Online Short-Term Remaining Useful Life Prediction of Fuel Cell Vehicles Based on Cloud System

Abstract

1. Introduction

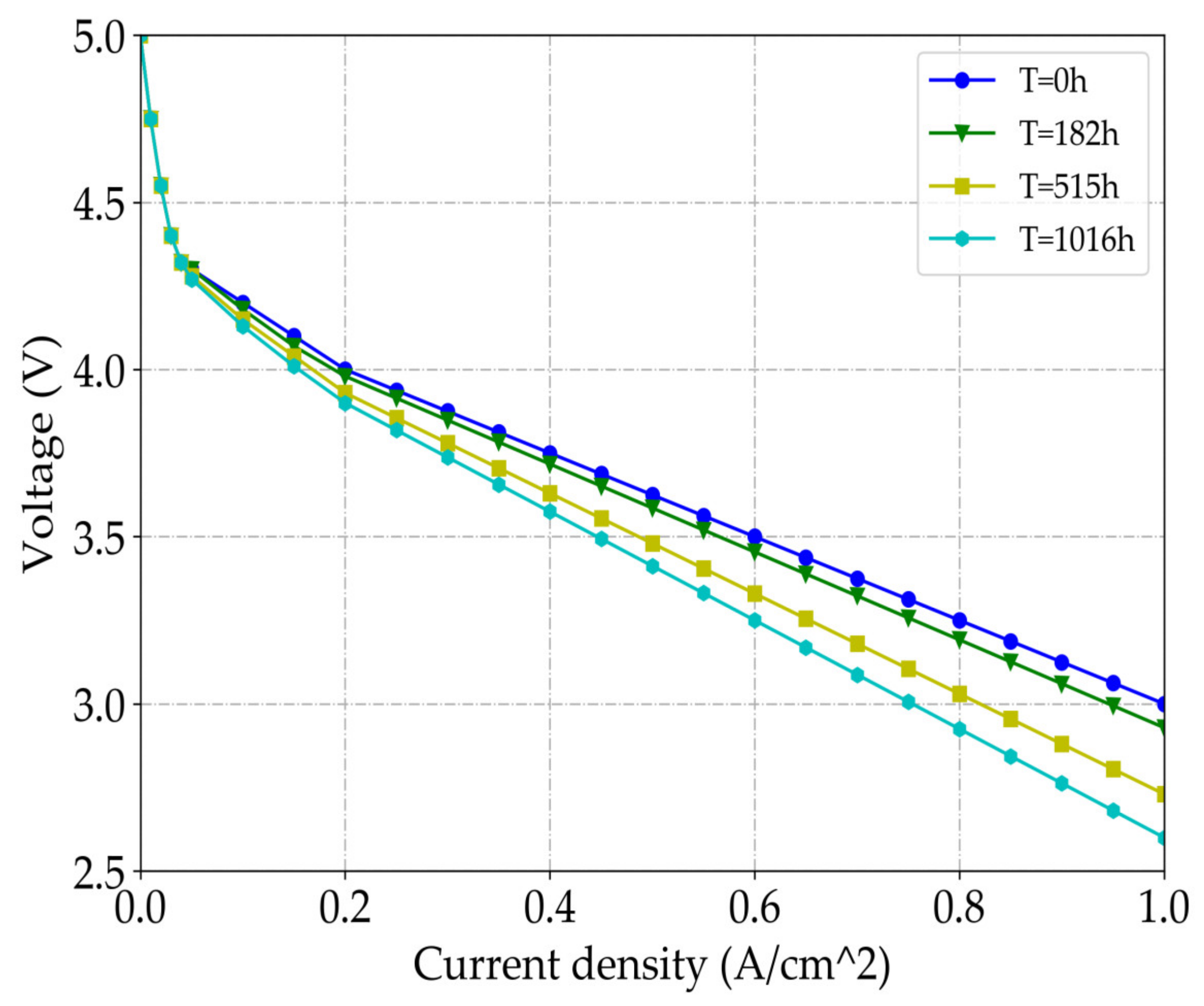

2. PEMFC Health Indicators under Multiple Operating Conditions

- The parameters need to be collected by the existing equipment on the fuel cell bus.

- The parameters on the fuel cell bus need to be collected online.

- The parameters must be able to better ignore the influence caused by abnormal conditions.

