2.1. Methodologies of Modeling Processes Combining Generation of Hybrid Systems on Organic Fuel and Photovoltaic Cells in a Single Energy Technology Complex Assessment and Regulation

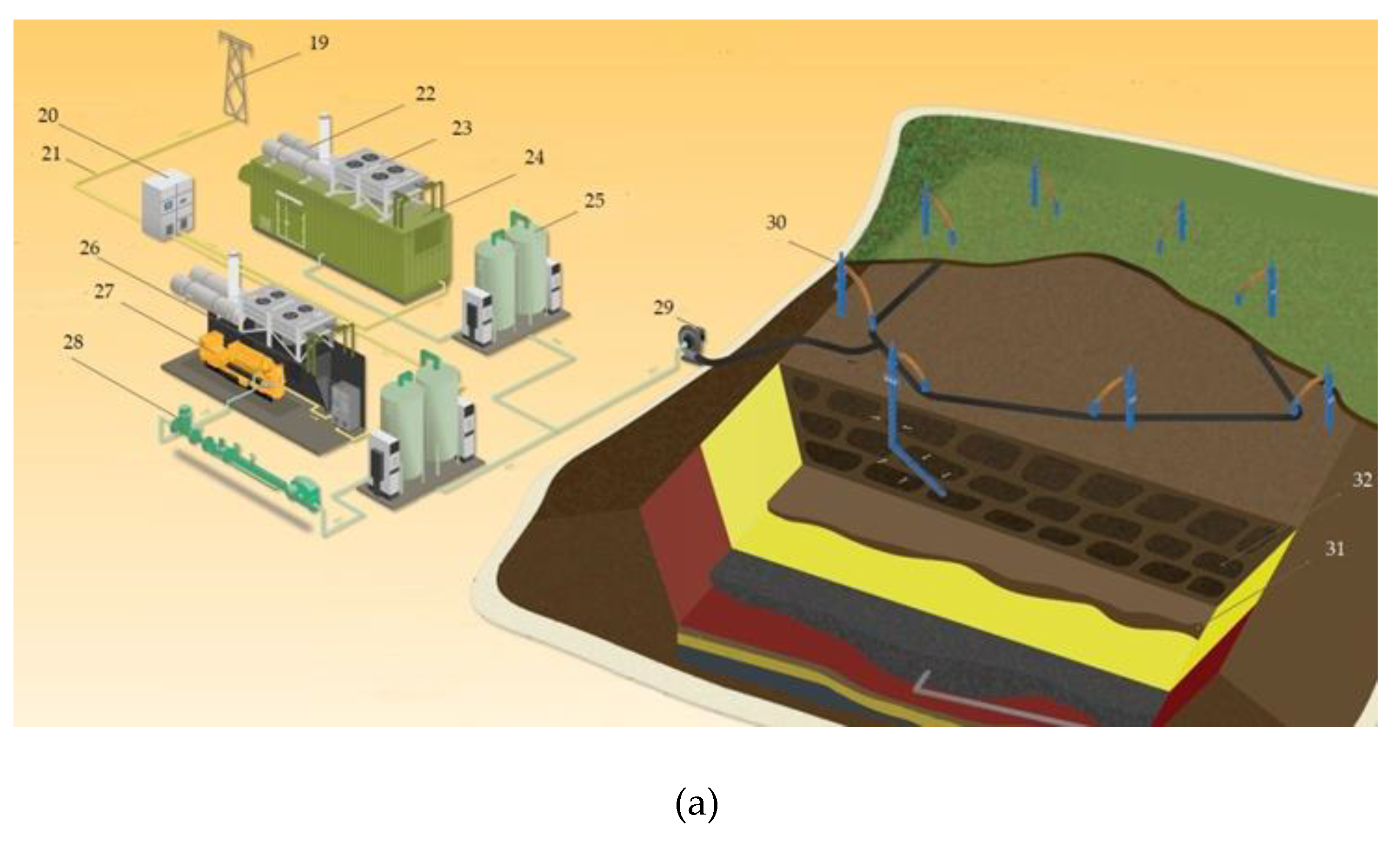

Achieving the goal of improving the quality of regulatory parameters in the study is proposed to be implemented in the concept of combining organizational, economic and mathematical models for the application of a system of information and technical and technological methods according to the criterion of maximizing 3-E efficiency. This defines the emergence of a new organization architecture using the information technology capabilities of the IoT and Energy and. Advanced digital processes of control and supervision are needed to implement the interaction of micro-and macro-network objects using transactional energy methods in a single hybrid-type ETC. The new architecture and structure involves a radical expansion of the range of autonomous sensors with a long service life, sensors-meters of various process parameters and other elements of cybernetic purpose. All these devices must be connected by a telemetry data network, partially shown in

Figure 1. The high importance of such technical means of the digital economy is confirmed by a positive assessment of the results of the study of the prospects for the complementary use of resources and energy distribution in the conditions of the modern industrial revolution [

21]. The effectiveness of their use has been proven to reduce repair costs, increase uptime, and reduce the need for personnel to synchronize processes with dispatchers. The article solves the problems identified by the lack of compliance of technologies and methods for the development of distributed hybrid energy with the factors of the industrial revolution. The insufficient degree of integration of objects I–V of industrial energy with the resources of scientific and educational objects of type VI for the organization of high-tech development of the macro-network of ETC in the knowledge economy is revealed. At many domestic enterprises of industrial heat and power engineering, evolutionary methods of modernization of individual elements of equipment with a low level of innovation of technologies and results prevail. Investment decisions on new construction and technical re-equipment projects are often made without modeling the processes of transition to technologies and organizational methods of energy saving based on the factors of the new industrial revolution [

22].

