Pellet Production from Miscanthus: Energy and Environmental Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of Production System

2.2. Goal and Scope Definition

2.2.1. Functional Unit

2.2.2. System Boundary

2.3. Inventory Analysis

- -

- -

- -

- the emissions of active ingredient of pesticides considered completely released into the soil according to Rivera Schmidt et al. [58].

2.4. Life Cycle Impact Assessment

- -

- Global Warming (GW), expressed as kg CO2 eq.;

- -

- Stratospheric Ozone depletion (ODP), expressed as mg CFC-11 eq.;

- -

- Ozone formation, Human health (HOFP), expressed as g NOx eq.;

- -

- Fine particulate matter formation (PMFP), expressed as g PM2.5 eq.;

- -

- Ozone formation, Terrestrial ecosystems (EOFP), expressed as g NOx eq.;

- -

- Terrestrial acidification (TAP), expressed as kg SO2 eq.;

- -

- Freshwater eutrophication (FEP), expressed as g P eq.;

- -

- Marine eutrophication (MEP), expressed as g N eq.;

- -

- Terrestrial ecotoxicity (TETP), expressed as kg 1,4 DCB eq.;

- -

- Freshwater ecotoxicity (FETP), expressed as kg 1,4 DCB eq.;

- -

- Marine ecotoxicity (METP), expressed as kg 1,4 DCB eq.;

- -

- Human carcinogenic toxicity (HTPc), expressed as kg 1,4 DCB eq.;

- -

- Human non carcinogenic toxicity (HTPnc), expressed as kg 1,4 DCB eq.;

- -

- Mineral resource scarcity (SOP), expressed as g Cu-eq.;

- -

- Fossil resource scarcity (FFP), expressed as kg oil-eq.