3. Self-Renewing RUL Prediction Model

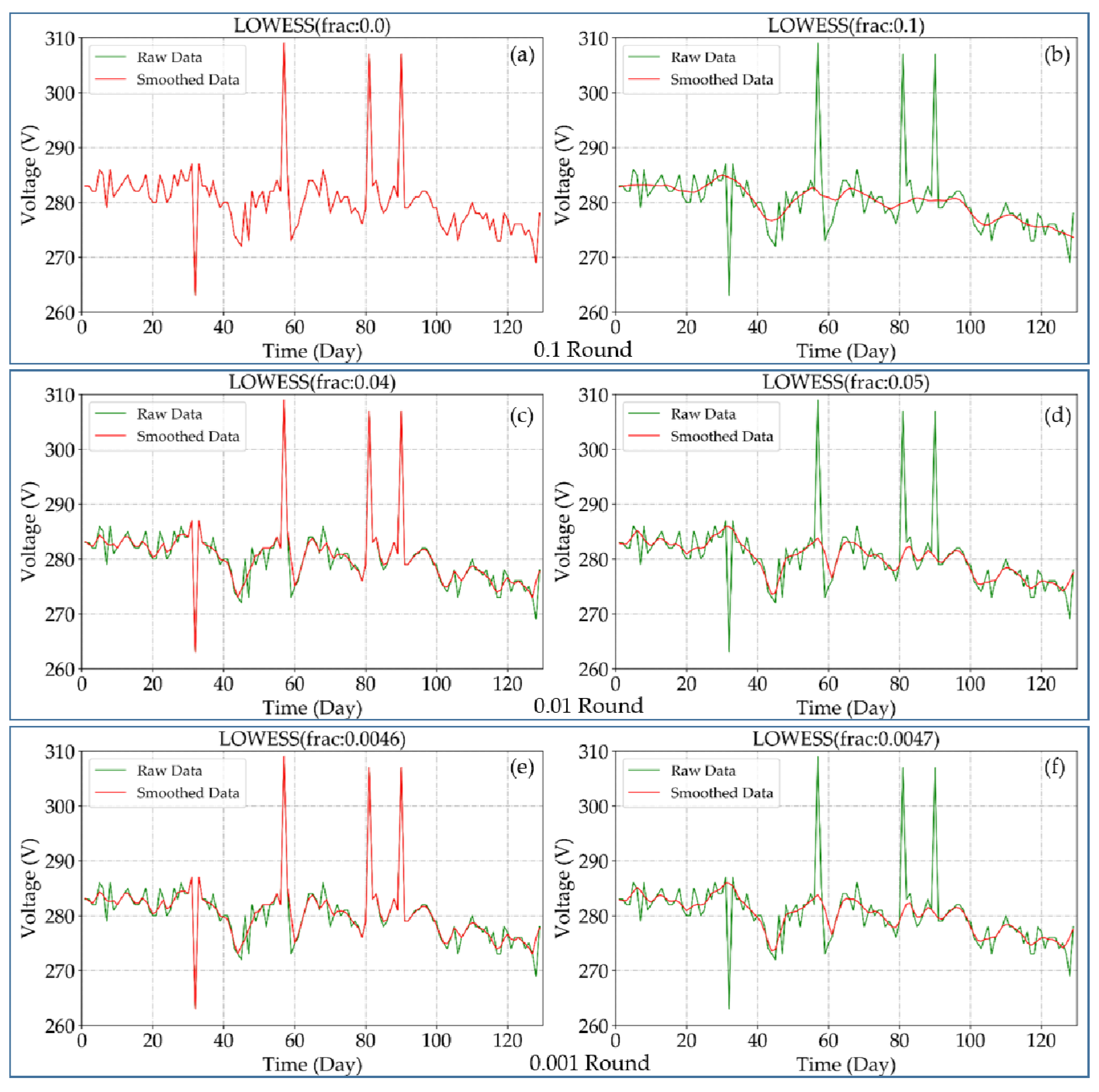

3.1. Noise Processing

- The step size , which indicates how long the data set should be intercepted to obtain a locally weighted regression line. The is the ratio of the original data; the value range is (0,1).

- The weight function , which is the above Equation (1) and can generally be a quadratic or cubic function.

- The iteration number is the number of local regression operations in the selected data set.

- The regression interval indicates how many points are separated for a weighted regression, and the interval points can be replaced by interpolation.

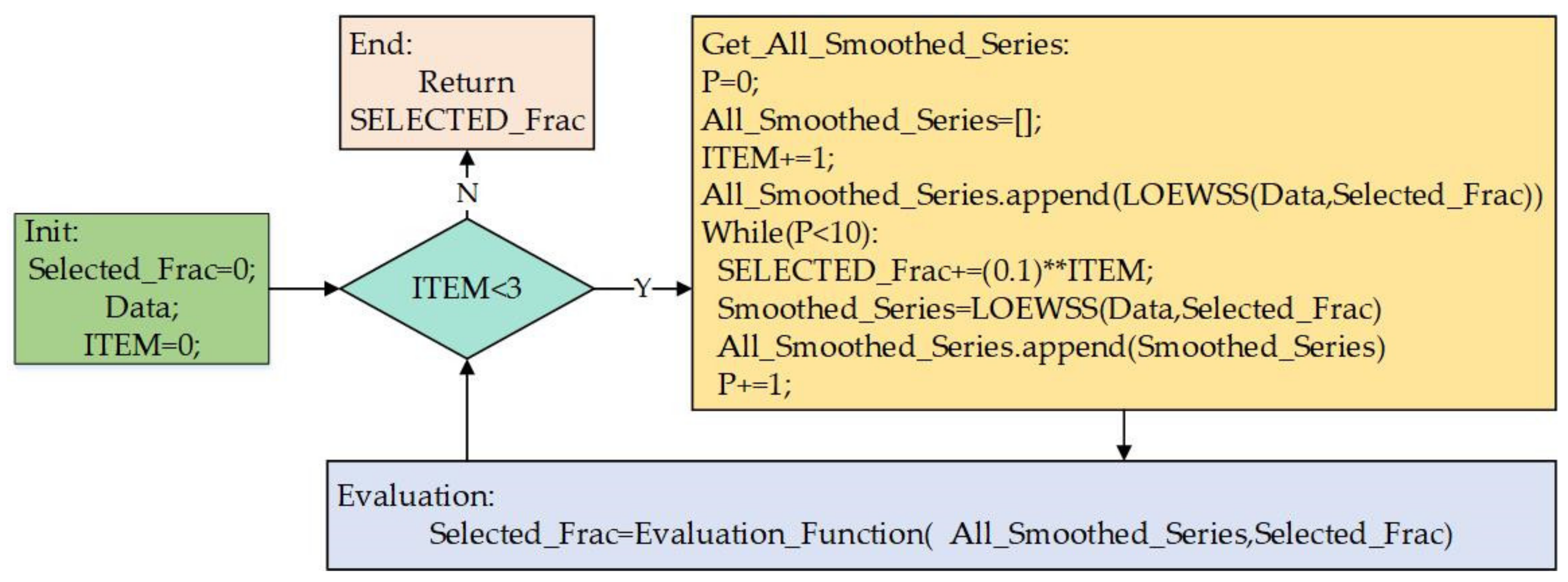

- Init: and are initialized, and then is input into the algorithm, which is the original data set.