Technical and technological models should describe the dynamics of the physical interaction of objects of the hybrid network of the complex being formed. Taking into account the scientific and practical results of the research, the article examines in detail the possibilities of improving the 3rd efficiency of hybrid energy micro-grid facilities [

1,

2,

3,

4,

5]. The predominantly heat-energy nature of the study determines the geographical limitations on the scale of the complex being formed: objects II-V can be placed at distances of no more than 25 km (the maximum possibility of network physical interaction according to the permissible 3rd efficiency of heat transfer). The micronet is formed as part of the ETC and implements the subject of scientific research in the design development of an innovative idea for the formation of a local market for energy sales and other results of the complex’s activities that are of value to their producers and consumers. Advanced digital processes of control and supervision of heat and electric energy production and consumption are studied in detail on the example of a microgrid. Such processes are effectively implemented and recorded in the form of energy transactions in the Internet of Things and Energy system using the information and analytical tools of big data and data science. The material complementary products obtained from the accumulated resources of SHIW, as well as the results of scientific and design developments, can also be evaluated in the model of the cost-effectiveness of processes using standard methods for estimating their cost.

The object of the study is the formation of a macro-network and a micro-network as part of the ETC, which provides such processes of control and supervision of the production and consumption of heat and electric energy with the organization of economic, machine-to-machine and physical interaction of objects of type I–V (

Figure 1). The creation of information and physical capabilities for their joint functioning requires improving the quality of control parameters and dispatching high-tech processes of integration of hybrid energy facilities. The implementation of the research concept is aimed at ensuring the 3rd efficiency of the dynamics of processes in terms of reducing anthropogenic loads on the environment. For this purpose, a combination of resources and technologies is proposed based on the integration of individual industrial and household energy installations into the ETC (

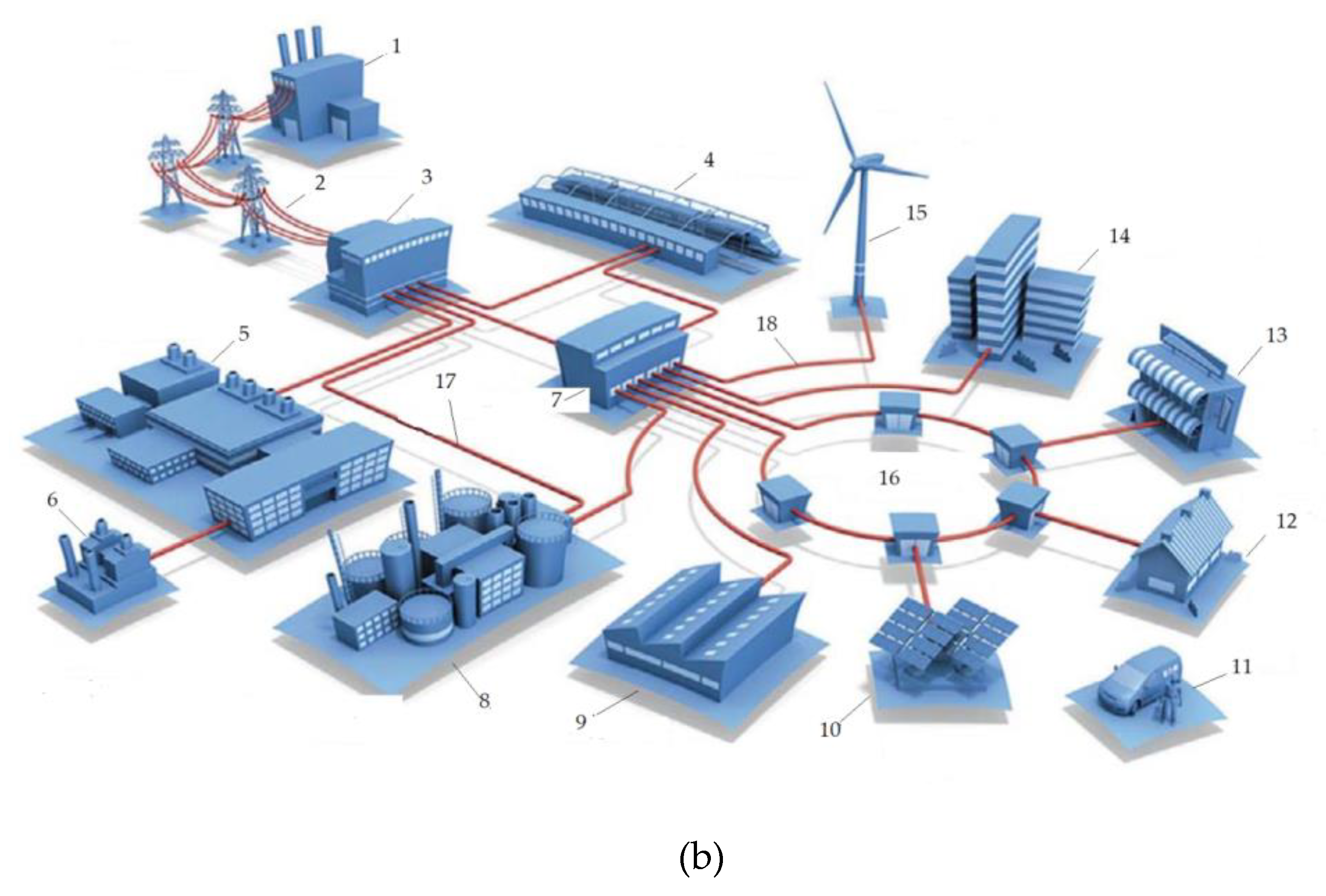

Figure 2).