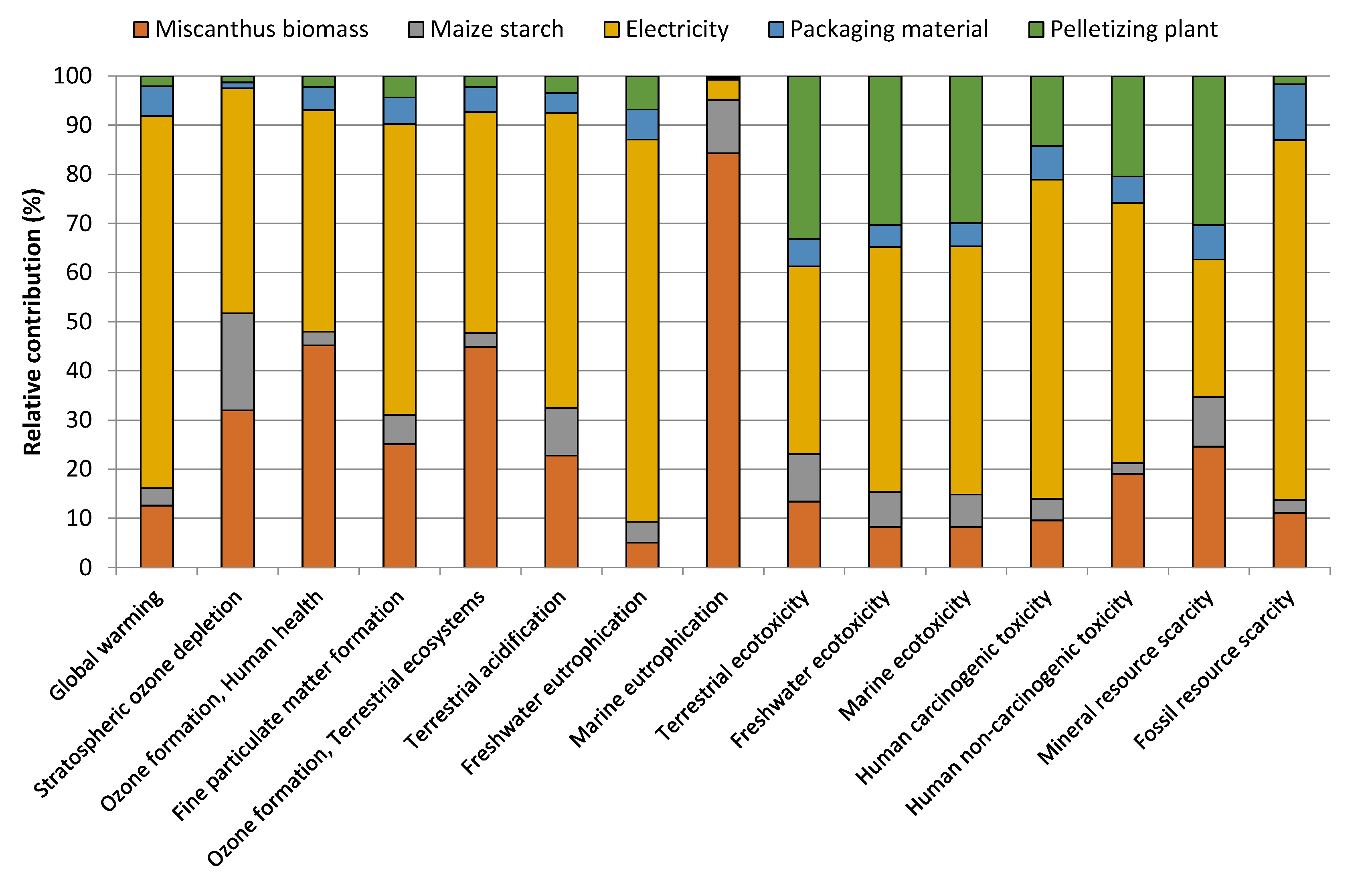

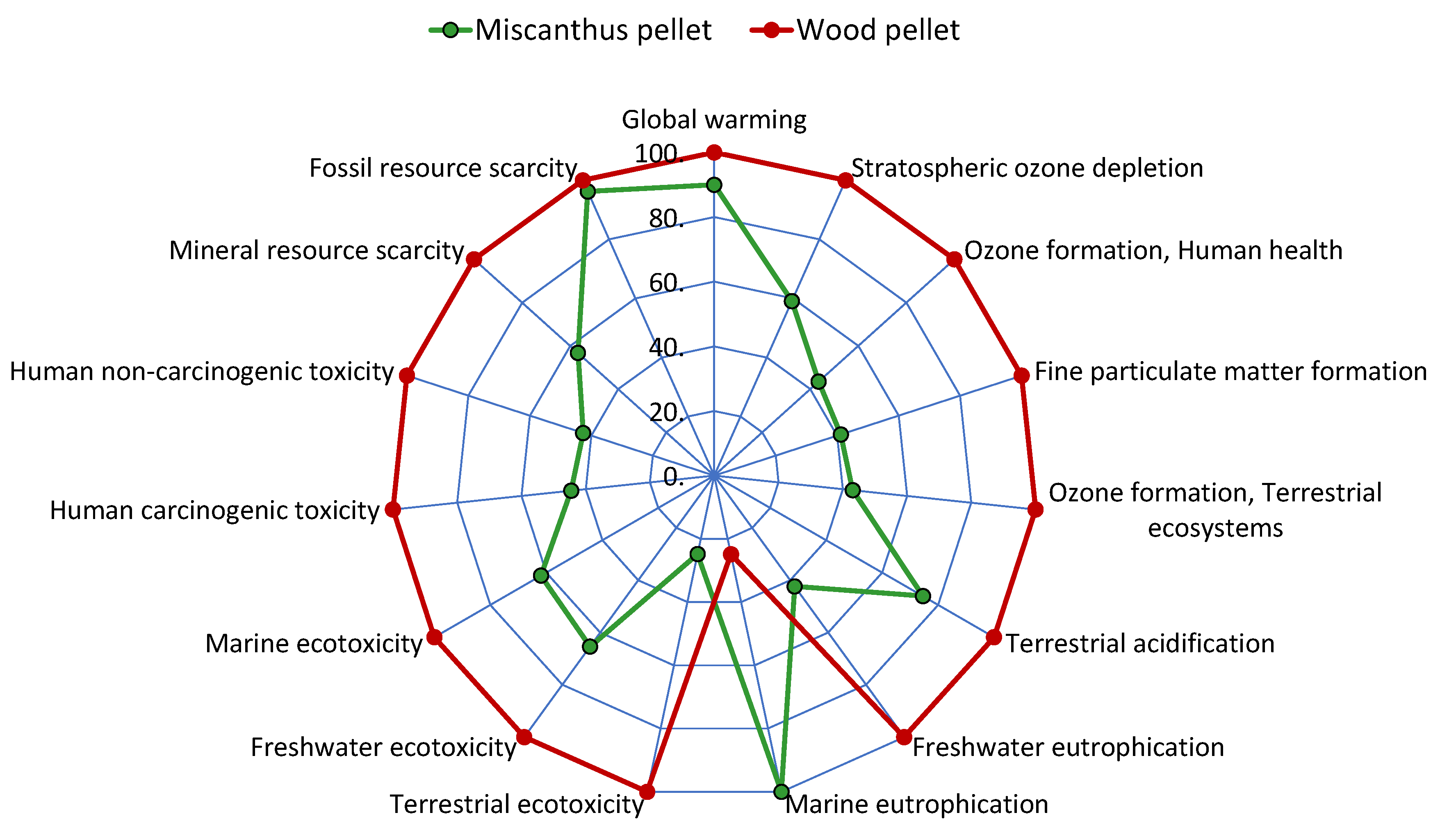

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Birgisdottir, H.; Moncaster, A.; Wiberg, A.H.; Chae, C.; Yokoyama, K.; Balouktsi, M.; Malmqvist, T. IEA EBC annex 57 ‘evaluation of embodied energy and CO2eq for building construction’. Energy Build. 2017, 154, 72–80. [Google Scholar] [CrossRef] [Green Version]

- Energy, G. CO2 Status Report; IEA (International Energy Agency): Paris, France, 2019. [Google Scholar]

- Lyytimäki, J. Renewable energy in the news: Environmental, economic, policy and technology discussion of biogas. Sustain. Prod. Consum. 2018, 15, 65–73. [Google Scholar] [CrossRef]

- Negri, M.; Bacenetti, J.; Manfredini, A.; Lovarelli, D.; Fiala, M.; Maggiore, T.M.; Bocchi, S. Evaluation of methane production from maize silage by harvest of different plant portions. Biomass Bioenergy 2014, 67, 339–346. [Google Scholar] [CrossRef]

- Ingrao, C.; Bacenetti, J.; Adamczyk, J.; Ferrante, V.; Messineo, A.; Huisingh, D. Investigating energy and environmental issues of agro-biogas derived energy systems: A comprehensive review of Life Cycle Assessments. Renew. Energy 2019, 136, 296–307c. [Google Scholar] [CrossRef]

- Kitzing, L.; Mitchell, C.; Morthorst, P.E. Renewable energy policies in Europe: Converging or diverging? Energy Policy 2012, 51, 192–201. [Google Scholar] [CrossRef] [Green Version]

