Dual and Ternary Biofuel Blends for Desalination Process: Emissions and Heat Recovered Assessment

Abstract

1. Introduction

2. Experimental Setup and Procedure

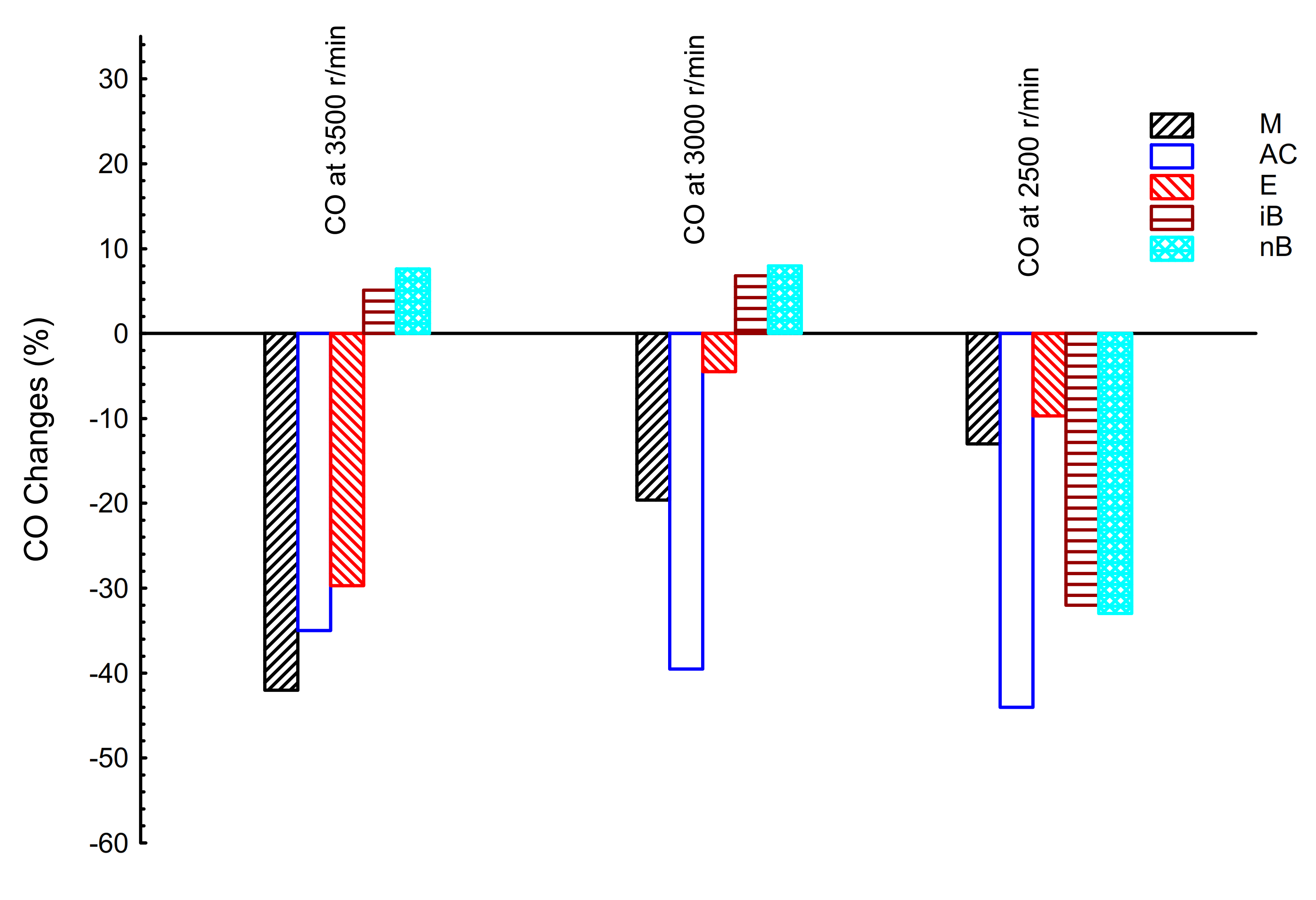

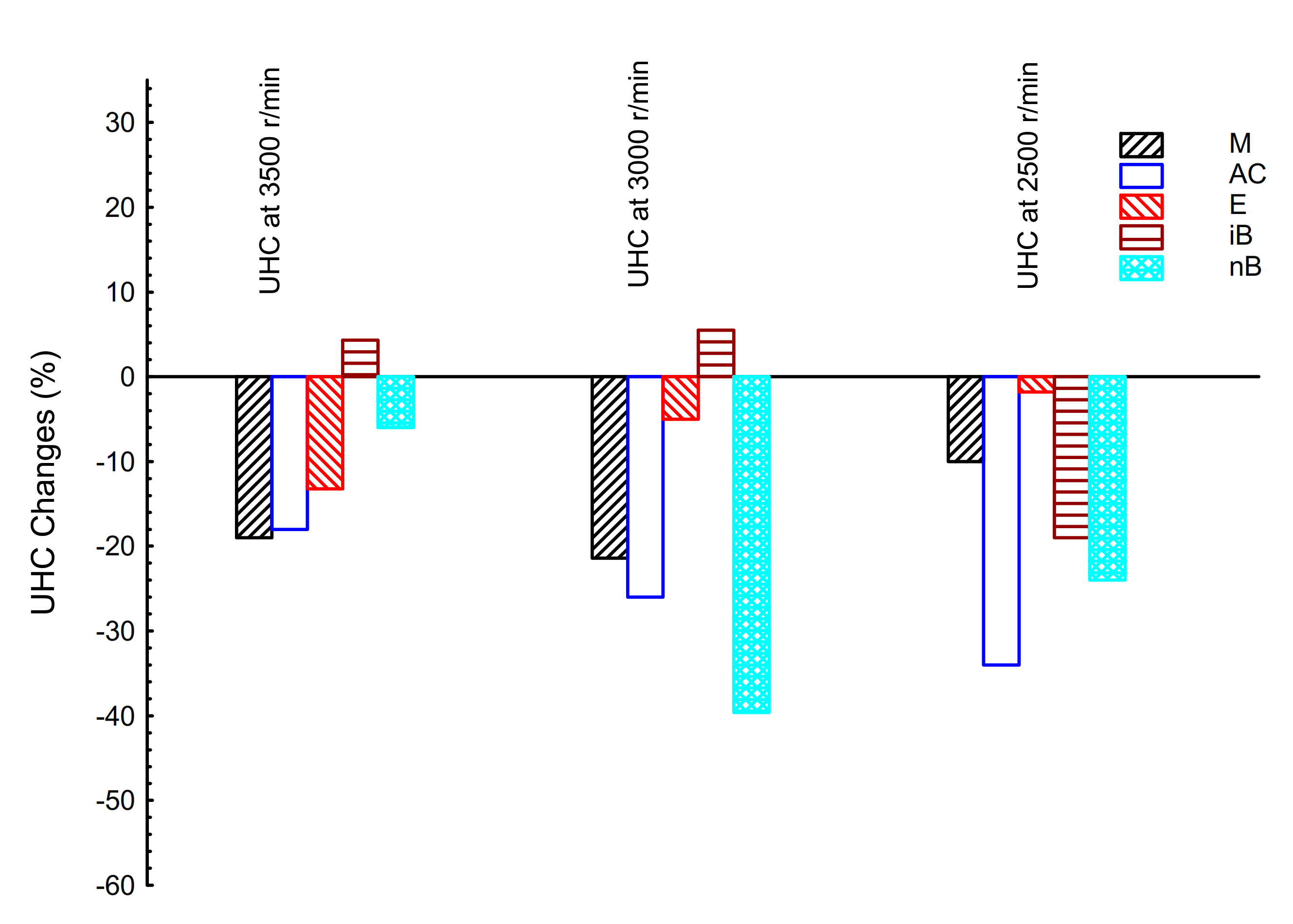

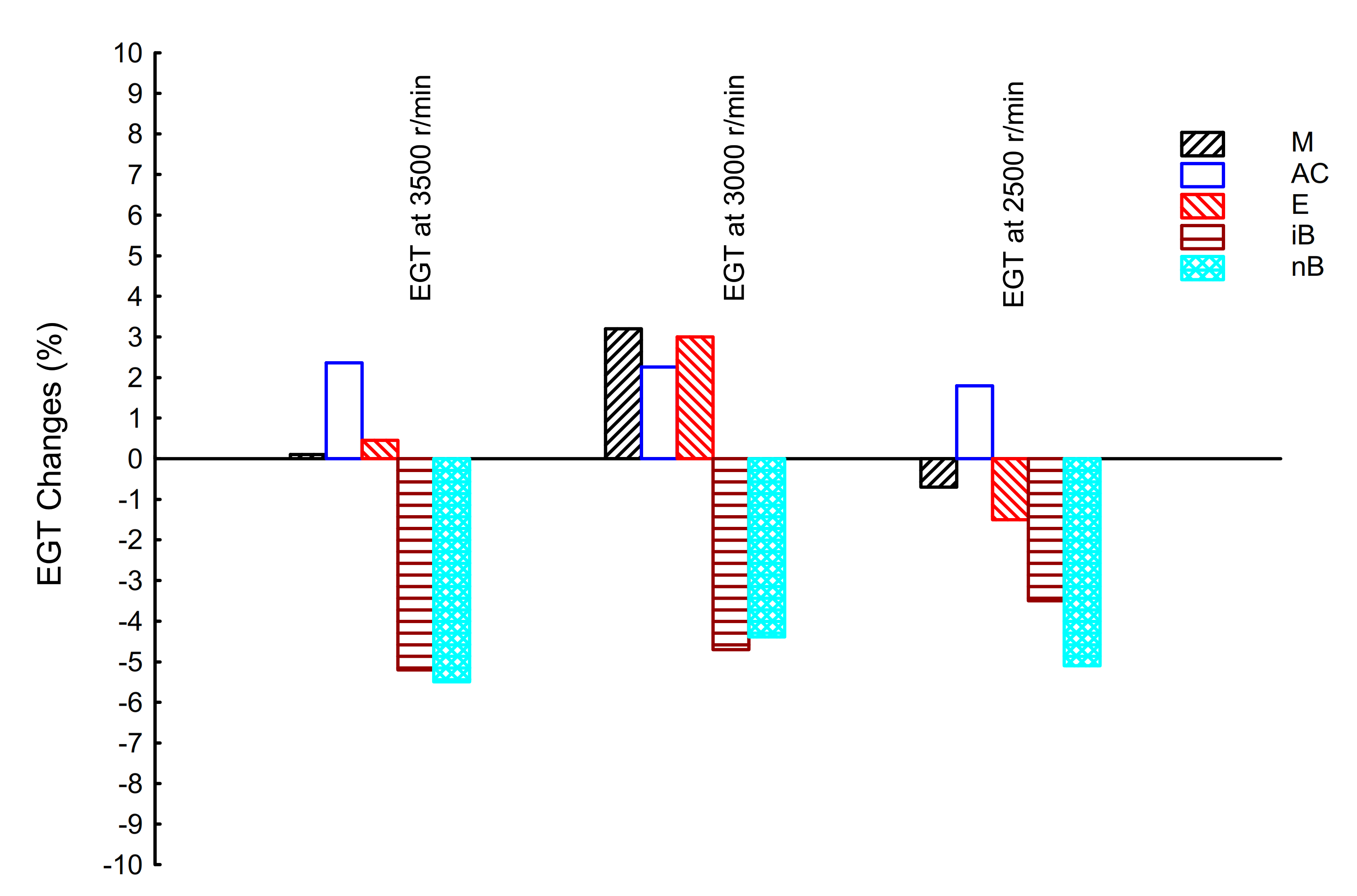

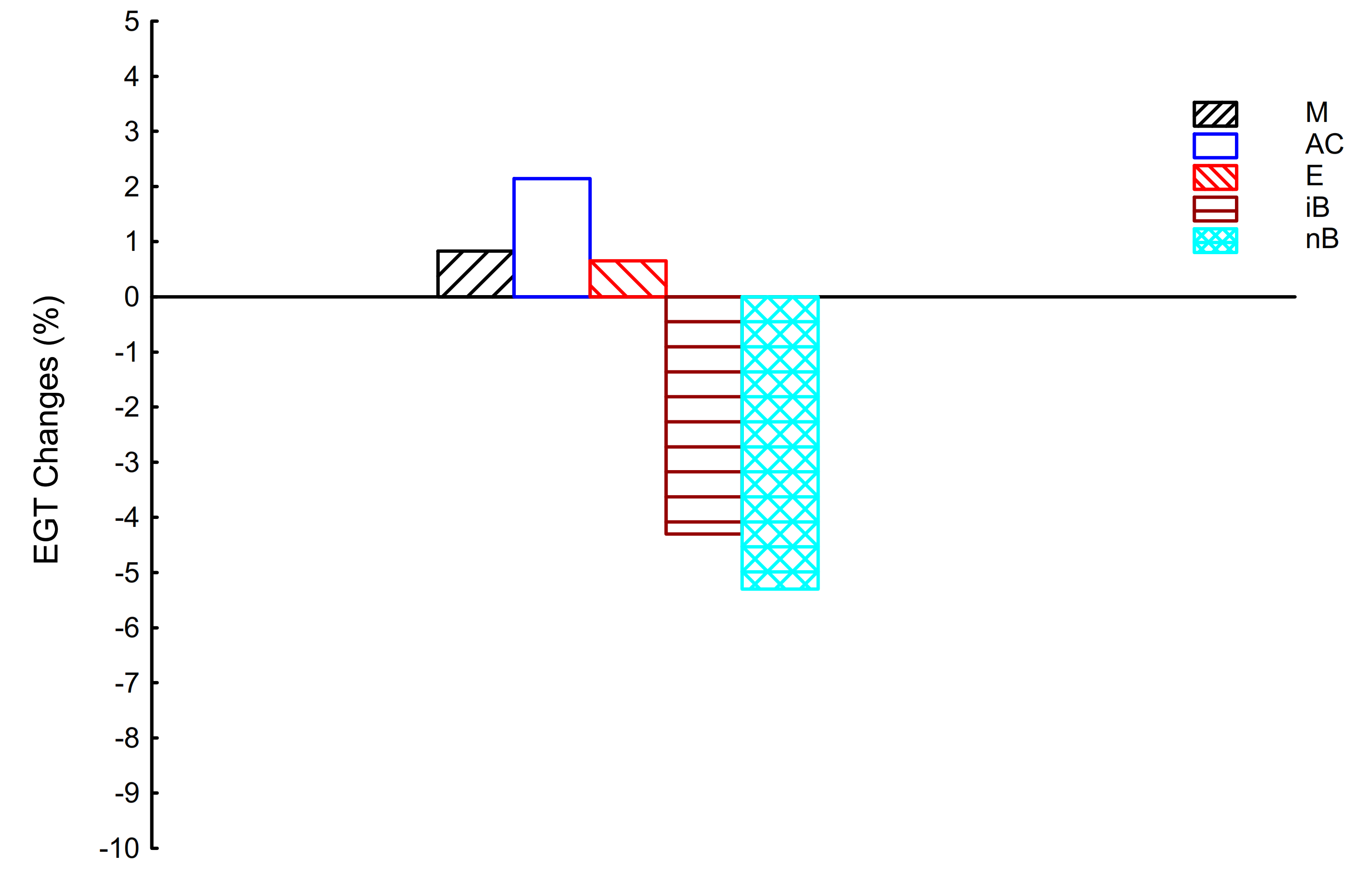

3. Results and Discussions

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Gleick, P.H. The World’s Water 2006–2007: The Biennial Report on Freshwater Resources; Island Press: Washington, DC, USA, 2006. [Google Scholar]

- Elsaid, K.; Kamil, M.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A. Environmental impact of desalination technologies: A review. Sci. Total Environ. 2020, 748, 141528. [Google Scholar] [CrossRef] [PubMed]