As an object of research, a micro-grid is defined as part of a single ETC and the following composition of hybrid distributed energy facilities: II-a landfill of accumulated SHIW, as a source of secondary combustible resources (biogas and other material waste for further processing) and additional fuel for a local boiler micro-network; III-heat-power installations of the type of heat pumps that use the property of the thermodynamic cycle of converting heat into work using water vapor. Such an organization of energy production is proposed for agricultural facilities (for example, greenhouses, livestock farms, grain dryers, root crops and fruits, small enterprises of other industries, trade, etc.), households and residential buildings with the ability to generate energy and transfer its surplus to the network. They require the production of heat in the form of hot water, as well as electricity using microturbines that use the accumulated biogas resources of the SHIW landfill. At the same time, it is proposed to exchange energy transactions with the conclusion of energy transactions on the Internet of Energy and Things. This requires thermal and electrical networks for physical connections to objects of type 4 and 5 (district and local boiler houses and energy storage). At the same time, the processes of control and supervision of energy transactions should be carried out using the big data and data science tools.

Hybrid systems may include, for example, organic fuel and photovoltaic cells combining heat and electrical generation. The use of alternative solar energy increases the energy independence of consumers. The autonomy allows you to sell the excess electricity produced in the micro-grid of the object III of the macro-grid of the ETC. Such a micro-network combines the functions of an autonomous and network, providing a backup power supply.

With sufficient insolation, the solar panels 3 generate electrical energy and feed it to a hybrid inverter that converts it for the needs of consumers. Unused electricity from the inverter goes to the batteries (object V in

Figure 1), and when they are fully charged, to the network for sale if there is a contract with the network company. The criterion for making such a decision is the excess of the tariff for the sale of electricity of the tariff for the purchase from the network. When the situation is reversed, it is better to save energy in the batteries to use it in the evening. In the case when the energy storage is already fully charged, and the generation capacity exceeds the current consumption, it is advisable to sell at any price. It is possible to underutilize the capacity of traditional energy and reduce the 3rd efficiency in the long term due to unjustified investments. If there is insufficient insolation, the solar cells do not work at full capacity. The missing energy will be supplied from the helium accumulators of the Type V facility, local installations using the biogas resources of the SHIW landfill, or centralized macro grid facilities. When setting up the automation of the multifunctional inverter 1, you can make priority decisions on the choice of a backup power source according to the criteria of maximum autonomy of the micro-network. This meets the criteria of its energy and economic efficiency with sufficient insolation during the year.

Figure 2 shows the options for the joint operation of traditional centralized and distributed hybrid energy facilities. They involve combining different sources of generation hybrid systems on organic fuel, wind energy and photovoltaic cells in a single ETC.

Micro-networks embedded in a hybrid power system should be evaluated according to the criteria of the regulatory quality of energy and the reliability of the functioning of existing distribution and high-voltage networks. Energy flows (generated electric and thermal energy, heat of the heated heat carrier with the use of renewable resources) have losses. The proposed methodology is aimed at reducing them in the processes of generation and transportation to consumers.

Figure 2 shows a diagram of interacting objects in a hybrid microgrid. It allows you to combine the possibilities of generating energy with the use of renewable resources in solar panels and diesel generators. In addition, the exchange of such types of energy with the traditional energy facilities indicated in

Figure 1 is taken into account. The organization of joint work is possible with the impact on the control system in the CСI according to the criteria for improving the reliability and 3rd efficiency of the distribution of energy flows.

Figure 3 shows a variant of the composition of microgrid objects that we selected to study the reliability of solar panels and determine the effective operating modes of a diesel generator. Such systems have recently been regulated by predictive regulation based on neural network algorithms. The parameters of hybrid installations are monitored using the organic part of the micro-grid, which includes diesel generators or local means of generating electric and thermal energy. Renewable resources, for example, installations that use solar and wind energy, are controlled minimally and operate mainly in automatic mode.

Standard control and measuring devices and automation are not able to increase the efficiency of the plant in the long term. It is necessary to use neural network algorithms that allow you to collect big data data, process it and make predictive control in the processes of mainly machine-to-machine interaction of micronet objects. This requires special mechanisms for combining management methods to coordinate the interests of traditional and renewable energy facilities.

The standard composition of monitoring sensors does not register an imbalance of energy and environmental efficiency goals, macro-and micro-grid objects. The technical implementation of advanced monitoring and dispatching processes requires the use of photo-and thermo-elements in the sensors and actuators of the IoT system to include micro-grid objects in the Energy Internet system. It is necessary to supplement them (

Table 3) to assess the 3-E efficiency and regulate the processes of objects operating in the microgrid, taking into account the mutual transfer of capacity and energy transactions in the Internet of Energy system. The use of sensors for temperature, pressure, and concentration of combustion products is justified. This is required to assess the quality of energy transmission and the completeness of energy use. The controllers should be used in conjunction with multi-zone controllers. Software systems based on neural network algorithms should be able to process a large array of data and select the weight coefficients of the controlled parameters. Therefore, Kosko neural network algorithms are suitable for these purposes [

1,

2,

3,

4,

5]. SCADA systems are designed for process control. All additional devices should be included in the control system of the dynamic simulator mechanism for combining methods of joint energy generation developed by us and presented in the article. The micro-networks in the ETC should use additional sensors of the IoT (Internet of Things) system and the Internet of Energy, built into the control and control systems of technological processes.

To organize economic relationships in the form of user transactions, they must be represented by digital assets that confirm the mutual transfer of capacities or products of producers and consumers. This is made out by signed contracts, documents of their verification and payment on the basis of inter-machine interaction of objects.