- Connolly, D.; Lund, H.; Mathiesen, B.V. Smart Energy Europe: The technical and economic impact of one potential 100% renewable energy scenario for the European Union. Renew. Sustain. Energy Rev. 2016, 60, 1634–1653. [Google Scholar] [CrossRef]

- Fusi, A.; Bacenetti, J.; Fiala, M.; Azapagic, A. Life cycle environmental impacts of electricity from biogas produced by anaerobic digestion. Front. Bioeng. Biotechnol. 2016, 4, 26. [Google Scholar] [CrossRef] [Green Version]

- Bacenetti, J.; Fusi, A.; Azapagic, A. Environmental sustainability of integrating the organic Rankin cycle with anaerobic digestion and combined heat and power generation. Sci. Total. Environ. 2019, 658, 684–696. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 17225-1:2014. In Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- ISO. ISO 17225-2:2014. In Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- Duca, D.; Riva, G.; Pedretti, E.F.; Toscano, G. Wood pellet quality with respect to EN 14961-2 standard and certifications. Fuel 2014, 135, 9–14. [Google Scholar] [CrossRef]

- Zanetti, M.; Brandelet, B.; Marini, D.; Sgarbossa, A.; Giorio, C.; Badocco, D.; Tapparo, A.; Grigolato, S.; Rogaume, C.; Rogaume, Y.; et al. Vineyard pruning residues pellets for use in domestic appliances: A quality assessment according to the EN ISO 17225. J. Agric. Eng. 2017, 48, 99. [Google Scholar] [CrossRef] [Green Version]

- Rabaçal, M.; Fernandes, U.; Costa, M. Combustion and emission characteristics of a domestic boiler fired with pellets of pine, industrial wood wastes and peach stones. Renew. Energy 2013, 51, 220–226. [Google Scholar] [CrossRef]