- Ng, K.C.; Shahzad, M.W. Sustainable desalination using ocean thermocline energy. Renew. Sustain. Energy Rev. 2018, 82, 240–246. [Google Scholar] [CrossRef]

- Alnajdi, O.; Calautit, J.K.; Wu, Y. Development of a multi-criteria decision making approach for sustainable seawater desalination technologies of medium and large-scale plants: A case study for Saudi Arabia’s vision 2030. Energy Procedia 2019, 158, 4274–4279. [Google Scholar] [CrossRef]

- Gleick, P.H.; Allen, L.; Cohen, M.J.; Cooley, H.; Christian–Smith, J.; Heberger, M.; Morrison, J.; Palaniappan, M.; Schulte, P. The World’s Water: The Biennial Report on Freshwater Resources; Island Press: Washington, DC, USA, 2012; Volume 7. [Google Scholar]

- Jones, E.; Qadir, M.; Van Vliet, M.T.; Smakhtin, V.; Kang, S.-M. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef]

- Heck, N.; Lykkebo Petersen, K.; Potts, D.C.; Haddad, B.; Paytan, A. Predictors of coastal stakeholders’ knowledge about seawater desalination impacts onmarine ecosystems. Sci. Total Environ. 2018, 639, 785–792. [Google Scholar] [CrossRef]

- Panagopoulos, A.; Haralambous, K.-J.J.; Loizidou, M. Desalination brine disposal methods and treatment technologies—A review. Sci. Total Environ. 2019, 693, 133545. [Google Scholar] [CrossRef]

- Ang, W.L.; Mohammad, A.W.; Johnson, D.; Hilal, N. Unlocking the application potential of forward osmosis through integrated/hybrid process. Sci. Total Environ. 2020, 706, 136047. [Google Scholar] [CrossRef]

- Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Baroutaji, A.; Olabi, A. Environmental impact of desalination processes: Mitigation and control strategies. Sci. Total Environ. 2020, 740, 140125. [Google Scholar] [CrossRef]

- Werner, M.; Schäfer, A.I. Social aspects of a solar–powered desalination unit for remote Australian communities. Desalination 2007, 203, 375–393. [Google Scholar] [CrossRef]

- McGrath, C. Renewable Desalination Market Analysis in Oceania, South Africa, Middle East & North Africa; Aquamarine Power: Edinburgh, UK, 2011. [Google Scholar]

- Malik, M.A.S.; Tiwari, N.; Kumar, A.; Sodha, M.S. Active and Passive Solar Distillation: A Review; Pergamon Press: Oxford, UK, 1982. [Google Scholar]