Processes whose parameters change abruptly or exponentially are particularly difficult to account for and model. This makes it necessary to use special mathematical software, used, for example, to represent the processes of signal transmission. Such features determine the additional use of tools for deeper analysis and digital modeling of Data Science processes [

7,

20]. It is based on providing real-time control and regulation using deep machine learning neural network algorithms using artificial intelligence. Similar processes are applied by us for regulation of the 3-E efficiency in power installations of objects of a micro-grid of ETC. At the same time, there is often a decrease in the stability of development processes due to abrupt changes in the processes during the transition to a new structure of interrelations of objects in the complex. Improvements of the radical type are also distinguished by the singularity (unusual) of the processes of transition to new technologies, methods of analysis and regulation of processes. It can be expressed in exponential, hyperbolic, and even jump-like (for example, sawtooth waveform), changes in indicators-properties of 3-E efficiency at zero or minimum transition time to their new level.

To ensure the sustainability of the proposed processes of control and supervision, it is necessary to form a model of a dynamic simulator of a mechanism for combining management methods for coordinating the interests of traditional and renewable energy facilities (

Figure 4).

The level of the balance of interests is ensured by the regulation of the quality indices of the regulation parameters according to the above criteria. The corresponding resulting indicators are evaluated by well-known approaches to thermodynamic modeling of the processes of increasing energy and environmental efficiency for separately functioning objects II-V of renewable and traditional energy (

Table 4).

Calculations show significant increases in the 3-E efficiency in the organization of interaction of objects of type II–V in the ETC. An additional increase in the indicator is achieved in terms of integration with an object of type VI. A radical improvement in the quality of parameter control is provided by the mechanism proposed in the article. To do this, it is necessary to use the process of control and supervision of energy transactions and increase the focus of technologies and methods on the rational organization of the cycles of the formation of ETC. The possibilities of contractual transfer of facilities’ capacities to each other can be realized by three types of interaction: organizational and economic (development of models and projects for combining methods and resources, execution of contracts for energy transactions and contracts for research and design development and their author support); machine-to-machine (monitoring of energy quality parameters and other commodity results of activity and data exchange); physical (creation of thermal and logistics networks for the implementation of transactions). At the same time, the imbalance of these interests often grows. The research concept can be implemented using the methods of the methodology of integration-balancing regulation of the three specified types of interactions of the objects of the formed complex. Its methods are most effectively implemented on the basis of energy transactions on the Internet of Energy using the tools of big data and data science [

20]. The data science toolkit is characterized by the ability to radically improve the efficiency of decision-making in real-time machine-readable estimates for concluding the necessary energy transactions on the Internet of Energy. In practice, there are interrelated subsystems and the main stages of the methodology for developing the appropriate platform. First, an organizational and economic platform for energy transactions on the Internet of Energy is being formed with an assessment of the quality of the parameters of regulation of the 3rd efficiency in the conditions of separate operation of objects (see

Figure 1). Further, special mathematical software is adapted for modeling and algorithmization of actions for solving problems of combining resources in the platform. Secondly, projects are being developed in the technical and technological areas of combining micro-and macro-network objects of a single ETC. Then the application of existing or adaptation and development of computer programs for transactional energy on the Internet of Energy based on machine learning methods for modeling and evaluating the progress of projects is justified (see

Figure 4).

Artificial intelligence neural network technologies make it possible in real time for several days (not months, as previously) to implement a cycle of activities for the development and experimental implementation of projects for high-tech resource combination based on the organization of transactions in the network of ETC objects. At the same time, the advanced capabilities of multivariate and multi-criteria analysis in such a digital platform are implemented without primary filtering of the source data. The method increases the depth and durability of business intelligence based on a series of operational solutions, without filtering the data. The use of neural network algorithms of deep machine learning provides the possibility of obtaining a machine-readable signal transmission control system at the output of the developed system, while increasing the speed and reliability of evaluating and regulating the parameters of interaction between ETC objects. Third, comparative thermodynamic calculations are carried out to assess the 3-E efficiency of two options: in the scheme of the process of control and supervision of separately functioning distributed energy facilities of the hybrid type (see

Figure 1 and

Table 2); in the energy transaction platform for organizing the interaction of microgrid objects after the completion of the subsequent stages of the development of organizational, economic and mathematical methods.

The development of organizational and economic models and methods of coordinated interaction of macro-and micro-grid objects is aimed at creating analog models that describe the processes for the formation and development of ETC. The combination of methods and integration of resources is supposed to be carried out in the transactional energy platform as an Internet of Things and Energy system. It is a high-tech basis for the functioning of the newly created coordination structure of the CCI network of complementary ETC objects. The criterion for improving the quality of the process of control and supervision for regulation should be the maximization of the 3-E efficiency of the use of traditional and renewable resources by methods of their integration. Therefore, the purpose of the Center is to use additional functions of monitoring and dispatching the processes of regulating commodity-money relations between producers and consumers of a diversified composition of energy and material products. In order to ensure the consistency of the interests of these objects in these three types of interaction, in addition to energy flows, logistics flows should also be taken into account. In this case, it is the sale of the results of research and design work and their author’s support for the operational implementation of business ideas in the areas of work of object V in projects to improve the 3-E efficiency of hybrid energy. At the same time, for the registration of energy transactions, the following should be determined and taken into account: sales and consumption of electric and thermal energy (taking into account the use of storage devices) of different quality parameters; complementary products formed when using diversified resources of renewable and traditional energy; provision of transactional services to energy producers and consumers (including households). Thus, two types of markets are formed and regulated, which are geographically limited by the physical possibilities of capacity transfer and other results of the ETC activity: a macro-network (see

Figure 1) with an unlimited scalable market (electricity and research and development); a micro-network (see

Figure 2) with local markets (mainly thermal energy, by-products, or secondary products, small amounts of electricity). Micro-networks are formed to increase the 3-E efficiency of interaction of hybrid distributed energy facilities located at distances of no more than 25 km.