- Ståhl, M.; Granström, K.; Berghel, J.; Renström, R. Industrial processes for biomass drying and their effects on the quality properties of wood pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Thrän, D.; Peetz, D.; Schaubach, K. Global Wood Pellet Industry and Trade Study 2017; IEA Bioenergy: Brussels, Belgium, 2017; ISBN 9781910154328. [Google Scholar]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Life cycle assessment of wood pellet production in Thailand. Sustainability 2020, 12, 6996. [Google Scholar] [CrossRef]

- Wood Pellets Market Size, Share & Trends Analysis Report by Application (Power Plants, Residential Heating, Commercial Heating, CHP Heating), by Region, and Segment Forecasts, 2020–2027. Report ID: GVR-2-68038-745-2. 2020, p. 118. Available online: https://www.grandviewresearch.com/industry-analysis/wood-pellets-market (accessed on 29 October 2020).

- Jonsson, R.; Rinaldi, F. The impact on global wood-product markets of increasing consumption of wood pellets within the European Union. Energy 2017, 133, 864–878. [Google Scholar] [CrossRef]

- Zamorano, M.; Popov, V.; Rodríguez, M.; García-Maraver, A. A comparative study of quality properties of pelletized agricultural and forestry lopping residues. Renew. Energy 2011, 36, 3133–3140. [Google Scholar] [CrossRef]

- González-García, S.; Bacenetti, J. Exploring the production of bio-energy from wood biomass. Italian case study. Sci. Total. Environ. 2019, 647, 158–168. [Google Scholar] [CrossRef]

- Bacenetti, J. Heat and cold production for winemaking using pruning residues: Environmental impact assessment. Appl. Energy 2019, 252, 113464. [Google Scholar] [CrossRef]

- Styles, D.; Gibbons, J.; Williams, A.P.; Dauber, J.; Stichnothe, H.; Urban, B.; Chadwick, D.R.; Jones, D.L. Consequential life cycle assessment of biogas, biofuel and biomass energy options within an arable crop rotation. GCB Bioenergy 2015, 7, 1305–1320. [Google Scholar] [CrossRef] [Green Version]

- Angelini, L.; Ceccarini, L.; O Di Nasso, N.N.; Bonari, E. Comparison of Arundo donax L. and Miscanthus x giganteus in a long-term field experiment in Central Italy: Analysis of productive characteristics and energy balance. Biomass Bioenergy 2009, 33, 635–643. [Google Scholar] [CrossRef]

- Liu, C.; Xiao, L.; Jiang, J.; Wang, W.; Gu, F.; Song, D.; Yi, Z.; Jin, Y.; Li, L. Biomass properties from different Miscanthus species. Food Energy Secur. 2013, 2, 12–19. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huismand, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenerg 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Heaton, E.A.; Dohleman, F.G.; Long, S.P. Meeting US biofuel goals with less land: The potential of Miscanthus. Glob. Chang. Biol. 2008, 14, 2000–2014. [Google Scholar] [CrossRef]

- Miguez, F.E.; Villamil, M.B.; Long, S.P.; Bollero, G.A. Meta-analysis of the effects of management factors on Miscanthus×giganteus growth and biomass production. Agric. For. Meteorol. 2008, 148, 1280–1292. [Google Scholar] [CrossRef]

- Maughan, M.; A Bollero, G.; Lee, D.K.; Darmody, R.G.; A Bonos, S.; Cortese, L.M.; Murphy, J.; E Gaussoin, R.; Sousek, M.; Williams, D.W.; et al. Miscanthus×giganteus productivity: The effects of management in different environments. Glob. Change Biol. Bioenergy 2012, 4, 253–265. [Google Scholar] [CrossRef]

- Bilandžija, N.; Voća, N.; Leto, J.; Jurišić, V.; Grubor, M.; Matin, A.; Krička, T. Yield and biomass composition of Miscanthus x giganteus in the mountain area of Croatia. Trans. Famena 2018, 42, 51–60. [Google Scholar] [CrossRef] [Green Version]