- Aayush, K. VarunSolar stills: A review. Renew. Sustain. Energy Rev. 2010, 14, 446–453. [Google Scholar]

- Tiwari Singh, G.N.; Tripathi Rajesh, H.N. Present status of solar distillation. Sol. Energy 2003, 75, 367–373. [Google Scholar] [CrossRef]

- Murugavel, K.K.; Chockalingam, K.; Srithar, K. Progresses in improving the effectiveness of the single basin passive solar still. Desalination 2008, 220, 677–686. [Google Scholar] [CrossRef]

- Sampathkumar, K.; Arjunan, T.V.; Pitchandi, P.; Senthilkumar, P. Active solar distillation—A detailed review. Renew. Sustain. Energy Rev. 2010, 14, 1503–1526. [Google Scholar] [CrossRef]

- Velmurugan, V.; Srithar, K. Performance analysis of solar stills based on various factors affecting the productivity—A review. Renew. Sustain. Energy Rev. 2011, 15, 1294–1304. [Google Scholar] [CrossRef]

- Kabeel, A.; El-Agouz, S. Review of researches and developments on solar stills. Desalination 2011, 276, 1–12. [Google Scholar] [CrossRef]

- Alsehli, M.; Saleh, B.; Elfasakhany, A.; Aly, A.A.; Bassuoni, M.M. Experimental study of a novel solar multi–effect distillation unit using alternate storage tanks. J. Water Reuse Desalin. 2020, 10, 120–132. [Google Scholar] [CrossRef]

- Elfasakhany, A. Performance assessment and productivity of a simple–type solar still integrated with nanocomposite energy storage system. Appl. Energy 2016, 183, 399–407. [Google Scholar] [CrossRef]

- Elfasakhany, A. Modeling of Pulverised Wood Flames. Ph.D. Thesis, Lund University, Fluid Mechanics Department, Lund, Sweden, 2005. [Google Scholar]

- Elfasakhany, A.; Tao, L.; Espenas, B.; Larfeldt, J.; Bai, X.S. Pulverised Wood Combustion in a Vertical Furnace: Experimental and Computational Analyses. Appl. Energy 2013, 112, 454–464. [Google Scholar] [CrossRef]

- Elfasakhany, A. Gasoline engine fueled with bioethanol–bio–acetone–gasoline blends: Performance and emissions exploration. Fuel 2020, 274, 117825. [Google Scholar] [CrossRef]

- Elfasakhany, A. Experimental investigation on SI engine using gasoline and a hybrid iso–butanol/gasoline fuel. Energy Convers. Manag. 2015, 95, 398–405. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-water-environment nexus underpinning future desalination sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Son, H.S.; Oh, S.J.; Ng, K.C. Desalination processes evaluation at common platform: A universal performance ratio (UPR) method. Appl. Therm. Eng. 2018, 134, 62–67. [Google Scholar] [CrossRef]

- Ng, K.C.; Shahzad, M.W.; Son, H.S.; Hamed, O.A. An exergy approach to efficiency evaluation of desalination. Appl. Phys. Lett. 2017, 110, 184101. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ng, K.C. A standard primary energy approach for comparing desalination processes. NPJ Clean Water 2019, 2, 1–7. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ybyraiymkul, D.; Ng, K.C. Desalination Processes’ Efficiency and Future Roadmap. Entropy 2019, 21, 84. [Google Scholar] [CrossRef]

- Gude, V.G. Thermal desalination of ballast water using onboard waste heat in marine industry. Int. J. Energy Res. 2019, 43, 6026–6037. [Google Scholar] [CrossRef]

- Ouyang, T.; Su, Z.; Gao, B.; Pan, M.; Chen, N.; Huang, H. Design and modeling of marine diesel engine multistage waste heat recovery system integrated with flue-gas desulfurization. Energy Convers. Manag. 2019, 196, 1353–1368. [Google Scholar] [CrossRef]

- Lion, S.; Vlaskos, I.; Taccani, R. A review of emissions reduction technologies for low and medium speed marine Diesel engines and their potential for waste heat recovery. Energy Convers. Manag. 2020, 207, 112553. [Google Scholar] [CrossRef]

- Lion, S.; Michos, C.N.; Vlaskos, I.; Rouaud, C.; Taccani, R. A review of waste heat recovery and Organic Rankine Cycles (ORC) in on-off highway vehicle Heavy Duty Diesel Engine applications. Renew. Sustain. Energy Rev. 2017, 79, 691–708. [Google Scholar] [CrossRef]

- Seyedkavoosi, S.; Javan, S.; Kota, K. Exergy-based optimization of an organic Rankine cycle (ORC) for waste heat recovery from an internal combustion engine (ICE). Appl. Therm. Eng. 2017, 126, 447–457. [Google Scholar] [CrossRef]