To achieve a compromise of goals within the boundaries of the platform, an analog model of a macro network of objects consisting of two pyramid-shaped functional blocks has been developed (

Figure 5). The arrows in the model show the rational direction of the processes of forming the platform and network in the cycle of changes with evolutionary changes from a low level of quality of the parameters of control and dispatching processes in the technologies of separate functioning of objects (quadrant 1) to its increase in the integration of individual objects (quadrant 2 in cycle 1). Next, in quadrant 3, there is a leap-step transition to a high level of 3-E efficiency of combining organizational methods and technologies. The stabilization of the achieved level of quality of parameters for regulating the interaction of traditional and renewable energy facilities in the new platform structure is achieved in quadrant 4 or in the next cycle.

The structure of the platform shows the interaction of blocks. The left pyramid represents the sequence and direction of the application of additional functions of control, evaluation, analysis, coordination of interaction with objects of type 6 (see

Figure 1). This is necessary for making decisions on changing the quality parameters of regulating the processes of improving technologies and methods. The goals of increasing the 3-E efficiency by the methods of the post-industrial knowledge economy are taken into account. The transfer of technologies and methods is the result of sales and author support of scientific and design developments. This increases the speed and efficiency of implementing business ideas in the areas under study in distributed hybrid energy projects. The right pyramid corresponds to the impact of material resources when selling technologies of four levels of novelty and 3-E efficiency.

To assess and regulate the processes of the impact of resource types, the analog model is combined with a quantitative display of curves on the graph of changes in the 3-E efficiency (H) over the cycle time (t). The three types of curves are further justified by mathematical proofs. They reliably represent the processes in cycle 1–4. The left pyramid defines the direction and sequence of” I–IV “ technologies and methods of using intangible resources of separately existing objects of education (level I), basic research (II), applied science (III), design development of equipment and business models of organizational methods of combining and their author service (support of implementation processes) (IV). The lack of constant cooperation or project interaction with separately functioning energy facilities leads to insufficient efficiency of their transformations. This use of the capabilities of individual objects of a low-tech type in the context of the disintegration of resources corresponds mainly to the industrial type of economic development. This is shown by the decrease in efficiency in cycle 1 and by the area ratio S of cycles 1 and 2 in

Figure 5.

The standard model of the direction and sequence of “I–IV” improvement of economic and organizational interaction of objects does not fully correspond to the challenges of the post-industrial knowledge economy. Therefore, it is proposed to integrate resources of non-material and material types within the boundaries of an effective platform and micro-network of high-tech development of distributed energy. The right pyramid represents the “4-1” pattern of direction and sequence of actions. It is distinguished by the use of the most developed high technologies and tools of Data Science, which dramatically increase the 3rd efficiency of processes in the context of the integration of objects II-V in the micronetwork of ETC (level 4). Arrow 1 shows the direct effects of these additional functions when using large databases for digital modeling based on artificial intelligence, the Internet of Things, and energy. In order to improve the quality of regulation of the enterprise’s relationships in the next cycle of high-tech transformations or to stabilize the achieved level of efficiency, a decision is made on the need to use more knowledge-intensive and innovative energy-saving technologies in the formed platform and micro-network: 4-business models, technical means and methods of low-quality parameters of control and dispatching processes in technologies of separate operation of objects that maintain or reduce the achieved level of 3-E efficiency; 3-the use of separate tools and methods for improving the quality of control parameters and dispatching processes in technologies for integrating separately functioning objects at the beginning of the formation of a micro-network and a macro-network of ETC; 2—the use of a full set of tools of control and supervision to ensure a leap transition to a high level of 3-E efficiency by combining the maximum number of organizational methods and technologies; 1—means of stabilizing the achieved level of quality of parameters for regulating the processes of interaction between traditional and renewable energy facilities in the new structure of the platform. Levels 1 and 2 are provided by the use of additive technologies of the digital industry based on digital doubles, the Internet of Things and other SMART technologies using artificial intelligence. Such high technologies should be transferred to the education system at level I to transfer the experience of their practical application and start a new development cycle.

Special additional resource integration management functions implement direct links (arrow 1) that have planned, regulatory, coordinating, or project impacts of data science tools. Feedback loops (arrow 2) implement the function of monitoring the results of high-tech development of objects in the complex. This allows you to more fully use the platform’s information networks for resource integration.

At the second stage of the implementation of the research concept it is necessary to justify and adapt mathematical methods for describing evolutionary and leap processes combining and applying Data Science tools in the specified development cycle.

For this purpose, the application of a new method of approximation of a generalized function of the form of a delta function by analytical functions is justified [

58]. It is established that they adequately allow to solve theoretical and applied problems of representation and analysis of the specified dynamics in relation to modeling of processes of interaction of objects of the formed ETC. The delta function can be defined by a functional of the following form [

58]:

with:

It is not difficult to see that for any

n the area of the figure under the graph of such a step function is equal to one. We find the values of the coefficients of the Fourier series on the segment, taking into account the theorem on the average value of a certain integral:

by virtue of the parity of the function;

Since the delta function is

and, noting that

find

Therefore, the expansion of the delta function into a Fourier series on the segment [−π,π] has the form:

For a finite series, we have an approximate relation:

It is established that the selected segment [−π,π] does not reduce the generality of our reasoning. Using variable substitution, the results are generalized to the case of an arbitrary segment. It is found that even with a significant number of harmonics (in our case

n = 1000) the approximation error is very high. This shows the Gibbs effect [

3], even though the delta function is non-negative. The minimum value of the constructed approximation is negative and is—69.182. Moreover, with an infinite increase in the number of terms in the approximating Fourier series, the minimum value of its sum tends to

. This corresponds to the statement proved earlier [

59] about the possible infinitely large error in the approximation using the Fourier series. In other words, the approximation by Fourier series, even with an infinite number of terms, does not correspond to the original delta function at all.