- The whole process is divided into three rounds—namely, 0.1 round, 0.01 round, and 0.001 round, which corresponds to items that equal 0, 1, and 2, respectively.

- Get_All_Smoothed_Series: based on the found from the previous round, traverse all the LOWESS sequences of in this round; there are a total of eleven groups.

- Evaluation: select the most suitable for this round through the evaluation function and assign it to .

- If the traversal is completed, it returns , which is the most suitable . Otherwise, skip back to the second step to continue.

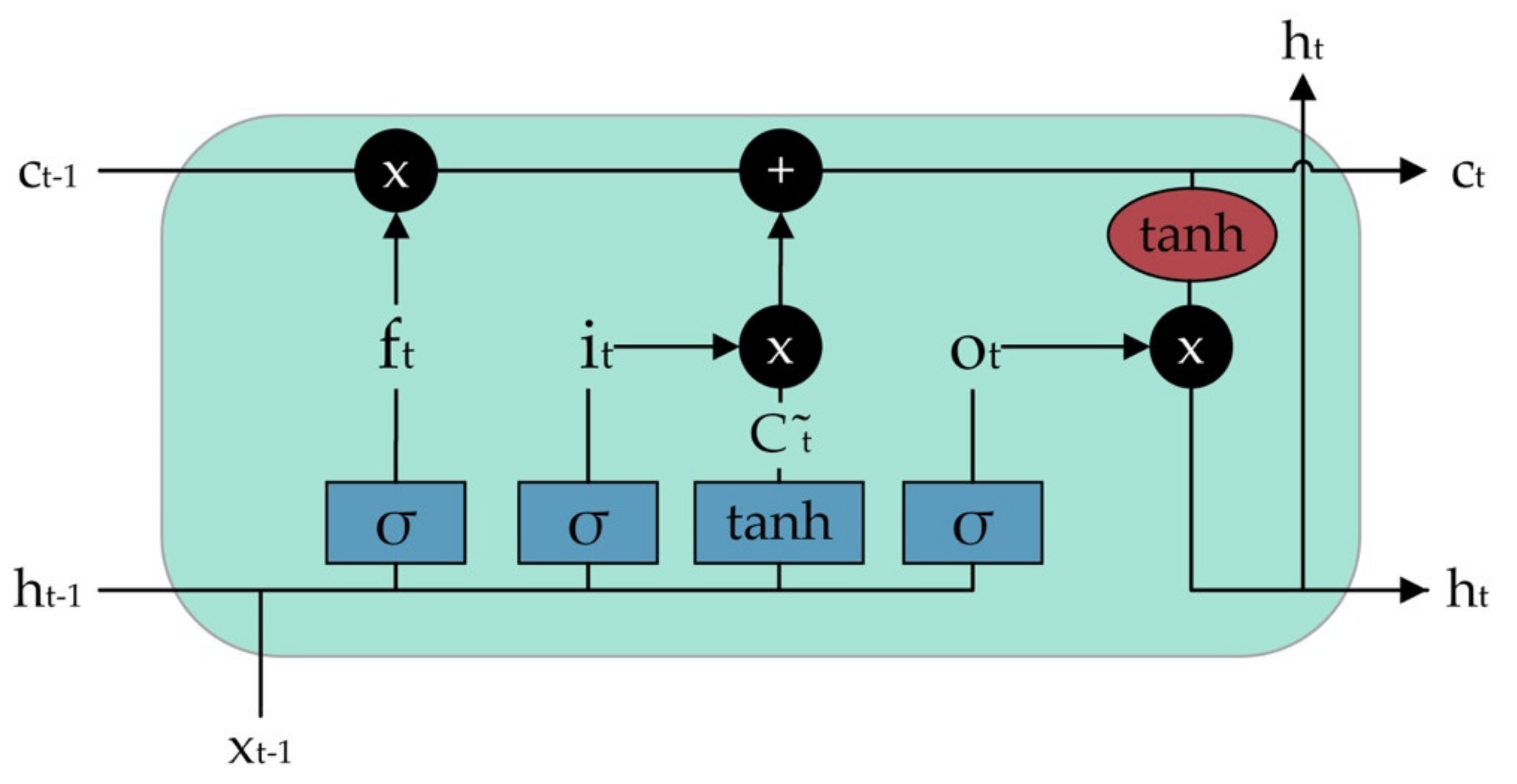

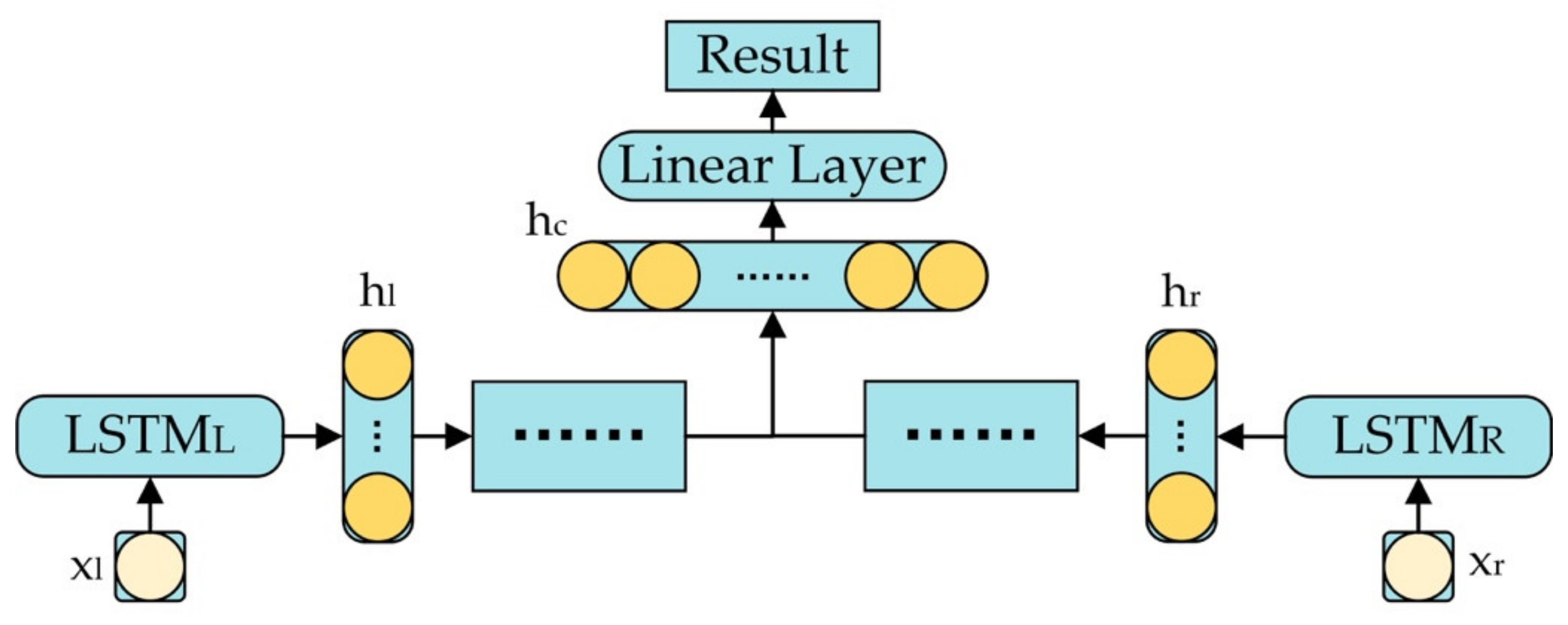

3.2. Short-Term RUL Prediction Model

4. Online Operation Scheme on Cloud System

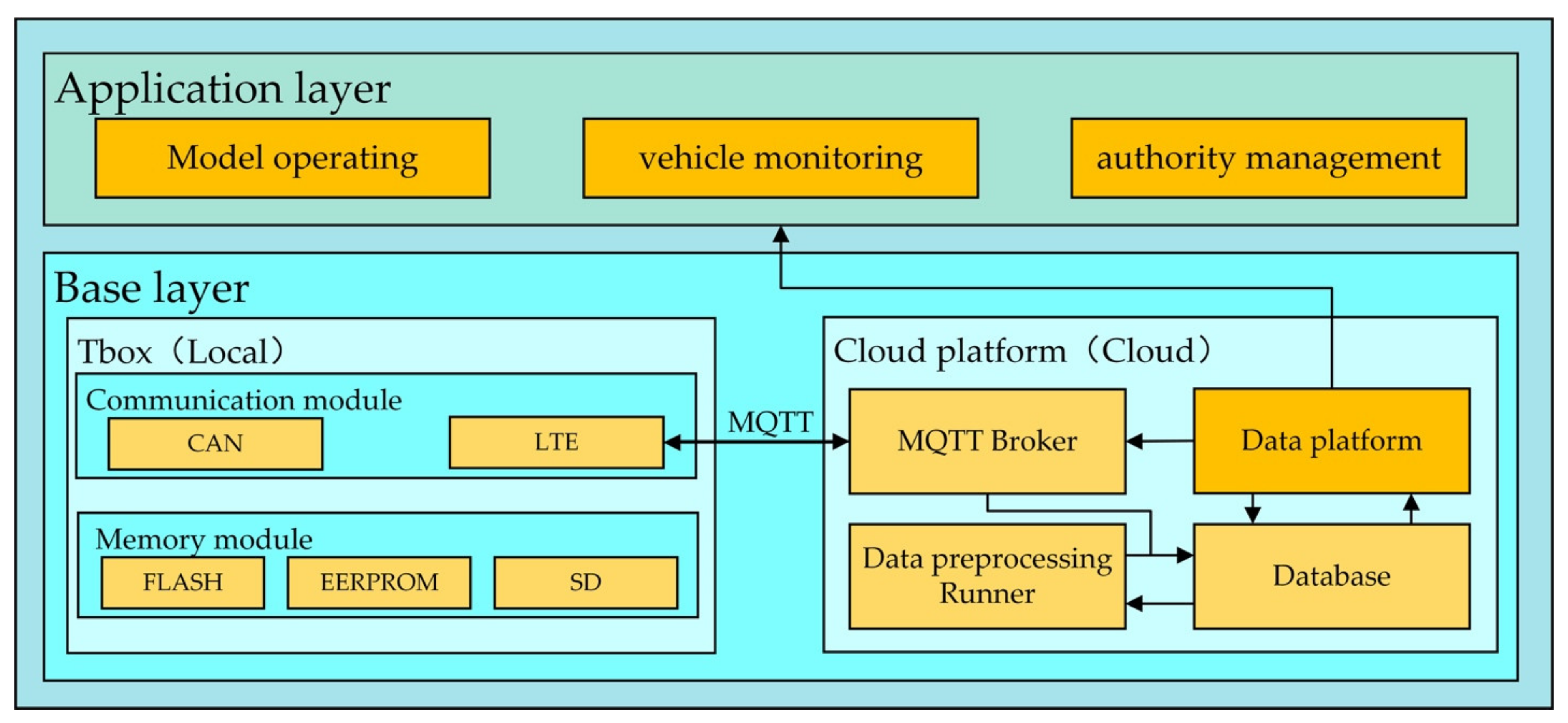

