardson, TX, USA, 2018; pp. 1–11. [Google Scholar]

- Tugan, M.F.; Weijermars, R. Improved EUR prediction for multi-fractured hydrocarbon wells based on 3-segment DCA: Implications for production forecasting of parent and child wells. J. Pet. Sci. Eng. 2020, 187, 106692. [Google Scholar] [CrossRef]

- Patzek, T.W. Barnett Shale in Texas: Promise and Problems. In Proceedings of the Seminar at the Bureau of Economic Geology, UT Austin, Austin, TX, USA, 26 May 2019. [Google Scholar] [CrossRef]

- Eftekhari, B.; Marder, M.; Patzek, T.W. Field data provide estimates of effective permeability, fracture spacing, well drainage area and incremental production in gas shales. J. Nat. Gas Sci. Eng. 2018, 56, 141–151. [Google Scholar] [CrossRef]

- Patzek, T.W. SPE 24040: Surveillance of South Belridge Diatomite. In Proceedings of the Western Regional SPE Meeting, Bakersfield, CA, USA, 30 March–1 April 1992. [Google Scholar] [CrossRef]

- Patzek, T.W.; Wardana, S.; Kirati, W. SPE187226-MS: A Simple Physics-Based Model Predicts Oil Production from Thousands of Horizontal Wells in Shales. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef] [Green Version]

- Saputra, W.; Kirati, W.; Patzek, T.W. Generalized Extreme Value Statistics, Physical Scaling and Forecasts of Oil Production in the Bakken Shale. Energies 2019, 12, 3641. [Google Scholar] [CrossRef] [Green Version]

- Saputra, W.; Kirati, W.; Patzek, T.W. Physical scaling of oil production rates and ultimate recovery from all horizontal wells in the Bakken shale. Energies 2020, 13, 2052. [Google Scholar] [CrossRef] [Green Version]

- Tarek, A. Reservoir Engineering Handbook, 4th ed.; Gulf Professional Publishing: Oxford, UK, 2010. [Google Scholar]

- Kenomore, M.; Hassan, M.; Malakooti, R.; Dhakal, H.; Shah, A. Shale gas production decline trend over time in the Barnett Shale. J. Pet. Sci. Eng. 2018, 165, 691–710. [Google Scholar] [CrossRef] [Green Version]

- Arps, J.J. Analysis of decline curves. Trans. AIME 1945, 160, 228–247. [Google Scholar] [CrossRef]

- Bailey, D. Decline Rate in Fractured Gas Wells. OGJ 1982, 117–118. [Google Scholar]

- Muralidharan, V.; Joshi, K. Myths and Facts of Forecasting Horizontal Well Production in Unconventional Reservoirs—Are We Complicating a Simple Analysis? In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; American Association of Petroleum Geologists: Tulsa, OK, USA, 2018. [Google Scholar]

- Aybar, U.; Eshkalak, M.O.; Sepehrnoori, K.; Patzek, T.W. The effect of natural fractures closure on long-term gas production from unconventional resources. J. Nat. Gas Sci. Eng. 2014, 21, 1205–1213. [Google Scholar] [CrossRef]

- Aybar, U.; Yu, W.; Eshkalak, M.O.; Sepehrnoori, K.; Patzek, T. Evaluation of production losses from unconventional shale reservoirs. J. Nat. Gas Sci. Eng. 2015, 23, 509–516. [Google Scholar] [CrossRef]

- Weijermars, R.; Nandlal, K.; Khanal, A.; Tugan, M.F. Comparison of pressure front with tracer front advance and principal flow regimes in hydraulically fractured wells in unconventional reservoirs. J. Pet. Sci. Eng. 2019, 183, 106407. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.; Hammes, U. Preliminary Classification of Matrix Pores in Mudrocks; The Gulf Coast Association of Geological Societies: New Orleans, LA, USA, 2010. [Google Scholar]

- Curtis, M.E.; Ambrose, R.J.; Sondergeld, C.H. Structural characterization of gas shales on the micro-and nano-scales. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Sakhaee-Pour, A.; Bryant, S.L. Gas permeability of shale. SPE Reserv. Eval. Eng. 2012, 15, 401–409. [Google Scholar] [CrossRef]

- Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S.; Moncrieff, J. Micro-structural studies of gas shales. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Tian, H.; Pana, L.; Xiao, X.; Wilkins, R.W.T.; Meng, Z.; Huangd, B. A preliminary study on the pore characterization of Lower Silurian black shales in the Chuandong Thrust Fold Belt, southwestern China using low pressure N2 adsorption and FE-SEM methods. Mar. Pet. Geol. 2013, 48, 8–19. [Google Scholar] [CrossRef]

- Slatt, R.M.; O′Brien, N.R. Pore types in the Barnett and Woodford gas shales: Contribution to understanding gas storage and migration pathways in fine-grained rocks. AAPG Bull. 2011, 95, 2017–2030. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, J.; Xue, H.; Wang, Y.; Wang, M.; Deng, C. Microstructural characteristics of the cretaceous Qingshankou formation shale, Songliao basin. Pet. Explor. Dev. 2013, 40, 61–68. [Google Scholar] [CrossRef]

- Berthonneau, J.; Obliger, A.; Valdenaire, P.L.; Grauby, O.; Ferry, D.; Chaudanson, D.; Levitz, P.; Kim, J.J.; Ulm, F.J.; Pellenq, R.J.M. Mesoscale structure, mechanics, and transport properties of source rocks’ organic pore networks. Proc. Natl. Acad. Sci. USA 2018, 115, 12365–12370. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anderson, D.M.; Nobakht, M.; Moghadam, S.; Mattar, L. Analysis of production data from fractured shale gas wells. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Fan, D. A Hybrid Transient Flow Model for Performance Evaluation of Shale Gas Reservoirs. Ph.D. Thesis, Department of Petroleum Engineering, Texas Tech University, Lubbock, TX, USA, 2015. [Google Scholar]

- Stalgorova, E.; Mattar, L. Practical analytical model to simulate production of horizontal wells with branch fractures. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012; Society of Petroleum Engineers: Richardson, TX, USA, 2012. [Google Scholar]

- Fan, D.; Ettehadtavakkol, A. Transient shale gas flow model. J. Nat. Gas Sci. Eng. 2016, 33, 1353–1363. [Google Scholar] [CrossRef]

- Yuan, B.; Zheng, D.; Moghanloo, R.G.; Wang, K. A novel integrated workflow for evaluation, optimization, and production predication in shale plays. Int. J. Coal Geol. 2017, 180, 18–28. [Google Scholar] [CrossRef]

- Darishchev, A.; Lemouzy, P.; Rouvroy, P. On simulation of flow in tight and shale gas reservoirs. In Proceedings of the SPE Unconventional Gas Conference and Exhibition, Muscat, Oman, 28–30 January 2013; Society of Petroleum Engineers: Richardson, TX, USA, 2013. [Google Scholar]

- Zheng, D.; Yuan, B.; Moghanloo, R.G. Analytical modeling dynamic drainage volume for transient flow towards multi-stage fractured wells in composite shale reservoirs. J. Pet. Sci. Eng. 2017, 149, 756–764. [Google Scholar] [CrossRef]

- Zheng, D.; Moghanloo, R.G.; Yuan, B.; Dong, X. Modeling dynamic drainage volume for multi-stage fractured wells in composite shale systems: New analytical solution for transient linear flow. In Proceedings of the SPE Asia Pacific Hydraulic Fracturing Conference, Beijing, China, 24–26 August 2016; Society of Petroleum Engineers: Richardson, TX, USA, 2016. [Google Scholar]

- Chang, J.; Yortsos, Y.C. Pressure transient analysis of fractal reservoirs. SPE Form. Eval. 1990, 5, 31–38. [Google Scholar] [CrossRef]

- Acuna, J.A.; Ershaghi, I.; Yortsos, Y.C. Practical application of fractal pressure transient analysis of naturally fractured reservoirs. SPE Form. Eval. 1995, 10, 173–179. [Google Scholar] [CrossRef]

- O Shaughnessy, B.; Procaccia, I. Diffusion on fractals. Phys. Rev. A 1985, 32, 3073. [Google Scholar] [CrossRef]

- Havlin, S.; Ben-Avraham, D. Diffusion in disordered media. Adv. Phys. 1987, 36, 695–798. [Google Scholar] [CrossRef]