The Gibbs effect leads to extremely negative consequences of using the partial sum of the trigonometric series as an approximating function for solving mathematical modeling problems, for example, in the study of periodic transformation processes of technical systems. The use of a sequence of step functions does not allow for the proper representation of the derivatives of the delta function, which are also generalized functions. The problem is that step functions have discontinuity points at which they are not differentiable in the mathematical sense. Therefore, to represent the derivatives of the delta function, you need to use an approximating sequence of analytical functions that have derivatives of any order.

To construct such a sequence, we use the fact that the delta function is a derivative of the function O. To construct such a sequence, we use the fact that the delta function is a derivative of the O. Heaviside function, or the unit jump function. It determines the estimates of the 3rd efficiency (H) by factors x of improving the quality of control parameters over time [

58,

59]:

It is proposed to approximate the Heaviside function with a sequence of functions of the form:

where the sequence of recursive functions

is defined by the relation:

It can be proved that the sequence fn(x) converges in norm to a function f0(x) in space L2 [0,π/2].

This allows us to make the assumptions shown in

Figure 5 by graphs of three consecutive approximations. We interpret them as the effects of the proposed increase in the number of additional quality functions of the control parameters from 9 to 11. This addition will allow you to evaluate and regulate transactions in a more complex macro-and micro-network of hybrid energy facilities. The values of A can model the increasing degree of impact of the quality parameters of the regulation of the processes of combining resources, which are taken into account when changing the planned indicators in the CCI at the stages of the development cycle [

59].

where

.

The thickness of the graph lines in

Figure 6 increases as the number of the approximating dependence increases.

Figure 7 shows the dynamics of the efficiency of energy generation and transmission processes by the factors of interaction between traditional and renewable energy facilities. The energy efficiency indicators of the hybrid complex of small distributed energy (solar panels in combination with a diesel generator from the type III objects) are taken into account according to

Table 1. The maximum corresponds to the working conditions as part of the micro-grid of the ETC. The dynamics is explained by the fact that in the interval of 15...20 months, there are factors that affect the efficiency of solar panels (winter and summer time) after reaching the maximum efficiency, its sharp abrupt decrease occurs.

The average indicator of the energy efficiency of a diesel generator separately operating for electricity generation and water heating as part of a large energy complex that uses traditional resources (for example, a central power plant from type IV facilities) is represented by an estimate of the maximum value according to

Table 1. The maximum corresponds to the conditions for joint operation of objects as part of a micro-grid of ETC. The dynamics is explained by the fact that in the interval of 15...20 months, there are factors that affect the amount of heated water (winter and summer). After reaching the maximum efficiency, there is a quite understandable decrease in it.

An integrated approach to the organization of economic, machine-to-machine and physical interaction of objects in accordance with the developed methodology provides a significant increase in the 3rd efficiency (

Table 5).

Using expressions for the first derived approximations of the Heaviside function, we obtain successive approximations

,

, and

for the delta function. Their graphs are shown in

Figure 5 and

Figure 6. With a sufficiently large number of nested and regulating functions, we obtain an approximating function

that fully corresponds to the function of the original function. Such a function can simulate processes that correspond to the high quality of the control parameters and the maximum 3-E efficiency.

Consequently, the proposed approximation methods give a much more accurate approximation of the delta function than the Fourier series. Moreover, the accuracy of the approximation can be increased to an arbitrarily large degree by increasing the number of nested functions. The height of the approximation peak (the amplitude) can be determined by the integral condition in the definition of the delta function. To do this, we differentiate the approximating functions of the considered sequence

and obtain in

Figure 8 the mapping of the processes of applying 9, 10, and 11 functions. Thus, the increase in the speed of applying the quality parameters of regulating the processes of interaction of micronetwork objects in the CSI of the complex is modeled by increasing the number of additional regulators [

58]:

Substituting in the resulting expression for the derivatives

, taking into account the parity of the function

, we find the value for the height of the peak of the approximating functions

. Thus, it is proposed to assess the maximum degree of impact of the quality parameters of regulation. At the same time, the maximum levels of 3-E efficiency and balance of interests of traditional and renewable energy facilities in the micro-grid are achieved [

58]:

The average reliability indicator—the probability of failure-free operation of small distributed power equipment with traditional and renewable resources (for example, a wind-powered installation) from the composition of type III objects) is represented by an estimate [

58,

59] using Equation (12):

where

r is the number of failures at the time of operation (use) of the installation,

N is the number of elements at the beginning of the use of wind energy.

The main advantages of using this indicator in calculations are two factors. First, the probability of failure-free operation is evaluated, taking into account all the factors that affect the reliability of the elements. Reliability assessment is carried out according to the criterion of the maximum indicator P. Secondly, the probability of failure-free operation is determined in the reliability assessment of complex systems consisting of more than one element. The dynamics shown in

Figure 9 is explained by the fact that in the interval of several months of operation of the installation, environmental factors, such as weather conditions, act. The average reliability indicator is the probability of failure-free operation of a large power plant that uses traditional resources (for example, traditional energy facilities of type IV). At the same time, the calculation is carried out according to the same formula, but the number of elements in the composition of large energy facilities is immeasurably greater, so the probability of trouble-free operation is not significantly reduced. This occurs after reaching the maximum reliability during the warranty period. Further, the probability of trouble-free operation is sharply reduced.

An integrated approach to the organization of economic, machine-to-machine and physical interaction of objects in accordance with the developed methodology provides a significant increase in reliability. Indeed, the tools of the control mechanism of the dynamic simulator of the mechanism for combining methods of joint energy generation, the Internet of Energy and things provide advanced diagnostics of equipment failures and opportunities for author supervision during its life cycle. This significantly increases the 3-E efficiency of the joint operation of micro-network objects. In absolute terms, for example, the gains in energy and environmental efficiency are determined as follows (the results of the calculations are summarized in

Table 5).