4.1. Cloud System

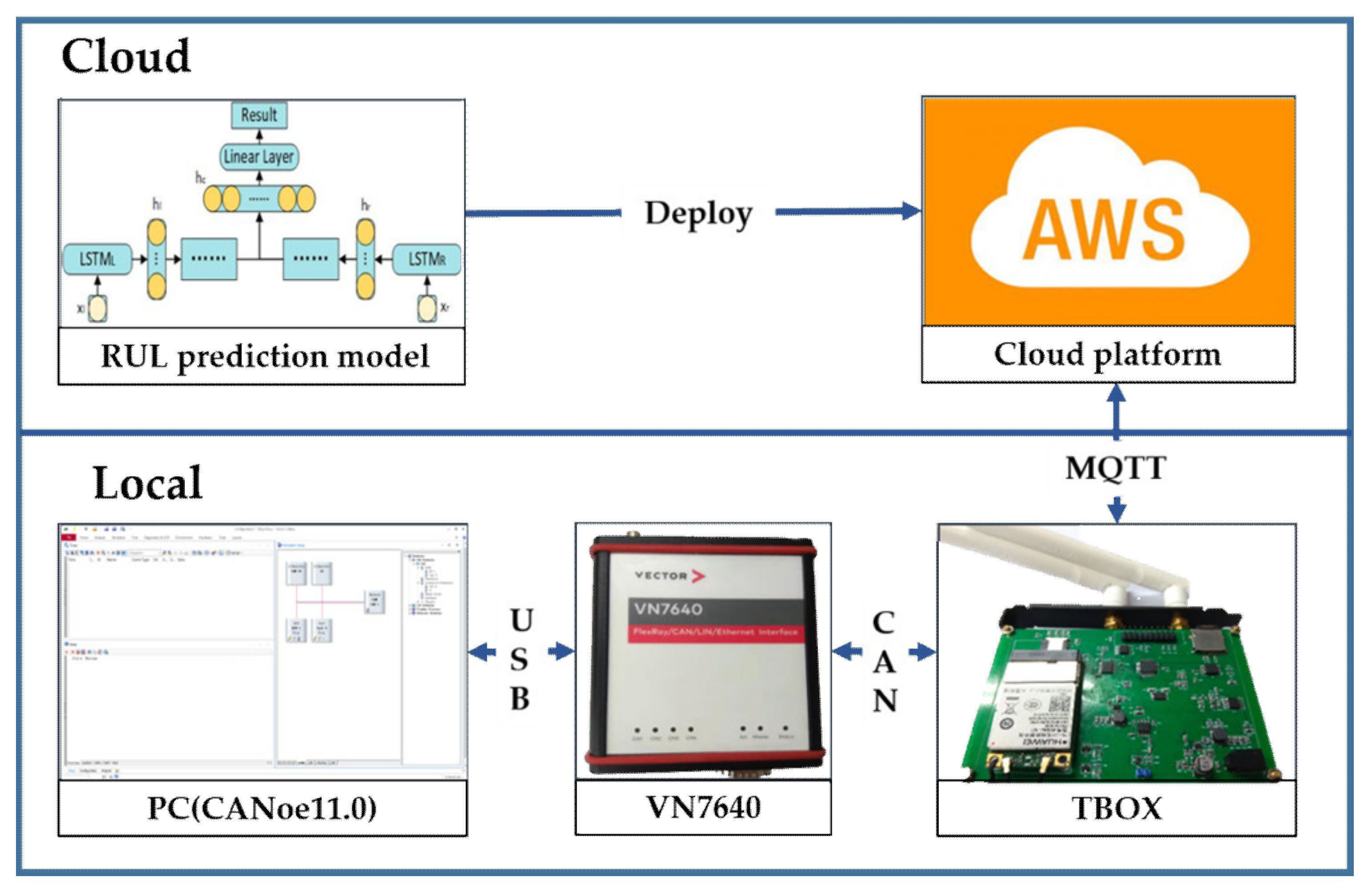

4.2. Online Operation Scheme

- The data platform has a RUL prediction task detector, which checks daily whether the model needs to be updated. Its judgment condition of trigger is whether the number of days from the last execution time of a task exceeds its update days (the number of update days is set to 5 days). If so, model training is triggered.

- Before the data denoising process, it is necessary to analyze whether the sequence is a white noise sequence. In the second step, historical data are taken out to perform white noise detection on them. Acorr-Ljung-Box was used to verify whether the data in this work were white noise. The is set to 1. and is calculated. The Stat is the Ljung–Box test statistic. The value is the evidence against a null hypothesis. The smaller the value, the stronger is the evidence for rejecting the null hypothesis. If is less than 0.05—that is, the data are not white noise data—skip to the third step. Otherwise, the cloud platform alarm is triggered for human intervention.

- Using adaptive LOWESS to smooth and denoise the data, the smoothed data are normalized and regularized to improve model training.

- The Glorot normal distribution is used to initialize the input weights, and the uniform random distribution is used to initialize the hidden layer threshold, which effectively avoid under-fitting to a certain extent. Subsequently, the data are input into the Bi-LSTM model for training.