- Olarewaju, J. Modeling fractured reservoirs with stochastic fractals. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 13–16 October 1996; Society of Petroleum Engineers: Richardson, TX, USA, 1996. [Google Scholar]

- Chang, J.; Yortsos, Y.C. A note on pressure-transient analysis of fractal reservoirs. SPE Adv. Technol. Ser. 1993, 1, 170–171. [Google Scholar] [CrossRef]

- Chakrabarty, C.; Tortike, W.S.; Ali, S.M.F. Complexities in the Analysis of Pressure-Transient Response for Non-Newtonian power-law fluid flow in fractal Reservoirs. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 2–4 November 1993; Society of Petroleum Engineers: Richardson, TX, USA, 1993. [Google Scholar]

- Chakrabarty, C.; Tortike, W.S.; Ali, S.M.F. Transient Flow Behaviour Of Non-Newtonian Power-Law Fluids In Fractal Reservoirs. In Proceedings of the Annual Technical Meeting, Calgary, AB, Canada, 9–12 May 1993; Petroleum Society of Canada: Calgary, AB, Canada, 1993. [Google Scholar]

- Beier, R.A. Pressure transient field data showing fractal reservoir structure. In Proceedings of the CIM/SPE International Technical Meeting, Calgary, AB, Canada, 10–13 June 1990; Petroleum Society of Canada: Calgary, AB, Canada, 1990. [Google Scholar]

- Flamenco-Lopez, F.; Camacho-Velazquez, R. Determination of fractal parameters of fracture networks using pressure-transient data. SPE Reserv. Eval. Eng. 2003, 6, 39–47. [Google Scholar] [CrossRef]

- Camacho-Velazquez, R.; Fuentes-Cruz, G.; Vasquez-Cruz, M.A. Decline curve analysis of fractured reservoirs with fractal geometry. In Proceedings of the International Oil Conference and Exhibition in Mexico, Cancun, Mexico, 31 August–2 September 2006; Society of Petroleum Engineers: Richardson, TX, USA, 2006. [Google Scholar]

- Camacho-Velazquez, R.; Vasquez-Cruz, M.A.; Castrejon-Aivar, A.; Arana-Ortiz, V. Pressure transient and decline curve behaviors in naturally fractured vuggy carbonate reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002; Society of Petroleum Engineers: Richardson, TX, USA, 2002. [Google Scholar]

- Fuentes-Cruz, G.; Camacho-Velazquez, R.; Vasquez-Cruz, M.A. A Unified Approach for Falloff and Buildup Tests Analysis Following a Short Injection/Production Time. In Proceedings of the SPE Western Regional Meeting, Anaheim, CA, USA, 27–29 May 2010; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Cossio Santizo, M. A Semi-Analytic Solution for Flow in Finite-Conductivity Vertical Fractures Using Fractal Theory. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2012. [Google Scholar]

- Cossio, M.; Moridis, G.; Blasingame, T.A. A Semianalytic Solution for Flow in Finite-Conductivity Vertical Fractures by Use of Fractal Theory. SPE J. 2013, 18, 83–96. [Google Scholar] [CrossRef]

- Wang, W.; Shahvali, M.; Su, Y. A semi-analytical fractal model for production from tight oil reservoirs with hydraulically fractured horizontal wells. Fuel 2015, 158, 612–618. [Google Scholar] [CrossRef]

- Fan, D.; Ettehadtavakkol, A. Semi-analytical modeling of shale gas flow through fractal induced fracture networks with microseismic data. Fuel 2017, 193, 444–459. [Google Scholar] [CrossRef]

- Wang, W.; Su, Y.; Sheng, G.; Cossio, M.; Shang, Y. A mathematical model considering complex fractures and fractal flow for pressure transient analysis of fractured horizontal wells in unconventional reservoirs. J. Nat. Gas Sci. Eng. 2015, 23, 139–147. [Google Scholar] [CrossRef]

- Marder, M.; Chen, C.H.; Patzek, T. Simple models of the hydrofracture process. Phys. Rev. E 2015, 92, 062408. [Google Scholar] [CrossRef] [Green Version]

- Khanal, A.; Weijermars, R. Pressure depletion and drained rock volume near hydraulically fractured parent and child wells. J. Pet. Sci. Eng. 2019, 172, 607–626. [Google Scholar] [CrossRef]