Since we have approximated the generalized functions by analytic functions, after differentiating them, we can find derivatives of any order and degree of accuracy. The constructed graphs of successive approximations of the first, second, and third derivatives of the delta function are proposed to be used to model the speed of the processes of digital control and dispatching advanced digital processes of control and supervision in a dynamic simulator of the mechanism for combining methods for coordinating the interests of complex objects (see

Figure 3).

In the conditions of the functioning of the ETC micro-network, the results of the analysis of the processes in

Figure 5,

Figure 6,

Figure 7 and

Figure 8 show that the manifestations of the Gibbs effect lead to extremely negative consequences of using the partial sum of the trigonometric series as an approximating function for solving mathematical modeling problems. This is established in the study of the dynamics of technical systems with the use of photo-and thermoelements for generation in distributed energy, monitoring of electrical and thermodynamic parameters of equipment (the scheme is given in

Section 5 of the article). It is necessary to adjust the readings of sensors and the effects of electric drives of industrial Internet of Things (IoT) actuators when implementing the processes of physical interaction of complex objects.

The indicated Gibbs effect in the approximation of functions by trigonometric expressions determined a critical attitude to the proof of some theorems of the theory of signal transmission. New possibilities of correcting Kotelnikov’s theorem, known in English literature as Nyquist’s theorem, are revealed. When proving the theorem, V. A. Kotelnikov used the so-called integral sine, defined by the expression , to approximate the functions.

Based on the integral sine, he constructs a function ,

where is the argument, some parameters.

It is stated that, with an increase T, this function tends to the limits shown in

Figure 10a, i.e., we quote verbatim, it is equal to zero at

and equal to

for

.

It is established that the graph of the limit function will have the form shown in

Figure 10b. That is, for any, even arbitrarily large, but finite values of the parameter T, there will always be those

for which the values of the function constructed by Kotelnikov will be different from

, and there will always be those

for which its values will be different from zero. Moreover, it is important to note that this difference tends to increase not to zero, but to a certain number, approximately equal to 0.281 [

58]. Therefore, in the practice of signal transmission, it is necessary to adjust their effects on the specified value of the coefficient, which we propose to call the Aliukov constant

2.2. Design of Methods of Combining Generation of Hybrid Systems on Organic Fuel and Photovoltaic Cells in a Single Energy Technology Complex Assessment and Regulation

The third stage of the study is to design the technical and technological composition of the equipment of manufacturers and consumers of the products of the formed ETC, the processes of which are justified by the results of modeling. This determined the need to develop an algorithmic scheme of the processes of the method of controlled improvement of the quality of control parameters according to the proposed criterion of increasing the 3-E efficiency. Decisions are made based on the following methodology (

Figure 11). The algorithmic model defines the stages of the methodology of research and design of the transactional energy platform and the network of the energy technology complex of hybrid objects.

Determination of the initial assessment of the level of imbalance of efficiency goals (H) over time (x) of cycle 1 of the application of modernization and evolutionary changes in technology and organizational methods in the modernization processes (see

Figure 4,

Figure 5 and

Figure 6 in the ranges—0.20...0.00 radians. This is modeled by comparing the estimates of the areas of the zones S, which reflect the increase in speed in cycle 1 and its decrease in cycle 2. Therefore, the static criteria for improving the quality of control in finite increments of the indicator-properties have the following inequalities and relations [

58]:

An increase in the area in cycle 2 or the value of the area ratio greater than 1 shows an increase in the quality of the control parameters in the space and time of innovative transformations. In addition, it defines the boundaries of the steps 1–4 of the cycle in

Figure 4 for the adoption and start of the implementation of the appropriate methods and processes. This is how the use of additional functions for the use of high-tech processes control and supervision is modeled: the transition from separate to joint operation of micro-and macro-network objects of the ETC.

Figure 11 shows an algorithm for developing and applying a methodology for improving the quality of energy parameters regulation according to criteria 3-E efficiency of joint operation of objects of the II-V microgrid. The objects are included in the objects of the macro network of the unified ETC and take into account environmental factors based on the integration-balancing methodology for organizing economic, machine-to-machine and physical interactions of objects. The methodology is applied based on the results of mathematical modeling of processes for improving the quality of regulatory parameters, based on new methods for approximating generalized functions. Steps 1–8 of the model correspond to the application of the methodology, organizational and mathematical models and methods of

Section 3 of this article. Steps 9–17 present the practical application of the results of mathematical modeling of processes in

Section 3,

Section 4 and

Section 5 of the article. For this purpose, the methods of physical modeling and error estimation of mathematical modeling are used.

The economic analysis of the quality of the process control parameters determined the need to display and model the conditional expansion of space and time for the application of processes control and supervision due to the high speed of regulation. The approximating trajectory of processes and results is shown in

Figure 12 by the polyline A-B-C-D-E. It is established that at the beginning of the development of high-tech methods for implementing innovative results (these technologies for combining resources and ensuring the quality of energy parameters) in the formed networks of ETC, the level of economic efficiency of the systems decreases [

20].

Therefore, the hypothesis of improving the quality of the parameters of regulation of high-tech processes of combining resources with the use of the methods and models of transaction organization proposed by us is valid. They make it possible to provide a zone of stability of the 3-E efficiency indicators in the estimates of economic loss reduction for several cycles. For its quantitative confirmation, analog-digital economic models of representation of management improvement processes are proposed. They use the well-known Gibbs effect in mathematics, which allows us to reveal the functional relationships of the indicator-the properties of the level of economic losses of the EL (the inverse value of efficiency) from the levels of innovation (LI) of the development of systems.