- The health indicator value of vehicle stack in the next five days is predicted through the trained model, followed by storage of the results in the cloud platform database.

5. Simulation Experimental Environment

6. Result and Discussion

6.1. Validation of Adaptive LOWESS and Bi-LSTM RUL Prediction Model

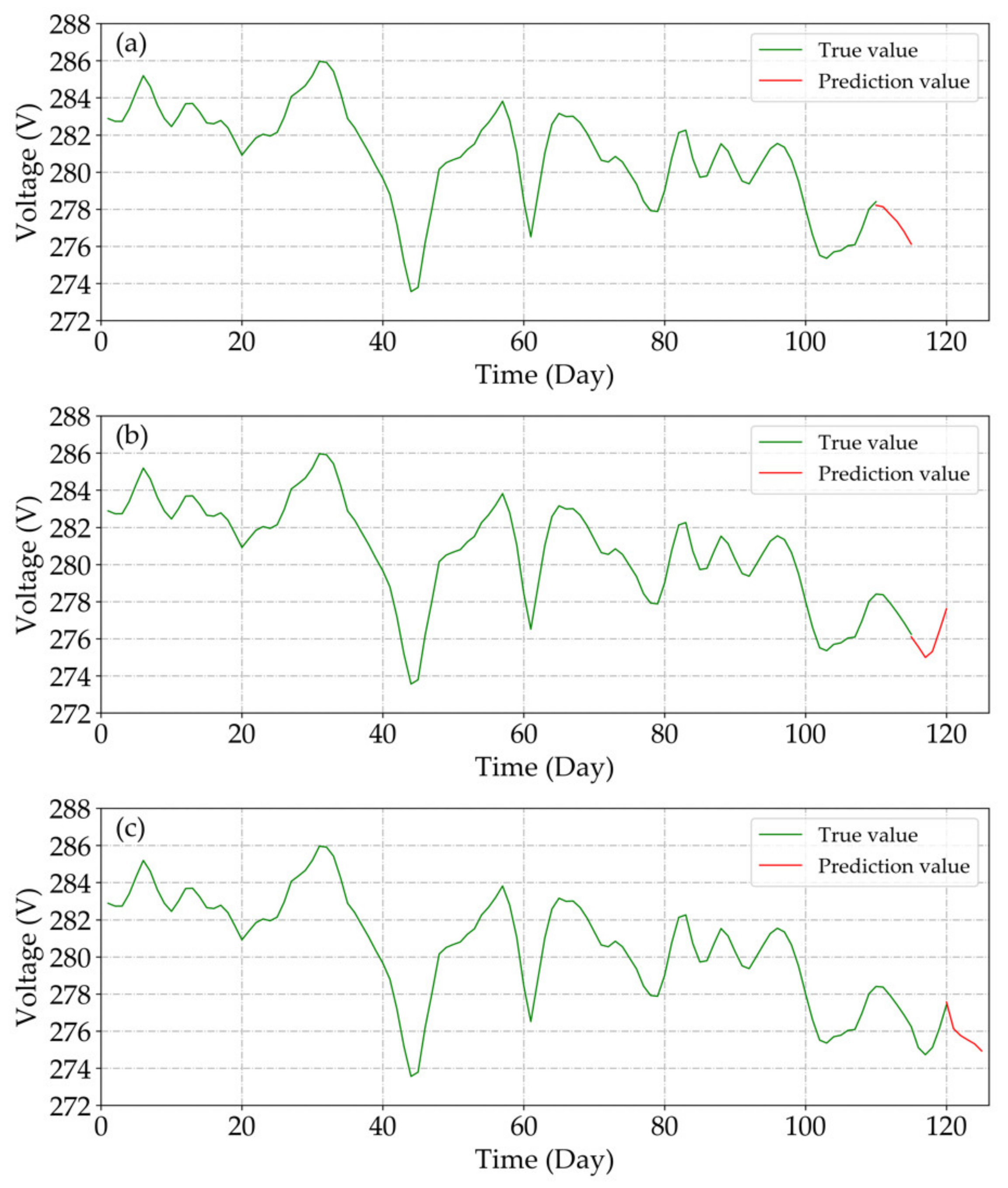

6.2. Verification of Online Operation Scheme of Self-Renewing Short-Term RUL Prediction Model

7. Conclusions

- The mode of daily stack voltage of 75 A operation condition used as the health index of the fuel cell bus stack avoided the influence of voltage recovery and random fluctuation. White noise detection can be used to verify that the parameter can better characterize the stack health state.

- The adaptive LOWESS and Bi-LSTM RUL prediction model was established. Adaptive LOWESS is used for adaptive denoising and preliminary feature extraction of stack voltage data, which not only enables the smoothed data series to retain the original fluctuation as much as possible, but also weakens the influence of abnormal points as much as possible. Subsequently, a Bi-LSTM model can be trained with the denoised sequence to realize short-term RUL prediction, which proved to be quite accurate and to have strong adaptability.