- Weijermars, R.; Khanal, A. Production Interference of Hydraulically Fractured Hydrocarbon Wells: New Tools for Optimization of Productivity and Economic Performance of Parent and Child Wells. In Proceedings of the SPE Europec featured at 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019; Society of Petroleum Engineers: Richardson, TX, USA, 2019. [Google Scholar]

- Weijermars, R.; van Harmelen, A.; Zuo, L. Flow interference between frac clusters (Part 2): Field example from the Midland basin (Wolfcamp formation, Spraberry trend field) with implications for hydraulic fracture design. In Proceedings of the Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017; Society of Exploration Geophysicists: Tulsa, OK, USA; American Association of Petroleum Geologists: Tulsa, OK, USA, 2017; pp. 989–1004. [Google Scholar]

- Pang, Y.; Soliman, M.Y.; Deng, H.; Emadi, H. Analysis of effective porosity and effective permeability in shale-gas reservoirs with consideration of gas adsorption and stress effects. SPE J. 2017, 22, 1–12. [Google Scholar] [CrossRef]

- O’Malley, D.; Karra, S.; Currier, R.P.; Makedonska, N.; Hyman, J.D.; Viswanathan, H.S. Where does water go during hydraulic fracturing? Groundwater 2016, 54, 488–497. [Google Scholar] [CrossRef]

- Adler, P.M.; Thovert, J.-F.; Mourzenko, V.V. Fractured Porous Media; Oxford University Press: Oxford, UK, 2013. [Google Scholar]

- Johri, M.; Zoback, M.D. The evolution of stimulated reservoir volume during hydraulic stimulation of shale gas formations. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013; Society of Exploration Geophysicists: Tulsa, OK, USA; American Association of Petroleum Geologists: Tulsa, OK, USA, 2013; pp. 1661–1671. [Google Scholar]

- Raterman, K.T.; Farrell, H.E.; Mora, O.S.; Janssen, A.L.; Gomez, G.A.; Busetti, S.; McEwen, J.; Friehauf, K.; Rutherford, J.; Reid, R.; et al. Sampling a Stimulated Rock Volume: An Eagle Ford Example. In Proceedings of the SPE Conference. Unconventional Resources Technology Conference (URTEC), Austin, TX, USA, 24–26 July 2017. [Google Scholar]

| Parameters | SI Units | Field Units |

|---|---|---|

| Matrix porosity, | 8% | |

| Matrix Permeability, | m | 50 nanodarcy |

| Gas saturation, | 0.6–0.8 | 0.6–0.8 |

| Initial pressure, | 24.1 MPa | 3500 psi |

| Reservoir temperature, T | 361 K | 190 °F |

| Hydrofracture pressure | 3.44 MPa | 500 psi |

| Fracture height, H | 30 m | 100 ft |

| Tip-to-tip fracture length, | 200 m | 590 ft |

| Half SRV width, d | 40–50 m | 131–164 ft |

| Parameters | Small Fractures | Large Fractures |

|---|---|---|

| 1 mm | 5 m | |

| 5 m | 50 m | |

| Volume | 400 m | 275 m |

| Area | m | m |

| Fractures | 360 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haider, S.; Saputra, W.; Patzek, T. The Key Factors That Determine the Economically Viable, Horizontal Hydrofractured Gas Wells in Mudrocks. Energies 2020, 13, 2348. https://doi.org/10.3390/en13092348

Haider S, Saputra W, Patzek T. The Key Factors That Determine the Economically Viable, Horizontal Hydrofractured Gas Wells in Mudrocks. Energies. 2020; 13(9):2348. https://doi.org/10.3390/en13092348

Chicago/Turabian StyleHaider, Syed, Wardana Saputra, and Tadeusz Patzek. 2020. "The Key Factors That Determine the Economically Viable, Horizontal Hydrofractured Gas Wells in Mudrocks" Energies 13, no. 9: 2348. https://doi.org/10.3390/en13092348

APA StyleHaider, S., Saputra, W., & Patzek, T. (2020). The Key Factors That Determine the Economically Viable, Horizontal Hydrofractured Gas Wells in Mudrocks. Energies, 13(9), 2348. https://doi.org/10.3390/en13092348