- Salimi, M.; Amidpour, M. Modeling, simulation, parametric study and economic assessment of reciprocating internal combustion engine integrated with multi-effect desalination unit. Energy Convers. Manag. 2017, 138, 299–311. [Google Scholar] [CrossRef]

- Chintala, V.; Kumar, S.; Pandey, J.K. A technical review on waste heat recovery from compression ignition engines using organic Rankine cycle. Renew. Sustain. Energy Rev. 2018, 81, 493–509. [Google Scholar] [CrossRef]

- Shafieian, A.; Khiadani, M. A multipurpose desalination, cooling, and air-conditioning system powered by waste heat recovery from diesel exhaust fumes and cooling water. Case Stud. Therm. Eng. 2020, 21, 100702. [Google Scholar] [CrossRef]

- Yang, F.; Cho, H.; Zhang, H.; Zhang, J. Thermoeconomic multi-objective optimization of a dual loop organic Rankine cycle (ORC) for CNG engine waste heat recovery. Appl. Energy 2017, 205, 1100–1118. [Google Scholar] [CrossRef]

- Asadi, A.; Meratizaman, M.; Hosseinjani, A.A. Feasibility study of small-scale gas engine integrated with innovative net-zero water desiccant cooling system and single-effect thermal desalination unit. Int. J. Refrig. 2020, 119, 276–293. [Google Scholar] [CrossRef]

- Elfasakhany, A. Investigation on performance and emissions characteristics of an internal combustion engine fuelled with petroleum gasoline and a hybrid methanol–gasoline fuel. Int. J. Eng. Tech. 2013, 13, 24–43. [Google Scholar]

- Elfasakhany, A. The Effects of Ethanol–Gasoline Blends on Performance and Exhaust Emission Characteristics of Spark Ignition Engines. Int. J. Automot. Eng. 2014, 4, 608–620. [Google Scholar]

- Elfasakhany, A. Exhaust emissions and performance of ternary iso–butanol–bio–methanol–gasoline and n–butanol–bio–ethanol–gasoline fuel blends in spark–ignition engines: Assessment and comparison. Energy 2018, 158, 830–844. [Google Scholar] [CrossRef]

- Gong, C.; Yi, L.; Zhang, Z.; Sun, J.; Liu, F. Assessment of ultra-lean burn characteristics for a stratified-charge direct-injection spark-ignition methanol engine under different high compression ratios. Appl. Energy 2020, 261, 114478. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y. An overview of methanol as an internal combustion engine fuel. Renew. Sustain. Energy Rev. 2015, 52, 477–493. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Yi, L.; Liu, F. Comparative study on combustion and emissions between methanol port-injection engine and methanol direct-injection engine with H2-enriched port-injection under lean-burn conditions. Energy Convers. Manag. 2019, 200, 112096. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Chen, Y.; Liu, J.; Liu, F.; Han, Y. Influence of ignition timing on combustion and emissions of a spark–ignition methanol engine with added hydrogen under lean-burn conditions. Fuel 2019, 235, 227–238. [Google Scholar] [CrossRef]

- Gong, C.; Li, Z.; Yi, L.; Huang, K.; Liu, F. Research on the performance of a hydrogen/methanol dual-injection assisted spark–ignition engine using late-injection strategy for methanol. Fuel 2020, 260, 116403. [Google Scholar] [CrossRef]

- Elfasakhany, A.; Mahrous, A.F. Performance and emissions assessment of n–butanol–methanol–gasoline blends as a fuel in spark–ignition engines. Alex. Eng. J. 2016, 55, 3015–3024. [Google Scholar] [CrossRef]

- Elfasakhany, A. Investigations on the effects of ethanol–methanol–gasoline blends in a spark-ignition engine: Performance and emissions analysis. Eng. Sci. Technol. Int. J. 2015, 18, 713–719. [Google Scholar] [CrossRef]

- Elfasakhany, A. Engine performance evaluation and pollutant emissions analysis using ternary bio-ethanol–iso-butanol–gasoline blends in gasoline engines. J. Clean. Prod. 2016, 139, 1057–1067. [Google Scholar] [CrossRef]

- Elfasakhany, A. Experimental study of dual n-butanol and iso-butanol additives on spark-ignition engine performance and emissions. Fuel 2016, 163, 166–174. [Google Scholar] [CrossRef]

- Elfasakhany, A. Experimental study on emissions and performance of an internal combustion engine fueled with gasoline and gasoline/n-butanol blends. Energy Convers. Manag. 2014, 88, 277–283. [Google Scholar] [CrossRef]