- Relying on TBOX and a cloud platform to realize real-time data updating, an online operation scheme of short-term RUL prediction scheme model is proposed, which realizes the short-term online prediction of RUL. The scheme was proved to be effective, which gives the model a strong powerful practicability.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anderson, R.; Zhang, L.; Ding, Y.; Blanco, M.; Bi, X.; Wilkinson, D.P. A critical review of two-phase flow in gas flow channels of proton exchange membrane fuel cells. J. Power Sources 2010, 195, 4531–4553. [Google Scholar] [CrossRef]

- Hu, G.; Fan, J.; Chen, S.; Liu, Y.; Cen, K. Three-dimensional numerical analysis of proton exchange membrane fuel cells (PEMFCs) with conventional and interdigitated flow fields. J. Power Sources 2004, 136, 1–9. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, X.Z.; Martin, J.J.; Wang, H.; Zhang, J.; Shen, J.; Wu, S.; Merida, W. A review of PEM fuel cell durability: Degradation mechanisms and mitigation strategies. J. Power Sources 2008, 184, 104–119. [Google Scholar] [CrossRef]

- Liu, H.; Chen, J.; Hissel, D.; Lu, J.; Hou, M.; Shao, Z. Prognostics methods and degradation indexes of proton ex-change membrane fuel cells: A review. Renew. Sustain. Energy Rev. 2020, 123, 109721. [Google Scholar] [CrossRef]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Péra, M.-C.; Zerhouni, N. Degradations analysis and aging modeling for health assessment and prognostics of PEMFC. Reliab. Eng. Syst. Saf. 2016, 148, 78–95. [Google Scholar] [CrossRef]

- Zhang, X.; Pisu, P. Prognostic-oriented Fuel Cell Catalyst Aging Modeling and Its Application to Health-Monitoring and Prognostics of a PEM Fuel Cell. Int. J. Progn. Health Manag. 2014, 5, 1–16. [Google Scholar] [CrossRef]

- Yin, S.; Xie, X.; Lam, J.; Cheung, K.C.; Gao, H. An Improved Incremental Learning Approach for KPI Prognosis of Dynamic Fuel Cell System. IEEE Trans. Cybern. 2015, 46, 3135–3144. [Google Scholar] [CrossRef]

- Qiao, L.Q.; Xun, L.J. State of health estimation combining robust deep feature learning with support vector regression. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 6207–6212. [Google Scholar]

- Wu, Y.; Breaz, E.; Gao, F.; Paire, D.; Miraoui, A. Nonlinear Performance Degradation Prediction of Proton Exchange Membrane Fuel Cells Using Relevance Vector Machine. IEEE Trans. Energy Convers. 2016, 31, 1570–1582. [Google Scholar] [CrossRef]

- Bressel, M.; Hilairet, M.; Hissel, D.; Bouamama, B.O. Remaining useful life prediction and uncertainty quantifica-tion of proton exchange membrane fuel cell under variable load. IEEE Trans. Ind. Electron. 2016, 63, 2569–2577. [Google Scholar] [CrossRef]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Péra, M.-C.; Zerhouni, N. Prognostics of PEM fuel cell in a particle filtering framework. Int. J. Hydrogen Energy 2014, 39, 481–494. [Google Scholar] [CrossRef]

- Ibrahim, M.; Steiner, N.Y.; Jemei, S.; Hissel, D. Wavelet-based approach for online fuel cell remaining useful life-time prediction. IEEE Trans. Ind. Electron. 2016, 63, 5057–5068. [Google Scholar]

- Liu, J.; Saxena, A.; Goebel, K.; Saha, B.; Wang, W. An Adaptive Recurrent Neural Network for Remaining Useful Life Prediction of Lithium-Ion Batteries. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Portland, OR, USA, 10–16 October 2010. [Google Scholar]

- Heimes, F.O. Recurrent neural networks for remaining useful life estimation. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008; pp. 1–6. [Google Scholar]

- Morando, S.; Jemei, S.; Hissel, D.; Gouriveau, R.; Zerhouni, N. Proton exchange membrane fuel cell ageing fore-casting algorithm based on Echo State Network. Int. J. Hydrogen Energy 2017, 42, 1472–1480. [Google Scholar] [CrossRef]

- Ma, R.; Breaz, E.; Liu, C.; Bai, H.; Briois, P.; Gao, F. Data-driven Prognostics for PEM Fuel Cell Degradation by Long Short-term Memory Network. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 102–107. [Google Scholar]

- Liu, J.; Li, Q.; Chen, W.; Yan, Y.; Qiu, Y.; Cao, T. Remaining useful life prediction of PEMFC based on long short-term memory recurrent neural networks. Int. J. Hydrogen Energy 2019, 44, 5470–5480. [Google Scholar] [CrossRef]

- Ma, J.; Liu, X.; Zou, X.; Yue, M.; Shang, P.; Kang, L.; Jemei, S.; Lu, C.; Ding, Y.; Zerhouni, N.; et al. Degradation prognosis for proton exchange membrane fuel cell based on hybrid transfer learning and intercell differences. ISA Trans. 2020. [Google Scholar] [CrossRef]

- Ma, R.; Yang, T.; Breaz, E.; Li, Z.; Briois, P.; Gao, F. Data-driven proton exchange membrane fuel cell degradation predication through deep learning method. Appl. Energy 2018, 231, 102–115. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Yang, H.; Han, Y.; Jiang, S.; Chen, W. Sequence fault diagnosis for PEMFC water management sub-system using deep learning with t-SNE. IEEE Access 2019, 7, 92009–92019. [Google Scholar] [CrossRef]

- Xue, X.; Hu, Y.; Qi, S. Remaining useful life estimation for proton exchange membrane fuel cell based on extreme learning machine. In Proceedings of the 2016 31st Youth Academic Annual Conference of Chinese Association of Automation (YAC), Wuhan, China, 11–13 November 2016; pp. 43–47. [Google Scholar]

- Javed, K.; Gouriveau, R.; Zerhouni, N.; Hissel, D. Prognostics of Proton Exchange Membrane Fuel Cells stack using an ensemble of constraints based connectionist networks. J. Power Sources 2016, 324, 745–757. [Google Scholar] [CrossRef]