- Bernardi, B.; Falcone, G.; Stillitano, T.; Benalia, S.; Strano, A.; Bacenetti, J.; De Luca, A.I. Harvesting system sustainability in Mediterranean olive cultivation. Sci. Total. Environ. 2018, 625, 1446–1458. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Paolotti, L.; Martino, G.; Marchini, A.; Boggia, A. Economic and environmental assessment of agro-energy wood biomass supply chains. Biomass Bioenergy 2017, 97, 172–185. [Google Scholar] [CrossRef]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural anaerobic digestion plants: What LCA studies pointed out and what can be done to make them more environmentally sustainable. Appl. Energy 2016, 179, 669–686. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, D.; Miguel, G.S.; Corona, B.; López, F. LCA of a multifunctional bioenergy chain based on pellet production. Fuel 2018, 215, 601–611. [Google Scholar] [CrossRef]

- Monteleone, B.; Chiesa, M.; Marzuoli, R.; Verma, V.; Schwarz, M.; Carlon, E.; Schmidl, C.; Denti, A.B. Life cycle analysis of small scale pellet boilers characterized by high efficiency and low emissions. Appl. Energy 2015, 155, 160–170. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef] [Green Version]

- Judl, J.; Koskela, S.; Korpela, T.; Karvosenoja, N.; Häyrinen, A.; Rantsi, J. Net environmental impacts of low-share wood pellet co-combustion in an existing coal-fired CHP (combined heat and power) production in Helsinki, Finland. Energy 2014, 77, 844–851. [Google Scholar] [CrossRef]

- Song, S.; Liu, P.; Xu, J.; Chong, C.; Huang, X.; Ma, L.; Li, Z.; Ni, W. Life cycle assessment and economic evaluation of pellet fuel from corn straw in China: A case study in Jilin Province. Energy 2017, 130, 373–381. [Google Scholar] [CrossRef]

- Wang, C.; Chang, Y.; Zhang, L.; Pang, M.; Hao, Y. A life-cycle comparison of the energy, environmental and economic impacts of coal versus wood pellets for generating heat in China. Energy 2017, 120, 374–384. [Google Scholar] [CrossRef]

- Perić, M.; Komatina, M.; Antonijević, D.; Bugarski, B.; Dželetović, Ž. Life cycle impact assessment of Miscanthus crop for sustainable household heating in Serbia. Forests 2018, 9, 654. [Google Scholar] [CrossRef] [Green Version]

- Perrin, A.; Wohlfahrt, J.; Morandi, F.; Østergård, H.; Flatberg, T.; De La Rua, C.; Gabrielle, B. Integrated design and sustainable assessment of innovative biomass supply chains: A case-study on miscanthus in France. Applied Energy 2017, 204, 66–77. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; McDonnell, K. Miscanthus production and processing in Ireland: An analysis of energy requirements and environmental impacts. Renew. Sustain. Energy Rev. 2013, 23, 412–420. [Google Scholar] [CrossRef] [Green Version]

- Sanscartier, D.; Deen, B.; Dias, G.; MacLean, H.L.; Dadfar, H.; McDonald, I.; Kludze, H. Implications of land class and environmental factors on life cycle GHG emissions of Miscanthus as a bioenergy feedstock. GCB Bioenergy 2014, 6, 401–413. [Google Scholar] [CrossRef]

- Brentrup, F.; Küsters, J.; Lammel, J.; Kuhlmann, H. Methods to estimate on-field nitrogen emissions from crop production as an input to LCA studies in the agricultural sector. Int. J. Life Cycle Assess. 2000, 5, 349–357. [Google Scholar] [CrossRef]

- Brandão, M.; I Canals, L.M.; Clift, R. Soil organic carbon changes in the cultivation of energy crops: Implications for GHG balances and soil quality for use in LCA. Biomass Bioenergy 2011, 35, 2323–2336. [Google Scholar] [CrossRef]

- Noya, I.; González-García, S.; Bacenetti, J.; Arroja, L.; Moreira, M.T. Comparative life cycle assessment of three representative feed cereals production in the Po Valley (Italy). J. Clean. Prod. 2015, 99, 250–265. [Google Scholar] [CrossRef]

- ISO. EN ISO 18134-1:2015. In Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. ISO 18122:2015. In Solid Biofuels—Determination of Ash Content; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. ISO 15210-1:2009. In Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- ISO. ISO 16948:2015. In Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Hamedani, S.R.; Colantoni, A.; Gallucci, F.; Salerno, M.; Silvestri, C.; Villarini, M. Comparative energy and environmental analysis of agro-pellet production from orchard woody biomass. Biomass Bioenergy 2019, 129, 105334. [Google Scholar] [CrossRef]