- Elfasakhany, A. Performance and emissions analysis on using acetone–gasoline fuel blends in spark-ignition engine. Eng. Sci. Technol. Int. J. 2016, 19, 1224–1232. [Google Scholar] [CrossRef][Green Version]

- Elfasakhany, A. Performance and emissions of spark–ignition engine using ethanol–methanol–gasoline, n–butanol–iso–butanol–gasoline and iso–butanol–ethanol–gasoline blends: A comparative study. Eng. Sci. Technol. 2016, 19, 2053–2059. [Google Scholar] [CrossRef]

- Elfasakhany, A. Investigations on performance and pollutant emissions of spark–ignition engines fueled with n–butanol–, iso–butanol–, ethanol–, methanol–, and acetone–gasoline blends: A comparative study. Renew. Sustain. Energy Rev. 2017, 71, 404–413. [Google Scholar] [CrossRef]

- Elfasakhany, A. Biofuels in Automobiles: Advantages and Disadvantages: A Review. Curr. Altern. Energy 2019, 3, 1–7. [Google Scholar] [CrossRef]

- Elfasakhany, A. Alcohols as Fuels in Spark Ignition Engines: Second Blended Generation; LAMBERT Academic Publishing: Saarbrücken, Germany, 2017; ISBN 978–3–659–97691–9. [Google Scholar]

- Elfasakhany, A. Benefits and Drawbacks on the Use Biofuels in Spark Ignition Engines; LAMBERT Academic Publishing: Beau-Bassin, Mauritius, 2017; ISBN 978–620–2–05720–2. [Google Scholar]

| Engine Specifications | |

| Cylinder(s) | 1 |

| Valves | 2 |

| Bore (mm) | 65.1 |

| Stroke (mm) | 44.4 |

| Compression ratio | 7:1 |

| Displacement (cm3) | 147.7 |

| Maximum power (KW) | 1.5 |

| Weight (Kg) | 17 Kg |

| Type | Spark-ignition |

| Gas Analyzer Specifications | |

| Warm-up period | 10 min |

| Weight | 9 kg |

| Exhaust gas temperature | 5–45 °C |

| Measurement ranges | CO 0–10 vol.% |

| CO2 0–20 vol.% | |

| UHC 0–2000 ppm vol. (as C6H14) | |

| Voltage | 230 V (+10%/–15%) |

| Frequency | 50 +/−1 Hz |

| Power consumption | Max. 45 VA |

| Range of apparatus heating | 0–130 °C, resolution ±1 °C |

| Property | Gasoline | Bioethanol | Biomethanol | Isobutanol | N-Butanol | Bio-Acetone |

|---|---|---|---|---|---|---|

| Chemical formula C3H6O | C8H15 | C2H5OH | CH3OH | C4H9OH | C4H9OH | C3H6O |

| Composition (C,H,O) % | 86, 14, 0 | 52, 13, 35 | 37.5, 12.5, 50 | 65, 13.5, 21.5 | 65, 13.5, 21.5 | 62, 10.5, 27.5 |

| Lower heating value (MJ/kg) | 43.5 | 27.0 | 20.1 | 33.3 | 33.1 | 29.6 |

| Heat of evaporation (kJ/kg) | 223.2 | 725.4 | 920.7 | 474.3 | 582 | 501.7 |

| Stoichiometric A/F ratio | 14.6 | 9.0 | 6.4 | 11.1 | 11.2 | 9.54 |

| Oxygen content, mass % | 0.0 | 34.7 | 49.9 | 21.6 | 21.6 | 27.6 |

| Density (kg/m3) | 760 | 790 | 796 | 802 | 810 | 791 |

| Sat. pressure at 38 °C (kPa) | 31 | 13.8 | 31.69 | 2.3 | 2.27 | 53.4 |

| Flash point (°C) | −40 | 21.1 | 11.1 | 28 | 35 | 17.8 |

| Auto–ignition temp. (°C) | 420 | 434 | 470 | 415 | 385 | 560 |

| Boiling point (°C) | 25–215 | 78.4 | 64.5 | 108 | 117.7 | 56.1 |

| Solubility in water | <0.1 | Fully miscible | Fully miscible | 10.6 | 7.7 | Miscible |