In each cycle, the zones of the minimum imbalance of goals in the estimates of the variability of the EL indicator are identified, depending on the LI technologies for combining resources that determine the development zones during the time period of cycles 1 and 2. In the cycle of evolutionary processes 1, methods of advanced investment are used in the subsystems for managing the integration of educational and research resources of objects of type VI (see

Figure 1) with minimal and poorly regulated growth of the development index of the LI. In quadrant 2, the modernization or development of methods and technologies for the joint work of objects in the micro-network begins. At the same time, economic losses and costs are slightly and evolutionarily reduced due to the use of short-term effects of low-tech development of separately functioning objects outside the ETC (segment AB of the linear representation of the loss function).

Zone 3 of the development process is characterized by an increase in investment costs for personnel training and research in the areas of developing high-tech methods for combining resources. In this article, these are technologies and organizational methods for the joint functioning of microgrid objects) in the negative zone (−1...0), shown by the direct BC. The increase in economic losses is explained by the fact that each additional increase in the level of 3-E efficiency in the development of new technologies and methods reduces the severity of the consumer reaction in assessing the utility and cost of the formed hybrid energy networks. In practice, a number of technologies and products that differ in the level of innovation are usually mastered. They show a range of estimates from a jump in the levels of efficiency and innovation in the development of a new technology to gradual changes in the modernization of individual elements of the system. The low ratings in cycle 1 are also explained by the lack of recognition of the uniqueness of households and residential buildings by energy consumers. New consumer properties of the processes of physical interaction during joint generation, executed by transactions (in the period tс1) are shown by negative estimates of the zones of increase in properties and the insignificance of the reduction in economic losses.

In cycle 2, a jump-like increase in the efficiency levels of technologies and organizational products is shown. Meaningfully, it is explained by similar reasons for the growth of economic losses in comparison with their value in cycle 1. This follows from the structural changes in Zones 4 and 5 in the creation of the CCI and the unified ETC. It is shown by the similar nature of the dependencies on direct AB and DE, BC and CD. Concretizing the hypothesis of the study, it can be assumed that the zone of compromise of the considered goals should be determined by balancing changes in the resulting property of economic losses in the specified range of estimates (−1...1). The stability of the zone boundaries should be regulated by additional functions in the special control system of the dynamic simulator of the method combination mechanism (see

Figure 4). The mechanism provides joint energy production in the CCI, where the management of the matching effects on the indicators of the integrated application of investment, intellectual and research resources of long-term development is carried out. Such impacts are developed based on the model of the integration-balancing regulation methodology and are cyclically implemented in the transactional energy platform (see

Figure 5). These processes are proposed to be modeled by mathematical functions of a stepwise form [

58]. The evolutionary changes are described by a set of nested sinusoidal maps of these functions. Systems with step characteristics and functions are classified as essentially nonlinear structures. Despite the simplicity of step functions over sections, the construction of solutions over the entire domain of their definition requires the use of special mathematical methods. For example, the method of priming with linking solutions for sections and switching surfaces makes it necessary to overcome significant mathematical difficulties, quite often the solution is obtained in a cumbersome form.

The features of the organizational and economic relationships of a complex system allowed us to neutralize the negative manifestations of the Gibbs effect. So, if we take as members of the partial aggregate the levels of innovation of technologies, methods and products, then their number in the developing system is known and far exceeds dozens of levels. Therefore, the fact that the maxima and minima of the amplitudes of the indicator-property of the EL remain unchanged under the specified condition can be interpreted as the relative stability of the oscillation range during the cycle. This corresponds to an increase in the quality of the parameters of regulation of the efficiency of innovative development according to the criterion of reducing the imbalance of the goals of hybrid energy facilities in cycles 1 and 2 on the basis of the proposed methodology.

For relative error , the proof is similar. Moreover, even with a fixed value for any , you can choose a function for which . As such a function, for example, you can take a function that has . It is known that even on the set of continuous functions , the Fourier series does not necessarily converge at every point.

New methods of approximation of step functions based on the use of trigonometric expressions in the form of recursive functions are proposed for modeling the processes of increasing the 3-E efficiency depending on the sequential increase in the number of objects of the ETC macro network (see

Table 5) [

59]. Let us consider, for example, in more detail the step function of economic losses f(x) = EL for an example of the application of Fourier series in the comparative analysis of the traditional decomposition and the representation of the proposed hypothesis. The Fourier series expansion of the function has all the disadvantages described above. To eliminate them [

58], it is proposed to approximate the original step function by a sequence of recursive periodic functions (14):

The graphs of the original function (the thickened line) and its five successive approximations in this case have the form shown in

Figure 13. They show a decrease in economic losses with an increase in the degrees of integration of the complex objects from one to five. As can be seen, even with relatively small values

, when using the iterative procedure (2), the graph of the approximating function approximates the original function (1) quite well. At the same time, the approximating functions obtained using the proposed method do not have the disadvantages of Fourier series expansion and the Gibbs effect. It is revealed that the functions

and

are odd and periodic with a period

. The functions

and

are periodic even. Therefore, it is sufficient to consider the sequence of approximating functions (6) on the segment

.

The continuity of the function of economic losses, determined by the levels of innovation of products, allowed us to establish quantifiable boundaries of the zone of compromise of the goals of microgrid objects. To do this, based on the results of differentiating the function according to Equation (1), the points of minimum B and maximum economic losses D must be determined. Thus, the boundaries of the zone of variability of the studied property of the economy of the joint development of objects, regulated by the control system of the CСI of the formed unified ETC, are also established.

Figure 14 shows the dynamics of the reliability indicator in assessing the probability of failures of equipment of energy facilities (for example, a combined source of electric and thermal energy on renewable biogas resources of the SHIW landfill from the composition of objects of type III) is represented by estimates of maximum values according to

Table 1. The probability of failure increases over time and this requires monitoring using the capabilities of the IoT system. The sensors of the system set the parameters of the critical point, the appearance of the standard value of the probability of equipment failure. The inclusion of Ios actuators in the automatic actions eliminates the need for standardized regulations for the operation of microgrid installations.