- Nemecek, T.; Kägi, T.; Blaser, S. Life cycle inventories of agricultural production systems. In Final Report Ecoinvent v2; No.15; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Lovarelli, D.; Bacenetti, J. Bridging the gap between reliable data collection and the environmental impact for mechanised field operations. Biosyst. Eng. 2017, 160, 109–123. [Google Scholar] [CrossRef]

- Talagai, N.; Marcu, M.V.; Zimbalatti, G.; Proto, A.R.; Borz, S.A. Productivity in partly mechanized planting operations of willow short rotation coppice. Biomass Bioenergy 2020, 138, 105609. [Google Scholar] [CrossRef]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. Change, Intergovernmental Panel On Climate. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Kanagawa, Japan, 2006. [Google Scholar]

- Prasuhn, V. Erfassung der PO4-Austräge für die Ökobilanzierung; Salca-Phosphor: Agroscope, Switzerland, 2006. [Google Scholar]

- Rivera, X.C.S.; Bacenetti, J.; Fusi, A.; Niero, M. The influence of fertiliser and pesticide emissions model on life cycle assessment of agricultural products: The case of Danish and Italian barley. Sci. Total. Environ. 2017, 592, 745–757. [Google Scholar] [CrossRef] [Green Version]

- Moreno Ruiz, E.; Valsasina, L.; FitzGerald, D.; Symeonidis, A.; Müller, J.; Minas, N.; Wernet, G. Documentation of Changes Implemented in Ecoinvent Database v3.7; Ecoinvent Association: Zürich, Switzerland, 2020. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Costantini, M.; Vázquez-Rowe, I.; Manzardo, A.; Bacenetti, J. Environmental impact assessment of beef cattle production in semi-intensive systems in Paraguay. Sustain. Prod. Consum. 2021, 27, 269–281. [Google Scholar] [CrossRef]

| Operation | Year | NN [1] | Tractor | Operative Machine | Note | ||

|---|---|---|---|---|---|---|---|

| Mass Power | Type, Main Characteristics (Mass) | Time h ha−1 | FC [2] kg ha−1 | ||||

| Primary soil tillage with ripper | 1 | 1 | 7800 kg 140 kW | Ripper, 3 anchors, 40 cm depth (1900 kg) | 0.83 | 35.6 | |

| Primary soil tillage ploughing | 1 | 1 | 7800 kg 140 kW | Ploughing, 4 furrows, 35 cm depth, (1050 kg) | 25.7 | ||

| Secondary soil tillage harrowing | 1 | 2 | 5600 kg 100 kW | Rotary harrow, 5 m width (2250 kg) | 22 | ||

| Transplanting | 1 | 1 | 5600 kg 100 kW | Transplanter (1250 kg) | 2 | 25 | 15,000 rhizomes ha−1 |

| Irrigation | 1 | 1 | Pump 240 kW | 2 | 70 | 400 m3 ha−1 | |

| Harvesting | From 1 to 15 | 1 | - | Forager 460 kW (13,150 kg) | 0.35 | 33.3 | [3] |

| Transport | From 1 to 15 | 1 | 7800 kg 140 kW | Trailer, 30 m3 (2200 kg) | 0.7 | 10 | 1.5 km |

| From 1 to 15 | 1 | 5600 kg 100 kW | Trailer, 30 m3 (2200 kg) | 0.7 | 10 | ||

| Chemical weeding | 15 | 1 | 4000 kg 65 kW | Sprayer, 24 m width (600 kg) | 1.0 | 3.3 | 10 L∙ha−1 [4] |

| Stumps chopping | 15 | 1 | 5600 kg 100 kW | Stalk-chopper, 3 m width (1250 kg) | 0.6 | 15 | |

| Process/Activity | Unit | Amount |

|---|---|---|

| Input | ||

| Chopped miscanthus | kg∙kg of pellet−1 | 1.11 |

| Maize starch | g∙kg of pellet−1 | 5 |

| Electricity | kWh∙kg of pellet−1 MWh∙year−1 | 0.204 224 |

| Packaging film | G∙kg of pellet−1 | 2.28 |

| Output | ||

| Wood pellet | Ton∙year−1 | 1103 |

| Moisture Content | Ash | Higher Heating Value | Lower Heating Value | C | H | N | O | Pellet Durability Index |

|---|---|---|---|---|---|---|---|---|

| 8.29% | 2.94% | 18.64 MJ∙kg−1 | 17.80 MJ∙kg−1 | 45.40% | 4.10% | 1.34% | 46.25% | 94.6% |