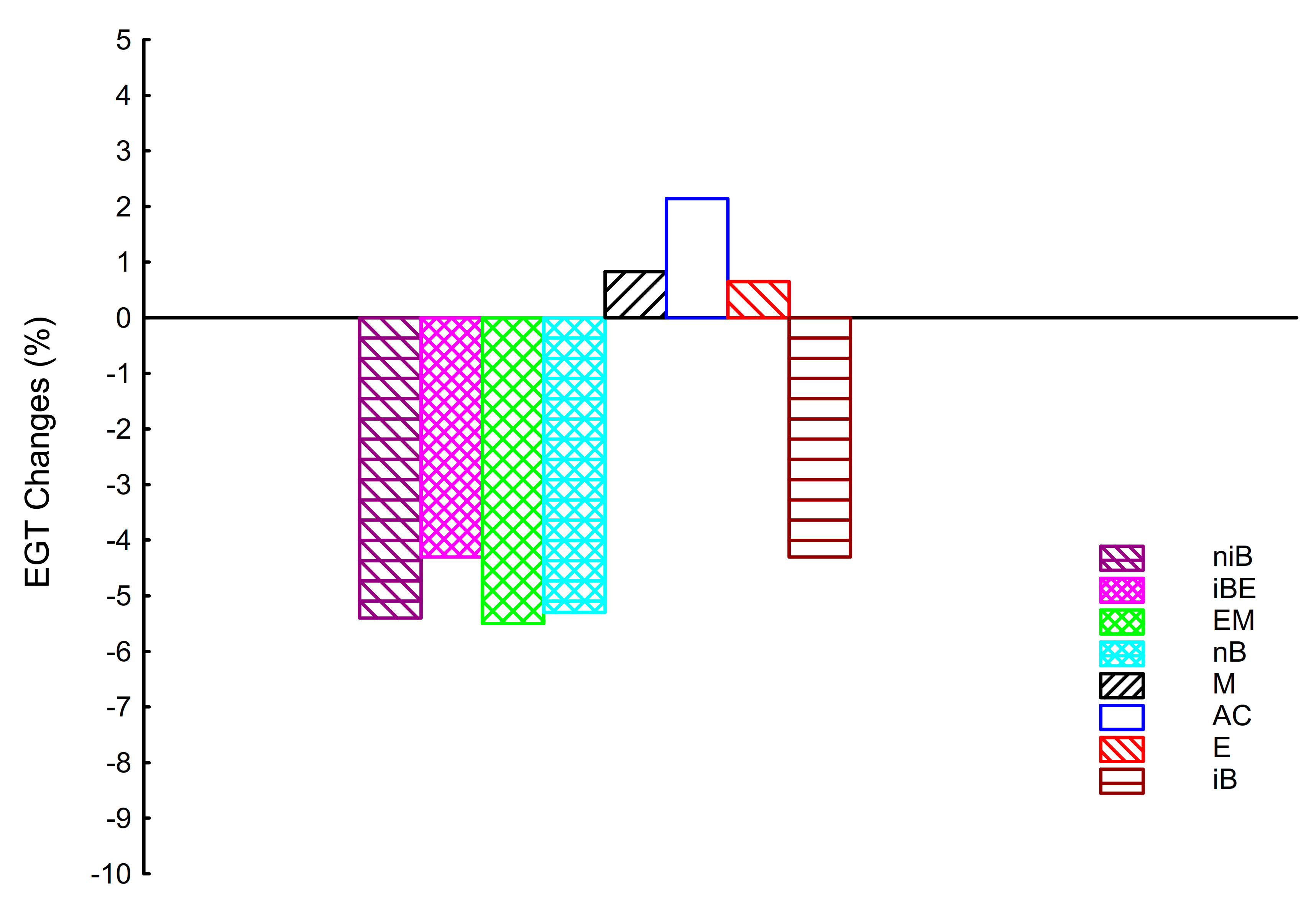

| Biofuel Blends | CO | UHC | CO2 | |

|---|---|---|---|---|

| Emissions | ||||

| M | −30 | −12.8 | 10 | |

| AC | −32 | −20 | −24.6 | |

| E | −20 | −10 | 4.6 | |

| iB | −11.6 | −6.8 | −36 | |

| nB | −10 | −16.2 | −35 | |

| niB | −5 | −13.5 | −18 | |

| iBE | −14 | −14 | −14 | |

| EM | −21 | −18 | 6.3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elfasakhany, A. Dual and Ternary Biofuel Blends for Desalination Process: Emissions and Heat Recovered Assessment. Energies 2021, 14, 61. https://doi.org/10.3390/en14010061

Elfasakhany A. Dual and Ternary Biofuel Blends for Desalination Process: Emissions and Heat Recovered Assessment. Energies. 2021; 14(1):61. https://doi.org/10.3390/en14010061

Chicago/Turabian StyleElfasakhany, Ashraf. 2021. "Dual and Ternary Biofuel Blends for Desalination Process: Emissions and Heat Recovered Assessment" Energies 14, no. 1: 61. https://doi.org/10.3390/en14010061

APA StyleElfasakhany, A. (2021). Dual and Ternary Biofuel Blends for Desalination Process: Emissions and Heat Recovered Assessment. Energies, 14(1), 61. https://doi.org/10.3390/en14010061