- Jacome, A.; Hissel, D.; Heiries, V.; Gerard, M.; Rosini, S. A Review of Model-Based Prognostic for Proton Exchange Membrane Fuel Cell under Automotive Load Cycling. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; pp. 1–5. [Google Scholar]

- Hua, Z.; Zheng, Z.; Péra, M.C.; Gao, F. Remaining useful life prediction of PEMFC systems based on the mul-ti-input echo state network. Appl. Energy 2020, 265, 114791. [Google Scholar] [CrossRef]

- Sutharssan, T.; Montalvao, D.; Chen, Y.K.; Wang, W.-C.; Pisac, C.; Elemara, H. A review on prognostics and health monitoring of proton exchange membrane fuel cell. Renew. Sustain. Energy Rev. 2017, 75, 440–450. [Google Scholar] [CrossRef]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Péra, M.C.; Zerhouni, N. Joint particle filters prognostics for PEMFC power prediction at constant current solicitation. IEEE Trans. Reliab. 2016, 65, 336–349. [Google Scholar] [CrossRef]

- Kim, T.; Oh, H.; Kim, H.; Youn, B.D. An Online-Applicable Model for Predicting Health Degradation of PEM Fuel Cells with Root Cause Analysis. IEEE Trans. Ind. Electron. 2016, 63, 7094–7103. [Google Scholar] [CrossRef]

- FCLAB Federation, FR CNRS 3539, France. FCLAB. 2014. IEEE PHM 2014 Data Challenge. Available online: http://eng.fclab.fr/ieee-phm-2014-data-challenge (accessed on 1 May 2014).

| Name | Value |

|---|---|

| Brand of fuel cell stack | POWERCELL S2 Series |

| Number of cells in fuel cell stack | 432 pieces |

| Rated Power | 40 kW |

| Max Efficiency | 55% |

| Stack mass | 31 kg |

| Parameter | Value | ||

|---|---|---|---|

| Operating Condition | 45 A | 75 A | 125 A |

| System Air Inlet Flow Rate | 900 Slpm | 1300 Slpm | 2100 Slpm |

| Stack Hydrogen Inlet Pressure | 13 Kpa | 13 Kpa | 14.5 Kpa |

| Stack Hydrogen Outlet Pressure | 12.8 Kpa | 12.7 Kpa | 14.1 Kpa |

| Stack Inlet Temperature | 70 °C | 70 °C | 70 °C |

| Stack Outlet Temperature | 71 °C | 72 °C | 74 °C |

| Items | Manufacturers | Function |

|---|---|---|

| CANoe11.0 software | VECTOR | Read data from storage files |

| VN7640 hardware interface | VECTOR | Send data to TBOX |

| TBOX | Self-developed | Send data to Cloud System |

| Cloud System | Amazon | 1. Receive and store data from the local 2. Execute the online operation schema |

| Model | RMSE | MAE | MAPE |

|---|---|---|---|

| Bi-LSTM | 0.413 | 0.376 | 0.136% |

| LSTM | 0.651 | 0.591 | 0.215% |

| 1D-CNN | 0.972 | 0.925 | 0.336% |

| Sequence | Stat | P |

|---|---|---|

| 1–110 days sequence | 4.37031913 | 0.03657014 |

| 1–115 days sequence | 5.69756858 | 0.01698843 |

| 1–120 days sequence | 0.0039299 | 0.0039299 |

| Round | Prediction Day | Prediction Value | True Value | MAE | RMSE | MAPE |

|---|---|---|---|---|---|---|

| 1 | 111 | 278.13 | 278.37 | 0.162 | 0.172 | 0.058% |

| 112 | 277.72 | 277.92 | ||||

| 113 | 277.33 | 277.41 | ||||

| 114 | 276.68 | 276.85 | ||||

| 115 | 276.12 | 276.24 | ||||

| 2 | 116 | 275.67 | 275.11 | 0.298 | 0.327 | 0.108% |

| 117 | 274.99 | 274.73 | ||||

| 118 | 275.31 | 275.11 | ||||

| 119 | 276.43 | 276.15 | ||||

| 120 | 277.61 | 277.42 | ||||

| 3 | 121 | 276.13 | 275.96 | 0.102 | 0.109 | 0.037% |

| 122 | 275.76 | 275.66 | ||||

| 123 | 275.53 | 275.64 | ||||

| 124 | 275.31 | 275.39 | ||||

| 125 | 274.93 | 274.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, T.; Xu, J.; Li, R.; Yao, N.; Yang, Y. Online Short-Term Remaining Useful Life Prediction of Fuel Cell Vehicles Based on Cloud System. Energies 2021, 14, 2806. https://doi.org/10.3390/en14102806

Ma T, Xu J, Li R, Yao N, Yang Y. Online Short-Term Remaining Useful Life Prediction of Fuel Cell Vehicles Based on Cloud System. Energies. 2021; 14(10):2806. https://doi.org/10.3390/en14102806

Chicago/Turabian StyleMa, Tiancai, Jianmiao Xu, Ruitao Li, Naiyuan Yao, and Yanbo Yang. 2021. "Online Short-Term Remaining Useful Life Prediction of Fuel Cell Vehicles Based on Cloud System" Energies 14, no. 10: 2806. https://doi.org/10.3390/en14102806

APA StyleMa, T., Xu, J., Li, R., Yao, N., & Yang, Y. (2021). Online Short-Term Remaining Useful Life Prediction of Fuel Cell Vehicles Based on Cloud System. Energies, 14(10), 2806. https://doi.org/10.3390/en14102806