| Process Retrieved from Database | Note |

|---|---|

| Tractor, 4-wheel, agricultural {GLO}|market for |APOS, U | Used to build soil tillage, planting, soil restoring and transport [1] |

| Diesel {CH}|market for|APOS, U | Used to build the different field operations [1] |

| Agricultural machinery, tillage {GLO}|market for|APOS, U | Used to build the process soil tillage, planting, and stump chopping [1] |

| Agricultural machinery, unspecified {GLO}|market for|APOS, U | Used to build herbicide application [1] |

| Harvester {GLO}|market for|APOS, U | Used to build the harvesting operation [1] |

| Agricultural trailer {GLO}|market for|APOS, U | Used to build the process the transport operation [1] |

| Lubricating oil {RER}|production|APOS, U | Used in the different field operations as well as at the pelletizing plant [1] |

| Shed {GLO}|market for|APOS, U | Used to build the different field operations |

| Glyphosate {GLO}|market for|APOS, U | Consumed during soil recovery |

| Miscanthus rhizome, for planting {DE}|production|APOS, U | Modified considering the Italian context and cultivation practice |

| Electricity, medium voltage {IT}|market for|APOS, U | Consumed at the pelletizing plant |

| Maize starch {GLO}|market for|APOS, U | Consumed at the pelletizing plant |

| Dust collector, electrostatic precipitator, for industrial use {GLO}|market for|APOS, U | Used to build the pelletizing process |

| Dust collector, multicyclone {GLO}|market for|APOS, U | Used to build the pelletizing process |

| Wood pellet factory {RER}|production|APOS, U | Used to build the pelletizing process |

| Packaging film, low density polyethylene {GLO}|market for|APOS, U | Consumed at the pelletizing plant |

| Impact Category | Unit | Total | Main Substance | Main Process |

|---|---|---|---|---|

| Global warming | kg CO2 eq. | 13.788 | CO2, fossil | Combine harvesting {GLO}|processing|Miscanthus|APOS, U [1] |

| Stratospheric ozone depletion | mg CFC11 eq. | 45.770 | NO | Emission N &P compounds |

| Ozone formation, Human health | kg NOx eq. | 0.153 | NOx | Combine harvesting {GLO}|processing|Miscanthus|APOS, U [1] |

| Fine particulate matter formation | g PM2.5 eq. | 41.400 | NOx & Particulates | Combine harvesting {GLO}|processing|Miscanthus|APOS, U [1] |

| Ozone formation, Terrestrial ecosystems | kg NOx eq. | 0.155 | NOx | Combine harvesting {GLO}|processing|Miscanthus|APOS, U [1] |

| Terrestrial acidification | kg SO2 eq. | 0.110 | NOx & NH3 | Combine harvesting {GLO}|processing|Miscanthus|APOS, U [1] |

| Freshwater eutrophication | g P eq. | 1.517 | PO43− | Harvester {GLO} market for|APOS [2] |

| Marine eutrophication | g N eq. | 47.995 | NO3− | Emission N &P compounds |

| Terrestrial ecotoxicity | kg 1,4DCB | 33.270 | Copper | Harvester {GLO} market for|APOS [3] |

| Freshwater ecotoxicity | kg 1,4DCB | 0.390 | Copper | Harvester {GLO} market for|APOS [4] |

| Marine ecotoxicity | kg 1,4DCB | 0.496 | Copper & zinc | Harvester {GLO} market for|APOS [4] |

| Human carcinogenic toxicity | kg 1,4DCB | 0.293 | Chromium VI | Harvester {GLO} market for|APOS [5] |

| Human non-carcinogenic toxicity | kg 1,4DCB | 16.766 | Zinc | Combine harvesting {ITA}|processing|Miscanthus|APOS, U |

| Mineral resource scarcity | g Cu eq. | 78.716 | Gold & Iron | Harvester {GLO} market for|APOS [6] |

| Fossil resource scarcity | kg oil eq. | 3.819 | Oil crude | Diesel {GLO} market for|APOS |

| Impact Category | FU = 1 ton | FU = 1 GJ | |

|---|---|---|---|

| Global warming | kg CO2 eq. | 121.640 | 6.796 |

| Stratospheric ozone depletion | mg CFC11 eq. | 159.037 | 8.885 |

| Ozone formation, Human health | kg NOx eq. | 375.776 | 20.993 |

| Fine particulate matter formation | g PM2.5 eq. | 183.354 | 10.243 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq. | 383.144 | 21.405 |

| Terrestrial acidification | kg SO2 eq. | 0.535 | 0.030 |

| Freshwater eutrophication | g P eq. | 33.624 | 1.878 |

| Marine eutrophication | g N eq. | 63.263 | 3.534 |

| Terrestrial ecotoxicity | kg 1,4DCB | 275.529 | 15.393 |

| Freshwater ecotoxicity | kg 1,4DCB | 5.258 | 0.294 |

| Marine ecotoxicity | kg 1,4DCB | 6.737 | 0.376 |

| Human carcinogenic toxicity | kg 1,4DCB | 3.400 | 0.190 |

| Human non-carcinogenic toxicity | kg 1,4DCB | 96.343 | 5.382 |

| Mineral resource scarcity | g Cu eq. | 355.915 | 19.884 |

| Fossil resource scarcity | kg oil eq. | 38.146 | 2.131 |

| Impact Category | Biomass Yield | Electricity | Packaging Material | |||

|---|---|---|---|---|---|---|

| +20% | −20% | +20% | −20% | +20% | −20% | |

| Global warming | 2.52% | −2.52% | −15.15% | 15.15% | −1.21% | 1.21% |

| Stratospheric ozone depletion | 6.39% | −6.39% | −9.15% | 9.15% | −0.24% | 0.24% |

| Ozone formation, Human health | 9.04% | −9.04% | −9.02% | 9.02% | −0.95% | 0.95% |

| Fine particulate matter formation | 5.01% | −5.01% | −11.84% | 11.84% | −1.08% | 1.08% |

| Ozone formation, Terrestrial ecosystems | 8.98% | −8.98% | −8.99% | 8.99% | −1.00% | 1.00% |

| Terrestrial acidification | 4.55% | −4.55% | −12.00% | 12.00% | −0.81% | 0.81% |

| Freshwater eutrophication | 1.00% | −1.00% | −15.55% | 15.55% | −1.22% | 1.22% |

| Marine eutrophication | 16.86% | −6.86% | −0.81% | 0.81% | −0.08% | 0.08% |

| Terrestrial ecotoxicity | 2.68% | −2.68% | −7.66% | 7.66% | −1.11% | 1.11% |

| Freshwater ecotoxicity | 1.65% | −1.65% | −9.96% | 9.96% | −0.90% | 0.90% |

| Marine ecotoxicity | 1.63% | −1.63% | −10.11% | 10.11% | −0.93% | 0.93% |

| Human carcinogenic toxicity | 1.91% | −1.91% | −13.00% | 13.00% | −1.36% | 1.36% |

| Human non-carcinogenic toxicity | 3.87% | −3.87% | −11.21% | 11.21% | −1.09% | 1.09% |

| Mineral resource scarcity | 4.91% | −4.91% | −5.60% | 5.60% | −1.40% | 1.40% |

| Fossil resource scarcity | 2.22% | −2.22% | −14.65% | 14.65% | −2.28% | 2.28% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fusi, A.; Bacenetti, J.; Proto, A.R.; Tedesco, D.E.A.; Pessina, D.; Facchinetti, D. Pellet Production from Miscanthus: Energy and Environmental Assessment. Energies 2021, 14, 73. https://doi.org/10.3390/en14010073

Fusi A, Bacenetti J, Proto AR, Tedesco DEA, Pessina D, Facchinetti D. Pellet Production from Miscanthus: Energy and Environmental Assessment. Energies. 2021; 14(1):73. https://doi.org/10.3390/en14010073

Chicago/Turabian StyleFusi, Alessandra, Jacopo Bacenetti, Andrea R. Proto, Doriana E. A. Tedesco, Domenico Pessina, and Davide Facchinetti. 2021. "Pellet Production from Miscanthus: Energy and Environmental Assessment" Energies 14, no. 1: 73. https://doi.org/10.3390/en14010073

APA StyleFusi, A., Bacenetti, J., Proto, A. R., Tedesco, D. E. A., Pessina, D., & Facchinetti, D. (2021). Pellet Production from Miscanthus: Energy and Environmental Assessment. Energies, 14(1), 73. https://doi.org/10.3390/en14010073